Bumper reinforcement and bumper device for vehicle

A bumper reinforcement and vehicle technology, applied in the field of bumper devices, can solve the problems of increased man-hours and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

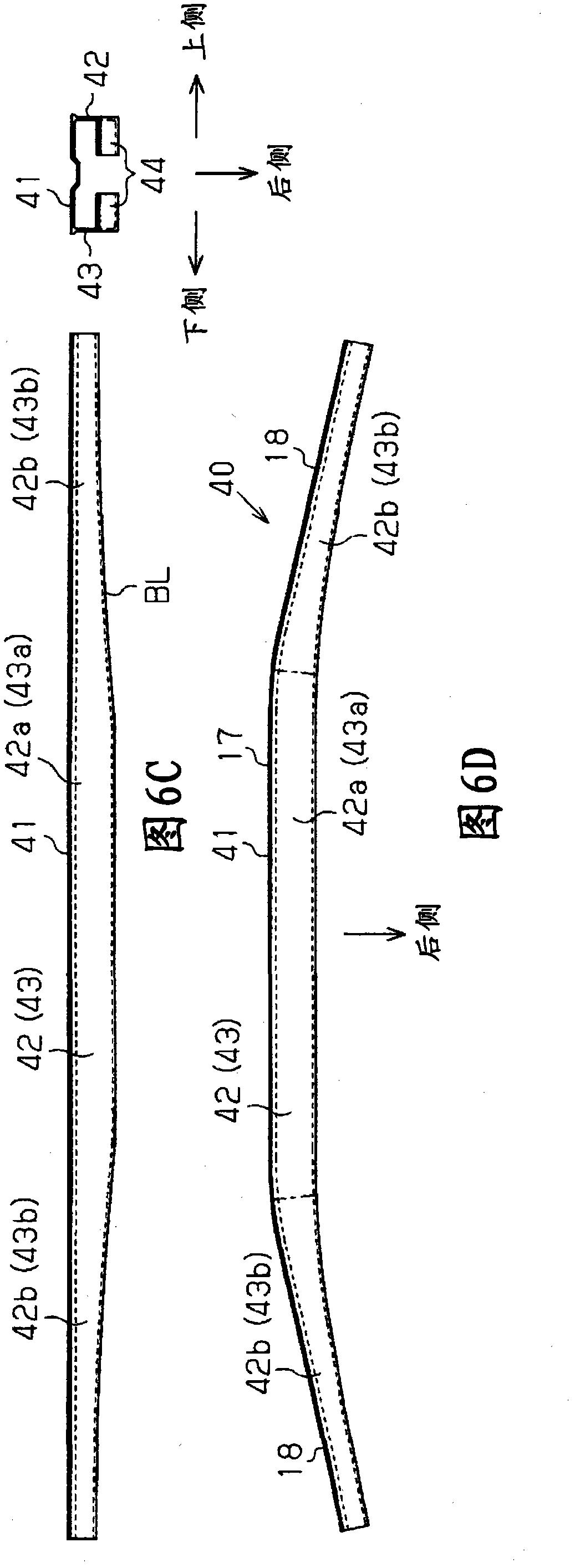

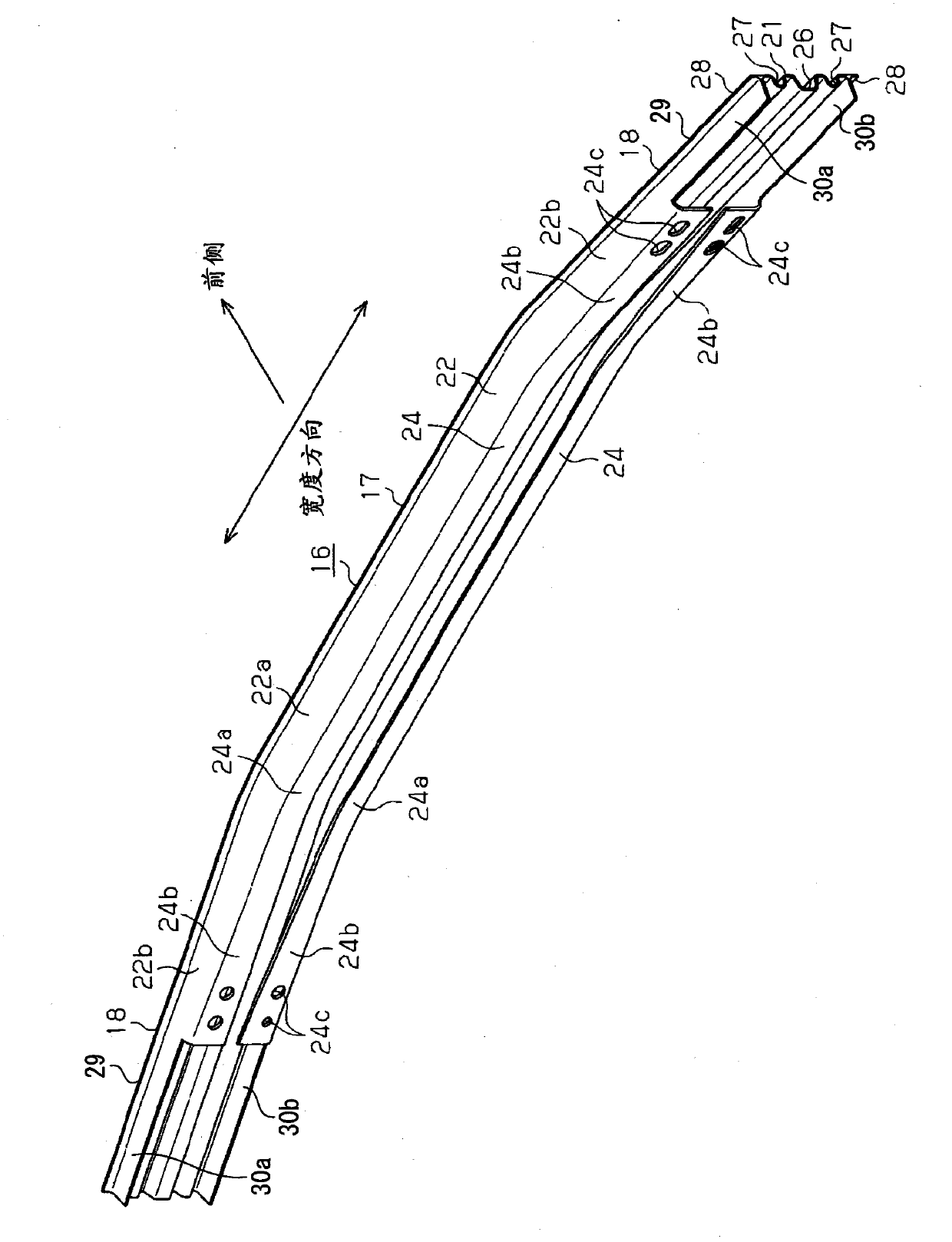

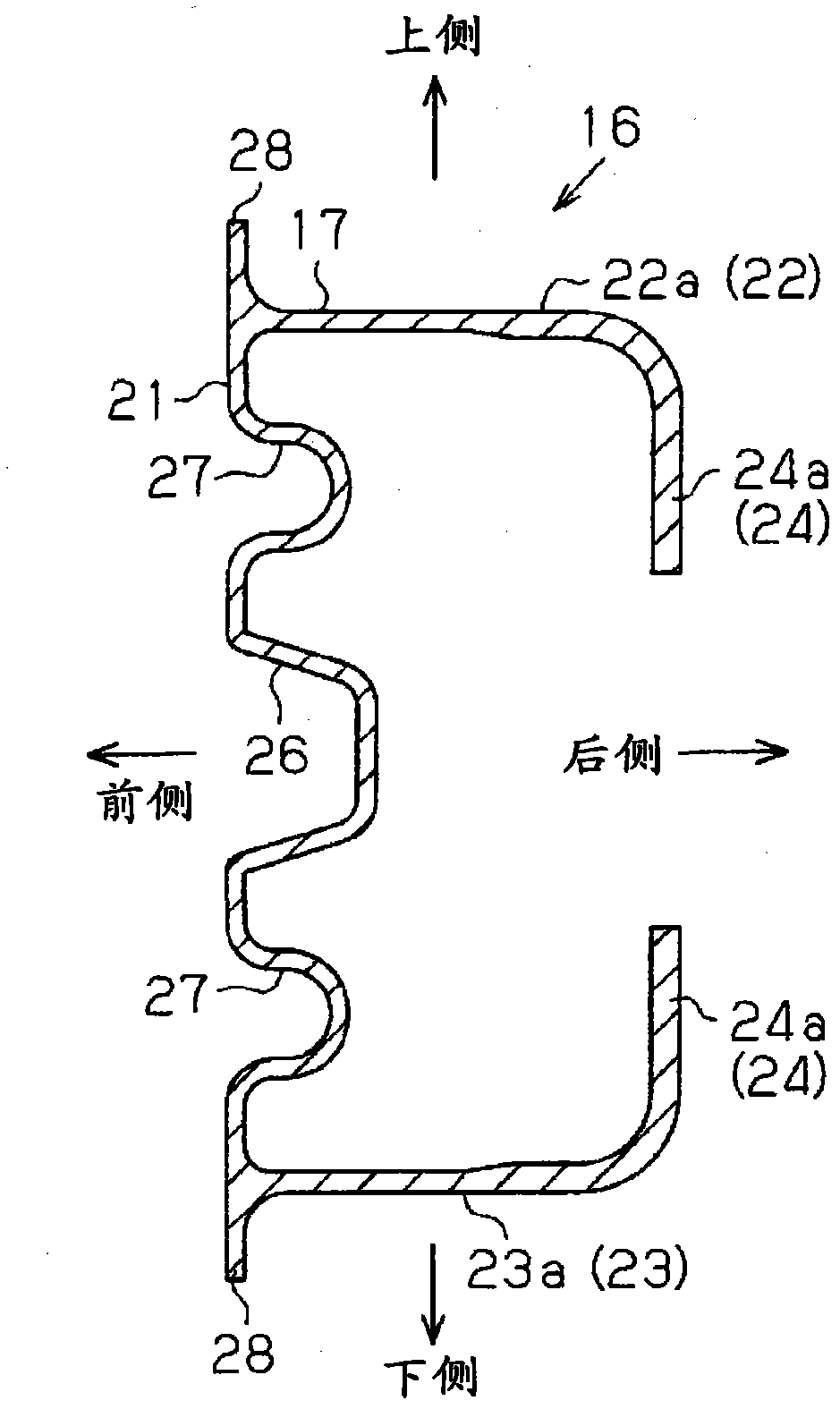

[0031] A first embodiment of the present disclosure will be described below with reference to the description of the drawings. exist image 3 A plan view of is showing a bumper device for a vehicle such as an automobile according to the first embodiment. Such as image 3 As shown, a pair of side members 11 made of, for example, a metal plate and extending in the longitudinal direction of the vehicle are arranged in the width direction of the vehicle. Each of the side members 11 corresponds to a hollow member having a cross-section of a substantially rectangular shape. The pair of side members 11 constitute a part of the vehicle body. Brackets 12 are welded to corresponding front ends of side members 11 to close corresponding openings of side members 11 . Each of the brackets 12 made of, for example, a metal plate is formed in a substantially rectangular shape.

[0032] A pair of smash boxes 13 are attached to respective front surfaces of brackets 12 welded to side members...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com