Liquid crystal display panel and liquid crystal display device

A liquid crystal display panel and liquid crystal display device technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve problems affecting product yield, increase manufacturing cost, increase manufacturing process steps, etc., achieve good liquid crystal pre-tilt effect, improve Viewing angle, effect of reducing manufacturing process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

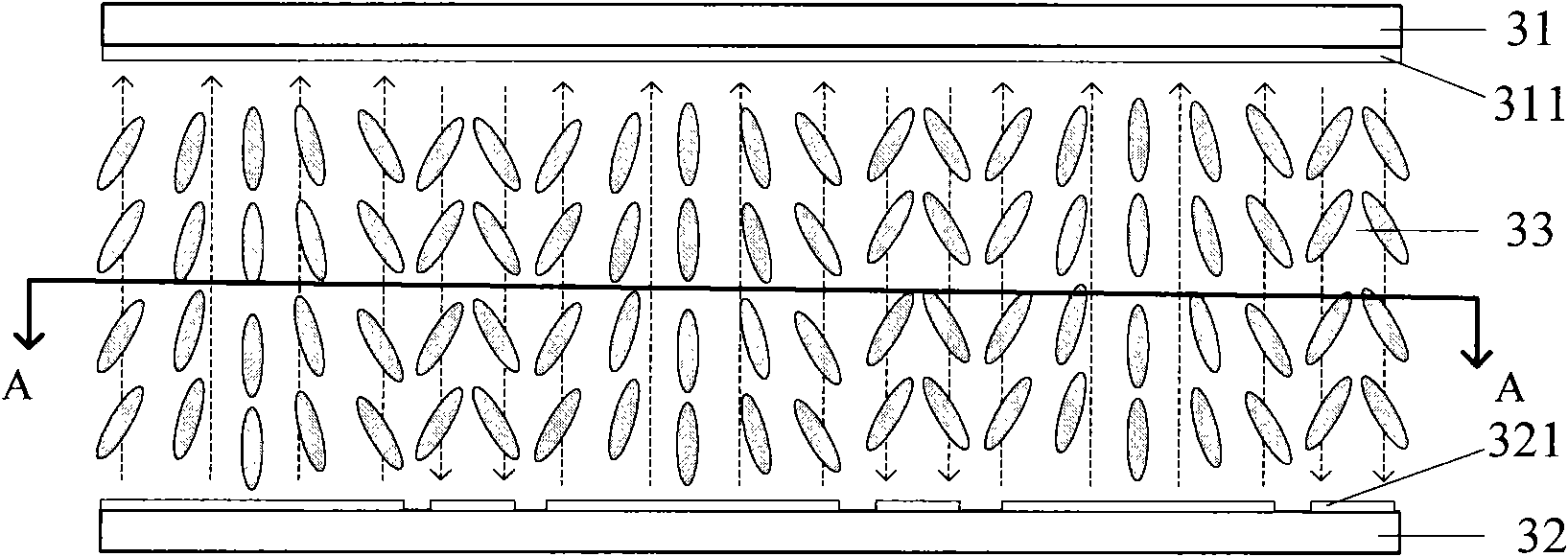

[0067] Please also see image 3 and Figure 4 , in this embodiment, the liquid crystal display panel includes a first substrate 31 and a second substrate 32 opposite to the first substrate 31 , and liquid crystal molecules 33 are sandwiched between the first substrate 31 and the second substrate 32 . In this embodiment, the first substrate 31 may be a color filter substrate, the second substrate 32 may be a thin film transistor array substrate, and the liquid crystal molecules 33 may be negative liquid crystal molecules, which are aligned vertically to the two substrates 31 and 32 . Wherein, a transparent electrode layer 311 is provided on the side close to the liquid crystal molecules 33 on the first substrate 31, and a plurality of sub-pixel electrodes 321 are provided on the side close to the liquid crystal molecules 33 on the second substrate 32, and each sub-pixel electrode 321 corresponds to a sub-pixel.

[0068] Each sub-pixel electrode 321 includes a first region 41 ...

Embodiment 2

[0084] The liquid crystal display panel 91 adopts the liquid crystal display panel designed with double grid lines as described in the foregoing liquid crystal display panel embodiment, and its circuit design is as follows Figure 14 shown. The driving circuit 92 drives the liquid crystal panel 91 in a row inversion driving manner, so that the polarity of the voltage applied to each sub-pixel electrode of the liquid crystal display panel 91 relative to the transparent electrode layer of the first substrate is opposite to that of the adjacent sub-pixel electrode. The voltage polarity of the transparent electrode layer of the first substrate is opposite.

[0085] Specifically, the schematic diagram of the driving signal of the driving circuit driver 92 driving the liquid crystal display panel 91 is as follows: Figure 15 shown, see again Figure 14 , in the liquid crystal display panel 91 , the first subpixel electrode and the second subpixel electrode in each row of subpixel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com