Patents

Literature

35results about How to "High technology added value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

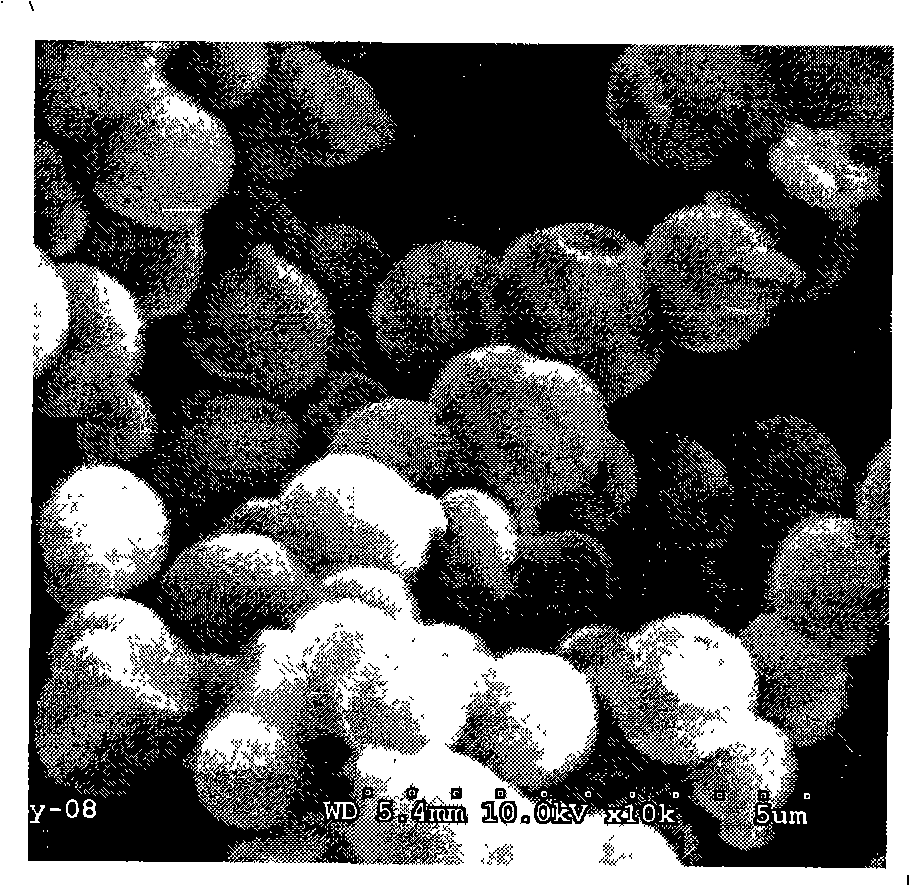

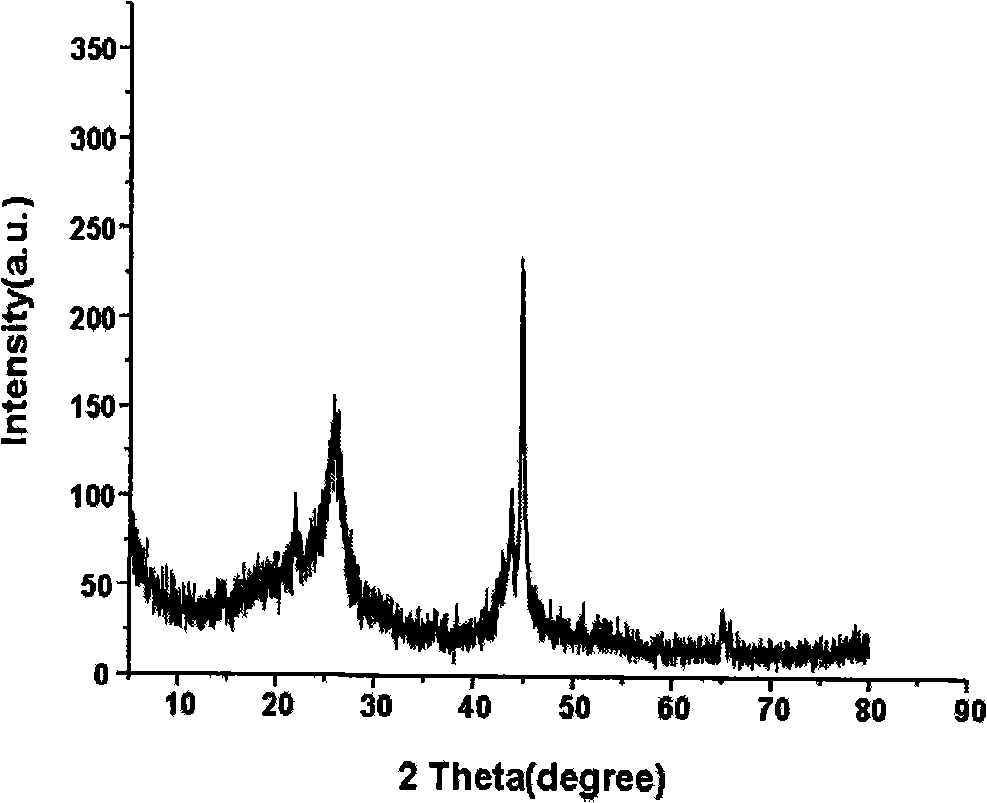

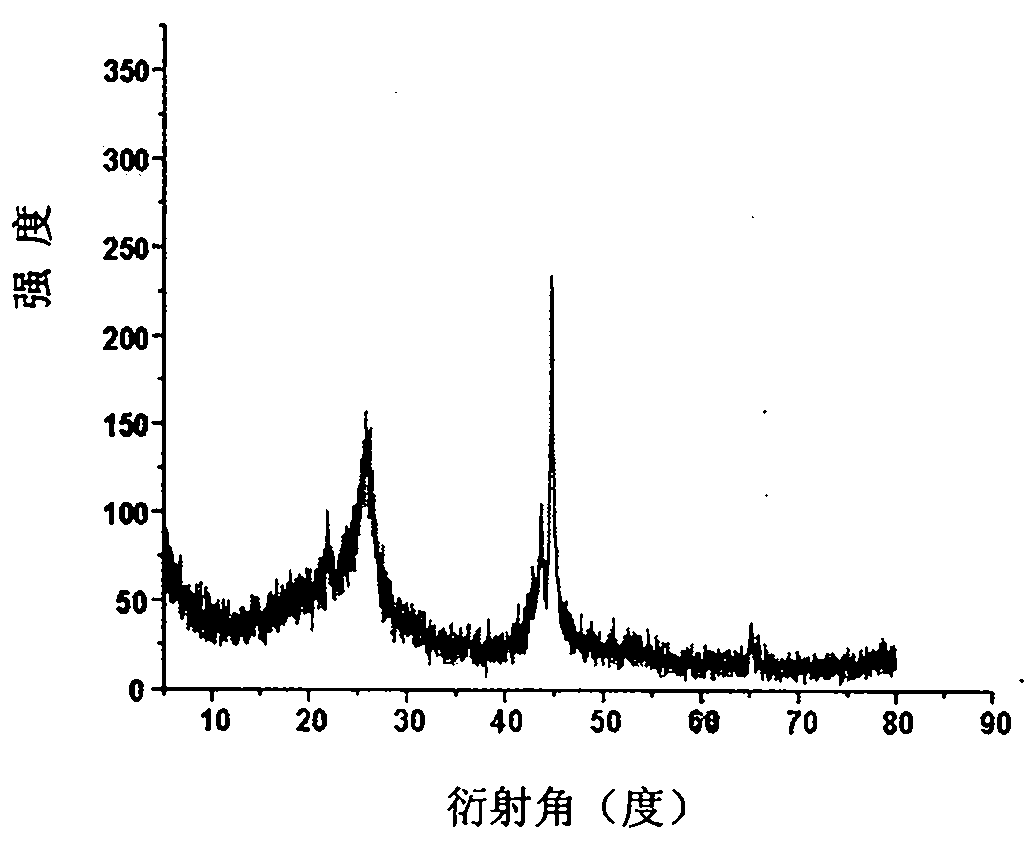

One-step synthesis method for hollow carbon case

The invention relates to a method for synthesizing a micro-nanometer level hollow polymer ball, a carbon ball and a graphitized ball by one step. The method comprises the following steps that: hydroxybenzene and aldehyde are used as raw materials; lysine is used as a catalyst; fatty alcohol is used as a solvent; a polymer hollow ball with an even dimension can be produced by polymerization at a temperature of 80 DEG C; and the polymer hollow ball is further charred to produce a hollow carbon ball. If Fe<3+> is introduced into the polymer hollow ball, the polymer hollow ball is charred to produce a graphitized hollow ball. Through changing a molar ratio of the hydroxybenzene and aldehyde, the catalyst amount and the type of the solvent, the hollow carbon ball with a grain diameter of between 0.6 and 2 mu m can be produced. The micro-nanometer level hollow carbon ball has an even and controllable grain diameter, high purity, smooth surface, stable performance and high technical added value, is suitable for a load type magnetic separation catalyst, an absorption separating agent of pigment and organic molecule and a separating agent of protein and salt and is used as an electrode material of a super capacitor with high power density and high energy density.

Owner:DALIAN UNIV OF TECH

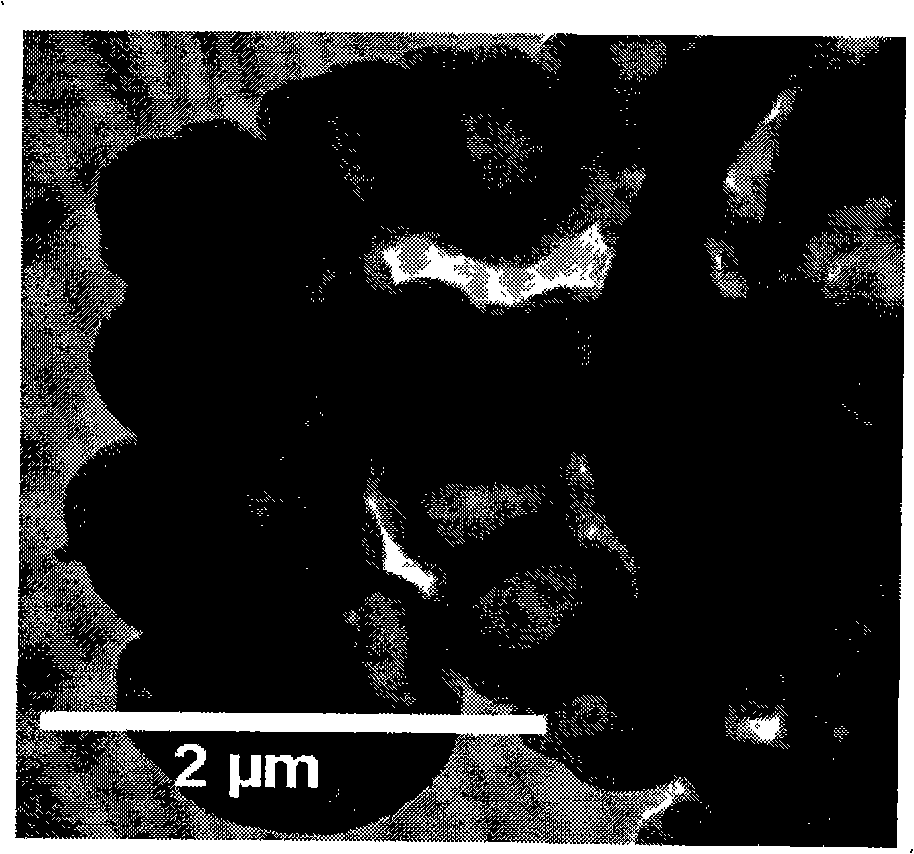

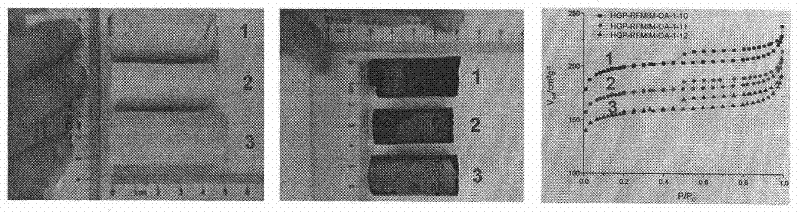

Method for quickly synthesizing block graded pore structural nitrogenous porous carbon

The invention relates to a method for quickly synthesizing block graded pore structural nitrogenous porous carbon. The method can synthesize characteristic porous carbons which comprise graded pore structural nitrogenous porous carbon, macropore-rich graded pore structural nitrogenous porous carbon, macropore-rich ordered nitrogenous mesoporous carbon and graded pore structural nitrogenous magnetic porous carbon. The porous carbon is quickly synthesized in one step by resorcinol and formaldehyde serving as raw materials, amino acid or imidazole compounds and organic amine serving as catalysts and water or ethanol aqueous solution serving as a solvent through a sol-gel process. The flow is simple, the preparation cost is low, the purity of a product is high, the selective range of raw materials is broad, and the method is convenient to apply and easy to implement large-scale preparation and has large application potential and market prospect.

Owner:DALIAN UNIV OF TECH

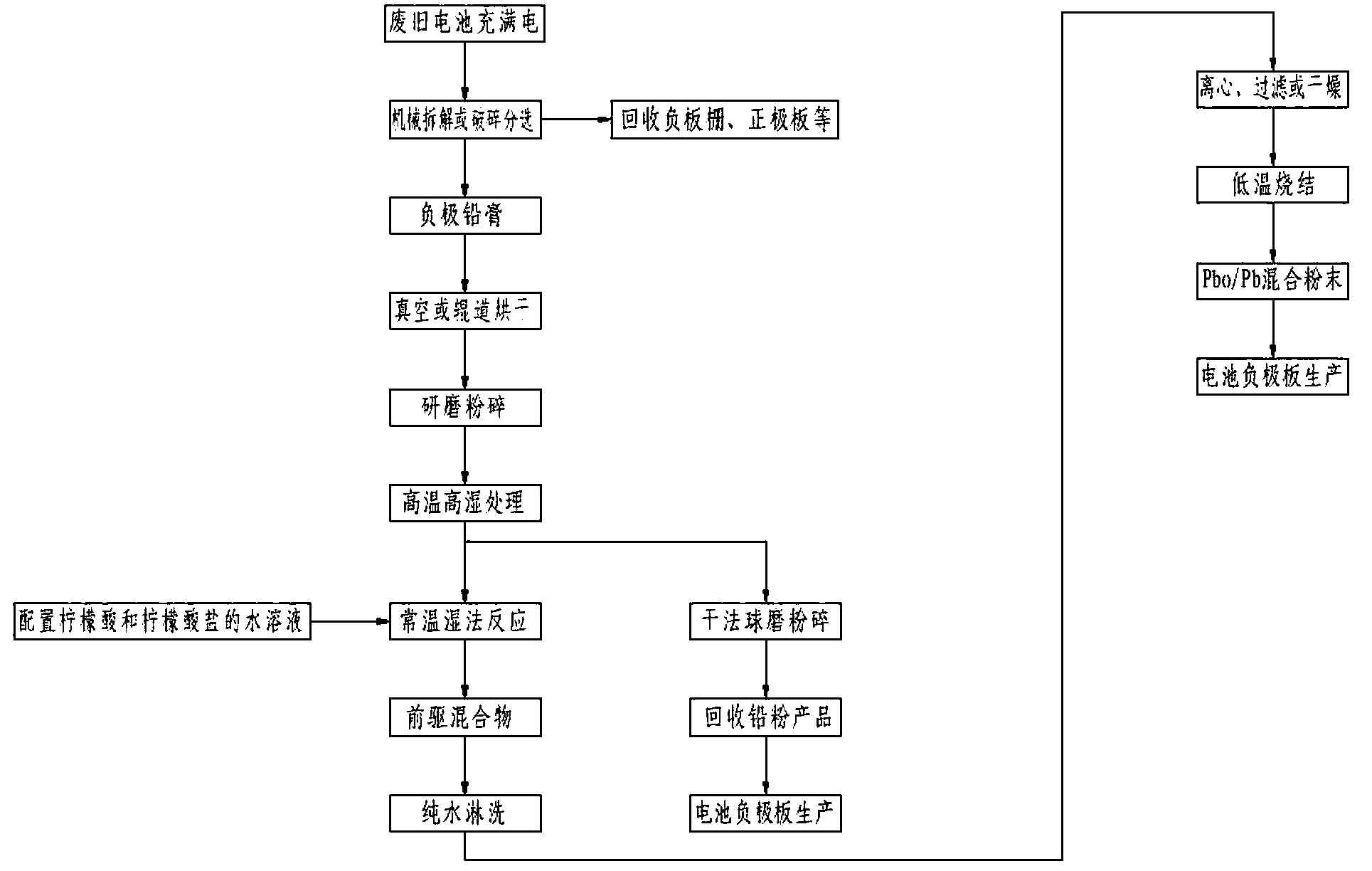

Method for recovering lead plaster of negative pole of disused lead acid storage battery and application of recovered lead plaster

ActiveCN103184340AReduce energy consumptionLarge specific surface areaWaste accumulators reclaimingProcess efficiency improvementElectrochemistryEnergy consumption

The invention discloses a method for recovering lead plaster of the negative pole of a disused lead acid storage battery and application of the recovered lead plaster. A preparation method of superfine lead powder comprises the following steps: firstly, a disused battery is fully charged; secondly, the lead plaster of the negative pole is separated from the lead acid storage battery; thirdly, the main substance of the lead plaster of the negative pole is changed into a lead raw material mainly composed of PbO and Pb via high temperature and humidity solidification; and lastly, dry grinding or crumbling of the lead raw material is carried out under the condition of oxygen, or wet treatment is carried out by using organic salt and organic acid to obtain superfine lead powder. The recovery method disclosed by the invention is low in cost, simple and convenient in process, high in recovery rate of lead, low in energy consumption and easy to achieve industrialization, and causes minor pollution to the environment during recovering the lead. The method directly prepares superfine lead powder which can be directly used to produce storage batteries. The superfine PbO powder prepared by the method has good performance, is high in technology added value, and can obtain a battery pole plate which has high electrochemistry capacity and a long charging / discharge service life.

Owner:SHENZHEN CENT POWER TECH

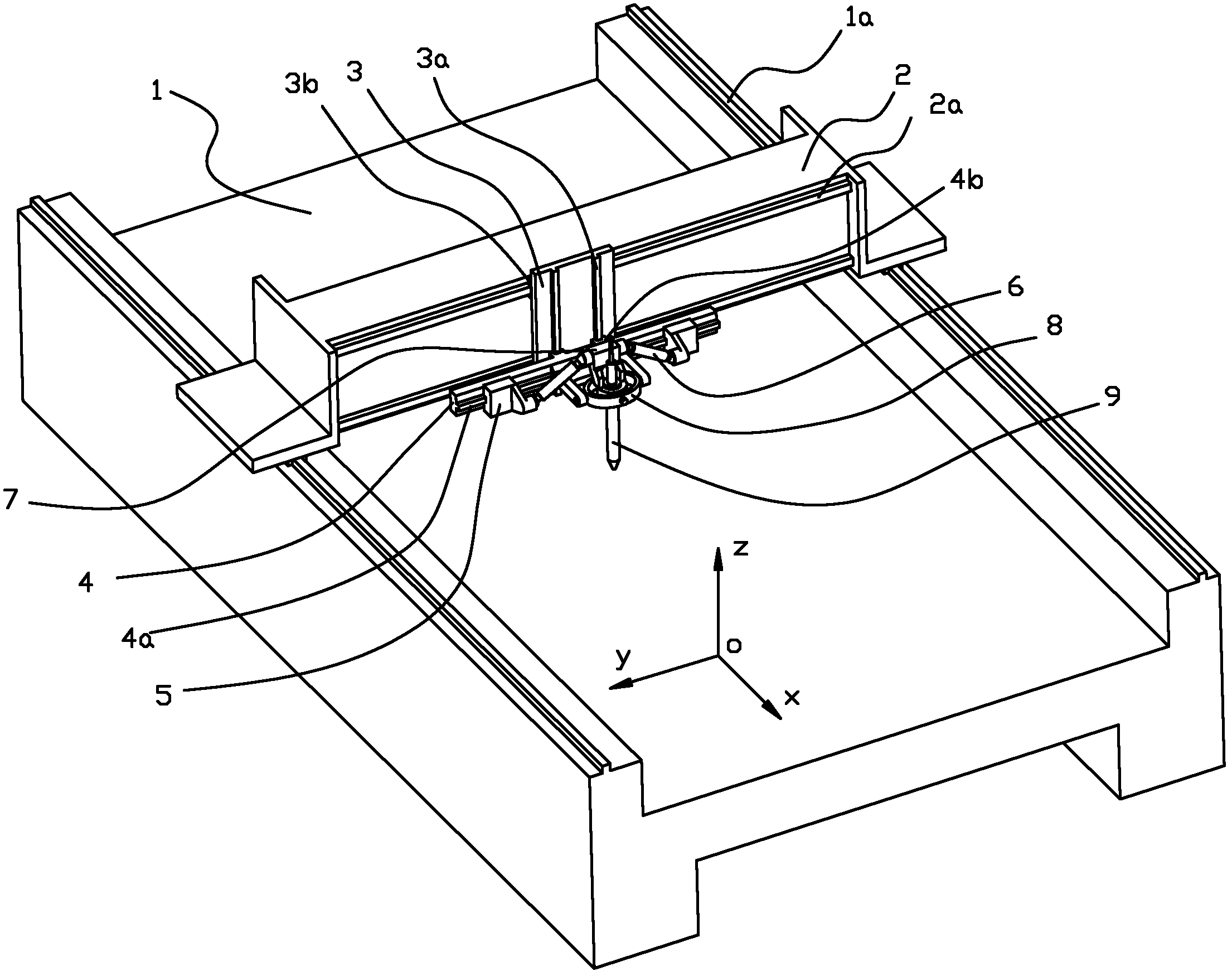

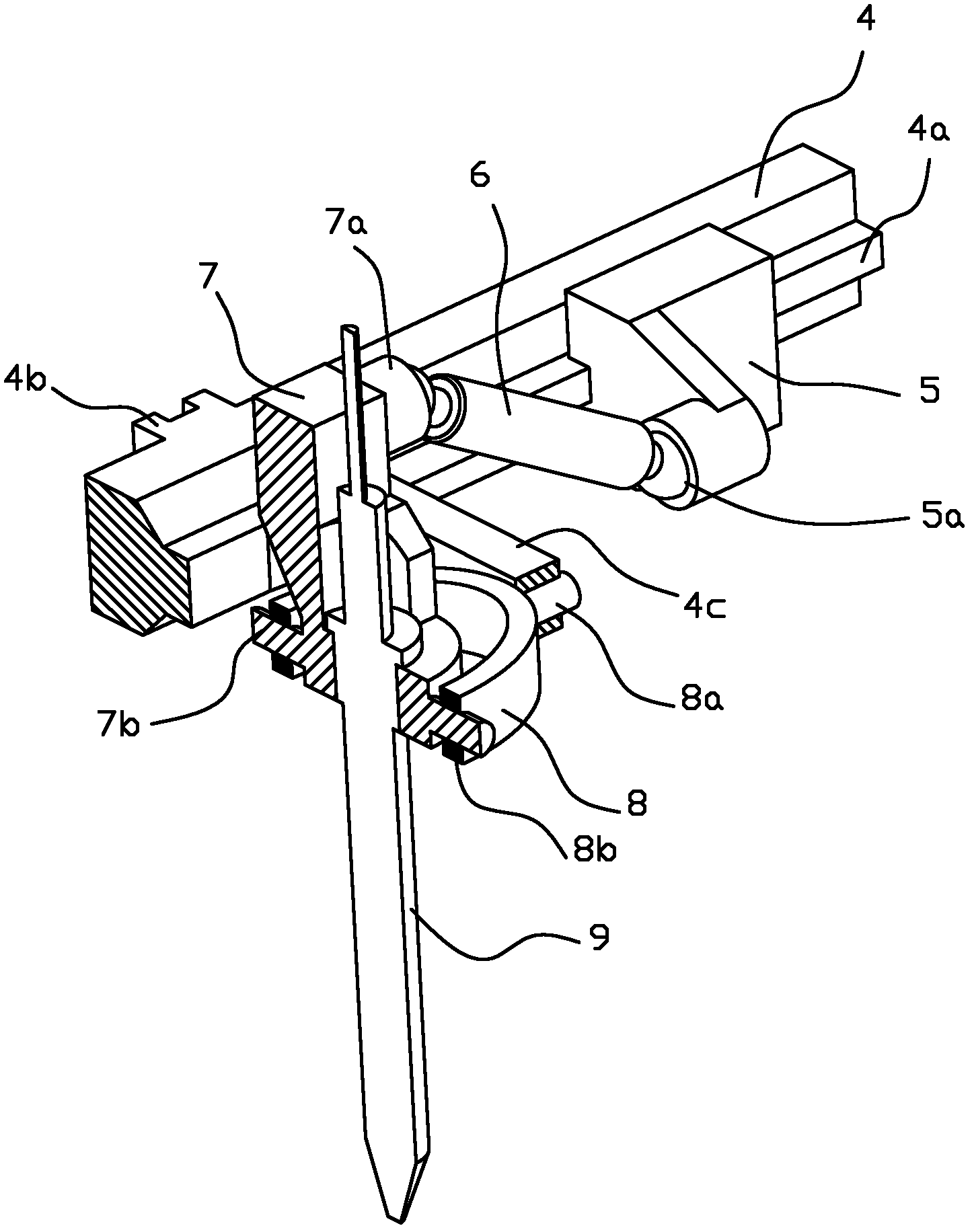

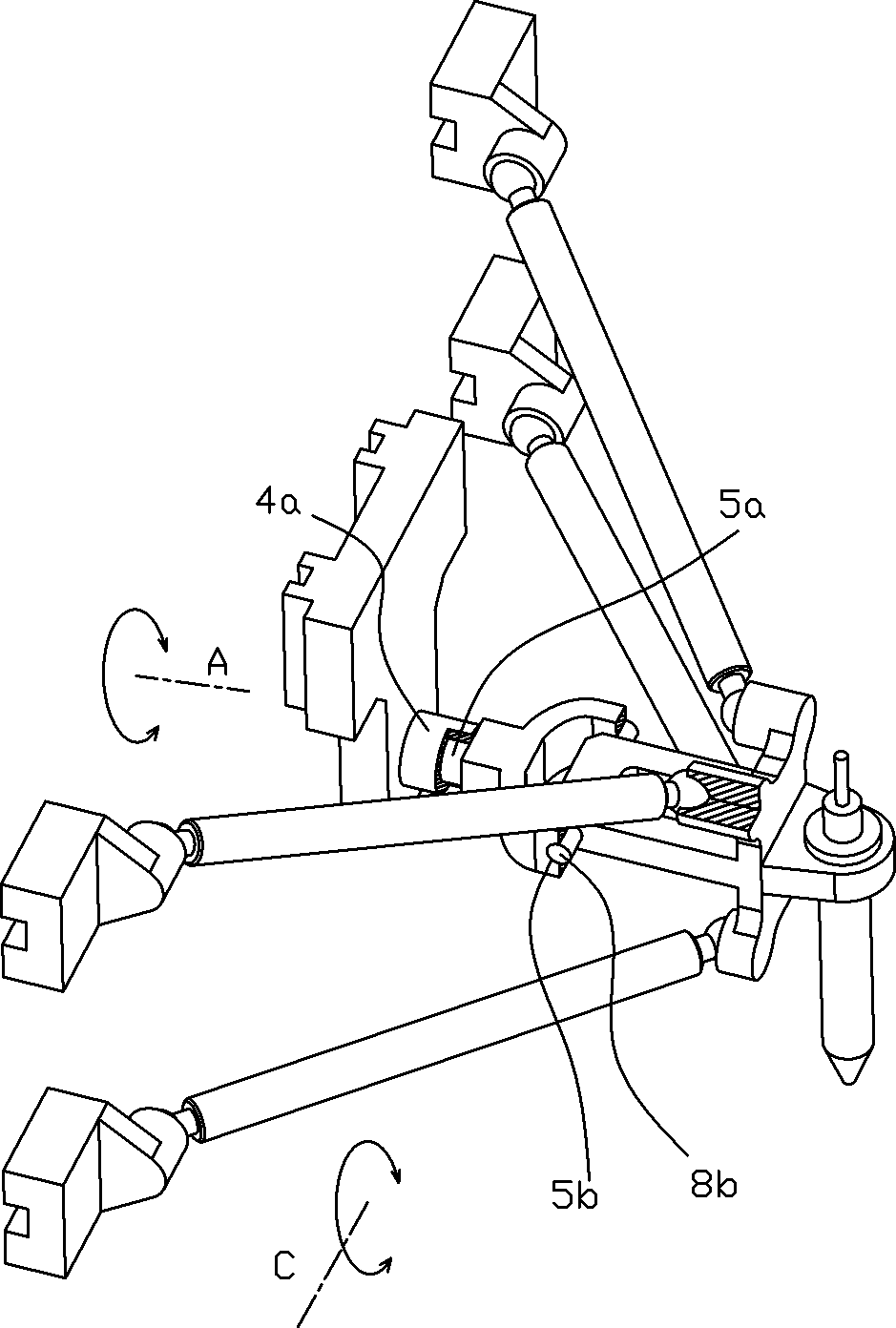

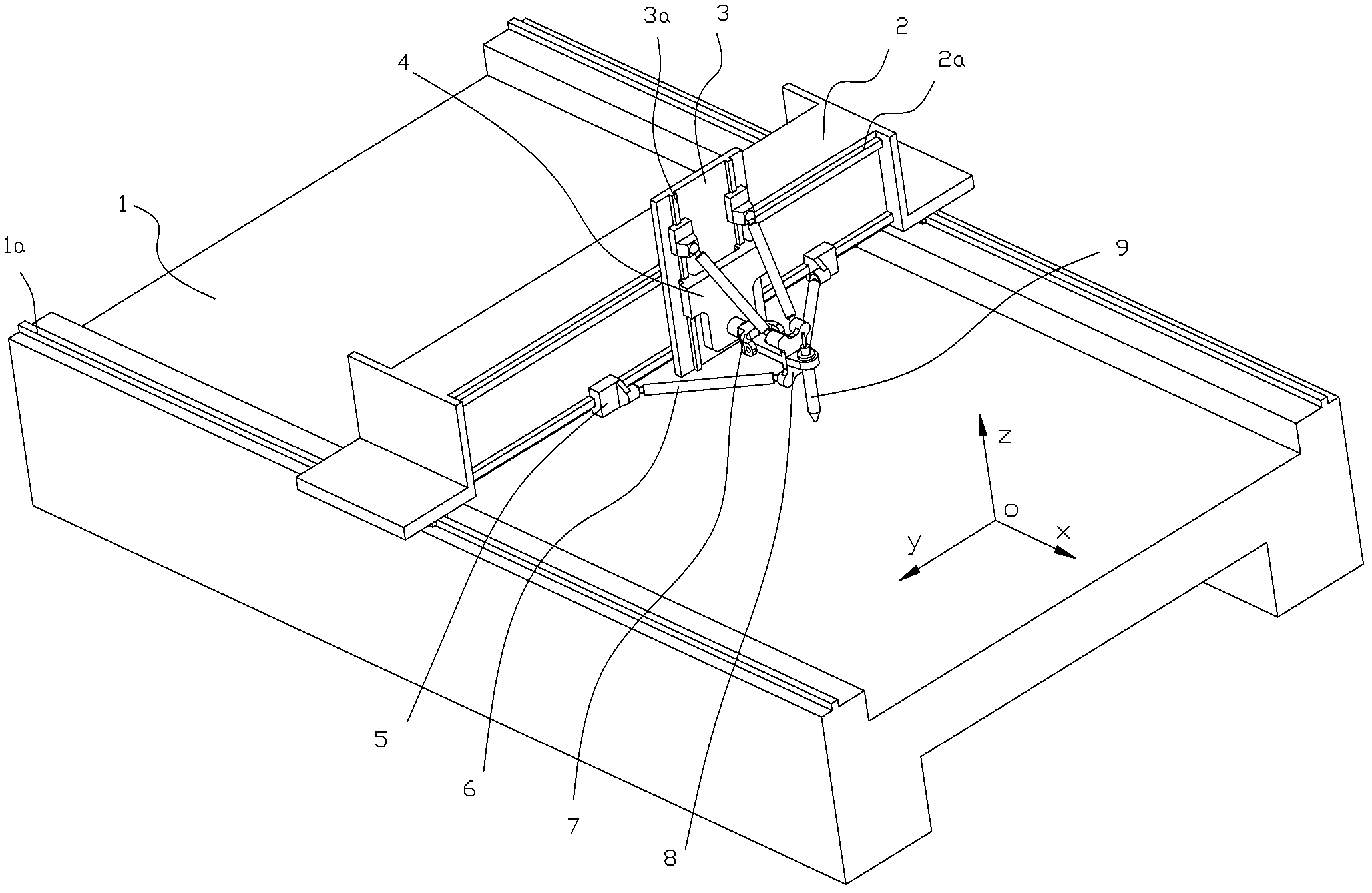

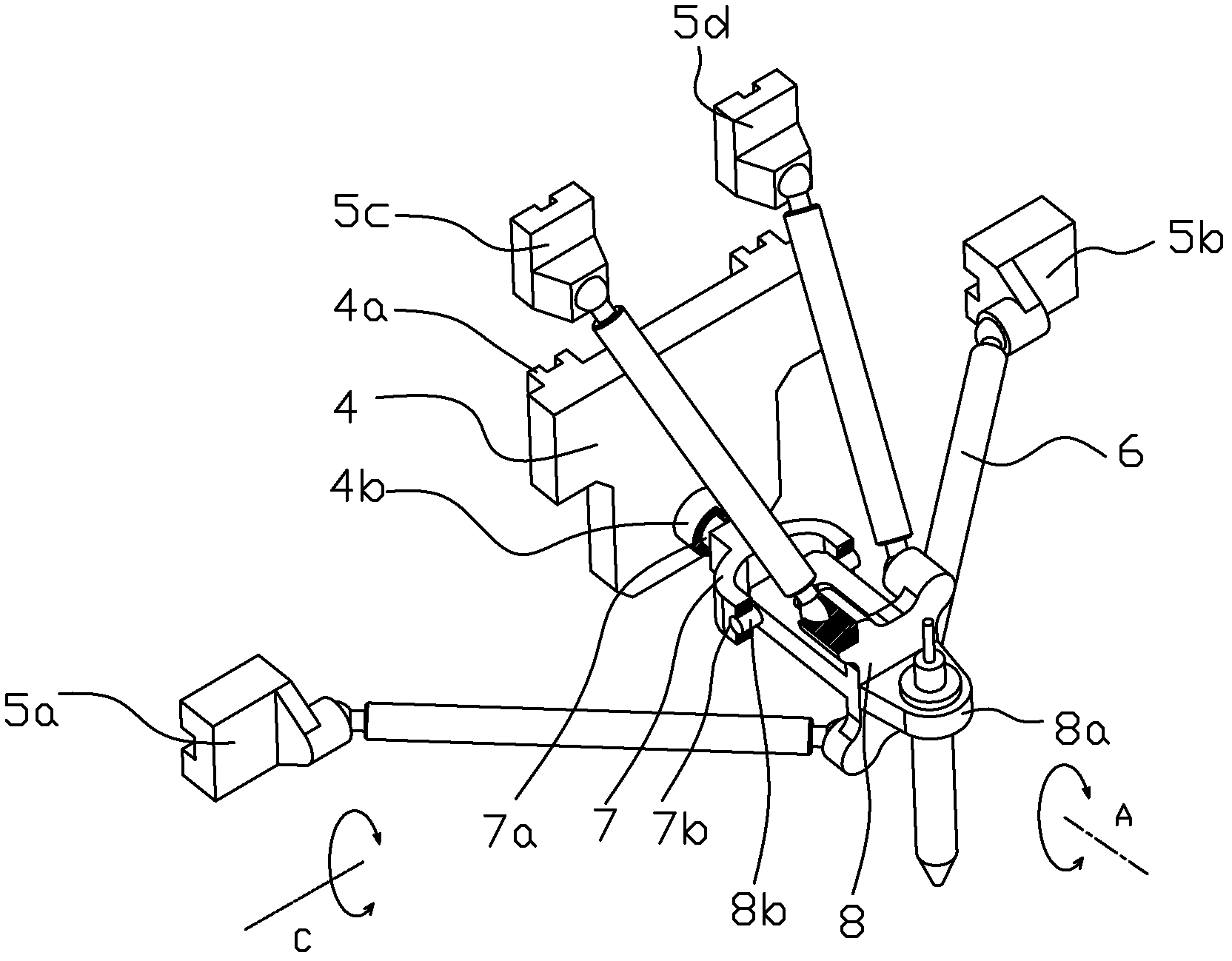

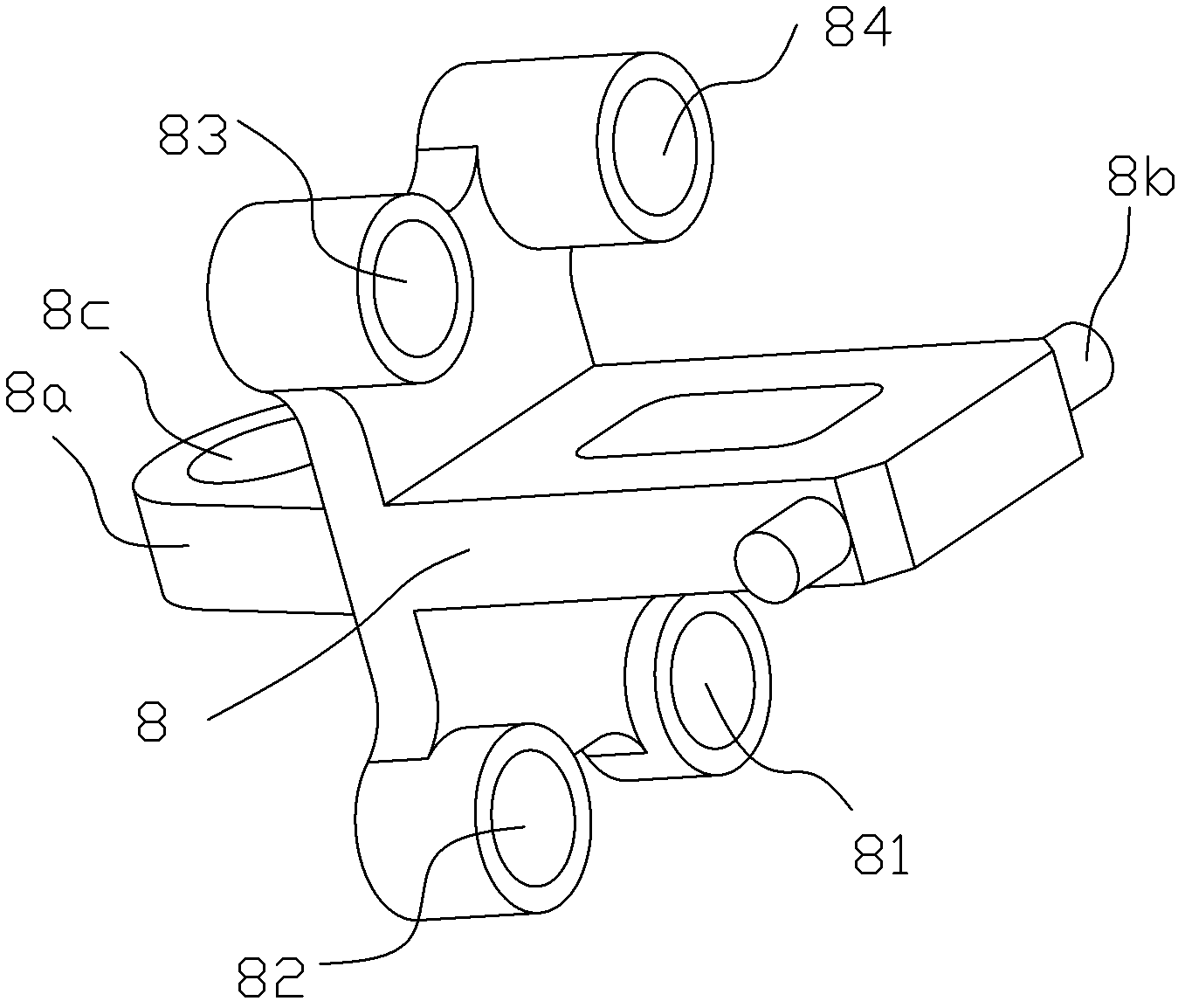

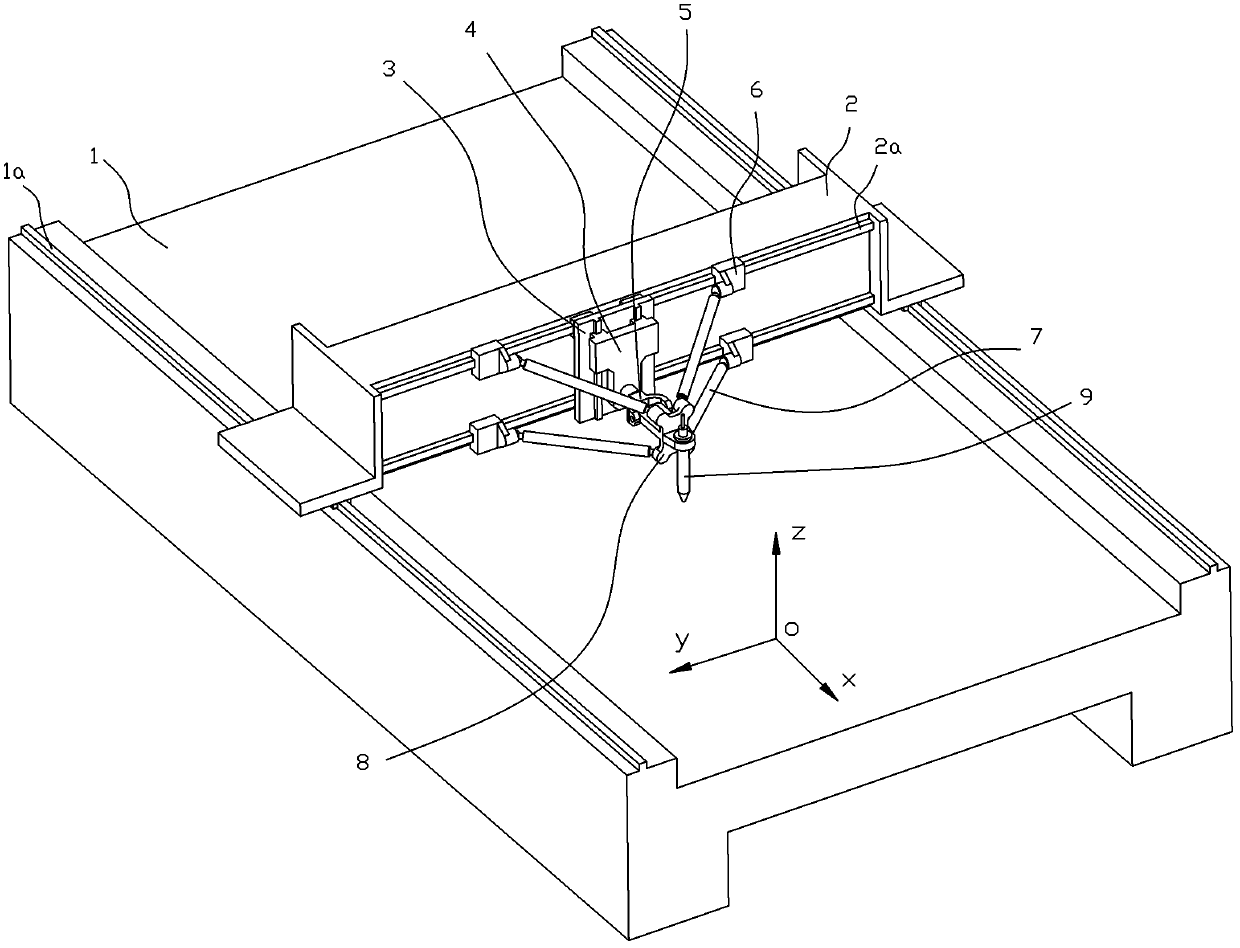

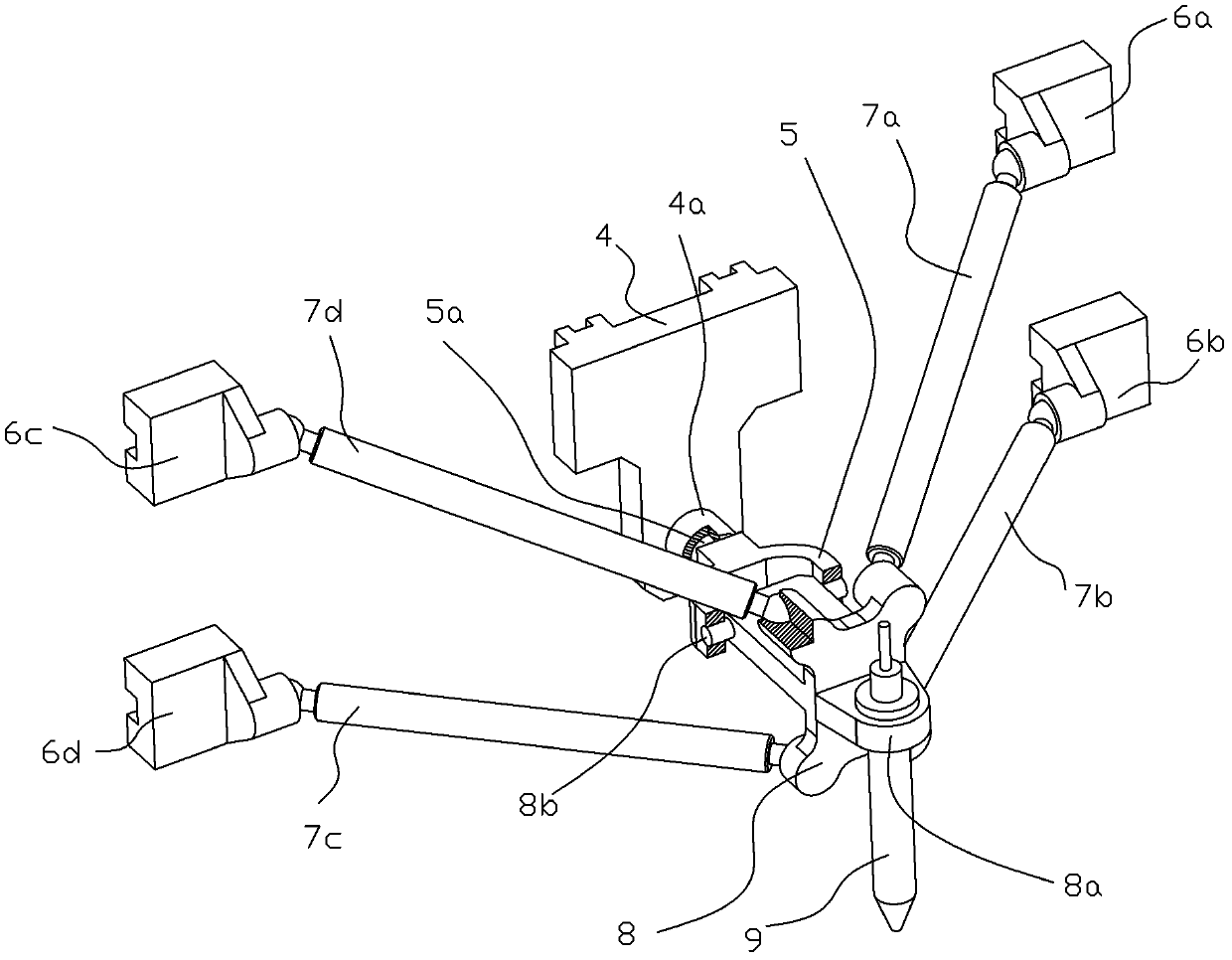

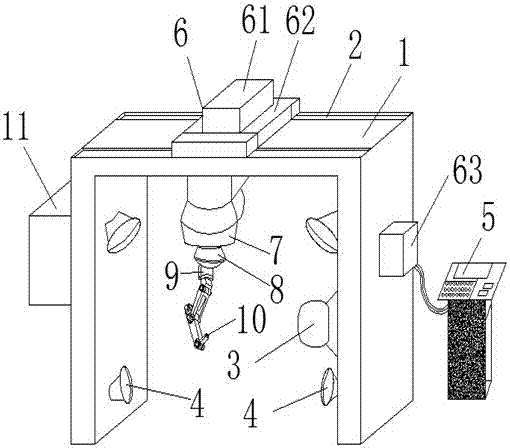

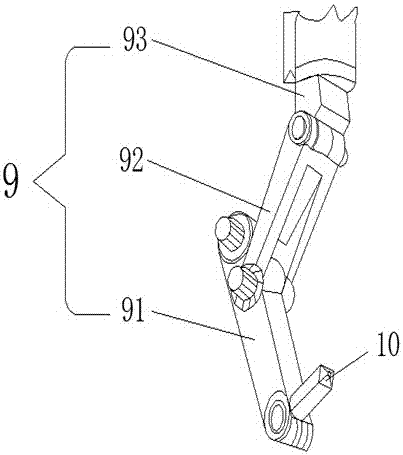

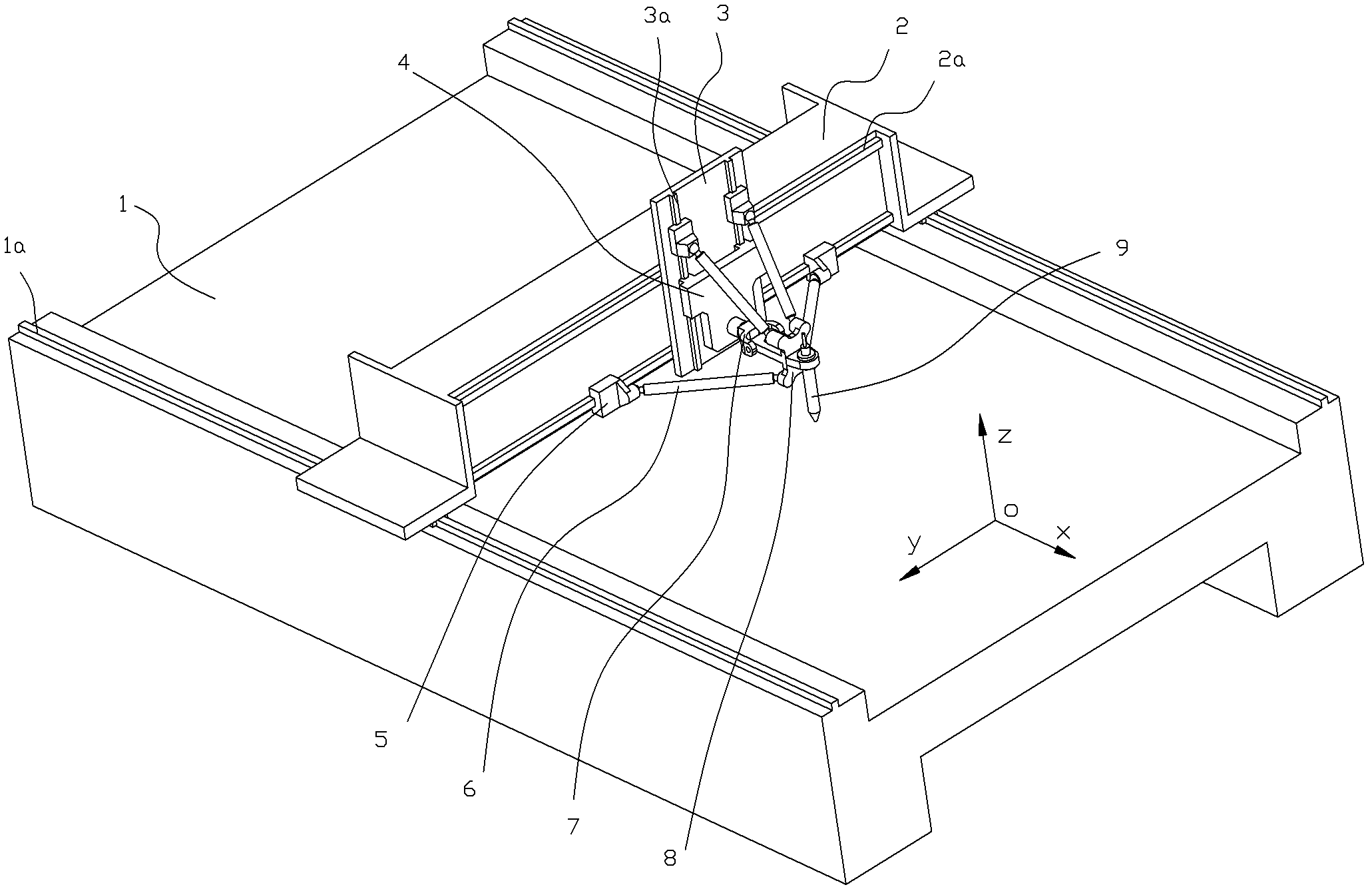

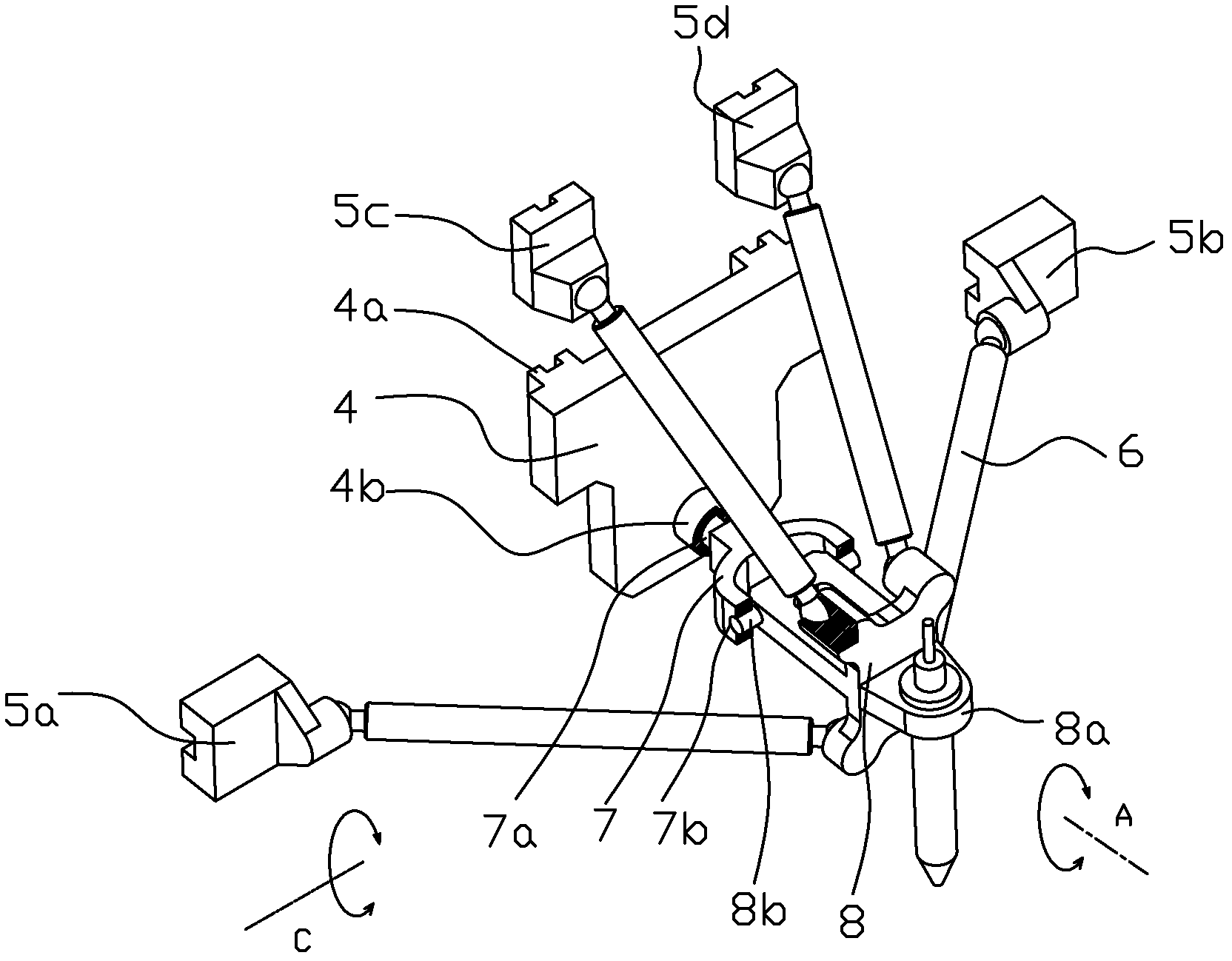

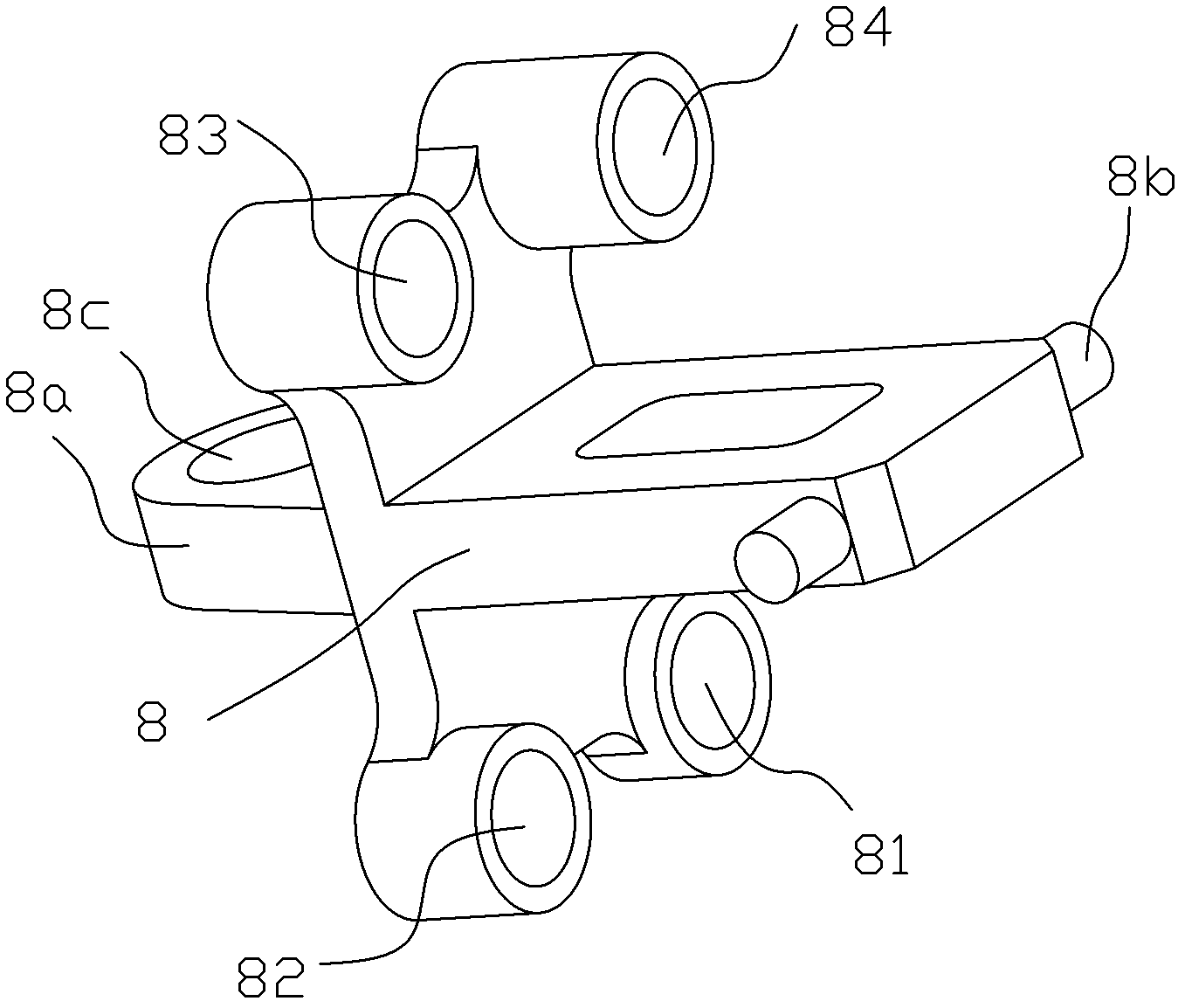

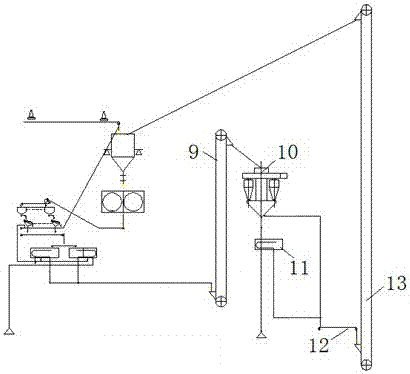

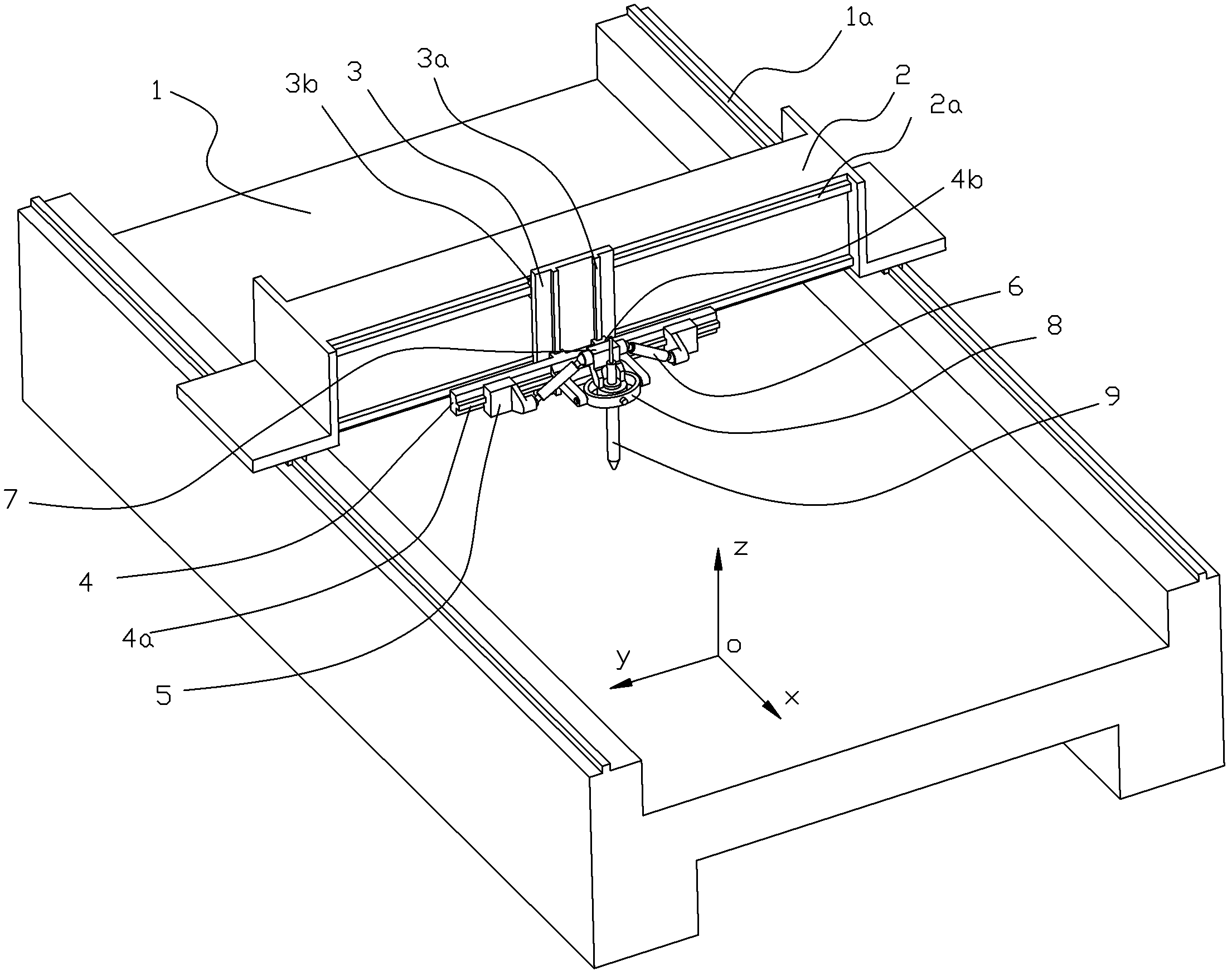

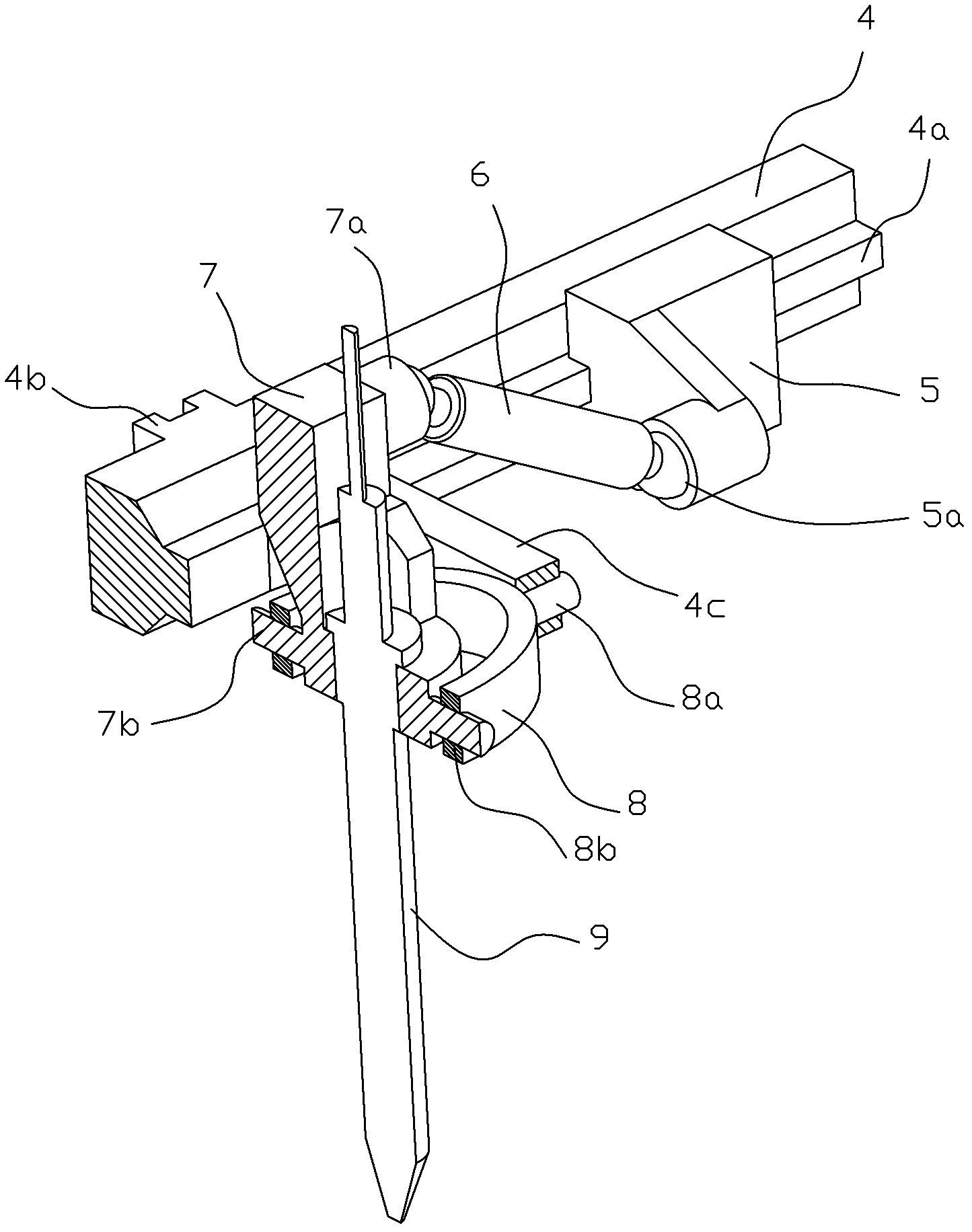

A hybrid five-axis laser cutting machine

ActiveCN102284795AExquisite structureSimple structureLaser beam welding apparatusNumerical controlLaser cutting

The invention discloses a hybrid five-axis laser cutting machine and relates to a laser cutting machine with a parallel and hybrid five-axis driving mechanism. The hybrid five-axis laser cutting machine has the characteristics of more flexible structure, larger rigidity, smaller inertia and higher precision and comprises a machine body, an X-direction guide rail, a cross beam, a laser cutting head and a controller, wherein a Y-direction guide rail is arranged on the side surface of the cross beam, and the laser cutting head is movably connected with the Y-direction guide rail on the side surface of the cross beam through a hybrid device; and the hybrid device comprises a Y supporting plate mechanism, a Z supporting plate mechanism, a driving frame, an annular support frame, a pair of driving block mechanisms and a pair of connecting rods. The five-axis motion of the conventional laser cutting head is realized through the hybrid device. As for the hybrid five-axis laser cutting machine, the concept is ingenious, all parts have flexible structures, the rigidity is great, the inertia is small and the motion precision can be further ensured. The laser cutting machine is a product formed by combining the machine tool technology, the robot technology and the numerical control technology, and compared with a traditional series machine tool, the laser cutting machine is simple in structure and is complex and accurate in mathematical operation. The laser cutting machine has the outstanding advantages of large rigidity, fast response, high precision, strong applicability, high technical added value and the like.

Owner:江苏扬力数控机床有限公司

Addition agent and process for producing 6-micron low-warping-degree electrolytic copper foil through addition agent

InactiveCN105002524ASolve the problem of large warpageImprove the level ofElectroforming processesElectrolysisMetallurgy

The invention provides an addition agent and a process for producing 6-micron low-warping-degree electrolytic copper foil through the addition agent, belongs to the technical field of electrolytic copper foil and particularly relates to addition agents. The addition agent is a water solution containing brightener SPS, polyglycol, thiourea and Cl-, wherein in the addition agent, the concentration of the SPS ranges from 6 g / l to 17 g / l; the concentration of the polyglycol ranges from 2 g / l to 15 g / l; the concentration of the thiourea ranges from 4 g / l to 15 g / l; the concentration of the Cl- ranges from 15 ppm to 25 ppm. The invention further discloses the process for producing the low-warping-degree electrolytic copper foil through the addition agent. The warping height of the 6-micron electrolytic copper foil produced through the addition agent and the process is smaller than or equal to 12 mm, the problem that the warping degree of existing 6-micron electrolytic copper foil is large is effectively solved, and the technical additional value is remarkably increased.

Owner:LINGBAO WASON COPPER FOIL

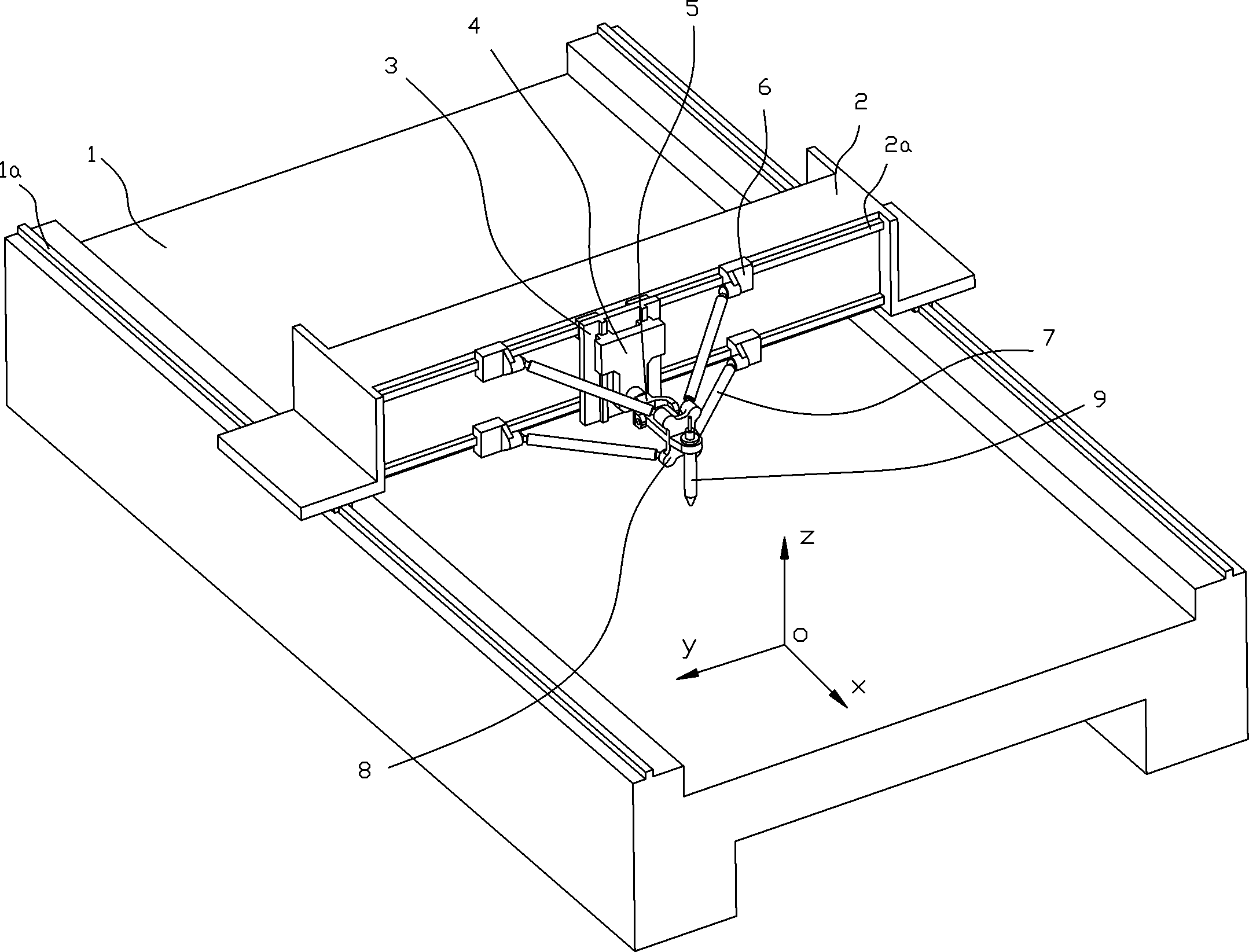

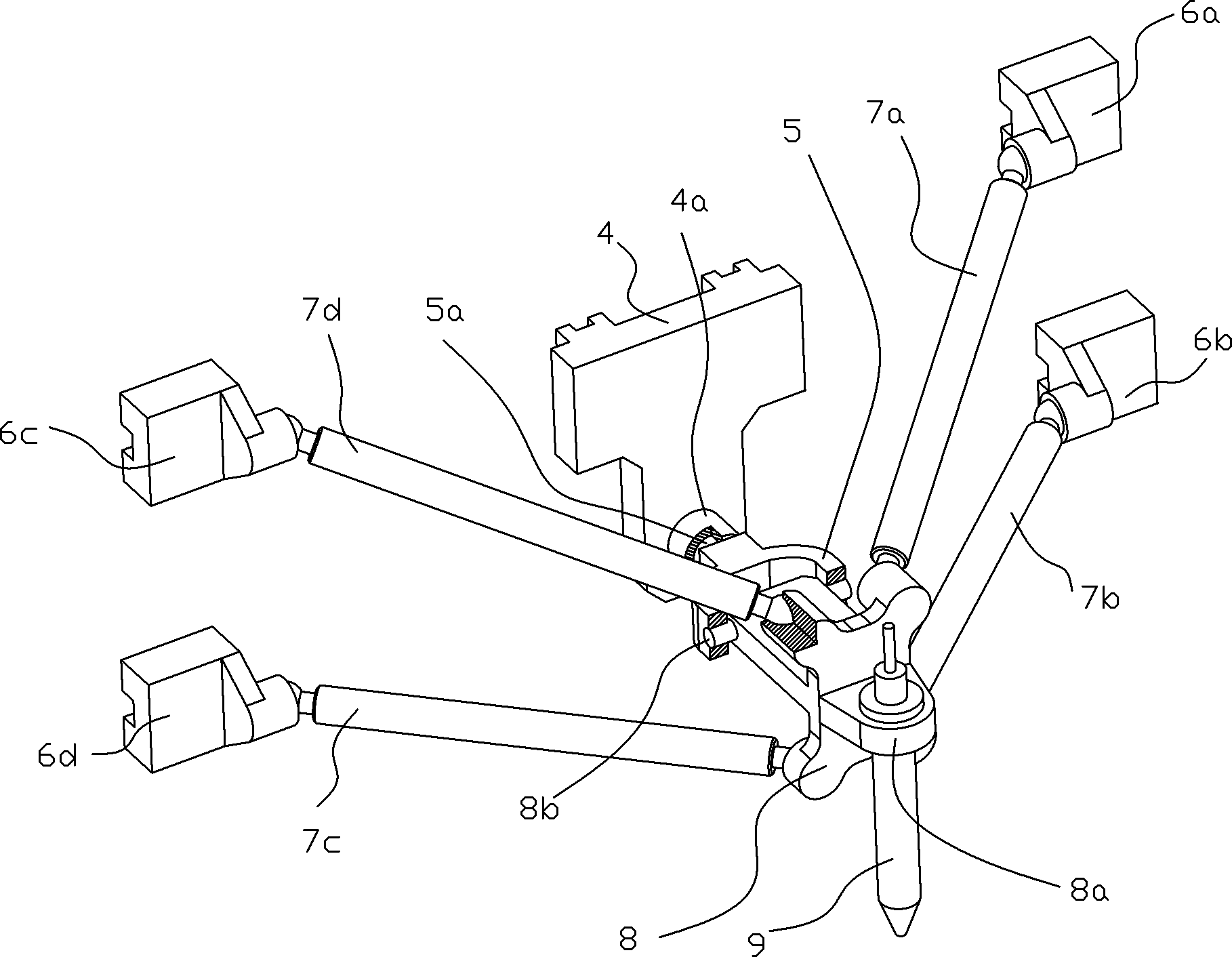

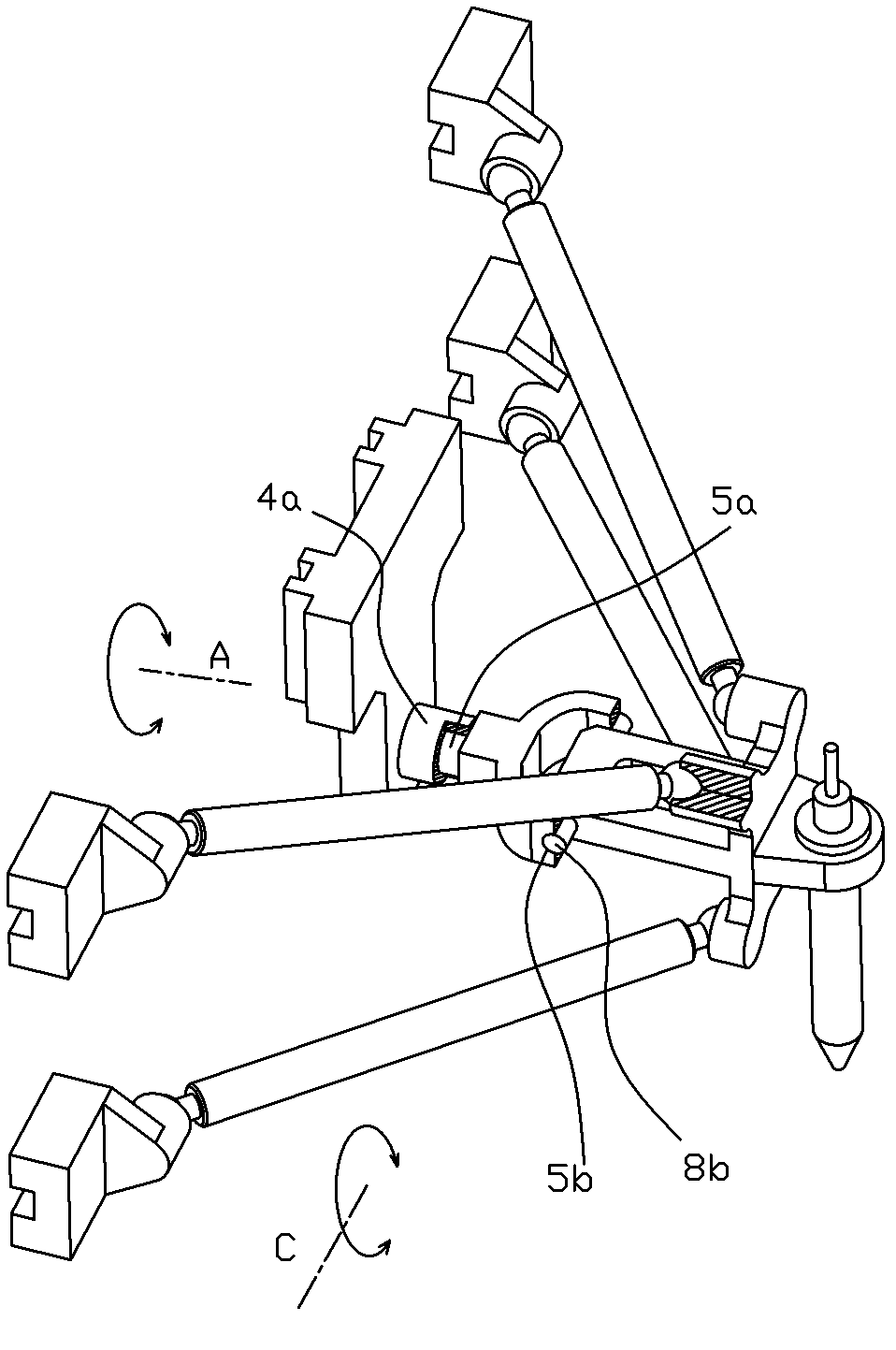

Imperfect degree-of-freedom parallel connection five-axis computerized numerical control laser cutting machine

ActiveCN102303186ARealize Joint MovementSmart structureLaser beam welding apparatusNumerical controlLaser cutting

The invention discloses an imperfect degree-of-freedom parallel connection five-axis computerized numerical control laser cutting machine, relating to a laser cutting machine with an imperfect degree-of-freedom parallel connection five- axis drive mechanism. The laser cutting machine comprises a machine body, an X-direction guide rail, a beam, a laser cutting heat and a controller, wherein the side surface of the beam is provided with a Y-direction guide rail, the laser cutting head is movably connected with the Y-direction guide rail through an imperfect degree-of-freedom parallel connectionmechanism; and the imperfect degree-of-freedom parallel connection mechanism comprises a Y-axis slide carriage device, a Z-axis slide carriage device, a cross, a laser head installing support, four equilong connecting rods and four linear driving devices. The invention realizes five-axis motion of the conventional laser cutting head through the imperfect degree-of-freedom parallel connection device, wherein the beam realizes basic X-direction motion relative to the motion of the machine body; four drive blocks respectively move and drive the laser heat installing support to make translation or rotation motion through respective connecting rods, mutual motion among the four drive blocks realizes combined motion of an Y axis, a Z axis, an A axis and a C axis; and the imperfect degree-of-freedom parallel connection five-axis computerized numerical control laser cutting machine has skilled structures of all parts, large rigidity and small inertia, so that the motion precision can be ensured.

Owner:江苏扬力数控机床有限公司

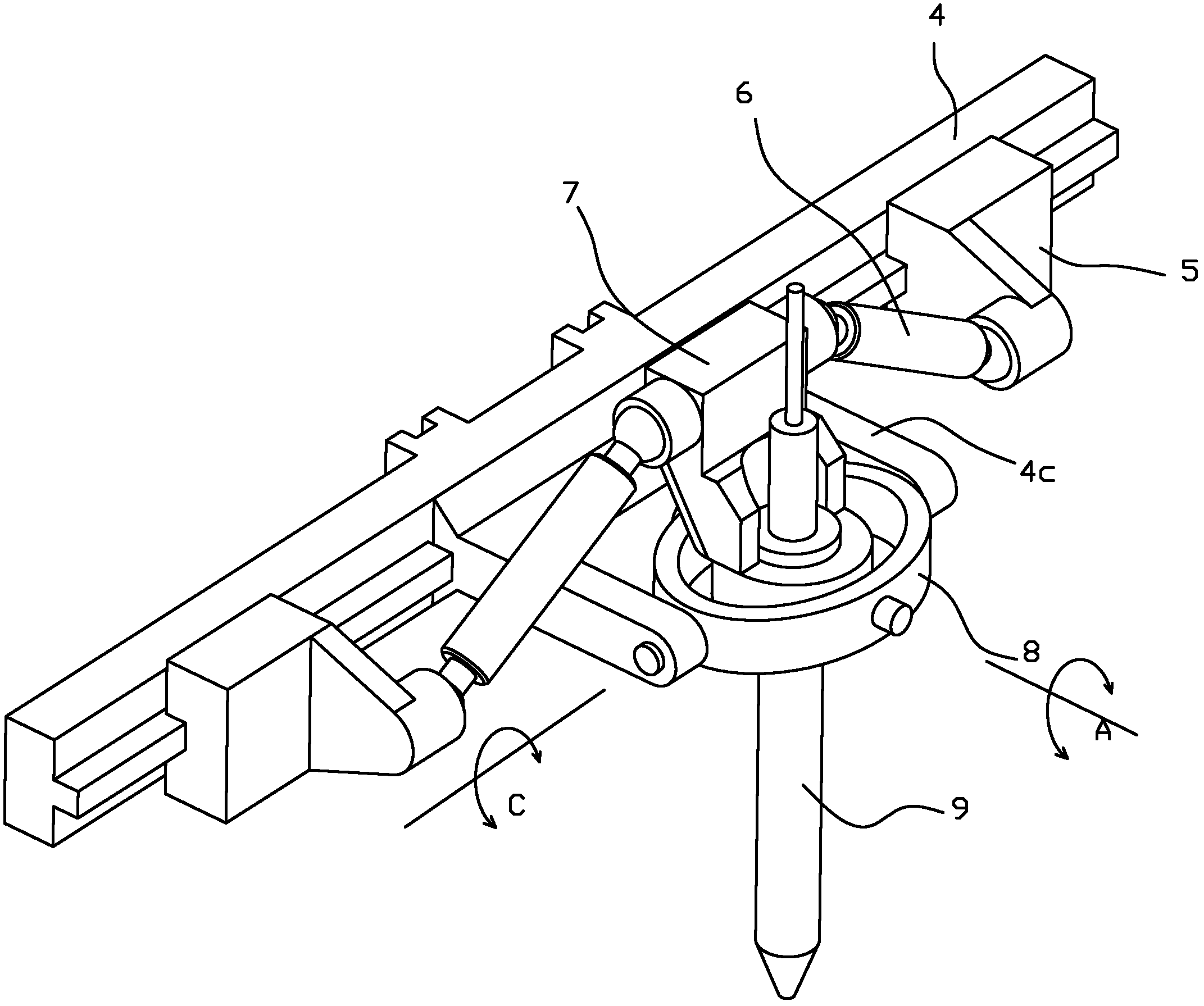

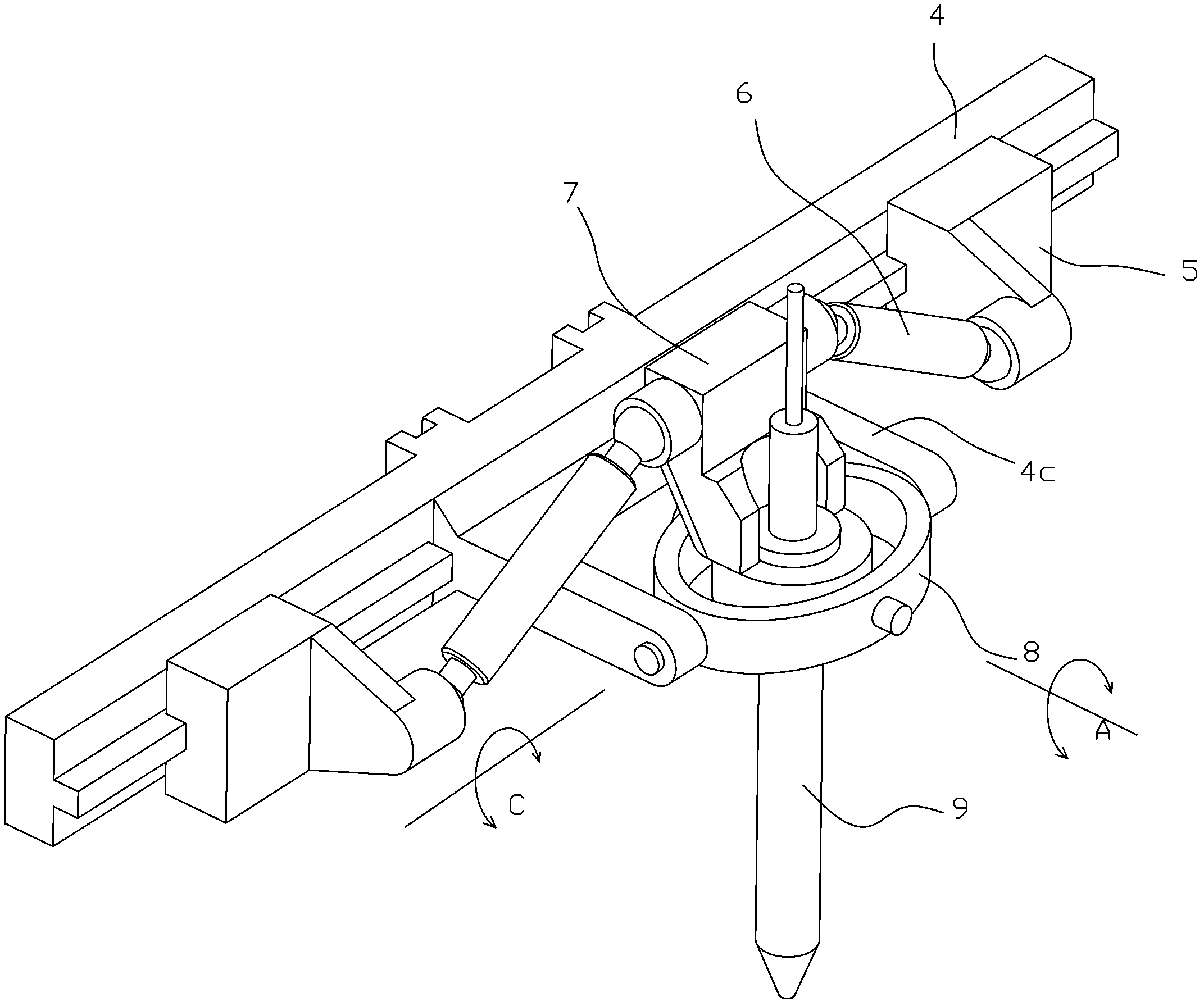

Three-dimensional five-axis computerized numerical control laser cutting machine

ActiveCN102303187AAvoid spatial symmetryImprove rigidityLaser beam welding apparatusNumerical controlLaser cutting

The invention discloses a three-dimensional five-axis computerized numerical control laser cutting machine, relating to a computerized numerical control laser cutting machine with a composite motion parallel connection five-axis drive mechanism, which comprises a machine body, an X-direction guide rail, a beam, a laser cutting head and a controller, wherein the side surface of the beam is provided with a Y-direction guide rail, and the laser cutting head is movably connected with the Y-direction guide rail on the side surface of the beam through a composite motion parallel connection mechanism. The invention realizes five-axis motion of the conventional laser cutting head through the composite motion parallel connection device, wherein the beam realizes basic X-direction motion relative to the motion of the machine body; and combined motion of an Y axis, a Z axis, an A axis and a C axis is realized through the composite motion parallel connection mechanism. The three-dimensional five-axis computerized numerical control laser cutting machine has an ingenious design, skilled structures of all parts, large rigidity and small inertia, so that the motion precision can be ensured. The three-dimensional five-axis computerized numerical control laser cutting machine integrates a lathe technology, a robot technology and a computerized numerical control technology, and has the advantages of simple structure and complex and accurate arithmetical operation in comparison with the traditional serial connection lathe. The three-dimensional five-axis computerized numerical control laser cutting machine has the remarkable advantages of large rigidity, rapid response speed, high precision, strong adaptability, high technical additional value and the like.

Owner:江苏扬力数控机床有限公司

Method for treating chromic slag by acid pickling process

InactiveCN1635170AEliminate Pollution PotentialReduce processing costsSolid waste disposalProcess efficiency improvementAfter treatmentSlag

The invention relates to a method for treating chromic slag by acid pickling process. Wherein: mixing waste acid and chromic slag, leading supersonic wave into the acid tank by supersonic wave generator, discharging the acid liquor after treatment, deacidizing the hexavalent chromium ion in chromic slag to trivalent chromium ion completely by treating the acid liquor. The invention adopts resource method for treating chromic slag, and realizes innocuousness, resource-saving and economic benefit increasing.

Owner:刘克柱

Chestnut processing method

The present invention discloses a chestnut processing method which comprises the following steps: (1) pretreating chestnut: successively carrying out water bath treating, low temperature storing, proper temperature sugar converting, cut treating, flavor enhancing, perfuming and enzyme inactivation treating, and then shelling the chestnuts to obtain chestnut kernels; (2) pulping chestnut kernels: successively soaking, crushing, pulping, and liquid and residue separating to obtain chestnut kernel clear liquid and slurry; (3) carrying out fine filtering of clear liquid; (4) blending clear liquid to obtain mellow and fragrant chestnut kernel turbid juice beverage and / or microfiltrated chestnut kernel turbid juice beverage and / or ultrafiltrated chestnut kernel clarified juice beverage; and (5) boiling slurry into sauce: carrying out sugar blending, first boiling, sauce blending, sauce boiling, filling and sterilizing of the slurry to be blended to obtain chestnut sauce. Using the chestnut processing method to treat a same batch of chestnut kernel raw materials, two or more than two chestnut products can be prepared orderly in large-scale production.

Owner:BEIJING FORESTRY UNIVERSITY

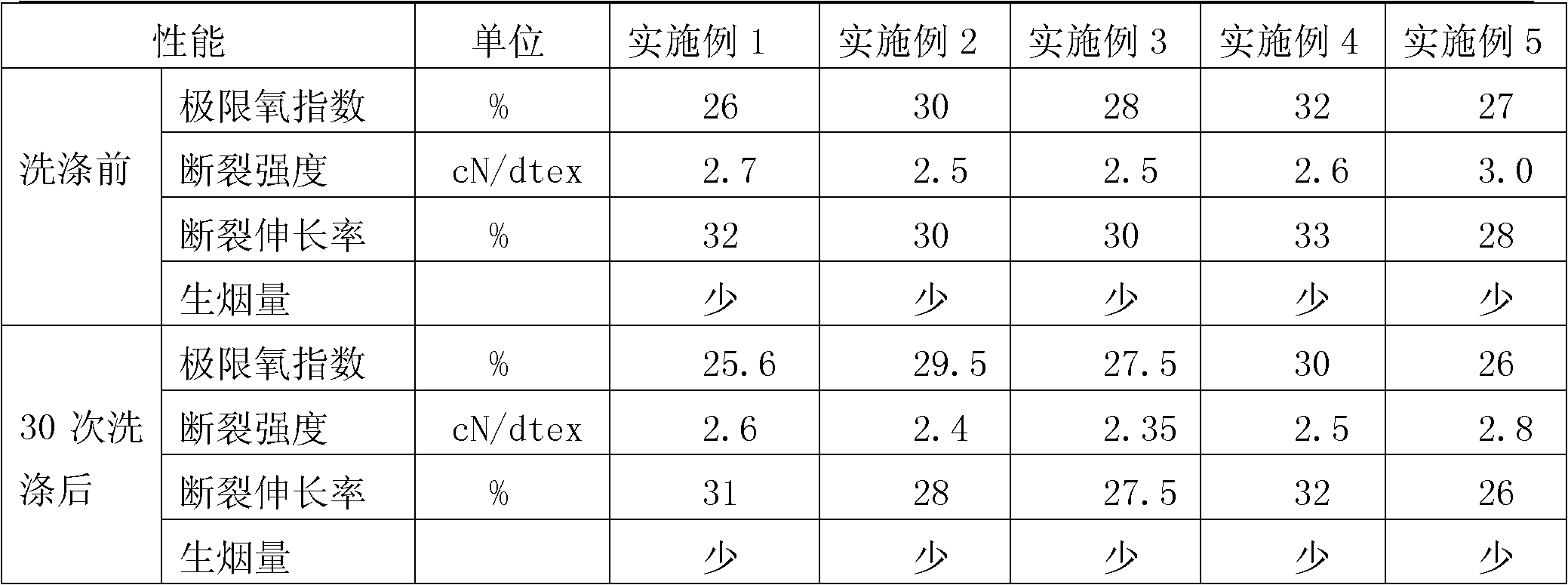

Preparation method of durable low-smoke halogen-free flame-retardant polyacrylonitrile fiber

InactiveCN102560747BGood flame retardant durabilityWill not migrateFlame-proof filament manufactureMonocomponent synthetic polymer artificial filamentSodium thiocyanateIrradiation

The invention relates to a preparation method of durable low-smoke halogen-free flame-retardant polyacrylonitrile fiber. The preparation method of durable low-smoke halogen-free flame-retardant polyacrylonitrile fiber is characterized by comprising the following steps: 1) blending spinning solution preparation: based on the mass parts of the polyacrylonitrile powder and the phosphorus-containing flame retardant, dissolving 65-80 parts of polyacrylonitrile powder and 20-35 parts of phosphorus-containing flame retardant into a 50-52wt% sodium thiocyanate aqueous solution, and mixing to obtain the blending spinning solution, wherein the ratio of the total mass of the polyacrylonitrile powder and the phosphorus-containing flame retardant to the mass of the 50-52wt% sodium thiocyanate aqueous solution is (10-15):100; 2) wet spinning; and 3) irradiation: irradiating primary flame-retardant polyacrylonitrile fiber in an electron beam accelerator with 0.5-5MeV or a <60>Co device to obtain the durable low-smoke halogen-free flame-retardant polyacrylonitrile fiber, wherein the irradiation dose is 20-50kGy. The fiber prepared by using the method has good flame-retardant durability and small smoke generation property.

Owner:WUHAN TEXTILE UNIV +1

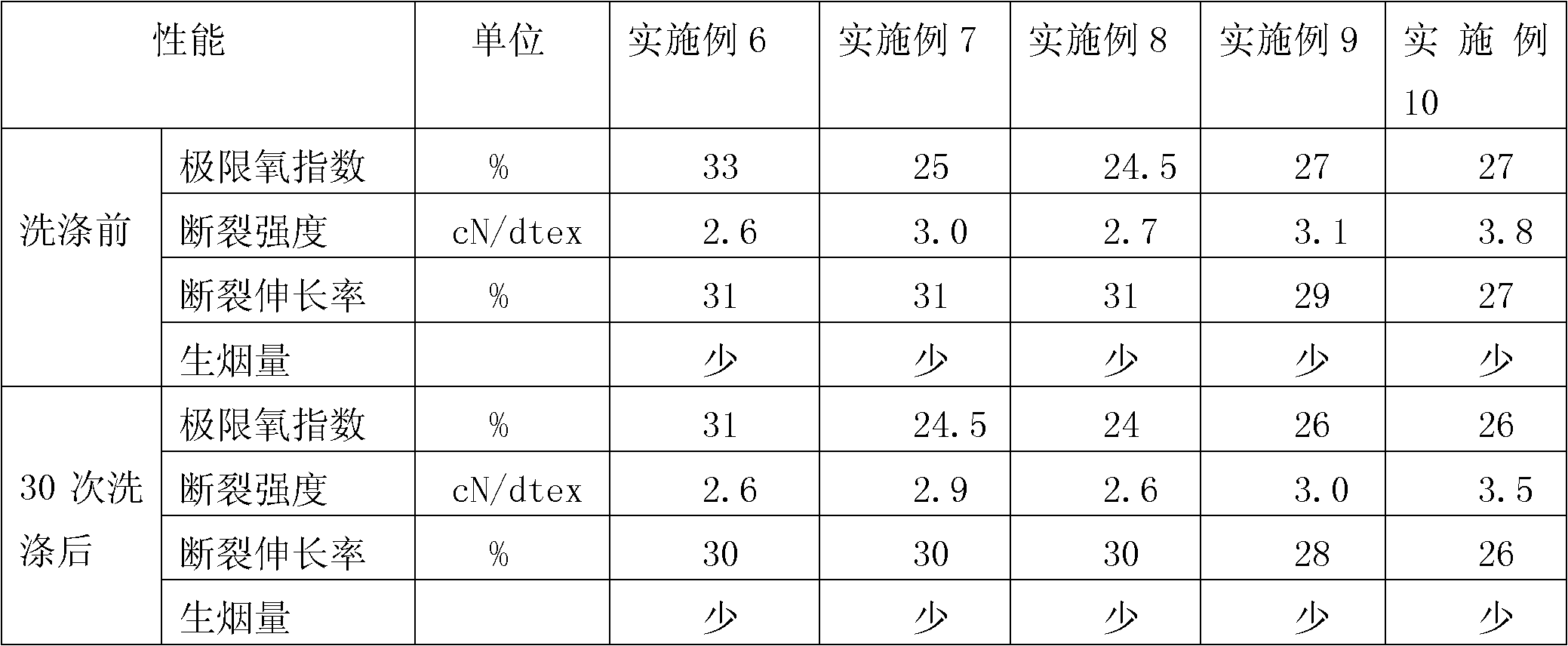

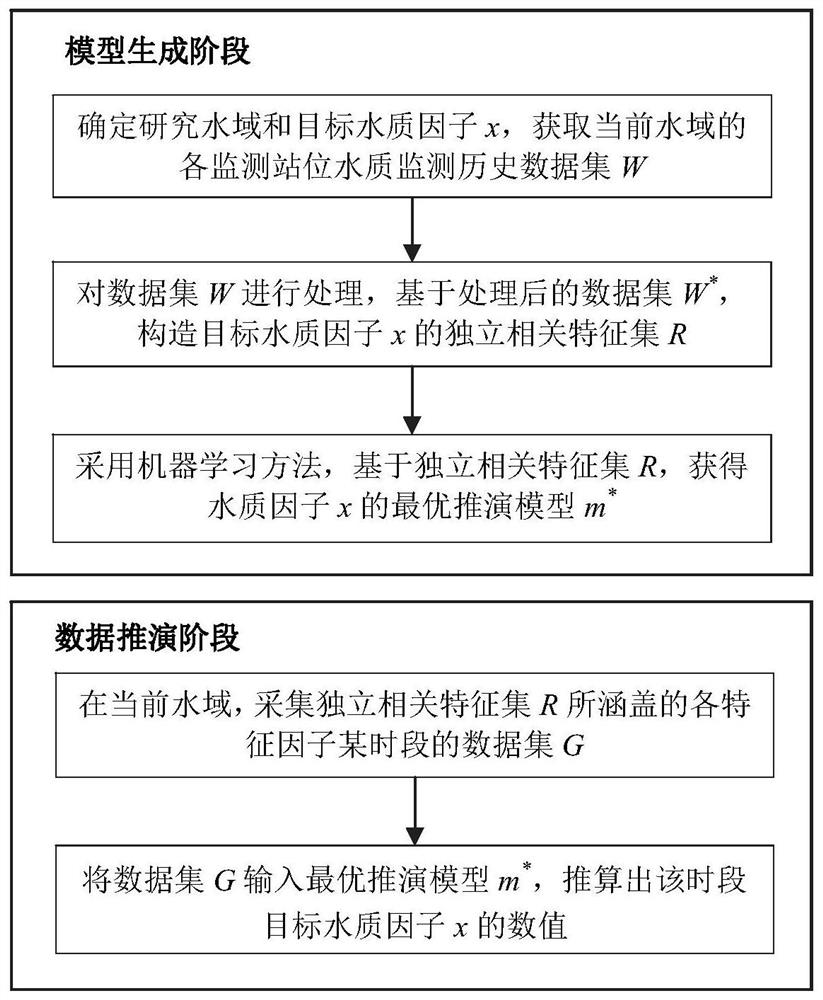

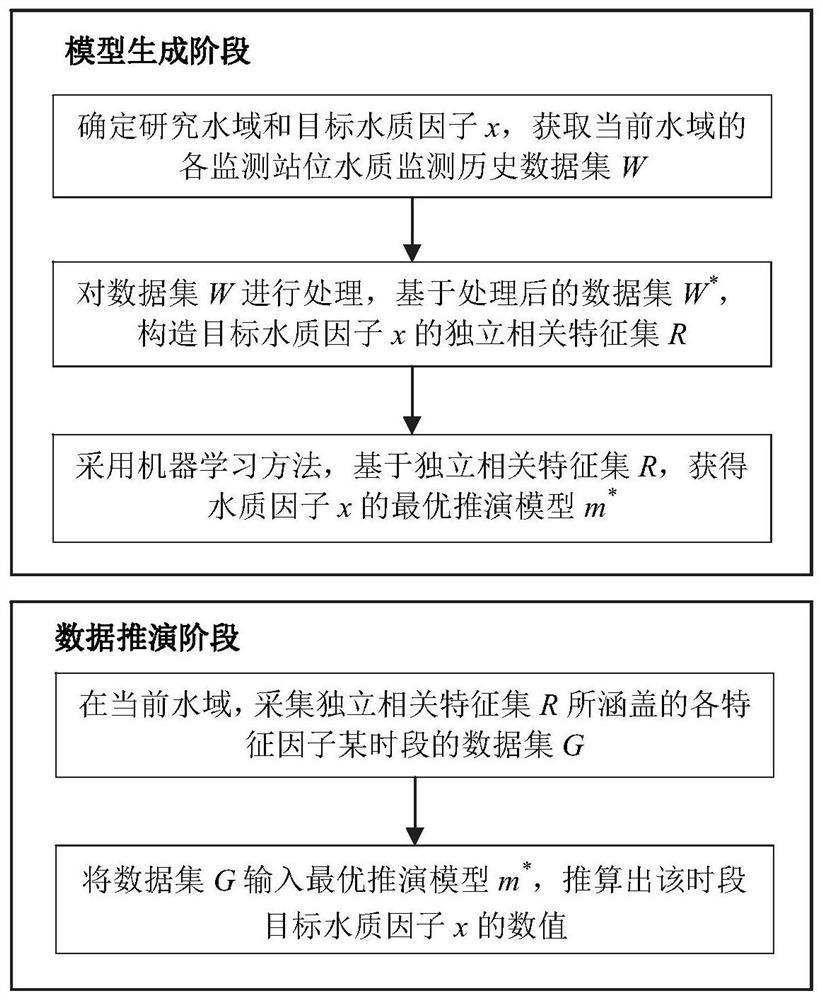

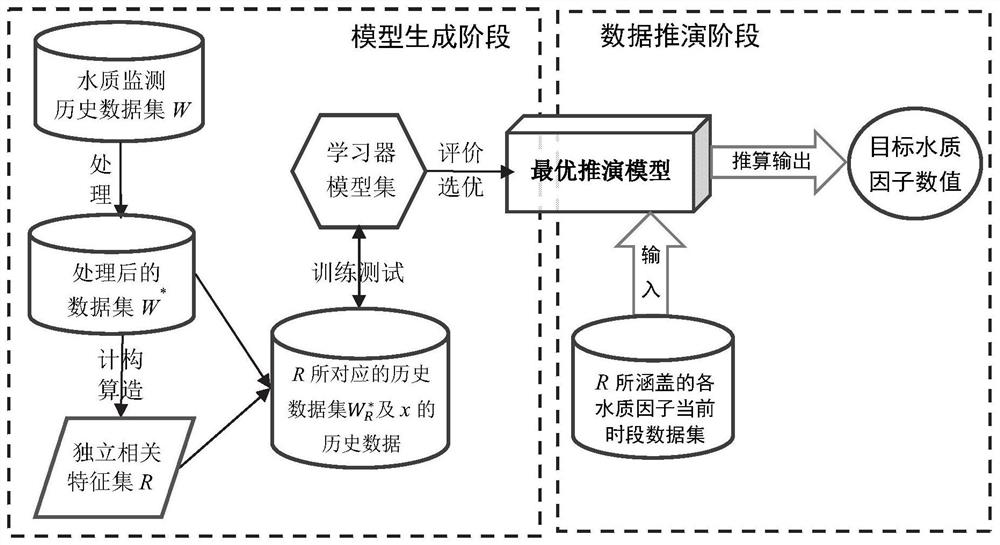

Water quality data deduction acquisition method and system based on machine learning

ActiveCN112233734ALower acquisition costsReduce pollutionCheminformatics data warehousingTesting waterData setData acquisition

The invention discloses a water quality data deduction obtaining method and system based on machine learning. The method is divided into a model generation stage and a model deduction stage. In the model generation stage, historical data of various characteristics acquired by all monitoring stations of a researched water area is analyzed and processed to obtain an independent related characteristic set of a target water quality factor and a corresponding historical data set, and based on the data set, an optimal deduction model of the target water quality factor is obtained through a machine learning method; and in the model deduction stage, data of each characteristic factor covered by the independent related characteristic set in a certain period of time is collected, the data is input into the optimal deduction model, and data of the target water quality factor in the period of time is reckoned. The water quality data acquisition method is a novel water quality data acquisition method without traditional data acquisition modes such as chemical reagent and sensor detection, can reduce environmental pollution and hidden danger caused by the traditional water quality data acquisition modes, and has the advantages of low cost, safety, environmental protection, high technical added value and the like.

Owner:SHANDONG UNIV

Method for recycling waste lead-acid battery negative electrode paste and application of recycled materials

ActiveCN103184340BLow costReduce energy consumptionWaste accumulators reclaimingProcess efficiency improvementElectrical batteryLead oxide

The invention discloses a method for recovering lead plaster of the negative pole of a disused lead acid storage battery and application of the recovered lead plaster. A preparation method of superfine lead powder comprises the following steps: firstly, a disused battery is fully charged; secondly, the lead plaster of the negative pole is separated from the lead acid storage battery; thirdly, the main substance of the lead plaster of the negative pole is changed into a lead raw material mainly composed of PbO and Pb via high temperature and humidity solidification; and lastly, dry grinding or crumbling of the lead raw material is carried out under the condition of oxygen, or wet treatment is carried out by using organic salt and organic acid to obtain superfine lead powder. The recovery method disclosed by the invention is low in cost, simple and convenient in process, high in recovery rate of lead, low in energy consumption and easy to achieve industrialization, and causes minor pollution to the environment during recovering the lead. The method directly prepares superfine lead powder which can be directly used to produce storage batteries. The superfine PbO powder prepared by the method has good performance, is high in technology added value, and can obtain a battery pole plate which has high electrochemistry capacity and a long charging / discharge service life.

Owner:SHENZHEN CENT POWER TECH

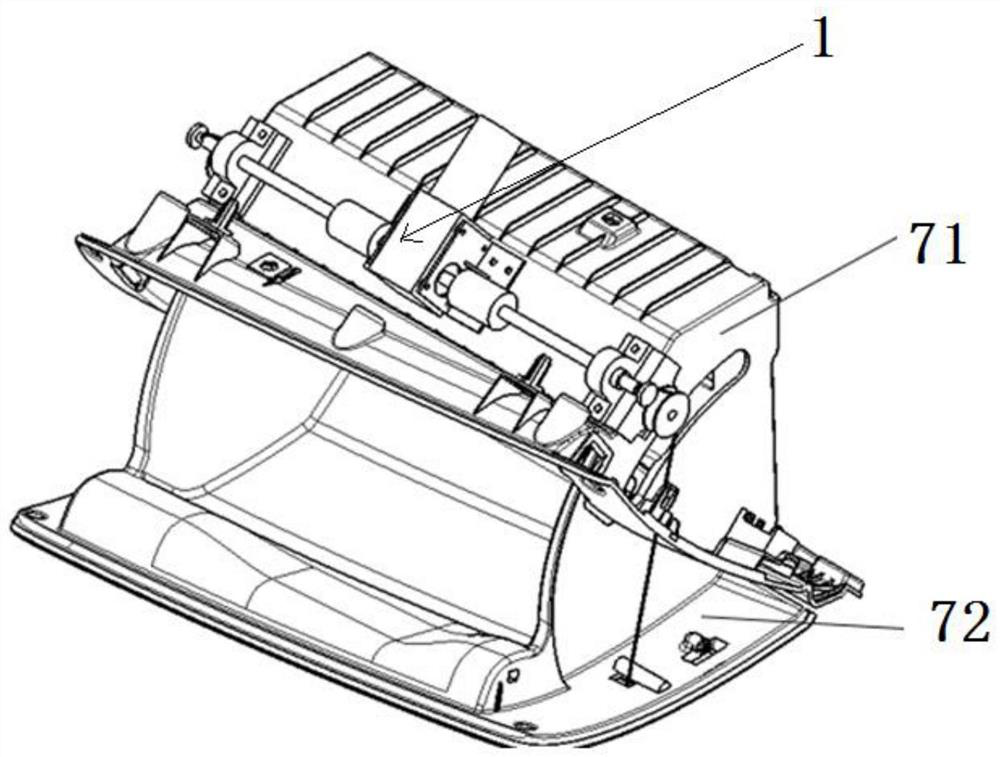

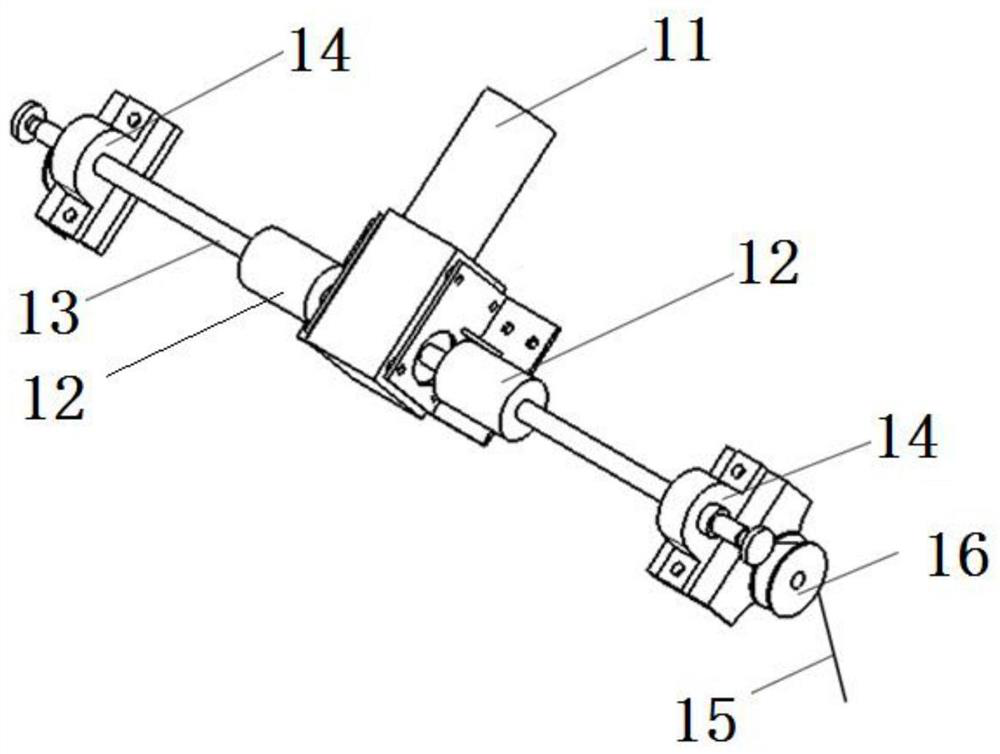

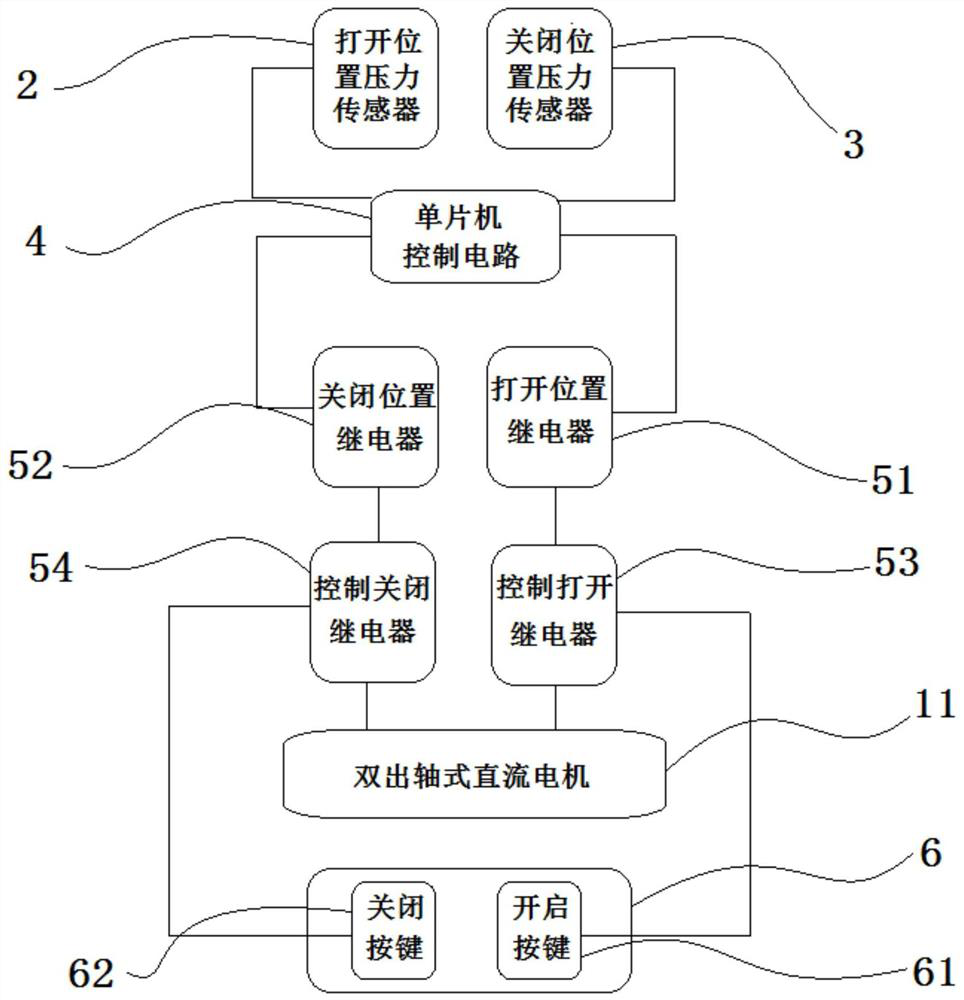

Opening and closing control mechanism of rolling line type electric glove box and control method thereof

ActiveCN112482921ASimple structureHigh process feasibilityPower-operated mechanismControl engineeringMicrocomputer control

The invention provides an opening and closing control mechanism of a rolling line type electric glove box. The opening and closing control mechanism comprises a rolling line transmission device, an opening position pressure sensor, a closing position pressure sensor, a single chip microcomputer control circuit, an opening position relay, a closing position relay, an opening control relay, a closing control relay and a touch switch. The opening and closing control mechanism is simple in structure, high in process feasibility, high in integration level and convenient to operate, rolling and paying-off of a rolling line are controlled through the touch switch, and therefore closing and opening of the glove box are controlled; and a vertical bearing plays a role in supporting a connecting rodand assisting in rotation, a fixed pulley is in friction contact with the rolling line, and the function of supporting and stabilizing a system is achieved. The opening and closing control mechanism of the rolling line type electric glove box can replace a traditional glove box lock mechanism scheme, the storage range of the glove box can be enlarged in space, the manufacturing cost of the glove box is reduced, and meanwhile the technical additional value of products is greatly improved.

Owner:CHANGCHUN FAWAY ADIENT AUTOMOTIVE SYST CO LTD

Imperfect degree-of-freedom parallel connection five-axis computerized numerical control laser cutting machine

ActiveCN102303186BRealize Joint MovementSmart structureLaser beam welding apparatusNumerical controlDegrees of freedom

The invention discloses an imperfect degree-of-freedom parallel connection five-axis computerized numerical control laser cutting machine, relating to a laser cutting machine with an imperfect degree-of-freedom parallel connection five- axis drive mechanism. The laser cutting machine comprises a machine body, an X-direction guide rail, a beam, a laser cutting heat and a controller, wherein the side surface of the beam is provided with a Y-direction guide rail, the laser cutting head is movably connected with the Y-direction guide rail through an imperfect degree-of-freedom parallel connection mechanism; and the imperfect degree-of-freedom parallel connection mechanism comprises a Y-axis slide carriage device, a Z-axis slide carriage device, a cross, a laser head installing support, four equilong connecting rods and four linear driving devices. The invention realizes five-axis motion of the conventional laser cutting head through the imperfect degree-of-freedom parallel connection device, wherein the beam realizes basic X-direction motion relative to the motion of the machine body; four drive blocks respectively move and drive the laser heat installing support to make translation or rotation motion through respective connecting rods, mutual motion among the four drive blocks realizes combined motion of an Y axis, a Z axis, an A axis and a C axis; and the imperfect degree-of-freedom parallel connection five-axis computerized numerical control laser cutting machine has skilled structures of all parts, large rigidity and small inertia, so that the motion precision can be ensured.

Owner:江苏扬力数控机床有限公司

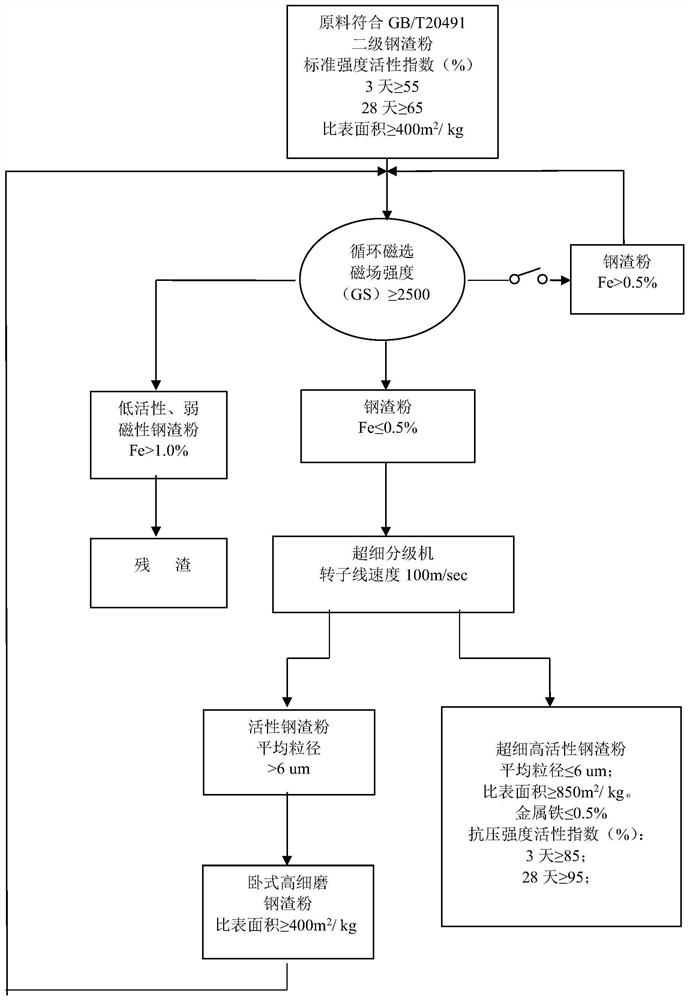

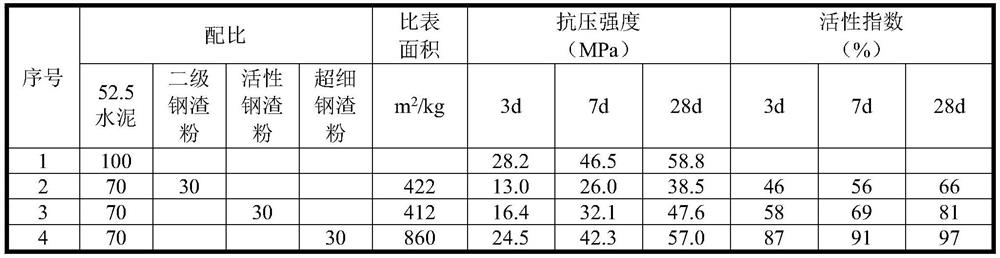

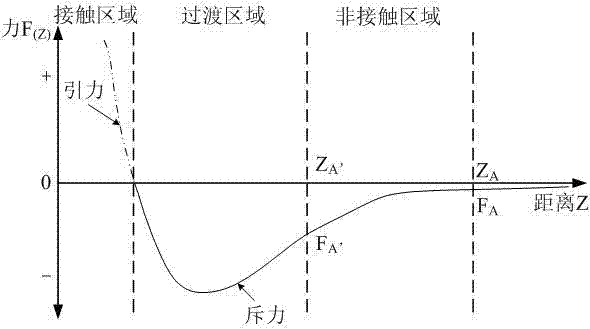

Ultra-fine high-activity steel slag powder and preparation method thereof

ActiveCN108033695BHigh activityReduce wearSolid waste managementCement productionCompressive resistanceSlag

The invention provides superfine high-activity steel slag powder and a preparation method thereof. According to the preparation method provided by the invention, a three-circulation process techniqueof circulated magnetic deironing, circulated superfine dry-type air separation degrading and circulated superfine grinding is adopted to prepare the superfine high-activity steel slag powder. The content of iron of the superfine high-activity steel slag powder provided by the invention is less than or equal to 0.5%, the average particle size of the powder is controlled to be less than or equal to6.0mu m, the specific surface area of the powder is greater than or equal to 850m<2> / kg, and the product has the characteristics of being high in early-stage pressure resistance. The three-day pressure resistance activity index (%) of the powder is greater than or equal to 85%, which is 1.55 times of a provided value of a seven-day pressure resistance activity index of secondary steel slag powderof the national standard Steel Slag Powder Used for Cement and Concrete, that is, GB / T20491, and the 28-day pressure resistance activity index (%) of the powder is greater than or equal to 95%, whichis 1.46 times of a provided value of secondary steel slag powder GB / T20491.

Owner:SHANGHAI HAILI NEW ENVIRONMENTAL PROTECTION BUILDING MATERIAL CO LTD

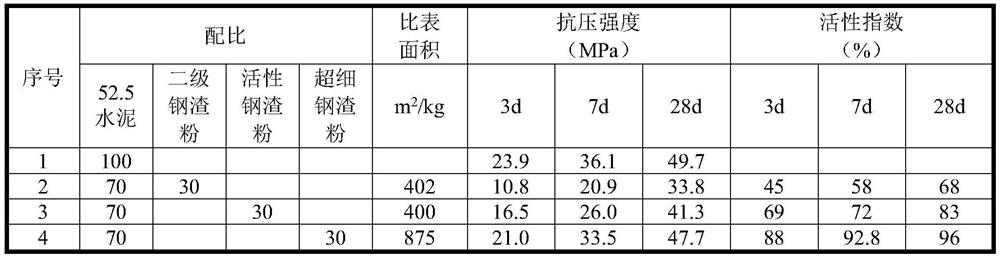

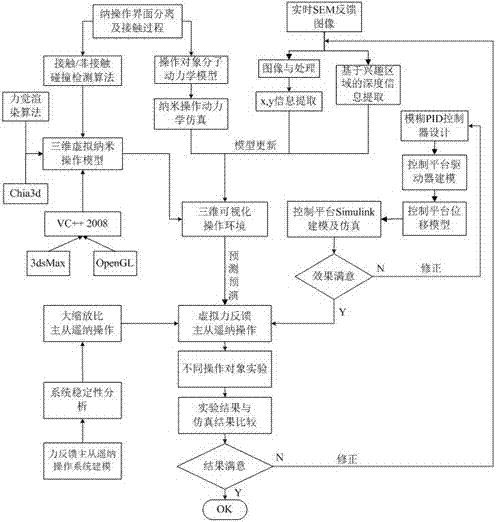

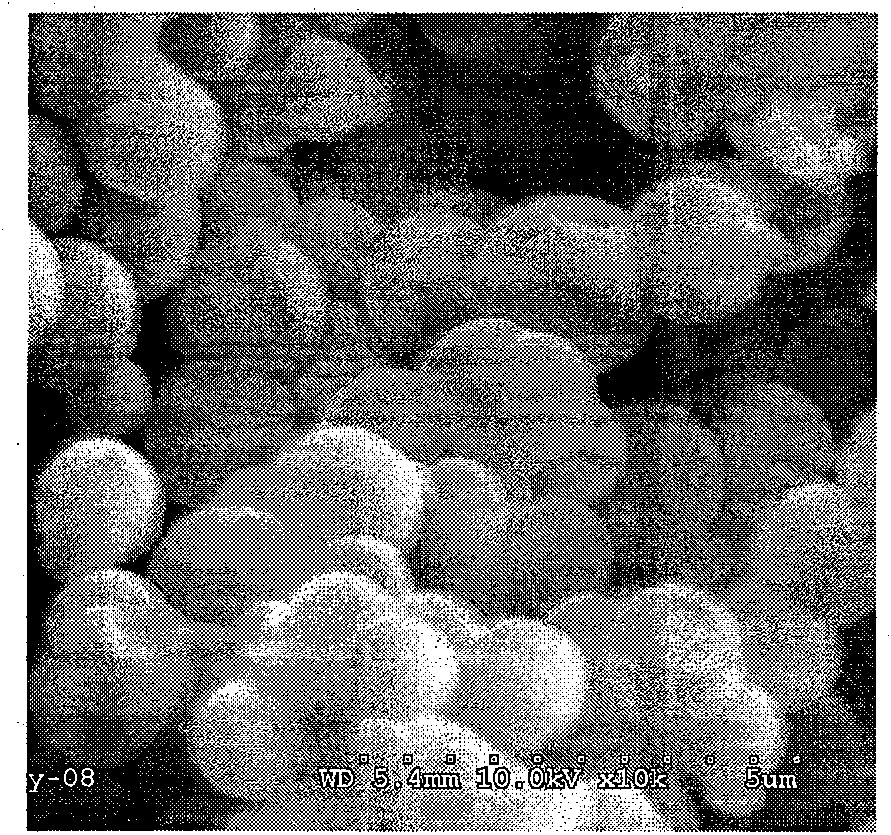

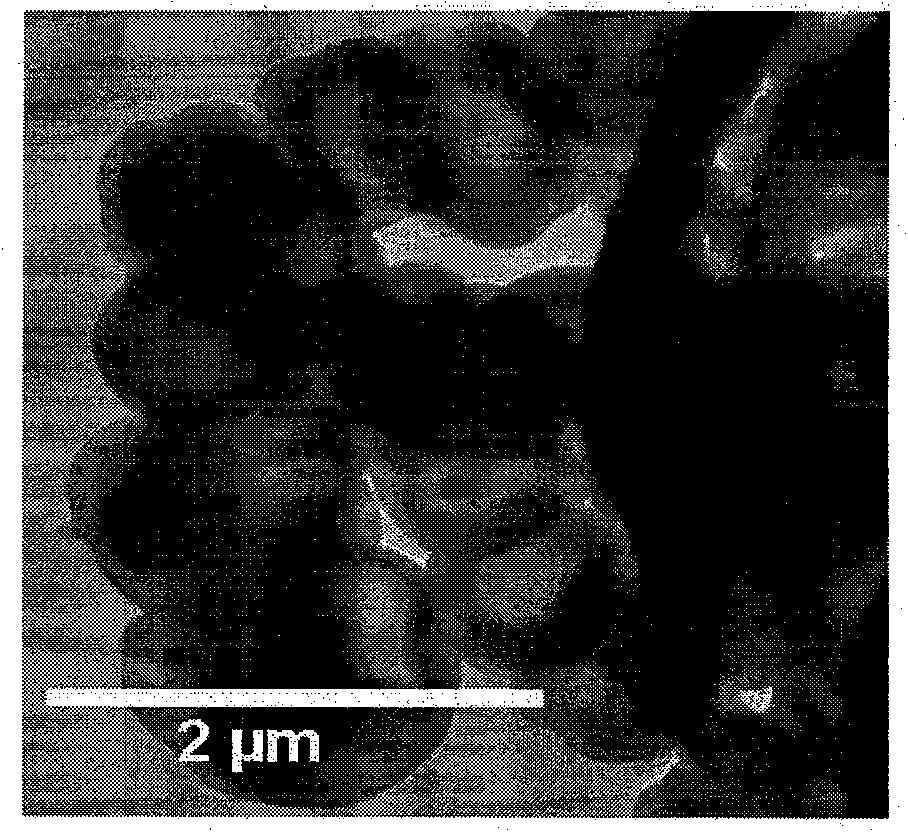

Closed-loop operating method and operating platform for nano members under SEM (scanning electron microscope)

InactiveCN108002344ASolve mobile efficiencyAddress positioning efficiencyNanostructure manipulationTime efficientScanning tunneling microscope

A closed-loop operating method and operating platform for nano members under SEM (scanning electron microscope) are provided. Studies on the closed-loop operating method and operating platform for nano members under SEM may provide theoretical basis and practical methods for the stable operation of nanoscale members and are more of important theoretical and practical significance to promoting thefurther development of related studies in the fields of China, such as NEMS (nano electro mechanical systems), bioengineering, photoelectric engineering and nano science. Work proceeded in projects includes basic studies, manly focused on providing related theories, methods and control strategies for the real-time efficient three-dimensional visual operation of nanoscale members in terms of mechanism and methodology, the development and functionalization of nano operating techniques can be substantially promoted, the method and platform are of important theoretical significance and practical value, and a platform is provided for system industrialization toward the fields, such as bioengineering, photoelectric engineering and information storage.

Owner:HARBIN UNIV OF SCI & TECH

Method and system for deduction and acquisition of water quality data based on machine learning

ActiveCN112233734BLower acquisition costsReduce pollutionCheminformatics data warehousingTesting waterData setWater quality

The present application discloses a method and system for obtaining water quality data deduction based on machine learning. The method is divided into a model generation stage and a model deduction stage. In the model generation stage, the historical data of various characteristics collected by each monitoring station in the water area under study is analyzed and processed, and the independent relevant feature set of the target water quality factor and its corresponding historical data set are obtained. The machine learning method obtains the optimal derivation model of the target water quality factor; in the model derivation stage, the data of each feature factor covered by the independent relevant feature set for a certain period of time is collected, and the data is input into the optimal derivation model, and the target water quality factor of the period is calculated. The data. The present application is a new water quality data acquisition method that does not require traditional data acquisition methods such as chemical reagents and sensor detection, can reduce environmental pollution and hidden dangers caused by traditional water quality data acquisition methods, and has the advantages of low cost, safety, environmental protection and high technical added value.

Owner:SHANDONG UNIV

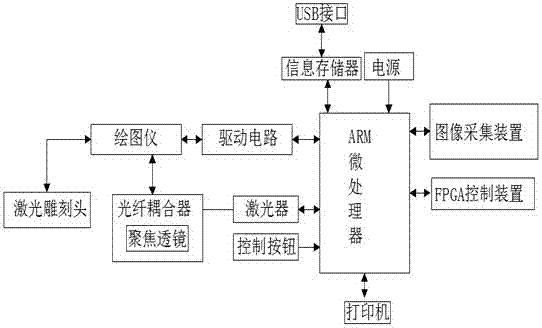

A three-dimensional laser engraving machine

ActiveCN105328345BQuality improvementHigh precisionLaser beam welding apparatusElectric machineCoupling

The invention discloses a three-dimensional laser engraving machine, which includes a bracket, an FPGA control device, a transmission mechanism and a mechanical transmission device. The top of the bracket is provided with a guide rail, and the servo motor is connected to the slider. The right side of the bracket is A driver is fixed, the driver is electrically connected to the servo motor and the FPGA control device through wires, the slider is slidably connected to the guide rail, the servo DC rotary motor is electrically connected to the FPGA control device, and the servo DC rotary motor The output shaft of the laser is connected to a laser through a coupling, and the lower end of the laser is fixedly connected to the mechanical transmission device. The lower end of the mechanical transmission device is provided with a laser engraving head. The present invention has simple structure, simple operation, complex and accurate mathematical operations, It has outstanding advantages such as high rigidity, fast response, high precision, strong adaptability, high technical added value and strong flexibility.

Owner:常德市德源招商投资有限公司

Preparation method, product and application of additive for electrolytic copper foil of flexible copper-clad plate

PendingCN114351190AHigh elongationLow costPrinted circuit manufactureElectroforming processesCelluloseSulfonate

The invention discloses a preparation method of an additive for an electrolytic copper foil of a flexible copper-clad plate, a product and application of the additive. The additive for the electrolytic copper foil of the flexible copper-clad plate comprises the following raw materials: sodium 3-mercaptopropane sulfonate, sodium dithiodipropane sulfonate, low-molecular glue, thiourea, sodium alcohol thiopropane sulfonate, polyethylene glycol 12000 # and hydroxyethyl cellulose 6000 #. The electrolytic copper foil produced by the additive disclosed by the invention is flat in surface crystal grain, low in profile, high in tensile strength and high in ductility, and has a relatively good adhesion effect and characteristics with a polyimide base film. The material can be used for a high-end flexible copper-clad plate (FCCL) circuit board base material. The additive is low in cost, wide in process application range and convenient in process control, and ensures product quality and benefits. After the high-temperature tensile strength of the copper foil reaches 500 MPa or above, the appearance and brightness of the foil surface are controlled only by adjusting the low-molecular glue and the sodium 3, 3 '-dithiodipropane sulfonate, the high-temperature tensile strength is improved, meanwhile, the ductility is kept at 4% or above, and the requirement of the market for the copper foil is completely met.

Owner:安徽华威铜箔科技有限公司

A kind of production method and production system of bevel gear

Owner:十堰万恒科贸发展有限公司

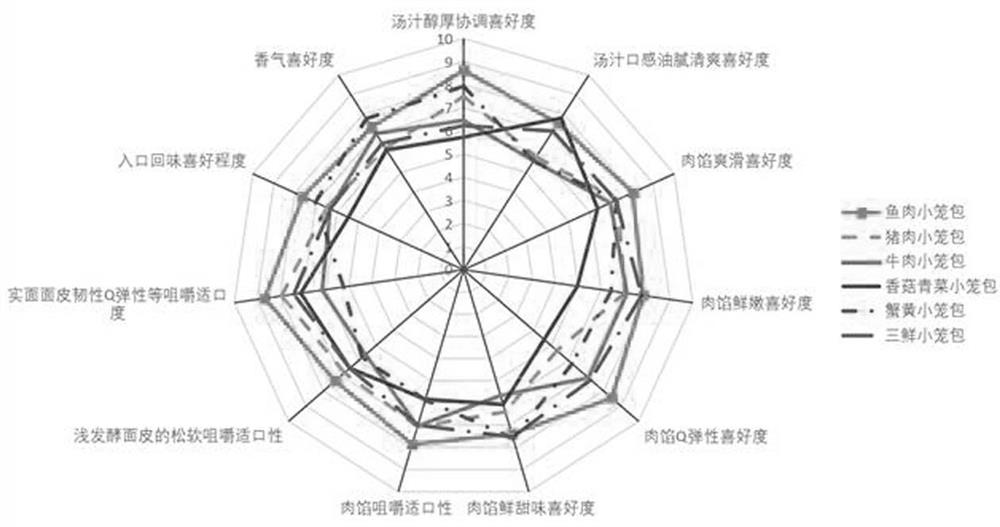

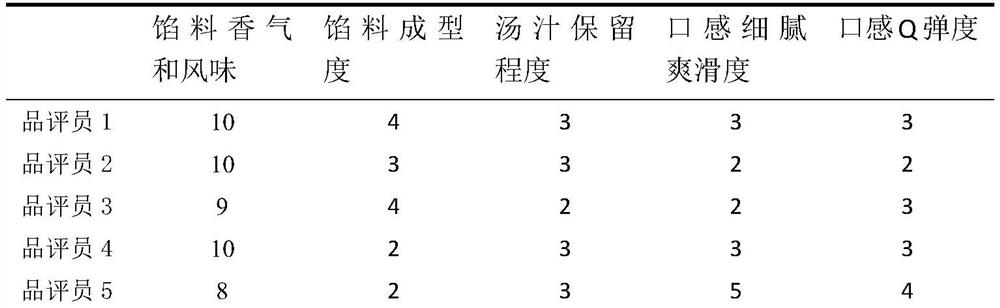

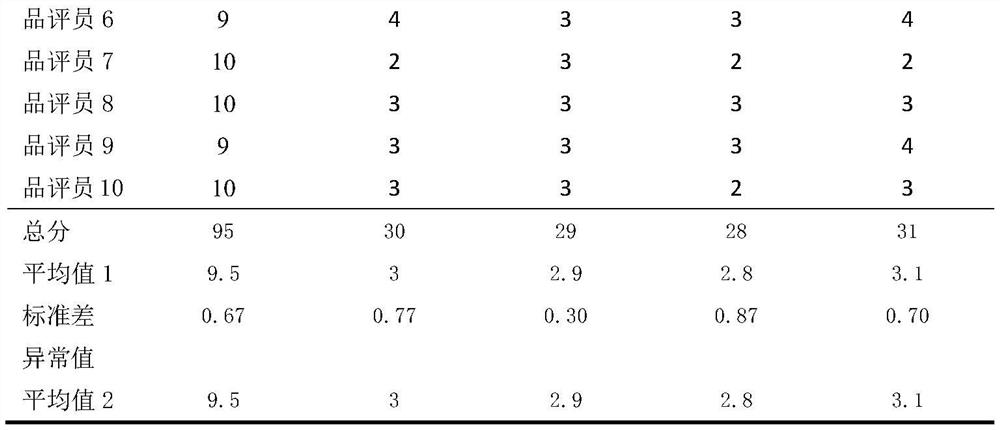

Fish meat steamed stuffed bun and making method thereof

PendingCN113575835APreserve fresh and sweet flavorHigh technology added valueFood preservationFood coatingBiotechnologyMeat paste

The invention discloses a fish meat steamed stuffed bun, and the fish meat steamed stuffed bun comprises a wrapper and stuffing; the stuffing is prepared from the following raw materials in parts by weight: 800-1000 parts of fish meat paste, 600-700 parts of soup stock, 150-200 parts of potato starch, 100-150 parts of bamboo shoot head homogenate, 60-100 parts of corn starch, 80-120 parts of chopped green onion, 20-30 parts of bruised ginger and 10-30 parts of white pepper powder. According to the product formula and the preparation method, no additive is added, and the meat of the stuffing is all fish meat paste obtained after fishbone removal of the fish body; processing residues of a plurality of agricultural product processing industries are used as additive-free food ingredient grade safe raw materials to establish an optimal formula, the stuffing formula which is good in taste and flavor and free of obvious sour taste and other flavor deterioration within 6 months in a frozen state is prepared, and the taste and the flavor are both considered; the fishbone soup is used for improving freshness and improving the taste effect of the fish meat, and the fishbone soup and the taste of the fish meat complement each other.

Owner:ZHEJIANG FORESTRY UNIVERSITY

One-step synthesis method for hollow carbon case

Owner:DALIAN UNIV OF TECH

Method of manufacturing decorative artistic porcelain

The invention discloses a method for producing decorative artistic porcelain, and aims to provide the decorative artistic porcelain which has strong stereo perception of surface pattern, lacquer-like and metal-like appearance, meets psychological requirement of people on seeking fashion and variation, can save energy, reduce consumption, reduce cost, and improve added value of product technology.The method is realized through the following technical proposal: petuntze is fired into a biscuit of the decorative artistic porcelain at medium temperature; an engraving layer is coated on the surface of the biscuit; the surface of the engraving layer is polished and smoothed, and is sprayed with white nitrocellulose primer; the required pattern is engraved on the engraving layer by a graver; residual stained paper is removed; membranella stained paper is stuck on a required position; the surface membranella is removed in 30 minutes; a layer of nitrodope is sprayed on the surface of the whole product; a metal foil film is stuck on the required position by adhesive; and a layer of light or matte polyester varnish is sprayed on the surface of the whole product to produce the product.

Owner:GUANGDONG SITONG GROUP

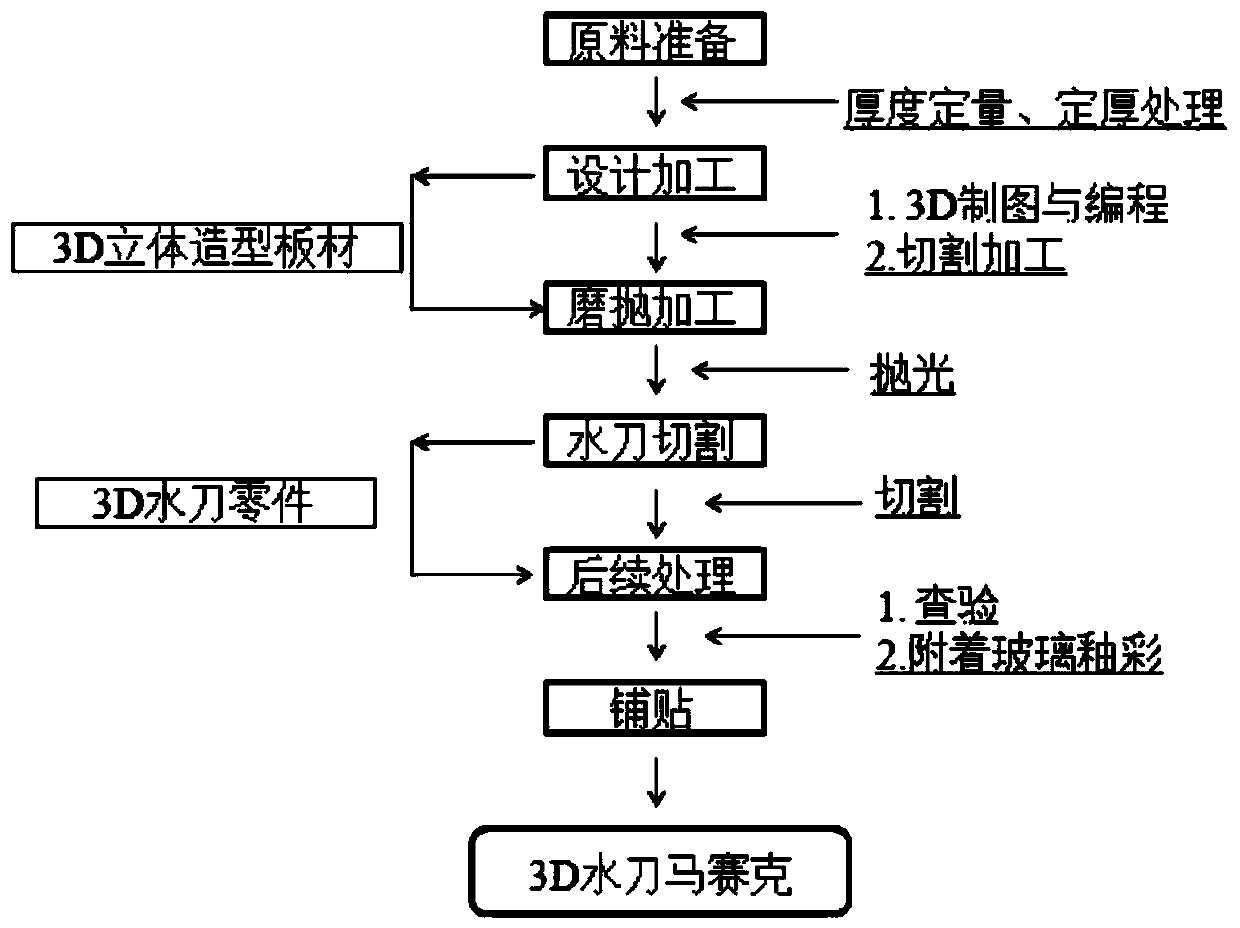

A 3D waterjet mosaic processing technology

ActiveCN107399193BHigh technology added valueAdditive manufacturing apparatusPolishing machines3d shapesAdditional values

The invention belongs to the field of building decoration materials, particularly relates to a 3D water jet mosaic machining process, and aims to solve the technical problem to provide the 3D water jet mosaic machining process which has a vertical-face 3D shape, high technical additional value and high art appreciation value. In order to solve the problem, the 3D water jet mosaic machining process disclosed by the invention comprises raw material preparation, design machining, grinding and polishing machining, water jet cutting, subsequent treatment and laying procedures. The method makes full use of decoration of the 3D shape for a mosaic art style, so that the problem of high difficulty in design and machining are solved; and 3D water jet mosaics prepared through the method fully show a three-dimensional sense of beauty of a product and can be widely applied to all types of high-end interior decoration environments.

Owner:成都再建装饰材料有限公司

Method for quickly synthesizing block graded pore structural nitrogenous porous carbon

The invention relates to a method for quickly synthesizing block graded pore structural nitrogenous porous carbon. The method can synthesize characteristic porous carbons which comprise graded pore structural nitrogenous porous carbon, macropore-rich graded pore structural nitrogenous porous carbon, macropore-rich ordered nitrogenous mesoporous carbon and graded pore structural nitrogenous magnetic porous carbon. The porous carbon is quickly synthesized in one step by resorcinol and formaldehyde serving as raw materials, amino acid or imidazole compounds and organic amine serving as catalystsand water or ethanol aqueous solution serving as a solvent through a sol-gel process. The flow is simple, the preparation cost is low, the purity of a product is high, the selective range of raw materials is broad, and the method is convenient to apply and easy to implement large-scale preparation and has large application potential and market prospect.

Owner:DALIAN UNIV OF TECH

Method for preparing anti-dripping polyester fibers

InactiveCN102174718BMolten dripping does not occurHigh technology added valueMonocomponent polyesters artificial filamentSynthetic polymer filament chemical after-treatmentPolyesterToxic gas

The invention relates to a method for preparing anti-dripping polyester fibers. The method is characterized by comprising the following steps: 1) mixing materials: drying polyester chips, putting the dried polyester chips into an agitator, adding a crosslinking agent with mass being 0.5-5% that of the polyester chips and mixing in the agitator to obtain a co-mixture; 2) carrying out blending extrusion: adding the co-mixture to a twin-screw extruder for blending granulation to obtain granules; 3) melt spinning: drying the granules and then carrying out melt spinning by the existing melt spinning method of the polyester fibers to obtain primary anti-dripping polyester fibers; and 4) directly processing the primary anti-dripping polyester fibers with a 1.0-5MeV electron accelerator under theconditions that the irradiation dose is 10-50kGy, the beam current of the electron accelerator is 3-15mA and the irradiation time is 3-8s to obtain the anti-dripping polyester fibers. The method has the following beneficial effects: the anti-dripping polyester fibers are free of melting and dripping when burnt, can effectively resist dripping and can not release toxic gases or smoke; and the method is simple and practical.

Owner:WUHAN TEXTILE UNIV +1

Three-dimensional five-axis computerized numerical control laser cutting machine

ActiveCN102303187BAvoid spatial symmetryImprove rigidityLaser beam welding apparatusNumerical controlLaser cutting

The invention discloses a three-dimensional five-axis computerized numerical control laser cutting machine, relating to a computerized numerical control laser cutting machine with a composite motion parallel connection five-axis drive mechanism, which comprises a machine body, an X-direction guide rail, a beam, a laser cutting head and a controller, wherein the side surface of the beam is provided with a Y-direction guide rail, and the laser cutting head is movably connected with the Y-direction guide rail on the side surface of the beam through a composite motion parallel connection mechanism. The invention realizes five-axis motion of the conventional laser cutting head through the composite motion parallel connection device, wherein the beam realizes basic X-direction motion relative to the motion of the machine body; and combined motion of an Y axis, a Z axis, an A axis and a C axis is realized through the composite motion parallel connection mechanism. The three-dimensional five-axis computerized numerical control laser cutting machine has an ingenious design, skilled structures of all parts, large rigidity and small inertia, so that the motion precision can be ensured. The three-dimensional five-axis computerized numerical control laser cutting machine integrates a lathe technology, a robot technology and a computerized numerical control technology, and has the advantages of simple structure and complex and accurate arithmetical operation in comparison with the traditional serial connection lathe. The three-dimensional five-axis computerized numerical control laser cutting machine has the remarkable advantages of large rigidity, rapid response speed, high precision, strong adaptability, high technical additional value and the like.

Owner:江苏扬力数控机床有限公司

Chestnut processing method

The invention discloses a method for processing chestnuts. The method comprises: (1) chestnut pretreatment: the chestnuts are sequentially subjected to water bath treatment, low-temperature storage, sugar conversion at a suitable temperature, scratching treatment, flavor enhancement, and flavoring and enzyme deactivation processing, and then shelling to obtain chestnut kernels; (2) chestnut kernel pulping: the chestnut kernels are sequentially soaked, crushed, pulped, and slag separated, so as to obtain chestnut kernel clear liquid and slurry; (3) clear liquid fine filtration (4) Clear liquid deployment, respectively obtain Luzhou-flavored chestnut kernel turbid juice drink and / or microfiltration chestnut kernel turbid juice drink and / or ultrafiltration chestnut clarified juice drink; The mud is sequentially processed with sugar and initial boiling, with sauce and sauce, filling and sterilization to obtain chestnut jam. By using the method and using the same batch of chestnut kernel raw materials, two or more chestnut product products can be sequentially prepared on a large scale.

Owner:BEIJING FORESTRY UNIVERSITY

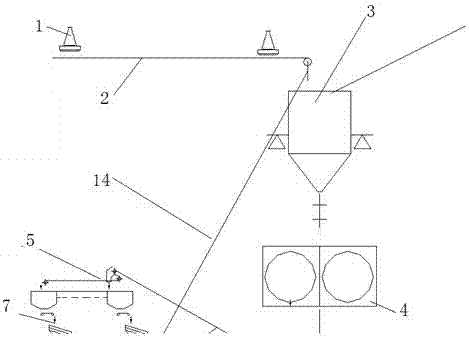

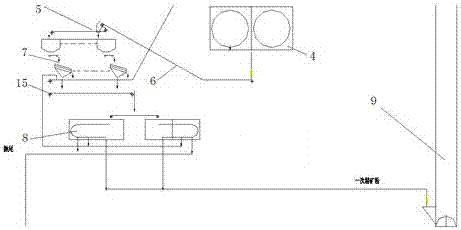

A kind of magnetite beneficiation method

InactiveCN103736663BPerfect development conditionsReduce constructionSolid separationTailings damMagnetite

The invention relates to the field of beneficiation, in particular to a magnetite beneficiation method. Through technological closed cycle production, technological path is shortened, and production and transport costs are remarkably saved; energy is saved by 0.5-1 degree / ton; plant construction area is reduced; building of tailings ponds is reduced due to dry discarding. By the beneficiation method, large-scale tailings discarding before milling is realized, milling grade is remarkably improved, and technical parameters of ball-milling magnetic separation sections are changed thoroughly. The magnetic-gravitational beneficiation process can be applied to preconcentration of low-grade ore, ore resources are pre-concentrated, the milling grade is improved, and beneficiation cost is reduced; the magnetic-gravitational beneficiation process can also be applied to recleaning of tailings to recover the tailings relatively concentrated on dry slope sections of tailings dams; the magnetic-gravitational beneficiation process can be further applied to powdered iron purification of dressing plants to discard lean intergrowth and gangue in powdered iron, product grade is improved, and technical additional value of products of the dressing plants is increased. The magnetic-gravitational beneficiation process substitutes for the wet-type magnetic separation process and is a qualitative leap for dry-type preconcentration and tailings discarding of beneficiation of mines.

Owner:陕西三沅重工发展股份有限公司

Hybrid five-axis laser cutting machine

ActiveCN102284795BExquisite structureSimple structureLaser beam welding apparatusNumerical controlLaser cutting

Owner:江苏扬力数控机床有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com