Commercial vehicle gear box three-speed gear induction quenching process

A three-speed gear and induction hardening technology, which is applied to the improvement of process efficiency, manufacturing tools, furnace types, etc., can solve the problems of no induction hardening technology, etc., and achieve the elimination of oil hole crack tendency, productivity improvement, and reasonable structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

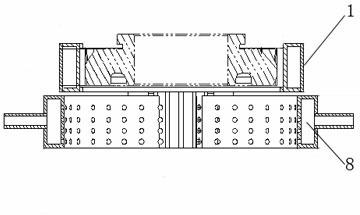

[0014] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings, induction hardening technical requirements, induction heating and quenching sequence design of three parts and induction hardening process of each part:

[0015] 1. Design of gear materials and induction hardening technical requirements

[0016] Selected material: 45# medium carbon steel

[0017] Original tissue state: normalizing HBW157~197

[0018] Surface hardness: HRc56~62

[0019] Hardened layer depth 1.0~2.2

[0020] Effective hardened layer depth limit value HV450

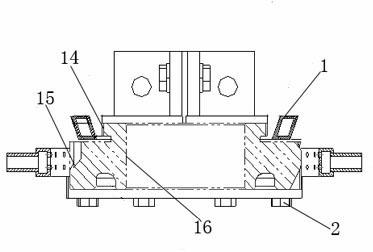

[0021] According to the actual service conditions of the gear parts, the induction hardening parts are designed to be three places, namely the meshing teeth 15, the coupling teeth 14 and the bearing holes 16 (such as figure 1 shown).

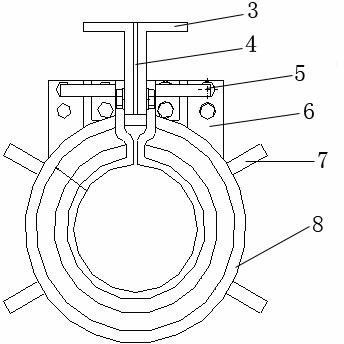

[0022] 2. The quenching sequence design of the meshing teeth, coupling teeth and bearing holes

[0023] Due to the short distance be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com