Lead-free copper alloy with limited Al and preparation method thereof

A lead-copper alloy and a manufacturing method technology are applied in the field of lead-free copper alloy and its preparation, which can solve the problems of unsuitability for casting and machining, achieve simple and convenient production operation, strong versatility, and improve tensile strength and elongation after fracture. effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation plan

[0014] Heat the master alloy in a furnace to 1100°C to melt, add trace elements into the container in turn, and heat up to 1200°C after slight stirring. After standing for half an hour, die-casting is carried out. The composition of the obtained casting is shown in the following table (according to % by weight):

[0015] Cu

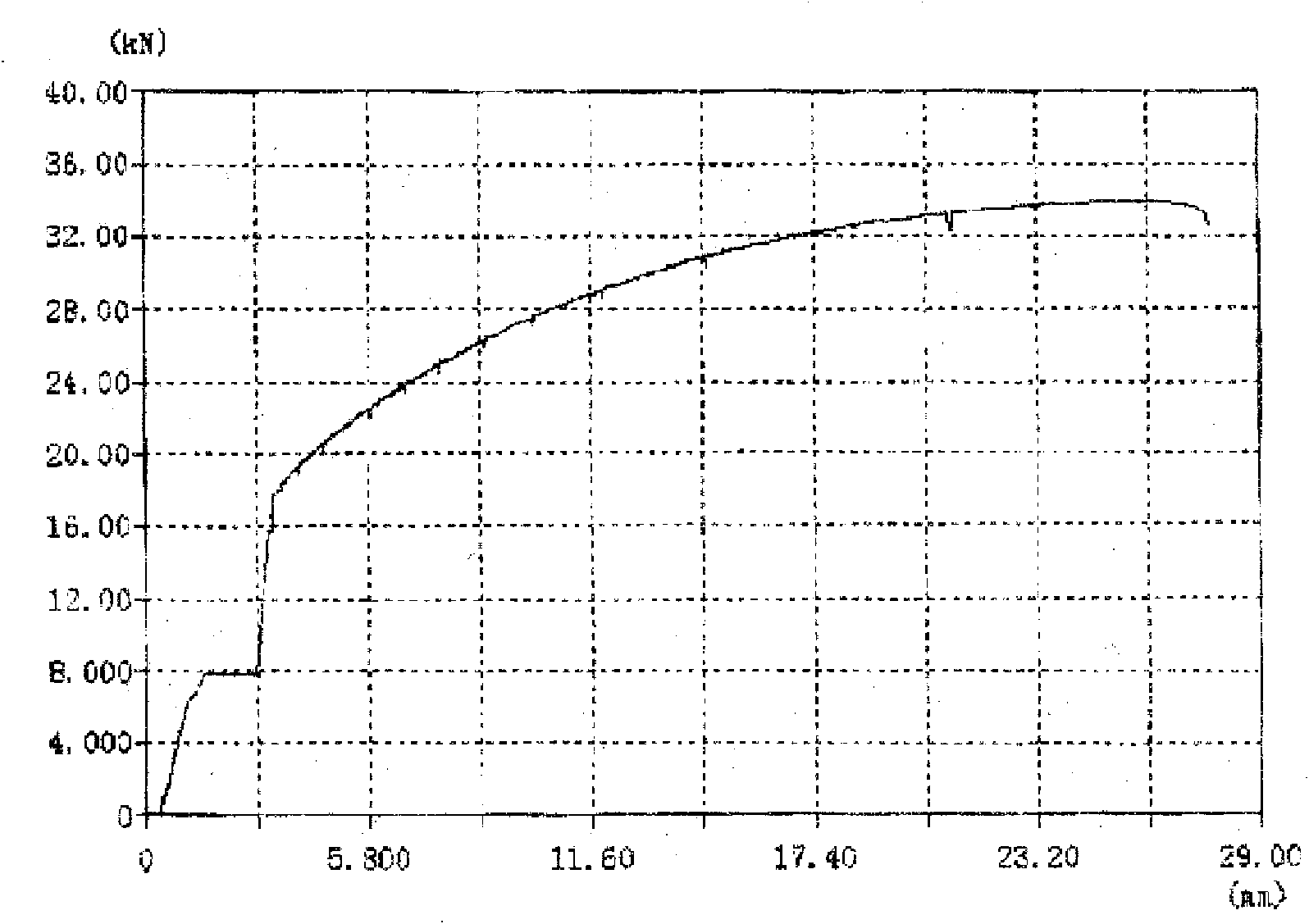

[0016] The alloy tensile sample is taken as 65mm in diameter, such as figure 1 As shown, the measured tensile properties are: σ b =500Mpa; σ 0.2 =115Mpa; δ 10 = 38.46%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com