Structure and manufacture of resistance(R) - capacitance(C) - diode(D) network thin-film IC with transverse venting diode

A technology of integrated circuits and diodes, which is applied in the field of microelectronic integrated circuit semiconductor devices, and can solve problems such as difficulty in manufacturing and incompatibility with the manufacturing process of semiconductor devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

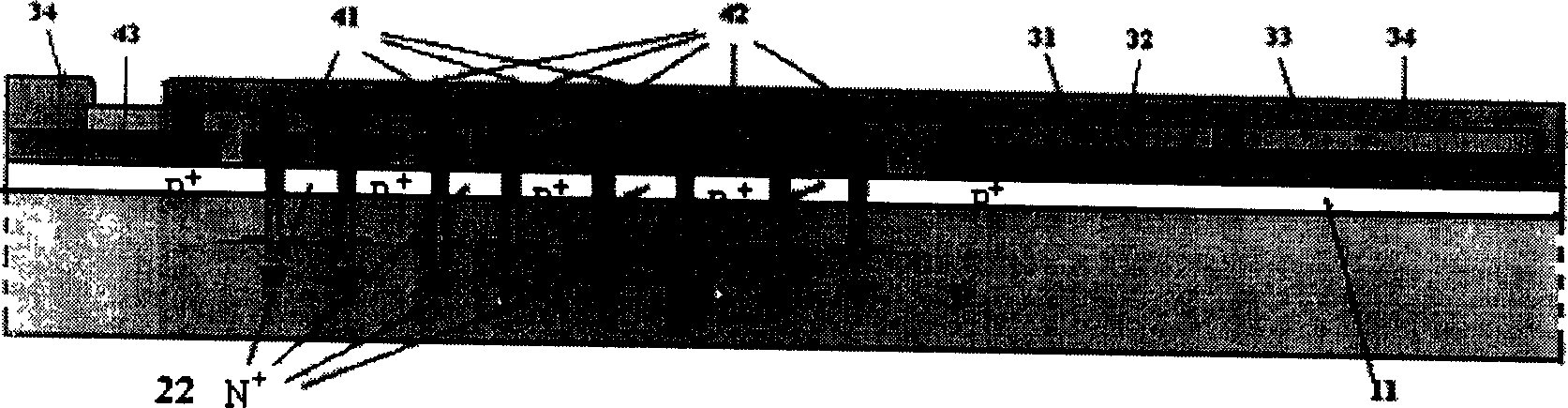

[0024] The resistance-capacitance-diode network thin film integrated circuit of the present invention has good anti-static discharge damage function and anti-electromagnetic radiation function, and the anti-static ability exceeds 5000V, which can completely protect the electrostatic discharge generated by the human body.

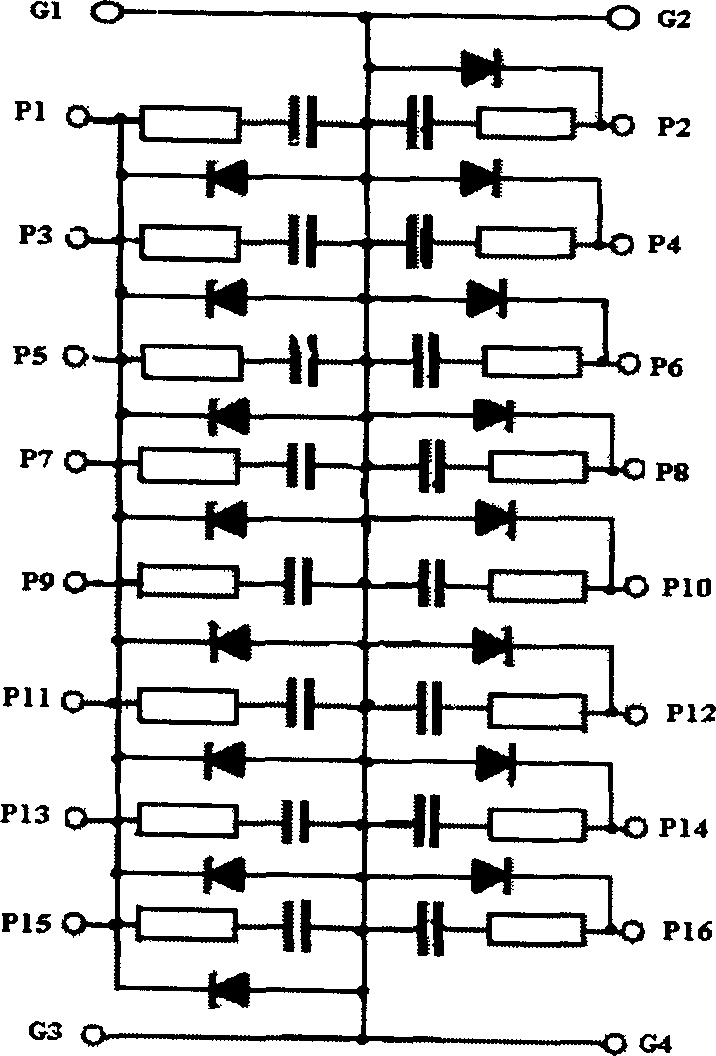

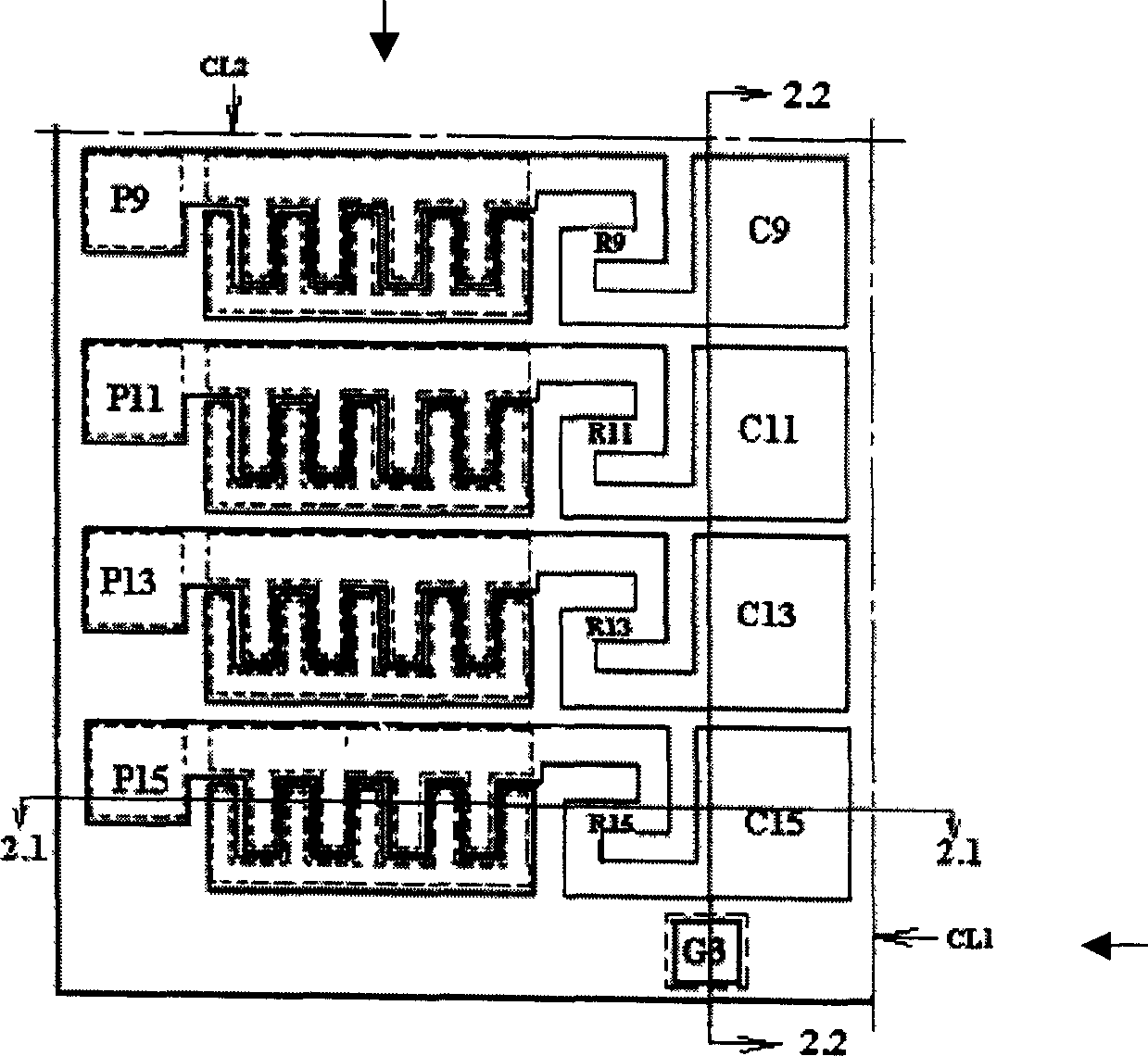

[0025] figure 1 The shown RCD network circuit can be processed into a semiconductor RCD network thin film integrated circuit chip according to the semiconductor manufacturing method provided by the present invention. The RCD network can be used as a filter to reduce electromagnetic and radio frequency interference, eliminate negative pulse voltage spikes and reduce high data transmission noise, etc. figure 1 , figure 2 Provide the circuit diagram and structure and component distribution diagram of the embodiment of the present invention;

[0026] Among them, there are 16 resistors and 16 capacitors Ci (i=1, 2...16) with the same value, and 16 diodes Di (i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com