Liquid crystal display device and driving method thereof

A technology of a liquid crystal display device and a driving method, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of complex process and high production cost, and achieve the goals of reducing process complexity, strong electric field strength, and ensuring the time of grid scanning signals Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

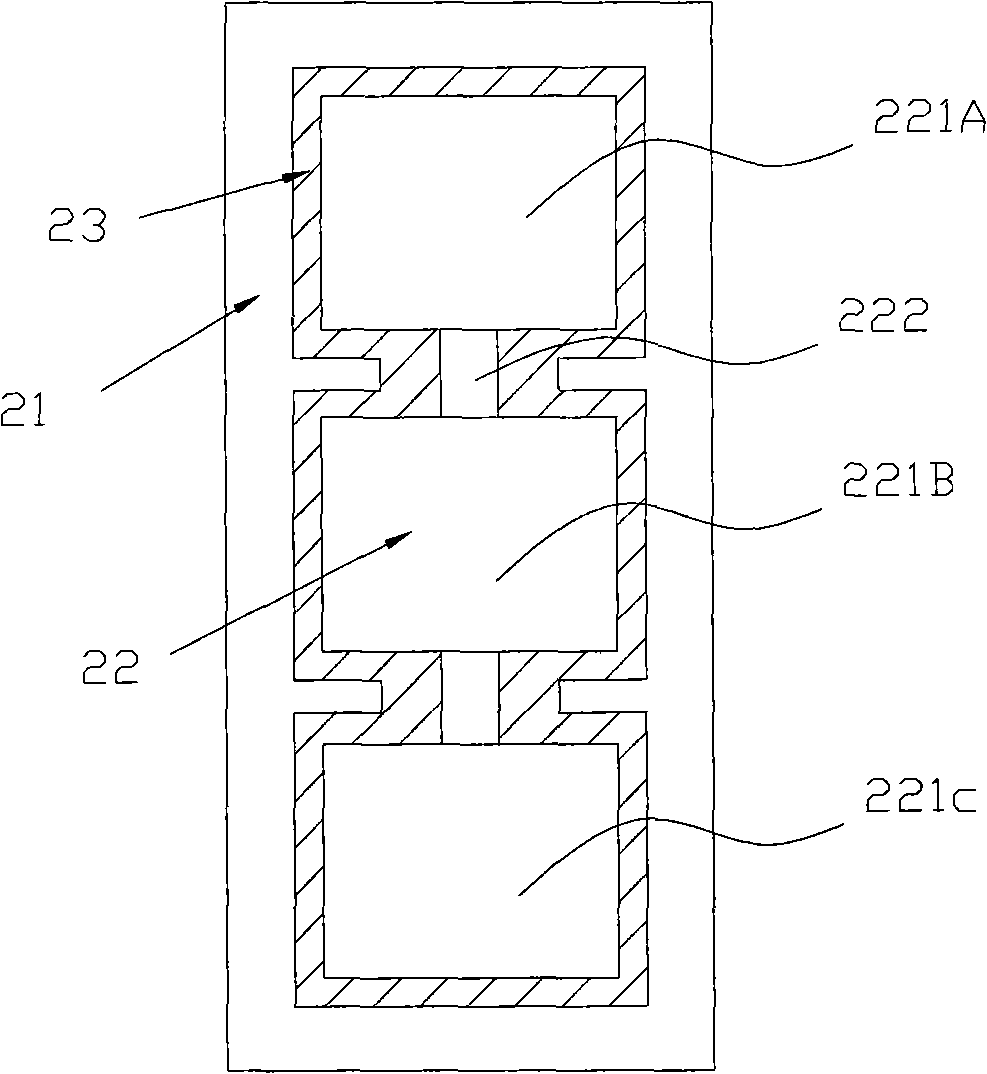

[0030] By forming the slit and the second common electrode in the process of forming the pixel electrode, when the driving signal is applied to the second common electrode, the liquid crystal molecules in the slit formed between the second common electrode and the pixel electrode are deflected in the pretilt direction In this way, the required electric field can be formed through exposure and development together with the slit and the second common electrode together with the pixel electrode, and the electric field in which the liquid crystal molecules are pretilted can be obtained without adding any process.

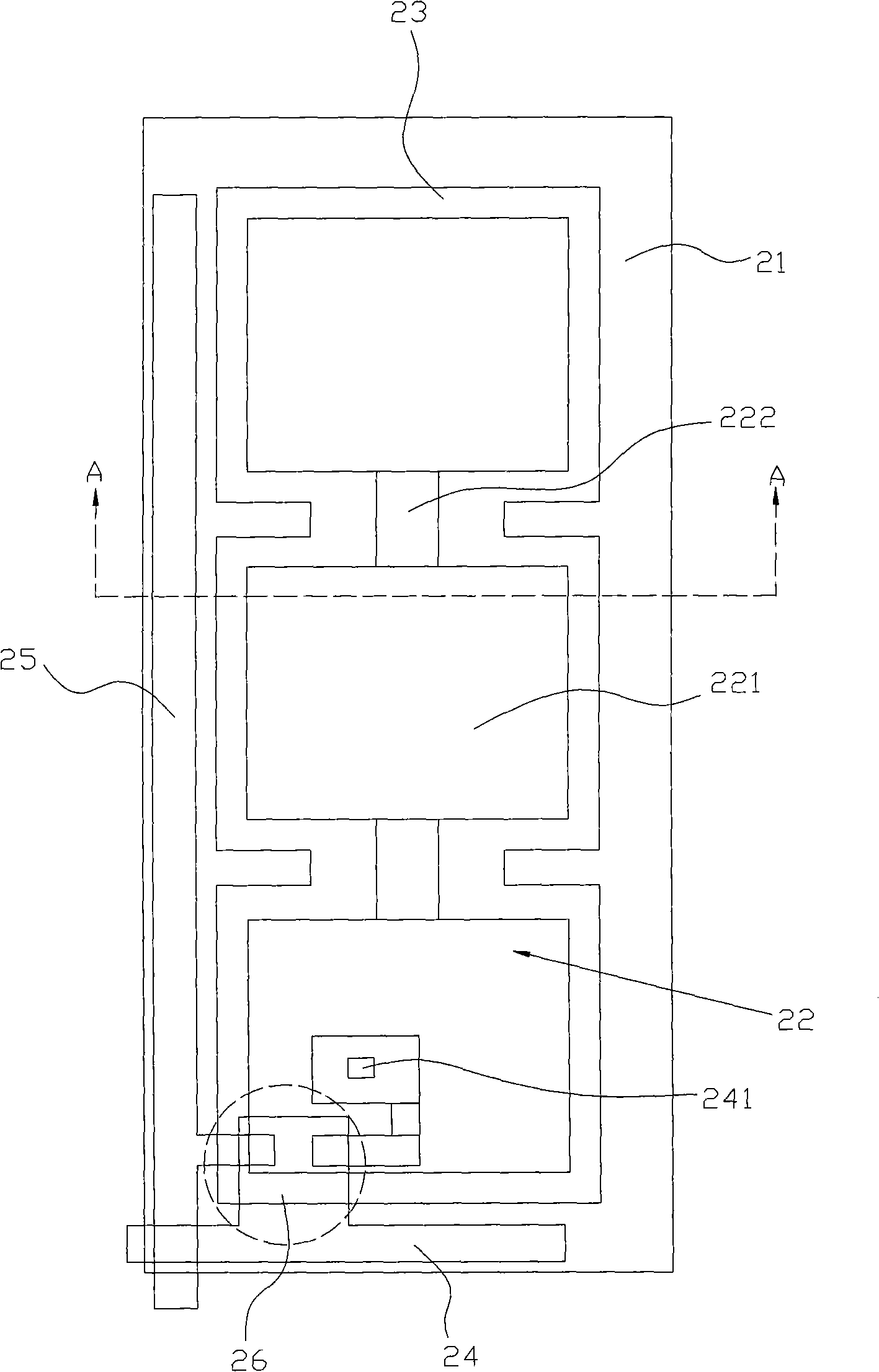

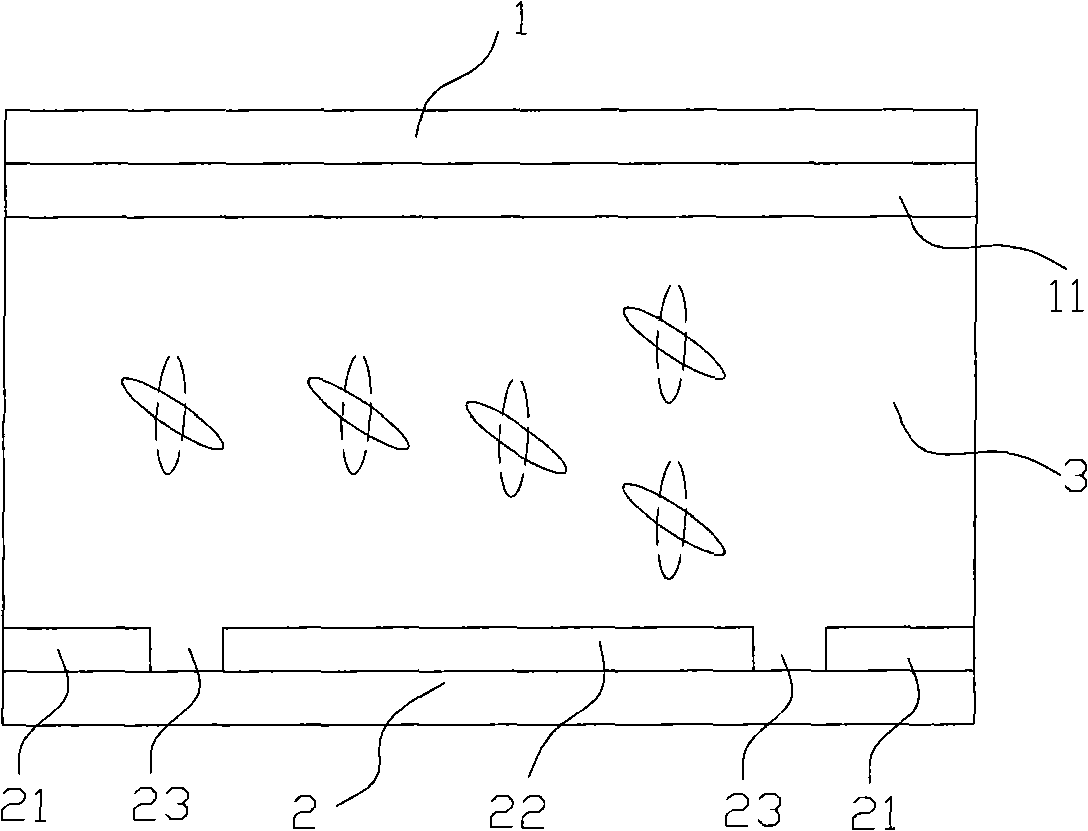

[0031] see figure 1 and figure 2 , the liquid crystal display device of the present invention includes a first substrate 1 , a second substrate 2 and a liquid crystal layer 3 .

[0032] A first common electrode 11 is disposed on the first substrate 1 .

[0033] A second common electrode 21 and a pixel electrode 22 are disposed on the surface of the second substrate 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com