Polyphenyl ether resin alloy material, preparation method thereof and refrigeration compressor

A technology of polyphenylene ether resin and alloy materials, which is applied in the direction of mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve problems such as unstable performance, stress cracking resistance and unsatisfactory low-temperature impact strength, and achieve production High efficiency, low temperature resistance and safety, stable working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] As another aspect of the embodiment of the present invention. The embodiment of the present invention also provides a preparation method of the above-mentioned polyphenylene ether resin alloy material of the embodiment of the present invention. In one embodiment, the preparation method of the polyphenylene ether resin alloy material in the embodiment of the present invention includes the following steps:

[0044] Step S01. Weighing the raw materials of each component: Weighing the raw materials of each component according to the components and contents contained in the polyphenylene ether resin alloy material according to the embodiment of the present invention;

[0045] Step S02. Melting and extruding the raw materials of each component weighed in step S01: performing melt extrusion processing of the raw materials of each component weighed in step S01.

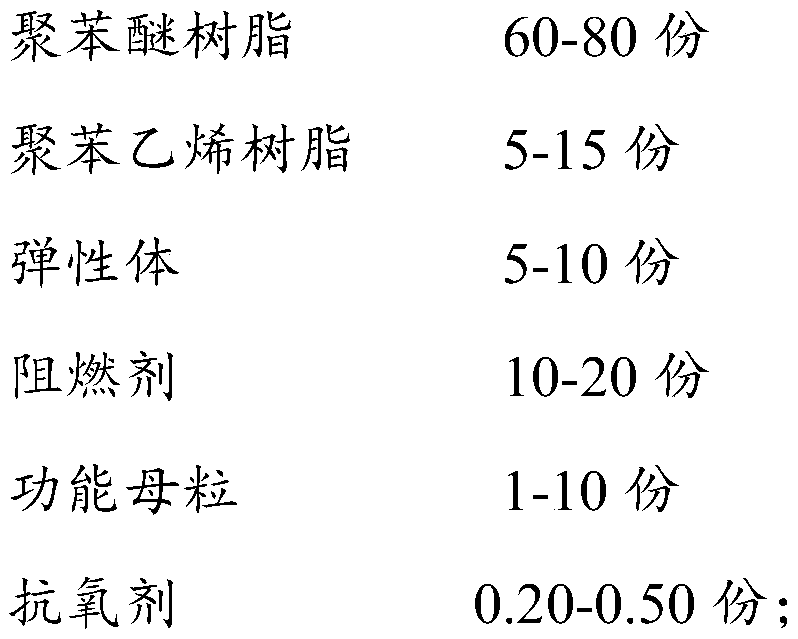

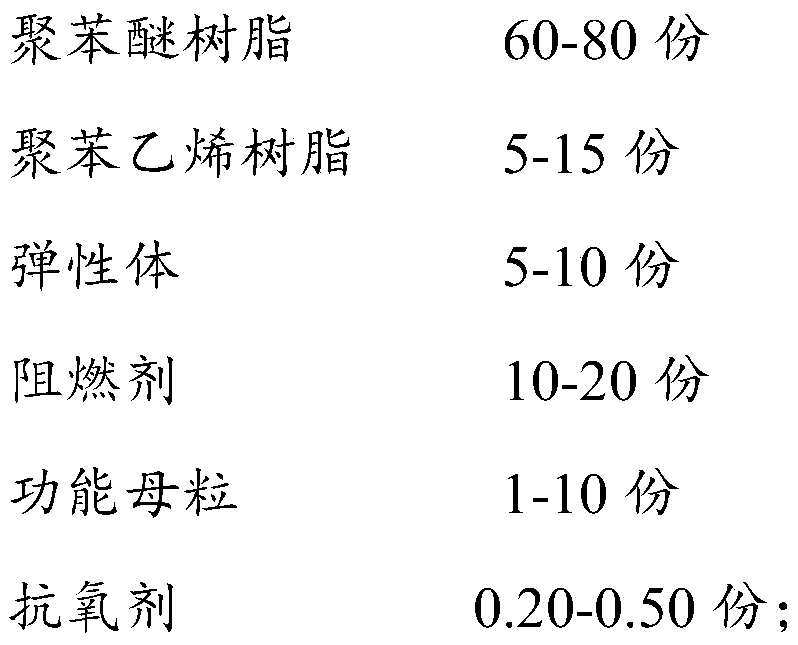

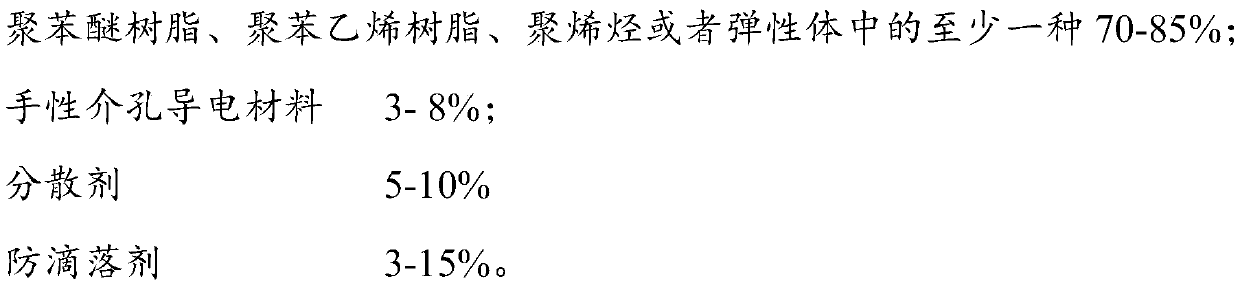

[0046] Specifically, the preferred content and type of each component in the polyphenylene ether resin alloy materi...

Embodiment 1

[0059] Embodiments of the present invention provide a polyphenylene ether resin alloy material and a preparation method thereof.

[0060] The polyphenylene ether resin alloy material contained the components shown in Example 1 in Table 1 below.

[0061] The preparation method is as follows: 65 parts of polyphenylene ether resin are added from the first weight loss feeding port, 12 parts of polystyrene, 1 part of polyolefin, 5 parts of elastomer, 3 parts of functional masterbatch, 0.3 parts of antioxidant after high mixing Finally, it is added from the second weight loss feeder port, and 12 parts of liquid flame retardant is added from the liquid feeding system, and then plasticized, melted, extruded, drawn, cooled, and pelletized through the twin-screw extruder. The pellets were dried in a blower drying oven at 120°C for 2-4 hours, and then injection molded to prepare test samples and products. The technological conditions of the melt extrusion treatment are as follows: the t...

Embodiment 2

[0063] Embodiments of the present invention provide a polyphenylene ether resin alloy material and a preparation method thereof.

[0064] The polyphenylene ether resin alloy material contained the components shown in Example 2 in Table 1 below.

[0065] The preparation method is as follows: 68 parts of polyphenylene ether resin are added from the first weight loss feeding port, 12 parts of polystyrene, 1 part of polyolefin, 6 parts of elastomer, 3 parts of flame retardant, 3 parts of functional masterbatch, 0.3 parts of The antioxidant is added from the second weight loss feeder port after high mixing, and 10 parts of liquid flame retardant is added from the liquid feeding system, and then plasticized, melted, extruded, drawn, cooled, and pelletized through the twin-screw extruder . The pellets were dried in a blower drying oven at 120°C for 2-4 hours, and then injection molded to prepare test samples and products. The technological conditions of the melt extrusion treatment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com