A plate bending limit device for commercial kitchen

A technology of limiting device and kitchen, which is applied in the field of sheet metal processing to achieve the effects of high efficiency, improved work efficiency and simple mechanism structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

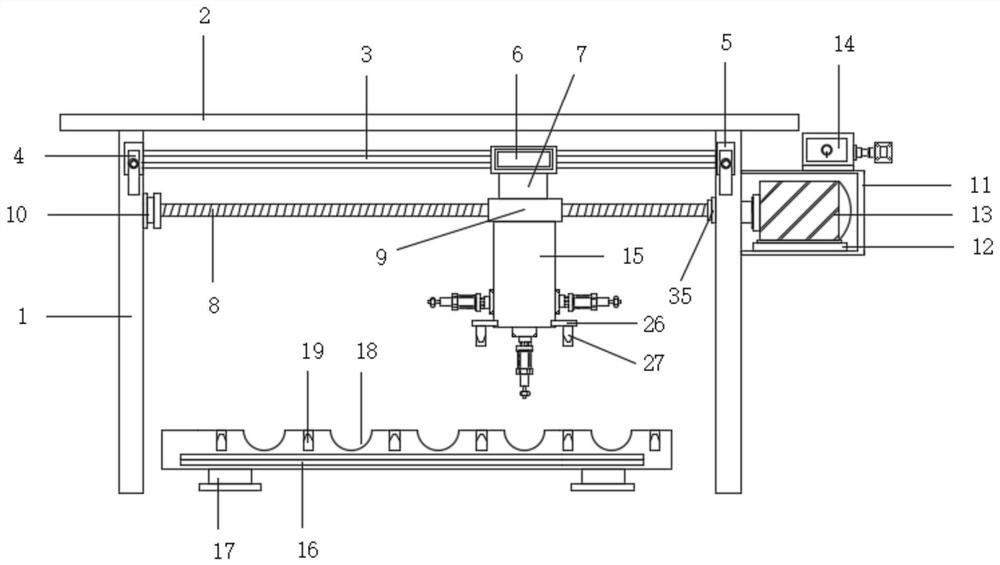

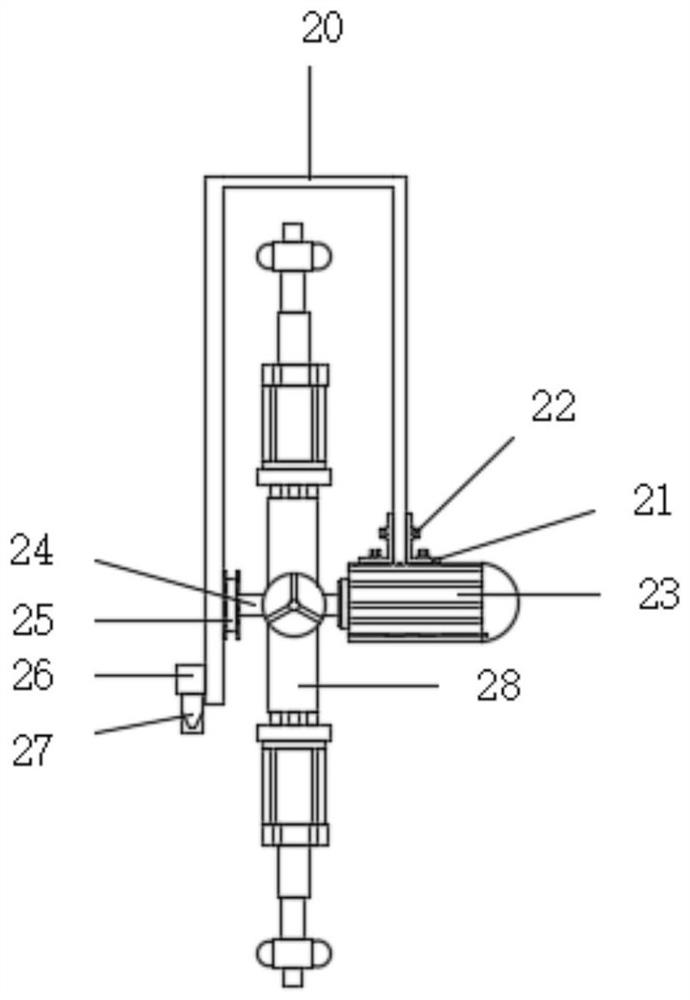

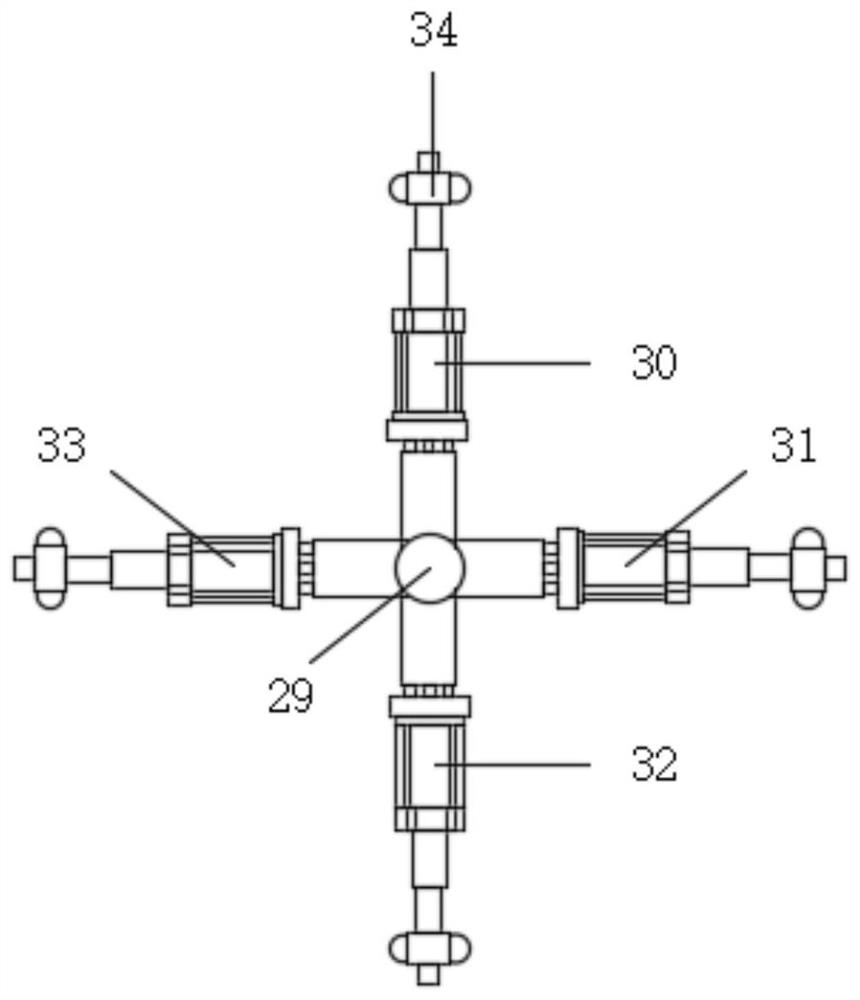

[0019] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: a plate bending and limiting device for commercial kitchens, including a bracket 1 and a bottom plate 16, the lower end of the bottom plate 16 is connected with load-bearing blocks 17 around, and the upper end of the bottom plate 16 is uniform There are several grooves 18, No. 1 inductors 19 are arranged between the grooves 18 and on the base plate 16, brackets 1 are arranged on both sides of the base plate 16, and the upper end of the bracket 1 is fixedly connected with a horizontal plate 2, A linear guide rail 3 is provided below the horizontal plate 2, both ends of the linear guide rail 3 are fixedly connected to the inner walls on both sides of the support 1, and one end of the linear guide rail 3 is fixedly connected to a No. 1 limit stopper 4, and the linear guide rail 3 3 The other end of the No. 1 limit block 4 is fixedly connected with the No. 2 limit block 5, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com