High-fluidity and high-toughness ASA material and preparation method thereof

A high-fluidity, high-toughness technology, applied in the field of engineering plastics, can solve the problems of large reduction in mechanical properties, limitations, and insufficient impact resistance, so as to ensure tensile strength and bending strength, reduce the use of additives, and improve fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

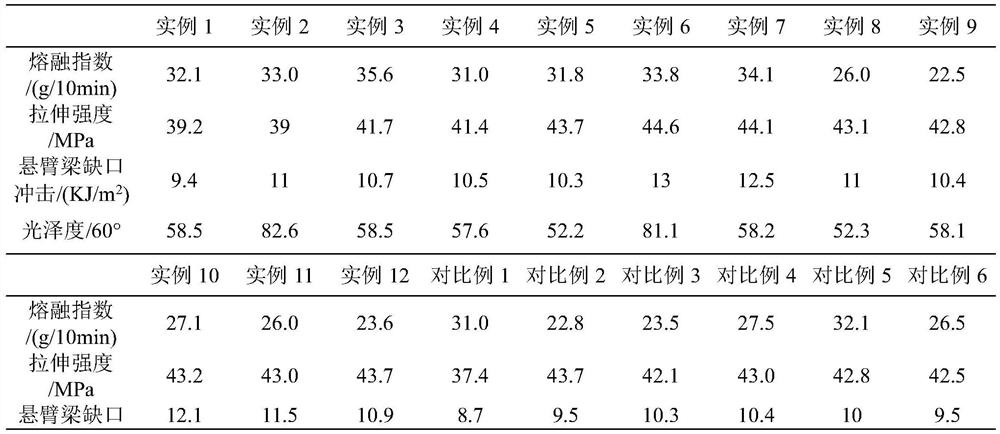

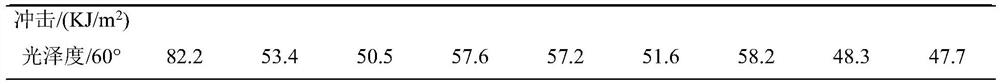

Examples

preparation example Construction

[0057] The present invention also provides a preparation method of ASA material with high fluidity and high toughness, comprising the following steps:

[0058] S1: Add high-rigidity resin, high-flow resin, small particle size ASA powder, and large particle size ASA powder in proportion to the high-speed mixer for preliminary mixing. The mixing speed of the mixer is 60r / min, and the mixture is mixed The time is 2-4 minutes. Through the visual inspection of personnel, observe whether the materials are mixed evenly; when mixing and stirring, the mixer can be placed in a lower temperature environment to avoid the aging of raw materials due to the increase in equipment temperature;

[0059] S2: Add matting powder, main antioxidant, auxiliary antioxidant, light stabilizer, ultraviolet absorber, lubricant and pigment to the materials mixed in step S1 in proportion to blend; the stirring speed during mixing is 60r / min, stirring and mixing time is 2-4 minutes; through the visual inspec...

Embodiment 1

[0064] An ASA material with high fluidity and high toughness, which consists of the following materials in parts by mass:

[0065] High-rigid resin: 8 parts;

[0066] High flow resin: 48 parts;

[0067] Small particle size ASA powder: 32 parts;

[0068] Large particle size ASA powder: 8 parts;

[0069] Matting powder: 2 parts;

[0070] Main antioxidant: 0.2 part;

[0071] Secondary antioxidant: 0.3 parts;

[0072] Light stabilizer: 0.5 parts;

[0073] UV absorber: 0.5 parts;

[0074] Lubricant: 0.5 parts.

[0075] The embodiment of the present invention provides the preparation method of the high-fluidity, high-toughness ASA material, comprising the following steps:

[0076] S1: Add high-rigidity resin, high-flow resin, small particle size ASA powder, and large particle size ASA powder in proportion to the high-speed mixer and perform preliminary mixing. The mixing speed of the mixer is 60r / min, stirring and mixing The time is 2-4 minutes;

[0077] S2: Add matting po...

Embodiment 2

[0080] The preparation method and steps are consistent with Example 1, except that:

[0081] An ASA material with high fluidity and high toughness, which consists of the following materials in parts by mass:

[0082] High-rigid resin: 10 parts;

[0083] High flow resin: 48 parts;

[0084] Small particle size ASA powder: 28 parts;

[0085] Large particle size ASA powder: 12 parts;

[0086] Matting powder: 0 parts;

[0087] Main antioxidant: 0.2 parts;

[0088] Secondary antioxidant: 0.3 parts;

[0089] Light stabilizer: 0.5 parts;

[0090] UV absorber: 0.5 parts;

[0091] Lubricant: 0.5 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com