Hybrid five-axis laser cutting machine

A laser cutting machine and laser cutting head technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of expensive three-dimensional laser cutting head, poor dynamic response speed of equipment, and low service life of parts, and achieve The effect of high rigidity, complex precision, and guaranteed motion accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

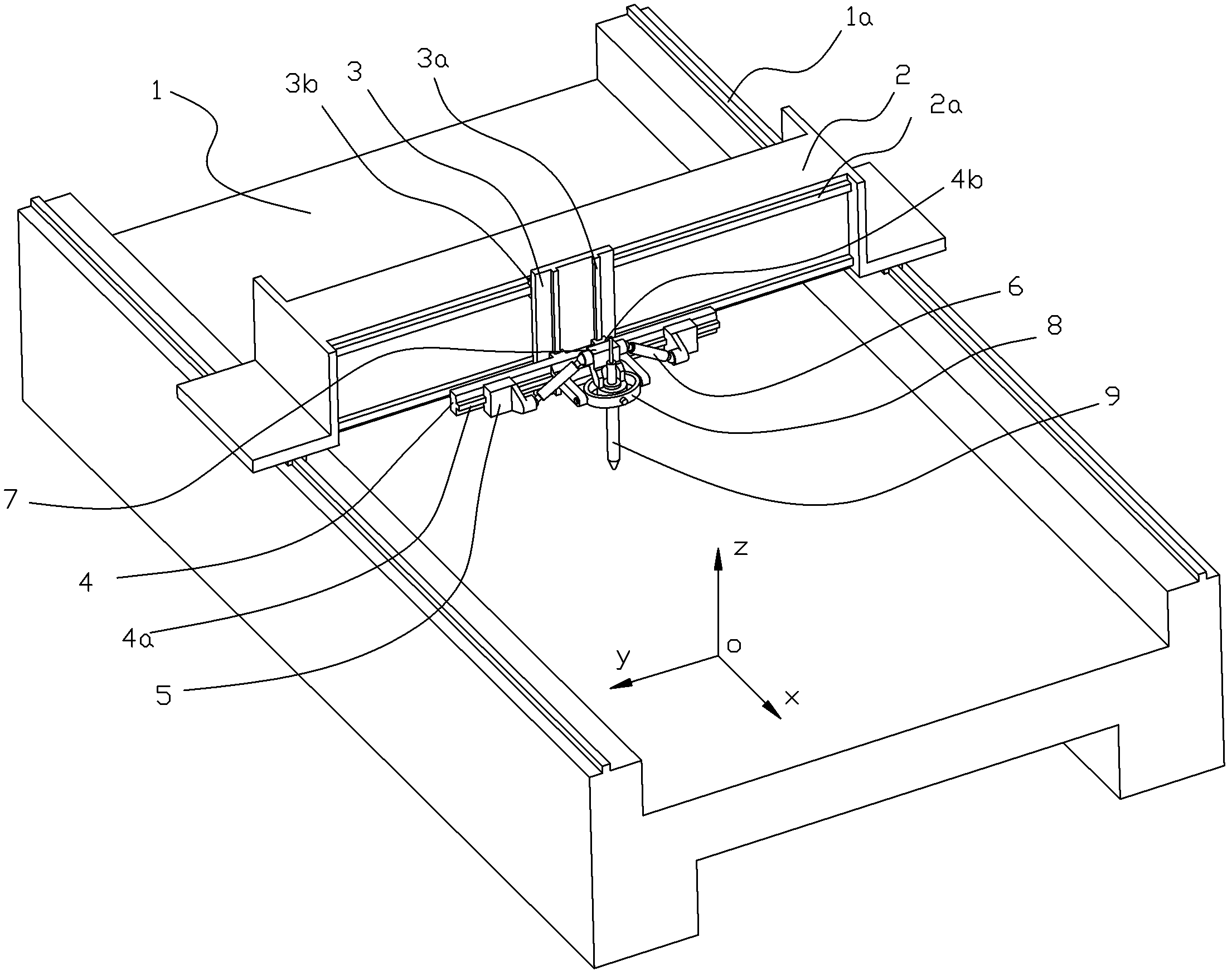

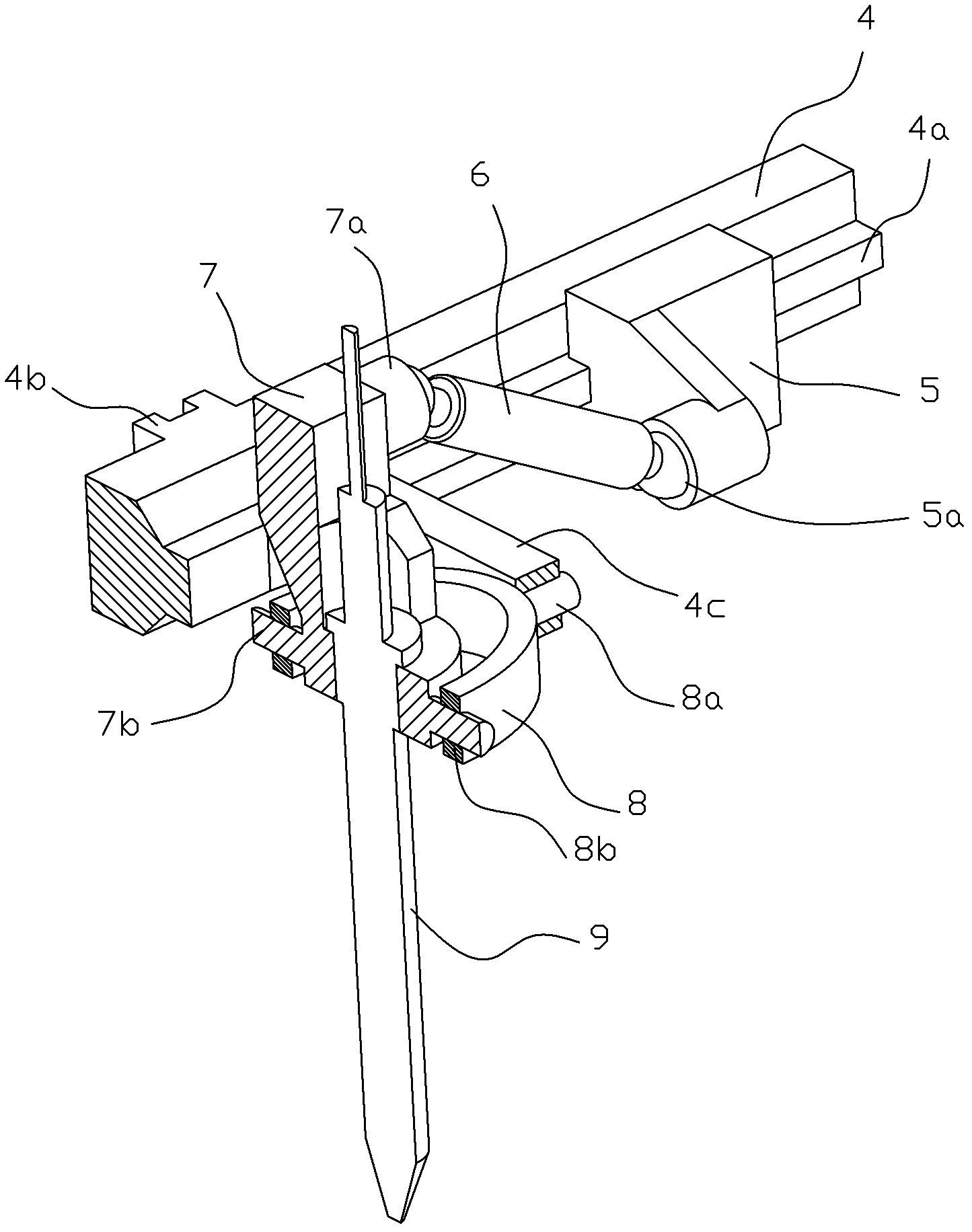

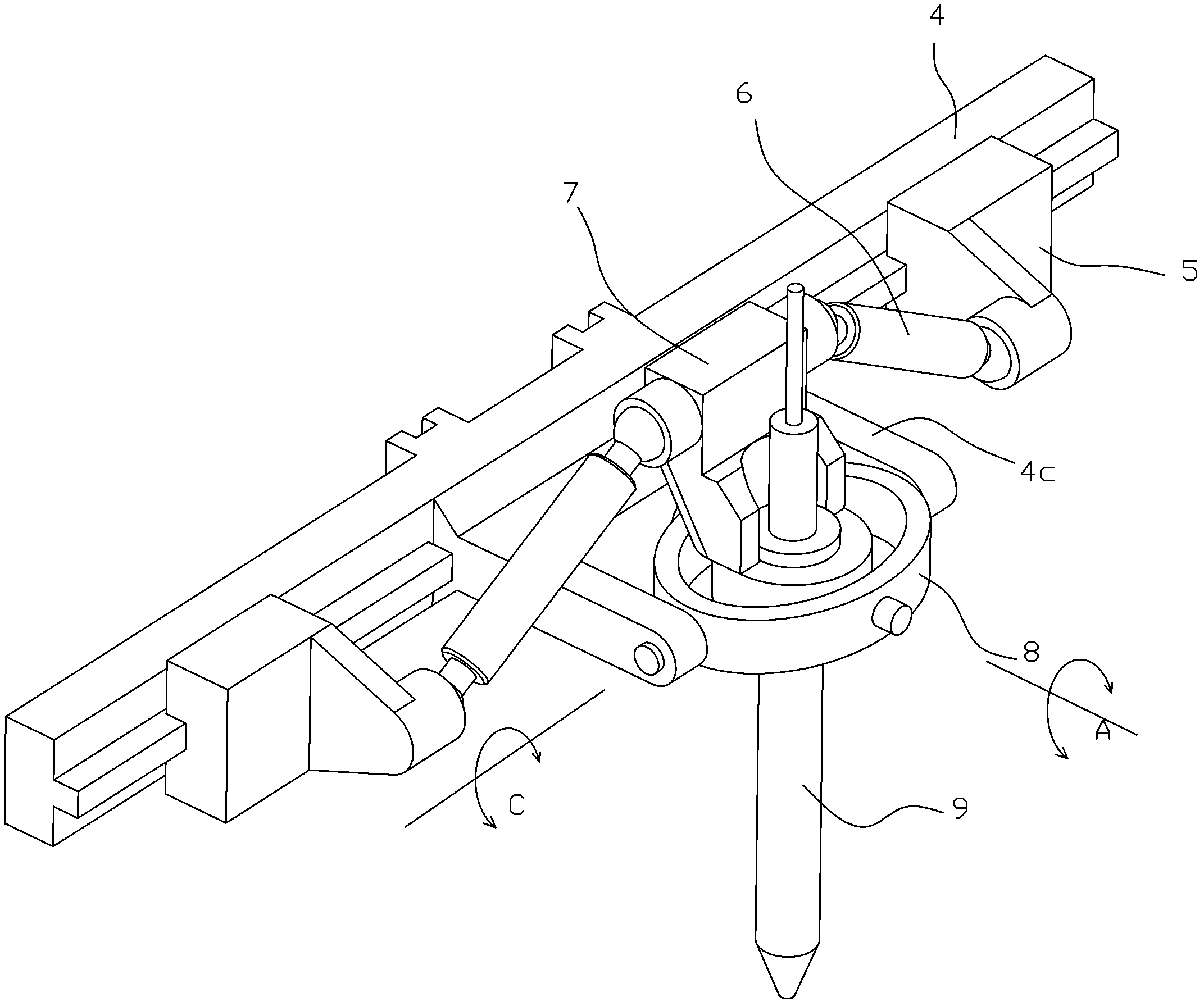

[0034] The present invention as Figure 1-3 As shown, the laser cutting machine includes a body 1, an X-guiding rail 1a arranged on the body 1, a beam 2 movably connected with the X-guiding rail 1a, a laser cutting head 9 and a controller. There is a Y-guiding rail 2a, and the laser cutting head 9 is movably connected to the Y-guiding rail 2a on the side of the beam 2 through a hybrid device;

[0035] The hybrid device includes a Y pallet 3 mechanism, a Z pallet 4 mechanism, a drive frame 7, an annular support frame 8, a pair of drive block 5 mechanisms and a pair of connecting rods 6 (a pair of connecting rods are equal in length);

[0036] Described Y pallet 3 mechanism comprises Y pallet 3 and Y pallet drive motor; The back side of described Y pallet 3 is provided with a pair of Y guide rail groove 3b, and the front is provided with a pair of Z guide rail 3a; Described Y pallet 3 3 is movably connected with the Y guide rail 2a through the pair of Y guide rail grooves 3b; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com