A device for removing colloidal impurities by coupling electrostatic field force with hydraulic action of multi-stage partitions

An electrostatic field and separator technology, applied in the field of colloidal impurity removal in raw water, can solve the problems of large area of sedimentation tank, increased environmental burden, tight land use and other problems, so as to reduce the area of the area, improve the volume utilization rate, increase the The effect of dwell time

Active Publication Date: 2022-06-03

GUANGDONG UNIV OF TECH

View PDF20 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The flocs formed after coagulation still need to be set up in a sedimentation tank for gravity sedimentation removal. The area of the sedimentation tank is quite large, and the current land use situation is tense and expensive

To sum up, the existing traditional method of treating colloidal impurities in raw water mainly adopts the method of coagulation treatment to remove colloidal impurities. Although the removal effect can be achieved, the process is tedious and cumbersome, and it is easy to cause secondary pollution and generate too much pollution. Mud, increasing the burden on the environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

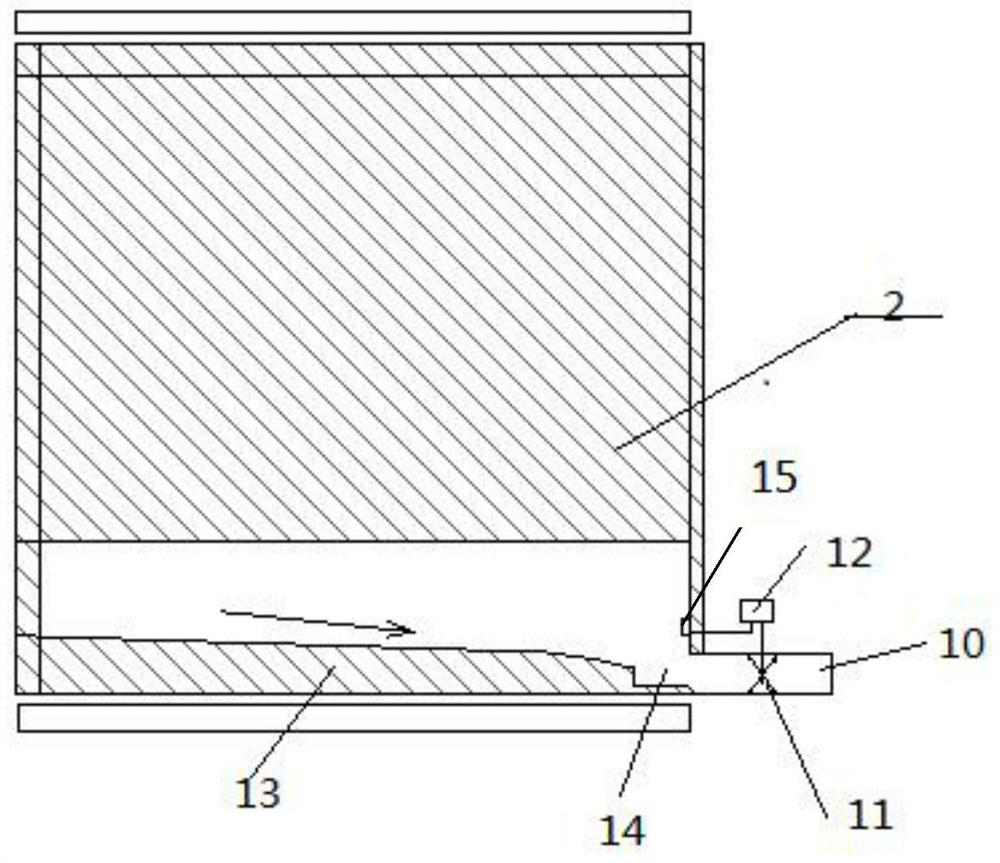

[0040] The length of the upper baffle and the lower baffle is 3 / 5~3 / 4 of the height of the settling chamber 9.

[0042] The slope of the mud discharge inclined plate 13 is 3 to 5%; the slope of the mud discharge groove 14 is 2 to 4%.

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

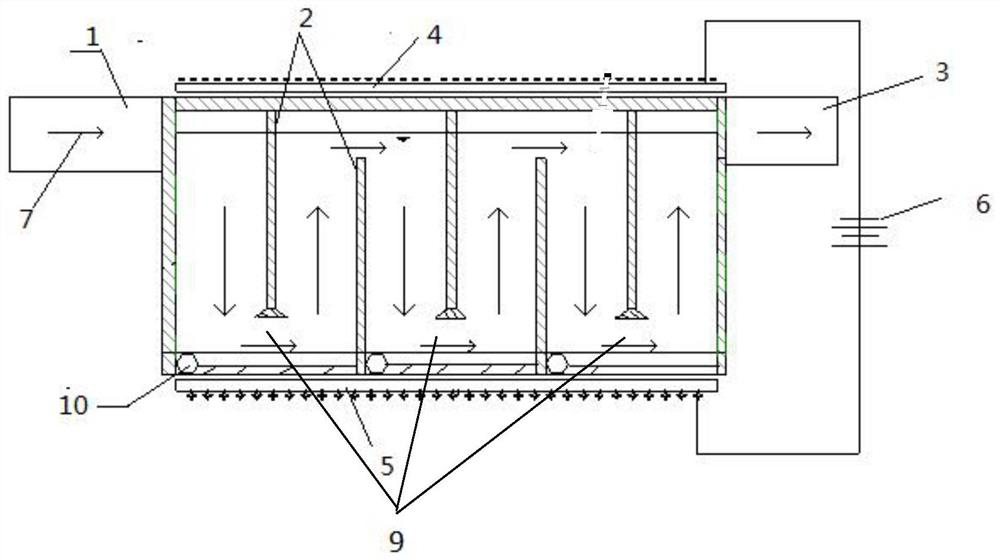

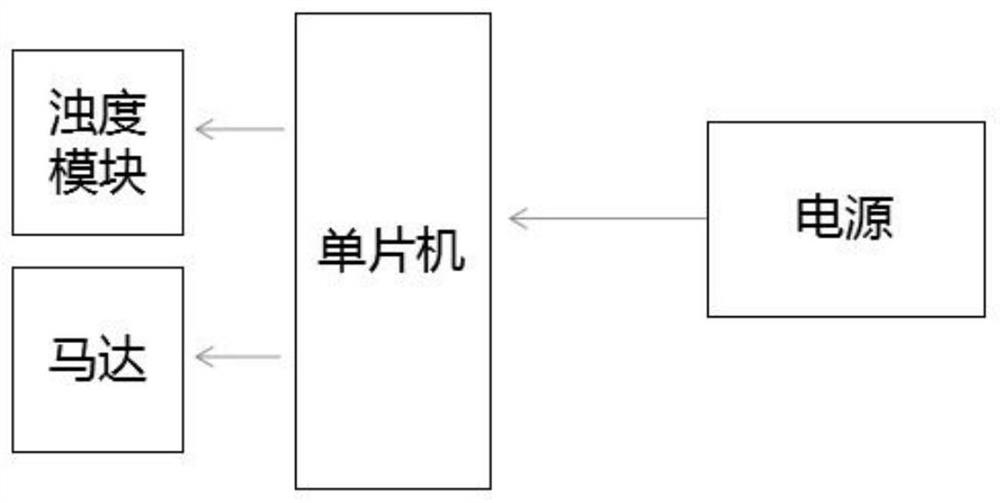

The invention belongs to the technical field of removing colloidal impurities in raw water, and discloses a device for removing colloidal impurities by electrostatic field force coupled with hydraulic action of multi-stage partitions. The device includes a settling chamber and an electric field generating device. The settling chamber is equipped with a multi-stage diversion partition and a sewage device. The multi-stage diversion partition is an upper partition and a lower partition arranged in a staggered manner, and divides the settlement chamber into several Processing units connected to each other; water inlets and water outlets are respectively provided on both sides of the top of the settling chamber; the sewage discharge device is provided at the bottom of the processing unit, and the electric field generator is provided with an anode plate and a cathode plate, and the anode plate and the cathode plate are parallel to each other Set on the bottom and top of the settling chamber, the anode plate and the cathode plate are connected through an external power supply. The device utilizes the characteristics of negative charges on the surface of colloidal particles, cleverly sets up multi-stage partitions to guide flow, and forms more favorable hydraulic conditions, so that colloidal particles can be in more favorable conditions for settlement, improve the settling efficiency of colloidal impurities, reduce consumption, and operate The process realizes automatic mud discharge.

Description

A device for removing colloidal impurities by electrostatic field force coupling multi-stage separator hydraulic action technical field The invention belongs to the technical field of colloidal impurity removal in raw water, more specifically, relate to a kind of electrostatic field force coupling It is a device for removing colloidal impurities by hydraulic action of stage separators. Background technique [0002] The impurities in raw water can be divided into solutes, colloids and suspended solids according to size. Solutes are true solutions ions or molecules. The particles of suspended matter are larger, when the water is still, the suspended matter with smaller density floats on the surface of the water, and the suspended matter with higher density sinks. Therefore, it is better to remove such impurities. Colloidal particles are mainly inorganic substances such as fine sediment, minerals, and organic substances such as humus. A substance is a collection of man...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C02F1/48

CPCC02F1/48C02F2301/028

Inventor 陈淑英谭倩蔡宴朋杨志峰

Owner GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com