Recycling method of abamectin fermented waste water

A technology of abamectin and fermentation wastewater, applied in the directions of fermentation, chemical instruments and methods, microorganism-based methods, etc., and can solve problems such as water resources waste, environmental pollution, environmental impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

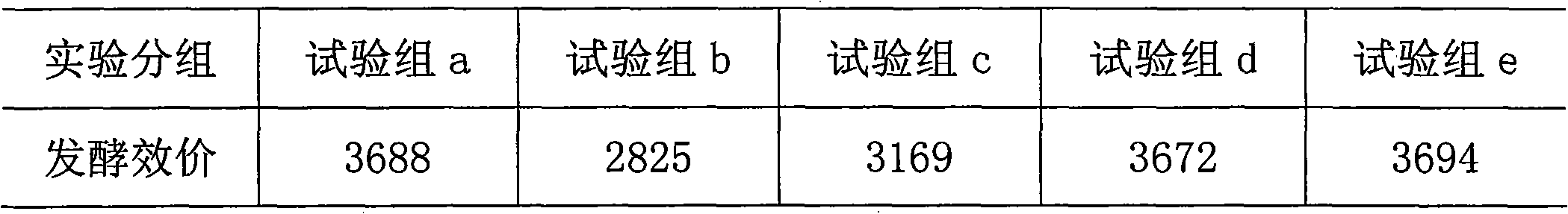

[0017] Embodiment 1: When producing Abamectin with treated and untreated Abamectin fermented waste water, the fermentation titer comparison.

[0018] Experimental group a: tap water was used to culture Streptomyces avermanii.

[0019] Experimental group b: Streptomyces avermanii was cultured with abamectin fermented wastewater without any treatment.

[0020] Experimental group c: the abamectin fermentation wastewater was treated by the following method and then reused for the cultivation of Streptomyces avermanii.

[0021] Treatment method: the wastewater is first filtered with a plate and frame with a filter cloth pore size of 10 microns; the filtrate is then filtered with a filter with a pore size less than 2.5 microns; the obtained fine filtrate is mixed with phosphoric acid and sulfuric acid (phosphoric acid: sulfuric acid = 1: 2. Volume ratio) to adjust the pH to 0.5. After heating up to 80°C, keep it warm for 30 minutes, then adjust the pH to 10 with lime milk. Apertur...

Embodiment 2

[0029] 1) press-filter the abamectin fermentation broth fermented for 255-280 hours to obtain a mycelium filter cake and a filtrate, and the resulting filtrate is the abamectin fermentation waste water;

[0030] 2) the abamectin fermentation waste water of step 1) gained is filtered through the filter of 10 microns, 5 microns and 1 micron respectively through aperture;

[0031] 3) Adjust the pH of the avermectin fermentation wastewater in step 2) to 2.5 with a mixture of phosphoric acid and sulfuric acid, then raise the temperature to 90°C, and keep it warm for 35 minutes, then adjust the pH to 12 with milk of lime or sodium hydroxide, and continue to keep warm After 35 minutes, cool and then filter through plate frame and multi-media filter;

[0032] 4) Put the abamectin fermented waste water through step 3) into the fermenter, adjust the pH to 7.5, then add 0.5% glucose, 0.25% ammonium sulfate, 0.01% potassium dihydrogen phosphate, and dihydrogen phosphate by the weight of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com