Formaldehyde gas sensor, making method and formaldehyde monitoring and treatment device

A technology of formaldehyde gas and production methods, applied in the direction of material electrochemical variables, etc., can solve the problems of harming human health and toxicity, and achieve low cost, simple operation, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

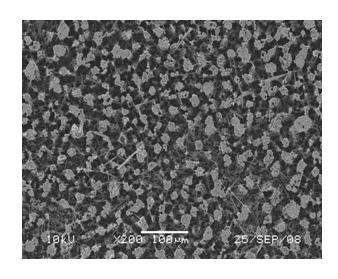

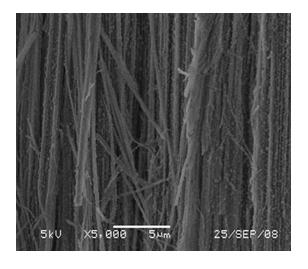

[0028] Such as figure 1 As shown, the working electrode 2 of the formaldehyde gas sensor 1 is a Pd-Ni / SiNWs formaldehyde catalytic electrode, which is installed in the middle of the sensor housing 4, and the counter electrode 3 is a Ni / SiNWs formaldehyde gas sensor electrode, which is installed in the sensor housing. At the inner bottom of the housing 4, the working electrode 2 and the counter electrode 3 are respectively connected to the corresponding tube angle 5 at the bottom of the sensor housing 4 through wires. The electrolyte 6 is filled between the working electrode 2 and the counter electrode 3, and the shell above the working electrode 2 The inner space is connected with the vent hole 9 on the top of the sensor housing 4 through the vent membrane 7 and the filter 8 . The electrolyte 6 has a concentration of 2 M L -1 of KOH solution. figure 2 SEM image of Ni / SiNWs array cathode, image 3 It is the SEM image of the Pd-Ni / SiNWs array anode.

example 2

[0029] Example 2 Manufacturing method of formaldehyde gas sensor electrode

[0030] 1) The preparation method of Ni / SiNWs formaldehyde gas sensor cathode is as follows: the surface area is about 1.0×0.5cm 2The SINWs sheet is a prefabricated electrode substrate, cleaned with deionized water, soaked in 1-5% TritonX-100 wetting agent for 30-60s to activate the surface, so that the surface of SiNWs can form a H-bond terminated surface.

[0031] Prepare the following chemical electrode array electroless plating solution: 1mol L -1 Nickel sulfate hexahydrate, 0.5 mol L -1 Ammonium sulfate, 0.005~0.010mol L -1 Lead chloride, 2.5mol L -1 Ammonium fluoride, 0.001mol L -1 Sodium lauryl sulfate, 0.2mol L -1 Sodium succinate, 0.2mol L -1 Sodium citrate. Mix the above plating solution and put it into 100 mL deionized water for ultrasonic dissolution for 20 min, then put it into a constant temperature water bath with a temperature control accuracy of 0.1°C and raise the temperature t...

example 3

[0034] Example 3 Formaldehyde monitoring and real-time processing device made of formaldehyde gas sensor

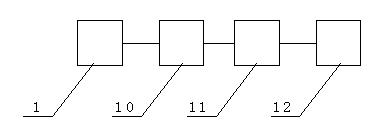

[0035] Such as Figure 4 As shown, the device is composed of a formaldehyde sensor 1 extended and connected in sequence, a single-chip microcomputer 10 whose model is STC12C5410, a peak current value holder 11 whose model is PKD01, and a display output device 12 whose model is LCD1602.

[0036] The device system is usually in a dormant state. When there is no formaldehyde gas molecule in the indoor air, no voltage will be generated on the electrode; if there is formaldehyde gas in the air, the formaldehyde molecule will catalyze oxidation on the Pd-Ni / SiNWs electrode and release charges, resulting in A catalytic voltage of about -0.7 V is generated on the electrode, which can wake up the STC12C5410 to work by interrupting, and then output a cyclic voltammetry scanning voltage on the triangular wave output circuit according to the program, which can promote the electrocata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com