Flame-retardant polypropylene plastic and preparation method thereof

A flame retardant polypropylene, polypropylene technology, applied in the field of polypropylene plastics, can solve the problems of low tensile strength and impact resistance, unfavorable processing and production, easy to burn, etc., to increase flame retardancy and heat resistance, Low cost of raw materials and improved impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of flame-retardant polypropylene plastic, the mass percentage of its raw materials is: propylene 16%, EPDM rubber 25%, glass fiber 20%, titanium tetrachloride 10%, triethylaluminum 4%, talc Powder 10%, inorganic aluminum hydroxide flame retardant 3%, silane coupling agent 10%, antioxidant 1% and catalyst 1%.

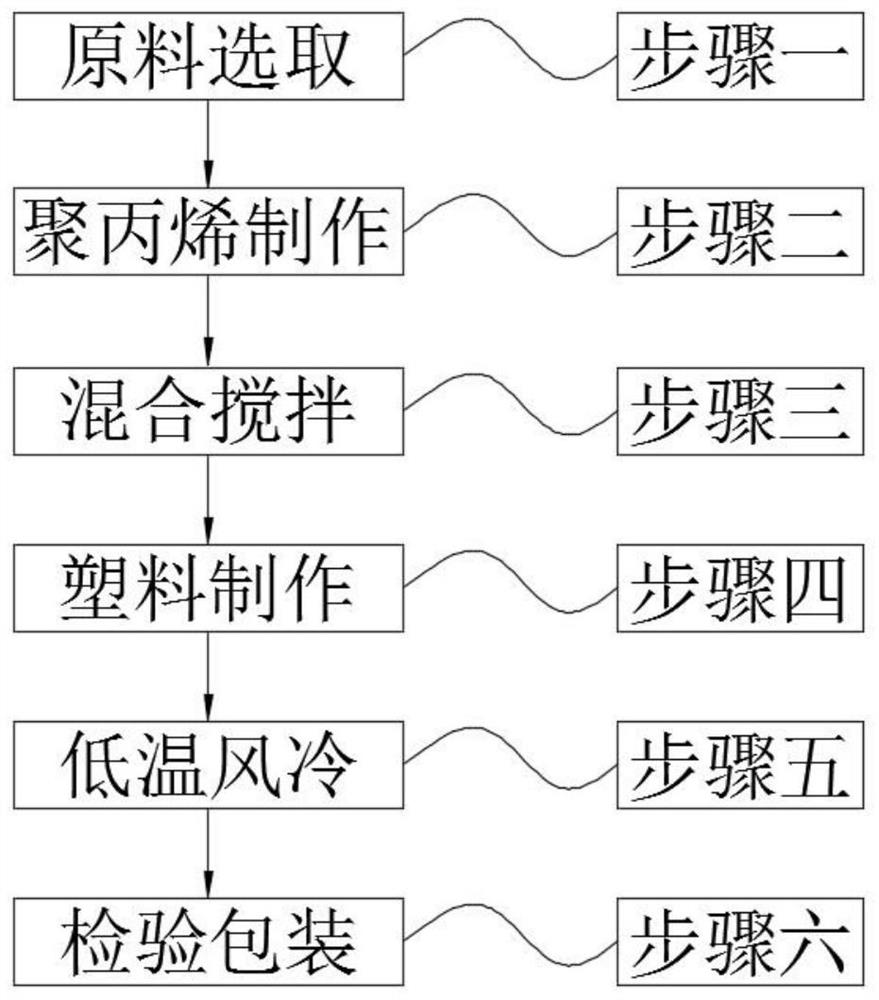

[0037] Flame-retardant polypropylene plastics are prepared by the following steps:

[0038] (1) Take raw materials according to the ratio of the above-mentioned components, wherein the volume of triethylaluminum accounts for about 1 / 3rd of the reactor capacity;

[0039] (2) Add the weighed triethylaluminum into the reactor, set the temperature at 25°C, and stir slowly for 10 minutes; then add titanium tetrachloride into the reactor, raise the temperature to 35°C, and stir slowly; keep the temperature constant change, slowly add propylene to the reactor while stirring, seal the reactor, and feed hydrogen until the solution in the reactor turns white and pro...

Embodiment 2

[0045] A flame-retardant polypropylene plastic, the mass percentage of each component of its raw materials is: 20% propylene, 22% EPDM rubber, 16% glass fiber, 14% titanium tetrachloride, 3% trichloride Ethyl aluminum, 15% talcum powder, 2% flame retardant, 7% coupling agent, 0.5% antioxidant and 0.5% catalyst.

[0046] Flame-retardant polypropylene plastics are prepared by the following steps:

[0047] (1) Take raw materials according to the ratio of the above-mentioned components, wherein the volume of triethylaluminum accounts for about 1 / 3rd of the reactor capacity;

[0048](2) Add the weighed triethylaluminum into the reaction kettle, set the temperature at 20°C, and stir slowly for 10 minutes; then add titanium tetrachloride into the reaction kettle, raise the temperature to 30°C, and stir slowly; keep the temperature constant change, slowly add propylene to the reactor while stirring, seal the reactor, and feed hydrogen until the solution in the reactor turns white and...

Embodiment 3

[0054] A kind of flame-retardant polypropylene plastic, the mass percentage of its raw material components is: 22% propylene, 26% EPDM rubber, 15% glass fiber, 16% titanium tetrachloride, 2% trichloride Ethyl aluminum, 12% talc, 1% flame retardant, 5% coupling agent, 0.5% antioxidant and 0.5% catalyst.

[0055] Flame-retardant polypropylene plastics are prepared by the following steps:

[0056] (1) Take raw materials according to the ratio of the above-mentioned components, wherein the volume of triethylaluminum accounts for about 1 / 3rd of the reactor capacity;

[0057] (2) Add the weighed triethylaluminum into the reaction kettle, set the temperature at 30°C, and stir slowly for 10 minutes; then add titanium tetrachloride into the reaction kettle, raise the temperature to 40°C, and stir slowly; keep the temperature constant change, slowly add propylene to the reactor while stirring, seal the reactor, and feed hydrogen until the solution in the reactor turns white and produce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com