A three-dimensional laser engraving machine

A laser engraving and three-dimensional technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problem of engraving high-quality large workpieces, long workpieces that cannot achieve multiple positioning engraving, and machines that do not have rotation , stretching and other issues, to achieve the effect of high rigidity, simple structure and high technical added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

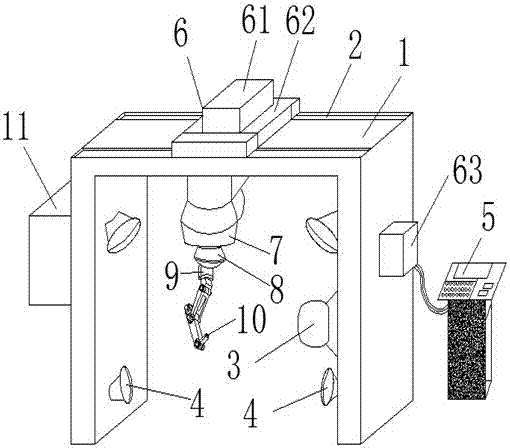

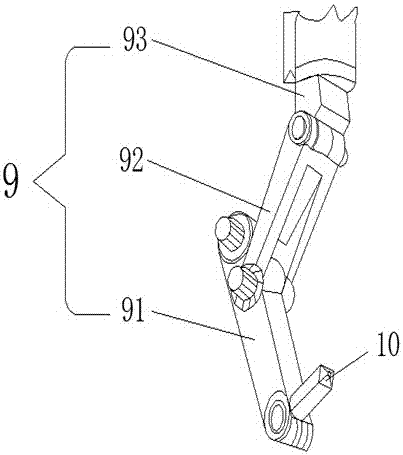

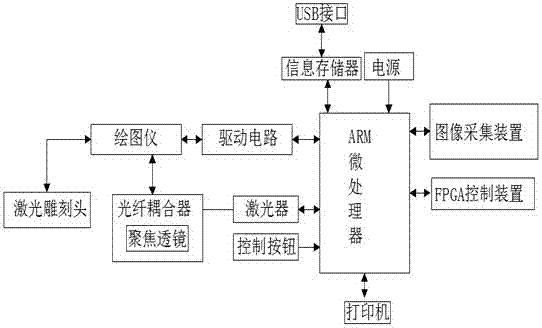

[0021] The present invention provides such Figure 1-3 A three-dimensional laser engraving machine shown includes a bracket 1, an FPGA control device 5, a transmission mechanism 6 and a mechanical transmission device 9, two groups of reflective convex mirrors 4 are symmetrically arranged on the two inner surfaces of the bracket 1, and the bracket The top of 1 is provided with guide rail 2, and described guide rail 2 is arranged as groove-shaped guide rail, and described guide rail 2 is symmetrically arranged in two groups, and the inner surface of described support 1 is provided with CCD camera device 3, and described CCD camera device 3 passes through Wire is electrically connected with FPGA control device 5, and described transmission mechanism 6 comprises servomotor 61 and slide block 62, and described servomotor 61 is connected with slide block 62 transmission, and the right side of described support 1 is fixed with driver 63, and described Driver 63 is electrically connec...

Embodiment 2

[0023] In addition to being the same as Embodiment 1, this embodiment is Figure 4Another structural schematic diagram of the mechanical transmission device, the mechanical transmission device 9 includes an X-axis drive device 94 and a Y-axis hydraulic telescopic device 95, and the X-axis drive device 94 includes an X-axis transmission block 941, an X-axis servo motor 942 and a fixed seat 943, the fixed seat 943 is fixedly connected with the laser 8 through a bearing, the front of the fixed seat 943 is provided with an X-axis guide rail 944, and the X-axis transmission block 941 is connected to the X-axis guide rail 944 in transmission, so The X-axis servo motor 942 is installed on the side of the X-axis transmission block 941 , the Y-axis hydraulic telescopic device 95 is provided with a hydraulic telescopic rod 951 , and the laser engraving head 10 is installed at the bottom of the hydraulic telescopic rod 951 . In this embodiment, the X-axis transmission block 941 is driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com