Nickel-based alloy, preparation method of nickel-based alloy and manufacturing product

A technology for nickel-based alloys and articles, applied in the field of nickel-based alloys and a manufactured article

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] The present application also provides the preparation method of above-mentioned nickel base alloy, it comprises the following steps:

[0078] A) preparing a nickel-based alloy ingot according to the composition ratio; treating the nickel-based alloy ingot through an atomization process to obtain nickel-based alloy powder;

[0079] Or, A') process the raw material of the nickel-based alloy whose composition is as described in the above scheme through an atomization process to obtain nickel-based alloy powder;

[0080] B) performing thermal consolidation molding on the nickel-based alloy powder to obtain an initial nickel-based alloy;

[0081] C) hot deforming the initial nickel-based alloy;

[0082] D) heat-treating the nickel-based alloy obtained in step C) to obtain a nickel-based alloy.

[0083] The present application also provides another preparation method of the nickel-based alloy of the above composition, comprising the following steps:

[0084] A) preparing n...

Embodiment

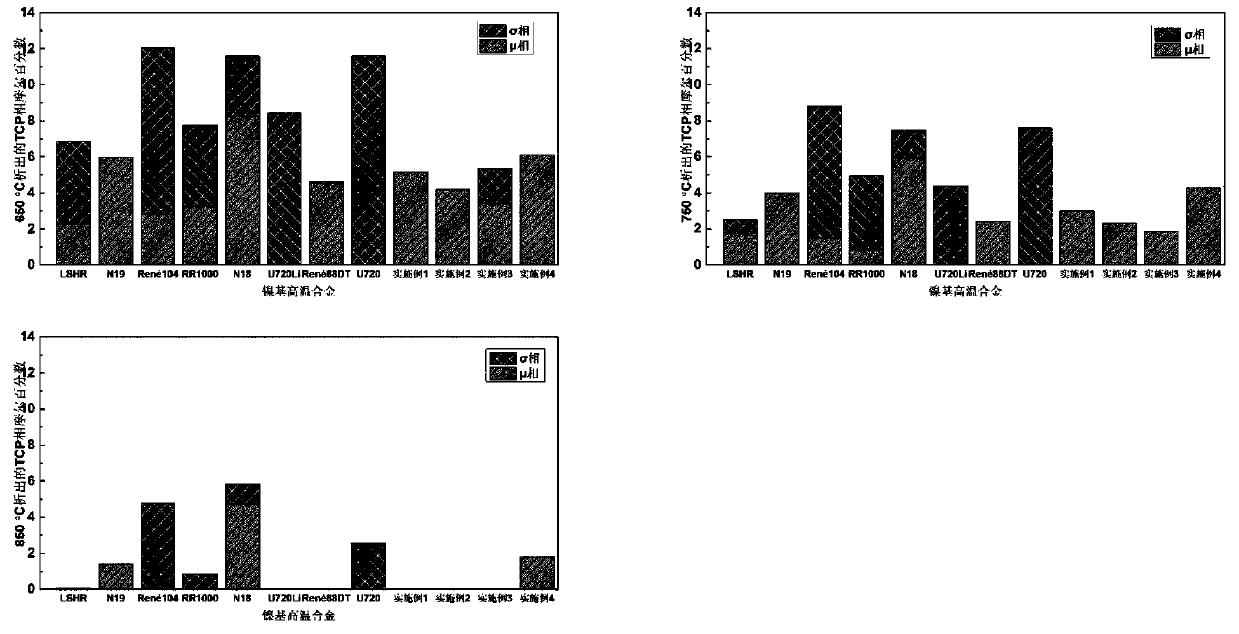

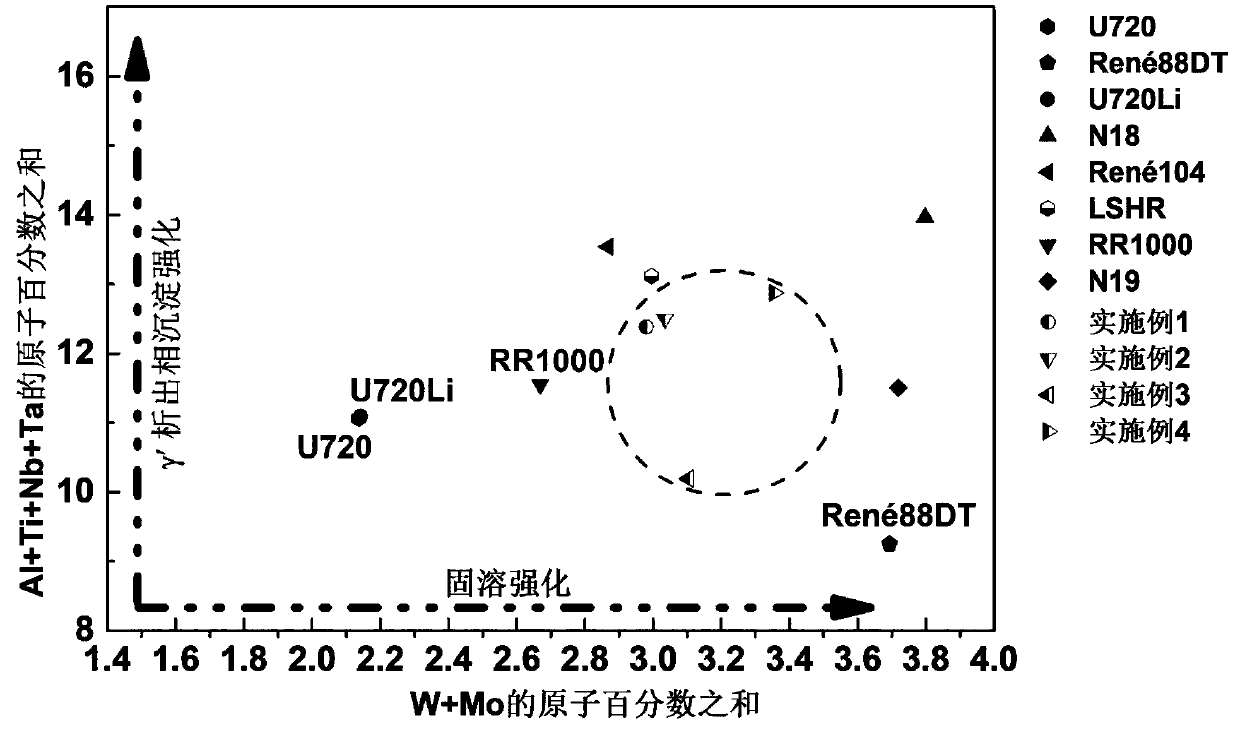

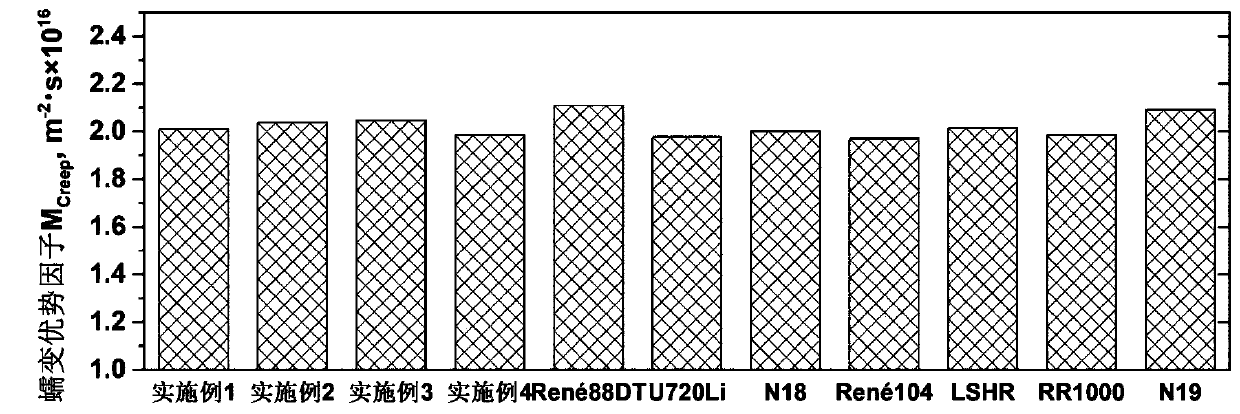

[0099] To prepare a nickel-based alloy, compare the range ratio of alloy elements provided in the present application with the ratio of alloy elements in the prior art. The comparative composition is shown in Table 1.

[0100] The nickel-based alloy in this example is prepared by casting + deformation process, and the specific preparation process is as follows:

[0101] (1) Prepare a master alloy ingot with a diameter of about 80mm of the following Table 1 components by vacuum smelting;

[0102] (2) Homogenize heat treatment at 1200°C for 4 hours to eliminate or reduce macroscopic element segregation in the alloy;

[0103] (3) performing hot extrusion deformation on the article at 1160° C. to obtain a uniform and fine grain structure;

[0104] (4) The alloy is treated by a heat treatment process of solid solution at sub-solution temperature + 700-800°C aging to control the γ′ precipitated phase to obtain a nickel-based alloy.

[0105] The composition data table of the nickel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com