Patents

Literature

42results about How to "Strong electric field" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

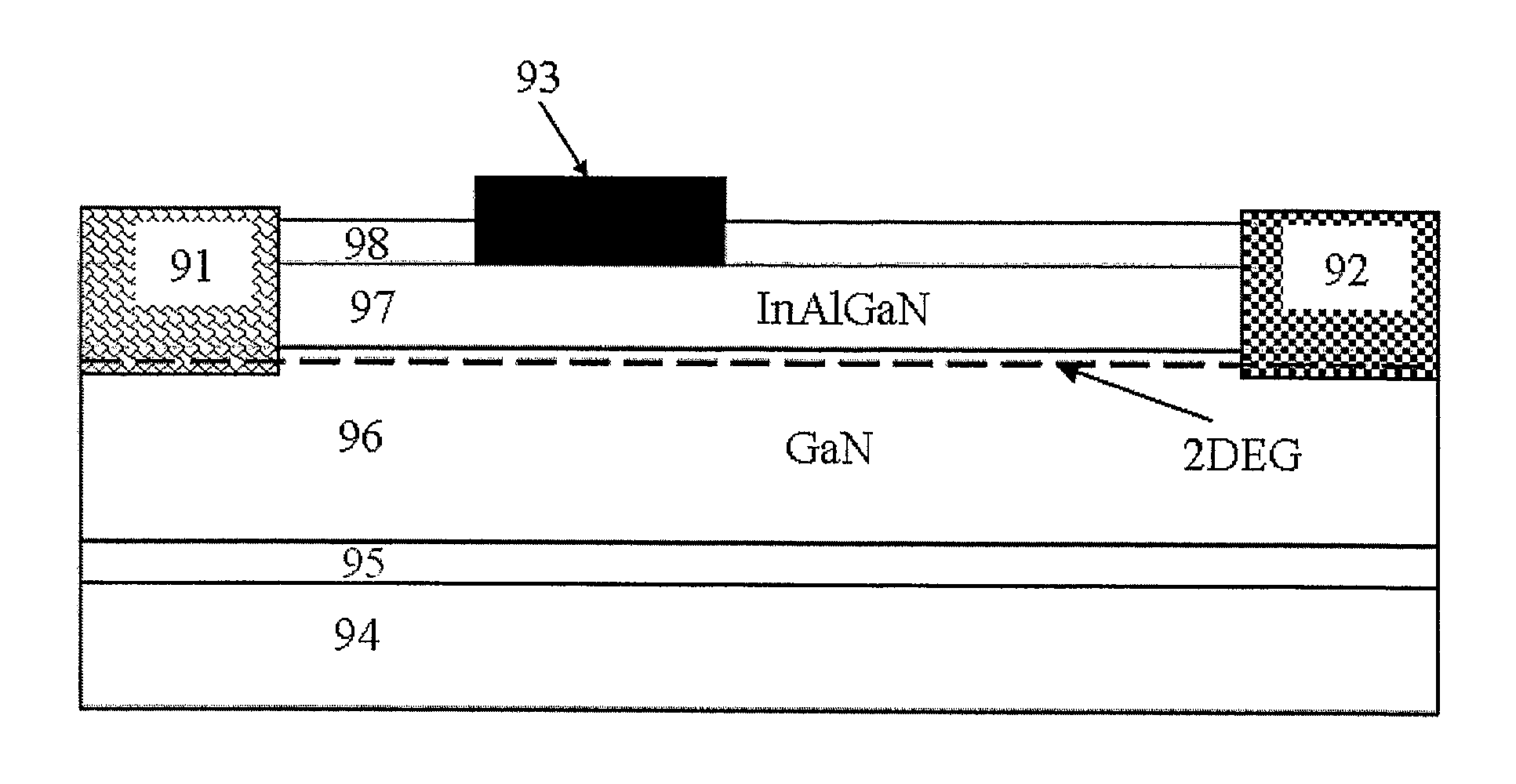

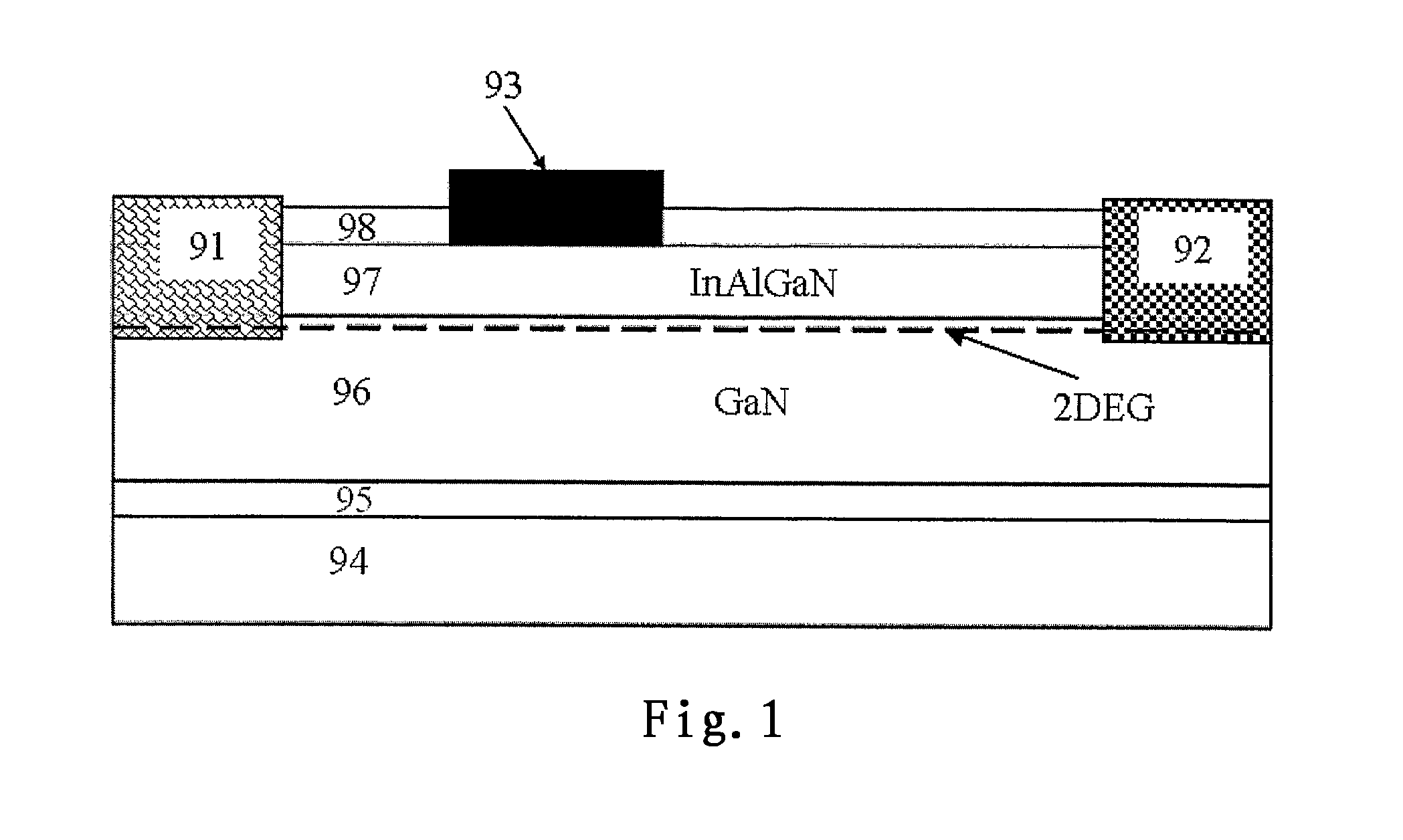

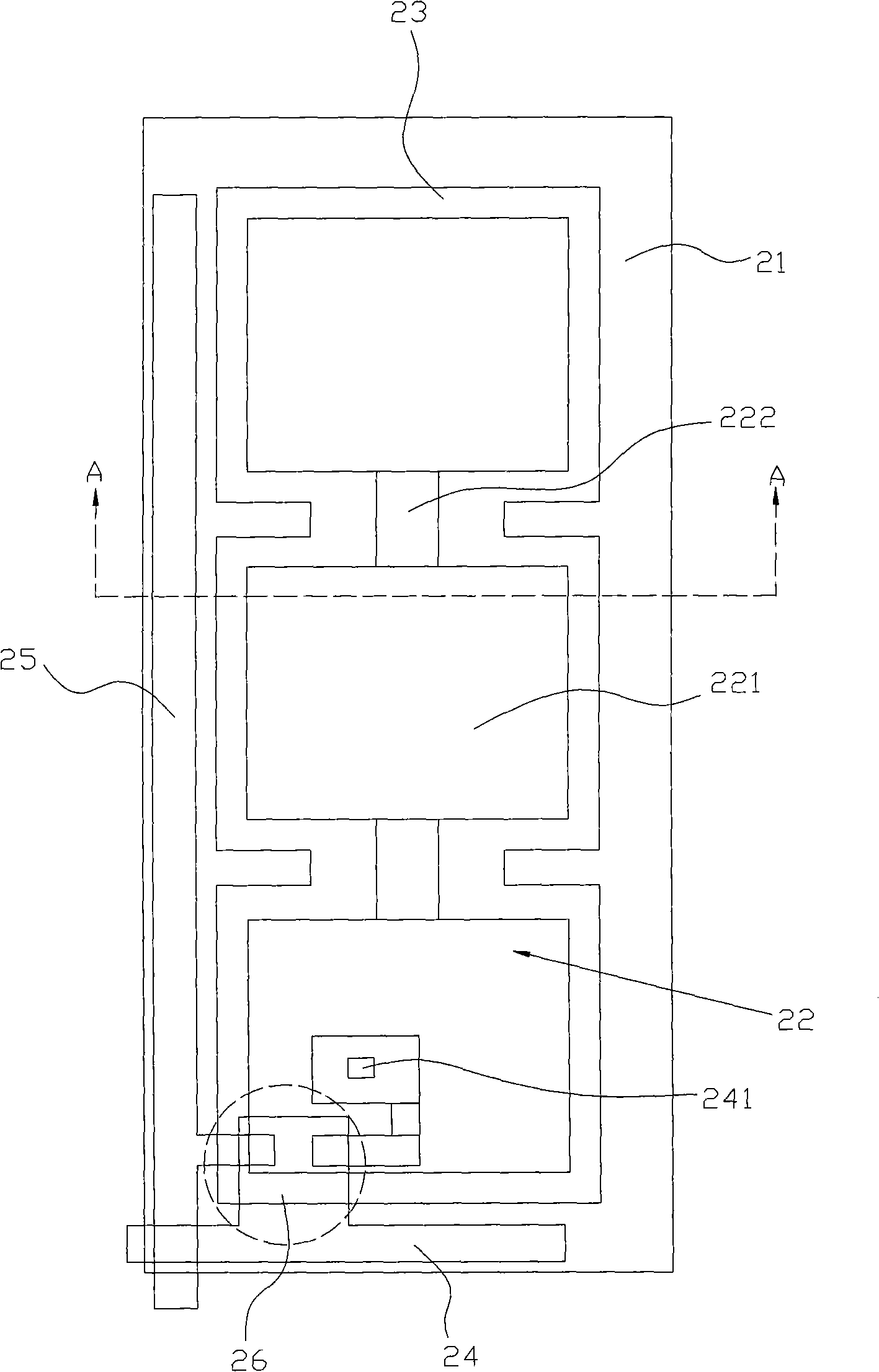

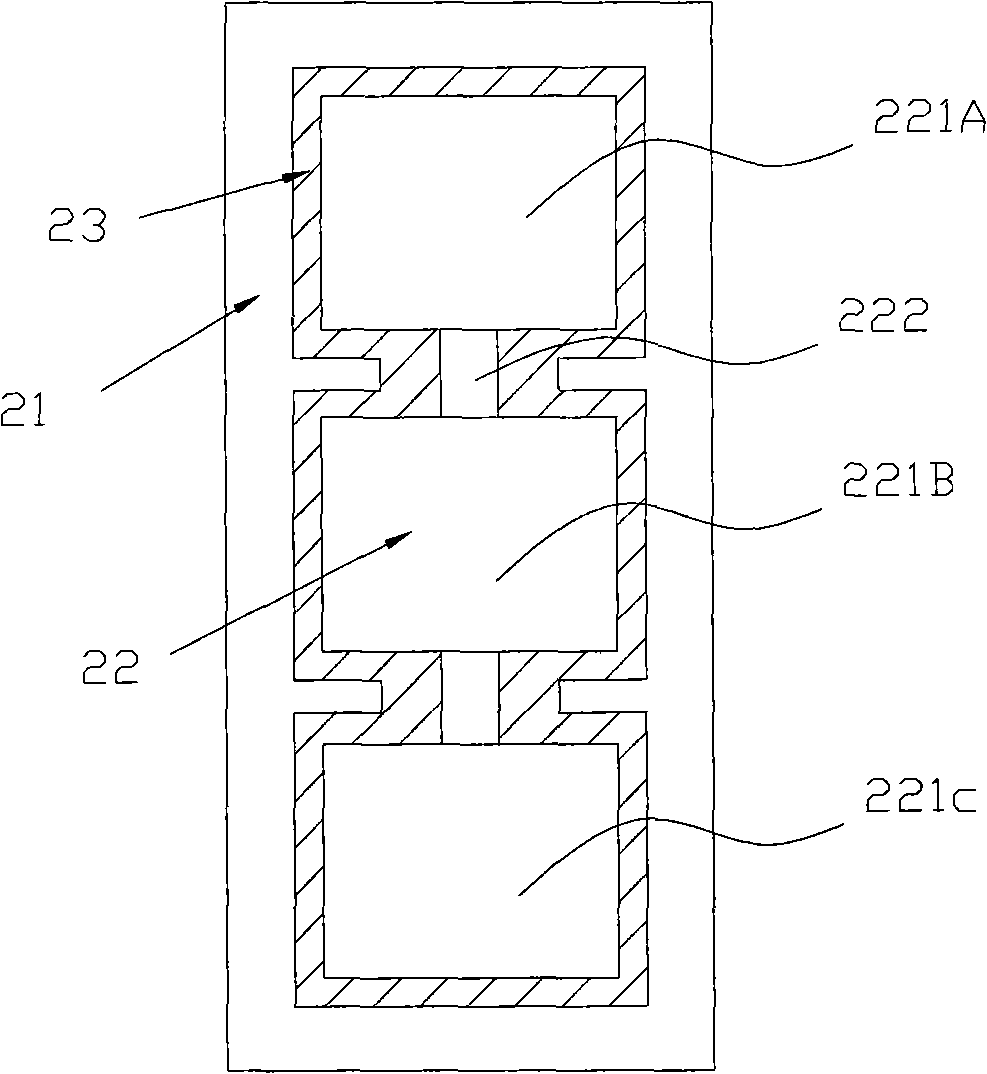

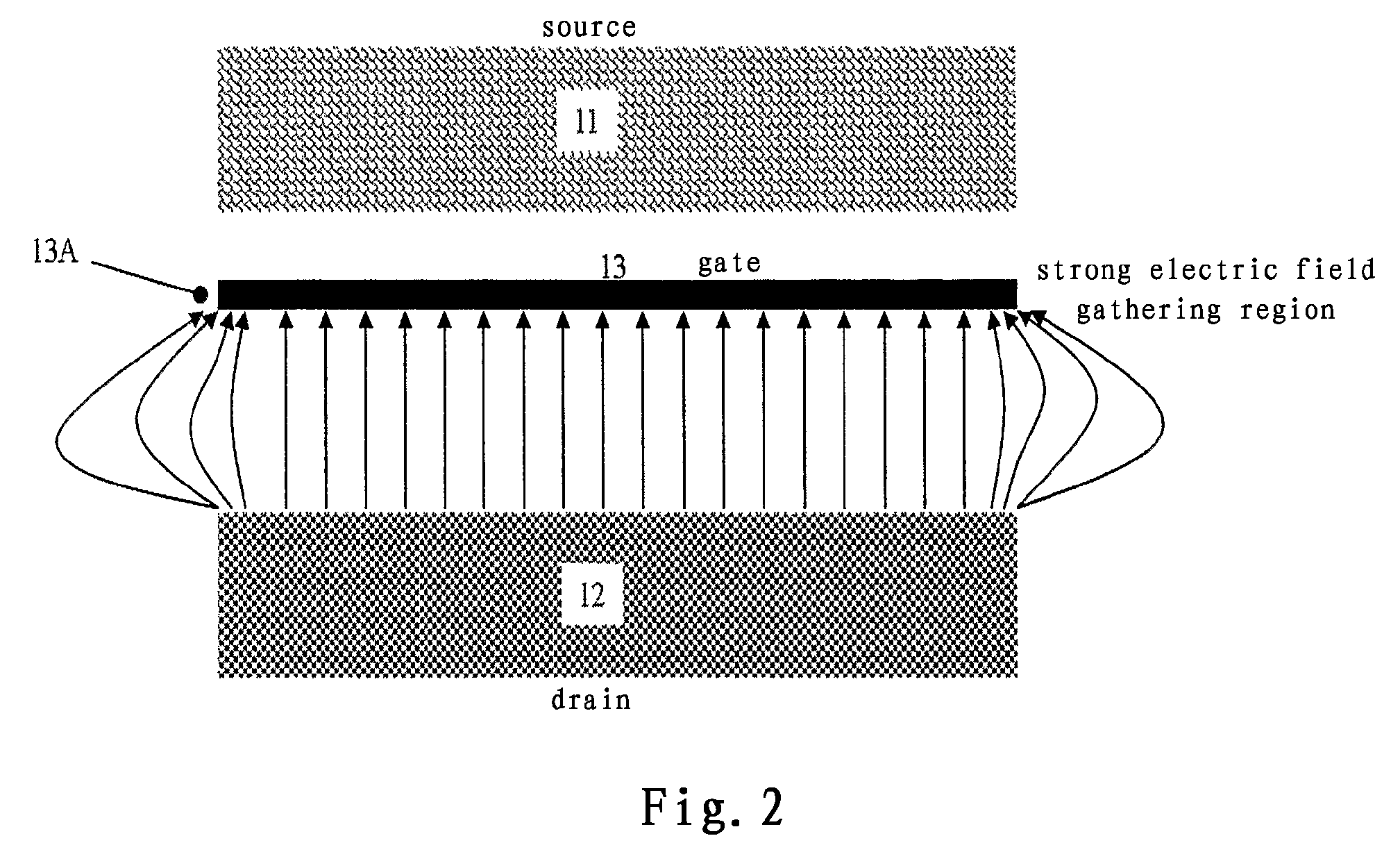

Semiconductor device and fabrication method thereof

ActiveUS20120280280A1Improve breakdown voltageIncrease unit areaSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor packageIsolation layer

The invention relates to a semiconductor device and a fabrication method thereof. A semiconductor device according to an aspect of the invention comprising: a semiconductor layer on a substrate; an isolation layer on the semiconductor layer; a source and a drain which are in contact with the semiconductor layer, each of the source and the drain comprises multiple fingers, and the multiple fingers of the source intersect the multiple fingers of the drain; and a gate on the isolation layer, the gate is located between the source and the drain and comprises a closed ring structure which encircles the multiple fingers of the source and the drain.

Owner:GPOWER SEMICON

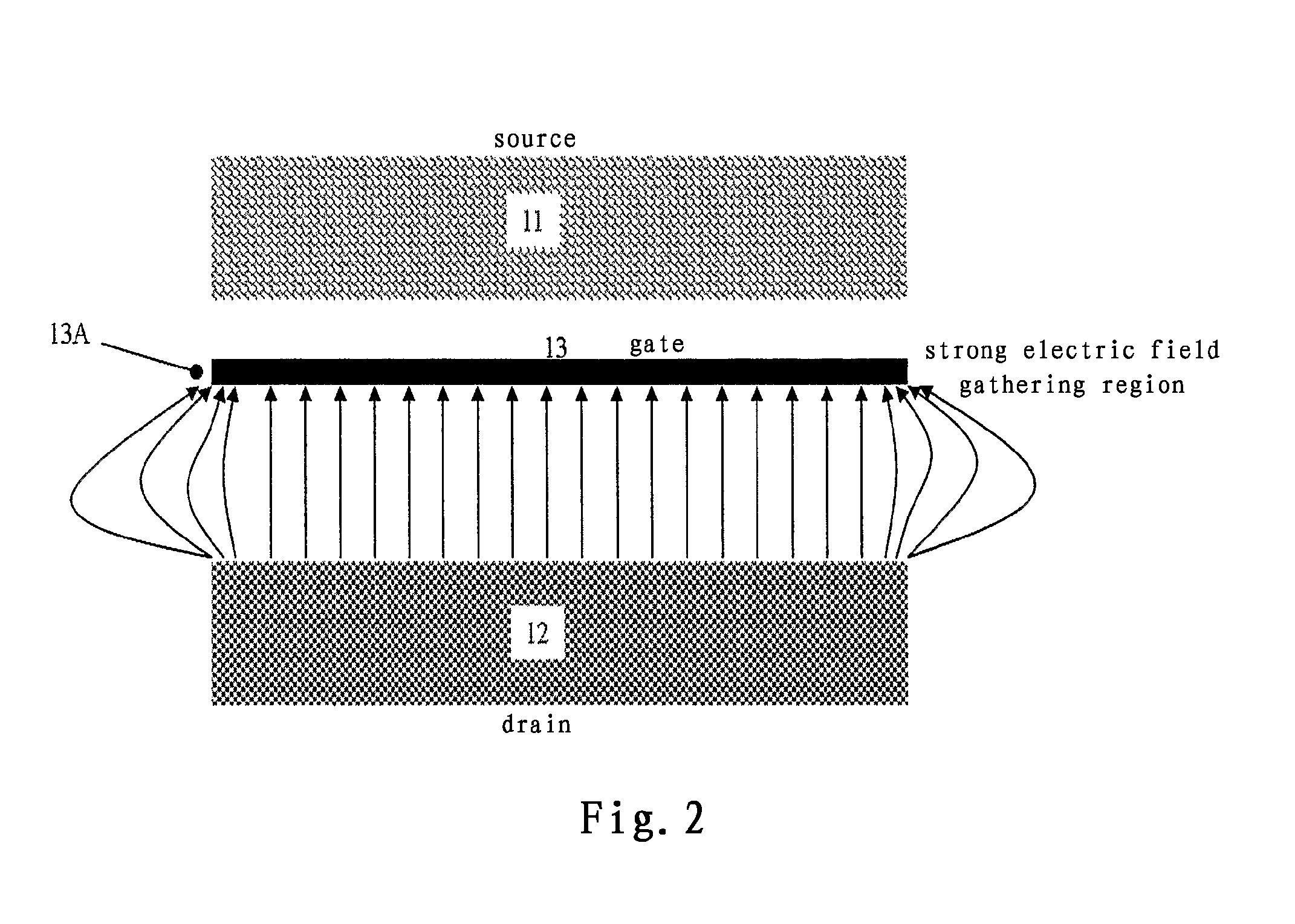

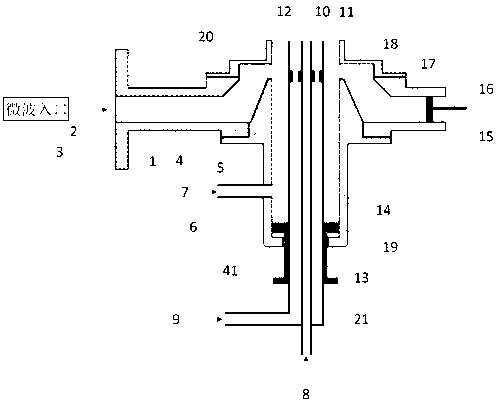

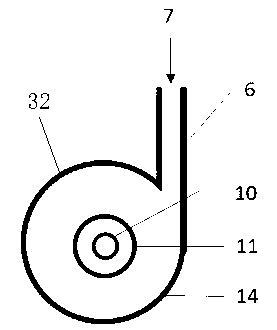

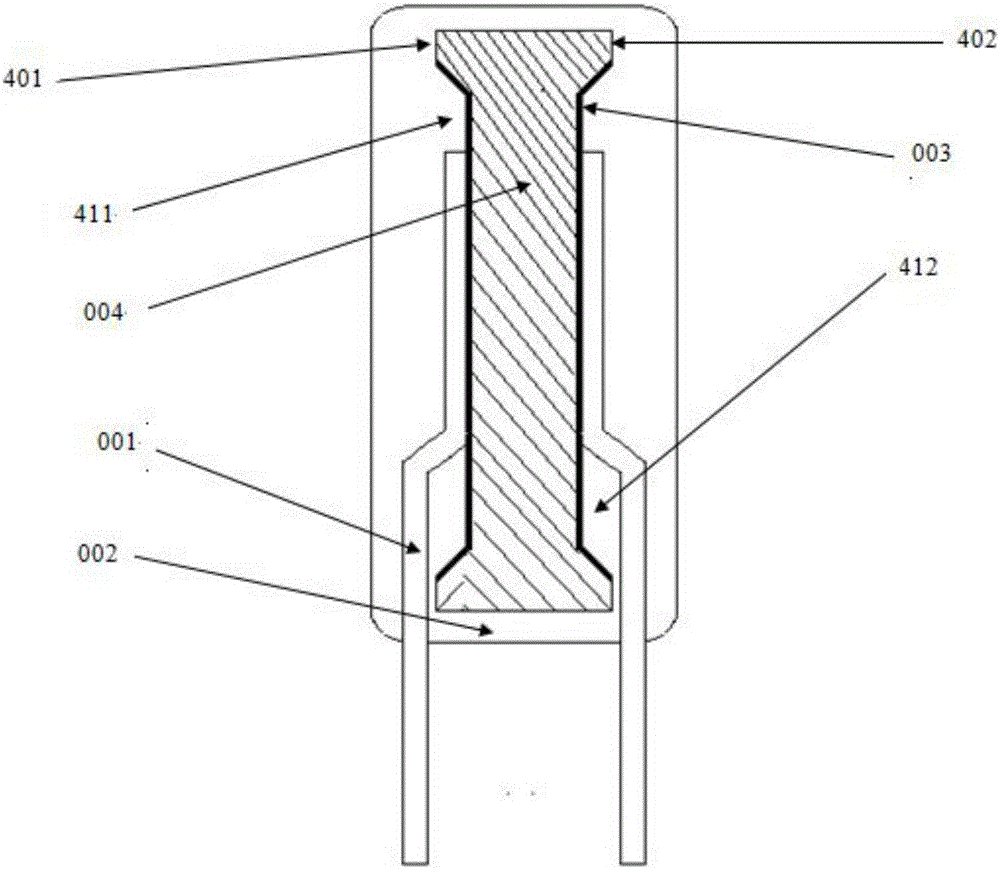

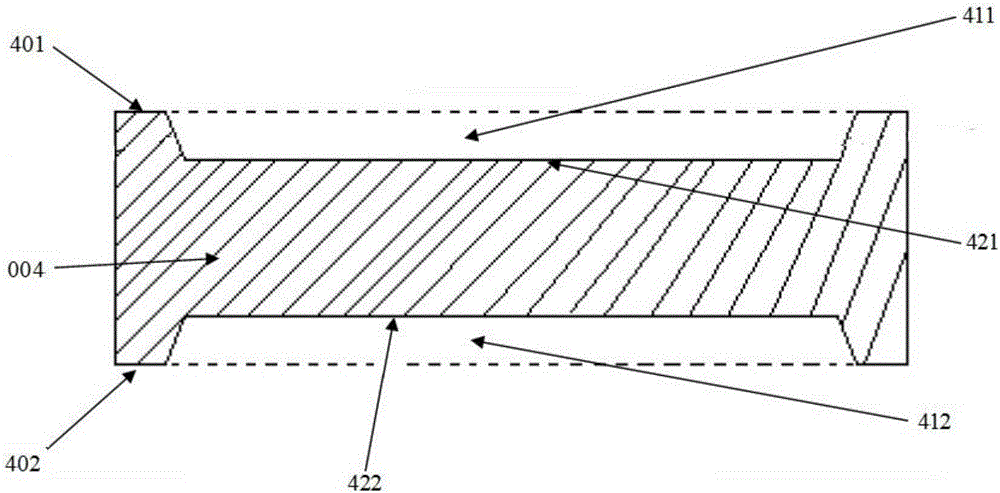

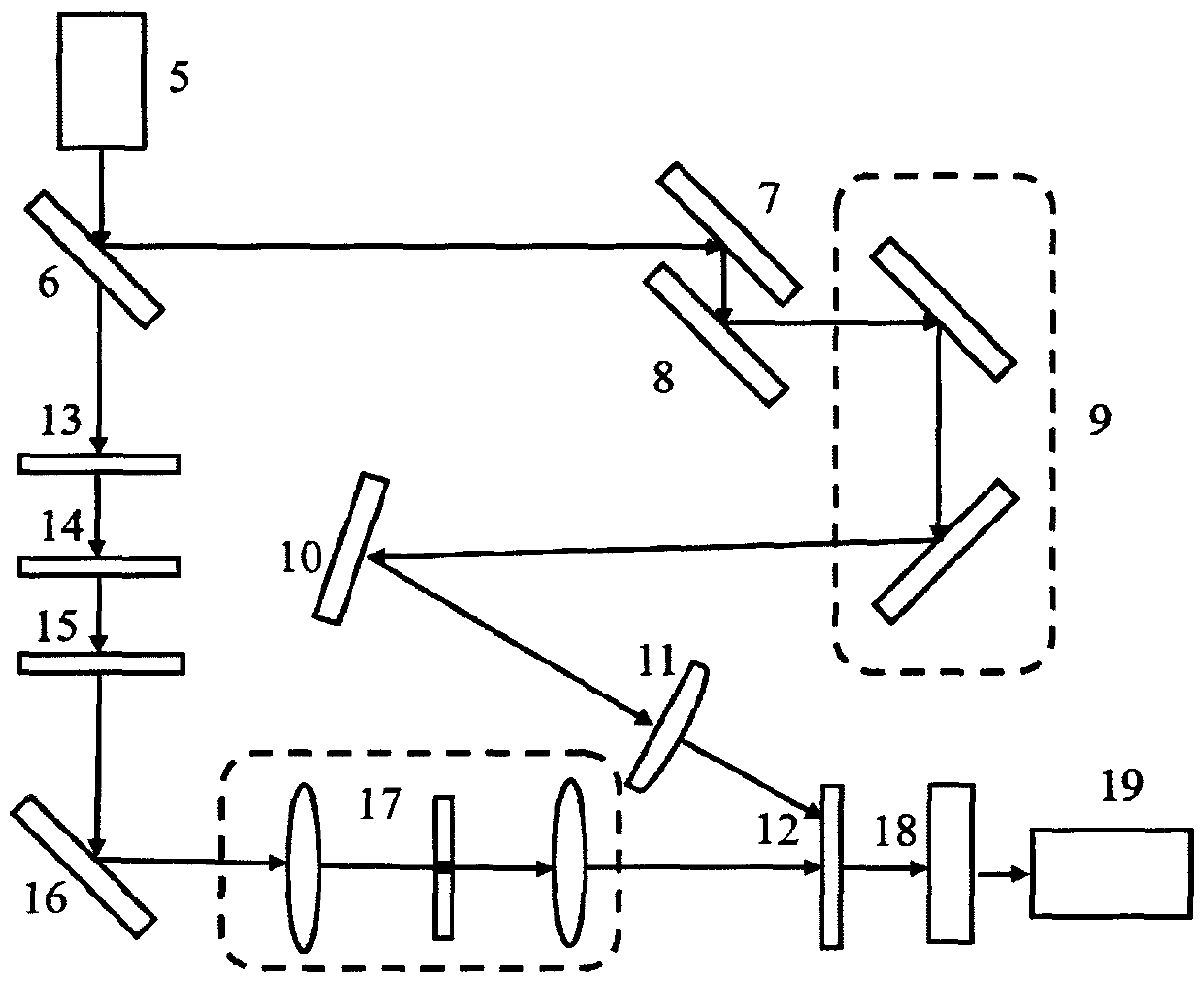

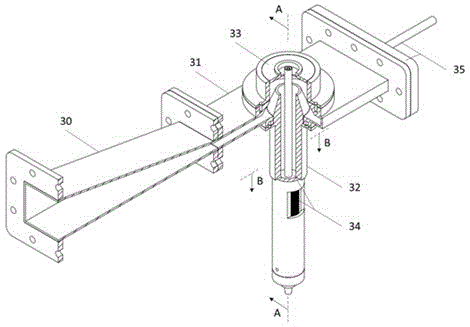

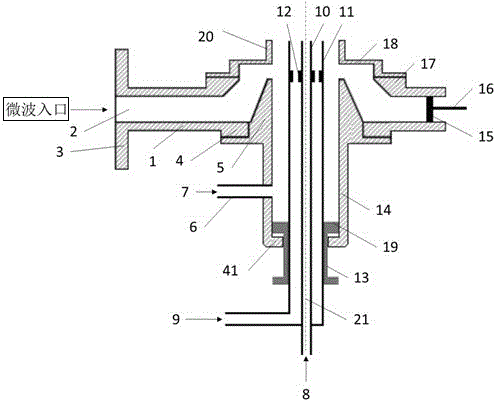

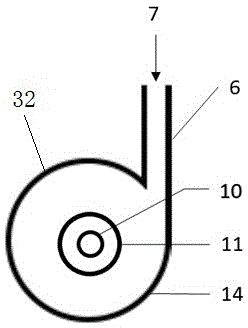

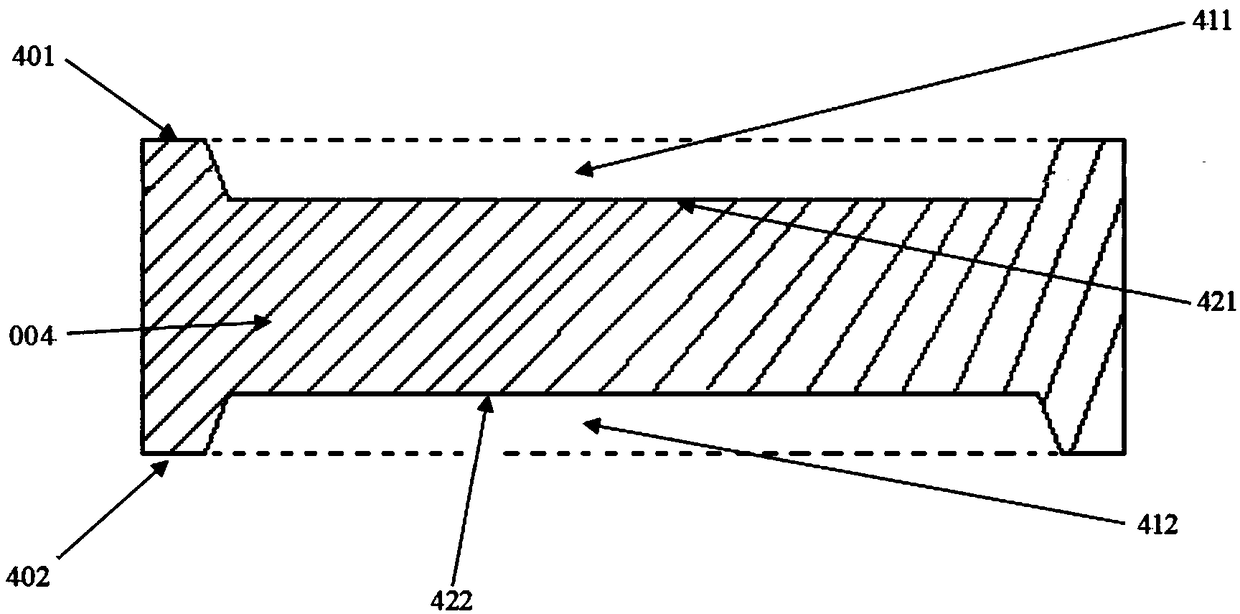

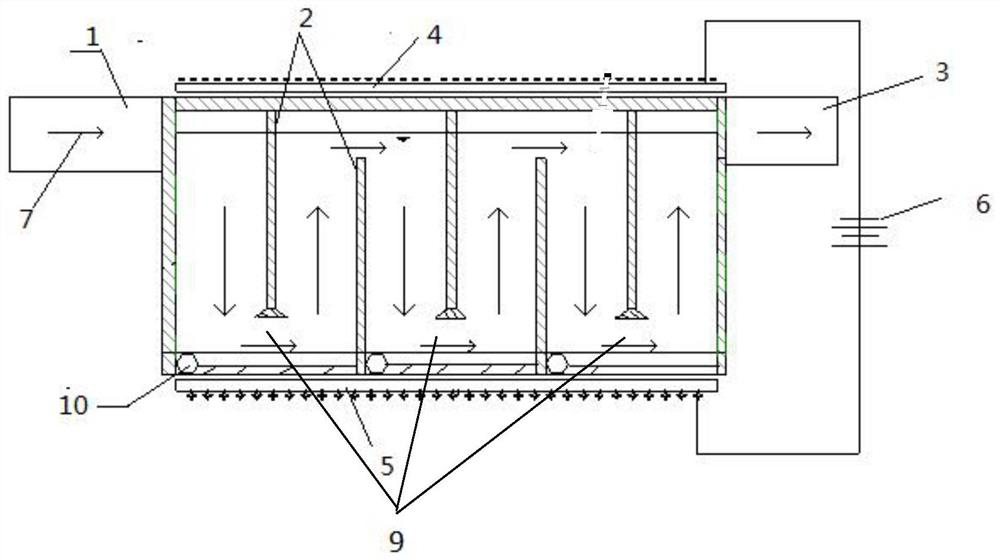

Waveguide direct-feed-type microwave plasma torch device

ActiveCN103269561AAchieve Impedance MatchingOptimizing Energy Coupling EfficiencyPlasma techniqueCoaxial cableEngineering

The invention provides a waveguide direct-feed-type microwave plasma torch device which comprises a waveguide portion, a tuning and auxiliary portion and a coaxial torch tube portion. The waveguide portion comprises a gradual-changing-type waveguide and a narrow-edge compression waveguide. The coaxial torch tube portion comprises an outer tube, a middle tube, an inner tube, a regulating stud and a coaxial centering washer. The tuning and auxiliary portion comprises a waveguide short-circuit sliding end, a torch tube reflection tuning end and a torch tube upper portion regulating end. The waveguide short-circuit sliding end comprises a waveguide short-circuit plate and a sliding rod. The torch tube reflection tuning end comprises the regulating stud and a reflection plate. The gradual-changing-type waveguide and the narrow-edge compression waveguide are directly fed into the metal coaxial torch tube, a formed plasma has a central channel so that a sample can be conveniently led into the plasma, and meanwhile bearing capacity for the sample is intensified. The device eliminates a coaxial cable, a coupling ring and the like, improves coupling efficiency, and expands the use power of the torch tube. The device can be used as an ionization source of an atomizer and an ionization source of an atom mass spectrum or used for decomposition and treatment of harmful chemicals and rubbish.

Owner:ZHEJIANG UNIV

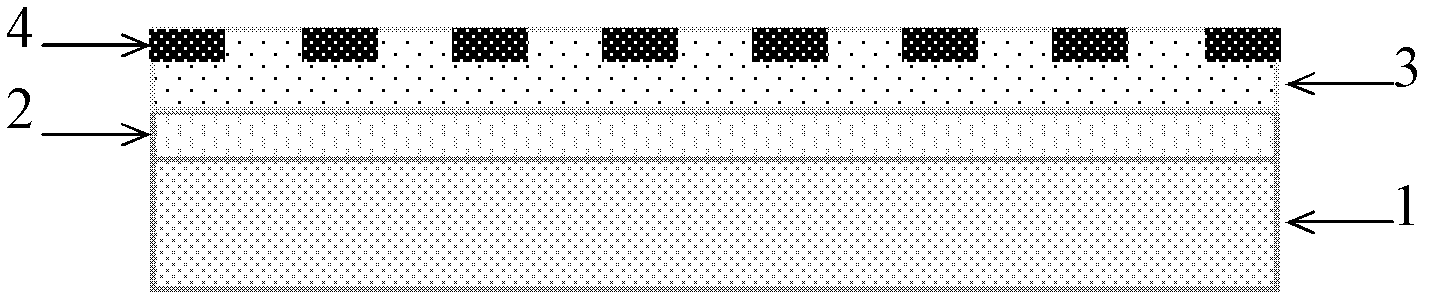

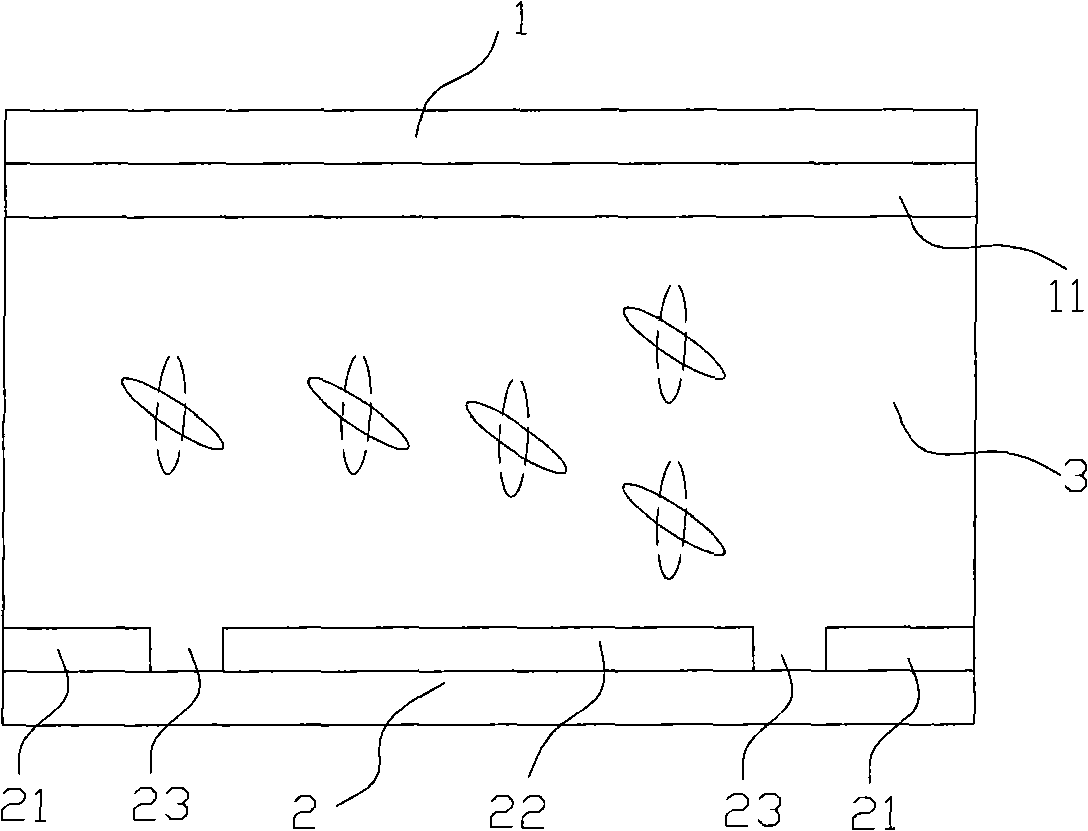

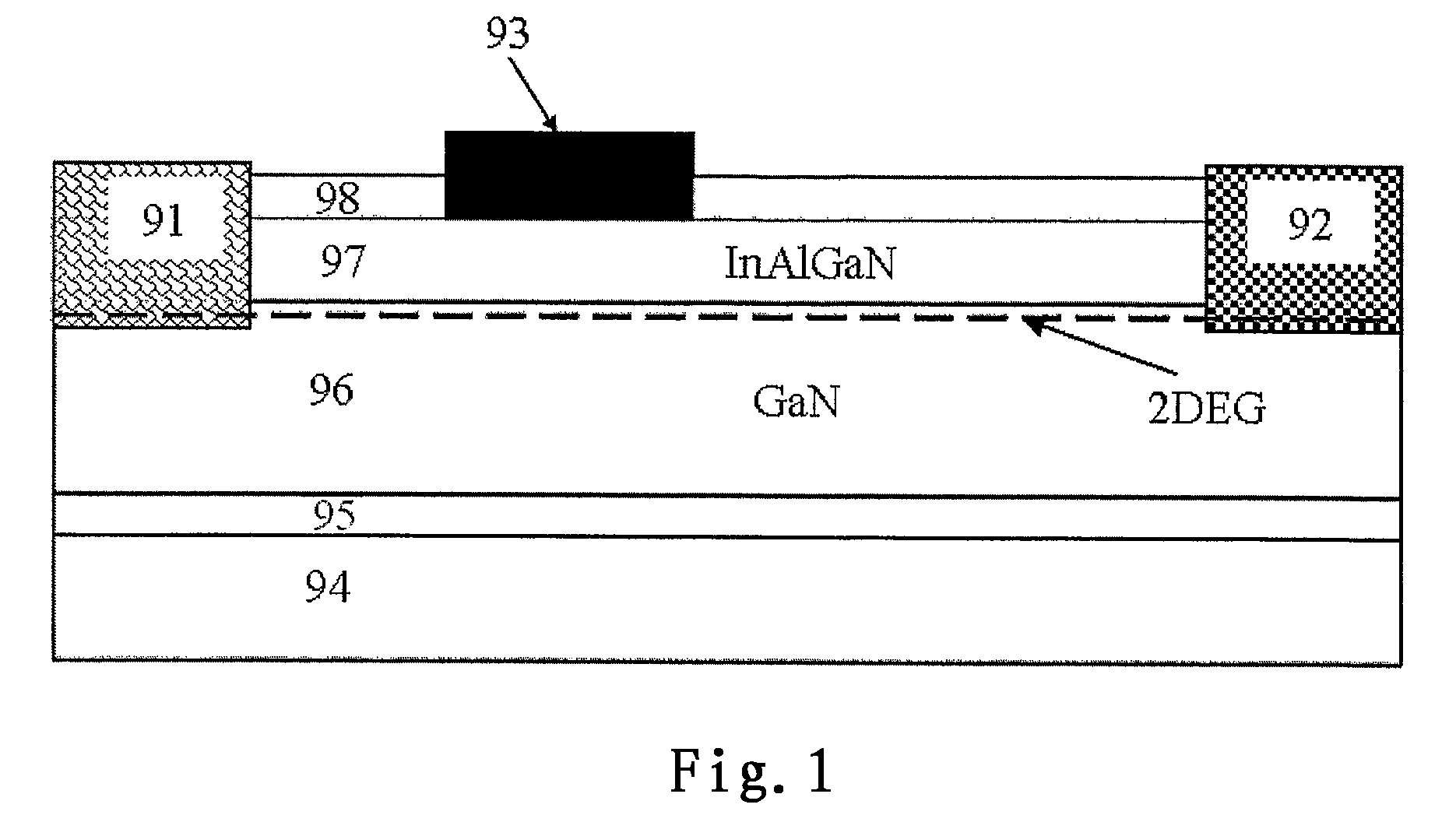

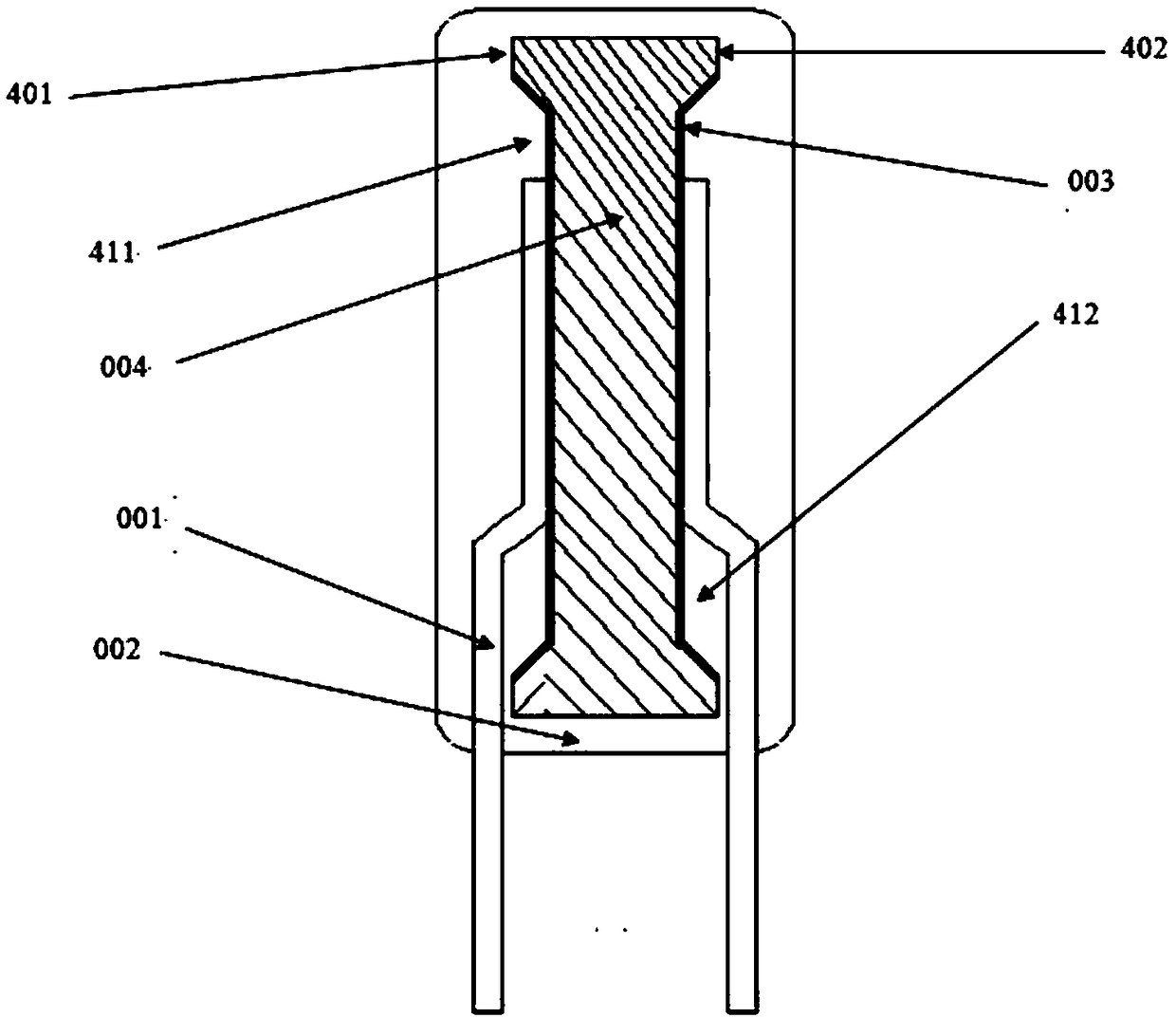

MSM (Metal-Semiconductor-Metal) photodetector with improved structure and preparation method thereof

InactiveCN102324445AAccelerated driftShort response timeFinal product manufactureSemiconductor devicesSemiconductor materialsPhotodetector

The invention discloses an MSM (Metal-Semiconductor-Metal) photodetector with an improved structure and a preparation method thereof. The detector comprises an active layer, a buffering layer and an insulating substrate arranged from upside to downside in sequence, wherein an electrode is also arranged on the active layer; and the electrode is at least locally buried in the active layer; the preparation method comprises the following steps of: etching an active layer surface mask overlapped on the insulating substrate to form a buried electrode channel and filling a conductive material in the buried electrode channel to form an electrode with a set form. According to the invention, the original surface electrode structure is replaced by the electrode structure buried in the semiconductor material so that the buried electrode can form an electric field in the horizontal direction in the interior of the material so as to obtain an electric field intensity stronger than that of a surface electrode structure; and the electron moves along an approximate straight track under the stronger field intensity effect so that the photon-generated carrier drift is accelerated, the response time of the device is effectively reduced, the responsiveness of the device is improved and the preparation process is simple and controllable.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

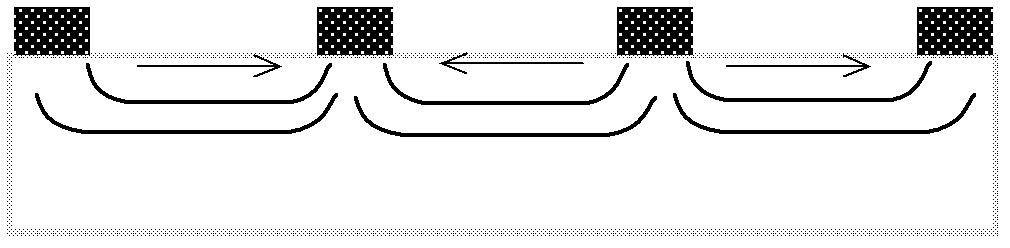

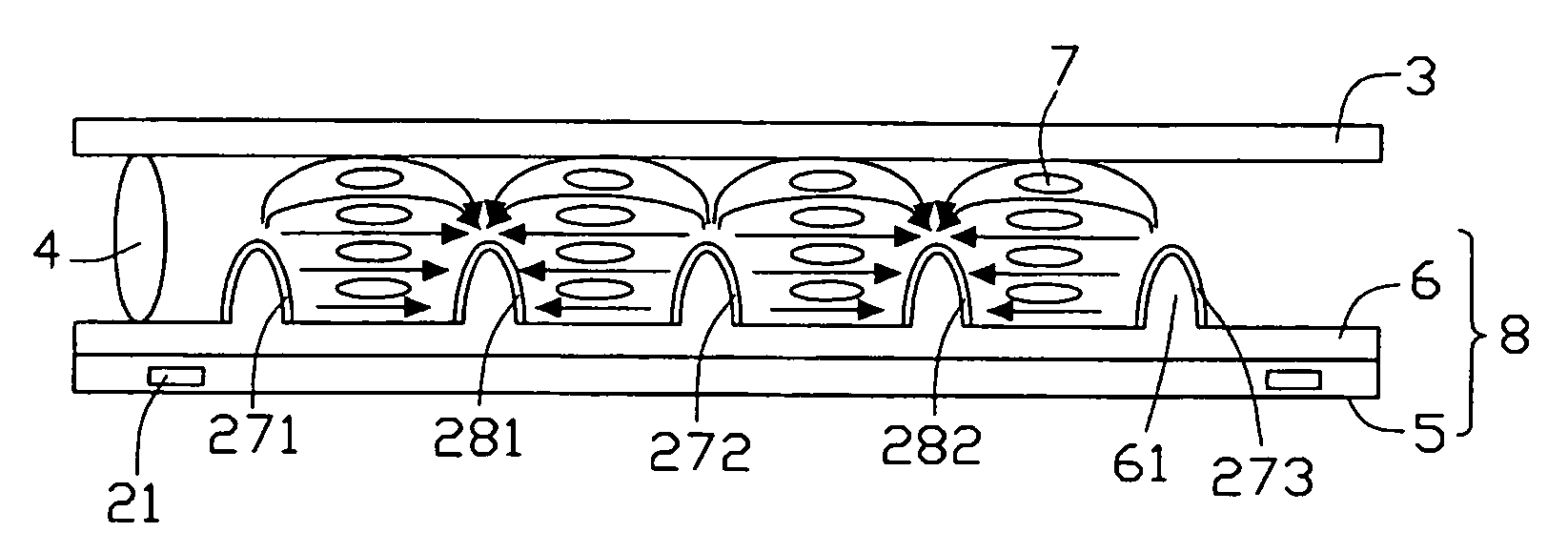

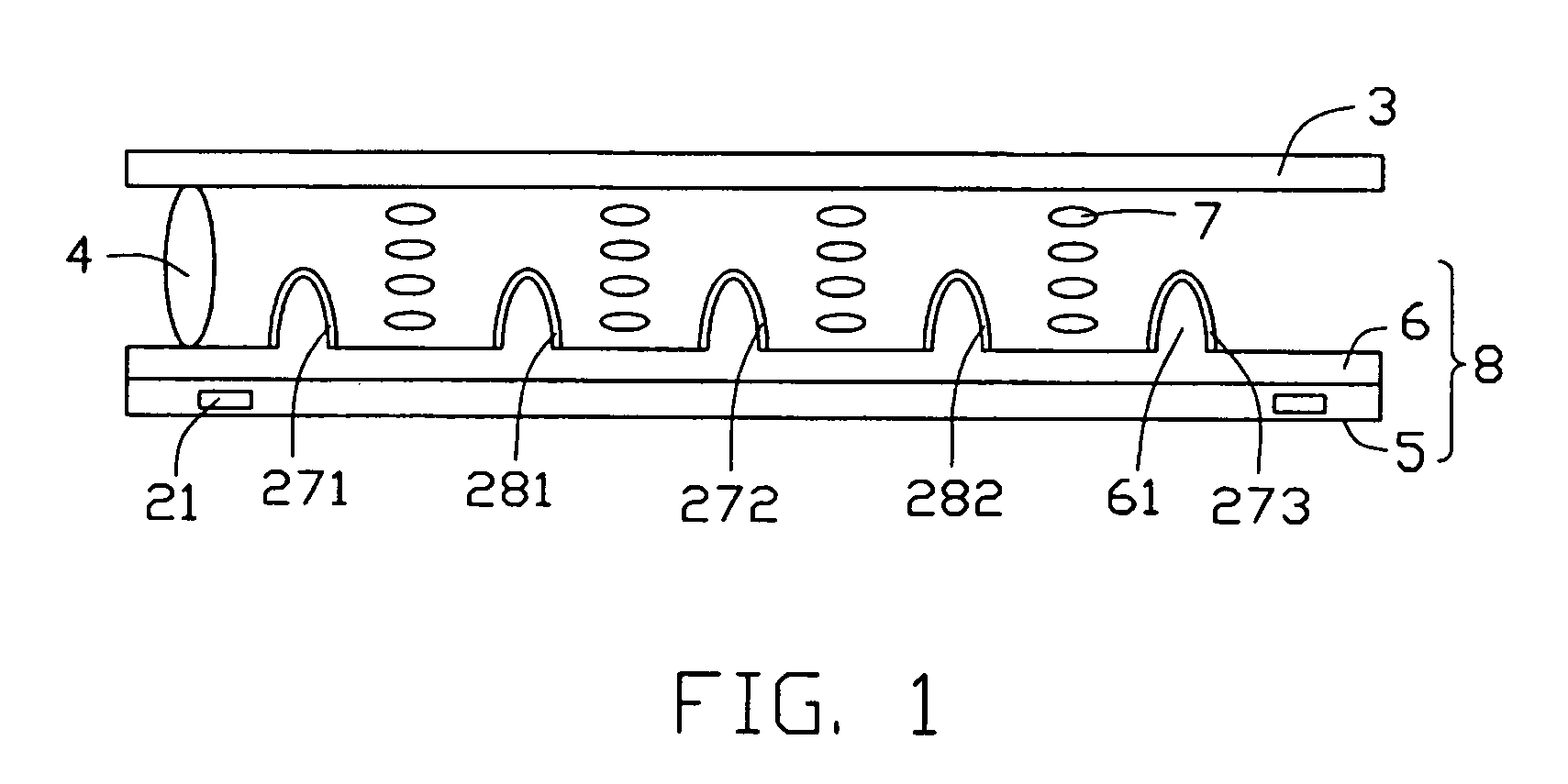

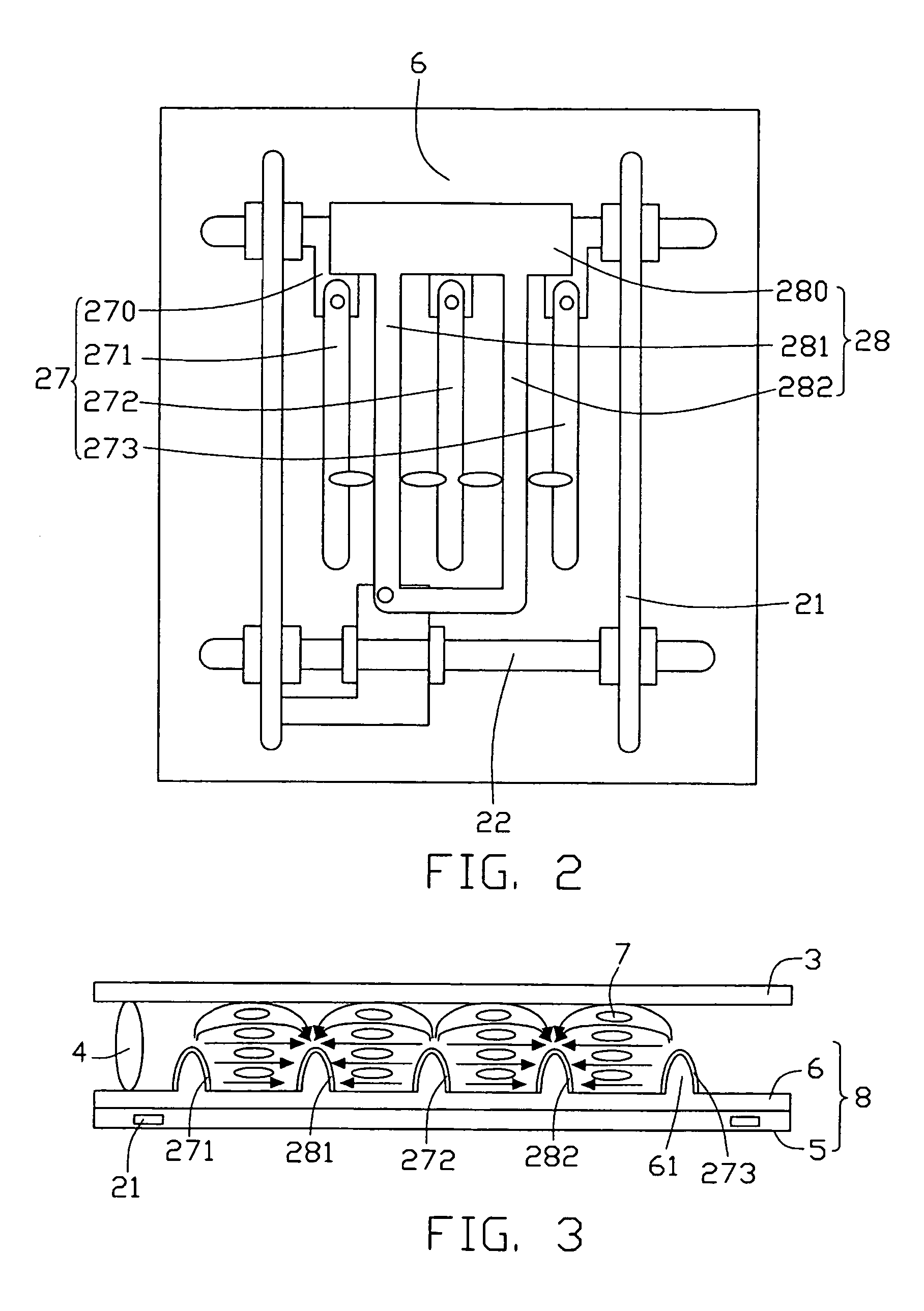

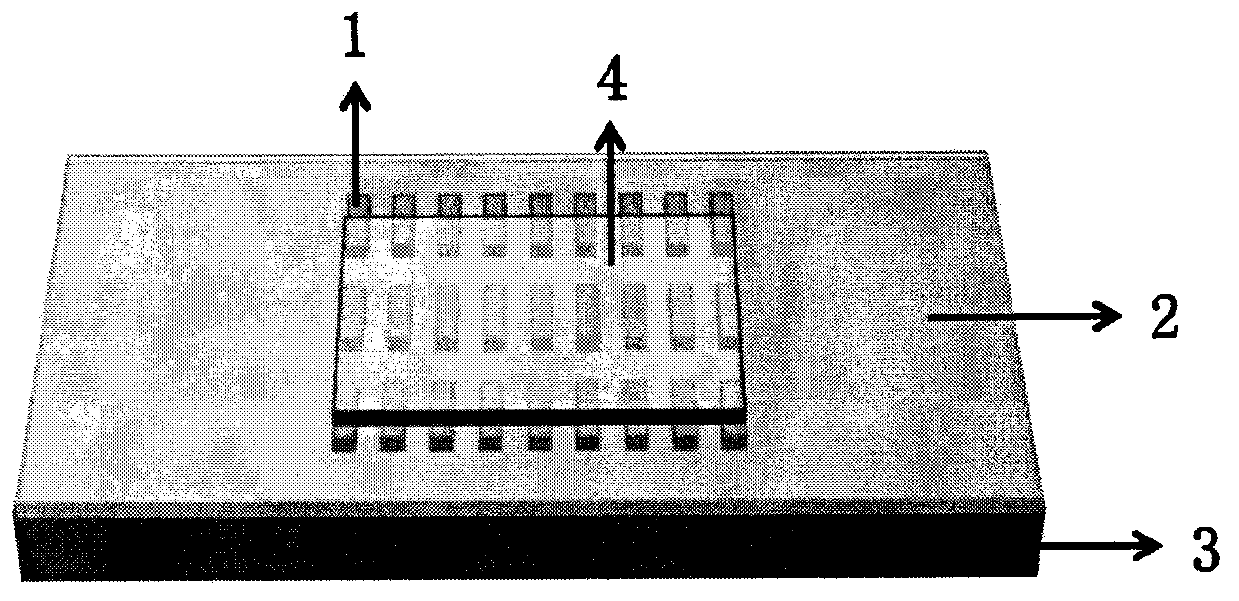

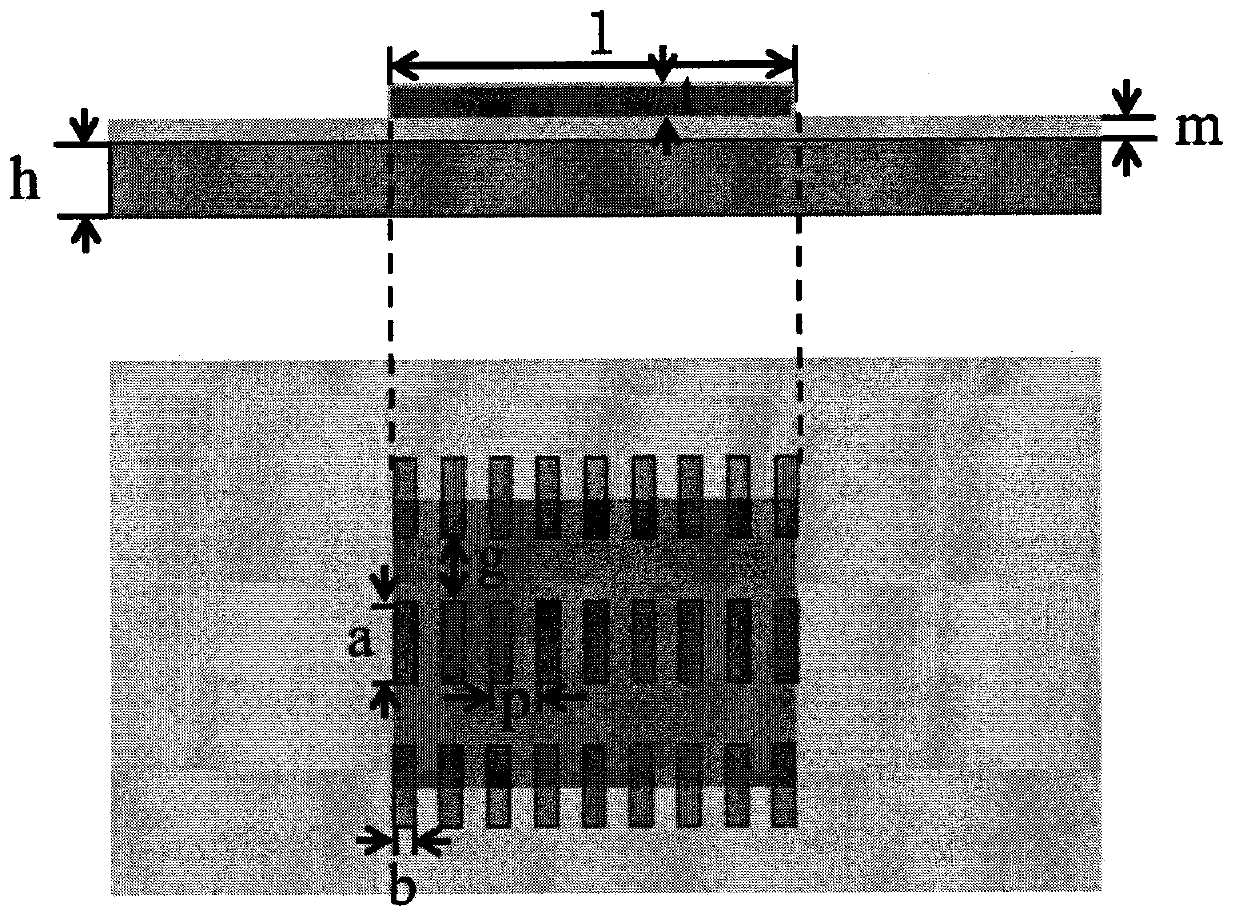

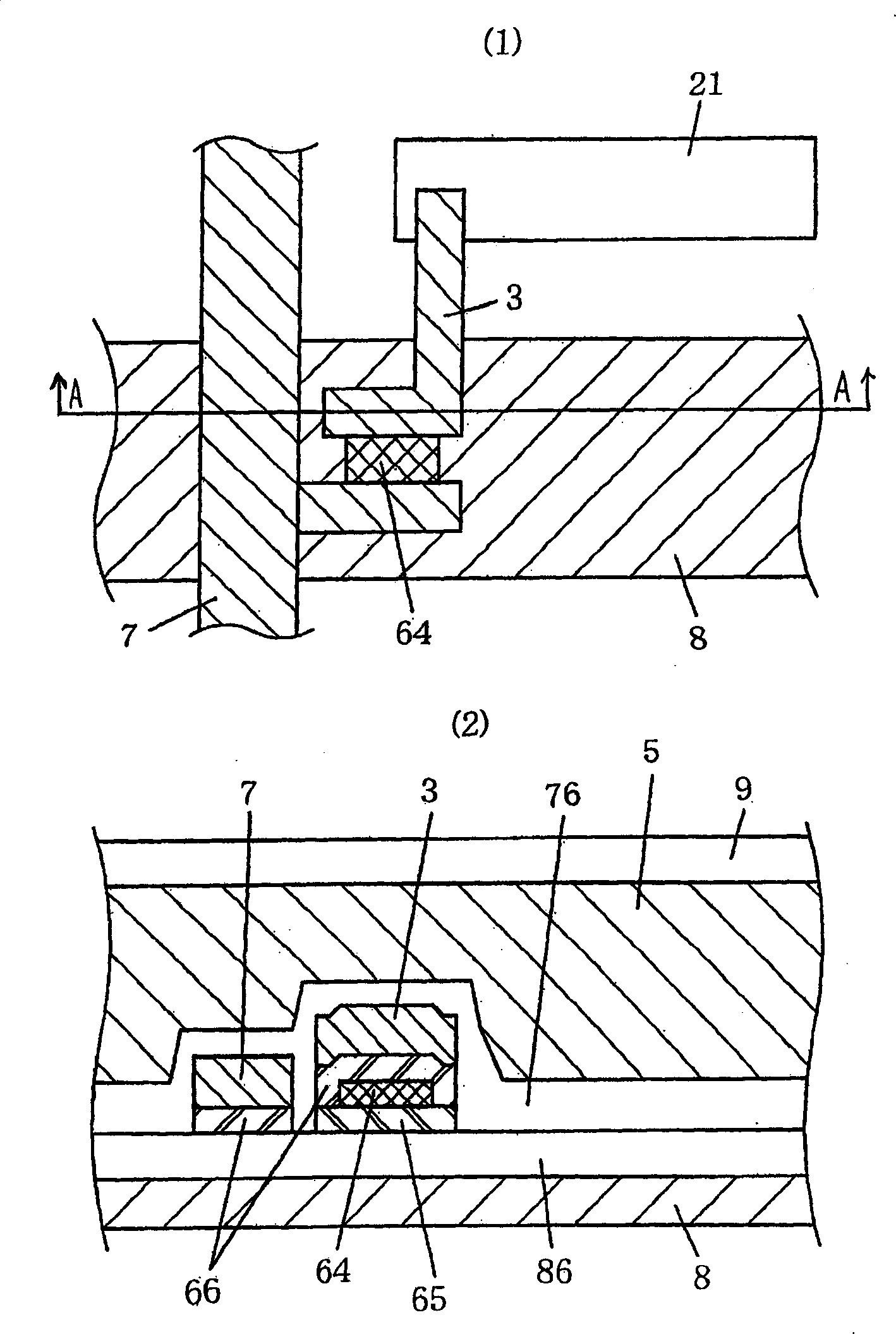

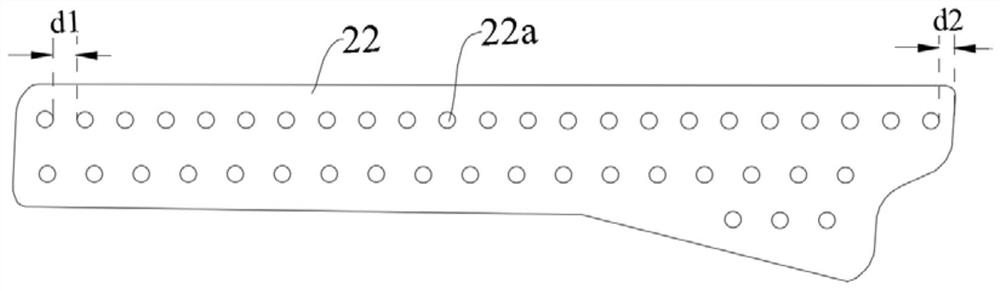

IPS type liquid crystal display with protrusive electrodes

InactiveUS7130011B2Improve picture qualityReduce the driving voltageNon-linear opticsIn planeLiquid-crystal display

An IPS (in-plane switching) liquid crystal display has a color filter substrate (3), a TFT (thin film transistor) substrate (8), and a liquid crystal layer (7) interposed therebetween. The TFT substrate includes a TFT plate (5), a protrusion layer (6), and an electrode matrix. The electrode matrix includes a plurality of transversely disposed gate lines (22), a plurality of longitudinally disposed data lines (21), switching elements, a plurality of common electrodes (27), and a plurality of pixel electrodes (28). The protrusion layer has a plurality of protrusion portions (61). The common and pixel electrodes are formed on the protrusion portions in one-to-one correspondence to provide an array of protrusive electrodes that generate a strong and highly uniform parallel electric field. This provides better picture quality, and can lower power consumption and / or yield a higher aperture ratio.

Owner:INNOLUX CORP

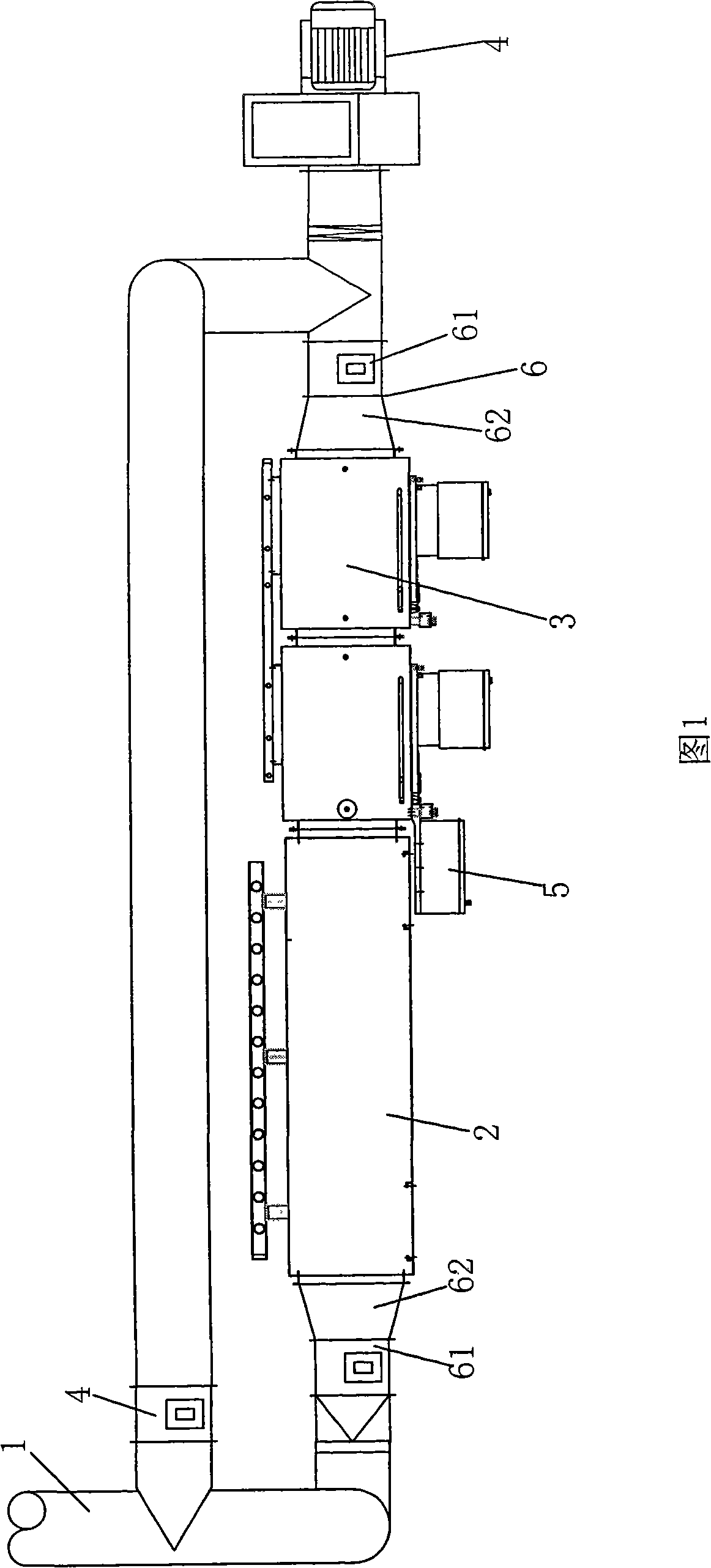

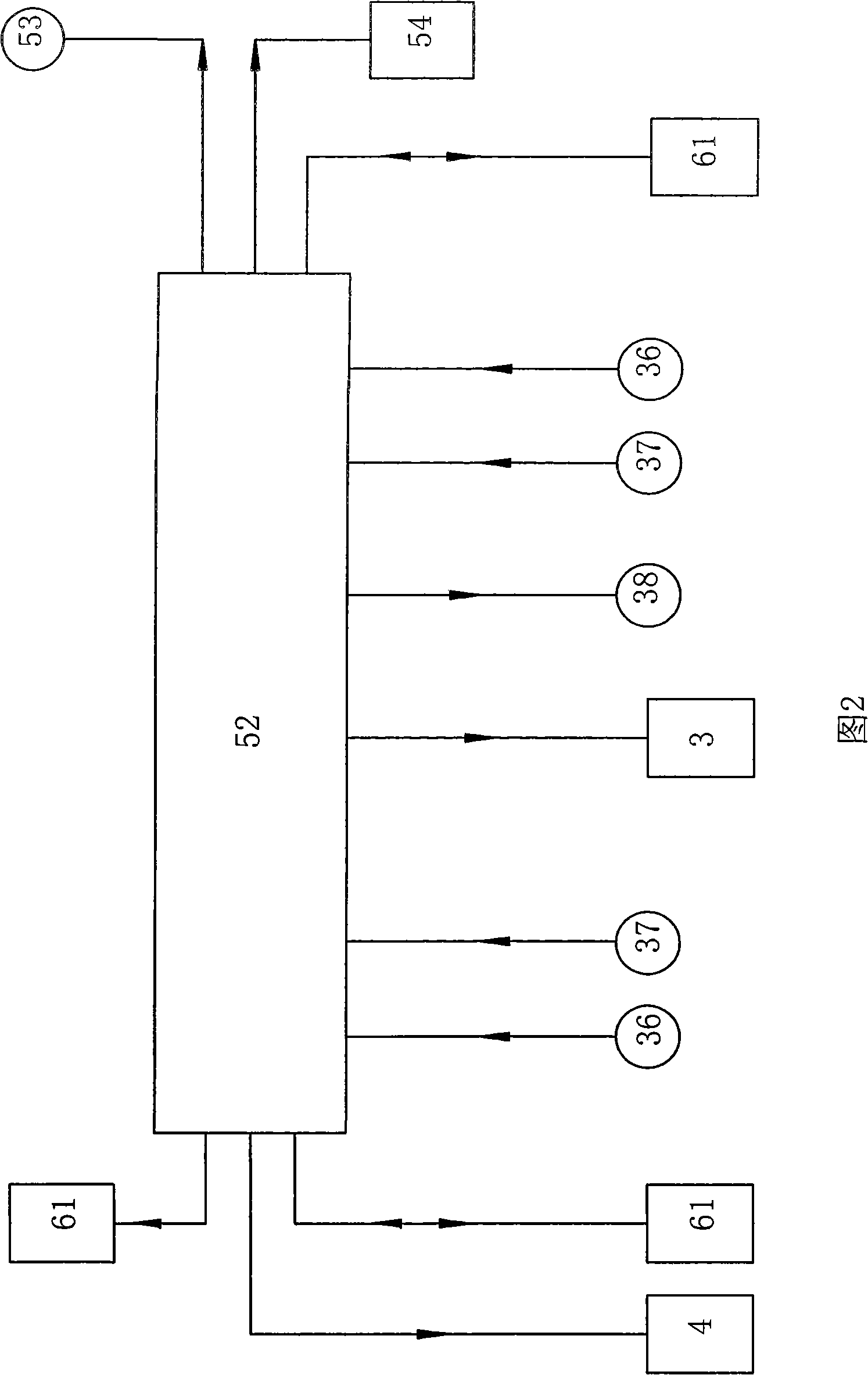

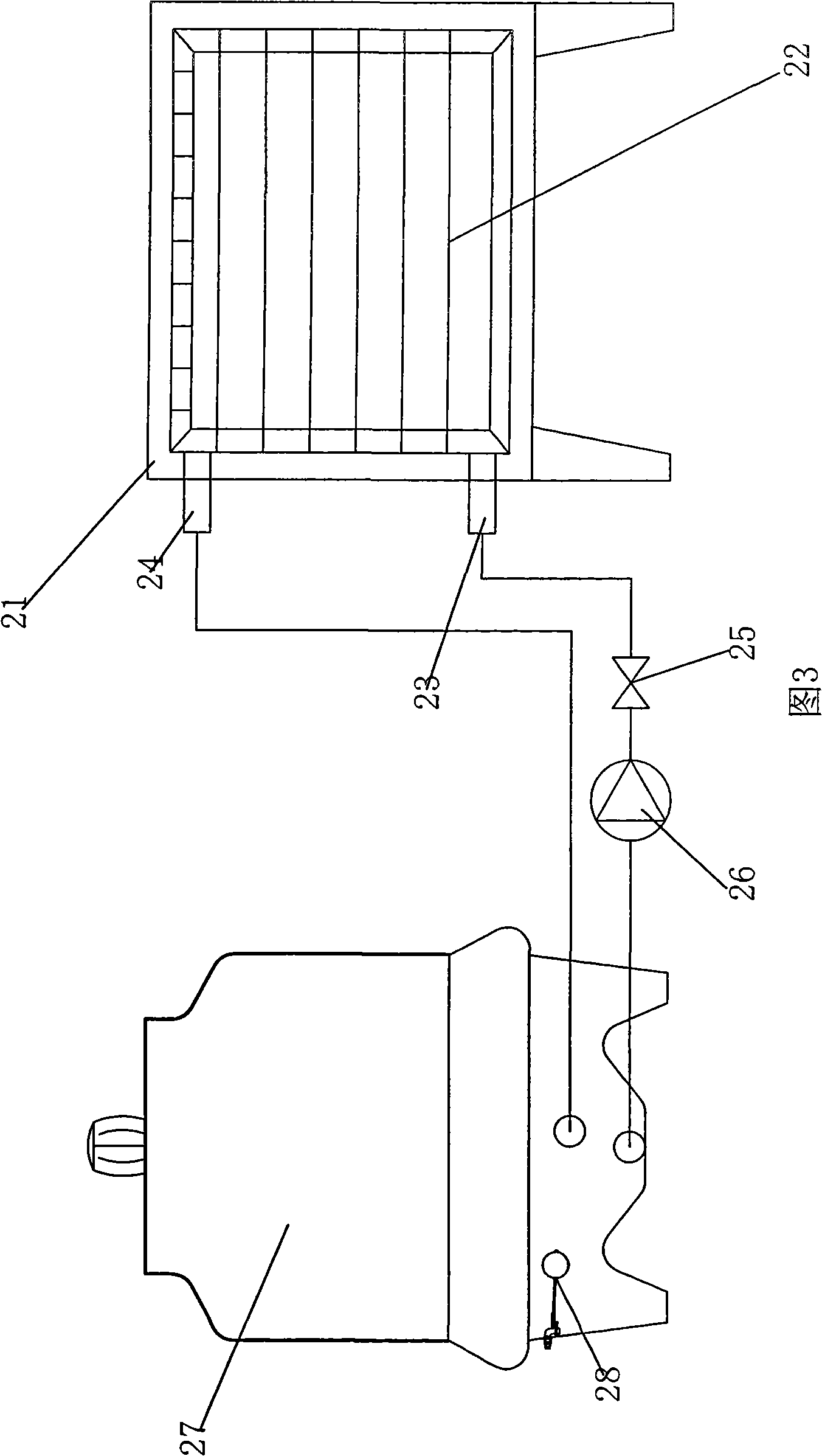

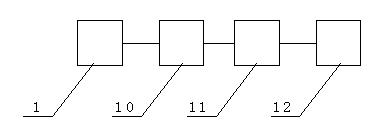

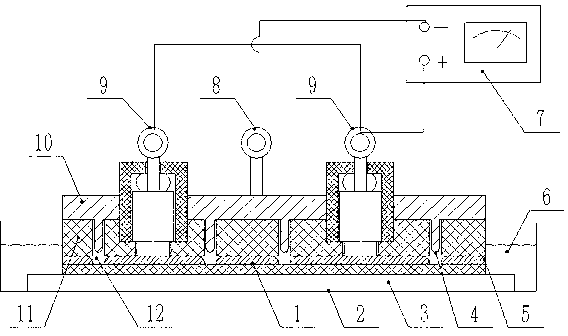

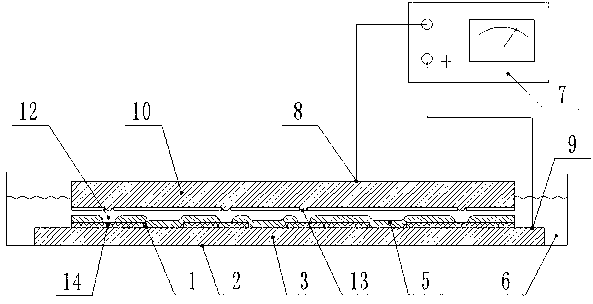

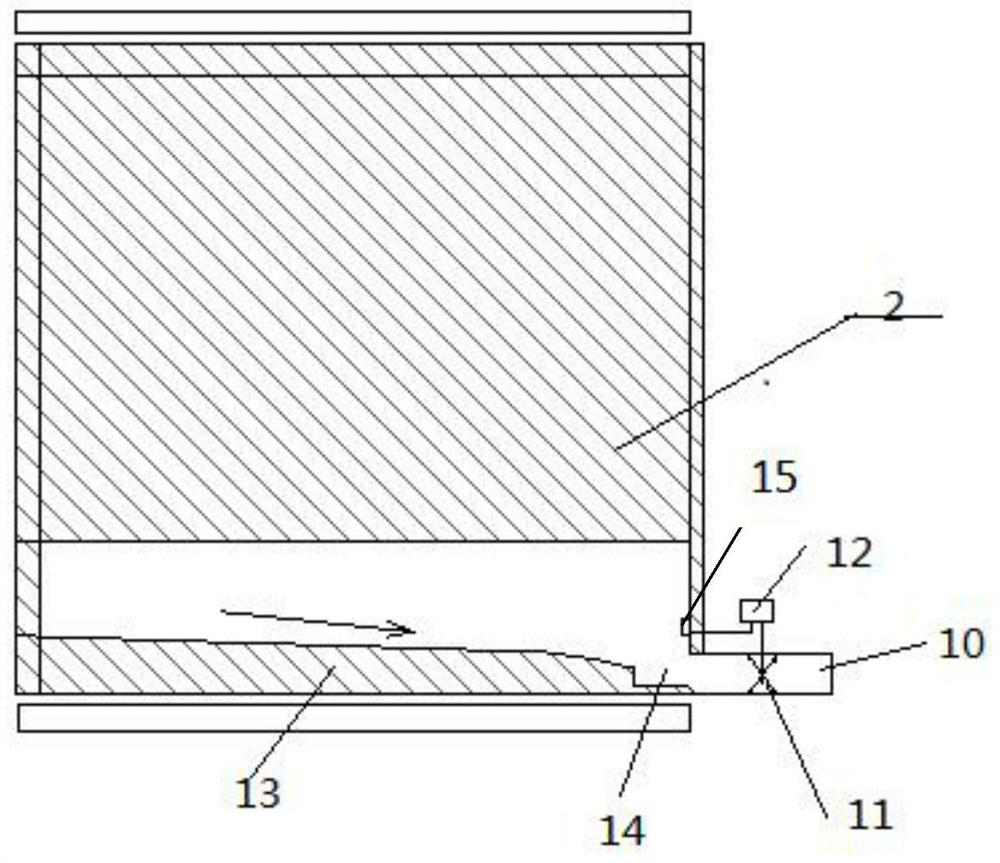

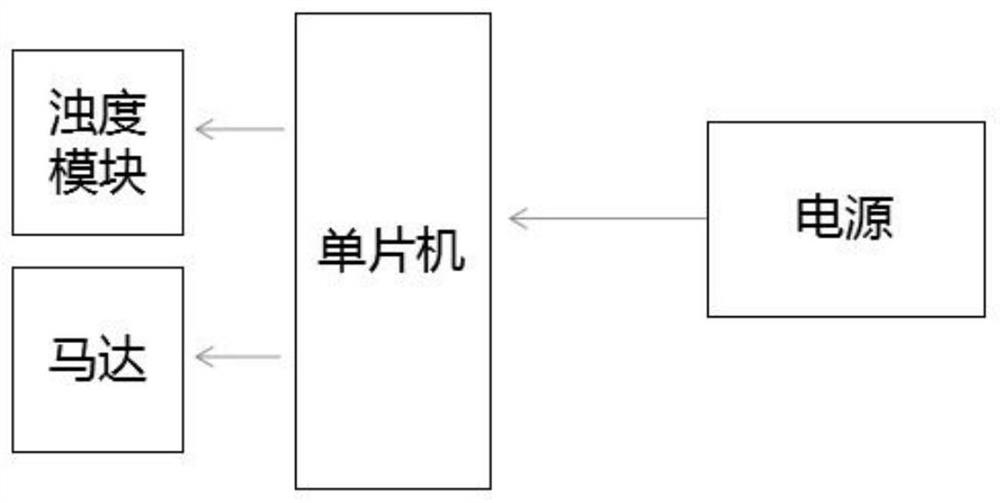

Cleaning type heat-treatment oil smoke collecting and arranging equipment

ActiveCN101298065AImprove work efficiencyImprove dust removal efficiencyExternal electric electrostatic seperatorElectrode constructionsThermal energyControl signal

The invention relates to a clean-type hot-treatment system for collecting and exhausting oil fume, which is characterized by comprising an oil fume inlet pipe (1), a temperature cooler (2) with heat exchange, an oil fume purifier (3), an exhaust fan (4) and a controller (5); the air outlet of the oil fume inlet pipe (1) is connected with the air inlet of the temperature cooler (2) with heat exchange; the air outlet of the temperature cooler (2) with heat exchange is connected with the air inlet of the oil fume purifier (3), and the air outlet of the oil fume purifier (3) is connected with the air inlet of the exhaust fan (4); the signal output end of the controller (5) is connected with the control signal input ends of both the oil fume purifier(3) and the exhaust fan (4); the signal input end of the controller (5) is connected with the signal output end of a temperature detector which is connected in the oil fume purifier (3). The heat of the oil fume is utilized by the invention, which is beneficial to save energy. The system of the invention has the advantages of wide application range, high working efficiency, high efficiency of dust collection and saving energy, which is especially applicable to the collection of oil fume particles that are smaller in particle diameter and lighter in weight.

Owner:GUANGDONG STRONG METAL TECH

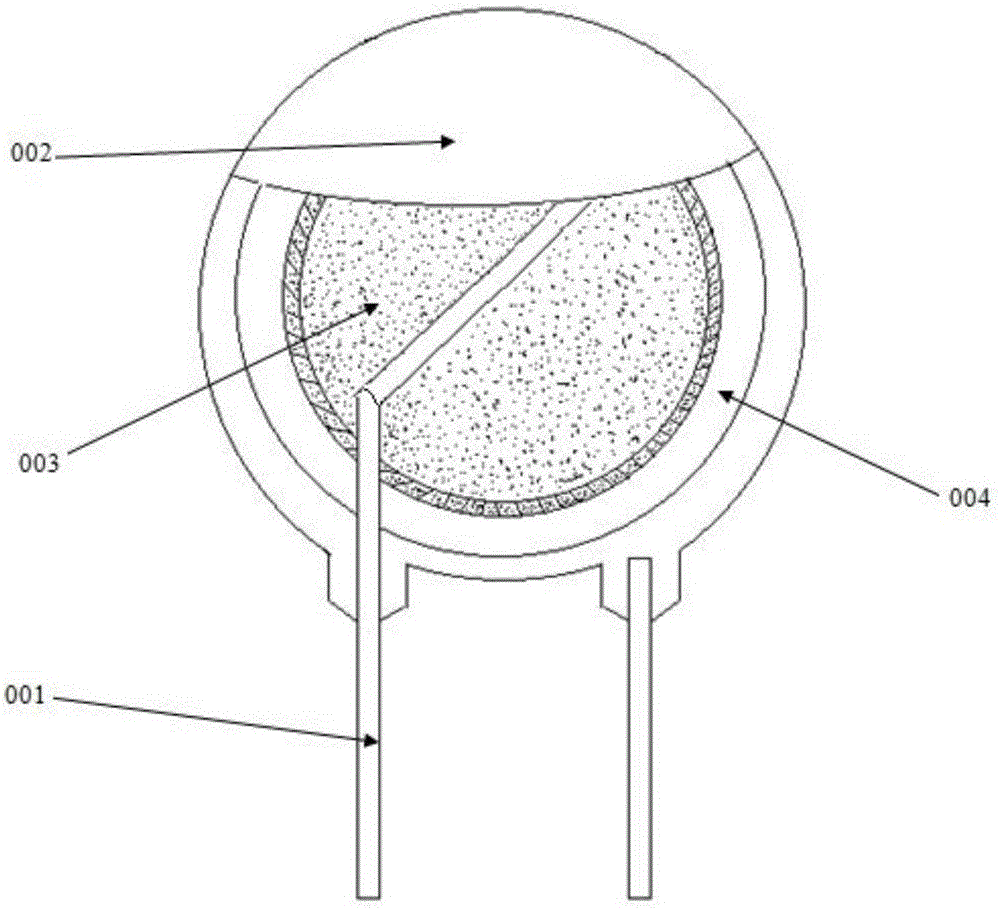

Piezoresistor and manufacturing process thereof

ActiveCN106782953APrecise positioningPrevent overflowResistor manufactureVaristorsCeramic substrateVaristor

The invention relates to a piezoresistor and a manufacturing process thereof. The piezoresistor is composed of a ceramic substrate, a leading-out end, an electrode layer and an insulating layer, wherein a concave area, namely, an electrode positioning area, is prefabricated on the ceramic substrate; the leading-out end is arranged on an electrode; the insulating layer is used for locally or wholly packaging the ceramic substrate, the electrode layer and the leading-out end; in the manner of sputtering or spraying electrode, an electrode hole of a mask plate is positioned and coated on a concave opening; a small electrode hole and a big concave opening form a bottle-shaped structure; the electrode is drifted and deposited into the concave opening so as to form the electrode and realize the concave opening being accurately filled with the electrode; the electrode eccentricity caused by the difference in diameter of the ceramic substrate in a batch sputtering process can be avoided; the thickness of the ceramic substrate at an edge of the concave opening is greater than the thickness of the interior; the reducing of the risk in edge arc crossing is benefited; the edge effect is weakened; the flowing property is greatly promoted; the preparation process of the piezoresistor comprises the following steps: manufacturing the ceramic substrate, performing electric polarization, connecting the leading-out end, coating the insulating layer, printing and testing.

Owner:KUSN WANFENG ELECTRONICS

Blue-phase LCD (Liquid Crystal Display) panel and blue-phase LCD device

ActiveCN102749767ADescribe wellStrong electric fieldStatic indicating devicesNon-linear opticsColor filmBlue phase liquid crystal

The invention discloses a blue-phase LCD (Liquid Crystal Display) panel which comprises an array substrate, a color film substrate and a blue-phase liquid crystal molecule, wherein the array substrate and the color film substrate are arranged opposite to each other; the blue-phase liquid crystal molecule is arranged between the array substrate and the color film substrate; the blue-phase LCD panel further comprises multiple first common electrodes with strip-type structures, multiple pixel electrode with strip-type structures and second common electrodes with strip-type structures; the multiple first common electrodes and the multiple pixel electrodes are alternately arranged on the array substrate; a spacing is reserved between the first common electrode and the pixel electrode which are adjacent to each other; the second common electrodes are arranged on the color film substrate; each second common electrode is arranged opposite to one first common electrode; and an electric field between the array substrate and the color film substrate is formed by virtue of the coaction of the pixel electrodes, the first common electrodes and the second common electrodes, so that the strength of the electric field between the array substrate and the color film substrate has stronger uniformity. According to the blue-phase LCD panel provided by the invention, smaller voltages are only needed to be provided for the pixel electrodes, the first common electrodes and the second common electrodes.

Owner:BOE TECH GRP CO LTD

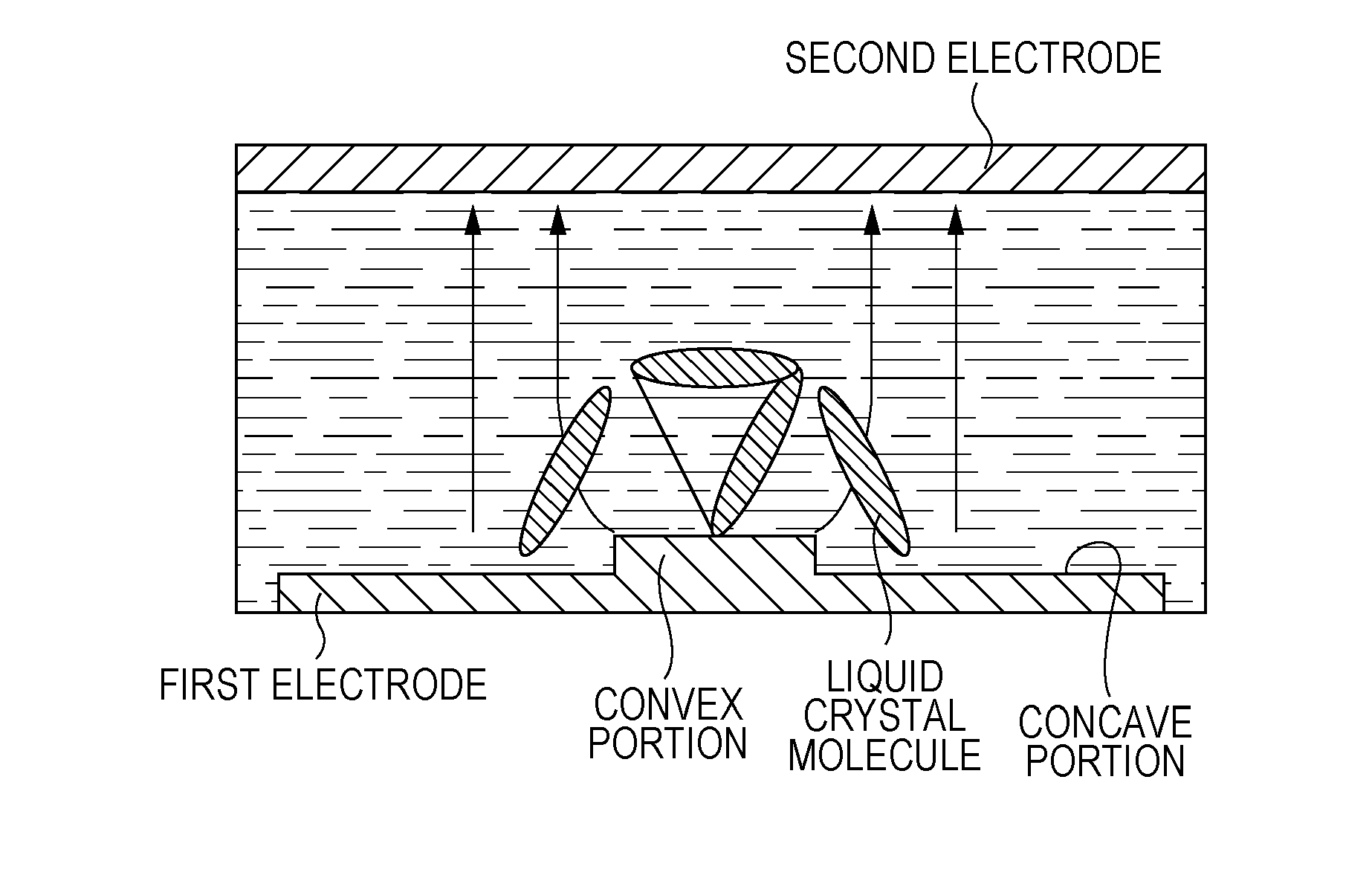

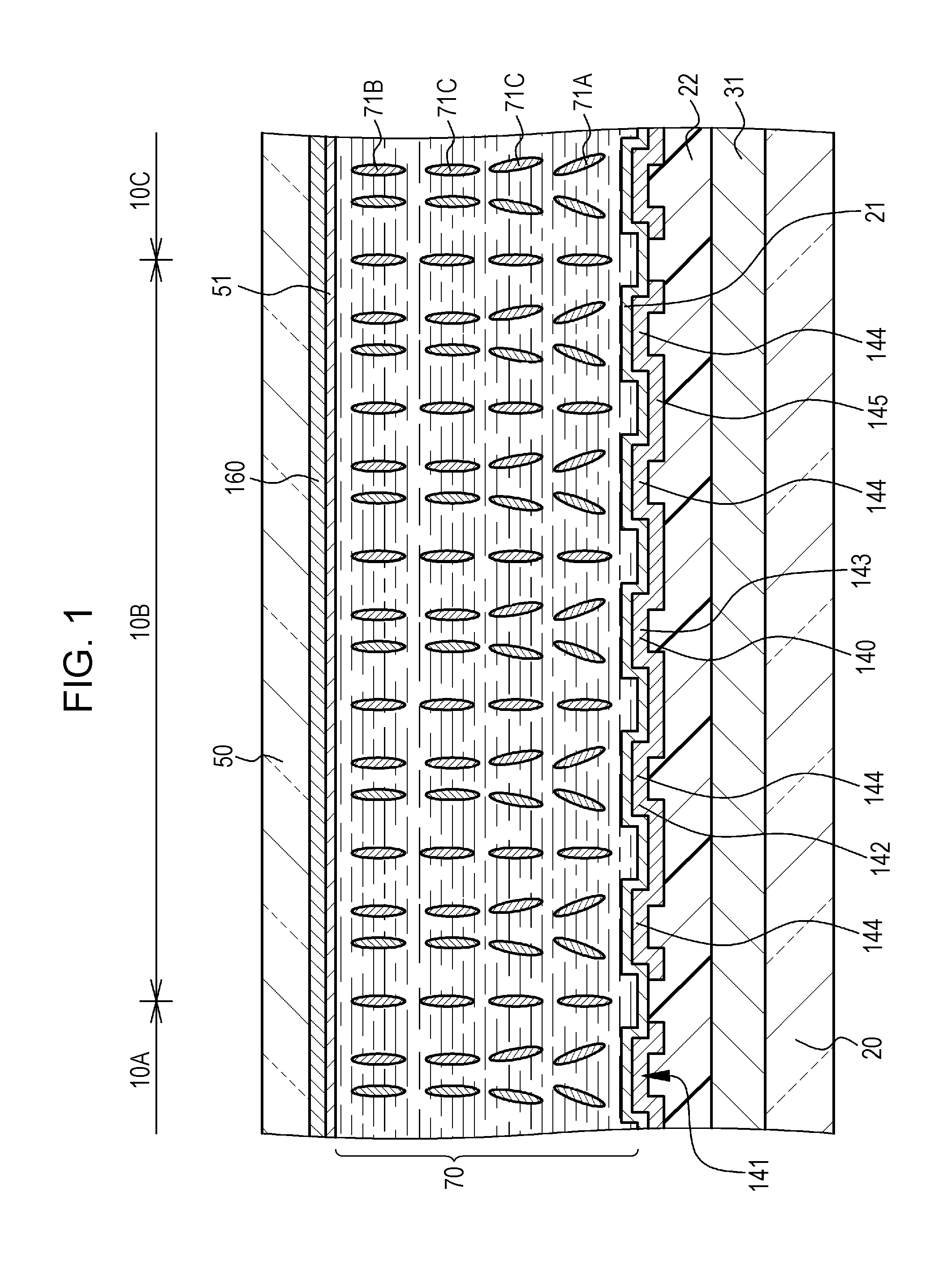

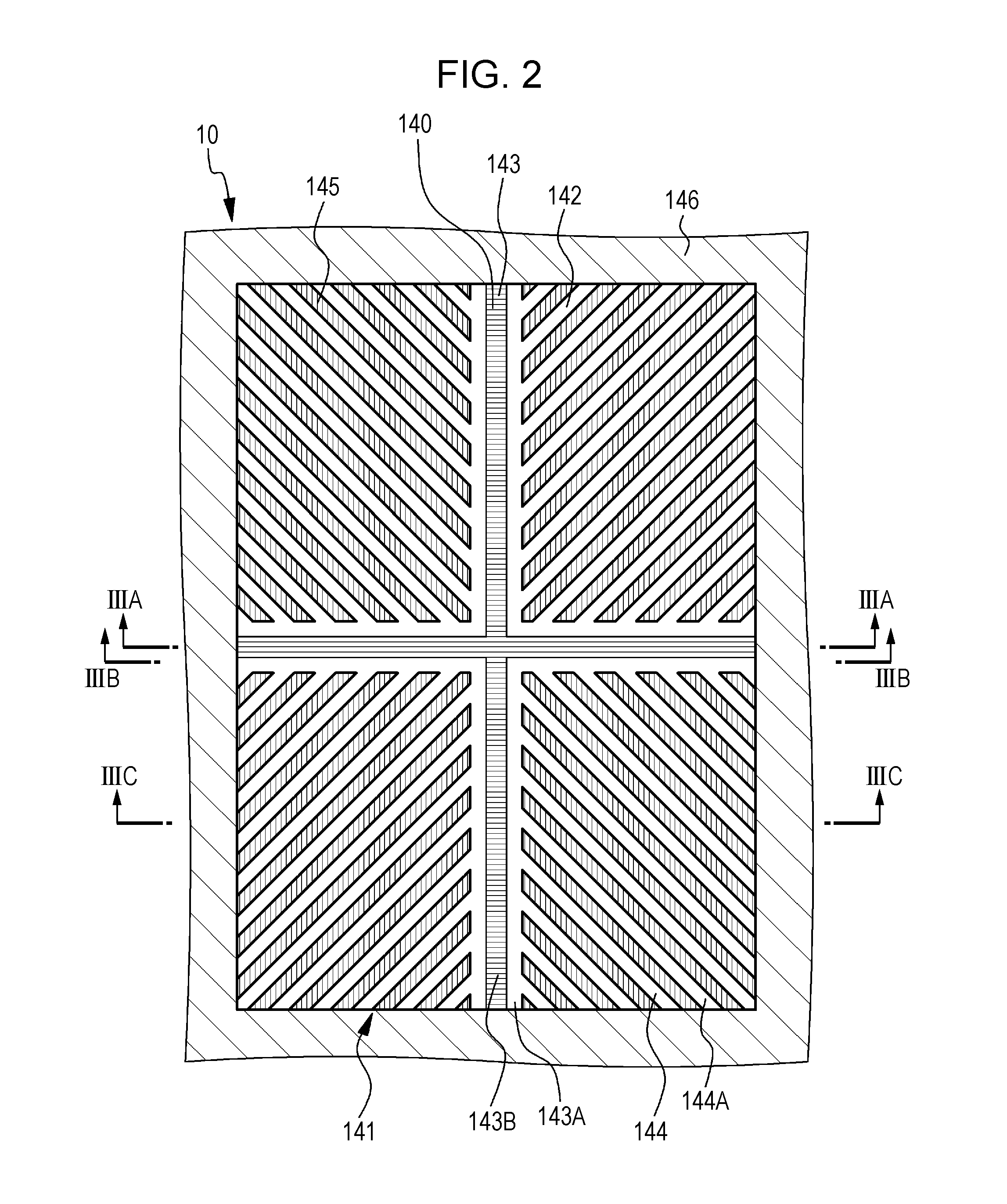

Liquid crystal display device

There is provided a liquid crystal display device comprising: a first substrate (20); a second substrate (50); a first electrode (140) formed on a first surface of the first substrate (20), the first surface facing the second substrate (50), the first electrode (140) including a plurality of convex and concave portions (141); a first oriented film (21) formed on the first surface of the first substrate (20); a second electrode (160) formed on a second surface of a second substrate (50), the second surface facing the first substrate (20); and a liquid crystal layer (70) provided between the first substrate (20) and the second substrate (50), wherein at least one of the convex portions (143,144) includes a plurality of stepped portions. There is also provided a method of manufacturing a liquid crystal display device.

Owner:SATURN LICENSING LLC

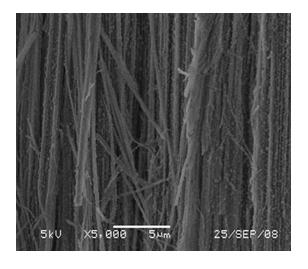

Formaldehyde gas sensor, making method and formaldehyde monitoring and treatment device

InactiveCN102384932AFacilitate catalytic reactionsStrong electric fieldMaterial electrochemical variablesNanoscopic scaleDiffusion layer

The invention discloses a formaldehyde gas sensor and a making method thereof and a formaldehyde monitoring and treatment device with the formaldehyde gas sensor. The formaldehyde gas sensor is an electrochemical two-electrode system, a Pd-Ni / SiNWs formaldehyde catalytic electrode is used as a working electrode, a Ni / SiNWs electrode is used as a counter electrode, and the formaldehyde gas sensor is made by electrolyte encapsulation. Each SiNWs of the Pd-Ni / SiNWs electrode in the designed formaldehyde gas sensor can be regarded as a micro electrode with a micro / nano-scale curvature radius tip,so that catalytic reaction of formaldehyde gas molecules on the surface of the Pd-Ni / SiNWs electrode is promoted. The clearances among numerous SiNWs also have micro or nano scale, so that the effective diffusion layer soaked into a solution is smaller, and meanwhile, the double-electrode layer of the solution / electrode interface has stronger electric field effect. The formaldehyde monitoring and treatment device can be used for monitoring the formaldehyde concentration in the indoor air and treating the formaldehyde in real time, and has the advantages of low cost, simplicity in operation, easiness in implementation and the like.

Owner:QIQIHAR UNIVERSITY

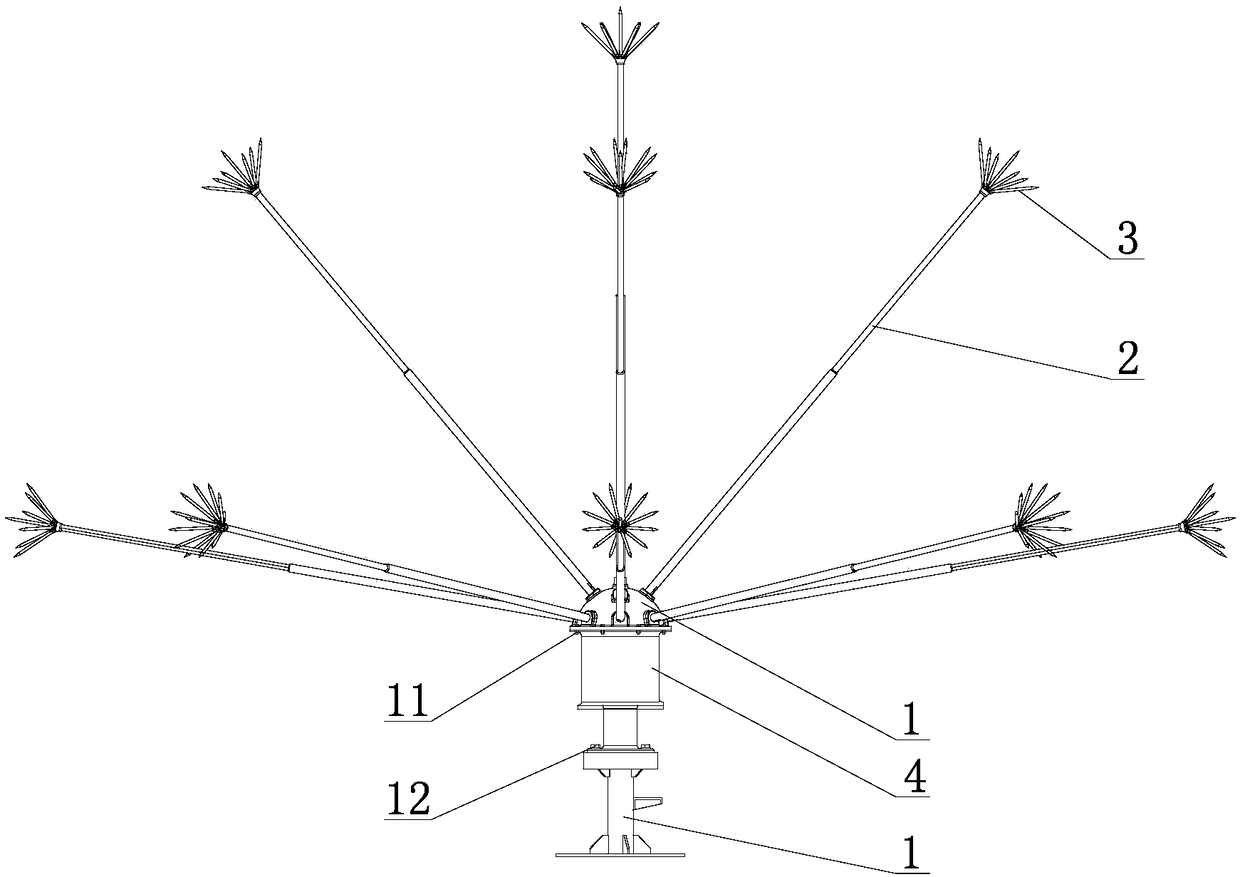

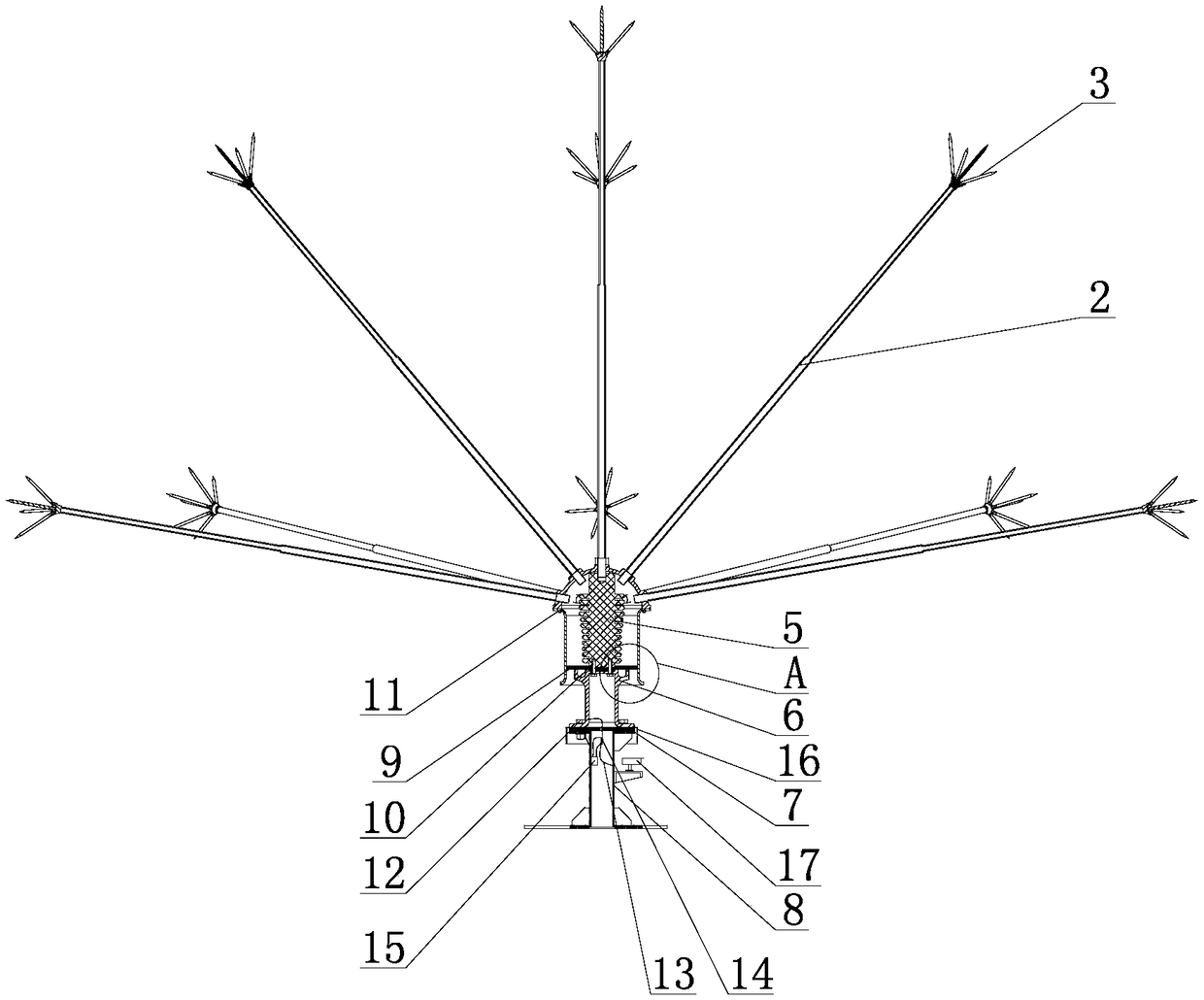

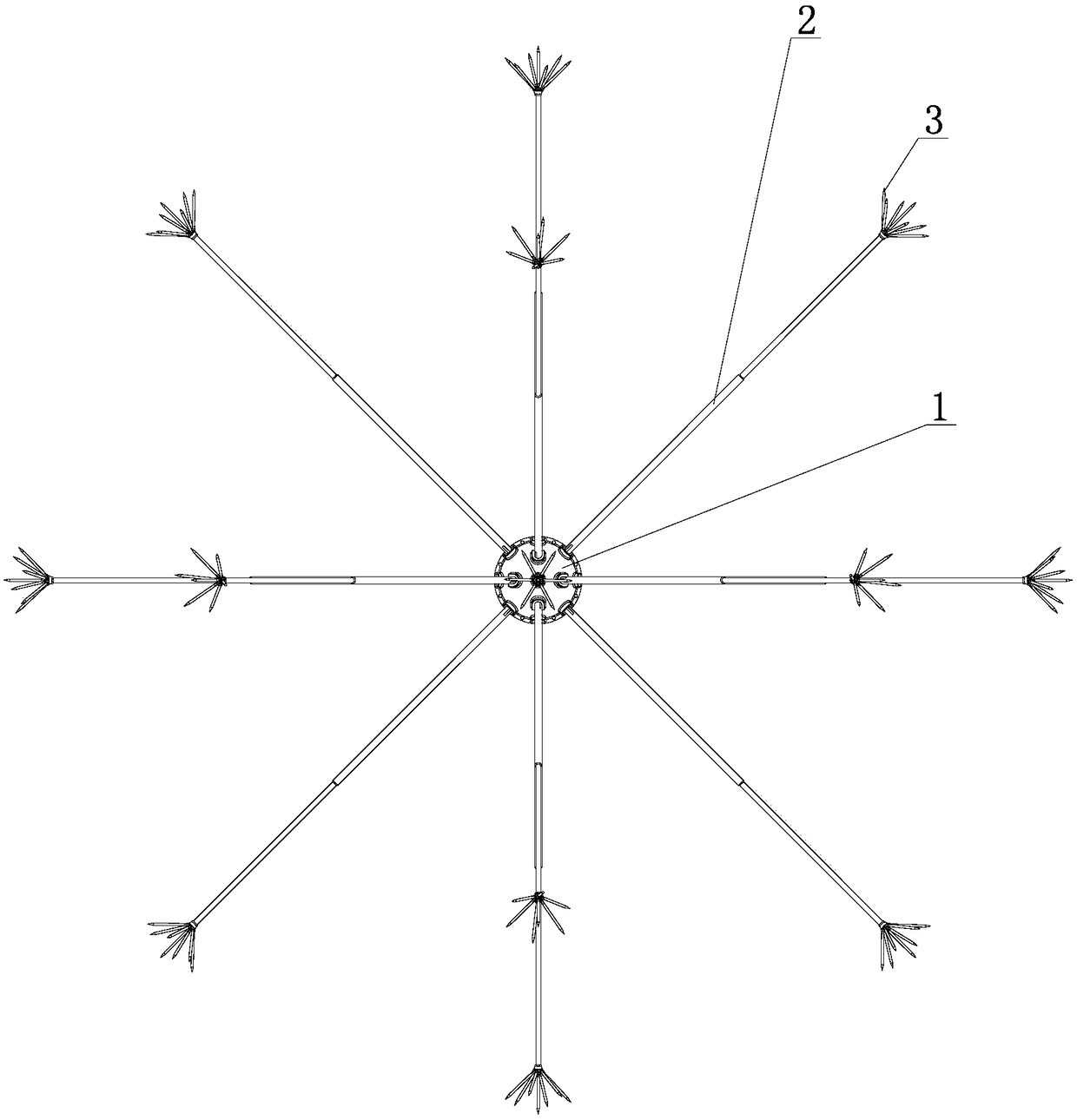

Corona field lightning arrester and lightning arresting method thereof

The invention provides a corona field lightning arrester and a lightning arresting method thereof. The corona field lightning arrester comprises a metal housing. The metal housing is uniformly provided with a plurality of discharge levers at intervals; the upper end of each discharge lever is provided with a plurality of upper discharge electrodes; the lower end of the metal housing is connected with a discharge cylinder; the discharge cylinder at the lower end of the metal housing is internally provided with an insulation support; the upper end of the insulation support is connected with thedischarge lever arranged at the top end of the metal housing; the lower end of the insulation support is connected with a lower discharge electrode; a discharge gap is arranged between the outer wallof the lower discharge electrode and the inner wall of the discharge cylinder; the lower end of the lower discharge electrode is connected with a transition section support through an insulation pad plate; and the lower discharge electrode is connected to the ground through a grounding wire. The corona field lightning arrester has the advantages of reasonable structure design, no need of a power supply, utilization of thundercloud electric field self-excited corona discharge, reliable and stable lightning arresting, no negative impact on the surrounding facilities, easy installation, high windresistance and online monitoring and the like.

Owner:山东中呈防雷科技有限公司

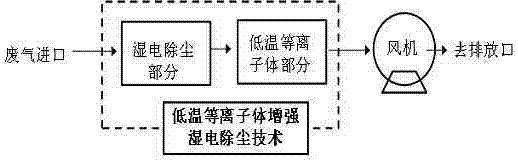

Industrial smoke dust removal method

InactiveCN106944259AEasy to chargeImprove collection effectExternal electric electrostatic seperatorElectricityEngineering

The invention discloses an industrial smoke dust removal method. The industrial smoke dust removal method comprises the steps of a front-stage wet electric precipitation part and a next-stage low-temperature plasma field processing part, and smoke is organically discharged through the front-stage wet electric precipitation part and the next-stage low-temperature plasma field processing part in sequence. According to the industrial smoke dust removal method, electric charges are loaded to a small amount of dust and water mist of a plasma applied field, deflection and directional movement occur in a subsequent electric field, and the dust and the water mist are collected to a polar plate and then flow down so as to be collected along the inner wall of a reactor, so that the effect of removing the dust and the water mist is achieved; the electric field intensity of the unit distance of equipment is high, and the charge and collection capability of the dust and the water mist can be increased under the action of two stages of electric fields, so that the dust and the water mist are deeply removed.

Owner:SHANGHAI IND TECH INST +2

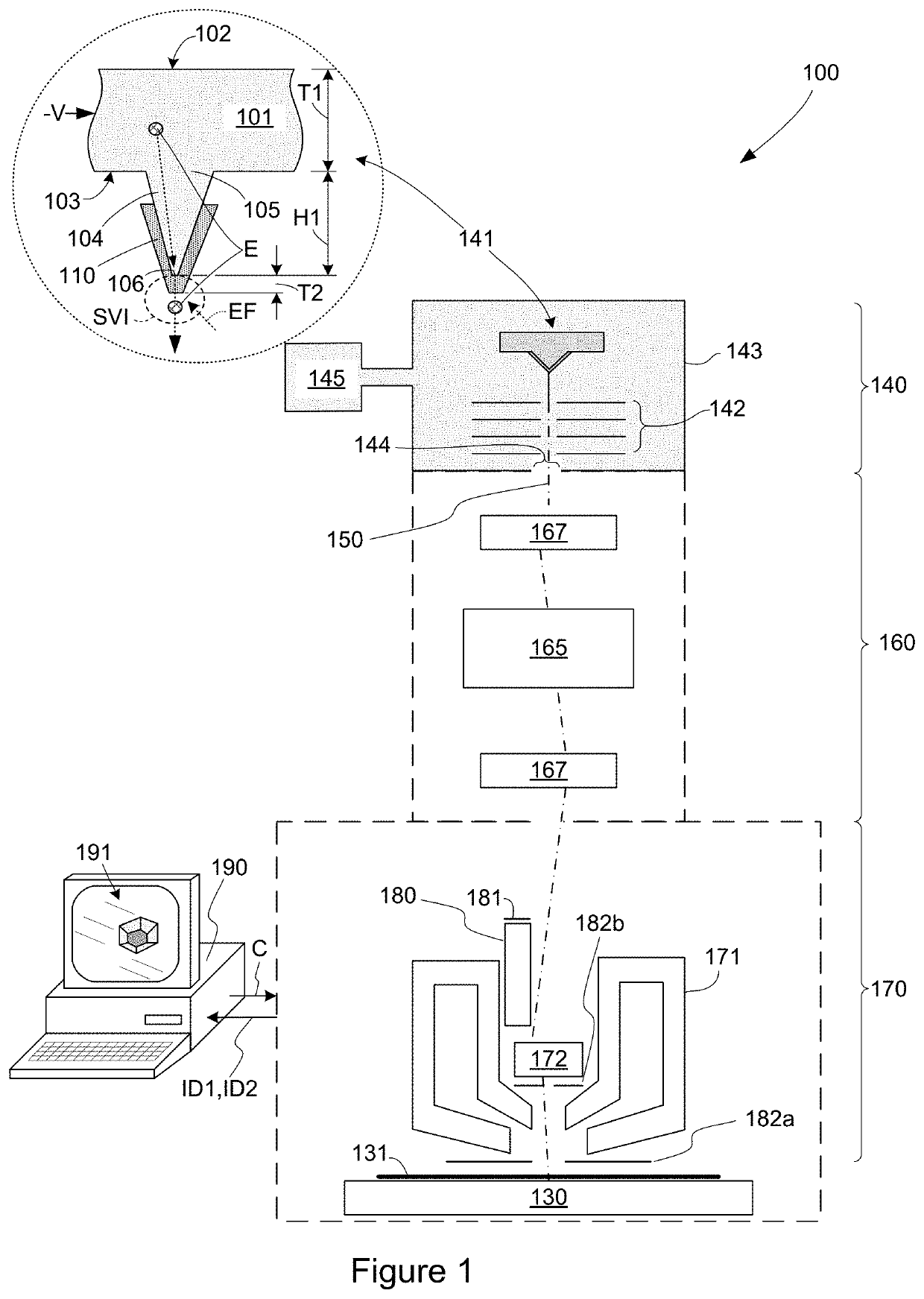

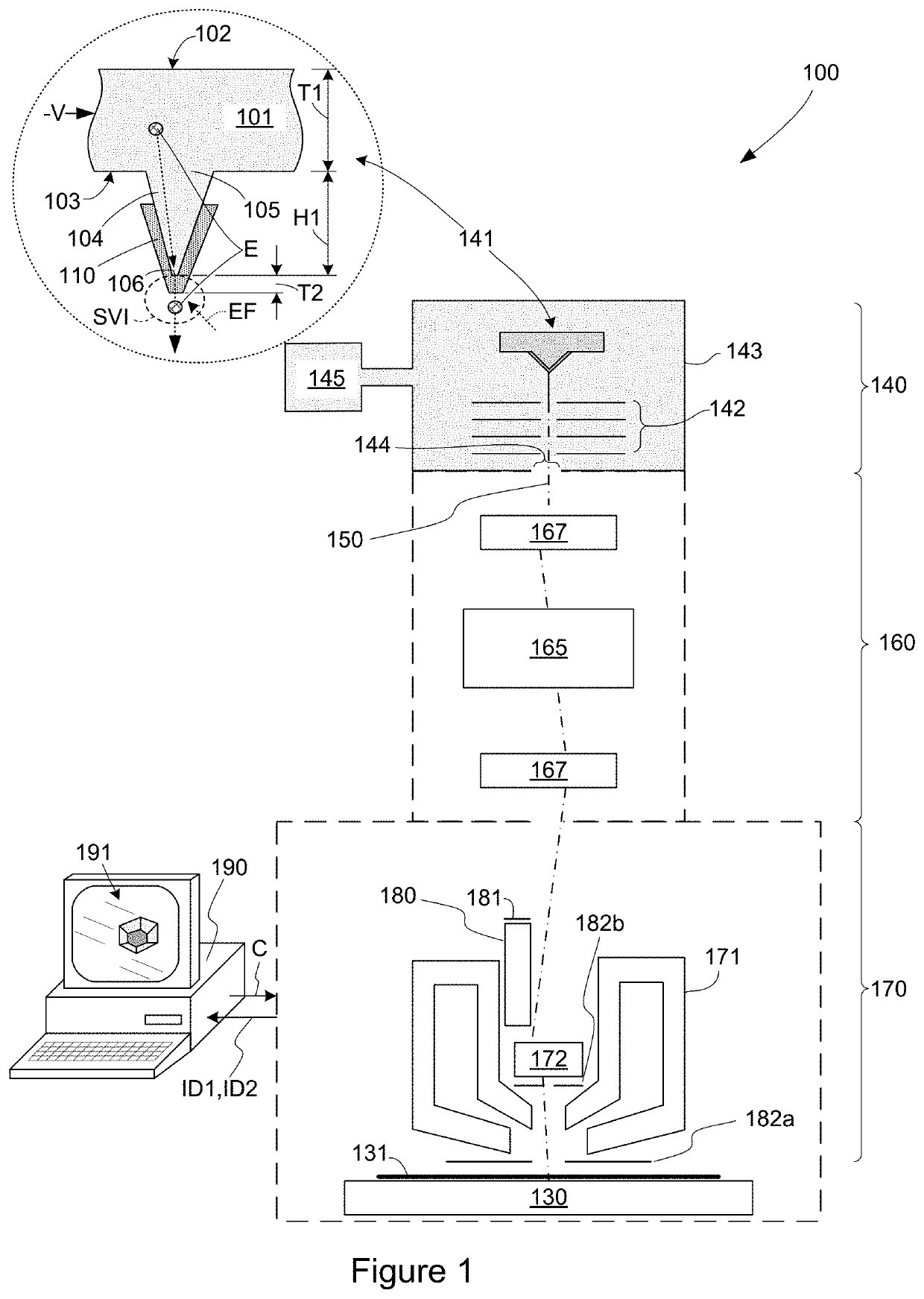

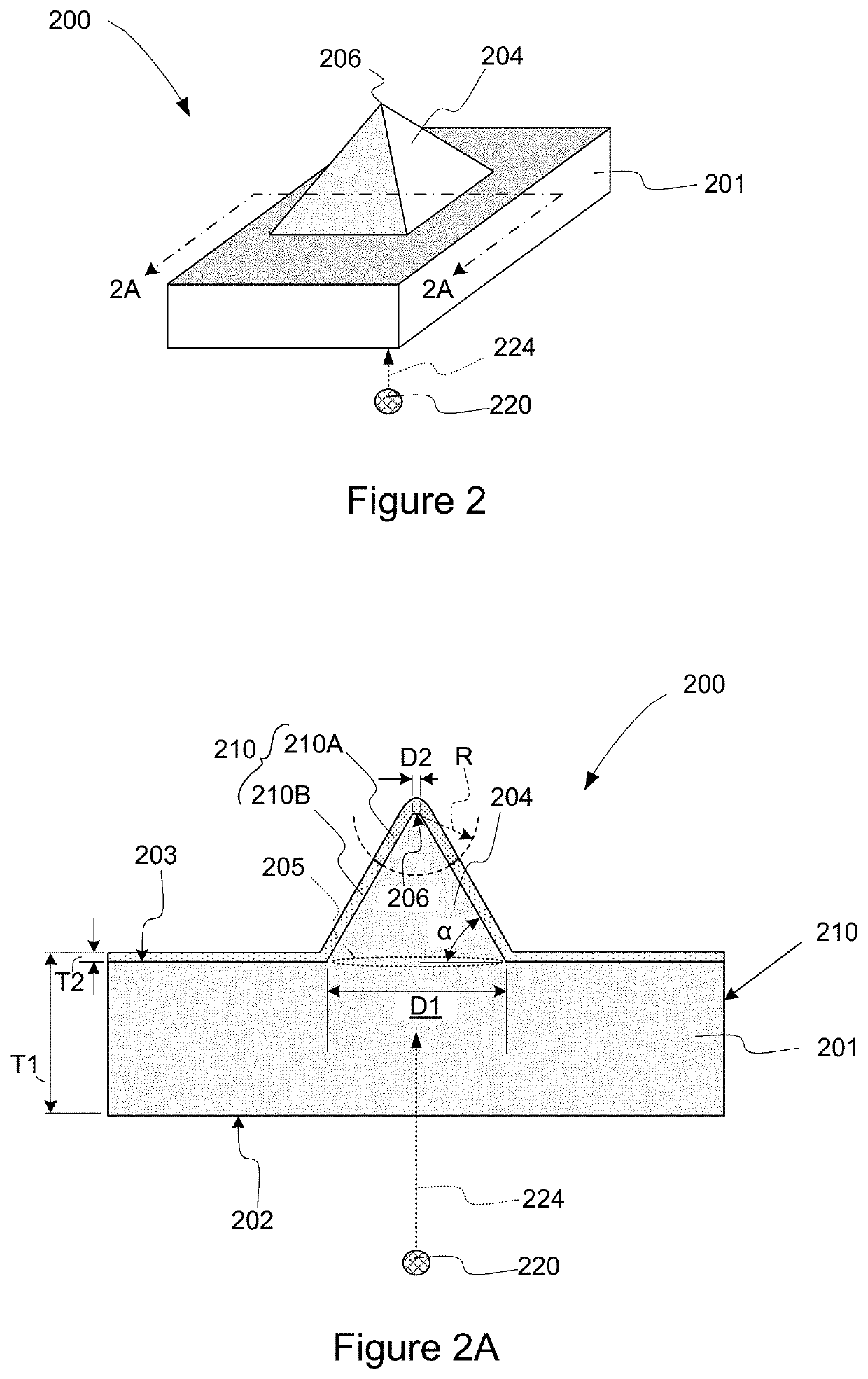

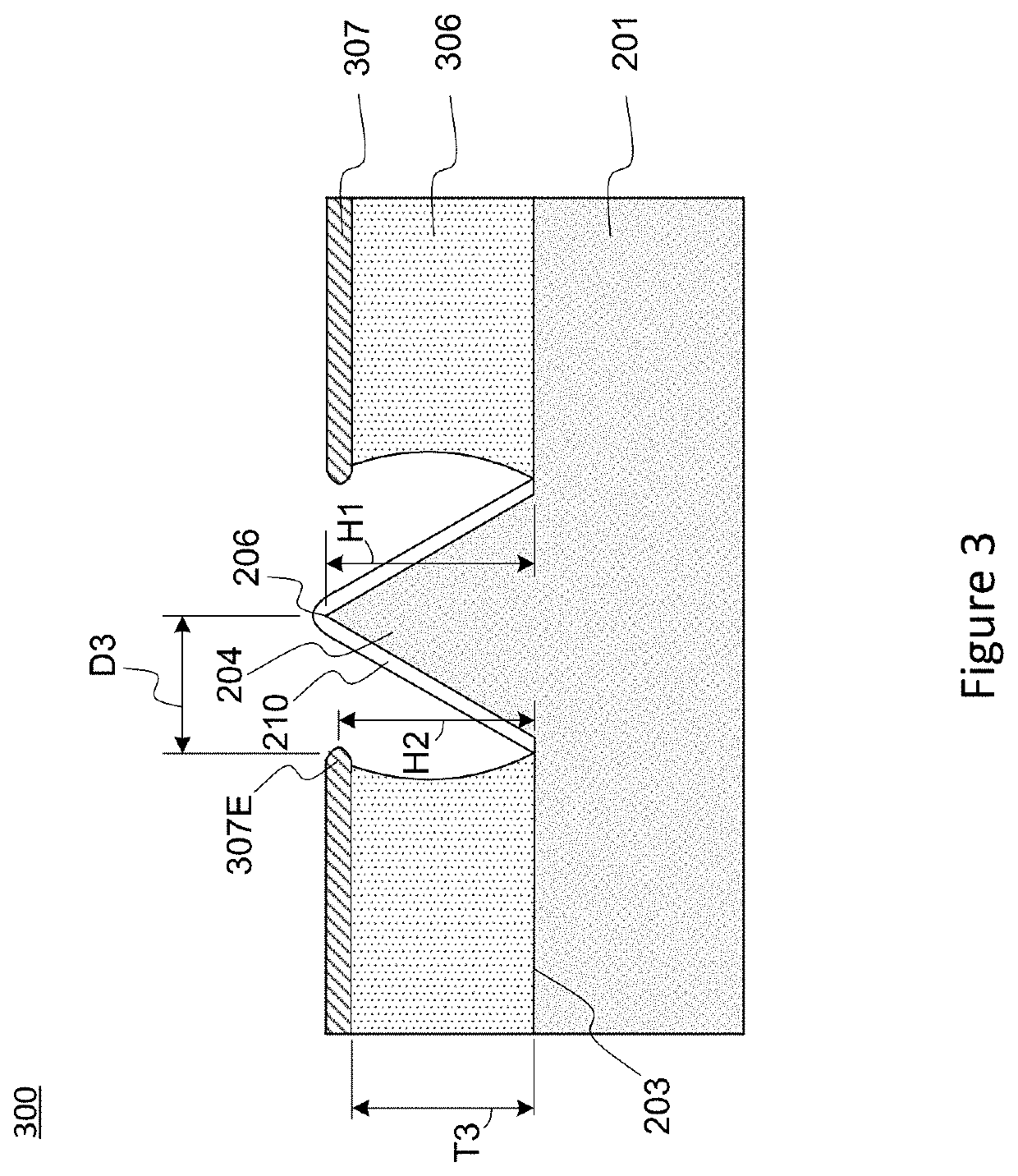

Electron gun and electron microscope

ActiveUS20200118783A1Improve work functionLower bandgapElectric discharge tubesElectron microscopeParticle physics

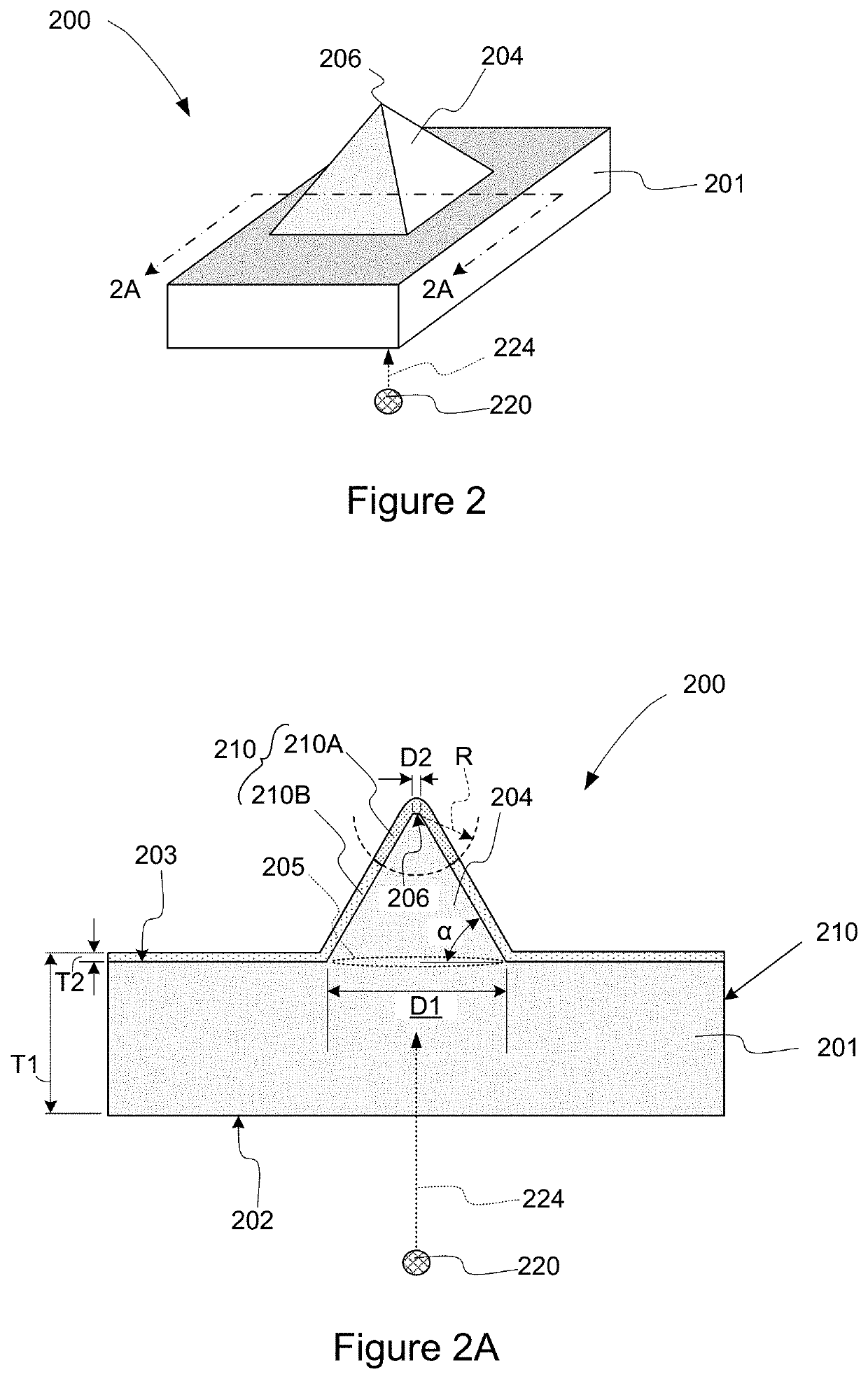

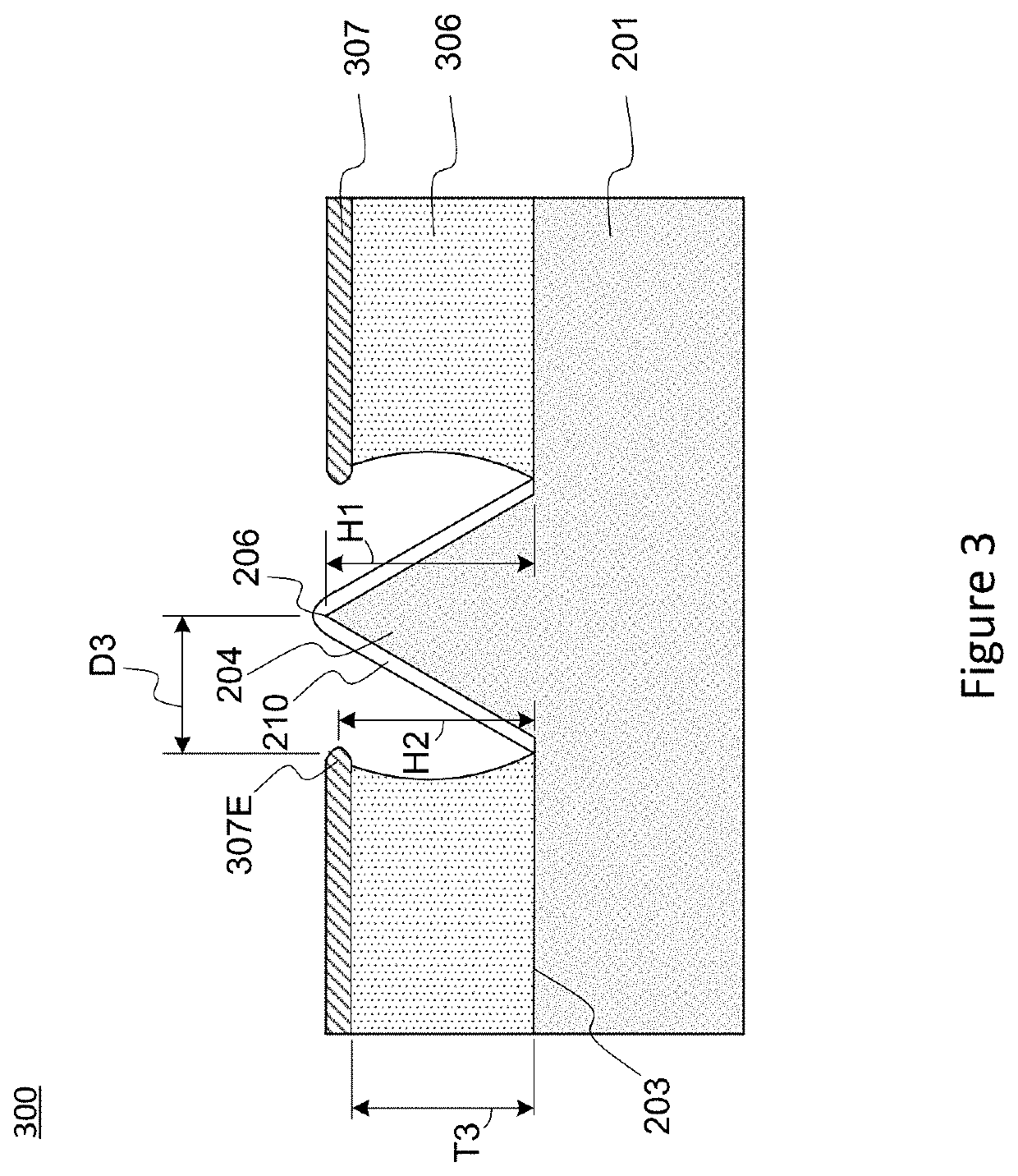

An electron gun for an electron microscope or similar device includes a field emitter cathode having a field emitter protrusion extending from the output surface of a monocrystalline silicon substrate, and electrodes configured to enhance the emission of electrons from a tip portion of the field emitter protrusion to generate a primary electron beam. A thin, contiguous SiC layer is disposed directly on at least the tip portion of the field emitter protrusion using a process that minimizes oxidation and defects in the SiC layer. Optional gate layers may be placed at, slightly lower than or slightly higher than the height of the field emitter tip portion to achieve high emission current and fast and accurate control of the primary emission beam. The field emitter can be p-type doped and configured to operate in a reverse bias mode, or the field emitter can be n-type doped.

Owner:KLA TENCOR TECH CORP +1

On-chip terahertz sensing enhancement device based on super-surface and lithium niobate hybrid structure

ActiveCN110160984AImplement feature detectionObvious observation of characteristic absorption peaksMaterial analysis by optical meansSmall sampleWavelength

The invention discloses an on-chip terahertz sensing enhancement device based on a super-surface and a lithium niobate hybrid structure. The purpose of the invention is to carrying out high-sensitivity detection on trace biochemicals. The detection of different medicine in a wider frequency range is realized by adjusting the length of a metal antenna and the thickness of dielectric layer silicon dioxide. The adopted scheme is as follows: a sub-wavelength lithium niobate waveguide surface on which a silicon dioxide layer is deposited is coated with an antenna array super-surface, and then a thin layer of chemicals is applied to the super-surface. Plasma on the local surface of the antenna is excited, and so the absorption of light in a characteristic frequency band by the substances is enhance so as to realize the high-sensitivity detection of the substances. The on-chip terahertz sensing enhancement device based on the super-surface and the lithium niobate hybrid structure solves the problems of weak signal caused by small sample size and weak light field effect. The on-chip terahertz sensing enhancement device based on the super-surface and the lithium niobate hybrid structure hasthe significant characteristics of simple device, small size, variety of measurement, high sensitivity, easy convenient and the like, and is widely used in the detection of terahertz characteristicsspectrums of trace substances in the field of biochemistry, medicine and the like.

Owner:NANKAI UNIV

Nanogold test kit for early diagnosis of trichinization

InactiveCN107607709AObvious advantagesIncreased reaction rate and growth rateMaterial analysisAntigenWidth ratio

The invention discloses a preparation method of a trichinella spiralis antigen labeled gold nanorod. The method comprises the following steps: preparing spherical gold nanoparticle seeds by reducing an HAuCl4 solution with a reducing agent; adding the spherical gold nanoparticle seeds into a growth medium, and enabling the spherical gold nanoparticle seeds to grow into a rod-shaped gold nanorod ina rod micelle solution; labeling the gold nanorod by using an antigen excreted by trichinella spiralis larvae, thereby obtaining the trichinella spiralis antigen labeled gold nanorod. The invention further provides a trichinella spiralis antigen labeled gold nanorod prepared by the method. The gold nanorod is synthesized by selecting a 'seed mediated growth method', and the length-width ratio hasobvious advantages compared with a spherical nanorod; a gold nanorod labeling technology can be applied to serological test of trichinella spiralis, the detection kit is high in detected antibody dilution, early in time and low in infection gradient compared with a mouse serum antibody ELISA (Enzyme-linked Immuno Sorbent Assay) detection kit, and a novel technology can be provided for detecting early trichinosis infection and low infection gradient.

Owner:DALI UNIV

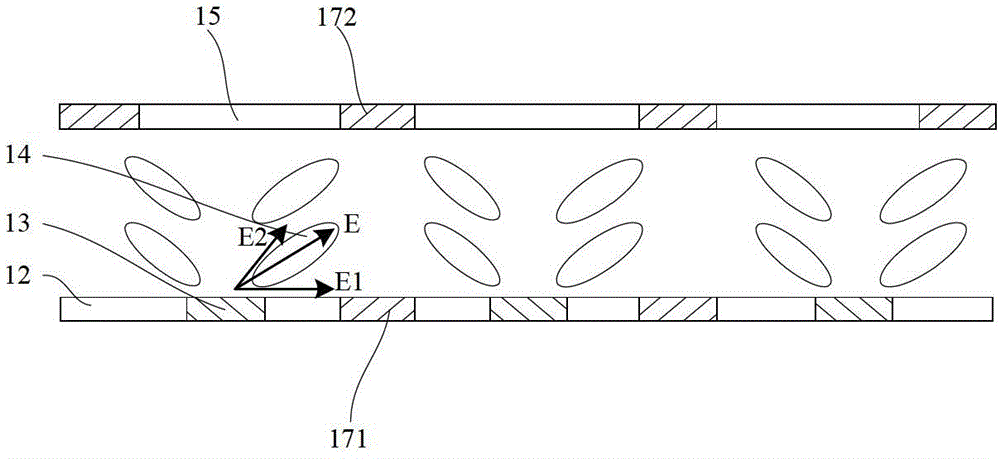

Liquid crystal display device and driving method thereof

ActiveCN102116972AThere will be no loss of contrastReduce manufacturing costNon-linear opticsVertical alignmentEngineering

The invention relates to a liquid crystal display device and a driving method thereof. The liquid crystal display device comprises a first base plate, a second base plate and liquid crystal molecules positioned between the first base plate and the second base plate. A first common electrode is arranged on the first base plate. A pixel electrode and a second common electrode are arranged on the surface of the second base plate over the first common electrode; the second common electrode surrounds the pixel electrode; a slit is formed between the second common electrode and the pixel electrode; and when the second common electrode obtains a driving signal, an electric field for driving the liquid crystal molecules positioned in the slit to pre-tilt is formed between the second common electrode and the pixel electrode. As the slit, the second common electrode and the pixel electrode are all formed through exposure development, the electric field required for the pre-tilt of the liquid crystal molecules is obtained under the situation that no process is added; and compared with the conventional MVA (Machinery Vibration Analysis) method and the conventional PVA (Patterned Vertical Alignment) method, the production cost and the process complexity are reduced.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

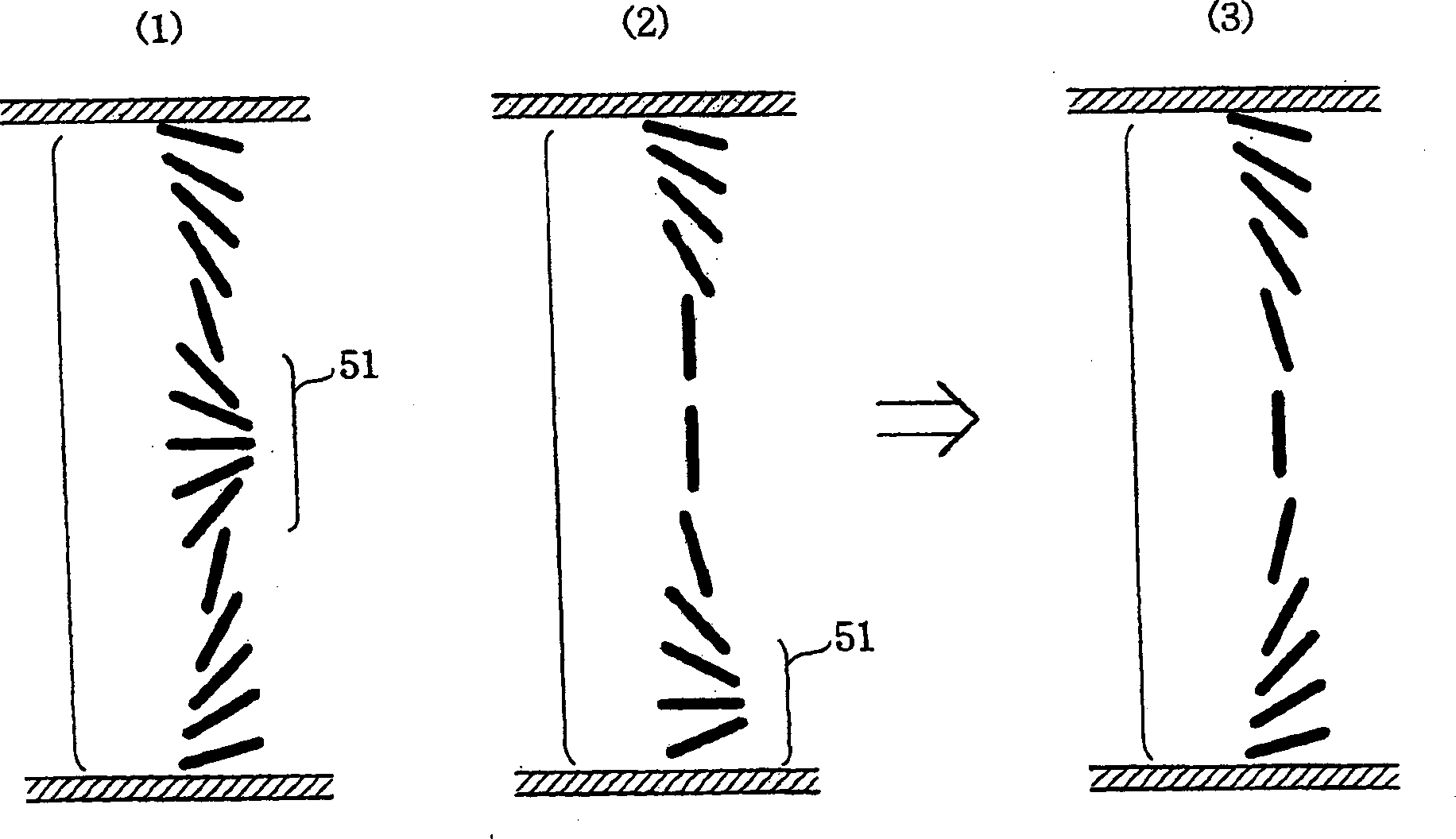

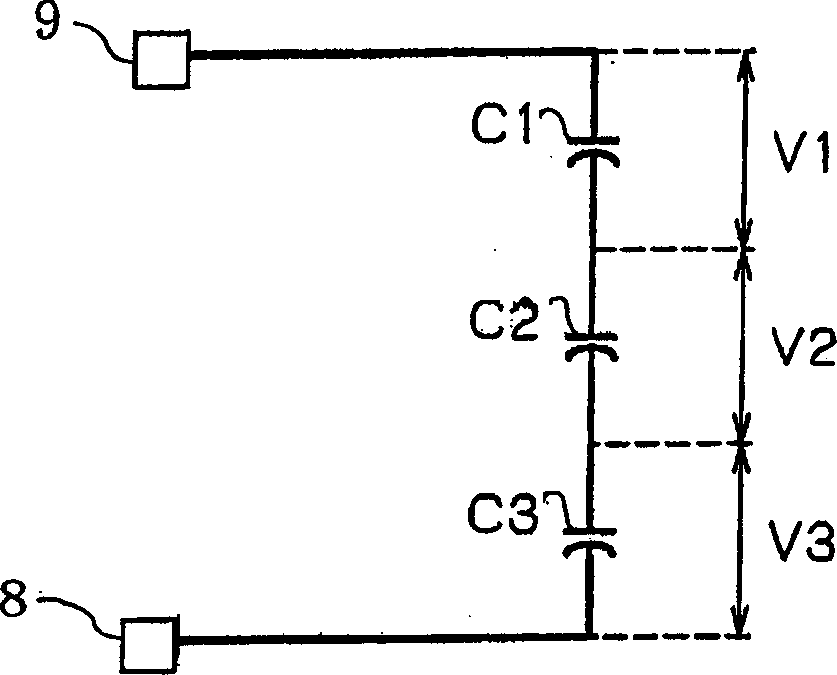

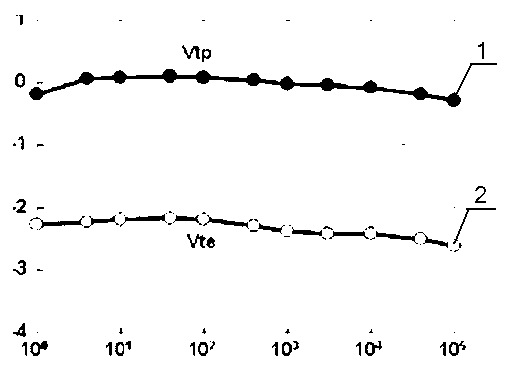

Drive technique for starting liquid crystal device

InactiveCN1327546AHigh speed responseWide field of visionStatic indicating devicesNon-linear opticsWide fieldPotential difference

A high-speed response and wide-view liquid crystal panel for switching liquid crystal called DCB type to bend orientation in a short time, in which a period is provided in which a higher than normal image display time A potential difference is continuously applied between the guard line of the liquid crystal panel and the counter electrode or between the pixel electrode and the counter electrode. Moreover, some ingenious ideas were put into the period of continuously adding the potential difference and injected into the structure of the pixel.

Owner:JAPAN DISPLAY CENTRAL CO LTD

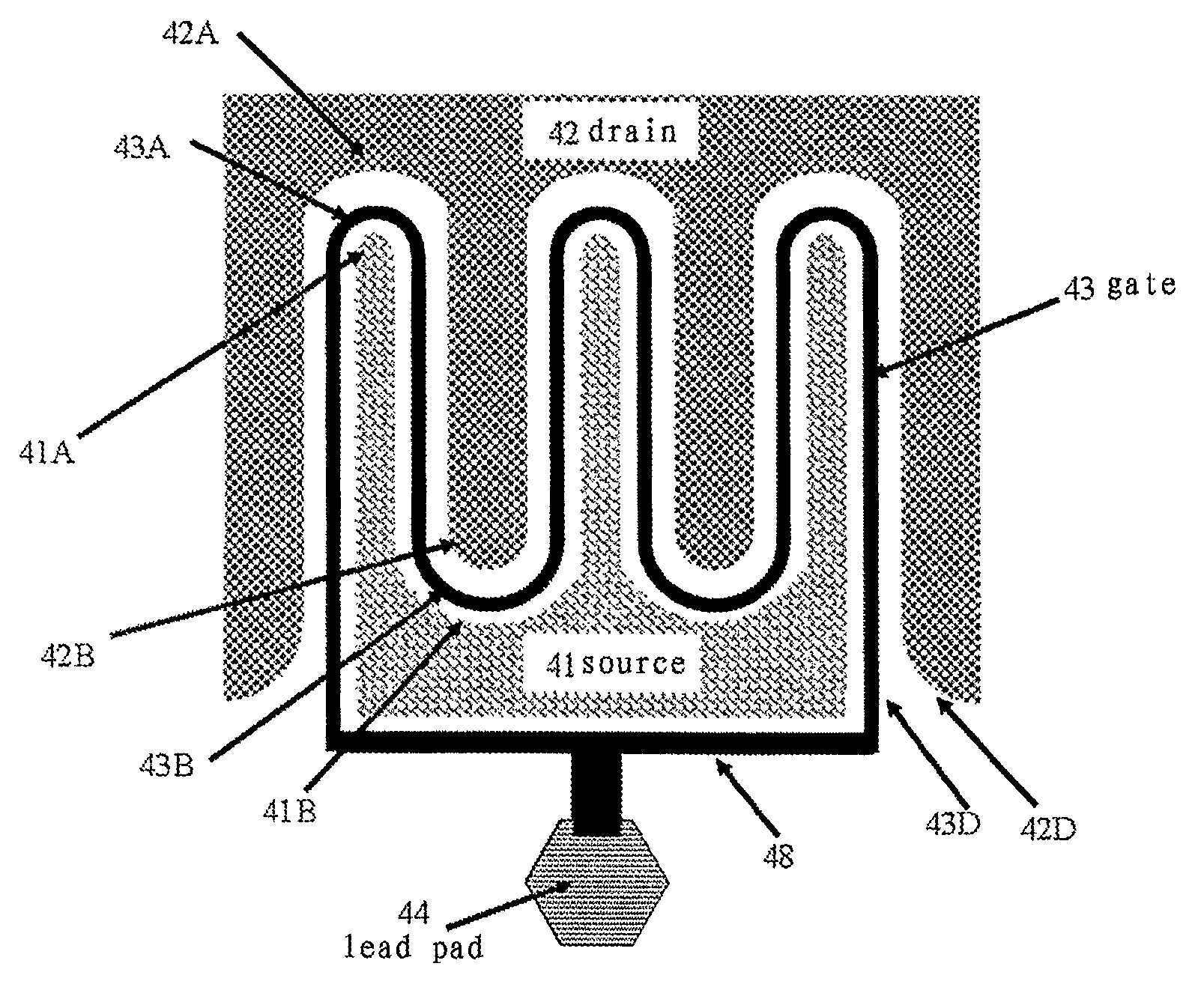

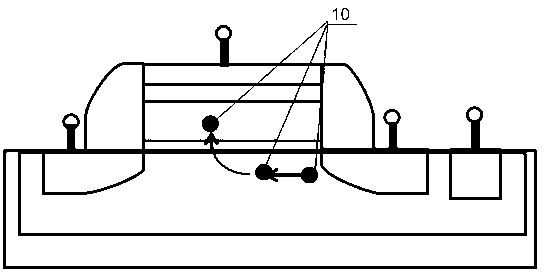

Semiconductor device and fabrication method thereof

ActiveUS8637905B2Improve breakdown voltageIncrease unit areaSemiconductor/solid-state device manufacturingSemiconductor devicesPower semiconductor deviceIsolation layer

The invention relates to a semiconductor device and a fabrication method thereof. A semiconductor device according to an aspect of the invention comprising: a semiconductor layer on a substrate; an isolation layer on the semiconductor layer; a source and a drain which are in contact with the semiconductor layer, each of the source and the drain comprises multiple fingers, and the multiple fingers of the source intersect the multiple fingers of the drain; and a gate on the isolation layer, the gate is located between the source and the drain and comprises a closed ring structure which encircles the multiple fingers of the source and the drain.

Owner:GPOWER SEMICON

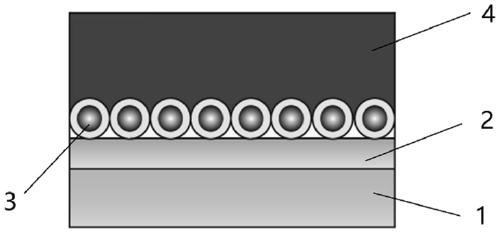

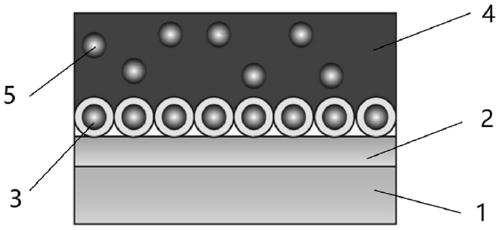

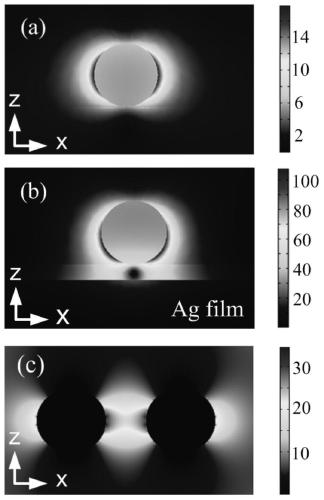

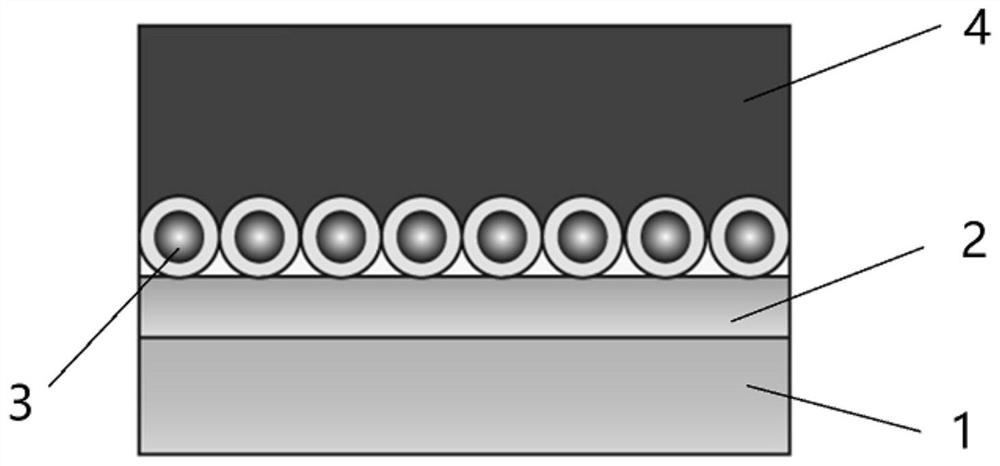

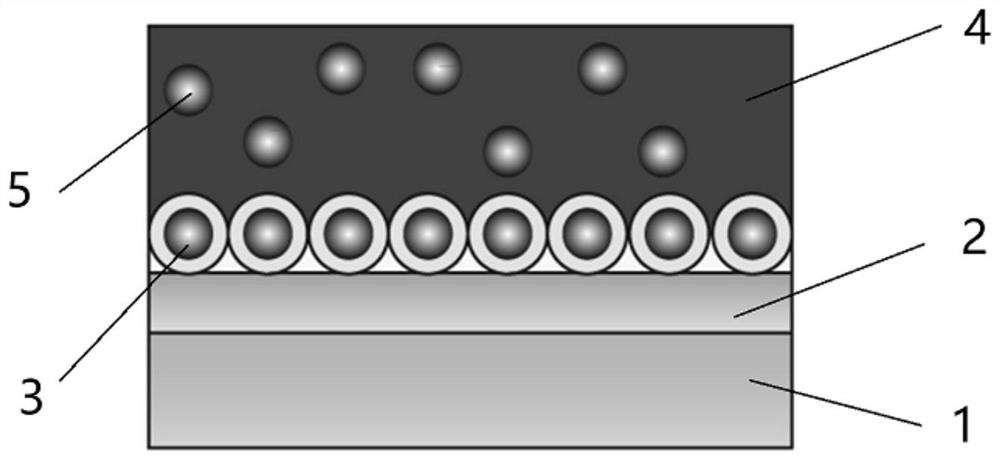

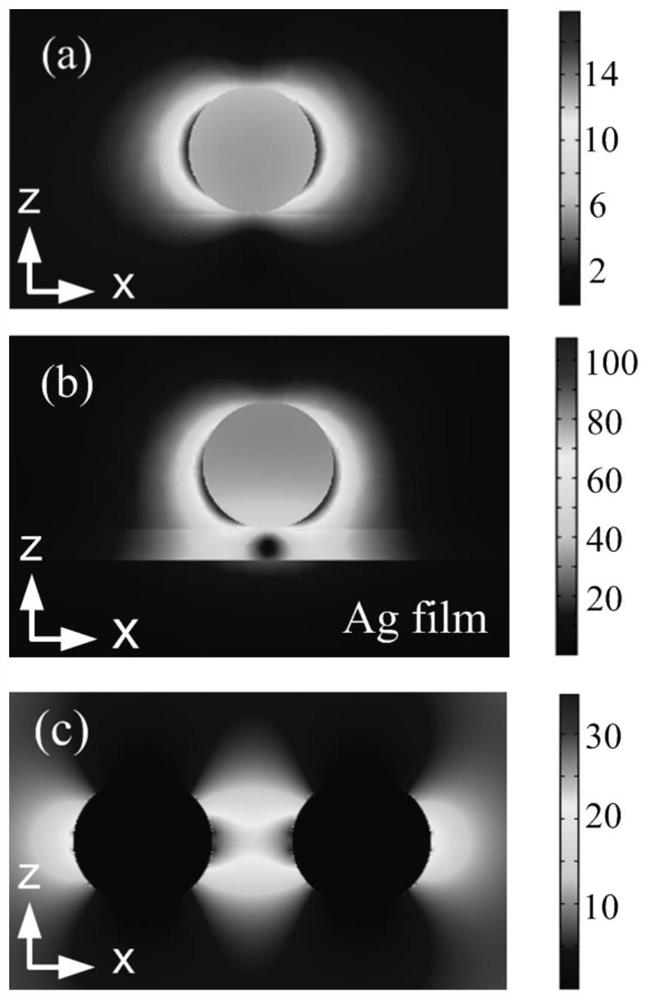

Organic solid laser based on metal nano core-shell structure-metal film plasma composite structure and preparation method

ActiveCN111313215AEnhanced Lasing PerformanceStrong local electric fieldMaterial nanotechnologyActive medium materialSurface plasmonPhysical chemistry

The invention discloses an organic solid laser based on a metal nano core-shell structure-metal film plasma composite structure. The organic solid laser comprises a substrate, a metal film layer, a core-shell structure layer and a gain dielectric layer which are sequentially stacked. The metal film layer is a metal film capable of generating a non-local surface plasma effect SPP. A shell layer material in the core-shell structure layer is an isolation medium material, and a central core material is first metal nanoparticles capable of realizing a localized surface plasma effect LSPR. The shelllayer of the core-shell structure is ingeniously used as the isolation layer, the distance between the LSPR and the SPP is regulated and controlled by changing the thickness of the shell layer, coupling between the LSPR and the SPP is achieved, then a strong local electric field is generated, the structure is simpler, and the preparation method is simpler and more convenient.

Owner:SHAANXI UNIV OF SCI & TECH

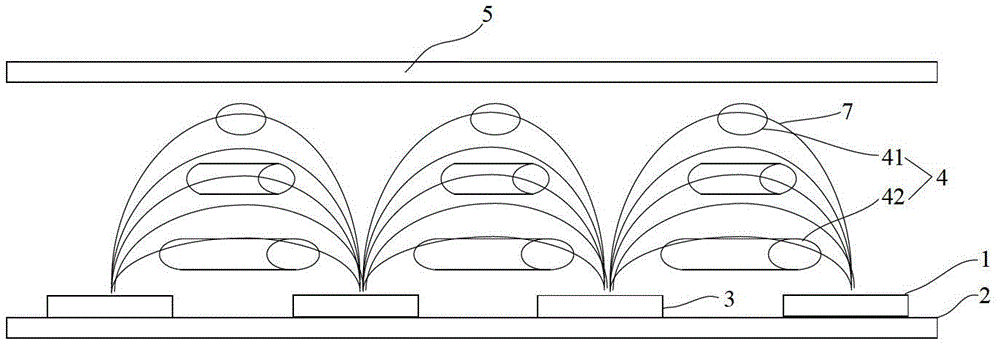

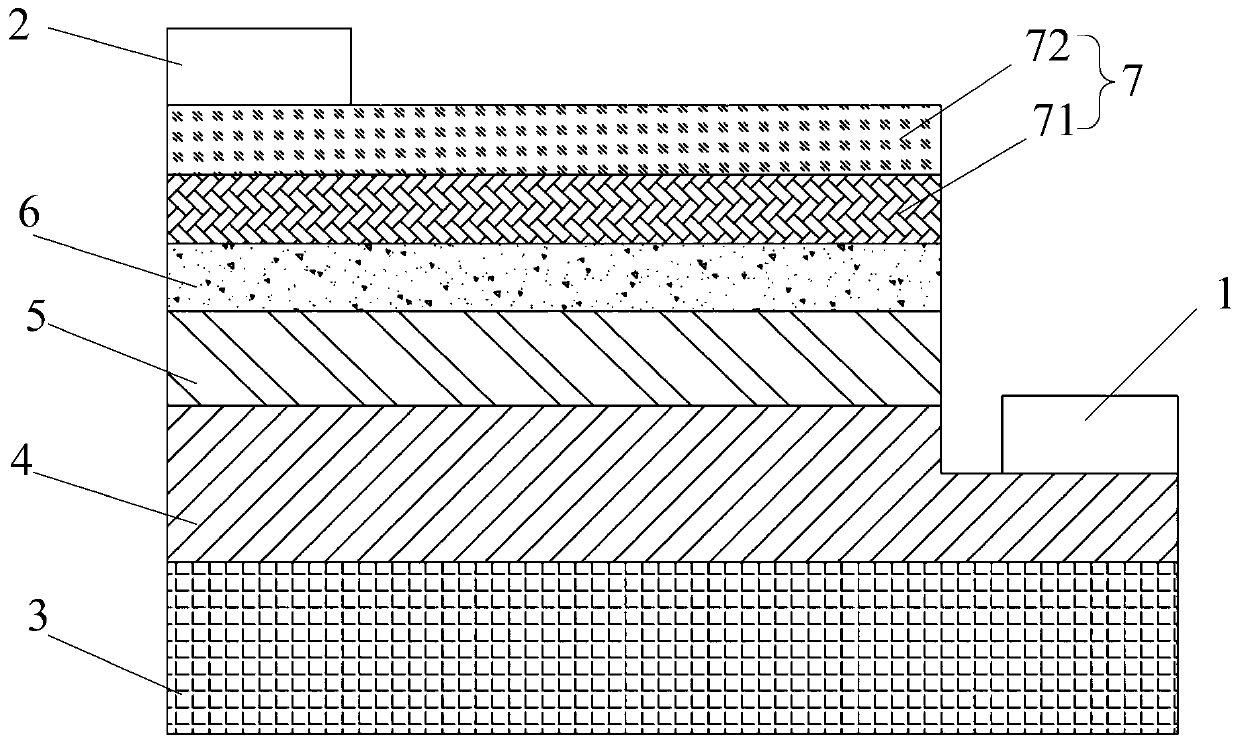

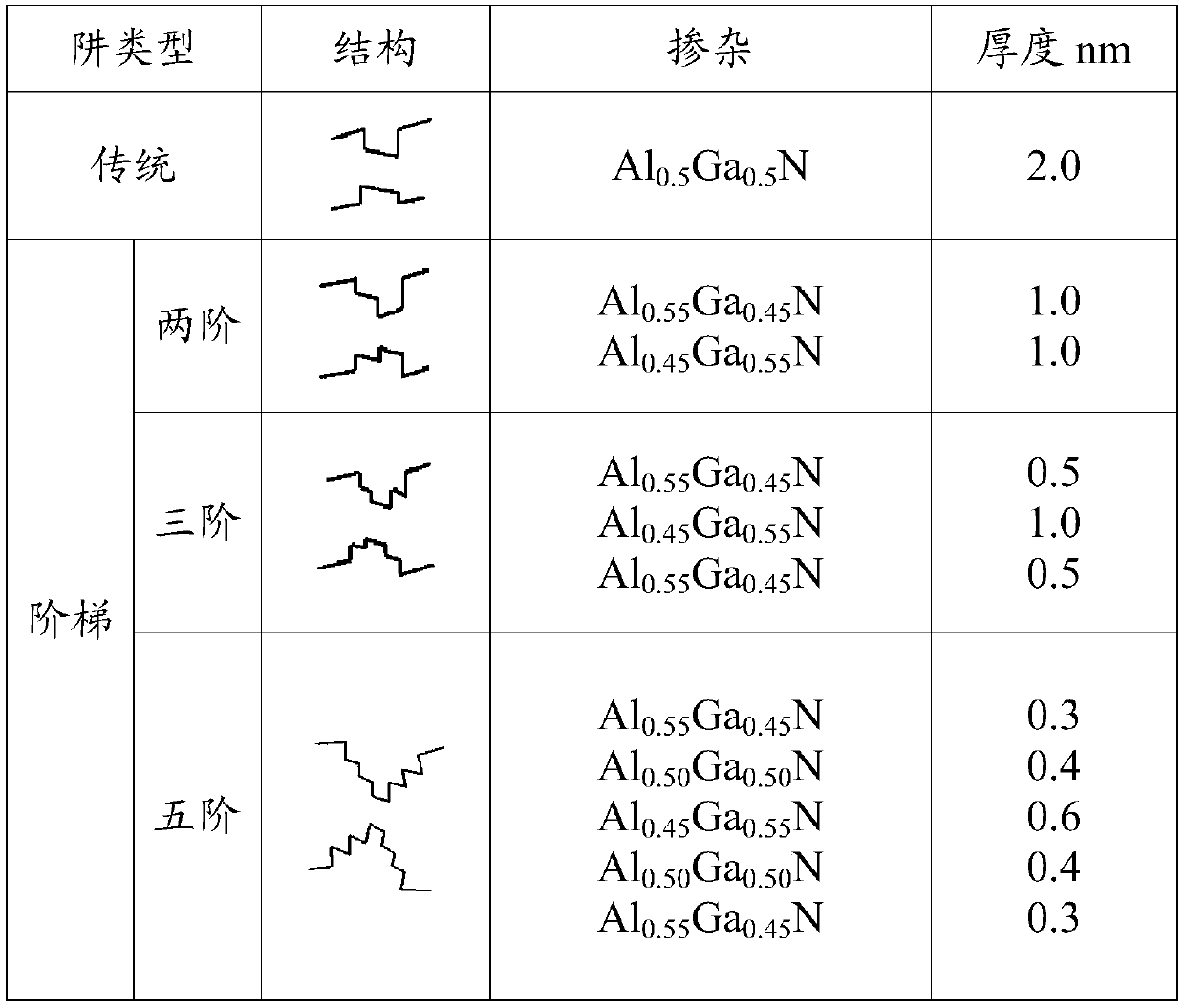

Light emitting diode with stepped quantum well structure and preparation method thereof

The invention discloses a light-emitting diode with a stepped quantum well structure. The light-emitting diode comprises an N-type electrode, a P-type electrode, a substrate, and an N-type conductivelayer, a quantum well active region, a P-type electronic barrier layer and a P-type conductive layer which are sequentially stacked on the substrate, wherein the N-type electrode is electrically connected with the N-type conductive layer; the P-type electrode is electrically connected with the P-type conductive layer; the quantum well active region comprises a quantum well layer and an Al0. 6Ga0.4N quantum barrier layer which are sequentially stacked on the N-type conductive layer; and the quantum well layer is a stepped quantum well, and the thickness of the quantum well layer is 2nm. By arranging the quantum well active region, an extremely strong polarization electric field cannot be caused, so that energy band bending caused by a polarization effect is improved, the electron and holewave function overlapping rate is improved, and finally the radiation recombination efficiency and the light emitting efficiency of the diode are improved.

Owner:HAINAN NORMAL UNIV

B4-flash device and manufacture method thereof

ActiveCN102938405AImprove performanceStrong electric fieldSolid-state devicesRead-only memoriesOptoelectronicsSilicon oxide

The invention provides a B4-flash device and a manufacture method thereof. The B4-flash device comprises a substrate, a first silicon oxide layer, a silicon nitride layer and a second silicon oxide layer, wherein the first silicon oxide layer, the silicon nitride layer and the second silicon oxide layer are sequentially installed on the substrate, the first silicon oxide layer comprises a first section, a second section and a third section which are sequentially distributed along a channel direction, and the thickness ratio of the first section, the second section and the third section is 1.5-2.5:0.8-1.2:1.5-2.5. An embodiment of the B4-flash device remits degeneration of silicon oxide and influences of electronic local area injection compiling and hole uniformity injection wiping through a heterogeneous silicon oxide structure so as to increase reliability of the device.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Electrostatic Thruster

InactiveUS20150252795A1Strong electric fieldConsiderable weightMachines/enginesUsing plasmaElectric fieldElectricity

The electrostatic thruster is an electrostatic propulsion device which produces a force by making the grounded conductors and the charged conductor composing the device experience a stronger electric field on one side of the device than the other side. This is done by surrounding each half of the inner conductor with its own dielectric of each dielectric's own unique permittivity and placing a grounded conductor above and below the inner conductor-double dielectric assembly. The dielectric with the higher permittivity will produce a weaker electric field on its half than the dielectric with the lower permittivity causing a non-zero net electrostatic force to move in the direction of the dielectric with the lower permittivity when the charged conductor is electrically powered.

Owner:TENACITYIP

Electron gun and electron microscope

ActiveUS10943760B2Improve work functionLower bandgapElectric discharge tubesElectron microscopeParticle physics

An electron gun for an electron microscope or similar device includes a field emitter cathode having a field emitter protrusion extending from the output surface of a monocrystalline silicon substrate, and electrodes configured to enhance the emission of electrons from a tip portion of the field emitter protrusion to generate a primary electron beam. A thin, contiguous SiC layer is disposed directly on at least the tip portion of the field emitter protrusion using a process that minimizes oxidation and defects in the SiC layer. Optional gate layers may be placed at, slightly lower than or slightly higher than the height of the field emitter tip portion to achieve high emission current and fast and accurate control of the primary emission beam. The field emitter can be p-type doped and configured to operate in a reverse bias mode, or the field emitter can be n-type doped.

Owner:KLA CORP +1

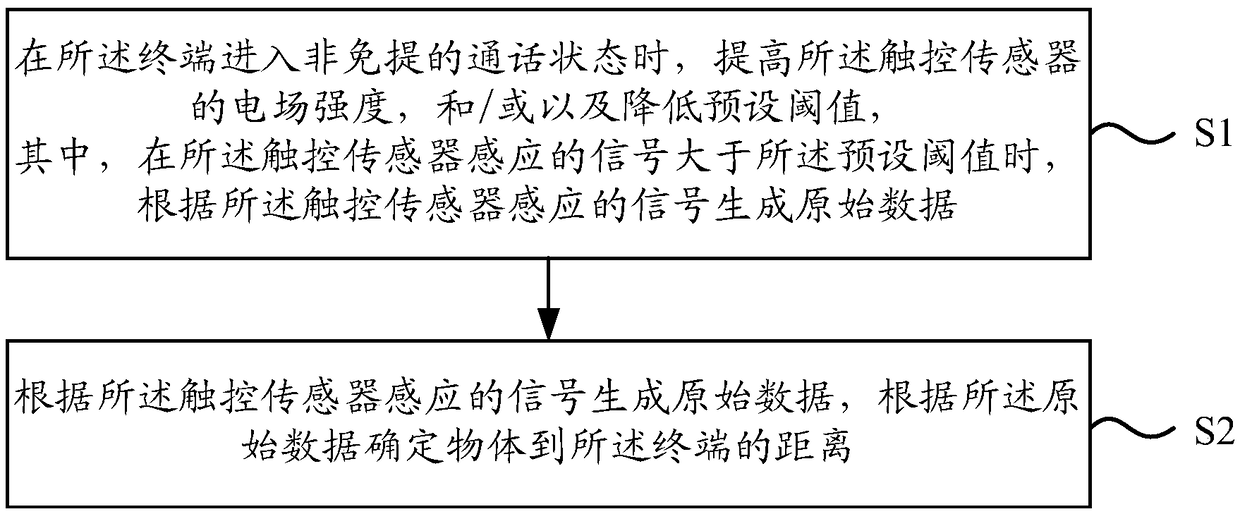

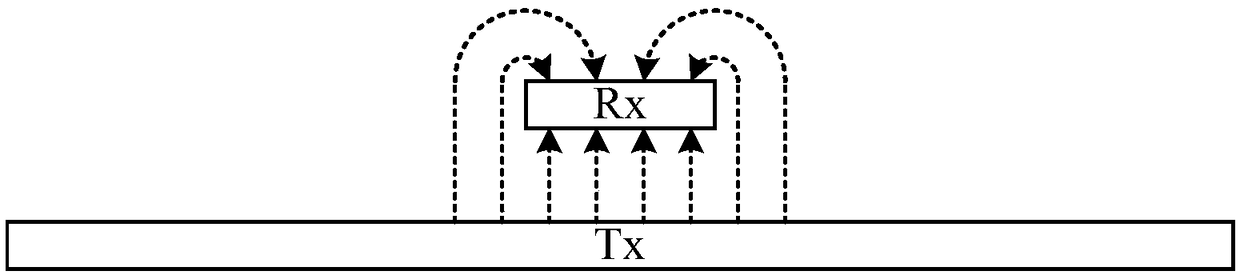

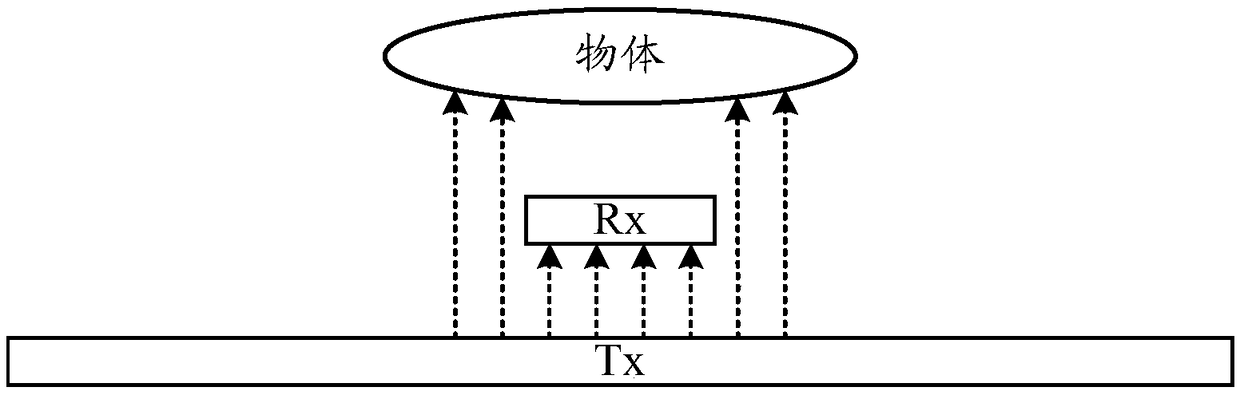

Distance sensing method and distance sensing device

InactiveCN109040422AIncrease the electric field strengthStrong electric fieldDevices with sensorUsing electrical meansOriginal dataHands free

A method for range sen For Terminal, the terminal comprises a capacitive touch sensor, The method comprises the following steps: when the terminal enters a non-hands-free communication state, increasing the electric field intensity of the touch sensor and / or decreasing a preset threshold value; wherein, when the signal sensed by the touch sensor is greater than the preset threshold value, generating original data according to the signal sensed by the touch sensor; generating raw data according to a signal sensed by the touch sensor, and determining a distance of the object from the terminal according to the raw data. According to an embodiment of the present disclosure, it is realized that the distance from the object to the terminal is determined by the touch sensor, and the touch sensoris provided in the terminal without arranging holes on one side of the terminal setting screen, thereby reducing the opening of the screen in the terminal setting and facilitating the increase of thearea ratio of the screen on the front side of the terminal.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

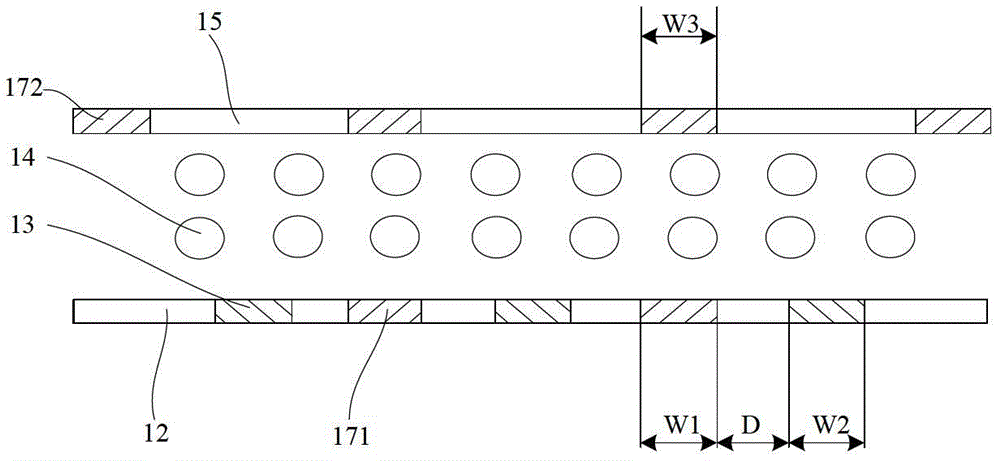

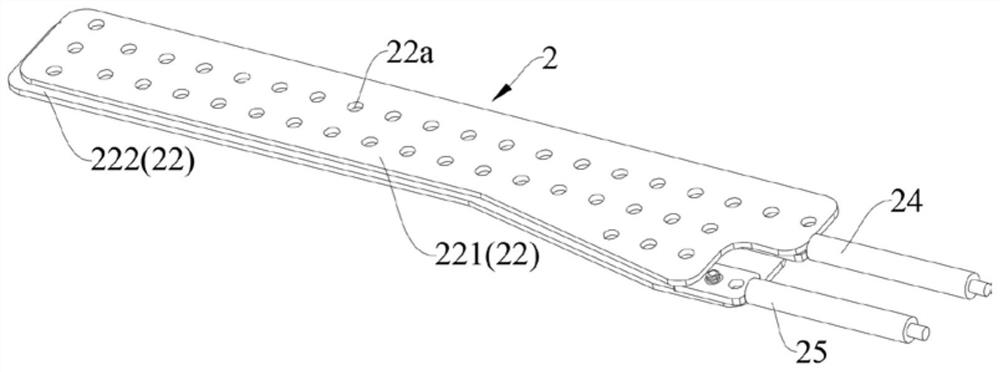

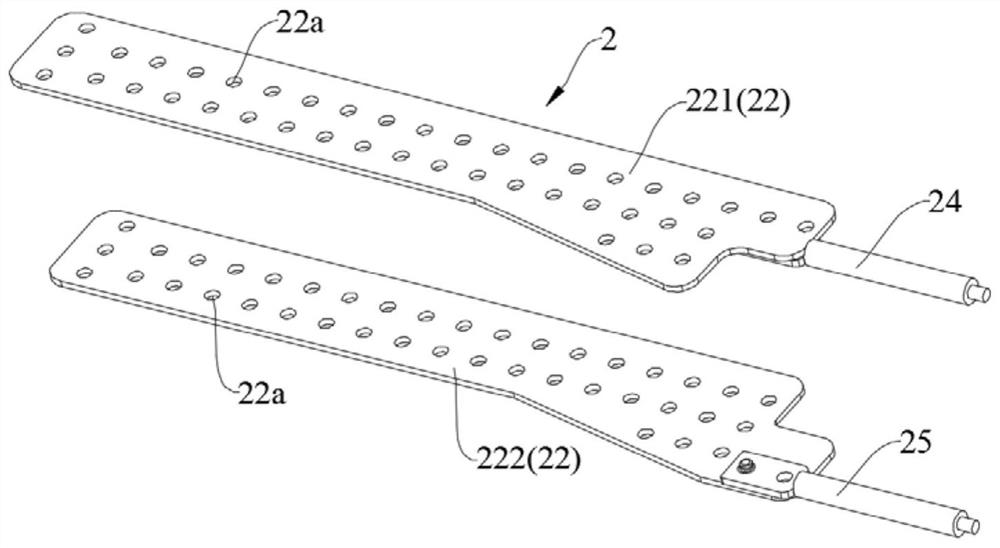

Electrode plate, electrolysis device and clothes treatment equipment

PendingCN112978864APrevent aggregate formationAvoid formingOther washing machinesWater/sewage treatmentElectrolysisElectrical field strength

The embodiment of the invention provides an electrode plate, an electrolysis device and clothes treatment equipment, a plurality of through holes penetrating through the electrode plate in the thickness direction of the electrode plate are formed in the electrode plate, and the density of the through holes in the electrode plate is 1-10 / cm < 2 >. According to the electrode plate disclosed by the embodiment of the invention, on one hand, the charge density of the junction surface of the inner wall of the through hole and the surface of the electrode plate is relatively high, and the electric field intensity nearby the junction surface is relatively high, so that the electrolysis efficiency can be greatly improved, more active substances such as hydroxyl radicals and active chlorine can be generated, and meanwhile, more microbubbles can also be generated; the sterilization, color crossing prevention and washing effects can be improved; on the other hand, water flow can flow from one side of the electrode plate to the other side of the electrode plate through the through holes, the water flow can take away microbubbles on the surface of the electrode plate and the inner wall surfaces of the through holes in time, and the microbubbles are prevented from gathering to form large bubbles.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Waveguide Direct Feed Microwave Plasma Torch Device

ActiveCN103269561BAchieve Impedance MatchingImprove coupling efficiencyPlasma techniqueCoaxial cableEngineering

The invention provides a waveguide direct-feed microwave plasma torch device, which is composed of a waveguide part, a tuning and auxiliary part, and a coaxial torch part. The waveguide part includes a gradient waveguide and a narrow-side compression waveguide; Tube, middle tube, inner tube, adjusting stud and coaxial centering washer; tuning and auxiliary parts include waveguide short-circuit sliding end, torch reflection tuning end and torch upper adjustment end, wherein the waveguide short-circuit sliding end is composed of waveguide short-circuit board Composed of sliding rods, the torch reflection tuning end includes adjustment studs and reflection plates. In the invention, microwave energy is directly fed into the metal coaxial torch through the tapered waveguide and the narrow-side waveguide, and the formed plasma has a central channel, which facilitates the introduction of samples and enhances the tolerance to samples. The device eliminates coaxial cables, coupling rings, etc., improves coupling efficiency, and expands the power of the torch tube. It can be used as an ionization source for atomizers and atomic mass spectrometers, or for the decomposition and treatment of harmful compounds and garbage.

Owner:ZHEJIANG UNIV

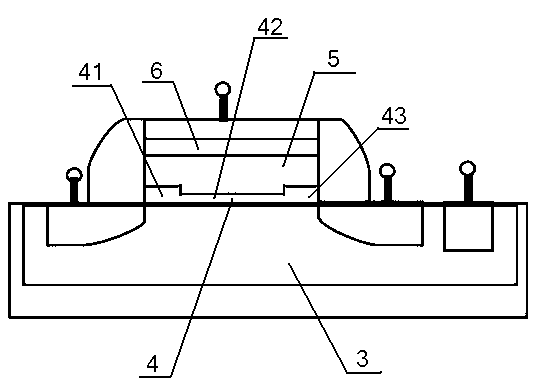

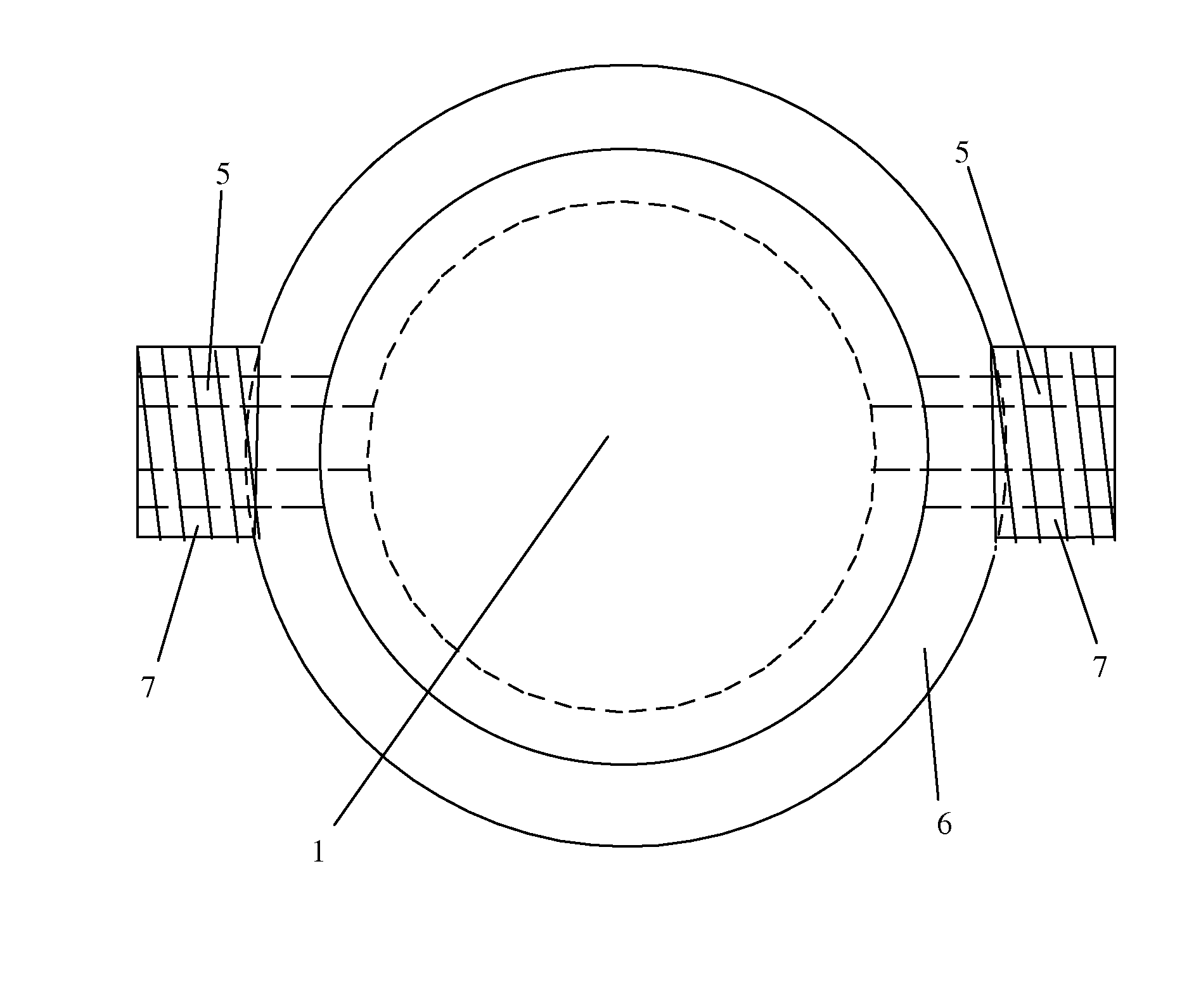

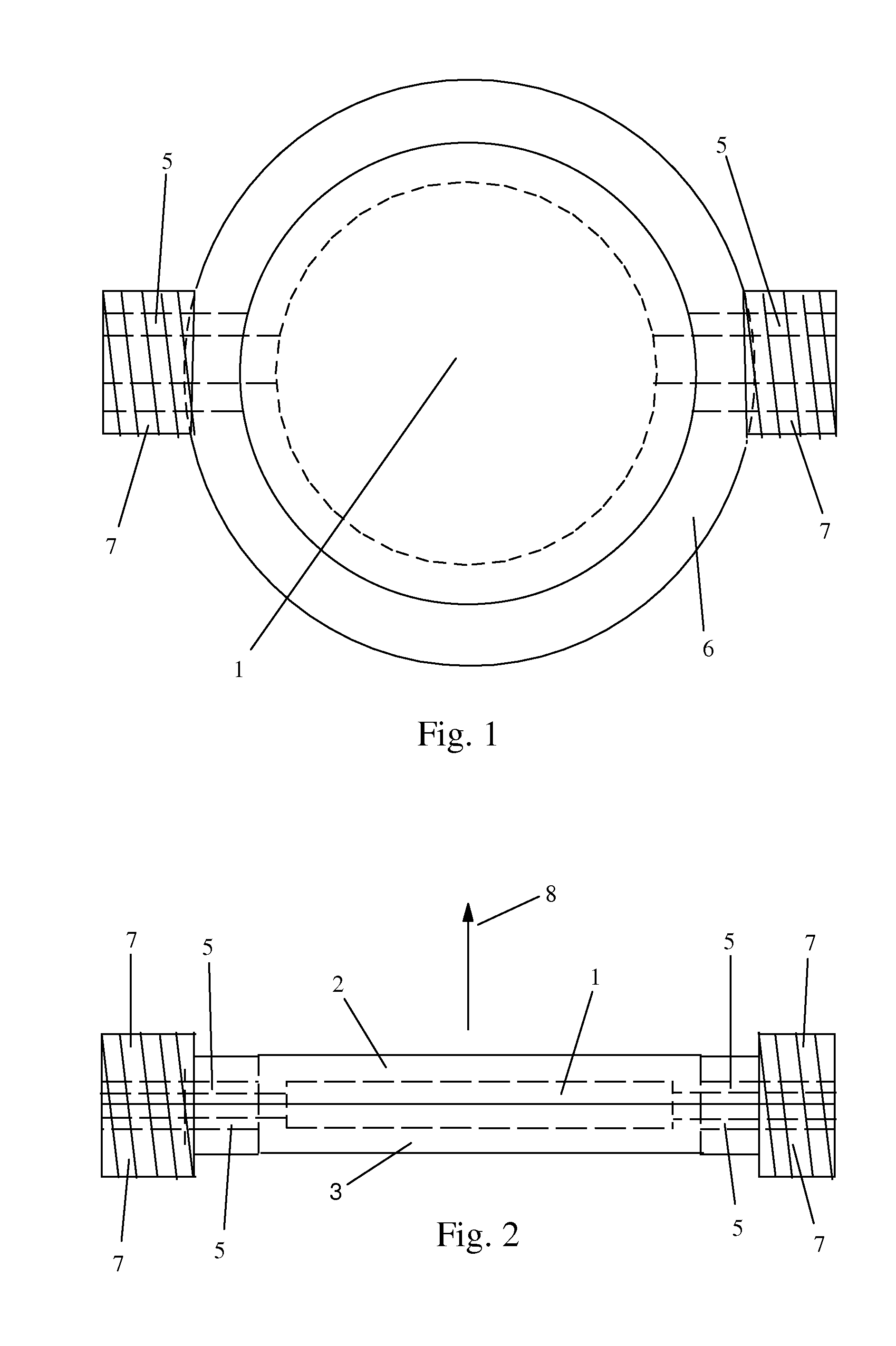

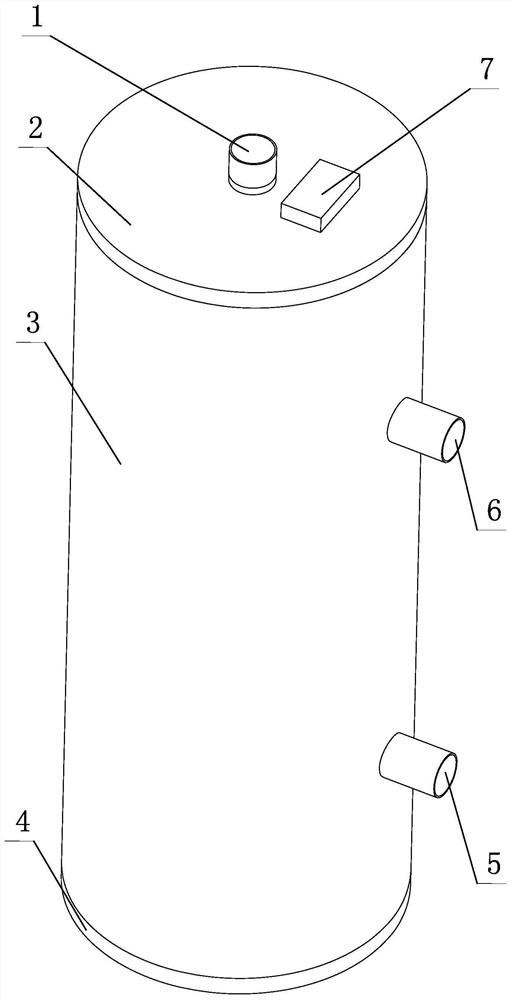

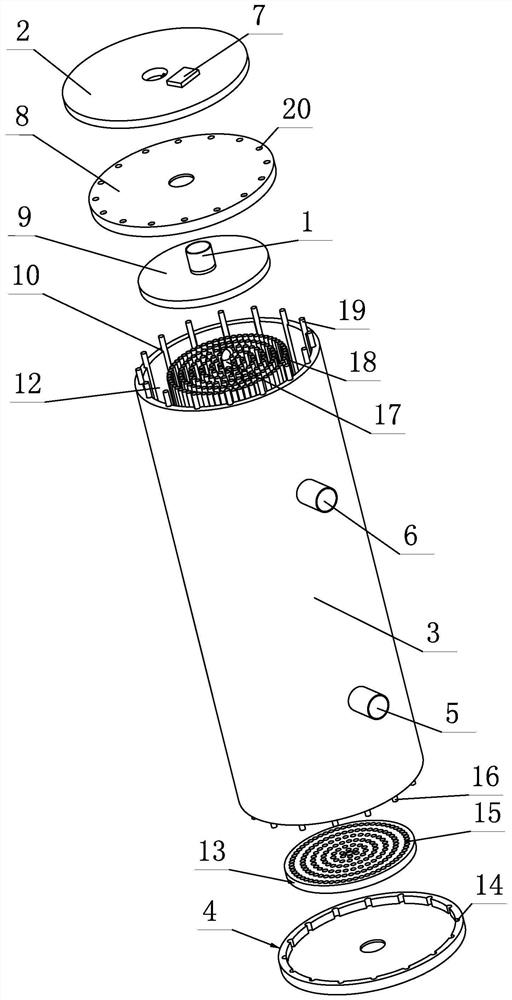

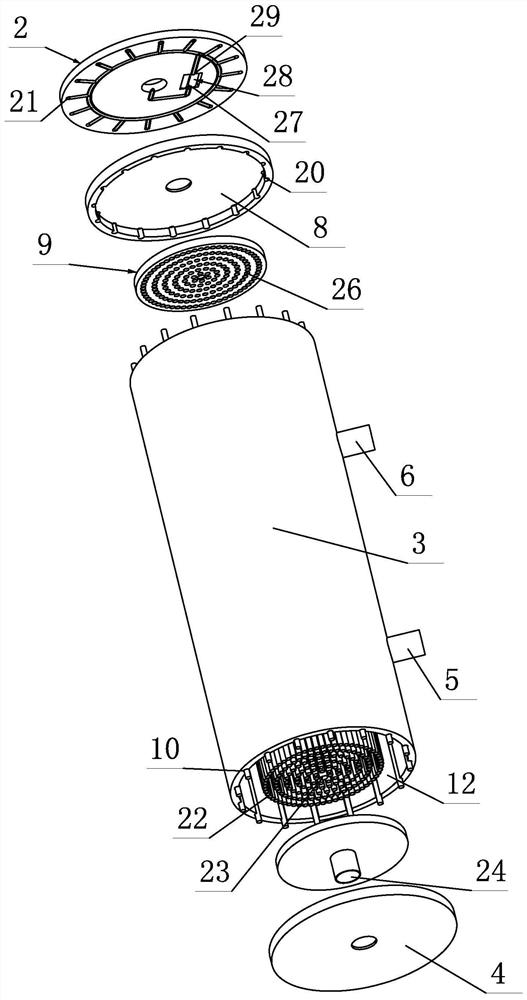

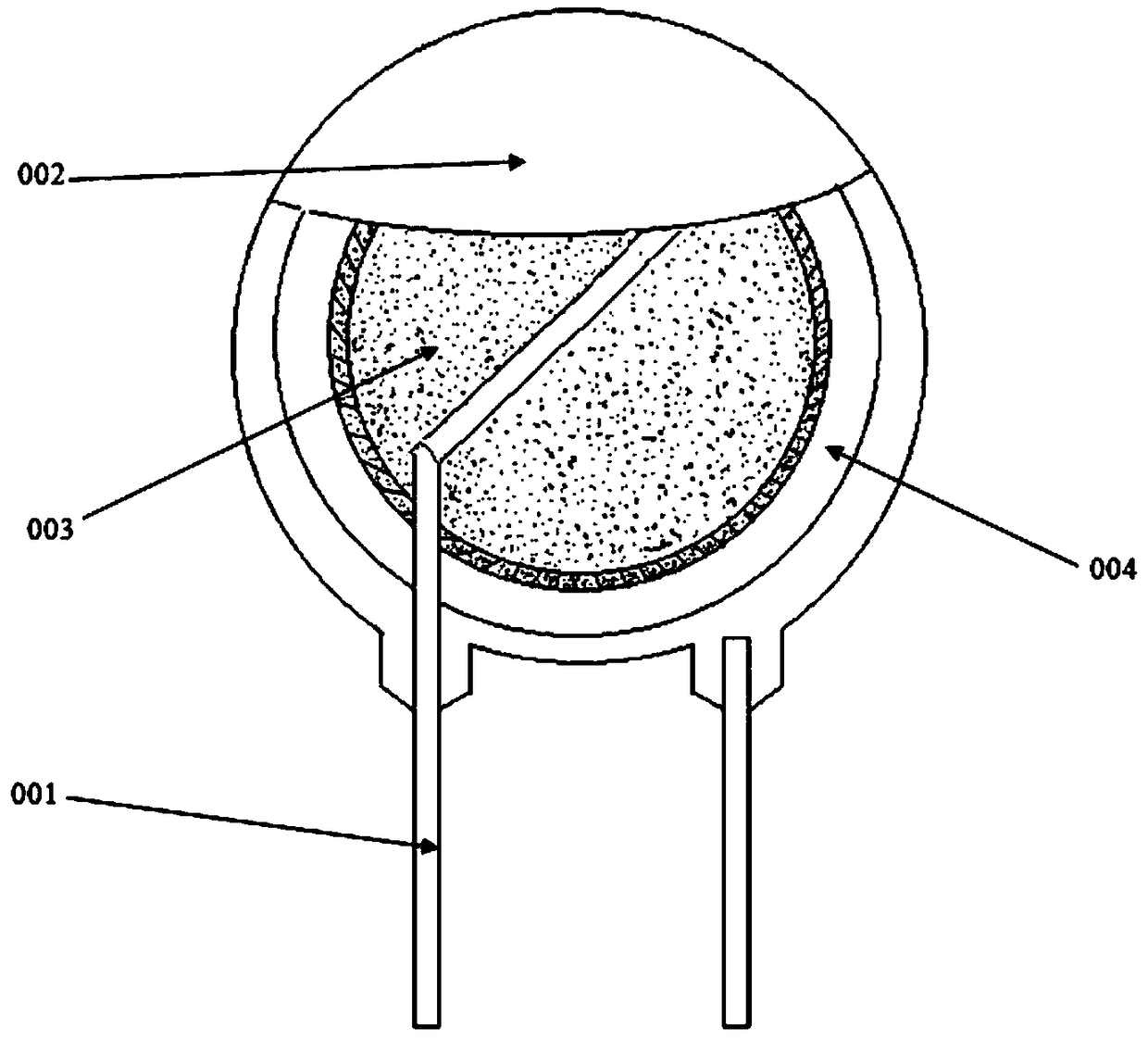

Bioreactor for artificial liver

PendingCN113181458AExtended service lifeIncrease contact areaOther blood circulation devicesDialysis systemsHollow fibreElectrical battery

The invention discloses a bioreactor for an artificial liver, and the bioreactor comprises a circular glass cylinder sealed by covers at the two ends, and a plurality of hollow fiber tubes made of hollow fiber membranes are arranged in the center in the circular cylinder; the blood inlet pipe is communicated with one ends of all the hollow fiber pipes, the blood outlet pipe is communicated with the other ends of all the hollow fiber pipes, the nutrient solution inlet pipe and the nutrient solution outlet pipe are communicated with the peripheral gap, a plurality of first rod type electrodes are fixed to the inner wall of the circular cylinder, and a second rod type electrode is fixed to the centers of the hollow fiber pipes. One end of each first rod-type electrode is electrically connected with the negative electrode of the battery, one end of each second rod-type electrode is electrically connected with the positive electrode of the battery, the first rod-type electrodes are uniformly distributed along the circumference of the inner wall of the circular glass cylinder, and an electric field which uniformly radiates in the radial direction is formed between the first rod-type electrodes and the second rod-type electrodes. The bioreactor of the artificial liver can fully remove protein binding toxins in blood, and the service life of the bioreactor of the artificial liver is prolonged.

Owner:浙大宁波理工学院

A kind of varistor and its manufacturing process

The invention relates to a piezoresistor and a manufacturing process thereof. The piezoresistor is composed of a ceramic substrate, a leading-out end, an electrode layer and an insulating layer, wherein a concave area, namely, an electrode positioning area, is prefabricated on the ceramic substrate; the leading-out end is arranged on an electrode; the insulating layer is used for locally or wholly packaging the ceramic substrate, the electrode layer and the leading-out end; in the manner of sputtering or spraying electrode, an electrode hole of a mask plate is positioned and coated on a concave opening; a small electrode hole and a big concave opening form a bottle-shaped structure; the electrode is drifted and deposited into the concave opening so as to form the electrode and realize the concave opening being accurately filled with the electrode; the electrode eccentricity caused by the difference in diameter of the ceramic substrate in a batch sputtering process can be avoided; the thickness of the ceramic substrate at an edge of the concave opening is greater than the thickness of the interior; the reducing of the risk in edge arc crossing is benefited; the edge effect is weakened; the flowing property is greatly promoted; the preparation process of the piezoresistor comprises the following steps: manufacturing the ceramic substrate, performing electric polarization, connecting the leading-out end, coating the insulating layer, printing and testing.

Owner:KUSN WANFENG ELECTRONICS

Method for manufacturing backboard used for packaging photovoltaic module

InactiveCN103346207AIncrease corrosion rateSave materialFinal product manufactureSemiconductor devicesThin layerBackplane

The invention provides a method for manufacturing a backboard used for packaging a photovoltaic module. The method for manufacturing the backboard used for packaging the photovoltaic module solves the problem that mask materials and materials consumed in removing masks in manufacturing a photovoltaic module backboard are wasted and a chemical corrosion technology poorly adapts to the technologies of different metal films. According to the method for manufacturing the backboard used for packaging the photovoltaic module, an electrolytic corrosion method with a template is used for replacing a chemical corrosion method in the prior art, a conducting circuit is formed on a metal thin layer of the backboard in an electrolytic corrosion mode and processes of manufacturing the masks and removing the masks afterwards are removed and thus, materials are saved, cost in manufacturing the backboards is reduced and pressure of environmental pollution is relieved.

Owner:SHUNDE SYSU INST FOR SOLAR ENERGY +1

Organic solid-state laser based on metal nano core-shell structure-metal thin film plasma composite structure and preparation method

ActiveCN111313215BLower lasing thresholdStrong local electric fieldMaterial nanotechnologyActive medium materialThin membraneGain

The invention discloses an organic solid-state laser based on a metal nano core-shell structure-metal thin film plasma composite structure, comprising a substrate, a metal thin film layer, a core-shell structure layer and a gain medium layer sequentially stacked; wherein, the metal thin film layer It is a metal thin film capable of producing non-localized surface plasmon effect SPP; the shell layer material in the core-shell structure layer is an isolation dielectric material, and the central core material is the first metal nanoparticle capable of realizing the localized surface plasmon effect LSPR. The present invention cleverly uses the shell of the core-shell structure as the isolation layer, and by changing the thickness of the shell, regulates the distance between the LSPR and the SPP, realizes the coupling between the two and generates a strong local electric field, the structure is simpler, and the preparation method Easier.

Owner:西安拓创光芯科技有限公司

A device for removing colloidal impurities by coupling electrostatic field force with hydraulic action of multi-stage partitions

ActiveCN111252871BAccelerated settlementFavorable hydraulic conditionsWater/sewage treatment by magnetic/electric fieldsSludgeHydraulic action

The invention belongs to the technical field of removing colloidal impurities in raw water, and discloses a device for removing colloidal impurities by electrostatic field force coupled with hydraulic action of multi-stage partitions. The device includes a settling chamber and an electric field generating device. The settling chamber is equipped with a multi-stage diversion partition and a sewage device. The multi-stage diversion partition is an upper partition and a lower partition arranged in a staggered manner, and divides the settlement chamber into several Processing units connected to each other; water inlets and water outlets are respectively provided on both sides of the top of the settling chamber; the sewage discharge device is provided at the bottom of the processing unit, and the electric field generator is provided with an anode plate and a cathode plate, and the anode plate and the cathode plate are parallel to each other Set on the bottom and top of the settling chamber, the anode plate and the cathode plate are connected through an external power supply. The device utilizes the characteristics of negative charges on the surface of colloidal particles, cleverly sets up multi-stage partitions to guide flow, and forms more favorable hydraulic conditions, so that colloidal particles can be in more favorable conditions for settlement, improve the settling efficiency of colloidal impurities, reduce consumption, and operate The process realizes automatic mud discharge.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com