A high-temperature creep-resistant molybdenum plate doped with K and Si elements and its preparation method

A technology of anti-creep and molybdenum plate, which is applied in the high-temperature creep-resistant molybdenum plate of Si element and its preparation, and the field of doping K, which can solve the problems of environmental interference and difficulty in exerting the high-temperature creep resistance of molybdenum plate. Achieve the effects of reducing doping types, good high temperature creep resistance, and improving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

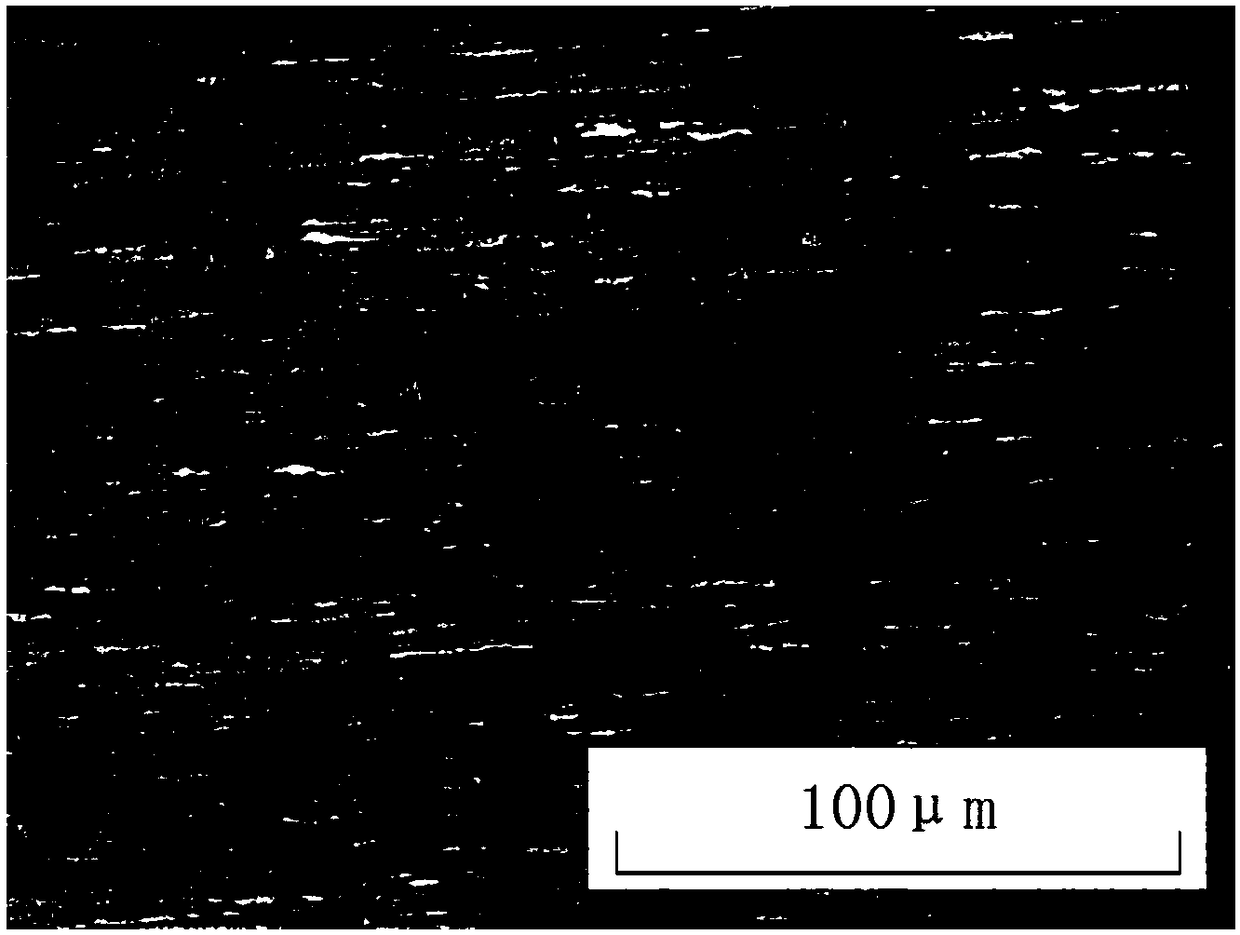

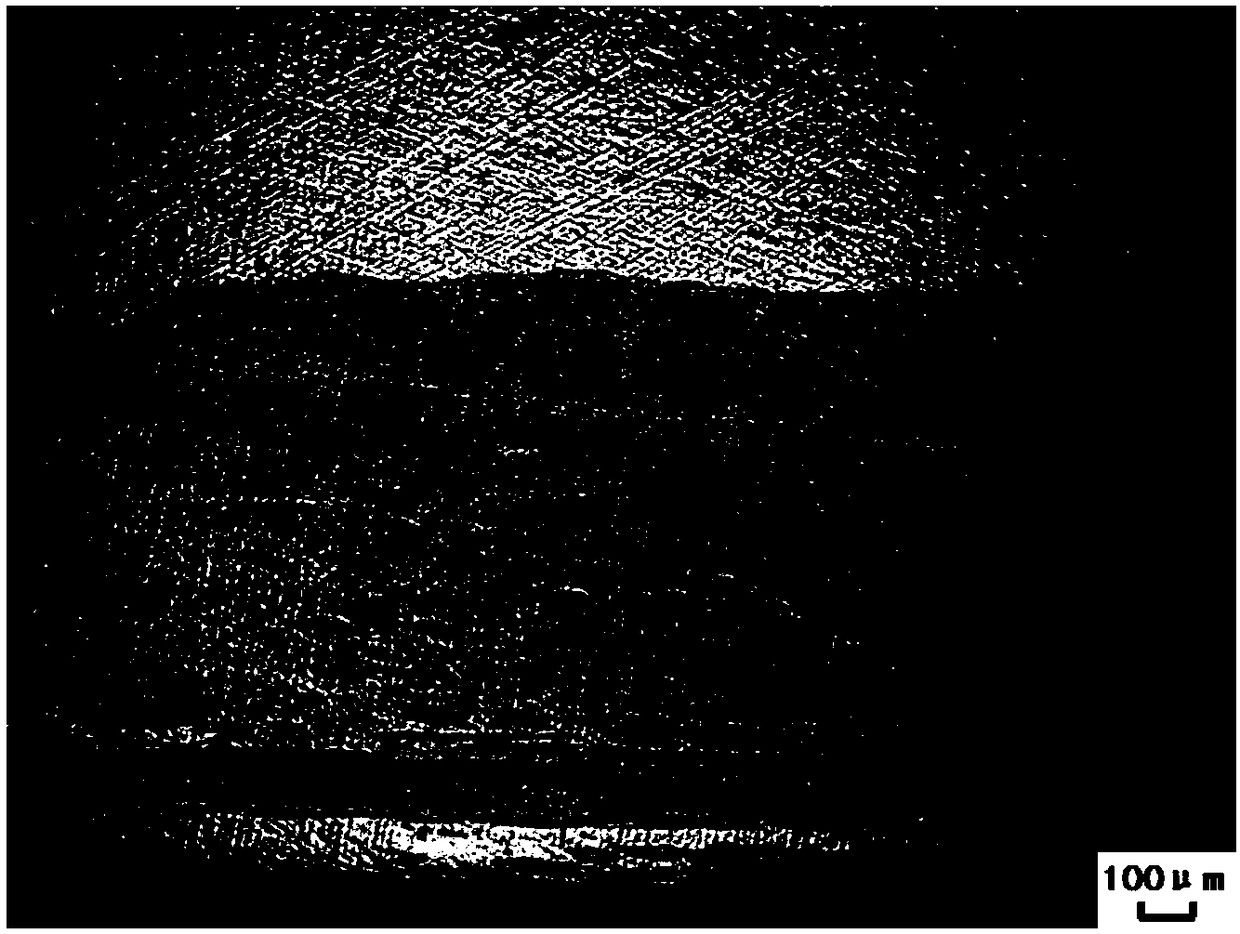

Image

Examples

Embodiment 1

[0036] A high-temperature creep-resistant molybdenum plate with a thickness of 4mm is produced, wherein K: 0.03% and Si: 0.04% in the molybdenum plate by weight percentage. In this embodiment, the K source is KNO 3 , Si source is H 2 SiO 3 , Mo source is ammonium tetramolybdate.

[0037] The specific preparation method is as follows:

[0038] (1) Considering the volatilization during reduction and sintering, K and Si are doped at 0.05% and 0.06%, respectively. KNO 3 、H 2 SiO 3 The weight ratio with ammonium tetramolybdate is: 0.2247:0.2738:200.

[0039] (2) Weigh 0.2247kg KNO respectively 3 , 0.2738 kg H 2 SiO 3 Formulated with KNO 3 、H 2 SiO 3 The mixed solution was diluted to 20L, poured into the doping solution tank of the double-cone vacuum drying doping pot, and set aside. 200kg ammonium tetramolybdate is loaded into the doping pot, and then the doping pot is started to rotate. Use the pressure of the air compressor to spray the mixed solution into the dopi...

Embodiment 2

[0048] A high-temperature creep-resistant molybdenum plate with a thickness of 2.5mm is produced, wherein K: 0.02% and Si: 0.03% in the molybdenum plate by weight percentage. In this embodiment, the K source is KNO 3 , Si source is H 2 SiO 3 , Mo source is ammonium tetramolybdate.

[0049] The specific preparation method is as follows:

[0050] (1) Considering the volatilization during reduction and sintering, K and Si were doped at 0.04% and 0.05%, respectively. KNO 3 、H 2 SiO 3 The weight ratio with ammonium tetramolybdate is: 0.1947:0.2417:200.

[0051] (2) Weigh 0.1947kg KNO respectively 3 , 0.2417kg H 2 SiO 3 Formulated with KNO 3 、H 2 SiO 3 The mixed solution was diluted to 18L, poured into the doping solution tank of the double-cone vacuum drying doping pot, and set aside. 200kg ammonium tetramolybdate is loaded into the doping pot, and then the doping pot is started to rotate. Use the pressure of the air compressor to spray the mixed solution into the do...

Embodiment 3

[0060] A high-temperature creep-resistant molybdenum plate with a thickness of 1 mm is produced, wherein K: 0.01% and Si: 0.01% are contained by weight percentage. In this embodiment, the K source is KNO 3 , Si source is H 2 SiO 3 , Mo source is ammonium tetramolybdate.

[0061] The specific preparation method is as follows:

[0062] (1) Considering the volatilization during reduction and sintering, K and Si are doped at 0.03% and 0.03%, respectively. KNO 3 、H 2 SiO 3 The weight ratio with ammonium tetramolybdate is: 0.1498:0.1611:200.

[0063] (2) Weigh 0.1498kg KNO respectively 3 , 0.1611 kg H 2 SiO 3 Formulated with KNO 3 、H 2 SiO 3 The mixed solution was diluted to 18L, poured into the doping solution tank of the double-cone vacuum drying doping pot, and set aside. 200kg ammonium tetramolybdate is loaded into the doping pot, and then the doping pot is started to rotate. Use the pressure of the air compressor to spray the mixed solution into the doping pot un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com