Composite drill bit with roller cone arranged on tool blade

A composite drill bit and roller cone technology, which is applied in construction and other directions, can solve the problems of tight local space of composite drill bits, assembly errors, and impact on product quality, etc., to increase space utilization, reduce assembly errors and reduce manufacturing process steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

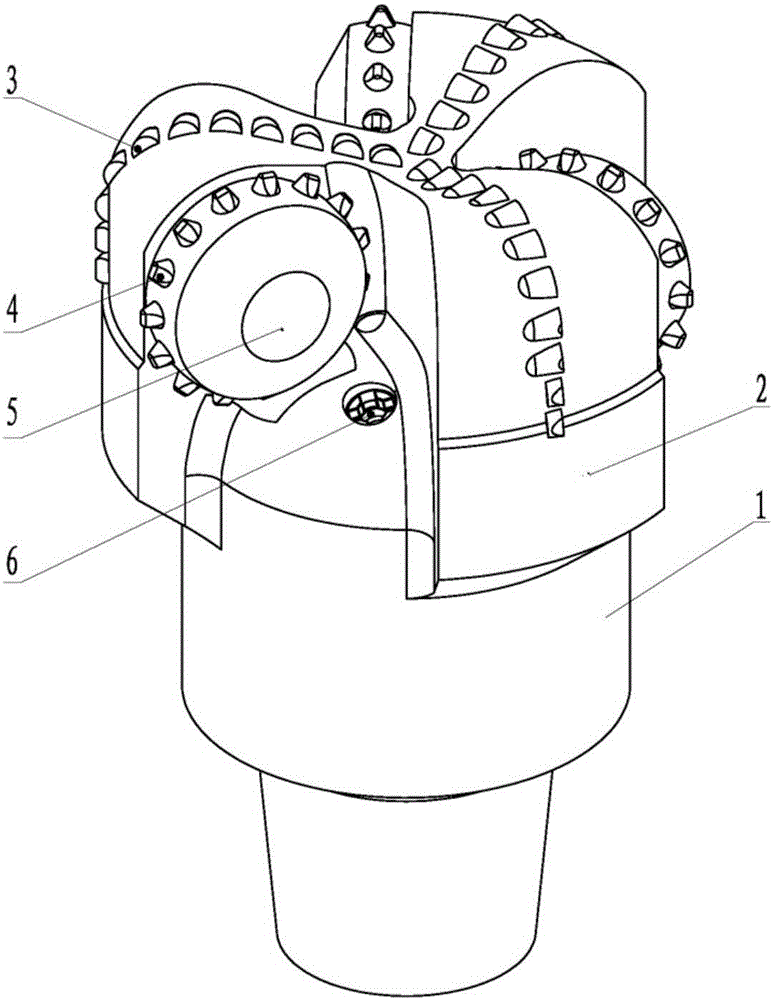

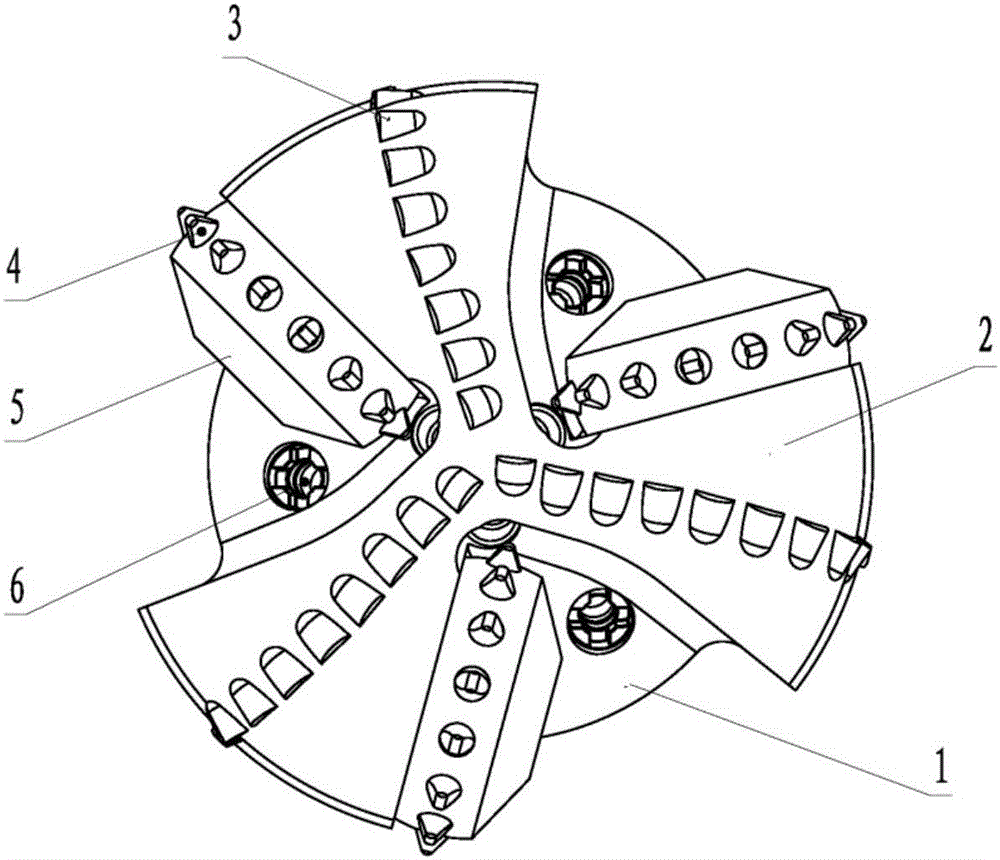

[0018] The present invention is a composite drill bit with cones arranged on blades, the structure of which is as follows: figure 1 As shown, the top view is as figure 2 As shown, the drill body 1 is included, the drill body 1 is provided with a fixed cutter 2 and a nozzle 6, the fixed cutter 2 is provided with a fixed cutting tooth 3 and a cone 5, and the cone 5 is provided with a cone cutter 4.

[0019] At least one cone 5 arranged on each fixed blade 2 ( figure 1 There is 1 cone 5 shown in).

[0020] The cone 5 is arranged in the inner cone area or the nose area or the shoulder area or the gage area corresponding to the fixed blade 2. A combination of one or more areas ( figure 1 The cone 5 shown in the figure is arranged in the corresponding shoulder area of the fixed blade 2).

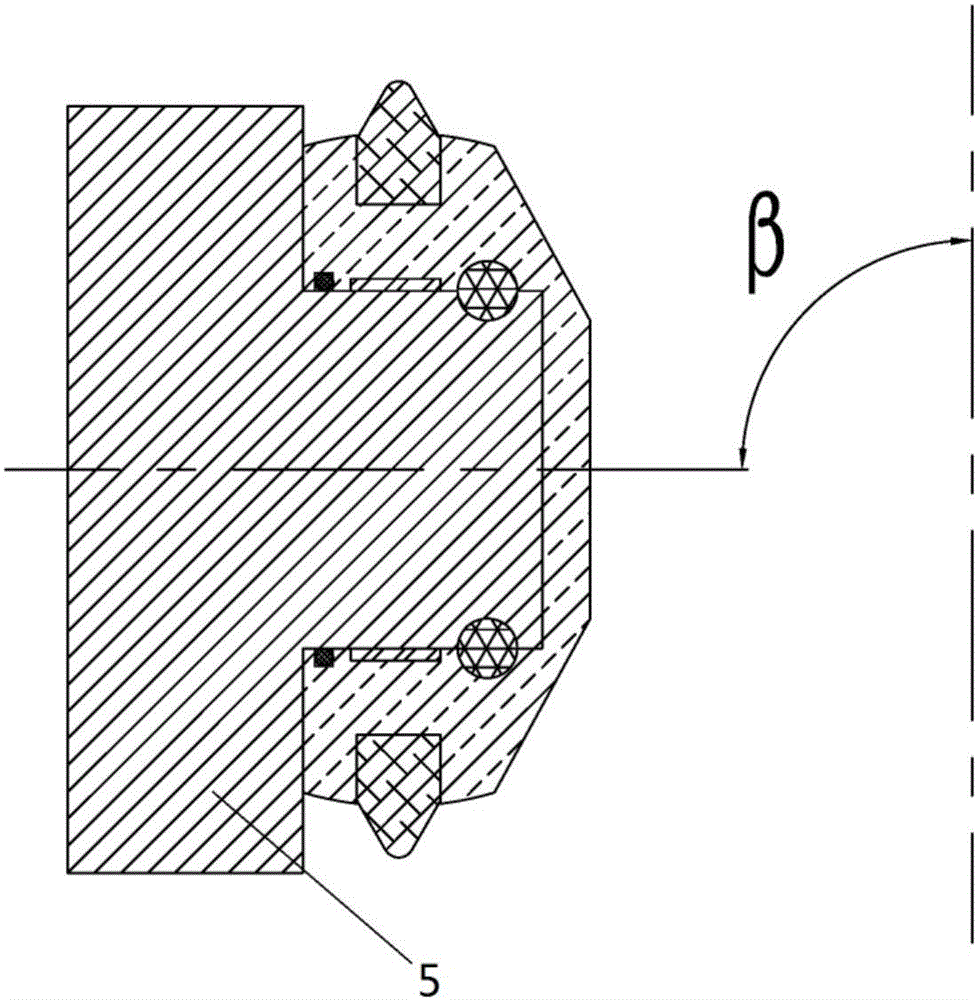

[0021] The normal height difference between the 4 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com