MSM (Metal-Semiconductor-Metal) photodetector with improved structure and preparation method thereof

A photodetector and improved structure technology, applied in the field of photodetection, can solve problems such as electron leakage, limited detection efficiency, and high requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

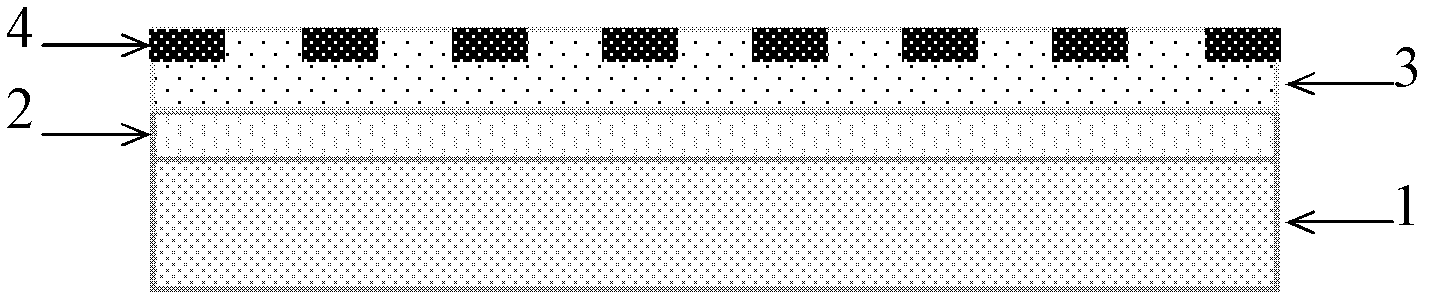

[0029] refer to figure 1 , The MSM detector of the buried electrode structure of the present invention includes a sapphire sink 1 , an AlN buffer layer 2 , a GaN active layer 3 , and a metal interdigitated electrode 4 from bottom to top. Its structural features are: the electrode structure buried in the material is used to replace the original surface electrode structure. In this way, the adverse effects of the surface state of the material on device performance such as increased dark current and poor metal contact performance can be improved. .

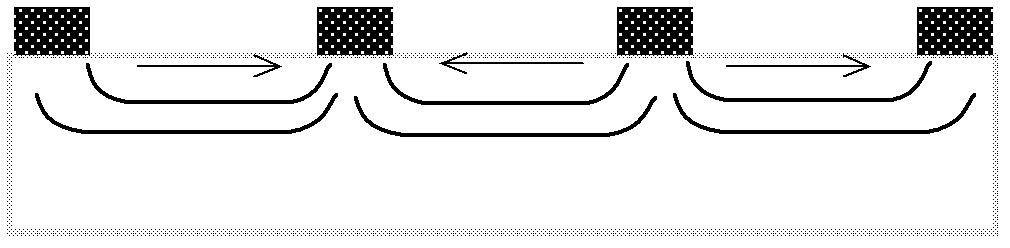

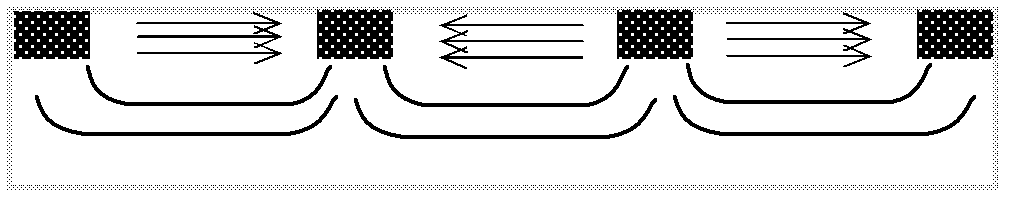

[0030] The electric field physical model of the MSM detector is as follows Figure 2a and Figure 2b shown, where Figure 2a It is a traditional planar electrode structure. For non-buried electrodes, the field strength decreases with the increase of the longitudinal depth of the active region. The attenuation is faster under the electrode and slower in the middle of the electrode. Figure 2b It is the buried electrode structure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com