Tilt vibration shakeout machine

The technology of shakeout machine and vibration motor is applied in the field of shakeout machine, which can solve the problems of conveyor belt slippage, poor workshop production environment, affecting productivity, etc., and achieve the effect of purifying the working environment, reducing air pollution and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

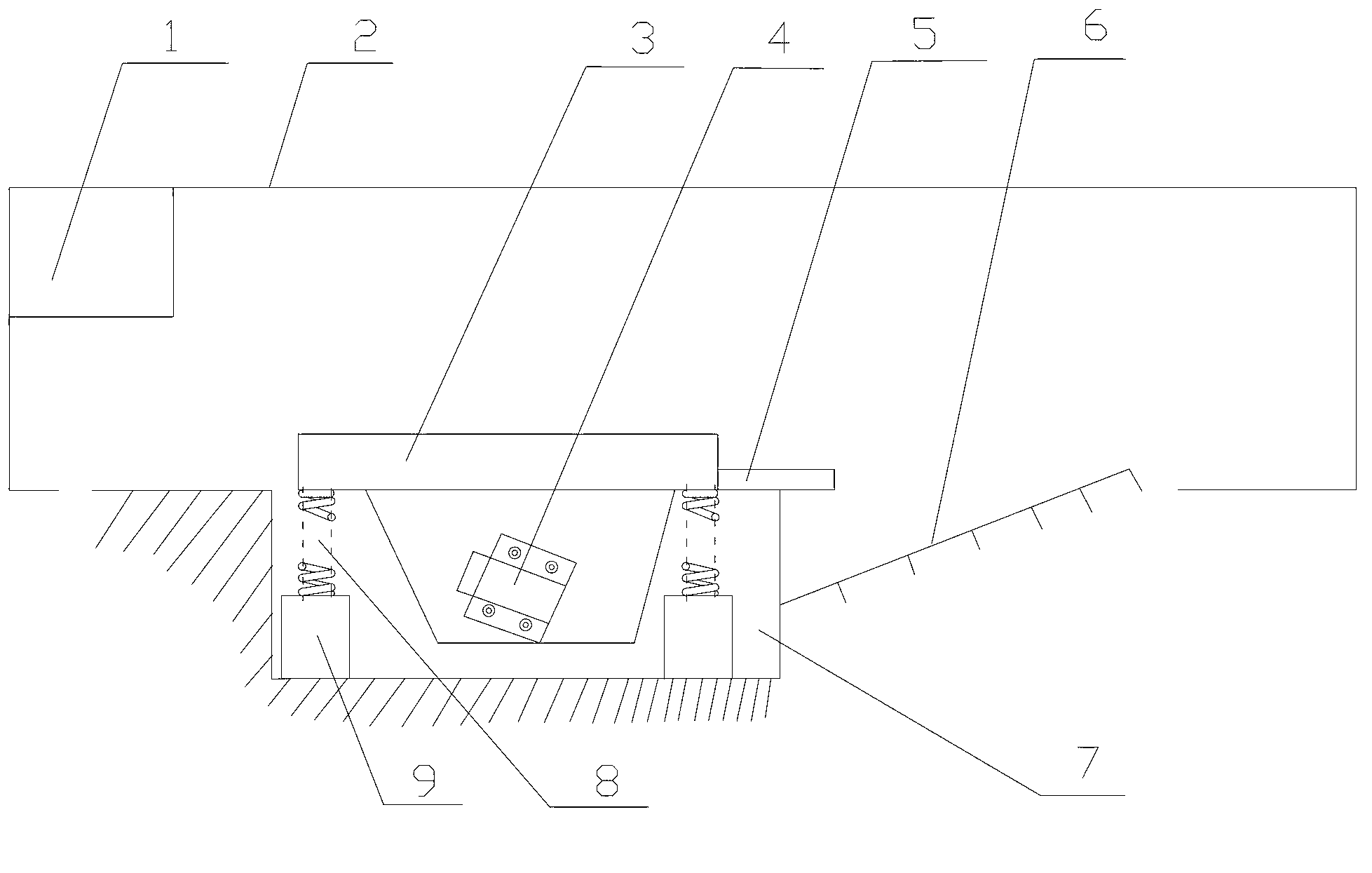

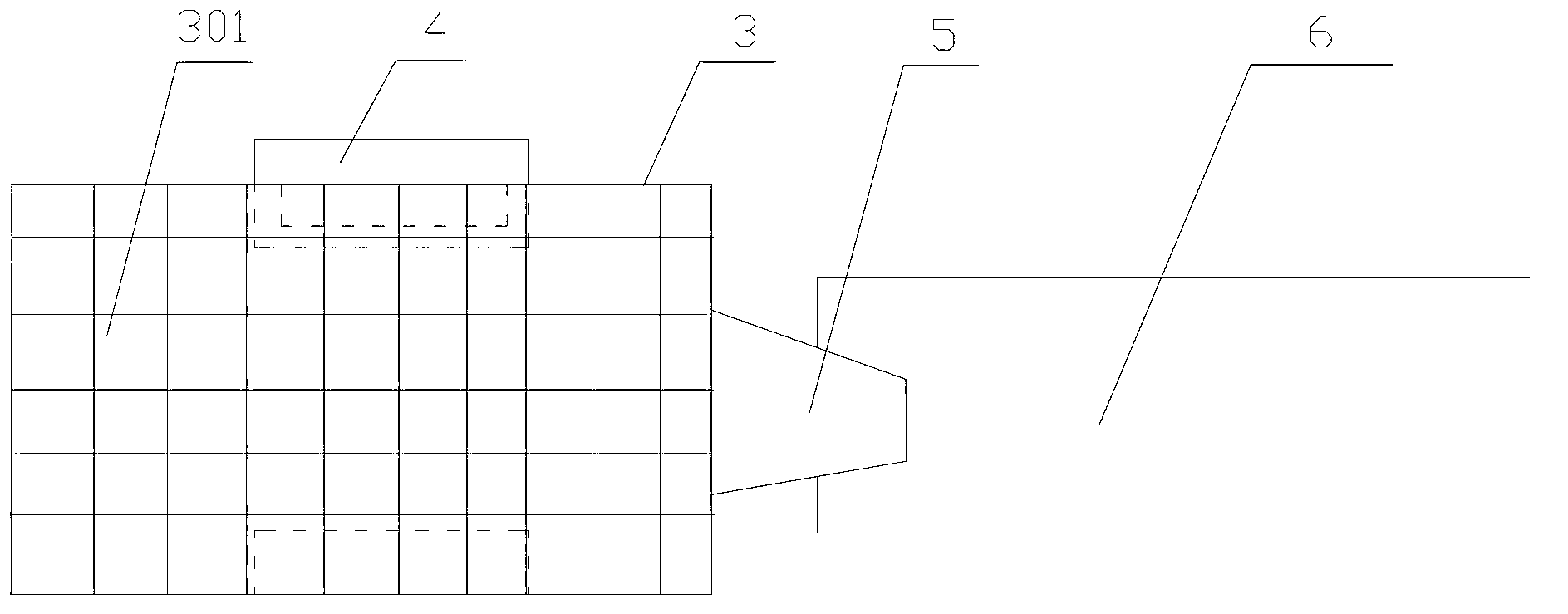

[0017] See figure 1 and figure 2 , an inclined vibrating shakeout machine, including a hopper 3, a vibrating motor 4 and a discharge port 5, the two sides of the hopper 3 are provided with a vibrating motor 4, the vibrating motor 4 is obliquely installed on both sides of the hopper 3, and one end of the hopper 3 A discharge port 5 is provided, and a conveyor belt 6 is provided at the lower part of the discharge port 5 . A grid 301 carrying castings is welded in the hopper 3, the bottom of the hopper 3 is flush with the upper horizontal surface (ground) of the foundation pit 7, the bottom of the hopper 3 is connected with the air spring 8, and the air spring 8 is fixedly connected with the support seat 9, and the support seat 9 are fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com