Electrode plate, electrolysis device and clothes treatment equipment

A technology of clothing treatment equipment and electrolysis device, applied in the field of electrolysis water, can solve the problems of easy accumulation of bubbles and low electrolysis efficiency of electrolysis electrodes, and achieve the effect of improving sterilization and improving electrolysis efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

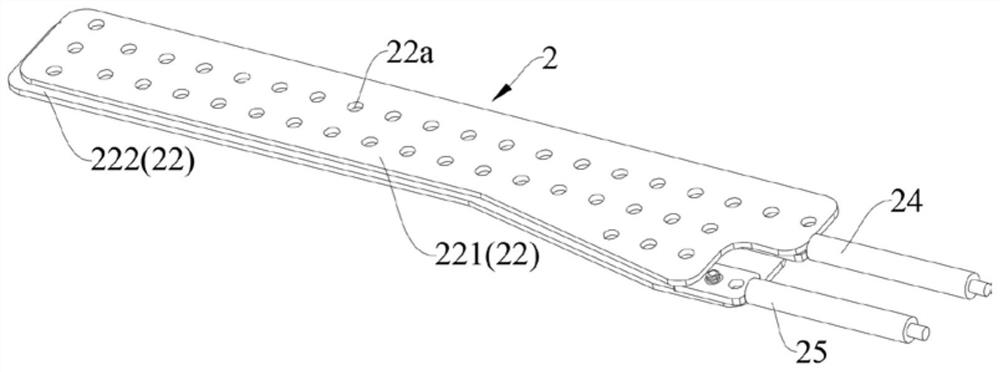

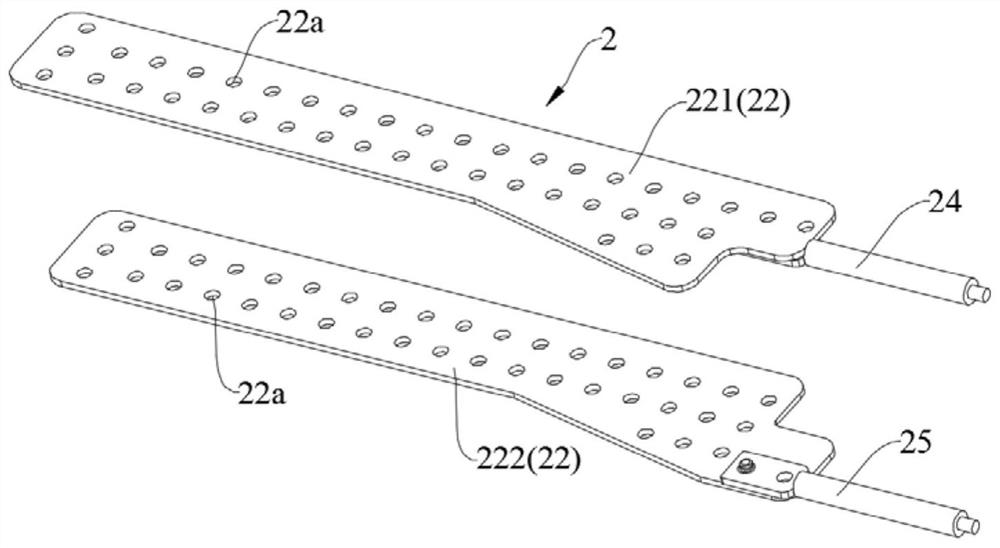

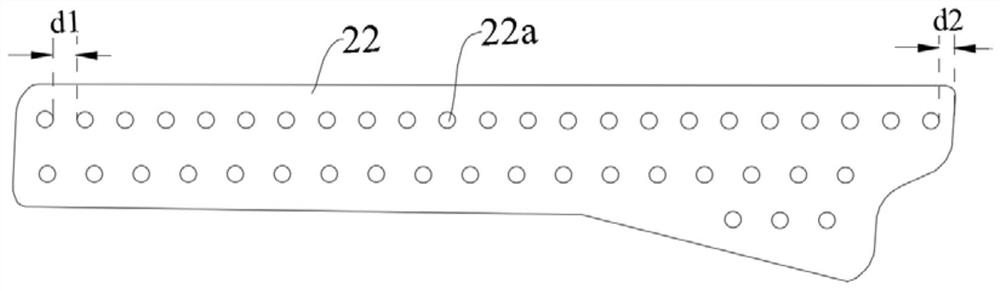

[0050] see Figure 4 , the laundry treatment device of the first embodiment of the present invention, the inner cylinder 62 is a perforated inner cylinder, the two electrode plates 22 are arranged between the outer barrel 61 and the inner cylinder 62, and the anode conductive connector 25 is far away from the anode plate 222 One end of the cathode plate 221 is located outside the outer barrel 61 , and the end of the cathode conductive connector 24 away from the cathode plate 221 is located outside the outer barrel 61 . Further, the two electrode plates 22 are arranged on the inner wall of the outer tub 61 along the height direction. In the clothes processing device of this embodiment, the density of the through holes 22a on the electrode plates 22 enables the electrode plates 22 to generate more hydroxyl radicals on the one hand. , Active chlorine and other active substances, on the other hand, fluff is not easy to block on the electrode plate 22 either.

no. 2 example

[0052] see Figure 5 , the clothes treatment equipment of the second embodiment of the present invention has most of the same structure as the above-mentioned first embodiment. The difference from the first embodiment is that in this embodiment, the two electrode plates 22 are arranged on the bottom wall of the outer tub 61 along the height direction. That is to say, the two electrode plates 22 are arranged at the lowest point of the outer tub 61, even when there is only a small amount of water in the outer tub 61, the electrode plates 22 can still contact the water in the outer tub 61.

no. 3 example

[0054] In the laundry treatment device according to the third embodiment of the present invention, the laundry treatment device has a water inlet passage communicated with the cylinder assembly 60, and the electrolysis device 2 is arranged on the water inlet passage to electrolyze the water in the water inlet passage. In the clothes processing equipment of this embodiment, the electrolysis device 2 is arranged on the water inlet channel, without using an additional water pump, regardless of whether there is water in the outer tub 61 or the inner tub 62, the electrolysis device 22 can be used normally, and the water entering the outer tub 62 can be used normally. The water in the barrel 61 or the inner cylinder 62 is electrolyzed.

[0055] It can be understood that, in the laundry treatment device of the third embodiment, the inner cylinder 62 may be a perforated inner cylinder, or may be a non-porous inner cylinder.

[0056] For an example, see Figure 12 to Figure 14 , the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com