Enzyme additive for cotton knitted fabric and preparation method and application thereof

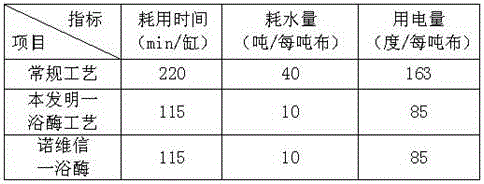

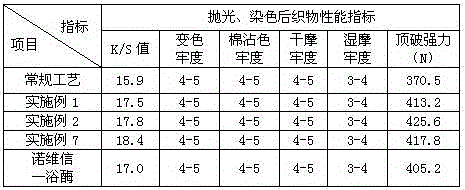

A technology for cotton knitted fabrics and enzyme additives, which is applied in textile and papermaking, fiber processing, biochemical fiber processing, etc., can solve the problems of insufficient formulation stability, increased sodium ion concentration, and little effect, and achieves polishing reproducibility. Good, short process flow, small color change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A method for preparing an enzyme auxiliary agent for cotton knitted fabrics, comprising the following steps:

[0036] Add neutral cellulase, oxygen-removing enzyme, protective agent, and enzyme activity accelerator in sequence in the reaction kettle, mix and stir slowly at room temperature for 30 minutes to obtain a liquid product.

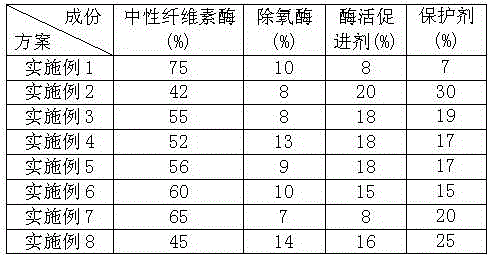

[0037] According to the above-mentioned preparation examples of the present invention, the composition and content in the formula are adjusted, and specific examples are shown in Table 1.

[0038] Table 1: Enzyme additives (by weight percentage) for cotton knitted fabrics with different compositions.

[0039]

[0040] Remarks for Table 1:

Embodiment 1

[0041] In Example 1: the protective agent consists of 3% sorbitol, 2% potassium sorbate and 2% deionized water.

Embodiment 2

[0042] In Example 2: the protective agent consists of 8% sorbitol, 5% potassium sorbate, 2% sucrose, 5% sodium chloride, and 10% deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com