Ultra-fine high-activity steel slag powder and preparation method thereof

A technology of steel slag powder and activity, which is applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., to achieve continuous operation, reduce wear, and achieve remarkable effects of originality and innovation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

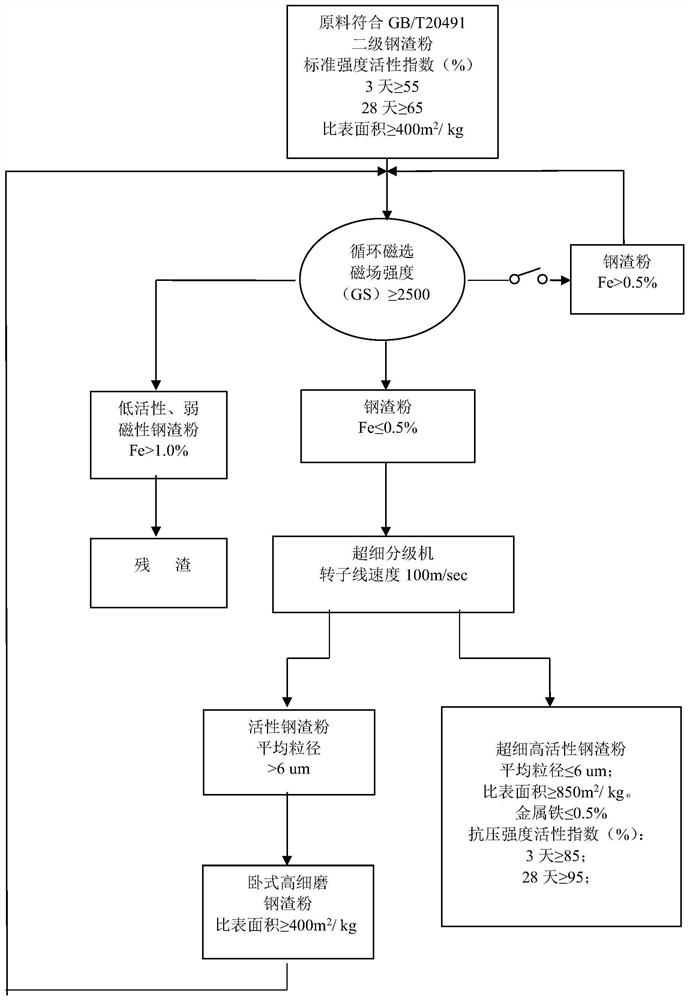

Method used

Image

Examples

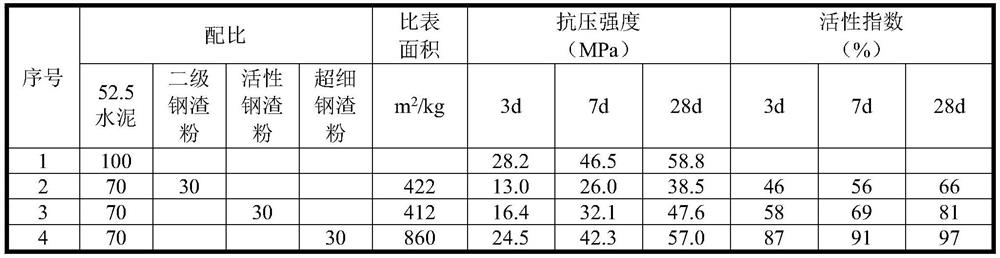

Embodiment (1

[0036] 1) A steel plant in Anhui meets the national standard "Steel slag powder used in cement and concrete", that is, GB / T20491 secondary steel slag powder as raw material, the main technical indicators are as follows:

[0037] Average particle size 12.4μm; metallic iron 1.94%, specific surface area 422m 2 / kg, density 3.41g / cm 3

[0038] 2) First put 160 kg of raw material steel slag into the dry magnetic separator in batches, adjust the magnetic field strength to 2500 (GS), adjust the feeding rate to 20 kg / hour, and start the automatic feeding button. After 8 hours, the specific surface area is 422m 2145 kilograms of active steel slag powder per kg, the metal iron content is reduced to 0.42% and 15 kilograms of low activity, weak magnetic residue.

[0039] 3) Put 100 kg of active steel slag powder into the hopper of the OS-I superfine classifier, adjust the linear speed of the rotor to 100 m per second, start the automatic feeding button, and carry out dry winnowing and ...

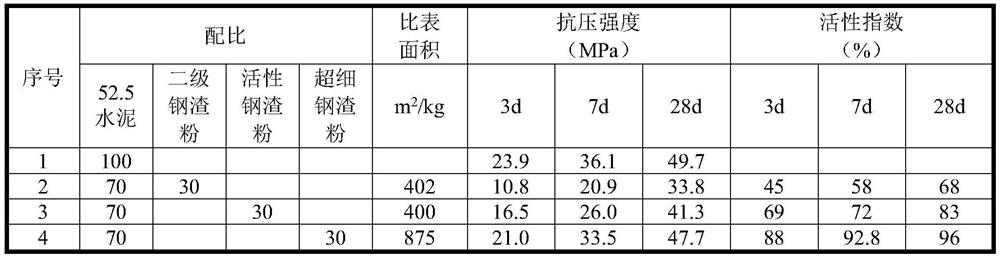

Embodiment 2

[0046] 1) A steel plant in Shandong meets the national standard "Steel slag powder used in cement and concrete", that is, GB / T20491 secondary steel slag powder as raw material, the main technical indicators are as follows:

[0047] The average particle size is 13μm; the metal iron content is 2.34%, the specific surface area is 402㎡ / ㎏, and the density is 3.60g / cm 3

[0048] 2) First put 160 kg of raw material steel slag into the dry magnetic separator in batches, adjust the magnetic field strength to 2500 (GS), adjust the feeding rate to 20 kg / hour, and start the automatic feeding button. After 8 hours, 144 kg of active steel slag powder with a specific surface area of 402㎡ / ㎏ was obtained, and the content of metallic iron was reduced to 0.42% and 16 kg of low activity and weak magnetic residue

[0049] 3) Put 100 kg of active steel slag powder into the hopper of the OS-I superfine classifier, adjust the linear speed of the rotor to 100m per second, start the automatic feedin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com