Preparation method of copper-foam-based hierarchical composite oxide monolithic denitrification catalyst

A technology of denitrification catalyst and composite oxide, which is applied in the field of preparation of foamed copper-based composite oxide monolithic denitration catalyst with hierarchical structure, can solve the problems of cumbersome preparation steps, easy falling off of active components, high processing cost, etc., so as to facilitate mass transfer , Avoid secondary pollution, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

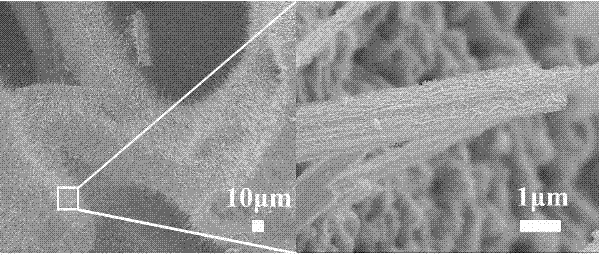

Embodiment 1

[0019] First cut the foamed copper into a circle, treat it in acetone to remove the surface oil, then ultrasonically wash it in dilute hydrochloric acid to remove the surface oxide, wash it with deionized water, dry it, and put it into a quartz tube , under a flowing air atmosphere, calcined at 400°C for 6h to produce copper foam coated with CuO nanowires; put the above copper foam into ferrous nitrate solution with a concentration of 0.002mol / L, and the copper foam was The dosage in the salt solution is 13g / L, transferred to the autoclave, heated at 180°C for 1h, and deposited Fe(OH) on the surface of CuO nanowires in situ 2 Particles; after natural cooling, the product was washed with deionized water until neutral, dried, and calcined at 500° C. for 3 hours to obtain the denitration catalyst.

[0020] Catalyst evaluation: put the prepared copper foam into a fixed-bed tubular reactor with an inner diameter of 20mm, and program the temperature to the required reaction temperat...

Embodiment 2

[0022] First cut the foamed copper into a circle, treat it in acetone to remove the surface oil, then ultrasonically wash it in dilute hydrochloric acid to remove the surface oxide, wash it with deionized water, dry it, and put it into a quartz tube , under a flowing air atmosphere, calcined at 500°C for 5 hours to obtain foamed copper coated with CuO nanowires; put the above-mentioned foamed copper into a ferrous sulfate solution with a concentration of 0.005mol / L, and the foamed copper was The dosage in the salt solution is 25g / L, transferred to the autoclave, heated at 170°C for 1 hour, and deposited Fe(OH) on the surface of CuO nanowires in situ 2 Particles; after natural cooling, the product is washed with deionized water to neutrality, dried, and calcined at 500° C. for 1 hour to obtain the denitration catalyst.

[0023] Catalyst evaluation: put the prepared copper foam into a fixed-bed tubular reactor with an inner diameter of 20mm, and program the temperature to the re...

Embodiment 3

[0025] First cut the foamed copper into a circle, treat it in acetone to remove the surface oil, then ultrasonically wash it in dilute hydrochloric acid to remove the surface oxide, wash it with deionized water, dry it, and put it into a quartz tube , in a flowing air atmosphere, calcined at 600°C for 4h to obtain copper foam coated with CuO nanowires; The dosage in the salt solution is 40g / L, transferred to the autoclave, heated at 160°C for 2 hours, and deposited Fe(OH) in situ on the surface of CuO nanowires 2Particles; after natural cooling, the product was washed with deionized water until neutral, dried, and calcined at 600° C. for 2 hours to obtain the denitration catalyst.

[0026] Catalyst evaluation: put the prepared copper foam into a fixed-bed tubular reactor with an inner diameter of 20mm, and program the temperature to the required reaction temperature to test the catalytic activity. The simulated flue gas is composed of N 2 , O 2 , NO and NH 3 Composition, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com