Cleaning type heat-treatment oil smoke collecting and arranging equipment

A clean, oily fume technology, applied in external electrostatic separators, electrode structures, electrostatic separation, etc., can solve the problems of wasting energy, narrow application range, low dust removal efficiency, etc., and achieve high dust removal efficiency, wide application range, and oil fume removal. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

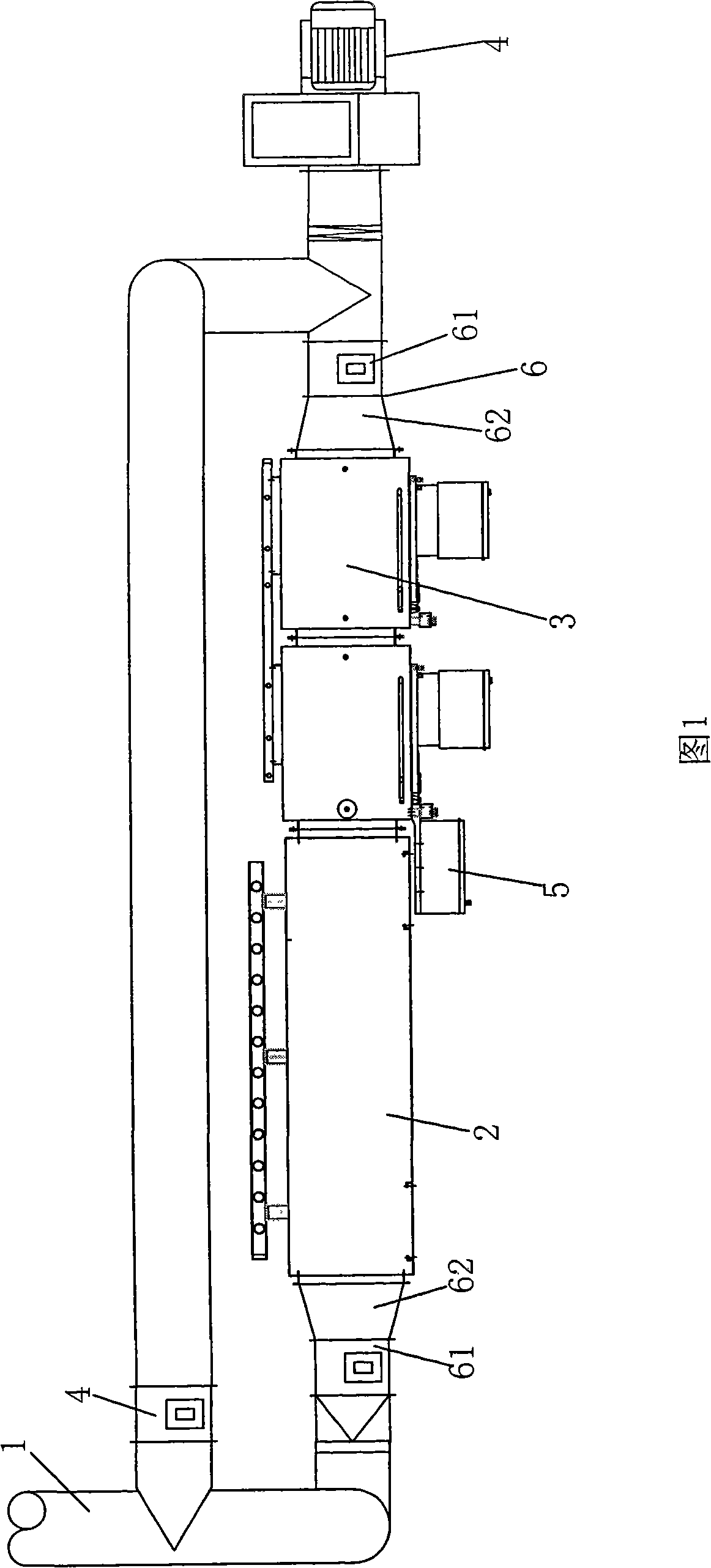

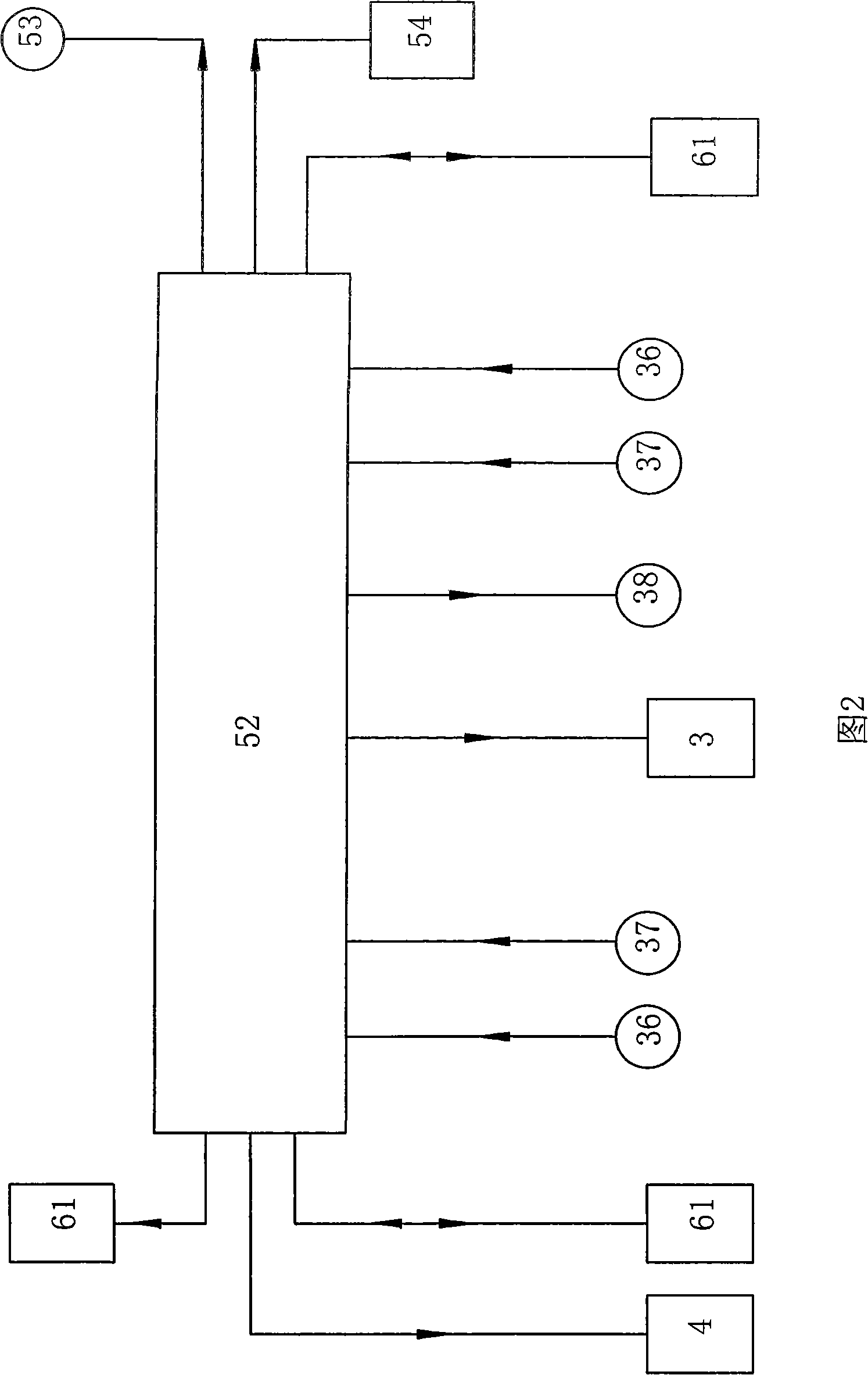

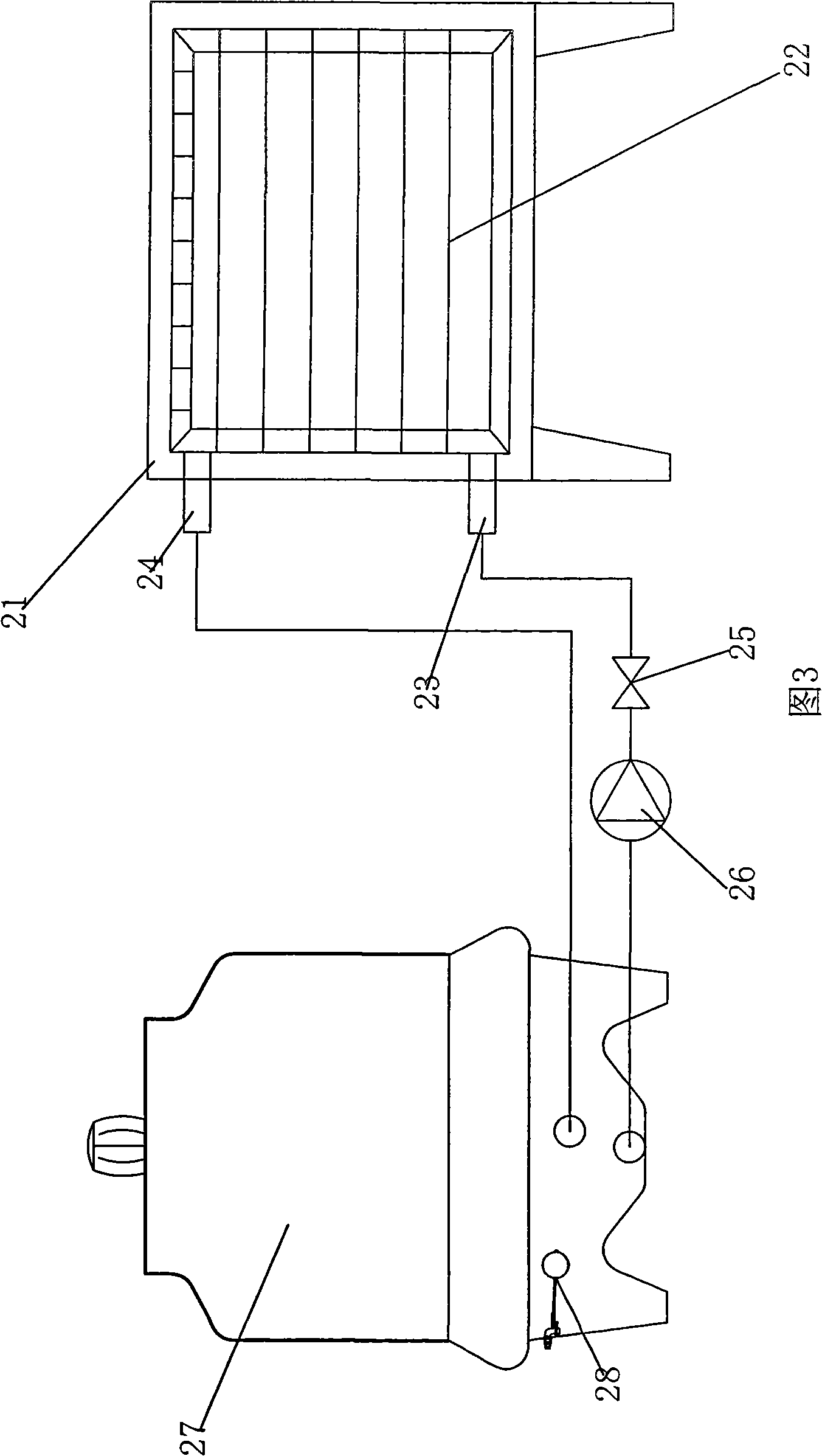

[0024] Referring to Fig. 1 and Fig. 2, this embodiment includes a fume inlet pipe 1, a heat exchange desuperheater 2, a high-voltage electrostatic degreaser 3, an exhaust fan 4 and a controller 5; the air outlet of the fume inlet pipe 1 and the heat exchange desuperheater The air inlet of 2 is connected, the heat exchange cooler 2, the high-voltage electrostatic oil fume remover 3 and the exhaust fan 4 are sequentially connected through pipelines; the controller 5 includes a PLC control circuit 52, the high-voltage electrostatic oil smoke remover 3, and the exhaust fan The signal input ends of 4 are respectively connected with the signal output ends of the PLC control circuit 52 .

[0025] In this embodiment, the air outlet of the oil fume pipe 1 is also connected to the exhaust fan 4 through a straight passage 5 with an exhaust valve, and the signal input end of the exhaust valve is connected to the signal output end of the PLC control circuit 52 . Between the fume inlet pip...

specific Embodiment 2

[0032] The characteristics of this embodiment are: the quantity of described honeycomb cylindrical electric field 32 is 1, 3, 4, 5 or 6, and one side of the casing is equipped with respectively corresponding to each honeycomb cylindrical electric field The bottom of the high-voltage solid power supply 33 and the casing are equipped with waste oil recovery pipes 34 corresponding to each honeycomb cylindrical electric field. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com