High-temperature resistant halogen-free flame-retardant cable material and preparation method thereof

A kind of flame retardant cable material, high temperature resistance technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of low temperature resistance level, low flame retardant level, tensile strength and elongation at break, etc., to achieve stress resistance Good cracking performance and the effect of improving temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

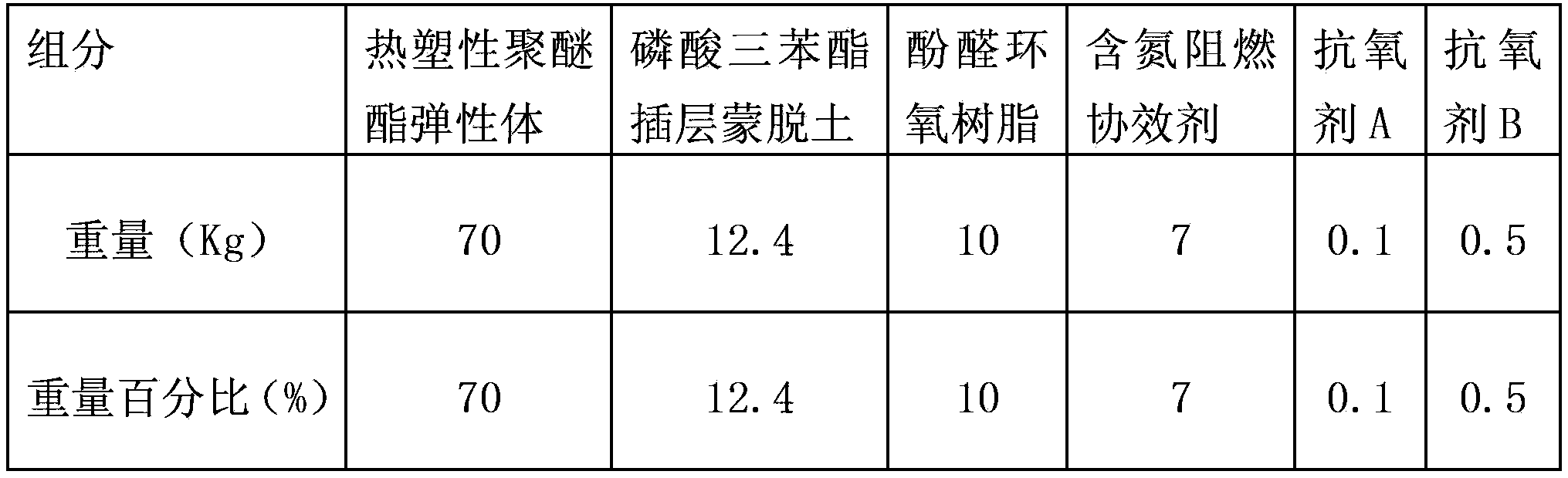

[0026] The components of the high temperature resistant halogen-free flame retardant cable material and the content of each component are as follows (total weight: 100Kg):

[0027]

[0028] Among them, the phenolic resin is a phenol-type novolac epoxy resin, selected from the PFNE7000 novolac epoxy resin produced by Hunan Jiashengde Material Technology Co., Ltd.; the nitrogen-containing flame retardant synergist is melamine cyanurate; the antioxidant A is bismuth (2,4-di-tert-butylphenyl)pentaerythritol diphosphate; Antioxidant B is (2,4,6-tri-tert-butylphenyl-2-butyl-2-ethyl)-1,3 -Propylene glycol phosphite; thermoplastic polyether ester elastomer with a Shore hardness of 45D, selected from XT1345 produced by Wuhan Southeast Xiangtai Chemical Co., Ltd.

[0029] The preparation process of the above-mentioned high-temperature-resistant halogen-free flame-retardant cable material includes the following steps:

[0030] a. Dry the thermoplastic polyether ester elastomer and tr...

Embodiment 2

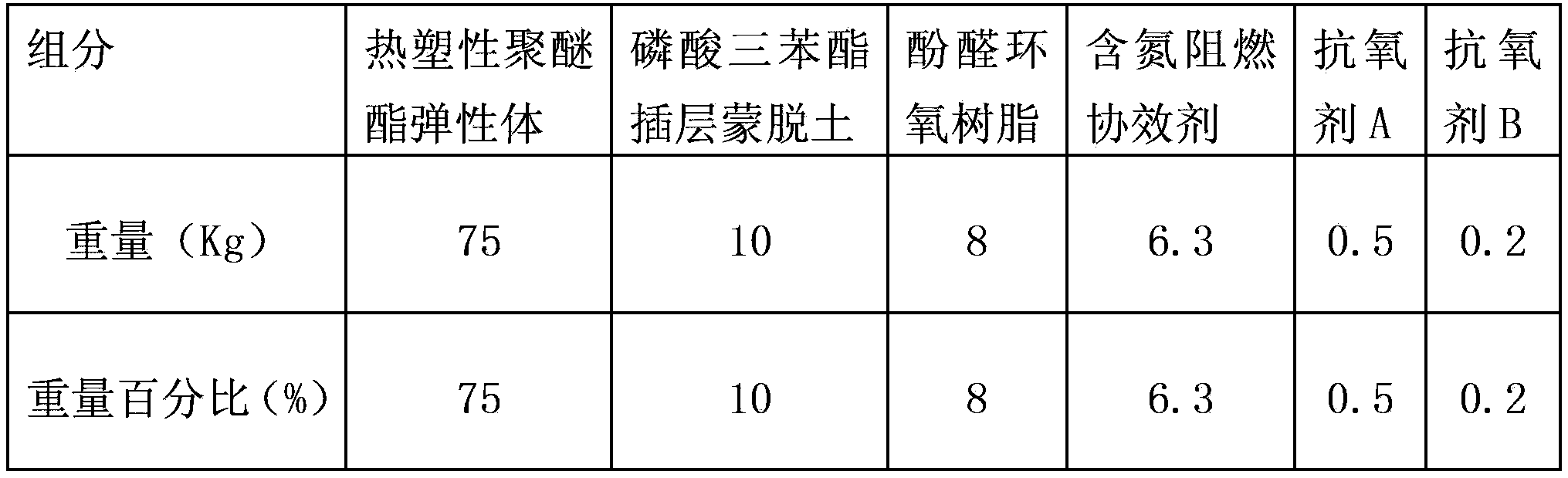

[0036] The components of the high temperature resistant halogen-free flame retardant cable material and the content of each component are as follows (total weight: 100Kg):

[0037]

[0038] Among them, the novolac epoxy resin is o-cresol type novolac epoxy resin, which is selected from the EOCN6000 novolac epoxy resin produced by Hunan Jiashengde Material Technology Co., Ltd.; the nitrogen-containing flame retardant synergist is melamine; the antioxidant A is four -[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythyl alcohol ester; Antioxidant B is 2,2'-ethylenebis(4,6-di-tert-butyl Base phenyl) fluorophosphite; the Shore hardness of the thermoplastic polyether ester elastomer is 50D, selected from the XT1350 type produced by Wuhan Southeast Xiangtai Chemical Co., Ltd.

[0039] The preparation process of the above-mentioned high-temperature-resistant halogen-free flame-retardant cable material includes the following steps:

[0040] a. Dry the thermoplastic polyeth...

Embodiment 3

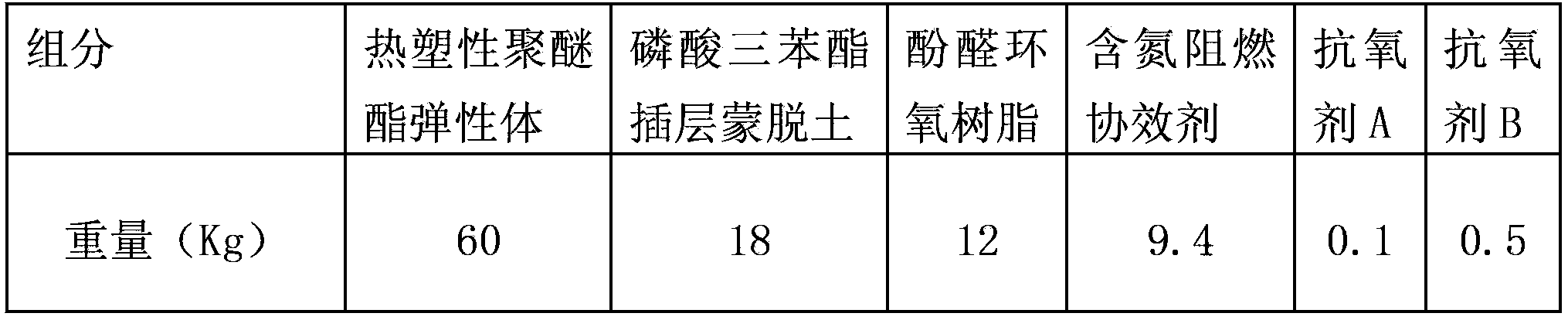

[0046] The components of the high temperature resistant halogen-free flame retardant cable material and the content of each component are as follows (total weight: 100Kg):

[0047]

[0048]

[0049] Among them, the novolac epoxy resin is bisphenol A novolac epoxy resin, which is selected from BPANE8200 novolac epoxy resin produced by Hunan Jiashengde Material Technology Co., Ltd.; the nitrogen-containing flame retardant synergist is melamine cyanurate; Agent A is β(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate; antioxidant B is bis(2,4-di-p-isopropylphenyl) pentaerythritol bisphosphite Ester; The Shore hardness of thermoplastic polyetherester elastomer is 60D.

[0050] The preparation process of the above-mentioned high-temperature-resistant halogen-free flame-retardant cable material includes the following steps:

[0051]a. Dry the thermoplastic polyether ester elastomer and triphenyl phosphate intercalated montmorillonite in the above raw materials at 120°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com