Polypropylene modified material for expansion water tank of automobile and preparation method thereof

A technology of expansion water tank and modified material, applied in the field of polypropylene modified material and its preparation, can solve the problems of inability to meet the production and use requirements of the expansion water tank, poor creep resistance at high temperature, poor heat sealing and welding performance, etc., and achieve excellent The effect of oxidation resistance, high and high temperature creep resistance, high and low temperature impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Ingredients: 75% propylene-ethylene block copolymer polypropylene, 20% linear low density polyethylene (LLDPE), 4.4% ethylene propylene diene monomer (EPDM), 0.3% sorbitol nucleating agent, hindered phenol antioxidant Agent 0.3%.

[0016] Preparation: Add the above-mentioned raw materials in proportion to a high-mixing pot for uniform mixing, and then extrude and granulate with a twin-screw extruder under the conditions of a processing temperature of 210-240°C and a screw speed of 210-240 rpm.

[0017] The other parts of this embodiment adopt the existing technology, which will not be repeated here.

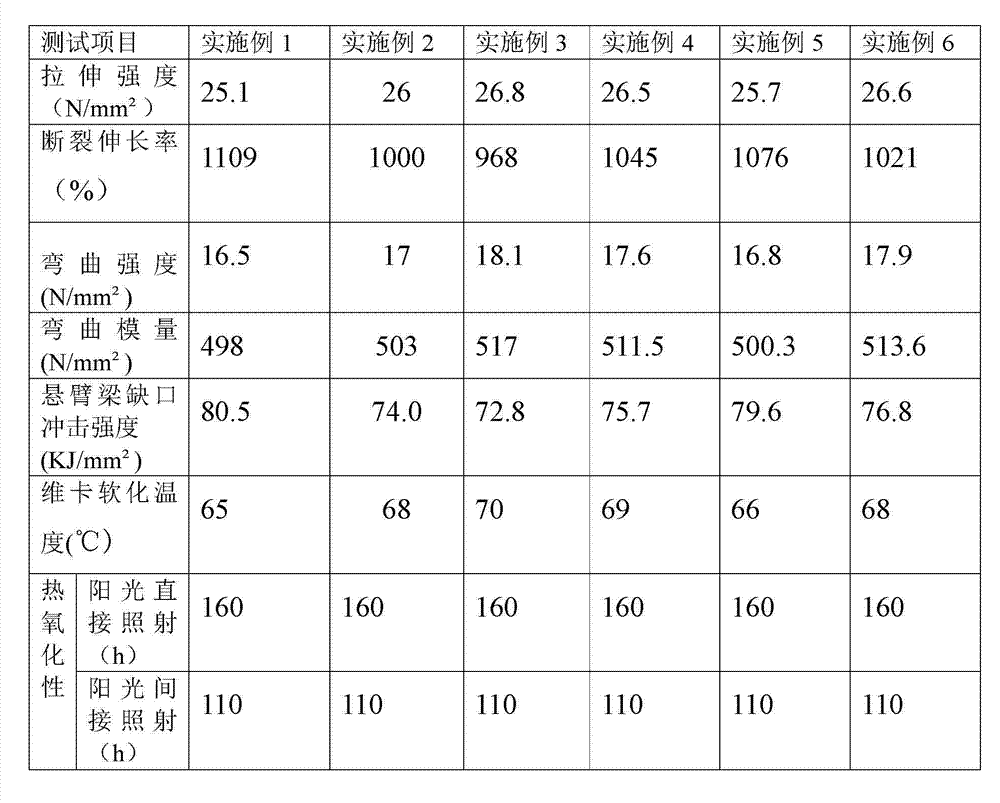

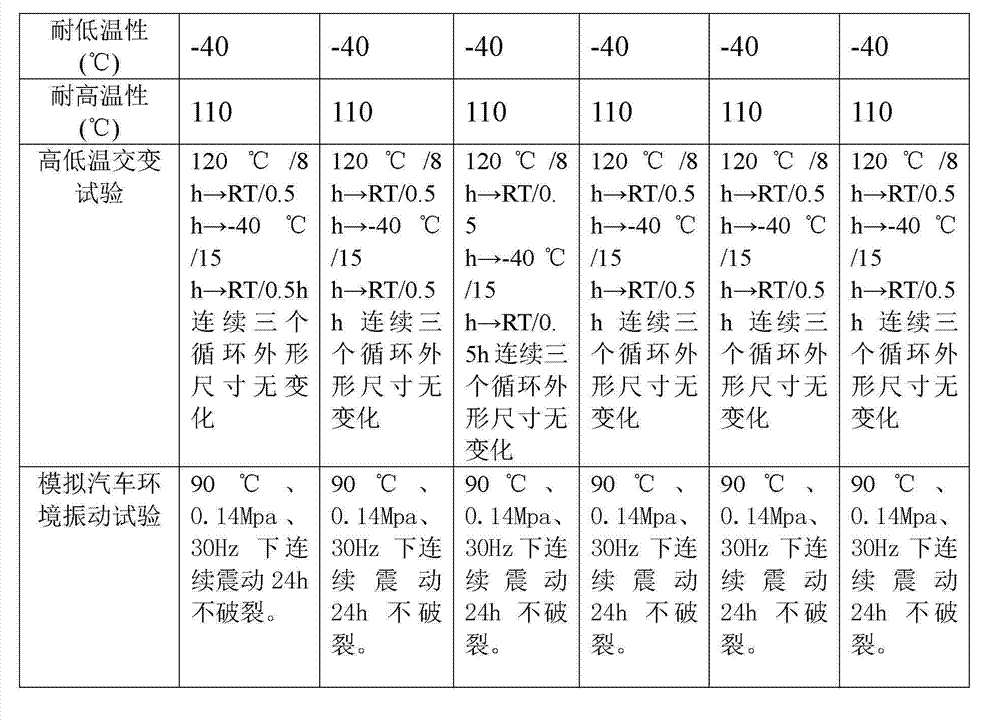

[0018] The modified polypropylene material for automobile expansion water tank obtained in this example has excellent properties, and its properties are shown in Table 1.

Embodiment 2

[0020] Ingredients: propylene-ethylene block copolymer polypropylene 80%, linear low density polyethylene (LLDPE) 14.5%, ethylene propylene diene monomer (EPDM) 5%, sorbitol nucleating agent 0.2%, hindered phenol antioxidant Agent 0.3%.

[0021] Preparation: Add the above-mentioned raw materials in proportion to a high-mixing pot for uniform mixing, and then extrude and granulate with a twin-screw extruder under the conditions of a processing temperature of 210-240°C and a screw speed of 210-240 rpm.

[0022] The other parts of this embodiment adopt the existing technology, which will not be repeated here.

[0023] The modified polypropylene material for automobile expansion water tank obtained in this example has excellent properties, and its properties are shown in Table 1.

Embodiment 3

[0025] Ingredients: propylene-ethylene block copolymer polypropylene 85%, linear low density polyethylene (LLDPE) 10%, ethylene propylene diene monomer (EPDM) 4%, sorbitol nucleating agent 0.5%, hindered phenol antioxidant Agent 0.5%.

[0026] Preparation: Add the above-mentioned raw materials in proportion to a high-mixing pot for uniform mixing, and then extrude and granulate with a twin-screw extruder under the conditions of a processing temperature of 210-240°C and a screw speed of 210-240 rpm.

[0027] The other parts of this embodiment adopt the existing technology, which will not be repeated here.

[0028] The modified polypropylene material for automobile expansion water tank obtained in this example has excellent properties, and its properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com