Convex-angle type hobbing cutter and manufacturing method thereof

A hob and lobe technology, which is applied in the direction of manufacturing tools, gear tooth manufacturing tools, gear tooth manufacturing devices, etc., can solve the problem that the manufacturing method of lobe-type involute hobs cannot effectively guarantee SAP, Df and tooth root thickness at the same time and other problems, to achieve the effect of ensuring the bending strength of the design tooth root and the bending strength of the tooth root

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Below in conjunction with accompanying drawing and specific embodiment the content of the present invention is described in further detail:

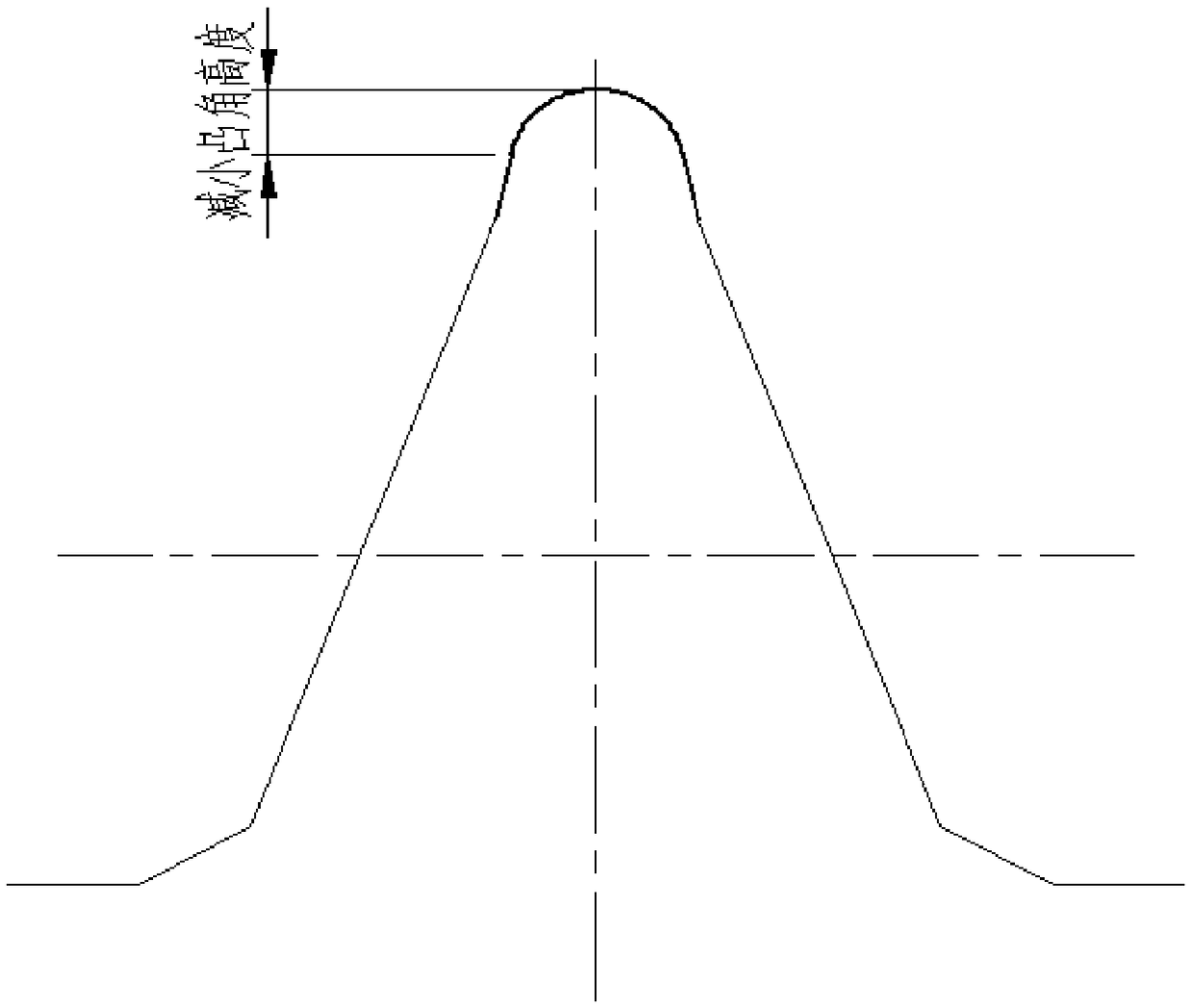

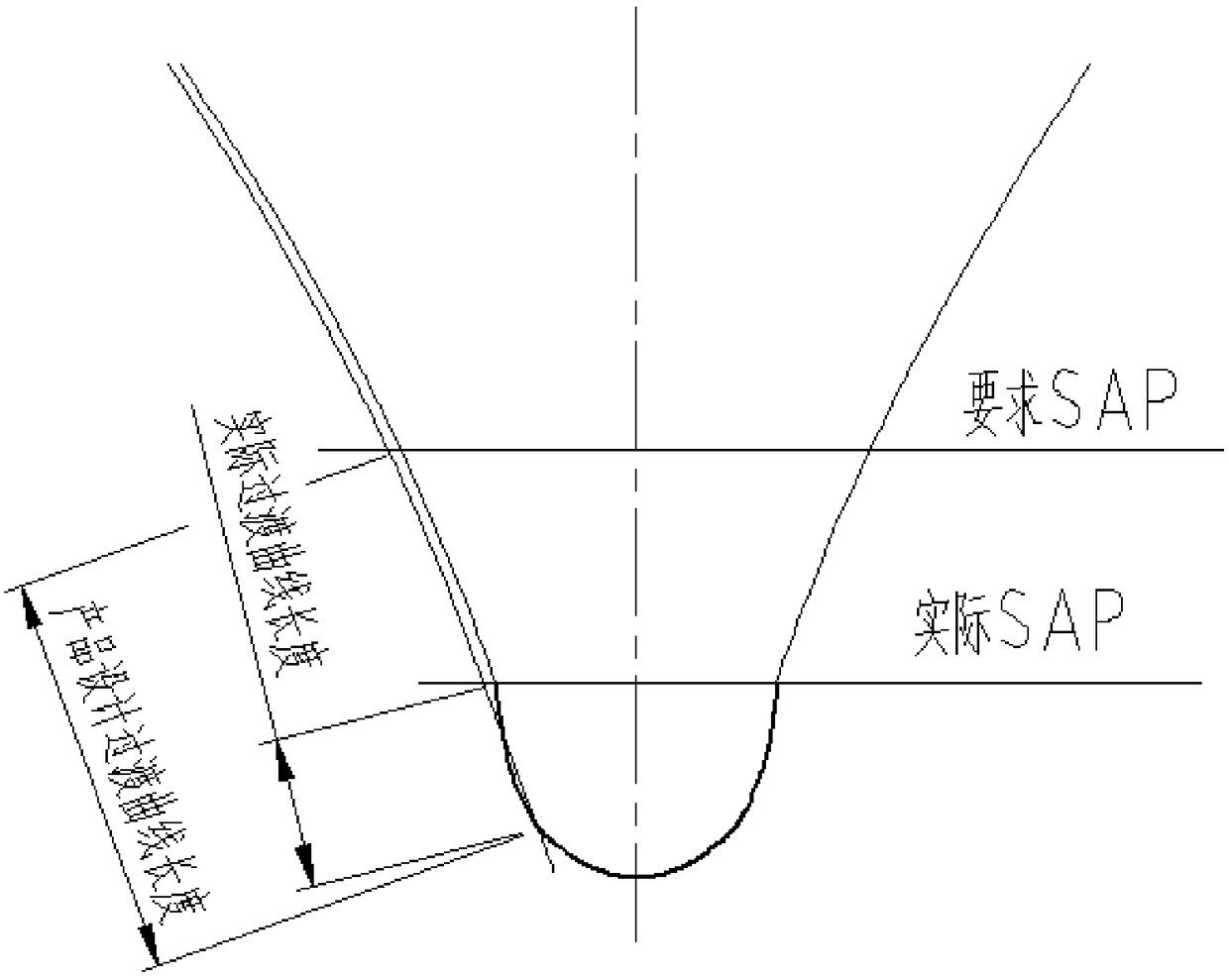

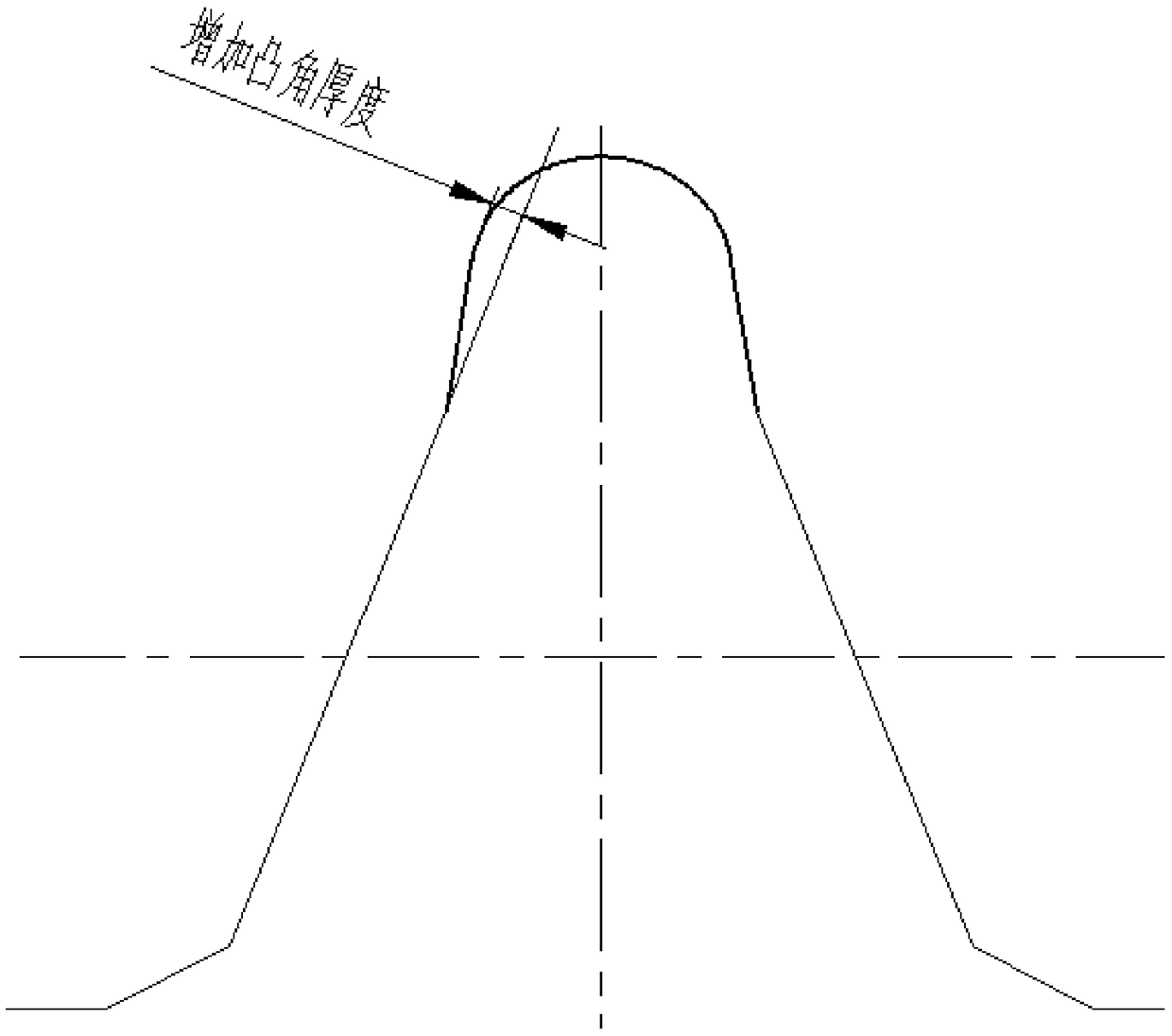

[0062] According to the generating principle of gear hobbing, the present invention adds a section of linear cutting edge parallel to the main cutting edge of the hob in the lobe structure of the hob, and completes most of the shape cutting of the transition curve by this section of straight line. The product processed by this kind of hob structure can keep the SAP, Df and tooth root thickness required by the gear design at the same time, and does not reduce the transition curve length of the product, so as to ensure that the tooth root bending strength of the gear does not decrease.

[0063] The upper end of the added straight cutting edge is tangent to the arc of the addendum, and the lower end extends to the position corresponding to the starting circle of the hobbing involute required by the product. Using this type of hob can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com