Patents

Literature

212 results about "Productivity gain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

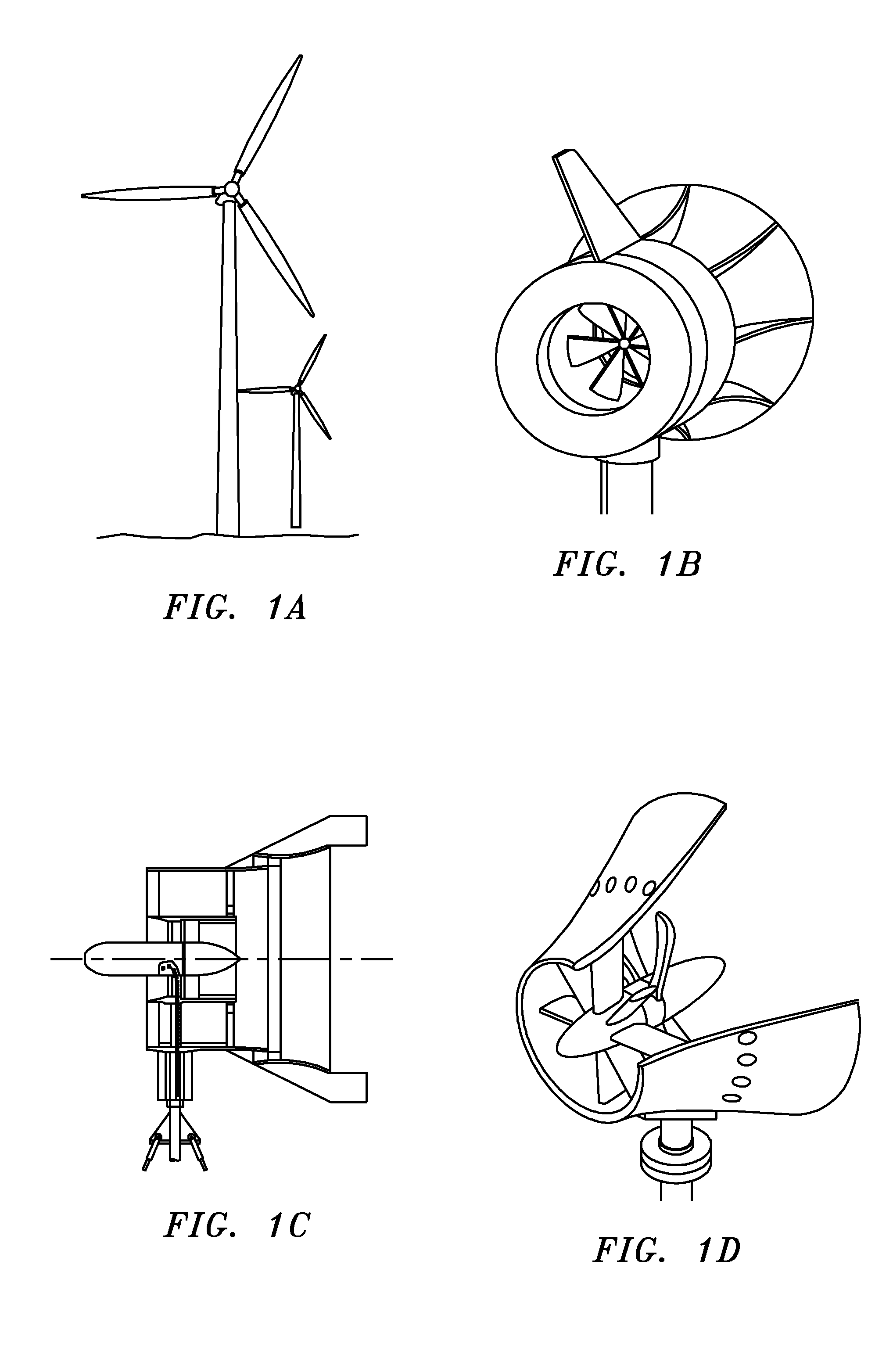

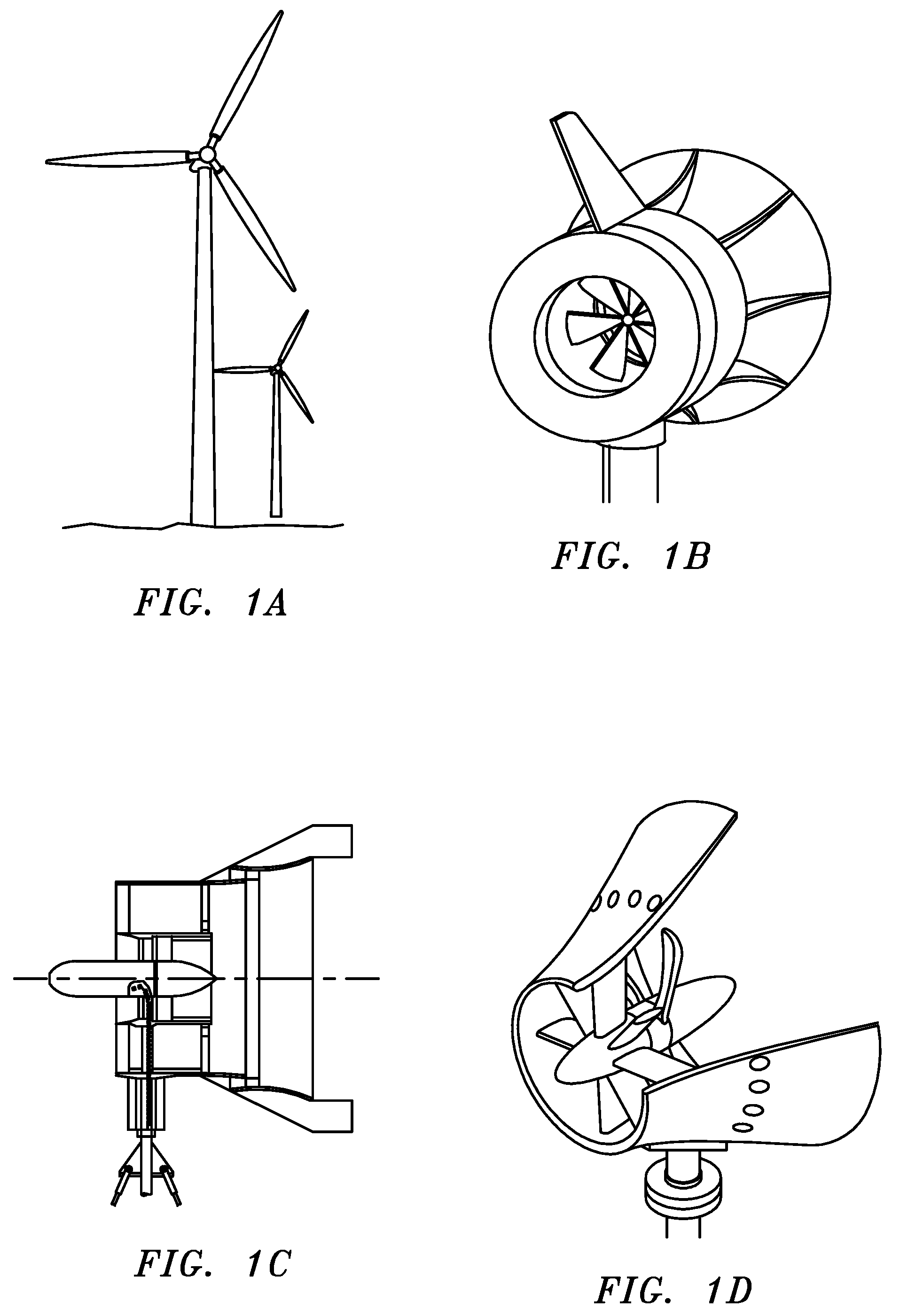

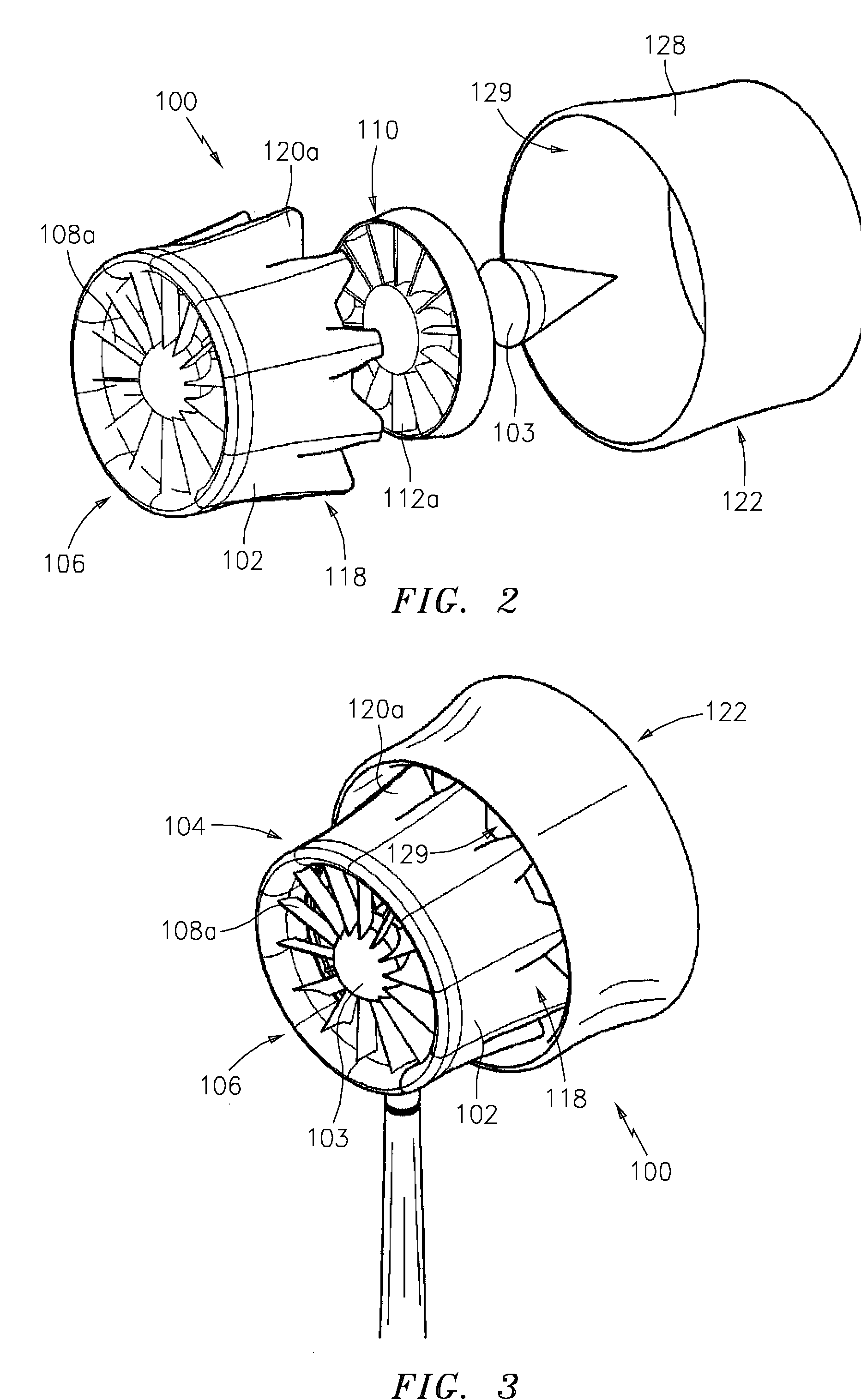

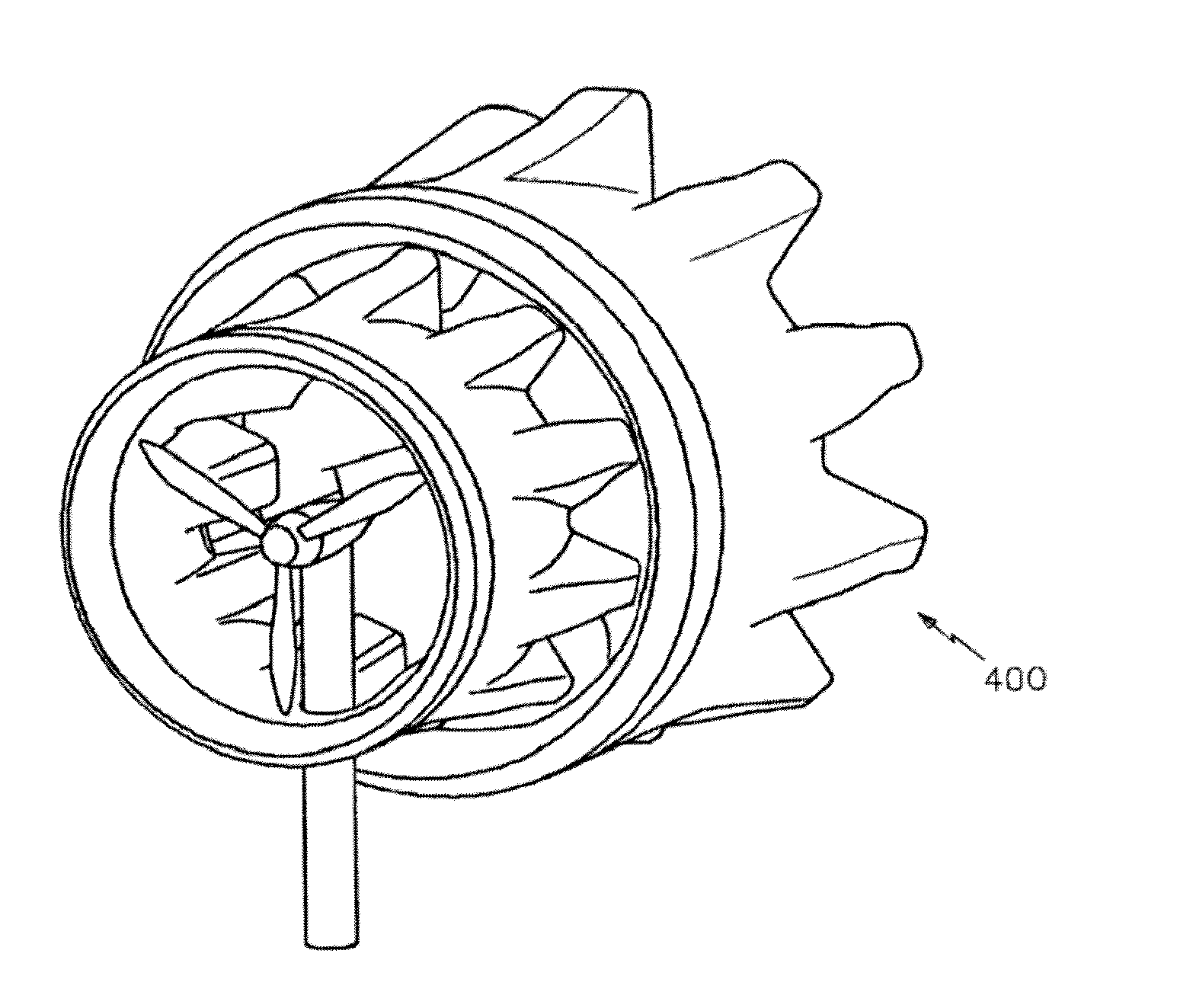

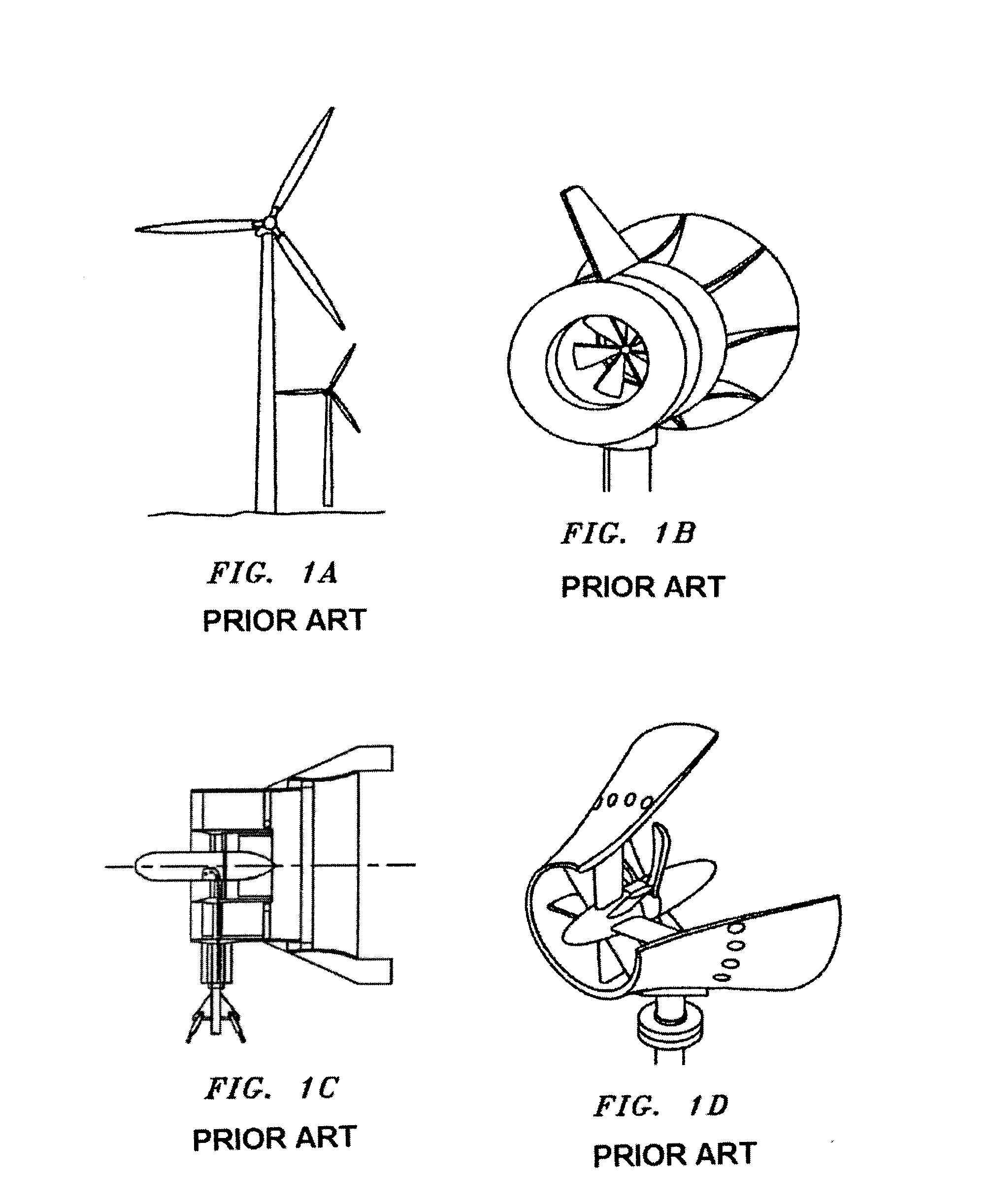

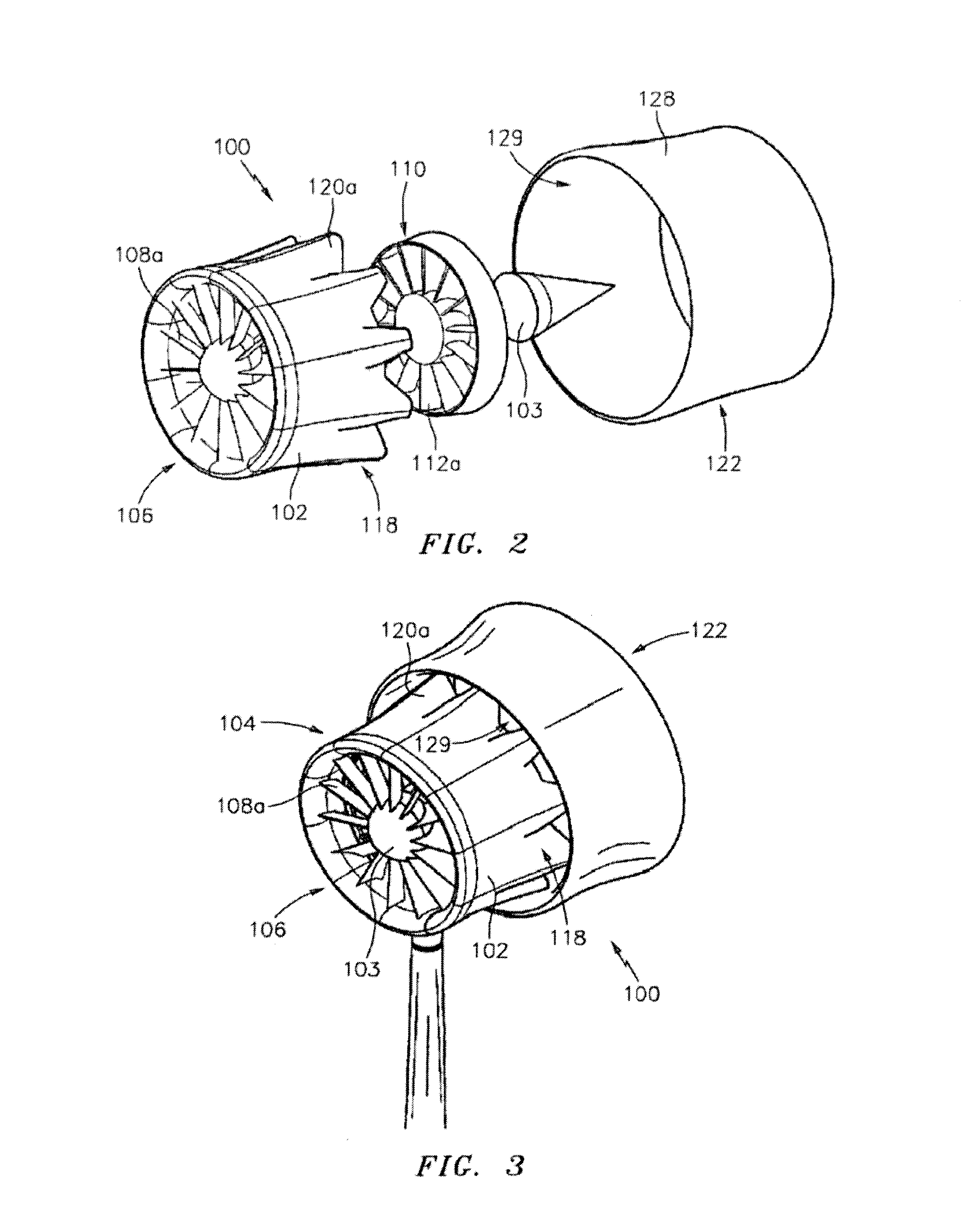

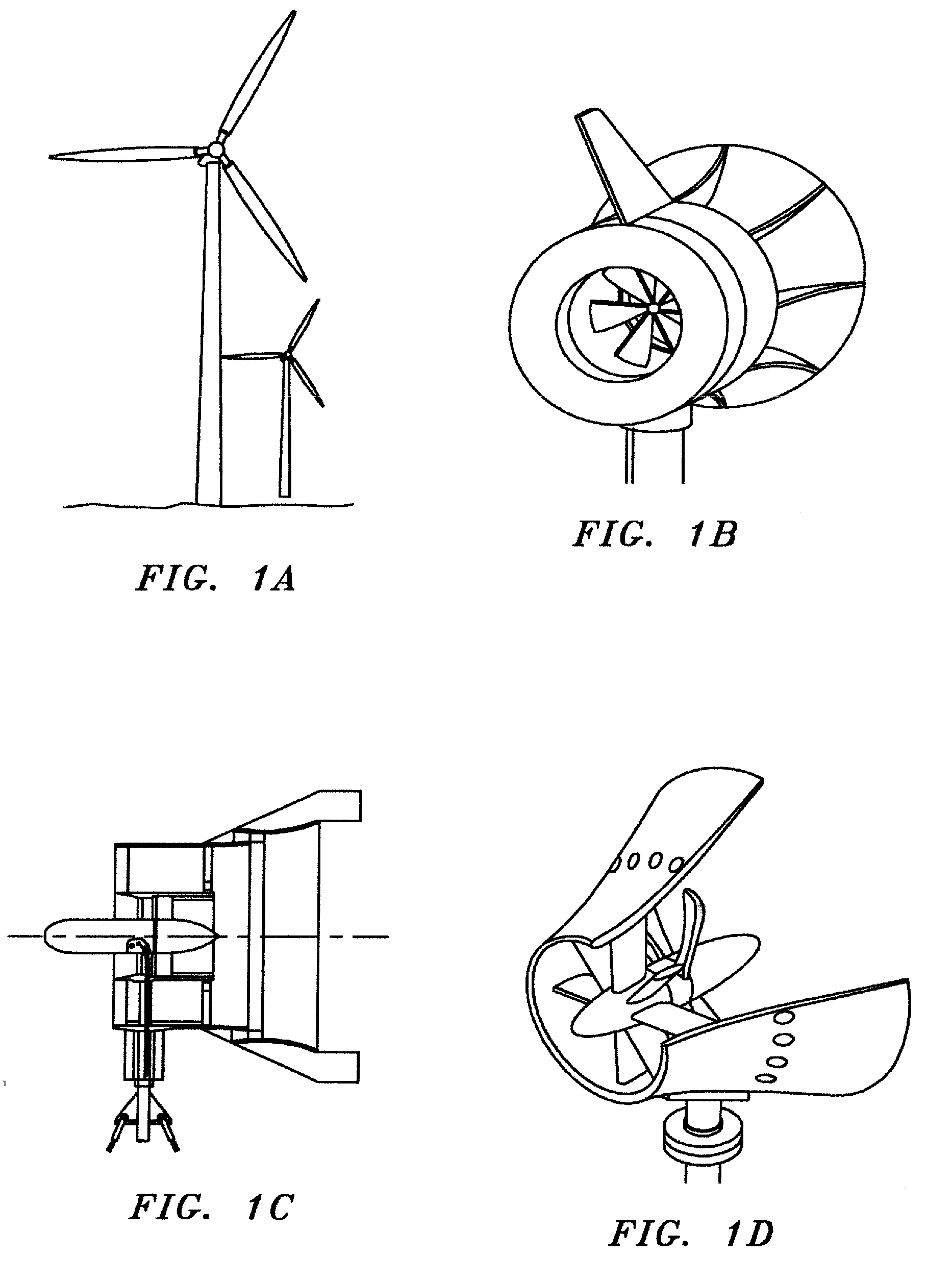

Wind turbine with mixers and ejectors

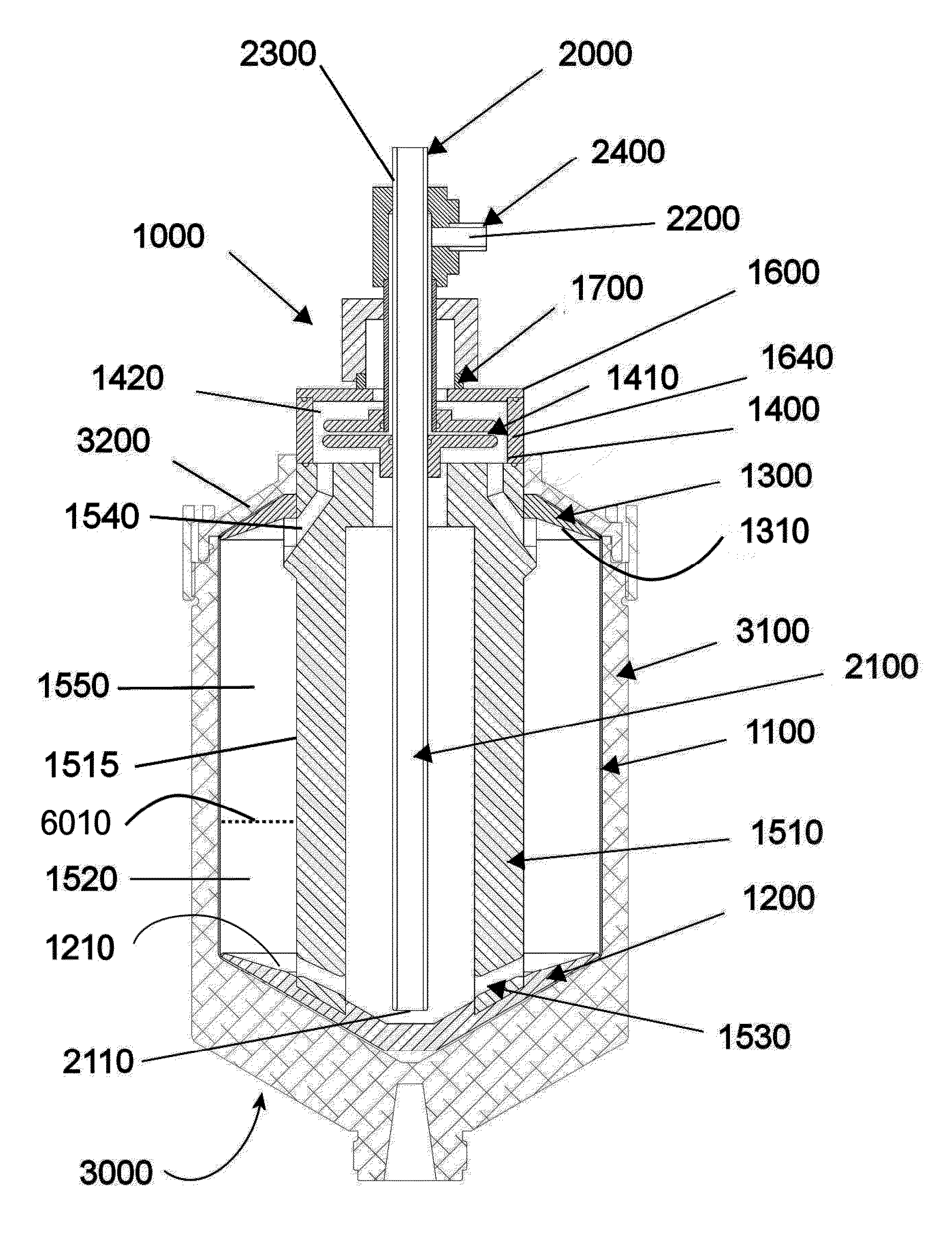

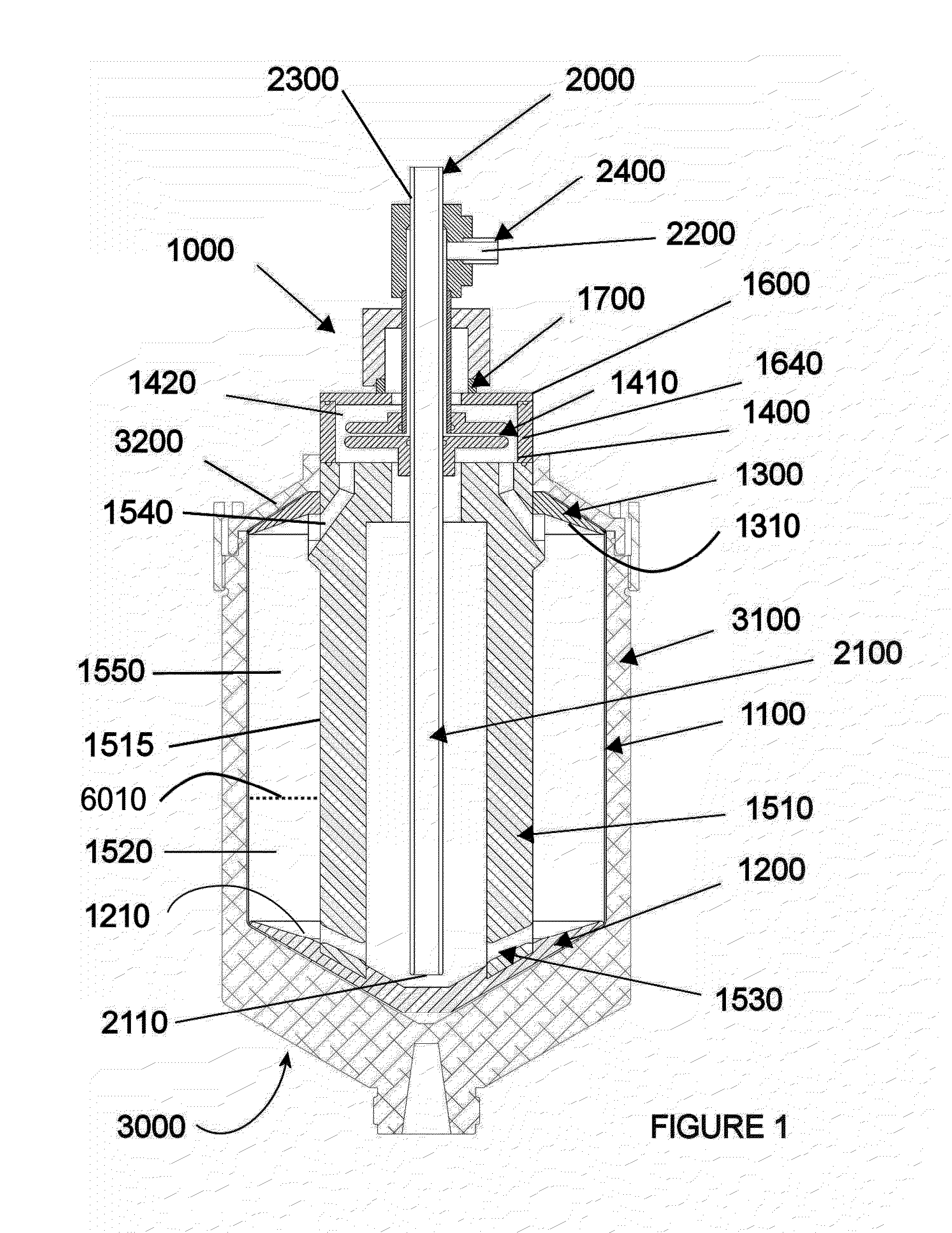

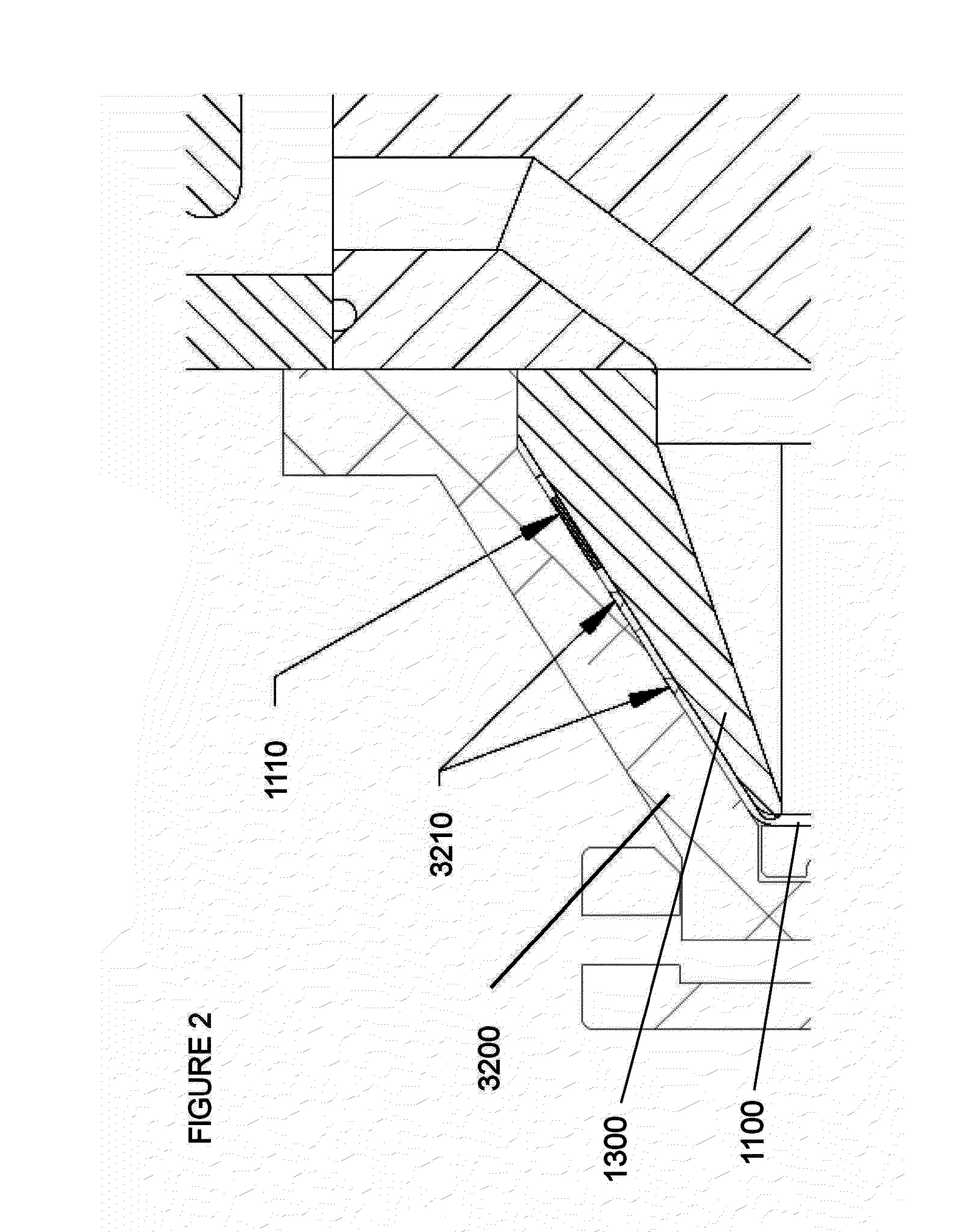

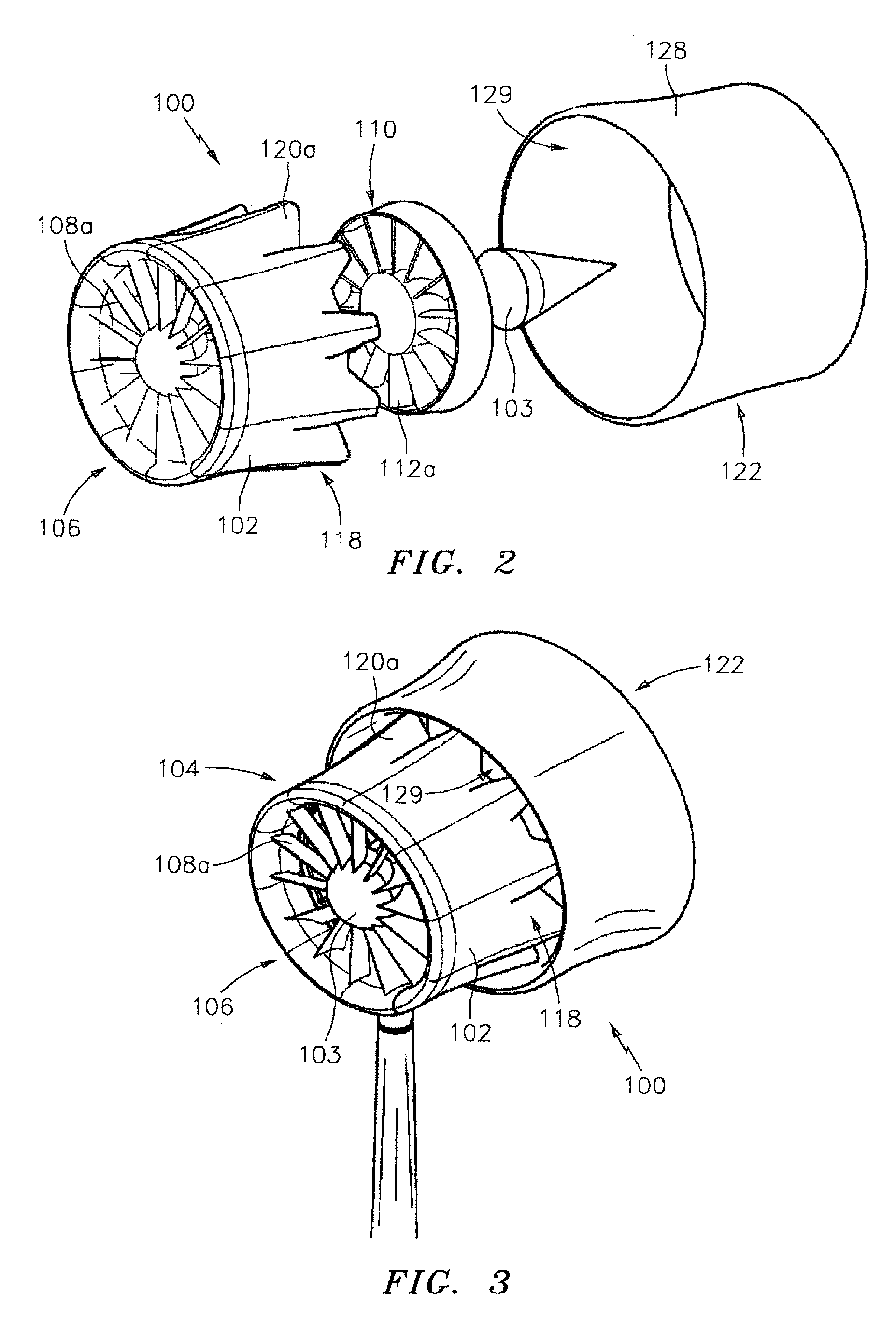

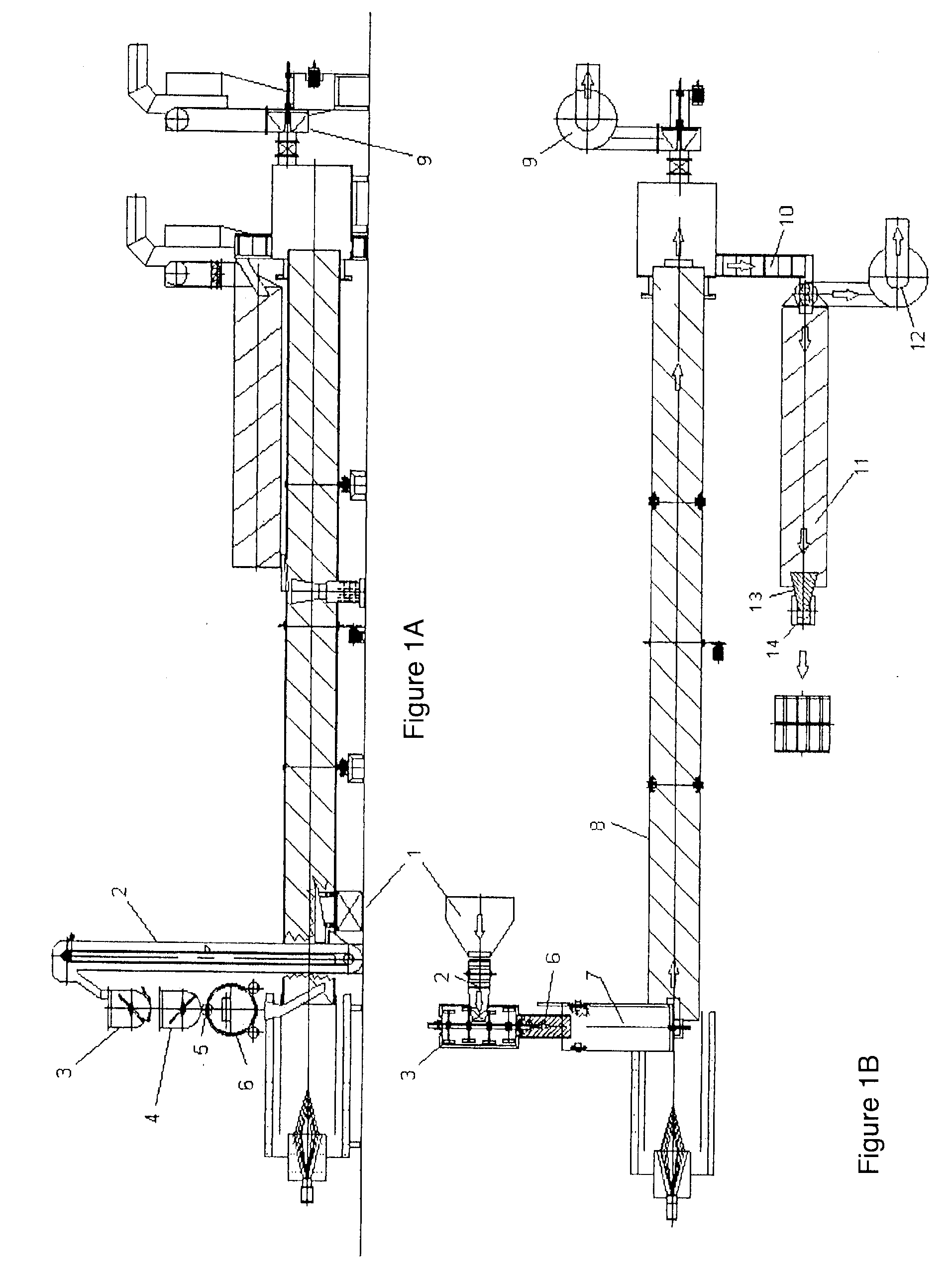

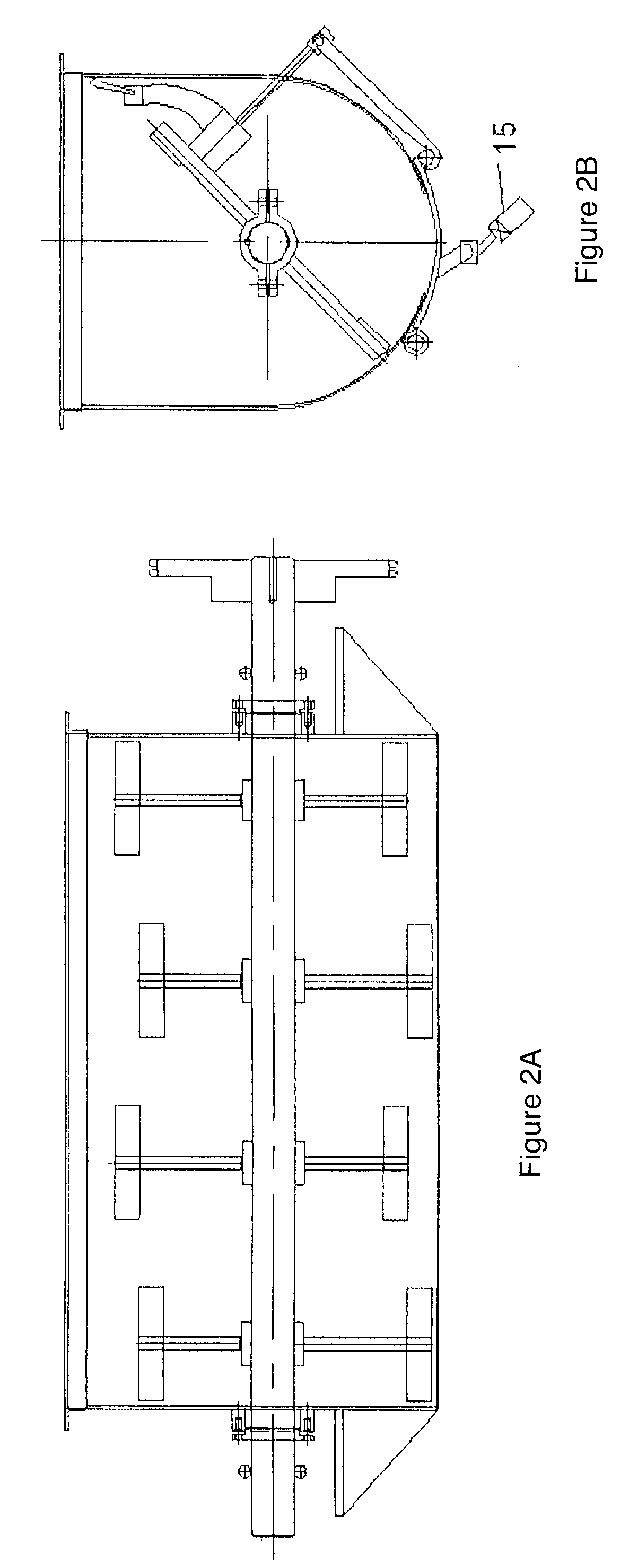

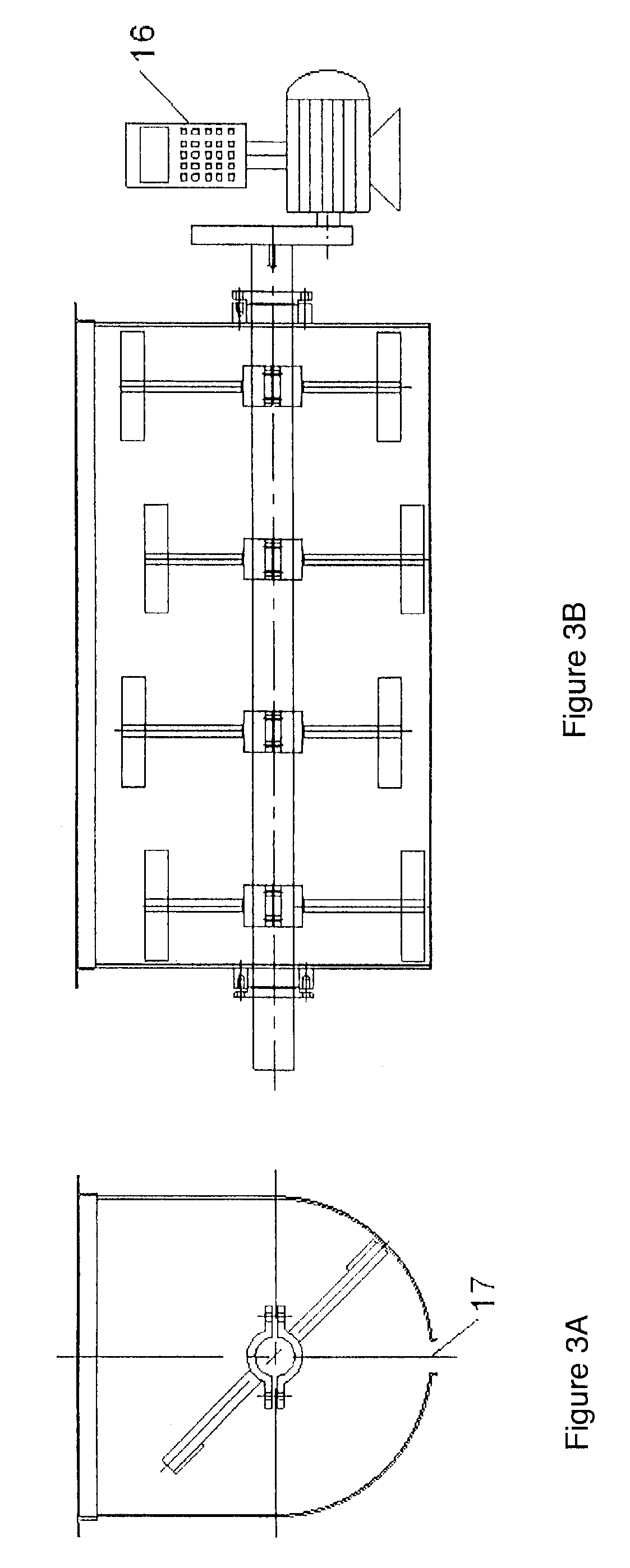

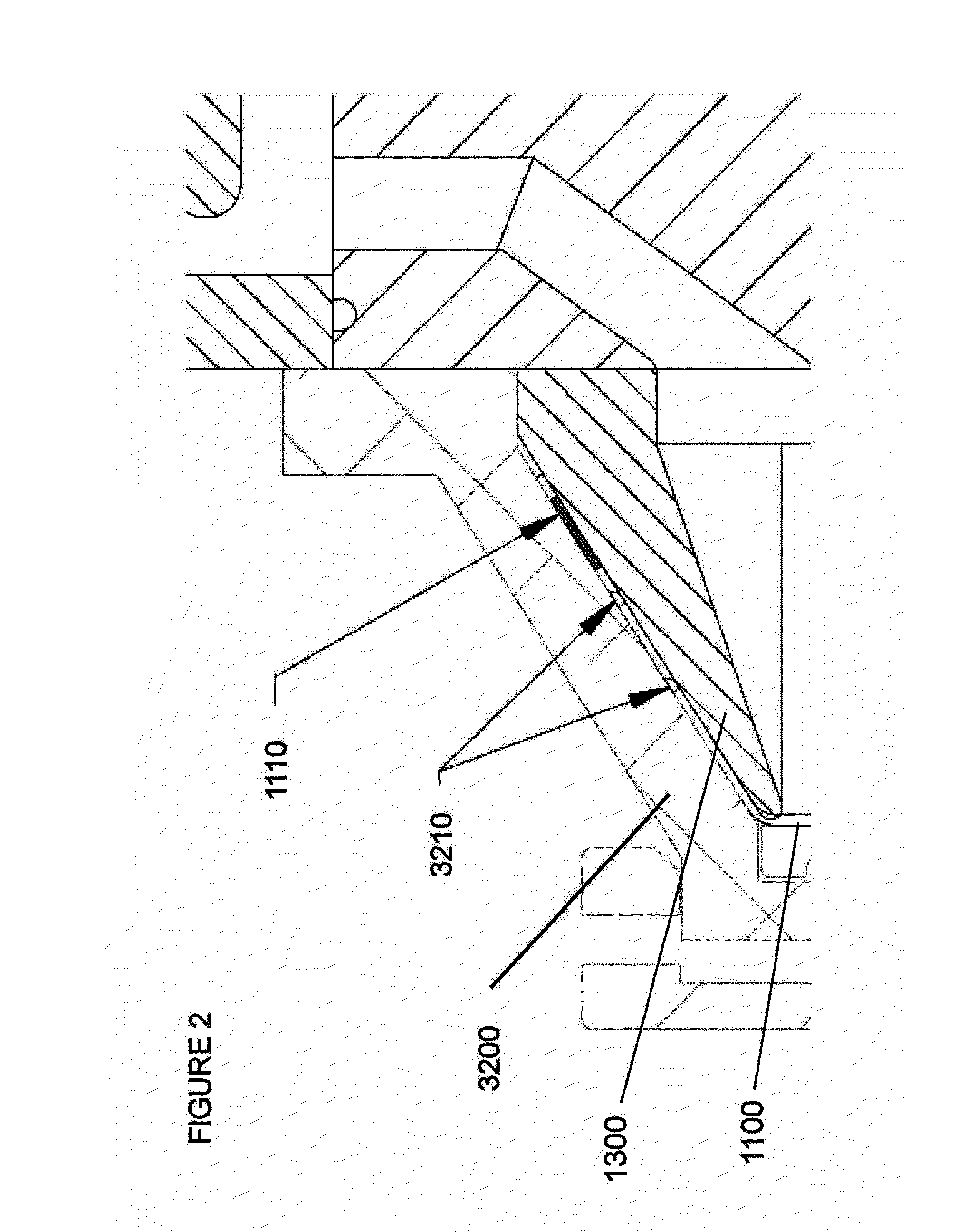

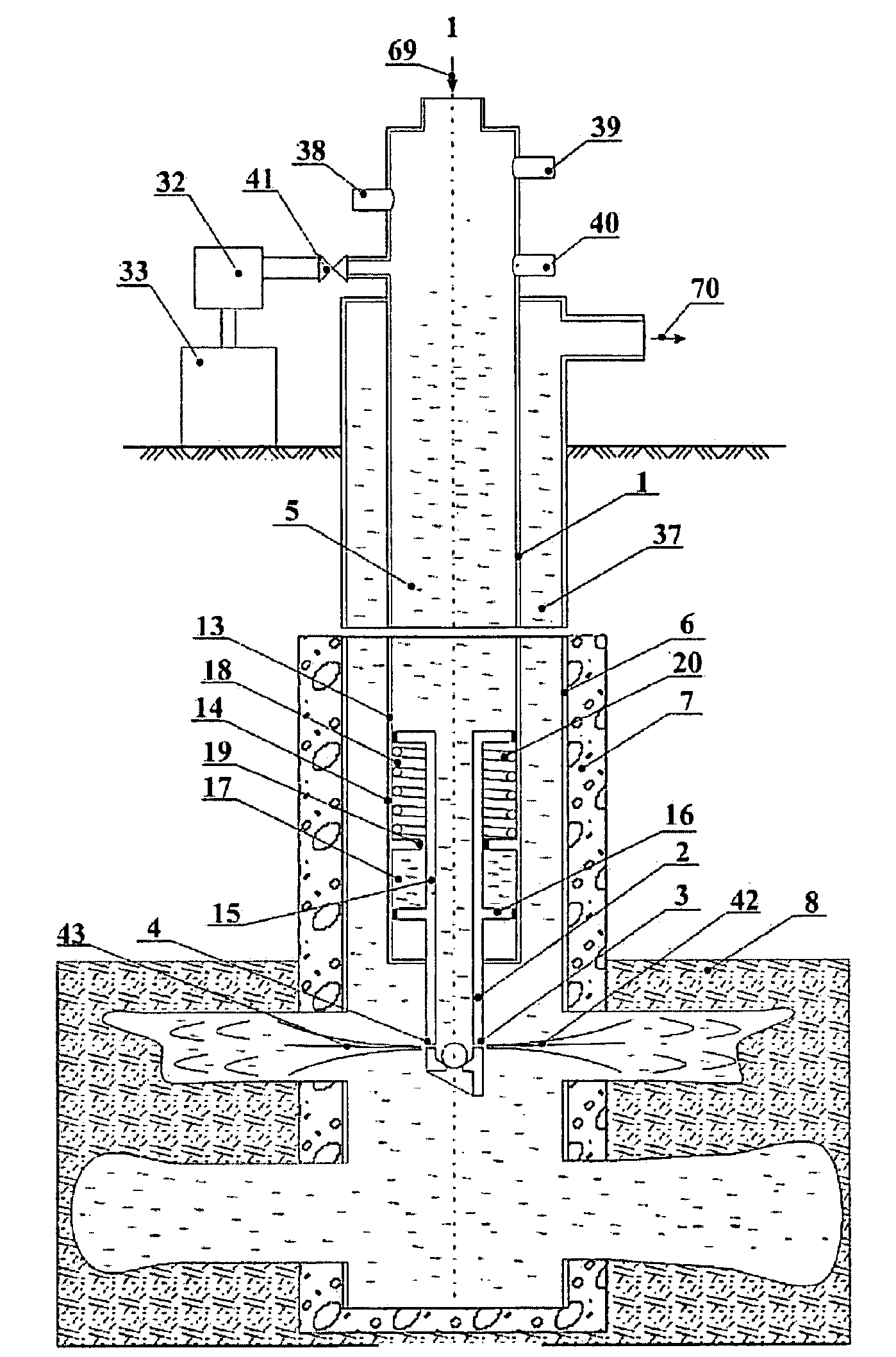

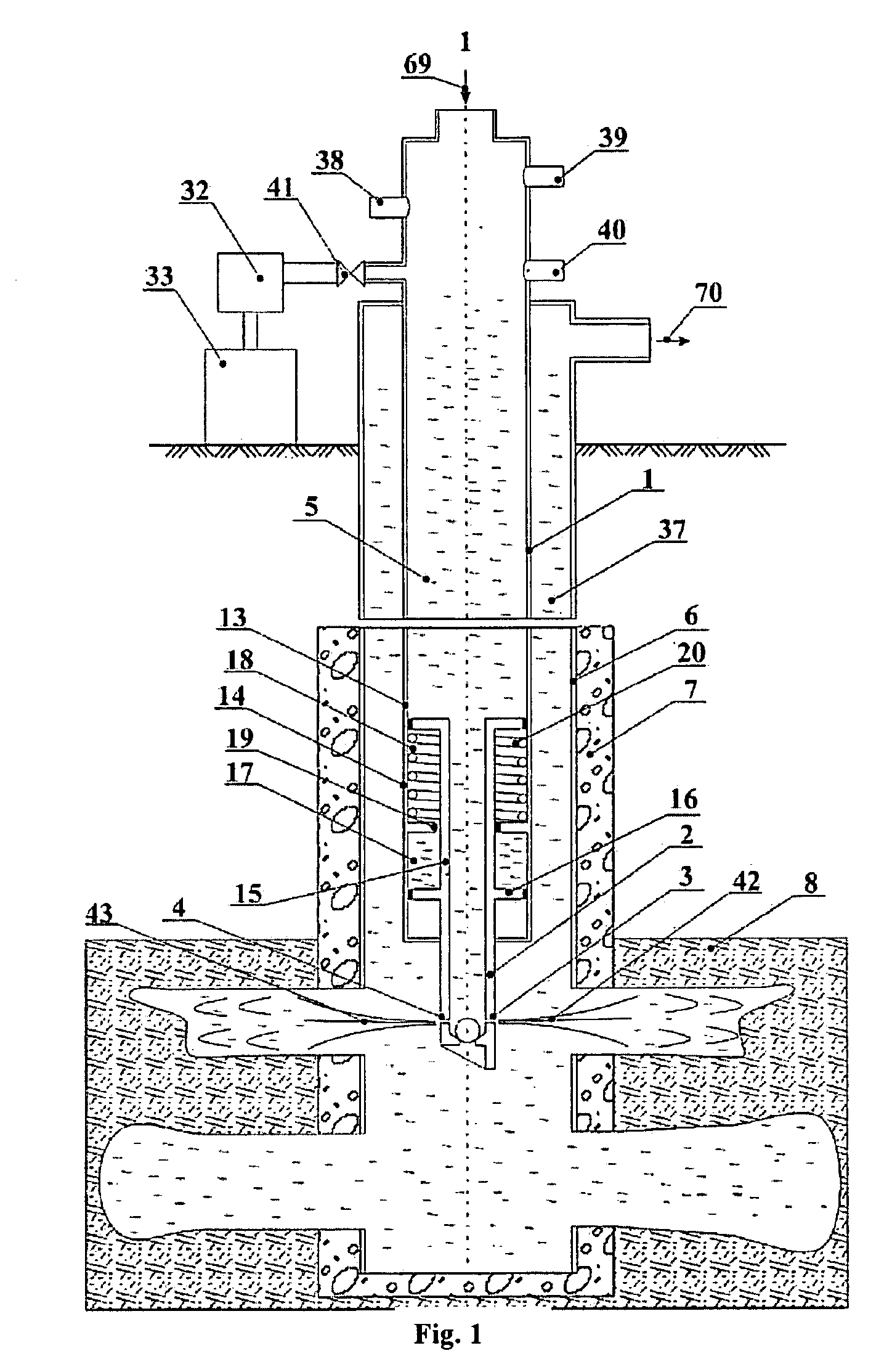

A Mixer / Ejector Wind Turbine (“MEWT”) system is disclosed which routinely exceeds the efficiencies of prior wind turbines. In the preferred embodiment, Applicants' MEWT incorporates advanced flow mixing technology, single and multi-stage ejector technology, aircraft and propulsion aerodynamics and noise abatement technologies in a unique manner to fluid-dynamically improve the operational effectiveness and efficiency of wind turbines, so that its operating efficiency routinely exceeds the Betz limit. Applicants' preferred MEWT embodiment comprises: an aerodynamically contoured turbine shroud with an inlet; a ring of stator vanes; a ring of rotating blades (i.e., an impeller) in line with the stator vanes; and a mixer / ejector pump to increase the flow volume through the turbine while rapidly mixing the low energy turbine exit flow with high energy bypass wind flow. The MEWT can produce three or more time the power of its un-shrouded counterparts for the same frontal area, and can increase the productivity of wind farms by a factor of two or more. The same MEWT is safer and quieter providing improved wind turbine options for populated areas.

Owner:FLODESIGN WIND TURBINE

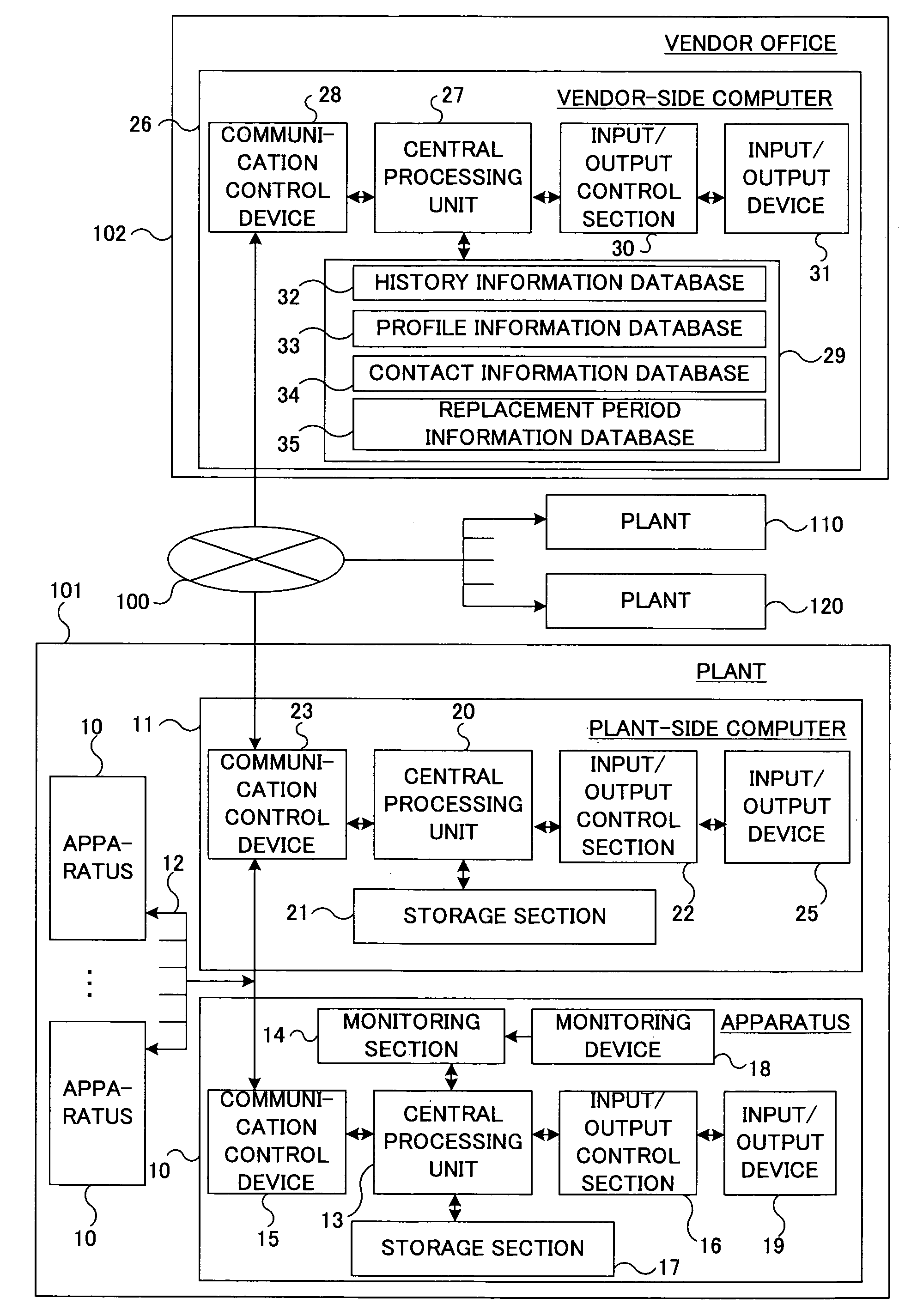

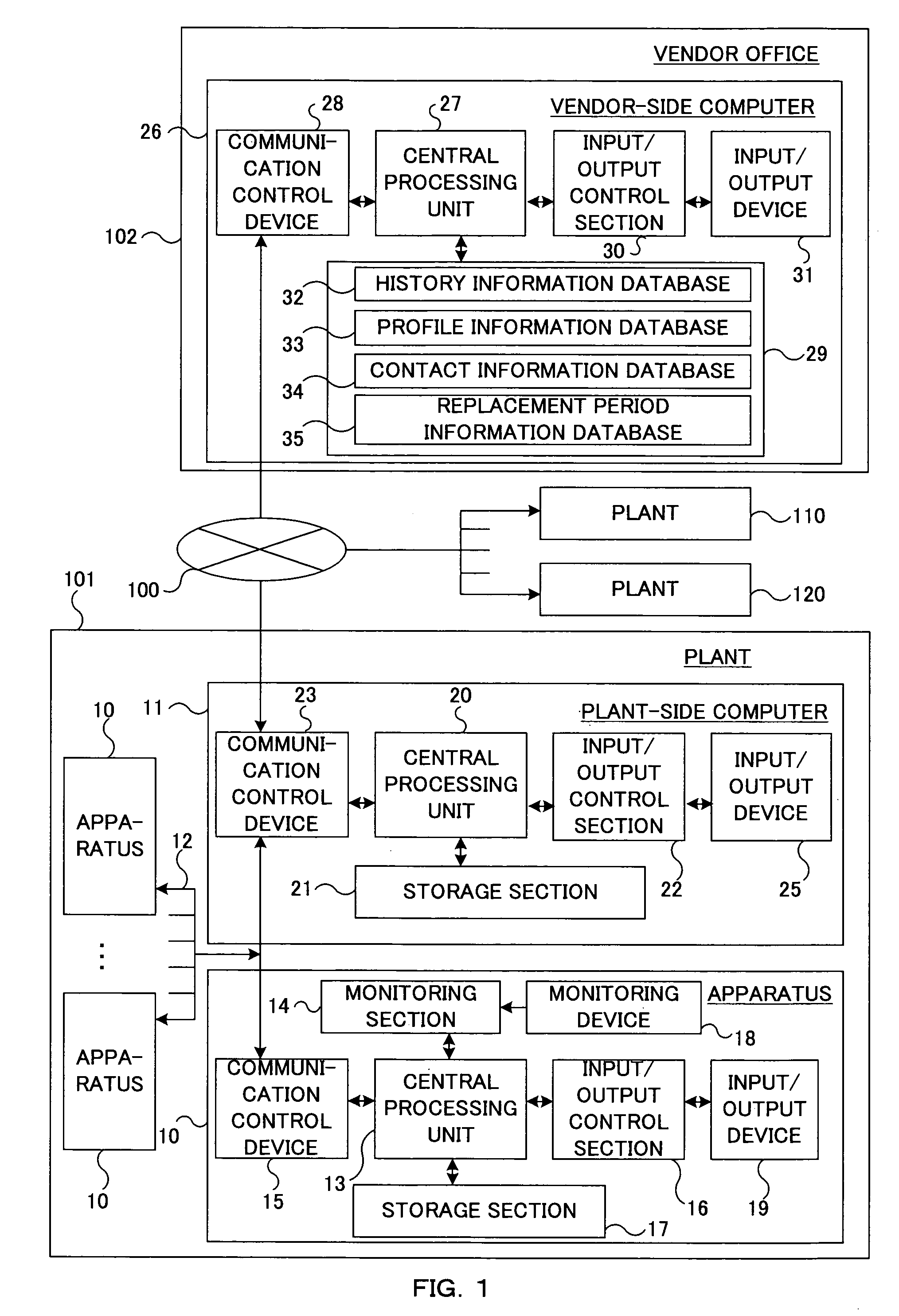

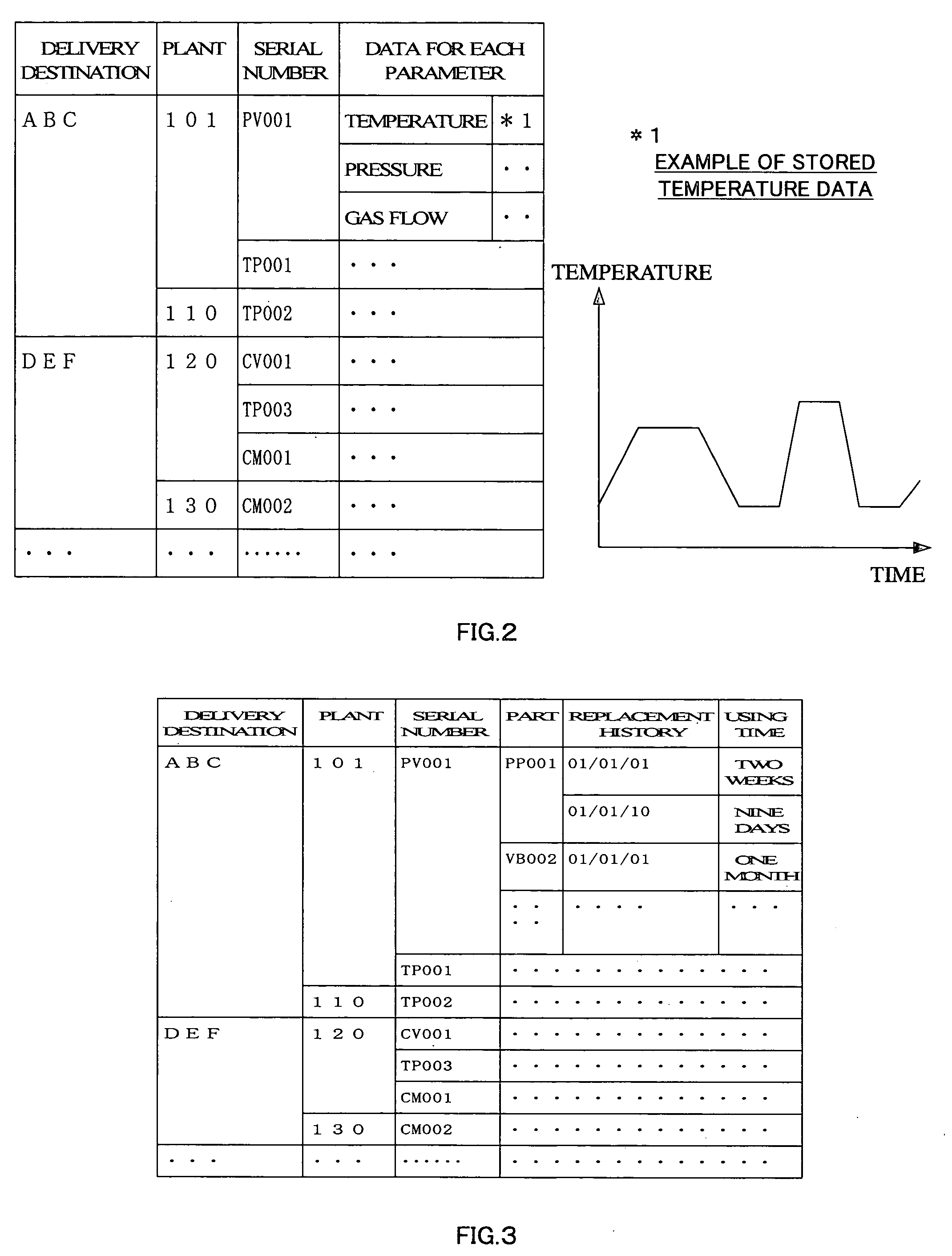

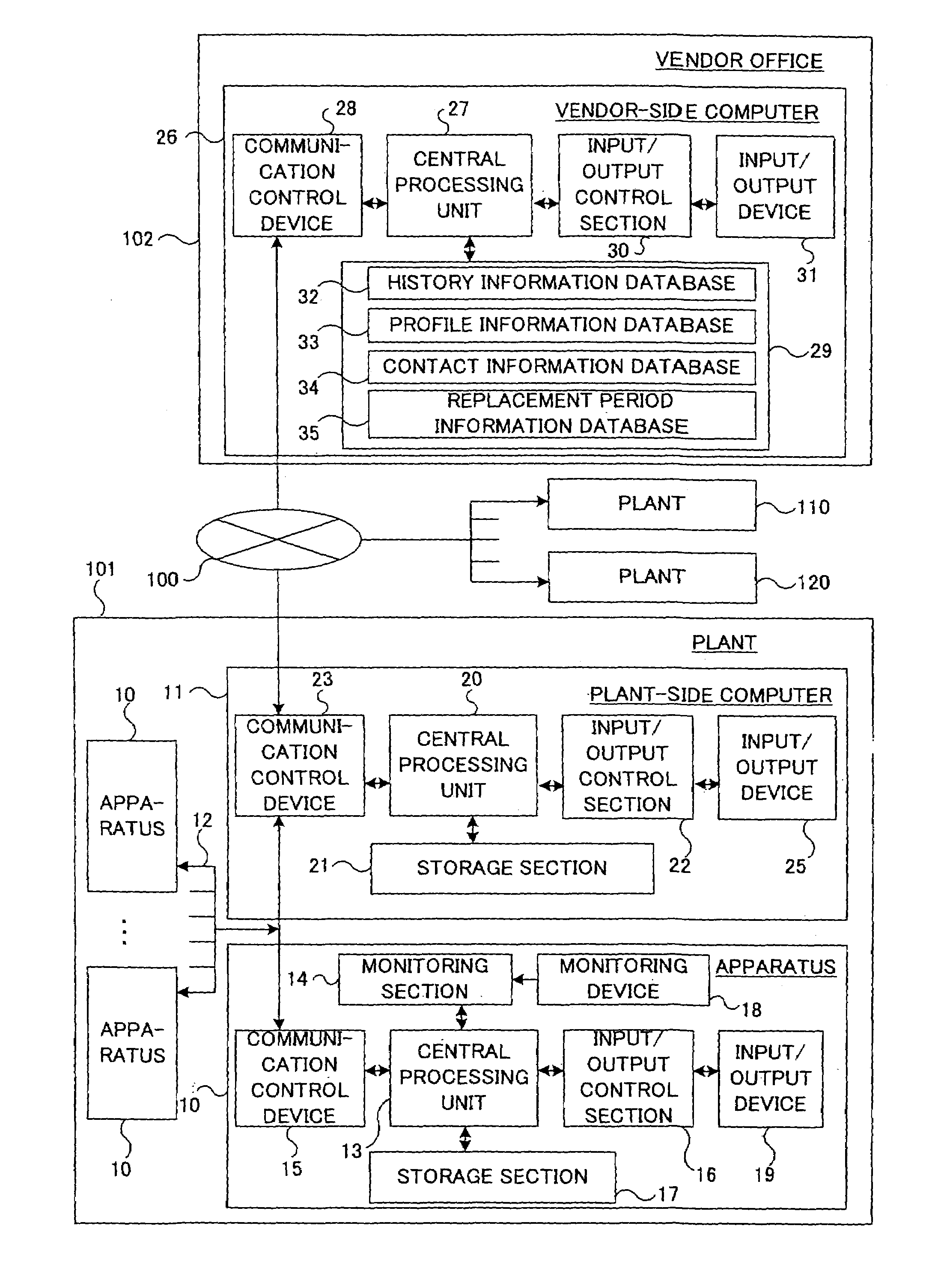

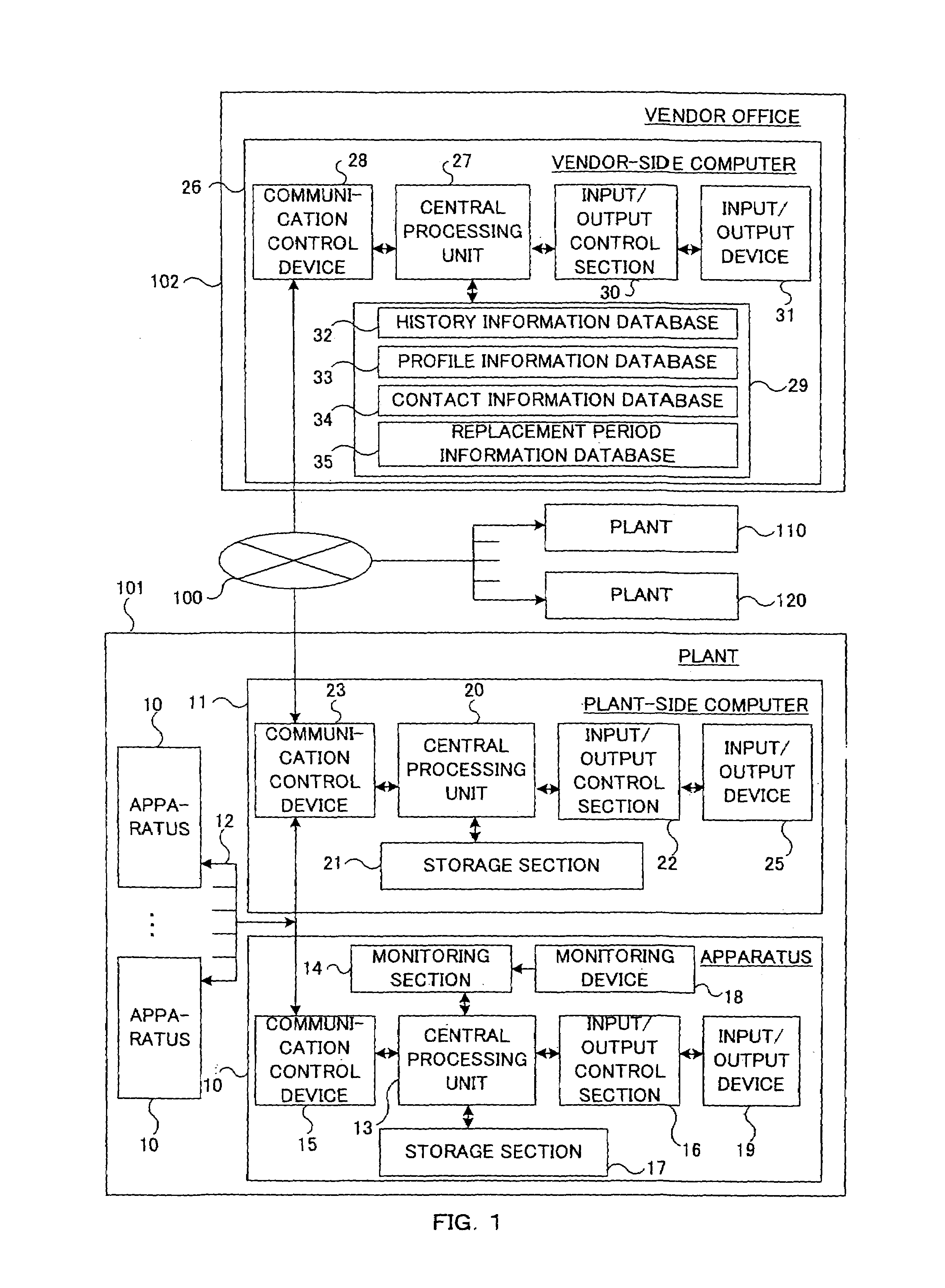

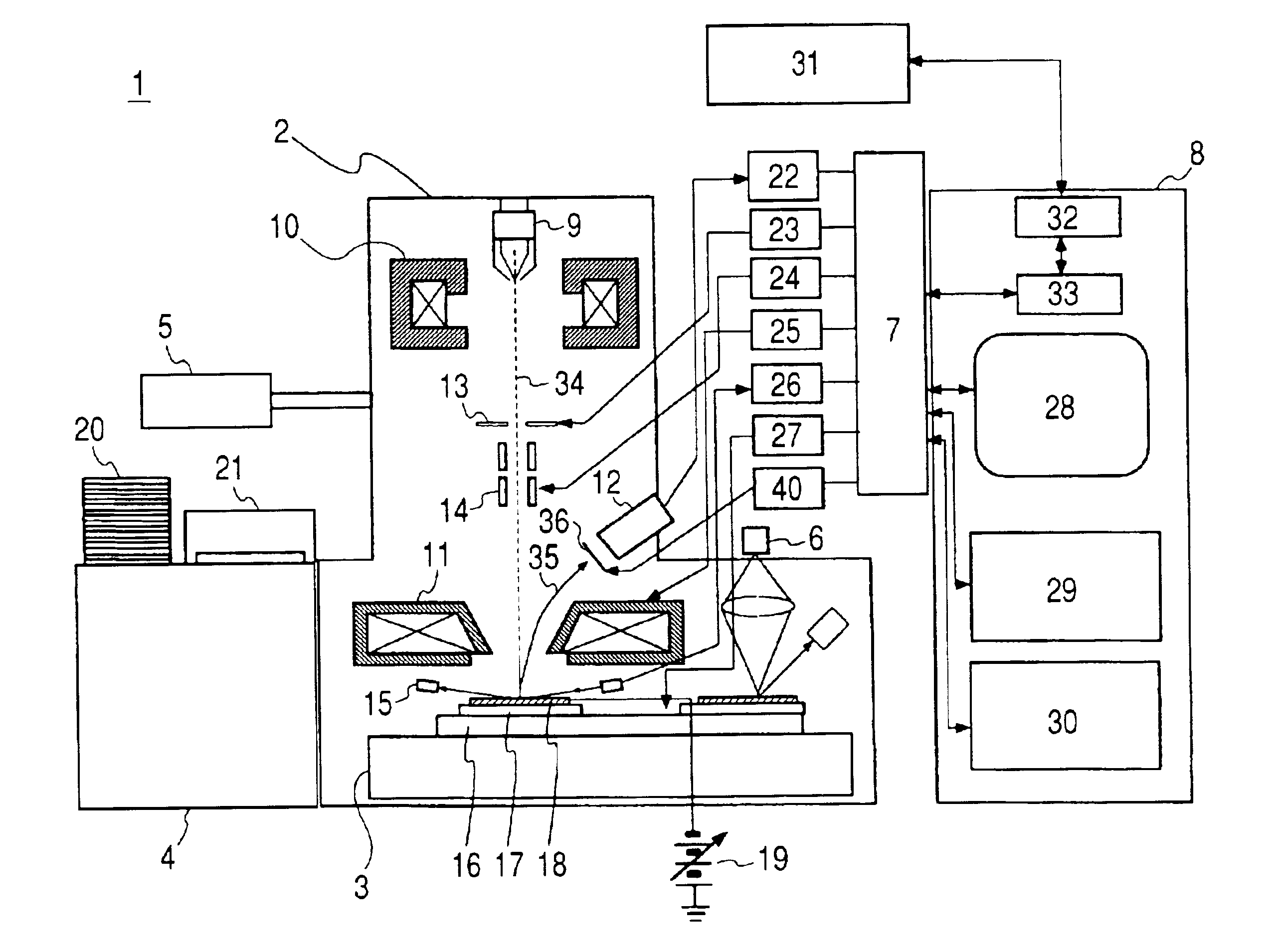

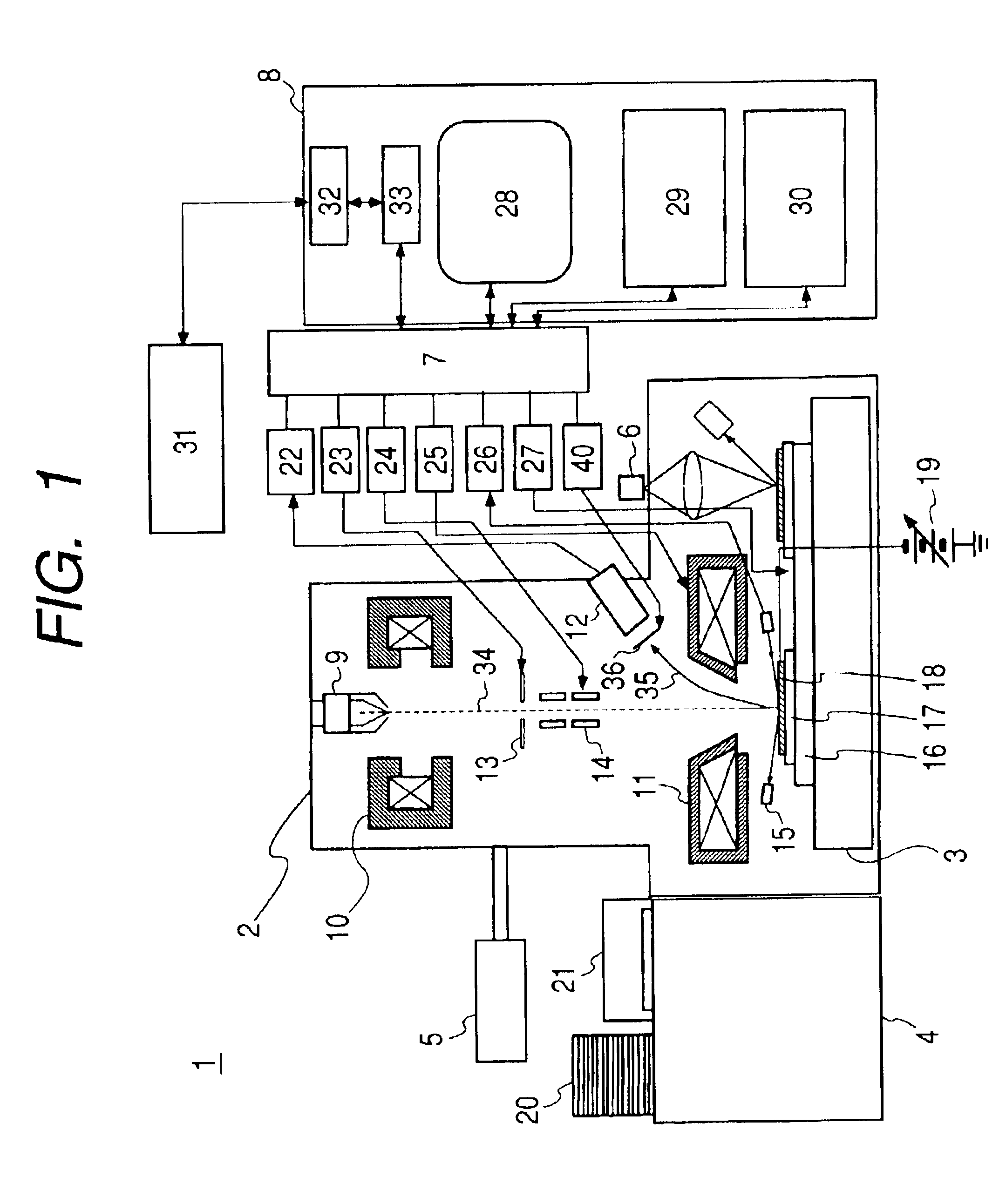

Apparatus productivity improving system and its method

InactiveUS7133807B2Improve productivityEfficient managementProgramme controlData processing applicationsProduction rateReliability engineering

There is provided a system and method for monitoring an apparatus from a remote location. A vendor-side computer obtains operating state data obtained by a monitoring device provided in an apparatus via a communication line, and monitors the operating state of the apparatus from a remote location. Maintenance data at a part replacing time is transmitted from the apparatus, and the vendor-side computer that has received maintenance data calculates an optimal replacement period of a part based on this. The calculated optimal replacement period of each part is sent to a plant. The plant feeds the optimal replacement period back to the operation of the apparatus, so that productivity can be improved.

Owner:TOKYO ELECTRON LTD

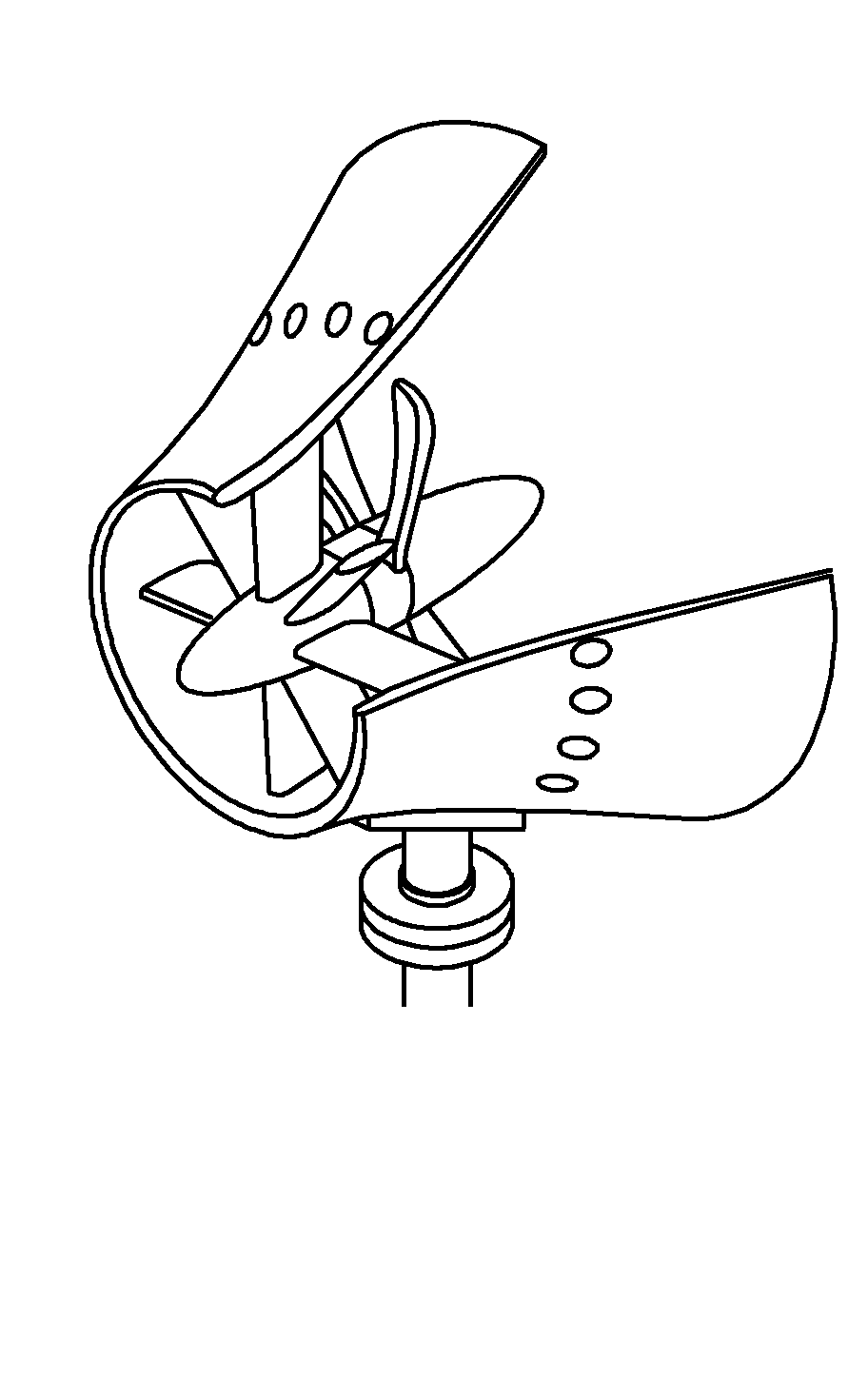

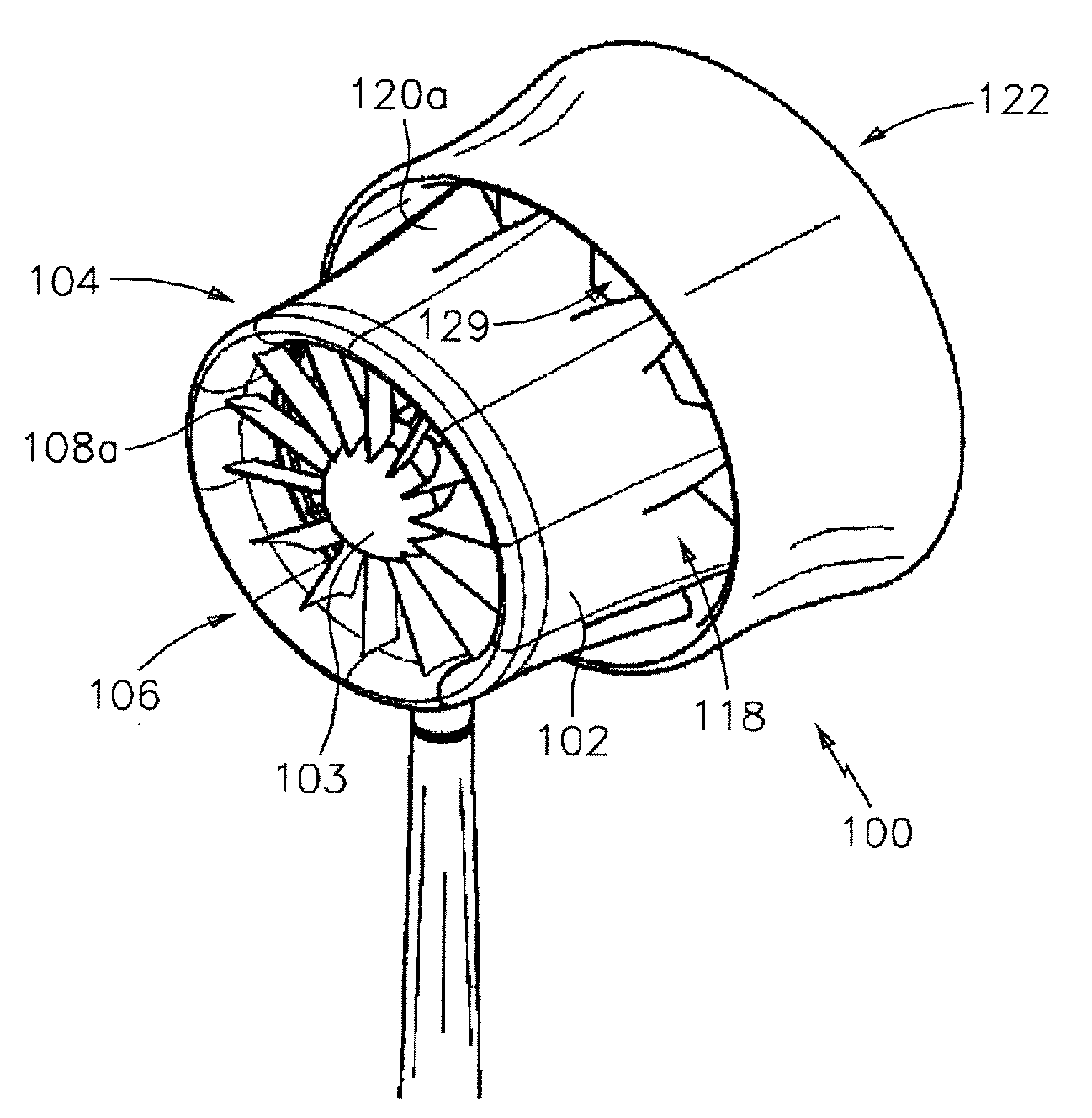

Wind turbine with mixers and ejectors

InactiveUS20090097964A1Improving sustainable efficiency of wind turbineOperation efficiency can be improvedPump componentsEngine fuctionsHigh energyPopulated area

A Mixer / Ejector Wind Turbine (“MEWT”) system is disclosed which routinely exceeds the efficiencies of prior wind turbines. In the preferred embodiment, Applicants' MEWT incorporates advanced flow mixing technology, ejector technology, aircraft and propulsion aerodynamics and noise abatement technologies in a unique manner to fluid-dynamically improve the operational effectiveness and efficiency of prior wind turbines, so that its operating efficiency routinely exceeds the Betz limit. Applicants' preferred MEWT embodiment comprises: a turbine shroud with a flared inlet; a ring of stator vanes; a ring of rotating blades (i.e., an impeller) in line with the stator vanes; and a mixer / ejector pump to increase the flow volume through the turbine while rapidly mixing the low energy turbine exit flow with high energy bypass wind flow. Unlike gas turbine mixers and ejectors which also mix with hot core exhaust gases, Applicants' preferred apparatus mixes only two air streams (i.e., wind): a primary air stream which rotates, and transfers energy to, the impeller while passing through the turbine; and a high energy bypass flow or “secondary” air stream which is entrained into the ejector, where the secondary air stream mixes with, and transfers energy to, the primary air stream. The MEWT can produce three or more time the power of its un-shrouded counterparts for the same frontal area, and can increase the productivity of wind farms by a factor of two or more. The same MEWT is safer and quieter providing improved wind turbine options for populated areas.

Owner:FLODESIGN WIND TURBINE

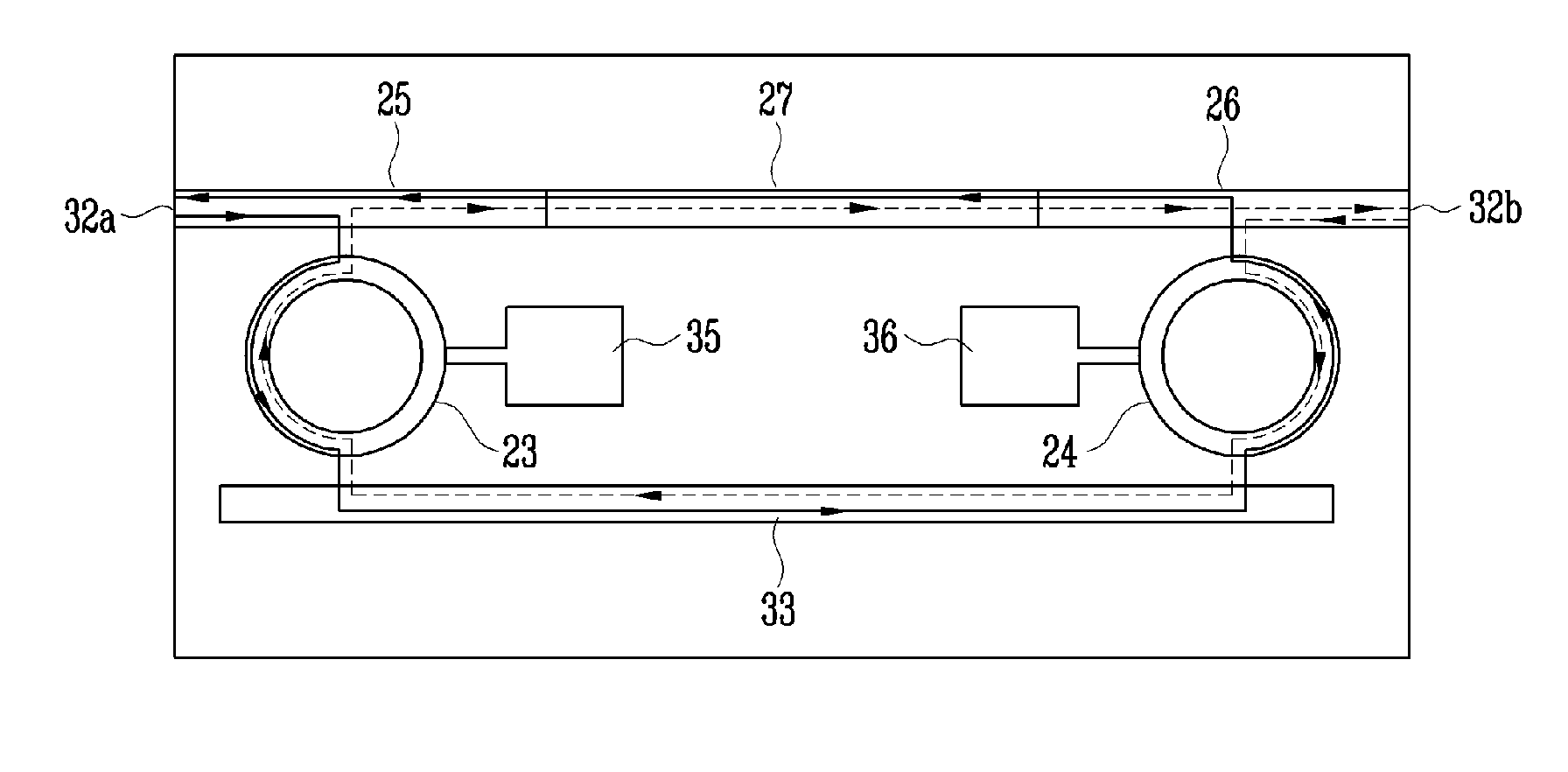

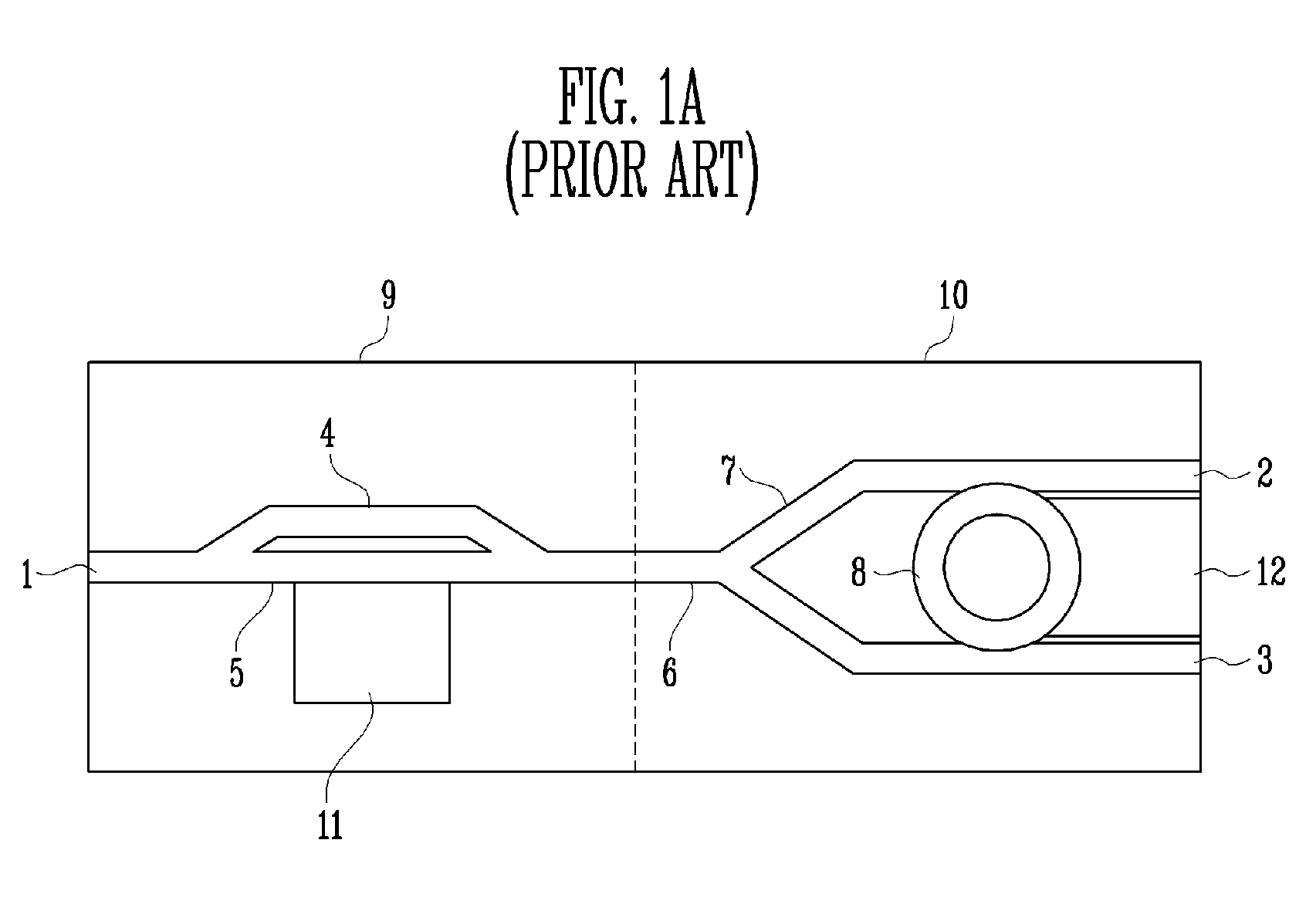

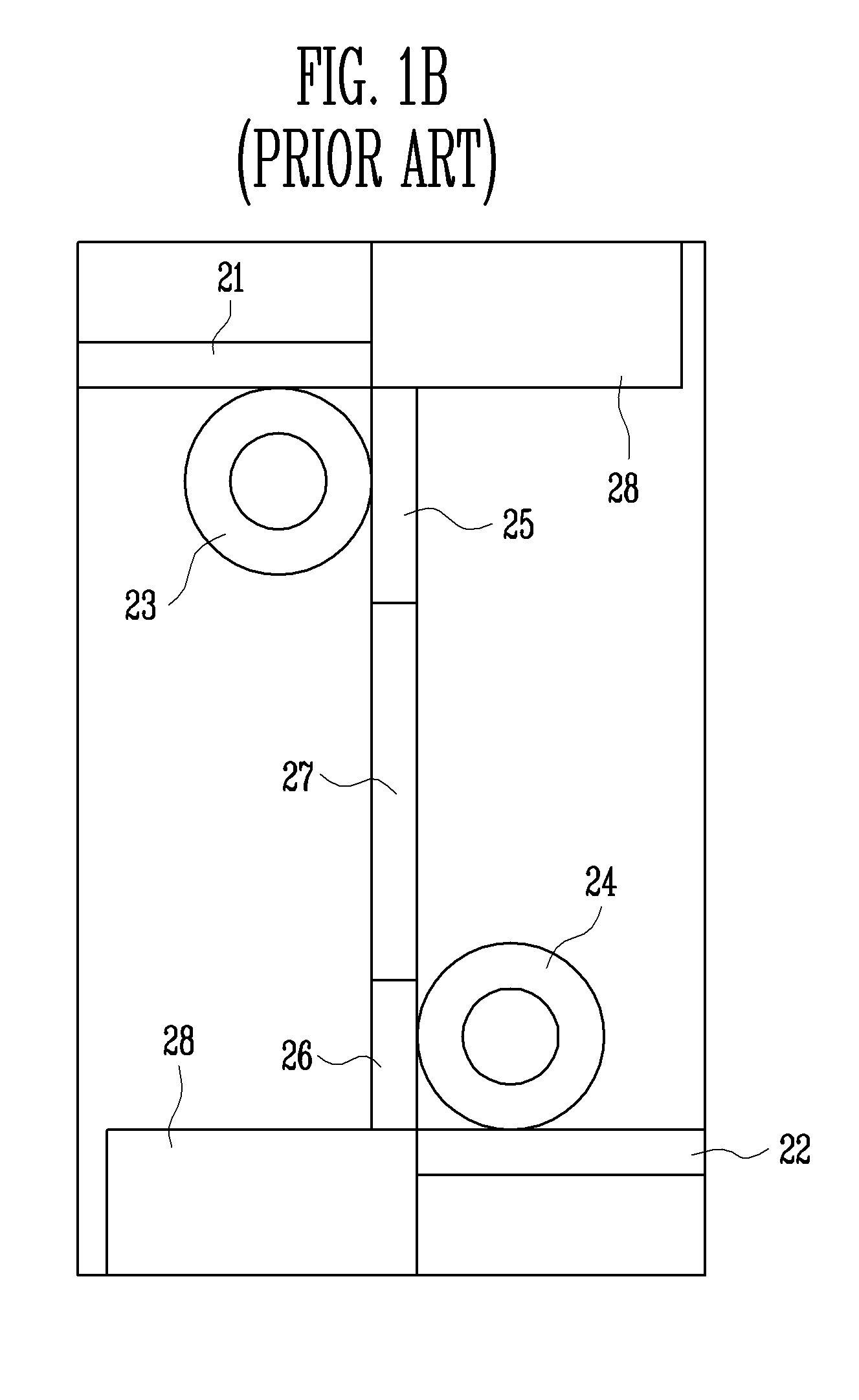

Wavelength tunable laser diode using double coupled ring resonator

InactiveUS20090154505A1Improve output characteristicsRapid wavelength tunabilityLaser detailsOptical light guidesProduction rateLength wave

A wavelength tunable laser diode using a double coupled ring resonator is provided. A new double coupled ring resonator structure is formed by a connection of two ring resonators having different radii so that stable laser oscillation occurs only in a resonant wavelength at which the two ring resonators are simultaneously resonated, and the effective refractive index of the two ring resonators is properly controlled differently for tunable laser oscillation wavelengths. The reproducibility of the optical coupling characteristics of the passive waveguides and the ring resonator can be assured by multi-mode couplers. This results in improved manufacturing productivity of the wavelength tunable laser diode. It is possible to amplify and output an output light without having an effect on oscillation wavelength characteristic by means of an optical amplifier integrated in an output end.

Owner:ELECTRONICS & TELECOMM RES INST

Method for preparing radiator element with complicated shape

InactiveCN101520287AAvoid inefficiencyAvoid wastingHeat exchange apparatusProduction rateDissolution

The invention relates to a method for preparing a radiator element with a complicated shape, which belongs to the technical field of powder metallurgy technology. The method is characterized by comprising the steps: the mixture of metal or ceramic powder and organic matters is used as a raw material, and the metal or ceramic powder and the organic matter are sufficiently mixed according to a volume ratio from 0.45 to 3.8; mixing is carried out for the mixture at the temperature from 110 DEG C to 145 DEG C for 40 minutes to 90 minutes, and the group components of the organic matters and metal or ceramic powder and the organic matters are sufficiently mixed and pelletized to obtain evenly mixed injection feeding materials; a preforming blank of the radiator element with microstructure is obtained by adopting a powder microinjection forming technology; a degreasing step is carried out through the dissolution of the organic matters in the solvent and the heat dissolving mechanism in a heating process to eliminate the organic matters; and then, the radiator element with the complicated shape is obtained by sintering function. The method overcomes the defects of lower efficiency of machine processing technology, waste of the raw materials and organization aliquation caused by casting and processing, accurately controls the organization, increases the production efficiency and greatly reduces processing cost.

Owner:UNIV OF SCI & TECH BEIJING

Apparatus productivity improving system and its method

InactiveUS7454317B2Improve productivityEfficient managementProgramme controlData processing applicationsProduction rateReliability engineering

There is provided a system and method for monitoring an apparatus from a remote location. A vendor-side computer obtains operating state data obtained by a monitoring device provided in an apparatus via a communication line, and monitors the operating state of the apparatus from a remote location. Maintenance data at a part replacing time is transmitted from the apparatus, and the vendor-side computer that has received maintenance data calculates an optimal replacement period of a part based on this. The calculated optimal replacement period of each part is sent to a plant. The plant feeds the optimal replacement period back to the operating of the apparatus.

Owner:TOKYO ELECTRON LTD

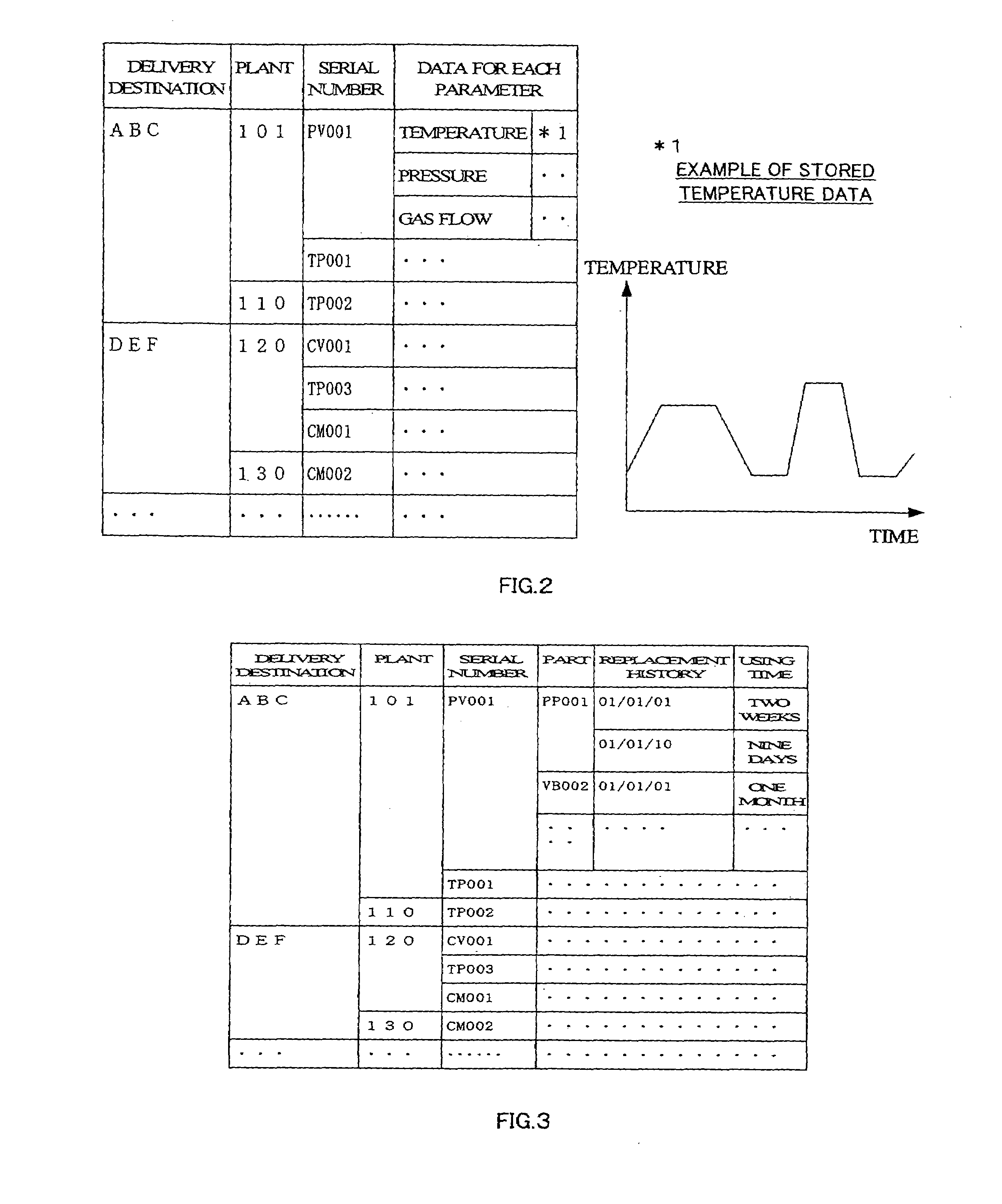

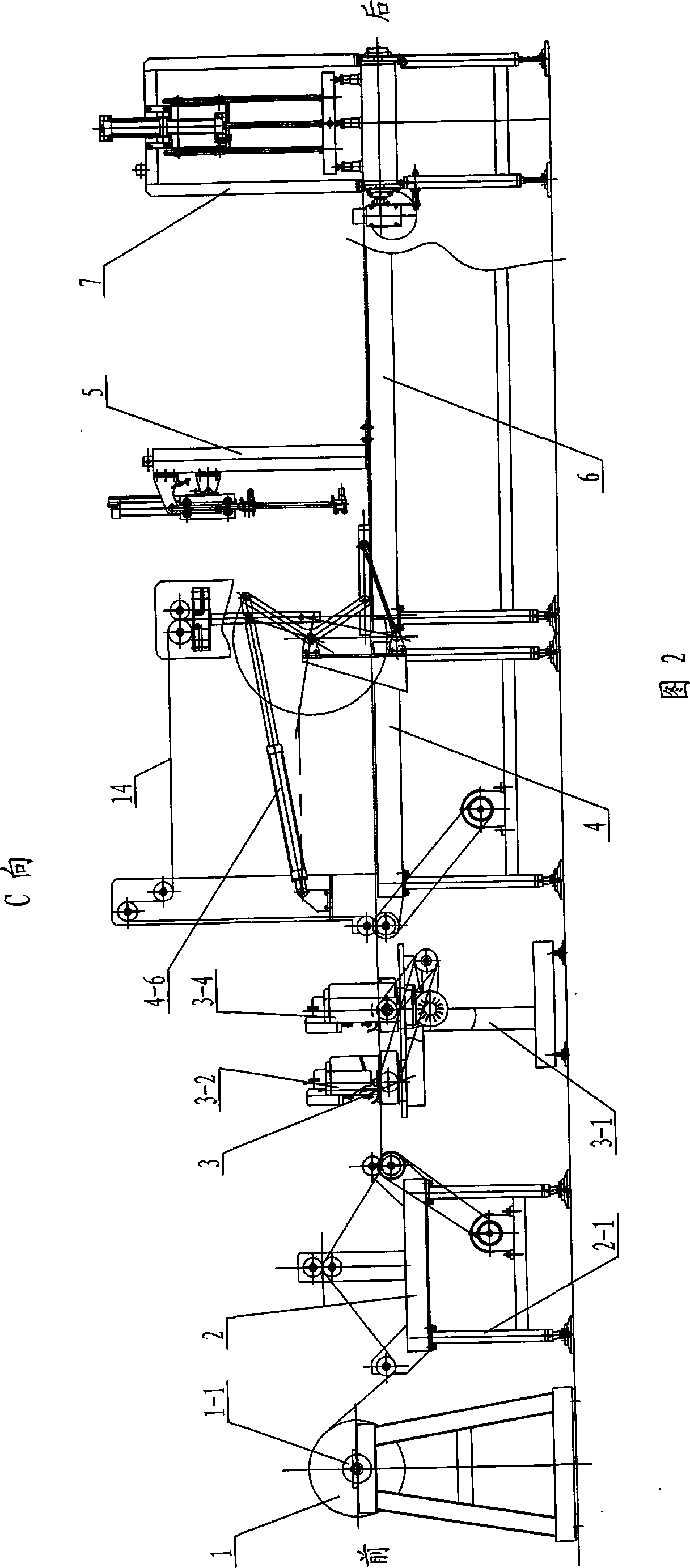

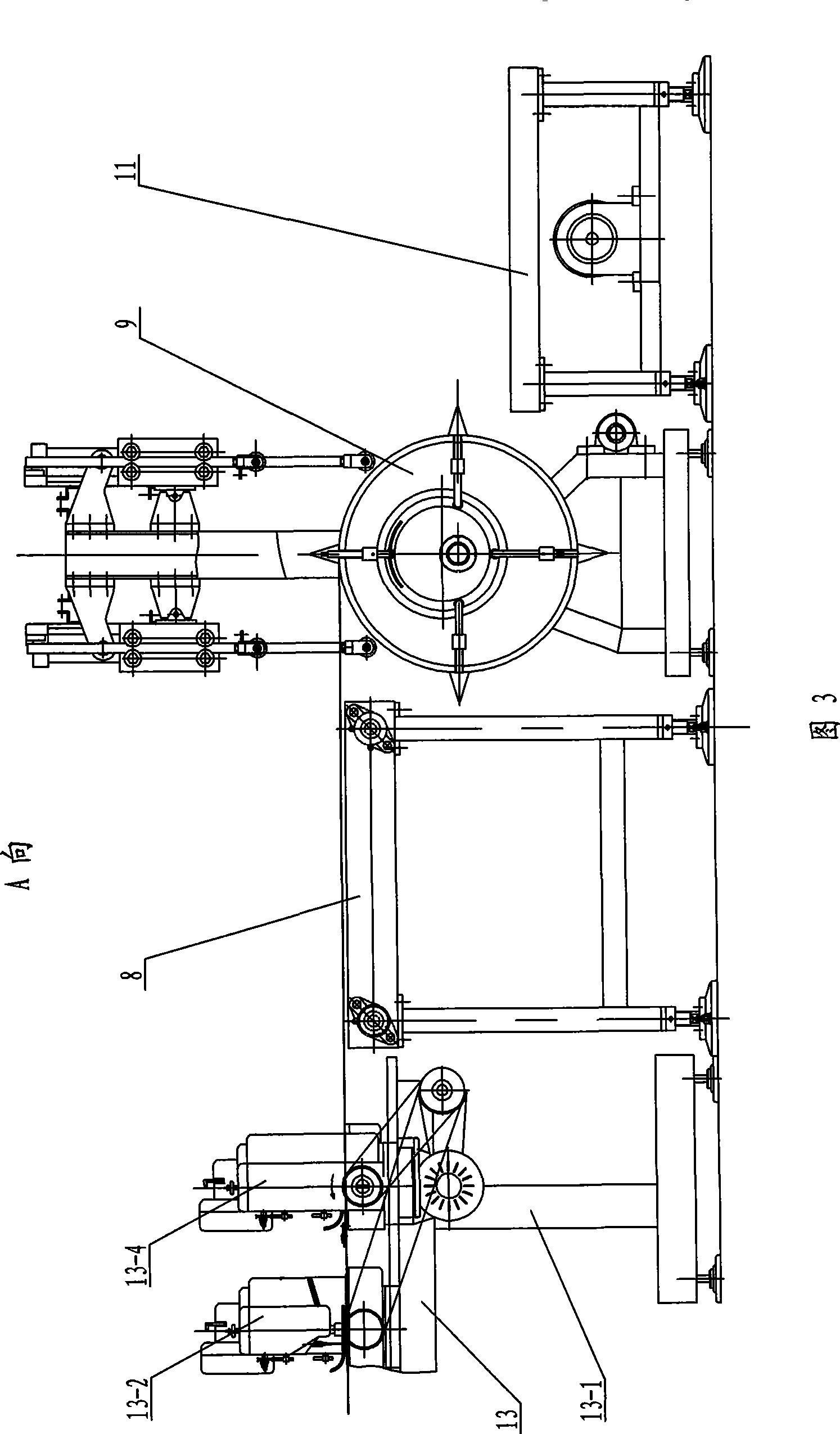

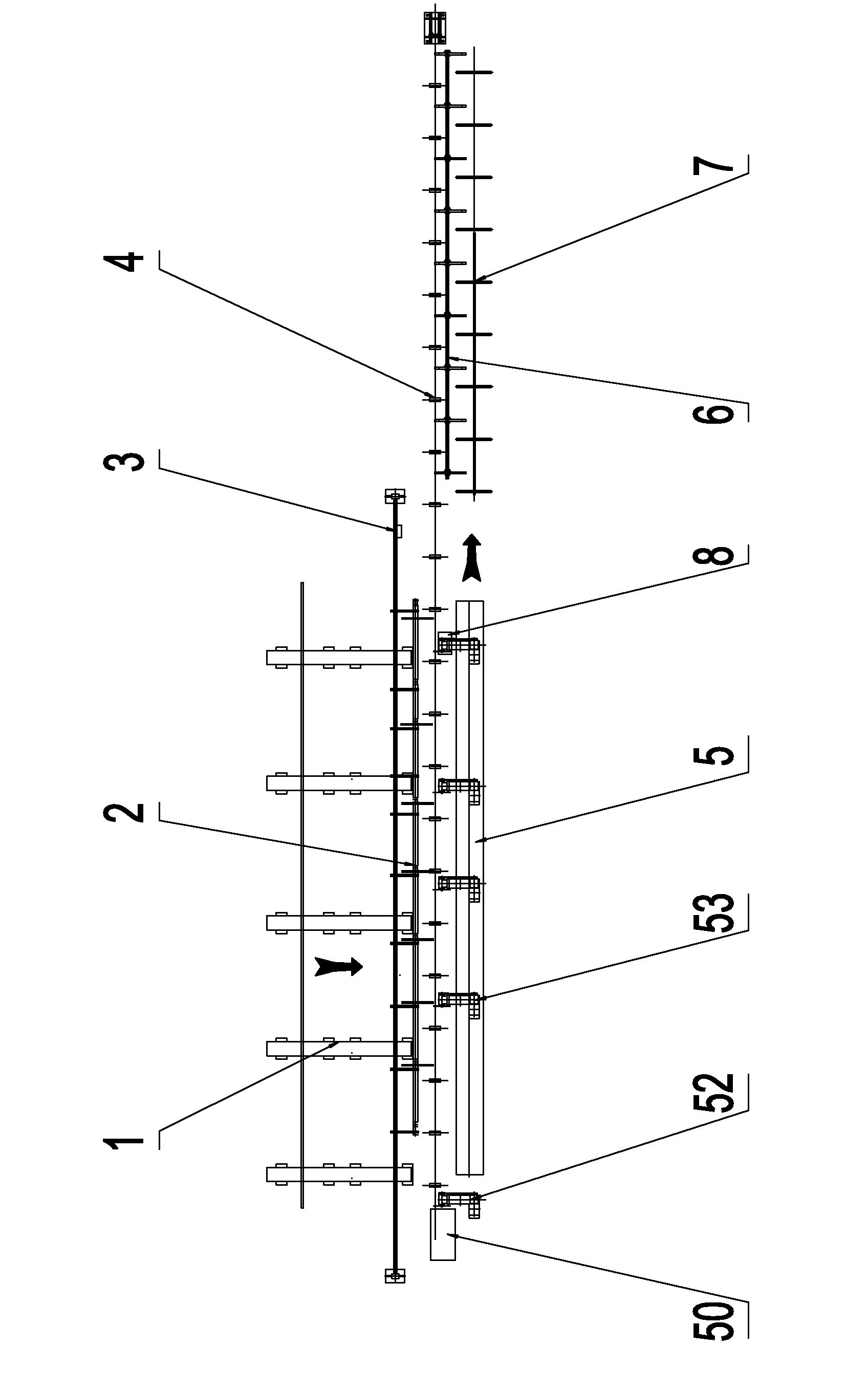

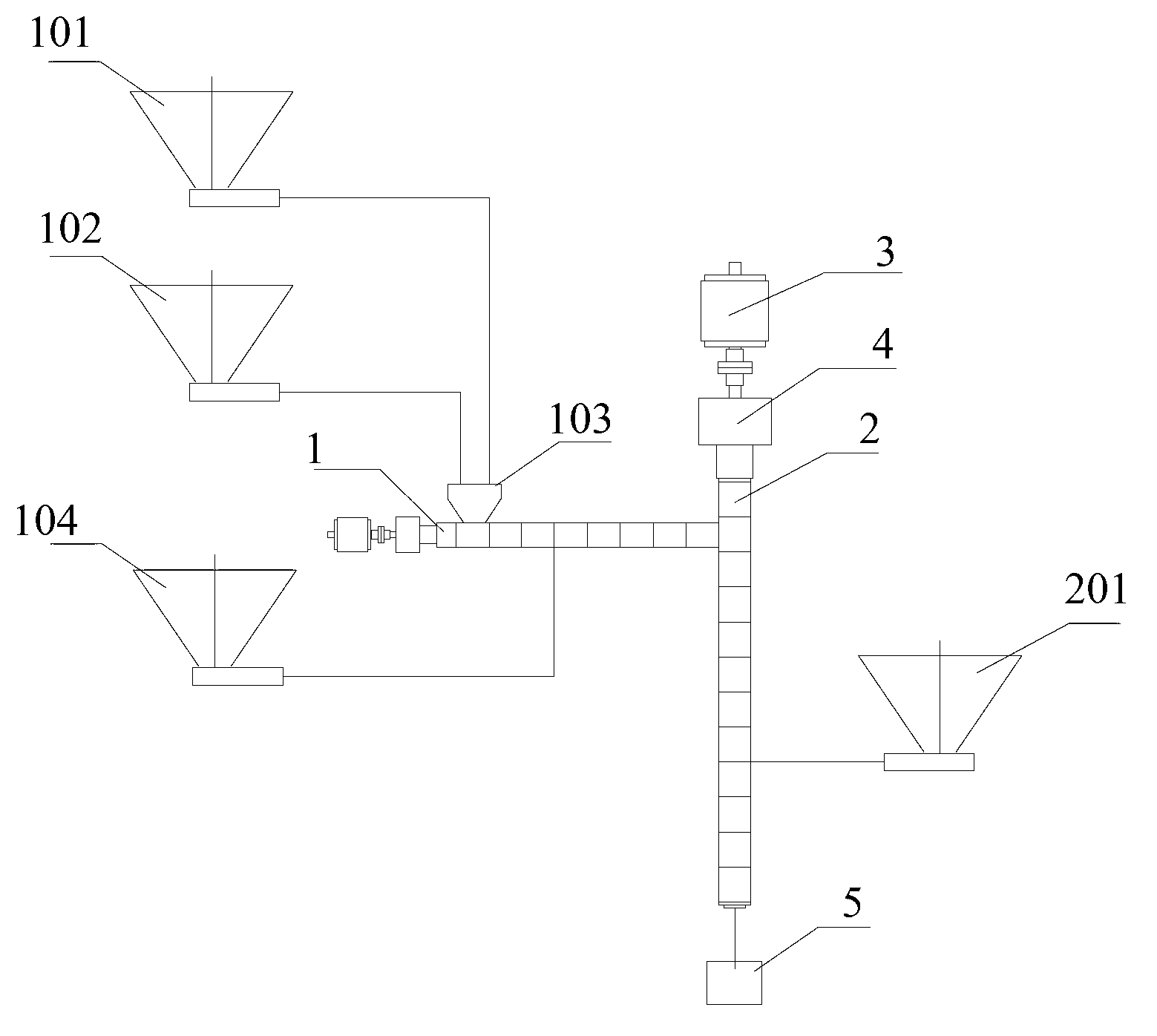

Shawl production chain

InactiveCN101387051AHigh degree of automationReduce Human Intervention FactorsSewing apparatusProduction rateProduction line

The invention provides a square towel production line, which relates to a sewing production line. The invention is to resolve the problems of manual production, low production rate and difficult quality guarantee existing in the prior production of square towel. A damp unreeling machine, a synchronous conveyor, a first double-head sewing device, a material taking conveyor and a conveyor are orderly arranged on the ground from the front to the rear along the longitudinal direction; a first transverse conveyor, a second double-head sewing device, a first middle conveyor, a first head cutting machine and a first material receiving machine are orderly arranged on the ground from the side end of the tail part of the conveyor along the transverse direction; a first sewing machine and a second sewing machine which are opposite to each other are fixedly arranged on a sewing machine rack platform; two beaders are fixedly arranged on the sewing machine rack platform respectively and on the front ends of the first sewing machine and the second sewing machine; a brander is fixed on the conveyor; and a first transverse material taking machine is arranged on a machine rack of the back end of the conveyor. The equipment of the invention has the advantages of harmonious operation and high automation, and improves the production rate by 5 to 6 times, simultaneously lowers labor intensity and ensures the quality.

Owner:张广生

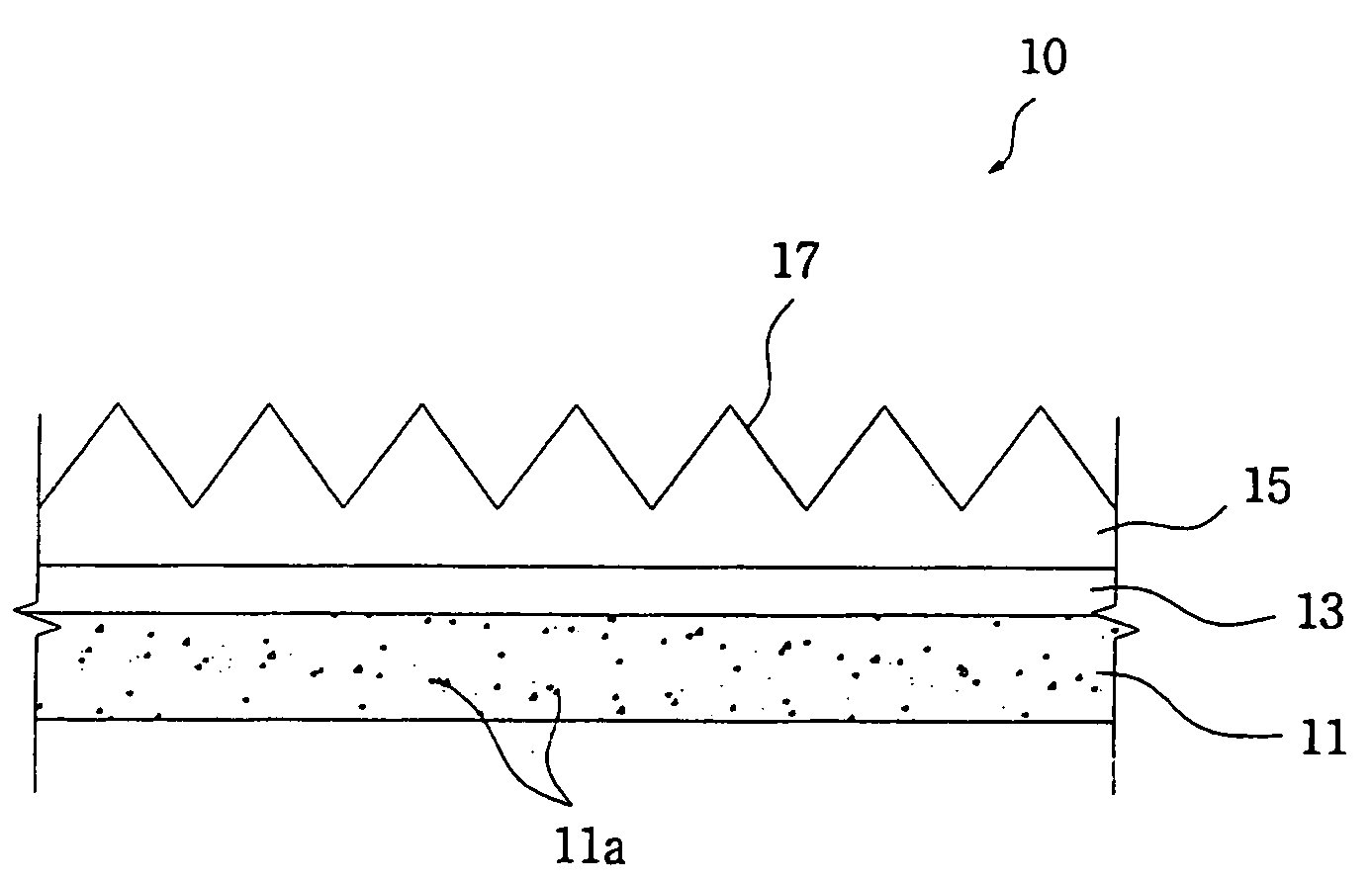

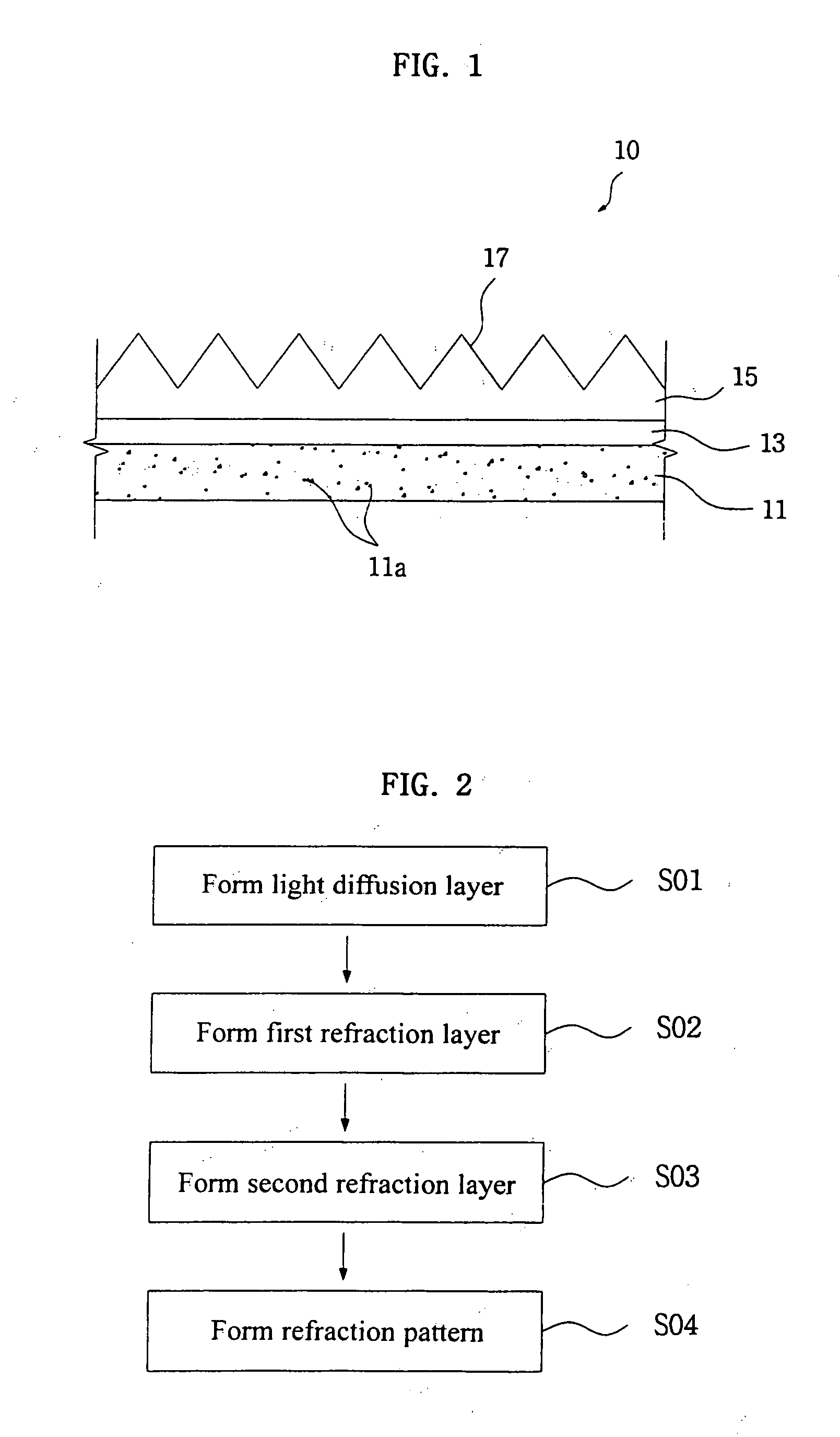

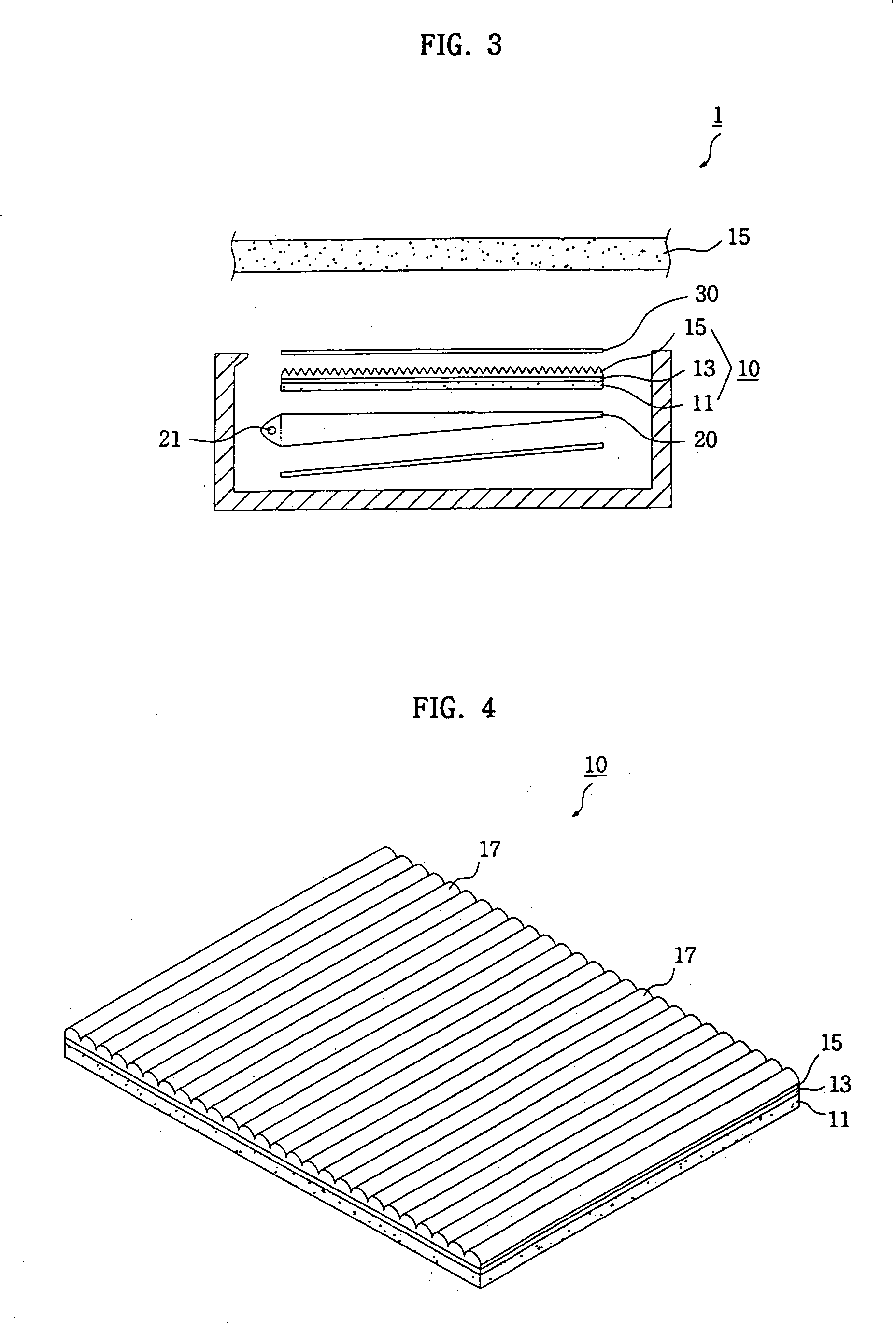

Optical film for backlight unit and method for manufacturing the same

InactiveUS20060114567A1Reduce lossesAvoid adsorptionMechanical apparatusDiffusing elementsManufacturing cost reductionForeign matter

The present invention relates to an optical film for a backlight unit and a method for manufacturing the same. The optical film of the present invention comprises a light diffusion layer in which light diffusing particles are distributed, a first refraction layer which has a relatively low index of refraction and is formed integrally on a top surface of the light diffusion layer, and a second refraction layer which has an index of refraction relatively higher than that of the first refraction layer and is formed integrally on a top surface of the first refraction layer and formed with a refraction pattern on a surface thereof. According to the present invention, the loss of light can be prevented, the adsorption of foreign substances in and the resultant scratch generation on the films can be avoided during the assembly process of the backlight unit, the productivity improvement and manufacturing cost reduction can be achieved, and the brightness of the backlight unit can be adjusted.

Owner:LMS +1

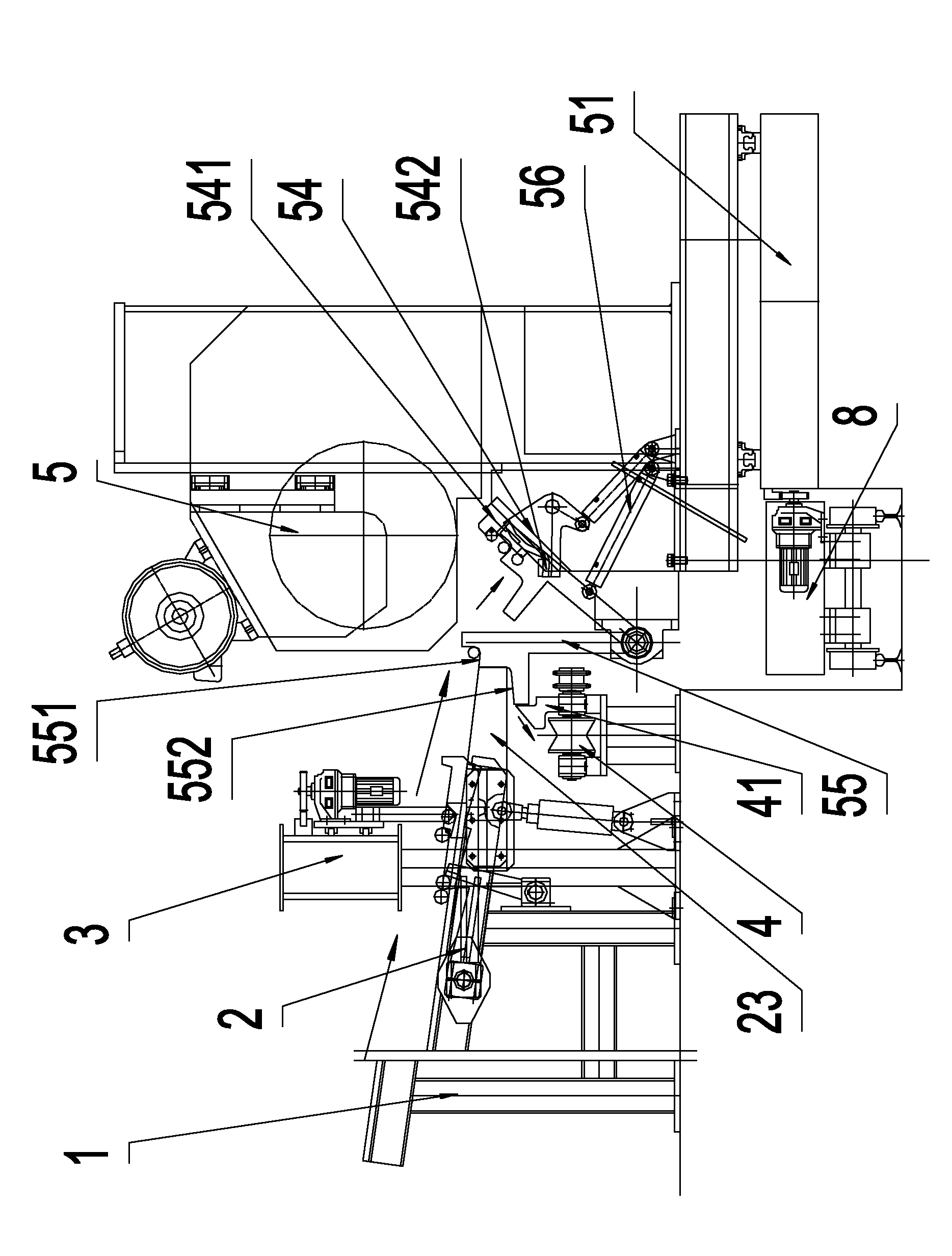

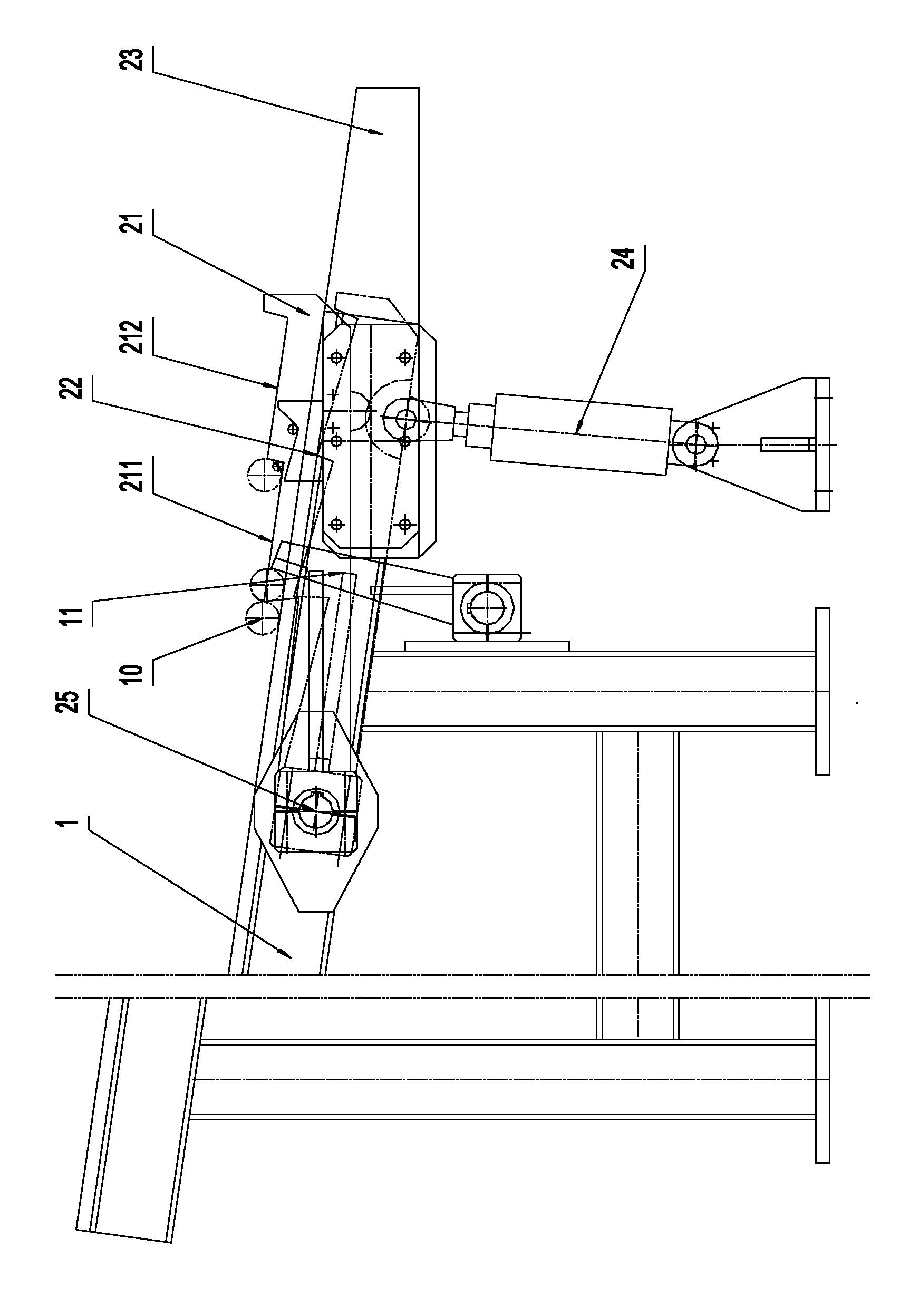

Fixed-length segmenting and sawing production line

InactiveCN101856749AReduce waiting timeFeed time reductionMetal sawing devicesMetal sawing accessoriesProduction lineProduction rate

The invention relates to a fixed-length segmenting and sawing production line which comprises a feeding rack, a poking mechanism, a sawing machine, a conveying roller way, a discharging mechanism, a finished product collecting groove and a scrap collecting trolley, wherein the members are sequentially arranged members. The discharging end of the feeding rack is provided with a baffle, and a discharging inclined plate is arranged on the conveying roller way. The production line also comprises a shear gauge. Compared with a traditional sawing and segmenting production line, the poking mechanism and the shear gauge are adopted and a before-sawing conveying roller way is omitted in the invention. The sawing machine is frequently fed by a poking dental plate of the poking mechanism in a stepping mode so that the sawing machine has short waiting time, feeding time is shortened by about 7 s / time, the sawing production efficiency is improved more than twice, the floor area is reduced by one third that the traditional type, and the equipment investment is decreased. Since the sawing machine adopts the structure that a feeding mechanism and a clamping device are mounted on a fixed saw and a moving saw, the segmentation position of raw materials are not limited and can be randomly determined, and the raw materials can be segmented in any length so that the market requirements are better met.

Owner:天津市天铁轧二制钢有限公司

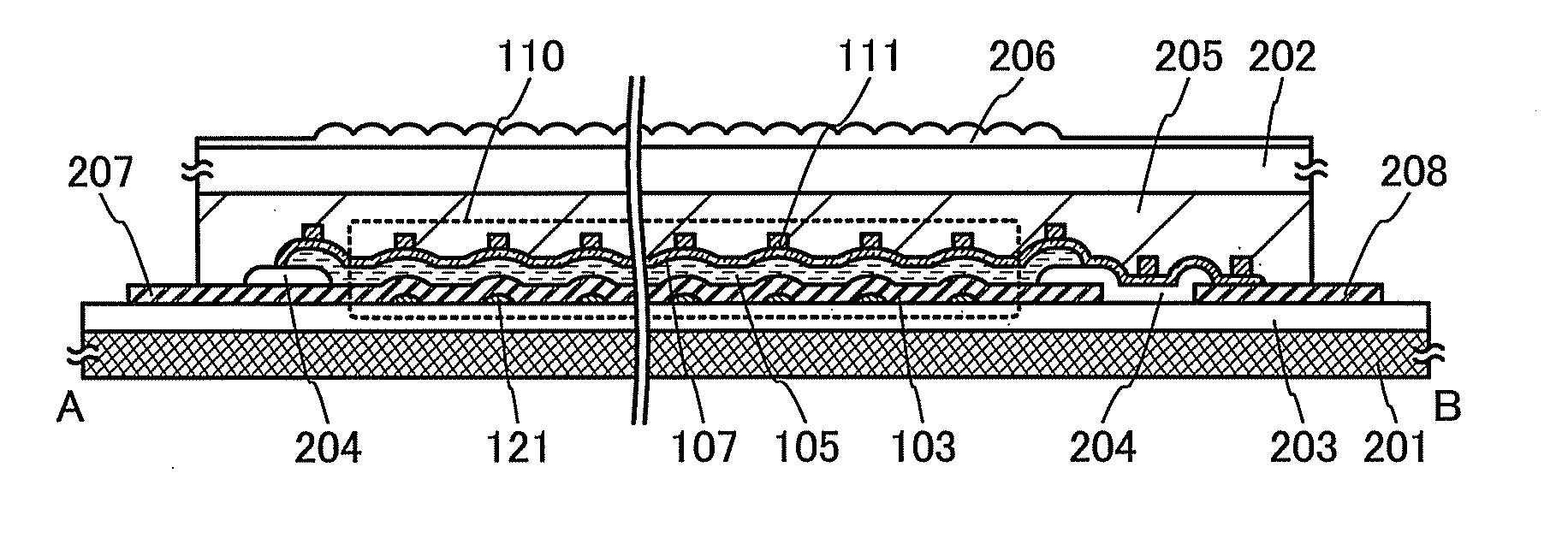

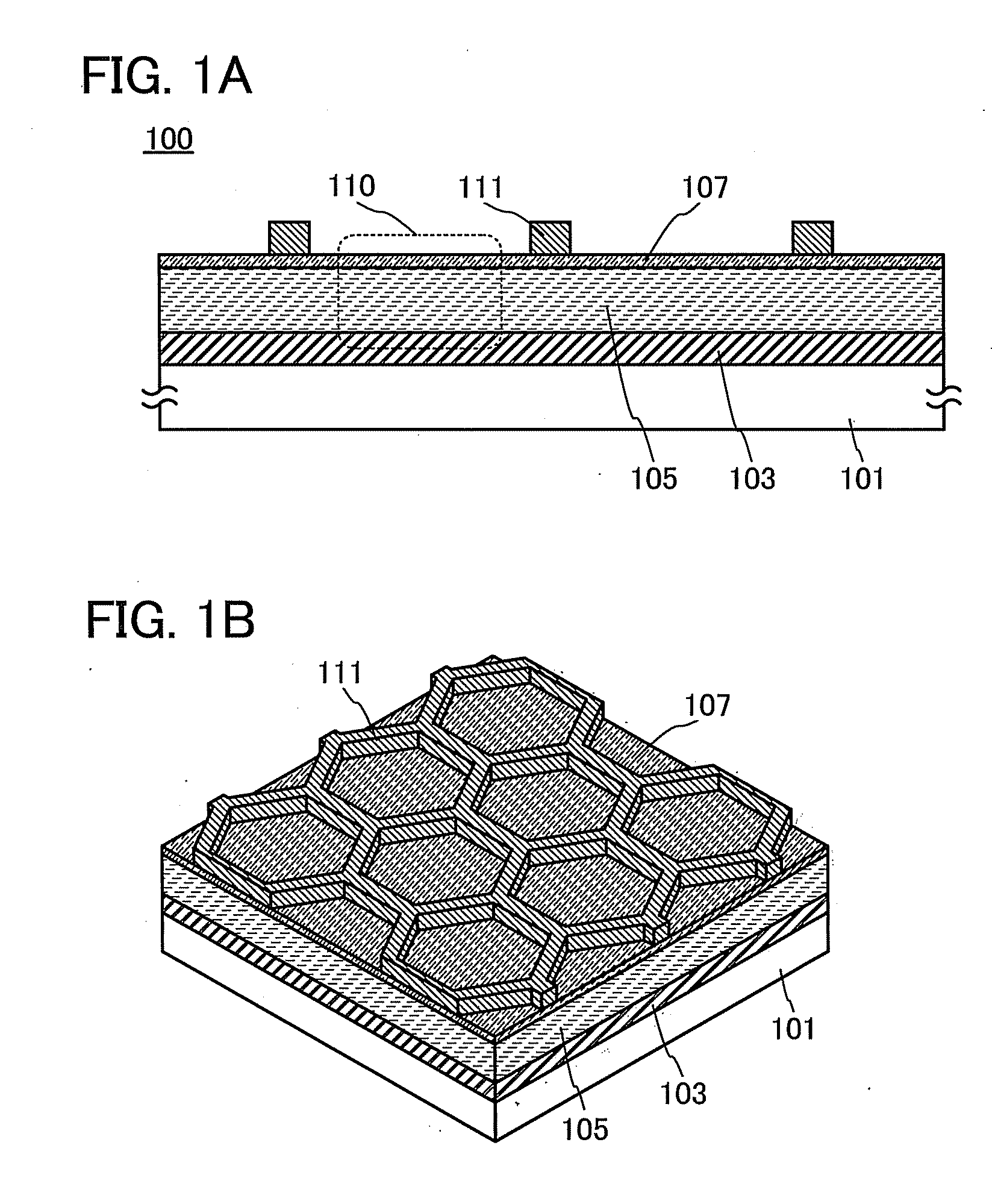

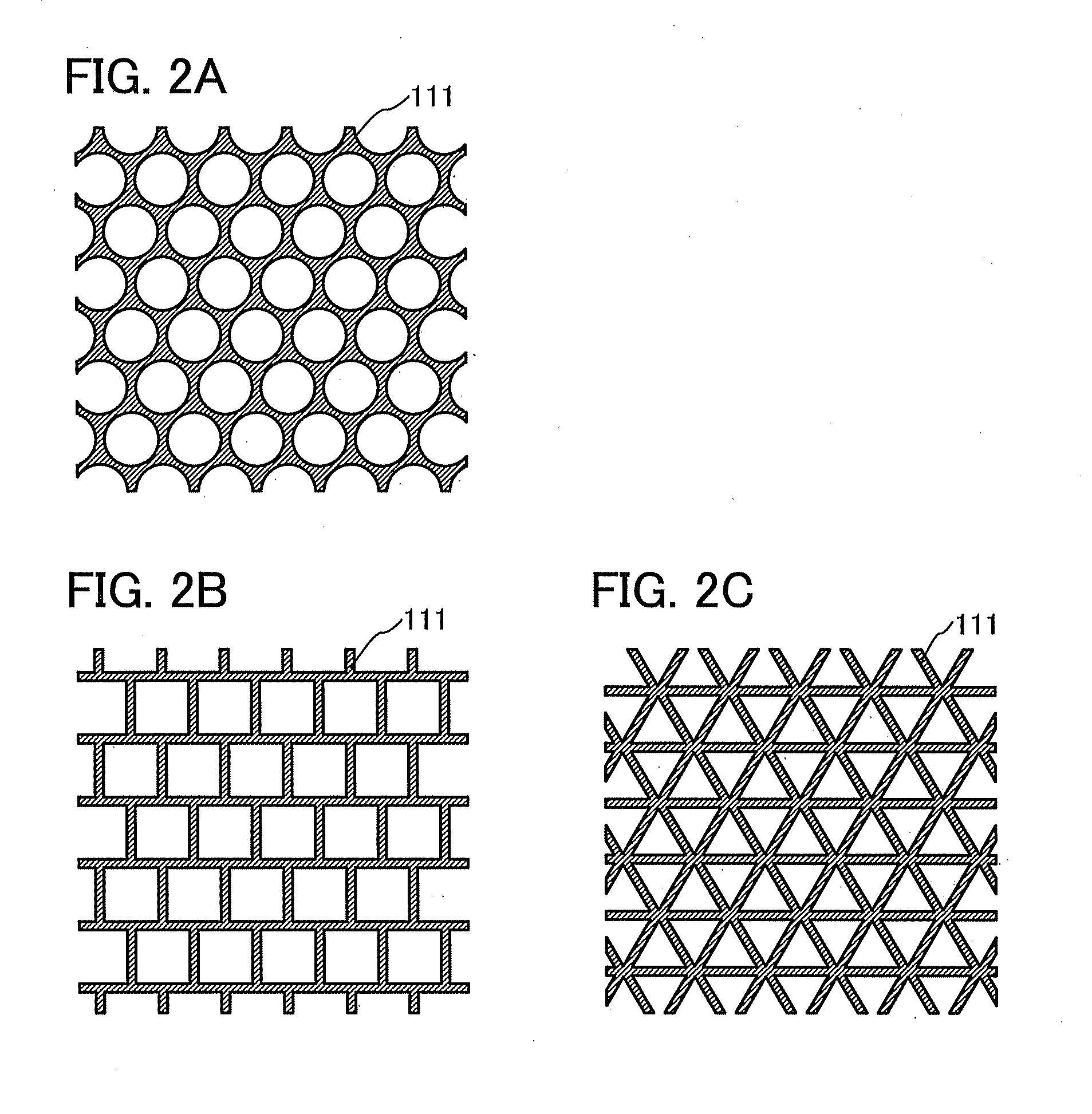

Light-Emitting Device and Manufacturing Method Thereof

InactiveUS20130240852A1Reliable and reliableLight extraction efficiencySolid-state devicesSemiconductor/solid-state device manufacturingProduction rateVoltage drop

Provided is a light-emitting device in which a voltage drop is suppressed and light extraction efficiency is increased. Provided is a light-emitting device with increased productivity. Provided is a light-emitting device with high reliability. An extremely thin conductive film from 3 nm to 50 nm is used as an electrode on a light-emitting side and an auxiliary wiring is provided in contact with the electrode. When the width of the auxiliary wiring is 100 μm or less, the auxiliary wiring is hardly perceived with the naked eye, so that a light-emitting device in which light extraction efficiency is increased and luminance is obtained uniformly. The extremely thin auxiliary wiring can be formed by nanoimprinting technology. With use of nanoimprinting technology, the width of the auxiliary wiring can be reduced to 10 nm or less.

Owner:SEMICON ENERGY LAB CO LTD

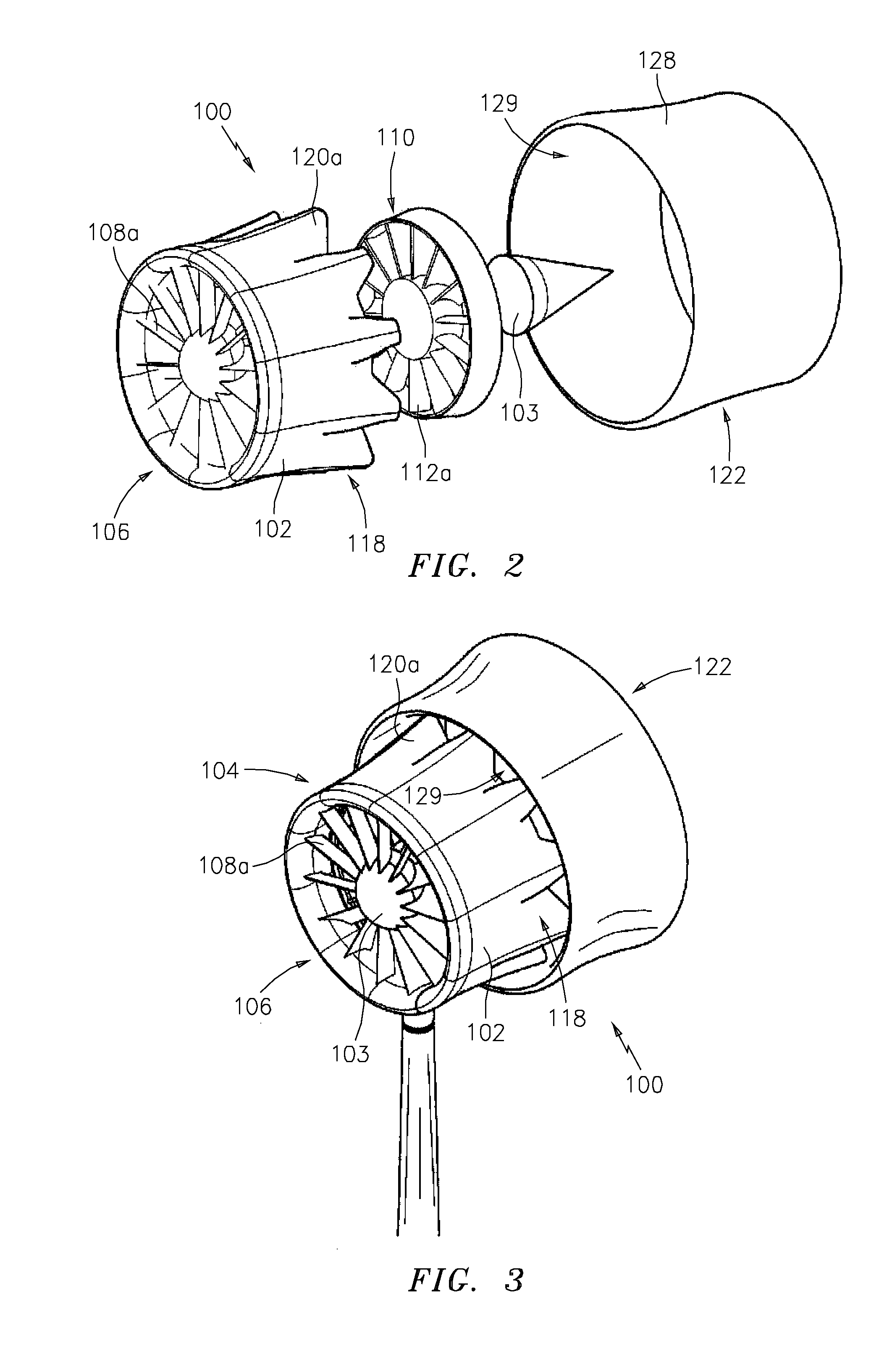

Turbine with mixers and ejectors

InactiveUS20100316493A1Minimize impactA large amountPump componentsEngine fuctionsImpellerHigh energy

A Mixer / Ejector Wind Turbine (“MEWT”) system is disclosed which routinely exceeds the efficiencies of prior wind turbines. Unique ejector concepts are used to fluid-dynamically improve many operational characteristics of conventional wind turbines for potential power generation improvements of 50% and above. Applicants' preferred MEWT embodiment comprises: an aerodynamically contoured turbine shroud with an inlet; a ring of stator vanes; a ring of rotating blades (i.e., an impeller) in line with the stator vanes; and a mixer / ejector pump to increase the flow volume through the turbine while rapidly mixing the low energy turbine exit flow with high energy bypass fluid flow. The MEWT can produce three or more time the power of its un-shrouded counterparts for the same frontal area, and can increase the productivity of wind farms by a factor of two or more. The same MEWT is safer and quieter providing improved wind turbine options for populated areas.

Owner:FLODESIGN WIND TURBINE

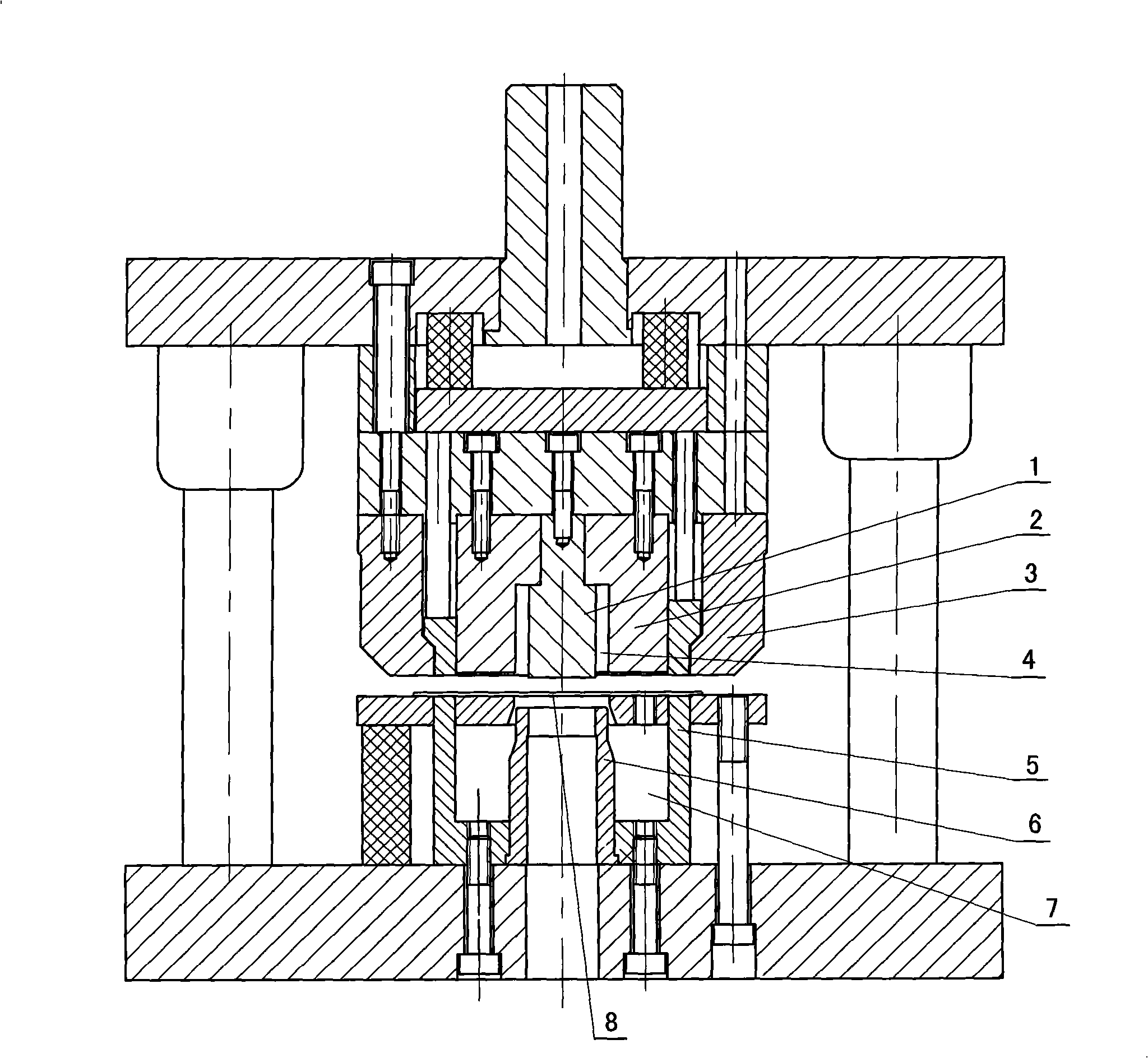

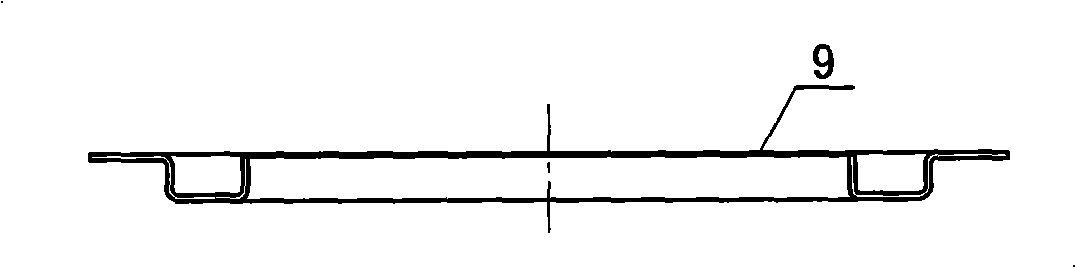

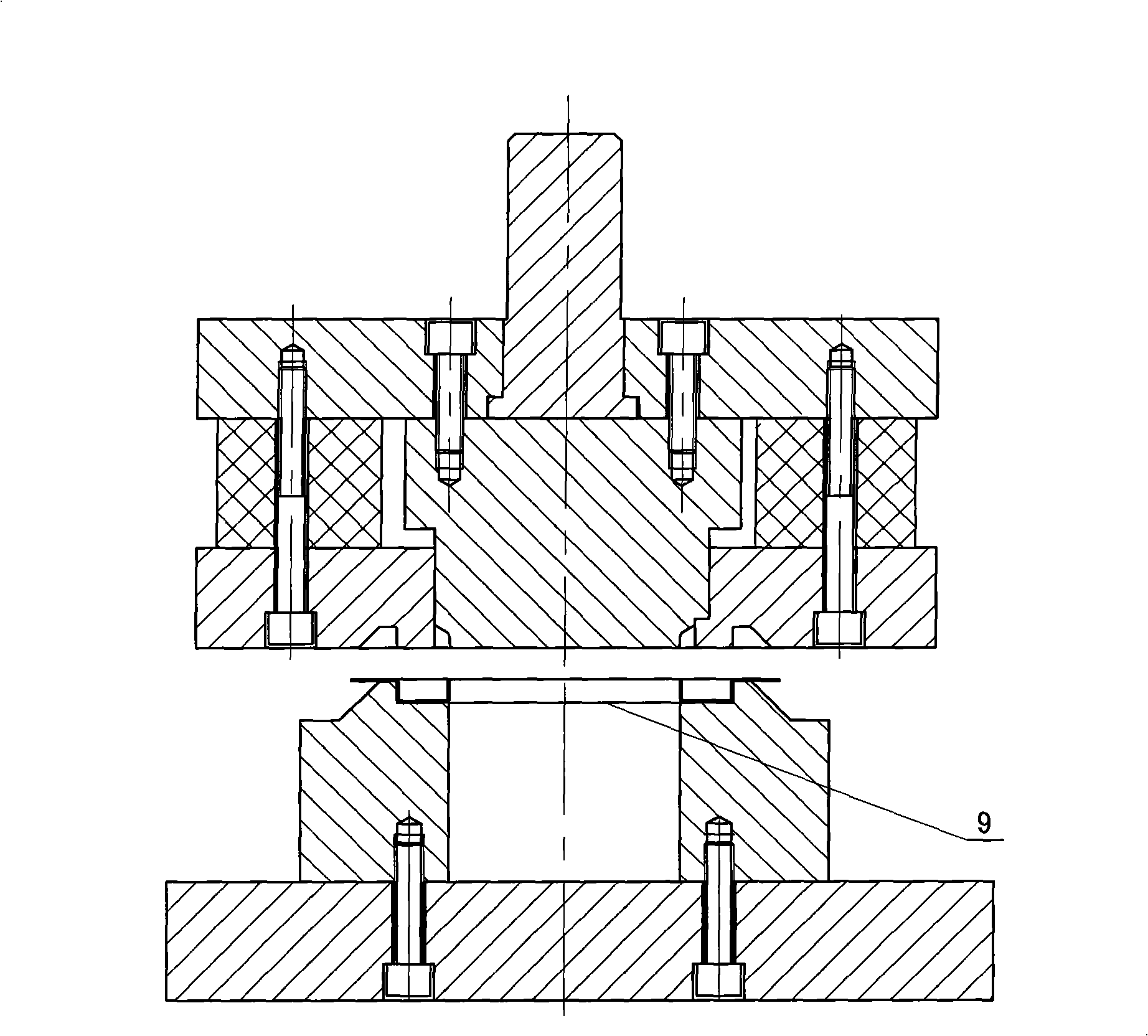

Technology for processing rotatable filter sealing ring fixed plate

InactiveCN101537454AReduce consumptionSmall amount of deformationShaping toolsProduction rateMaterial consumption

A technology for processing a rotatable filter sealing ring fixed plate is completed on a die by a stamping way and comprises the following steps of punching a metal sheet, flanging the edge of the punched hole, extending the external side of the flanging part, blanking and cutting to obtain a semi-finished product; and folding the edge of the semi-finished product and the flanging position of the through hole on the semi-finished product. The technology has reasonable process; and compared with the existing machining process, the technology has the active effects of less processing and dies investment, higher productivity, lower material consumption and reject rate, and the like.

Owner:蚌埠市瑞泰汽配制造有限公司

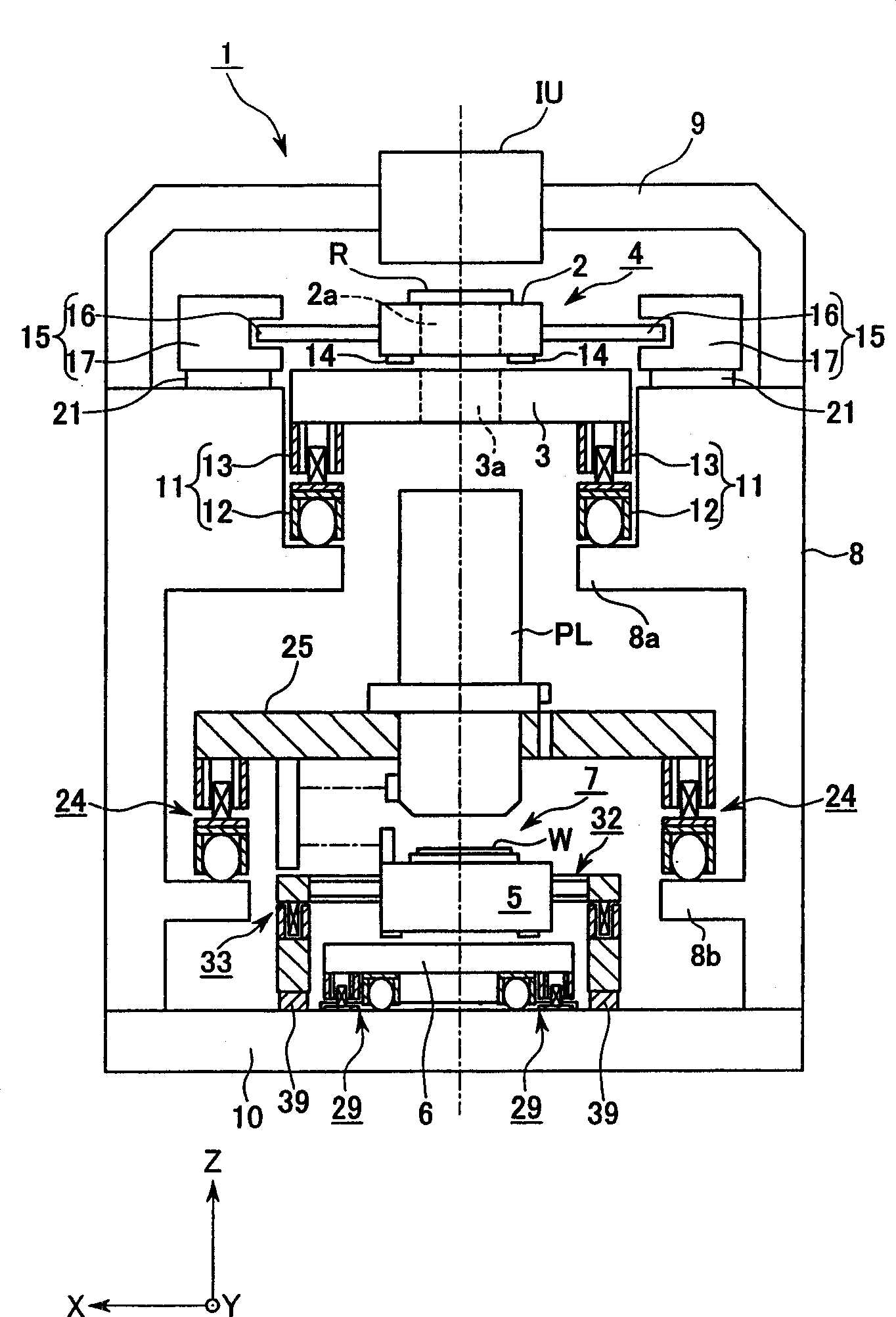

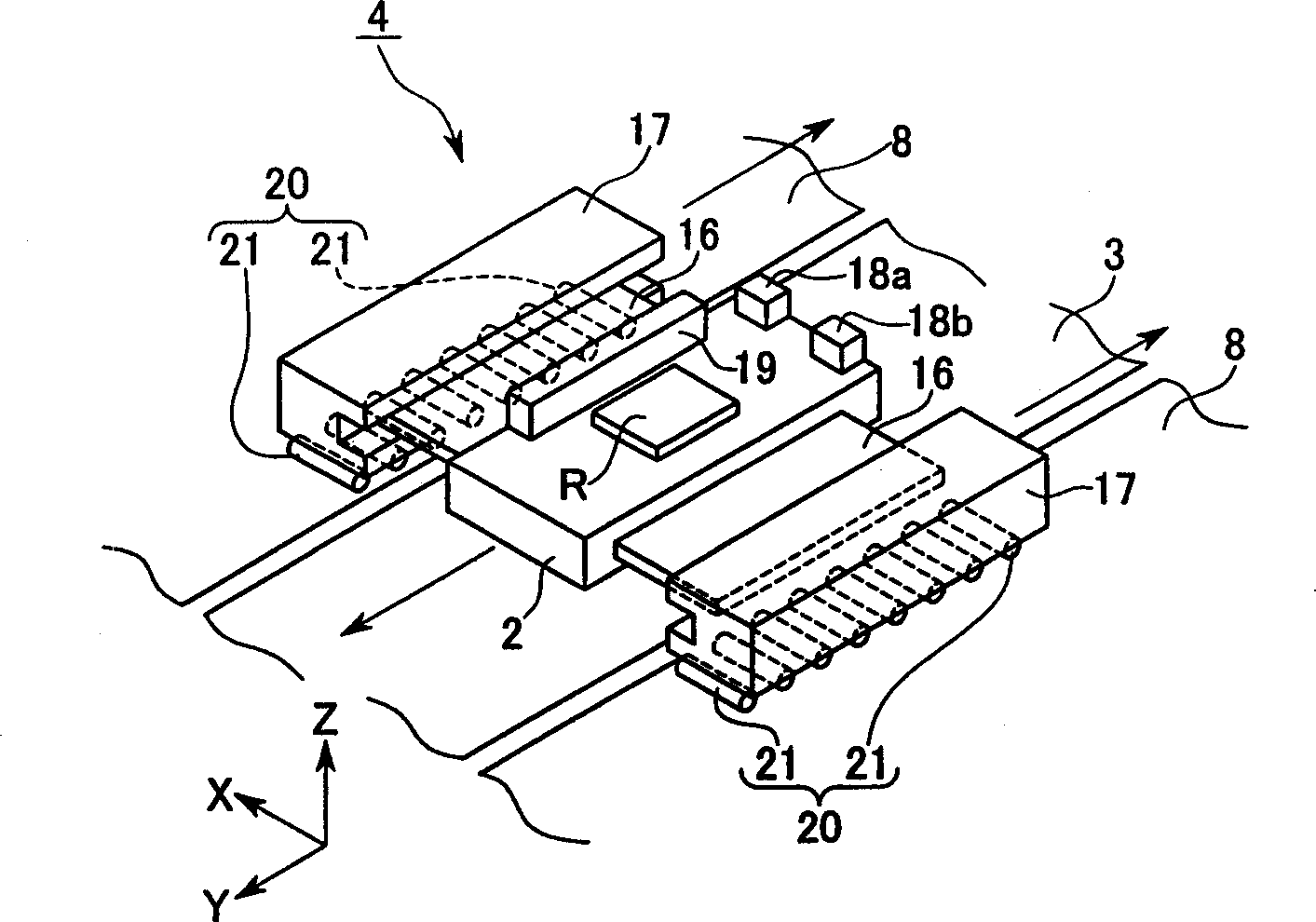

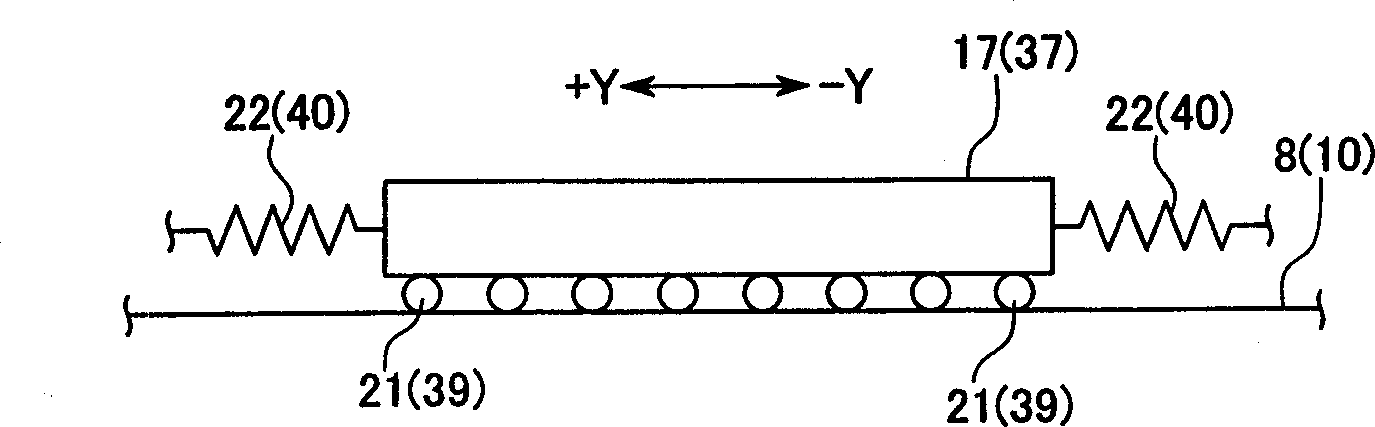

Substrate, stage device, method of driving stage, exposure system and exposure method

InactiveCN1373900AMaintain positional controlAvoid problems such as swayingSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusProduction rateResidual vibration

The object stage device (4) includes: a support part (8), which is vibrateably and independently arranged relative to the fixed plate (3); and a reaction force stage (17), which is The resulting reaction force is free to move on the support (8) in said one direction. Thereby, since problems such as shaking due to the reaction force can be avoided, the adjustment time can be shortened, productivity can be improved, and transmission of residual vibration of the support portion to the fixed plate can be suppressed.

Owner:NIKON CORP

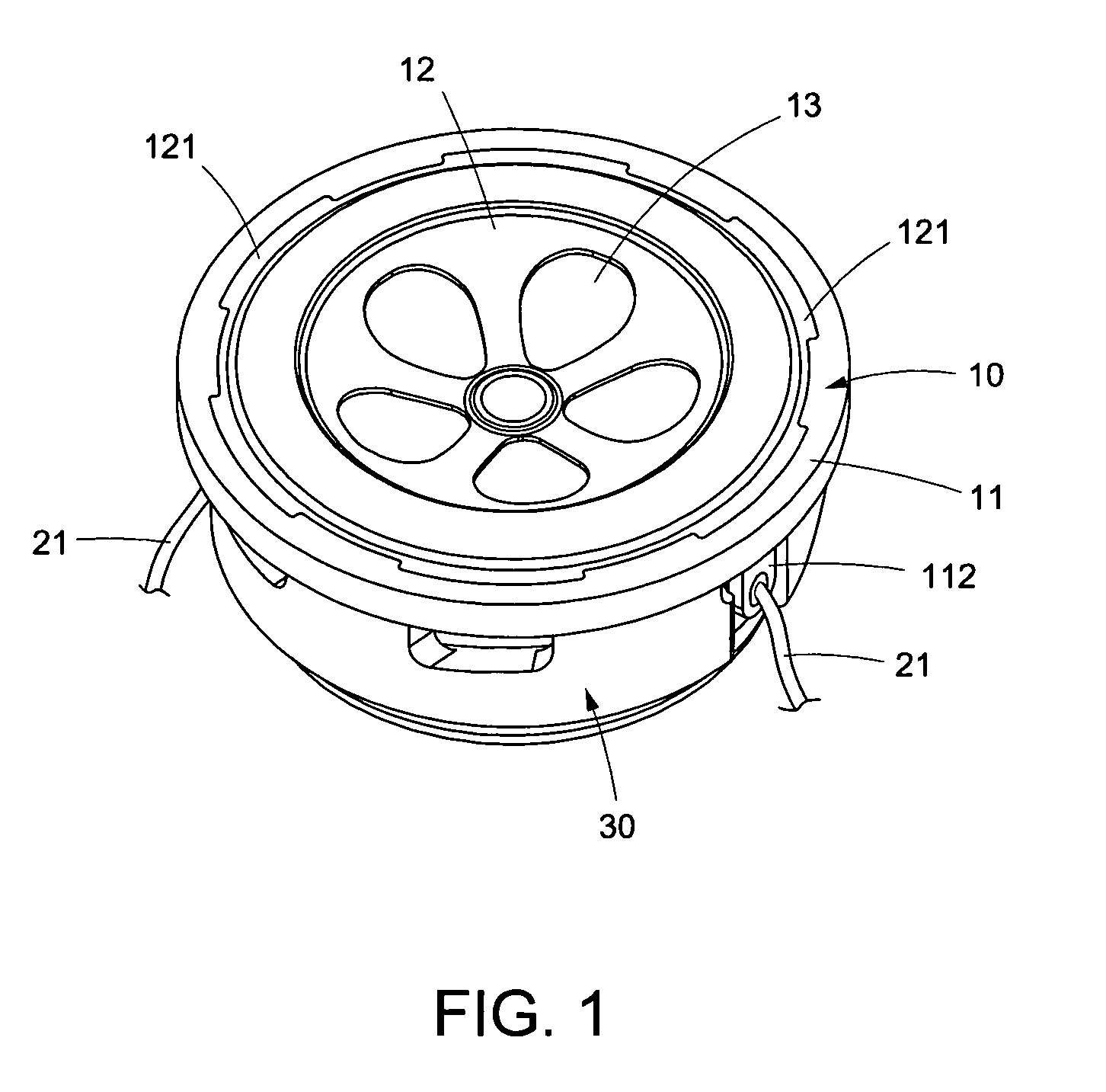

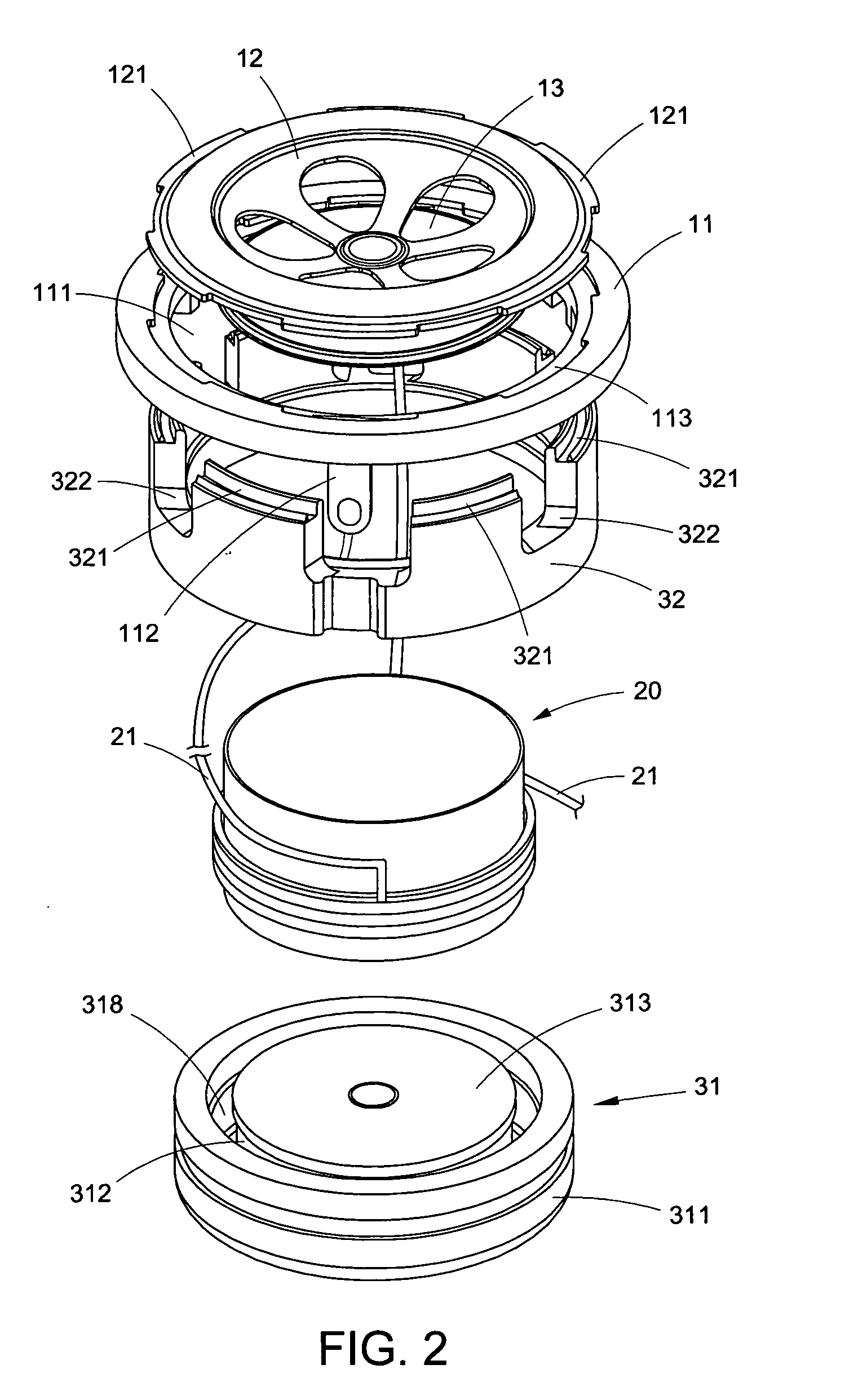

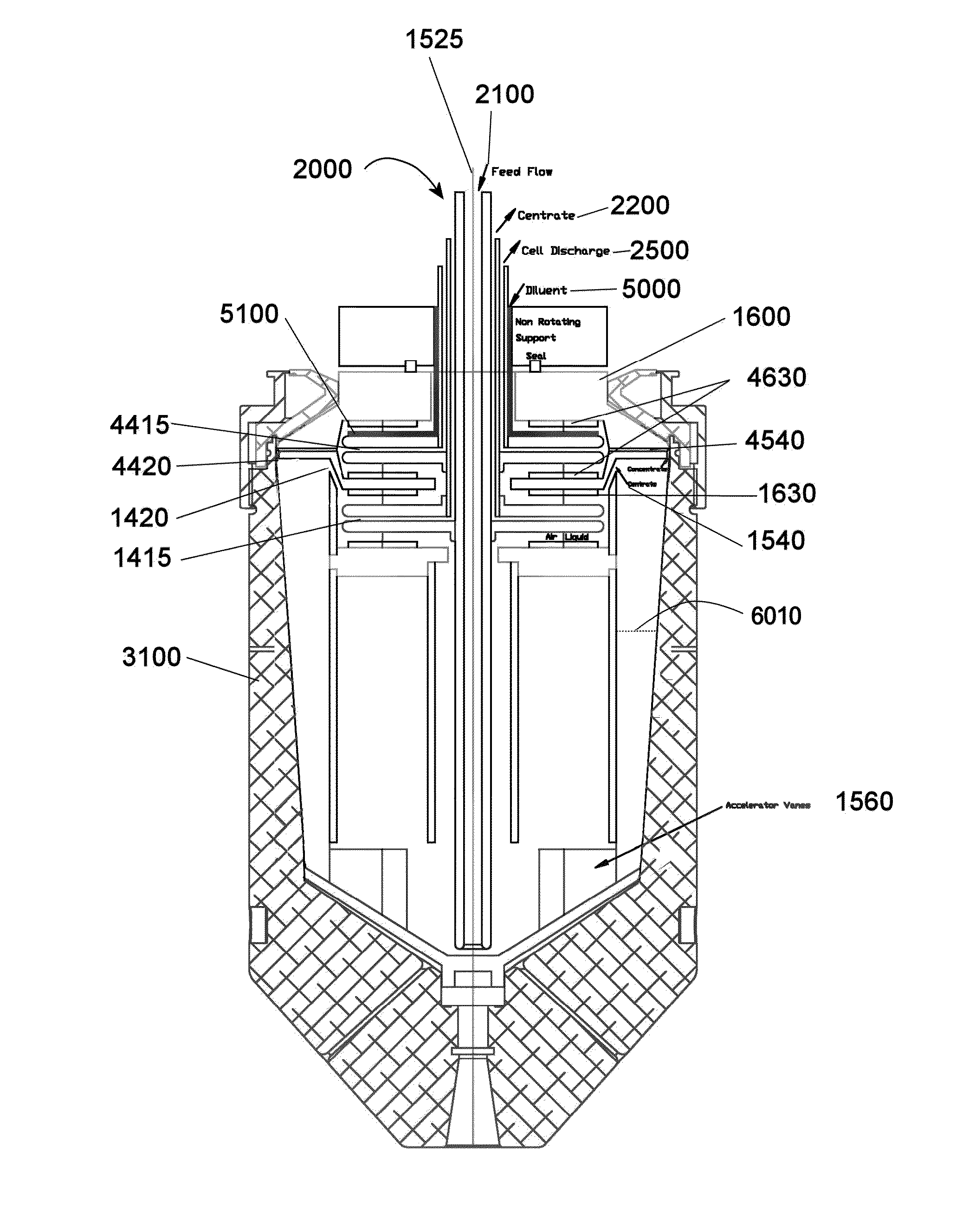

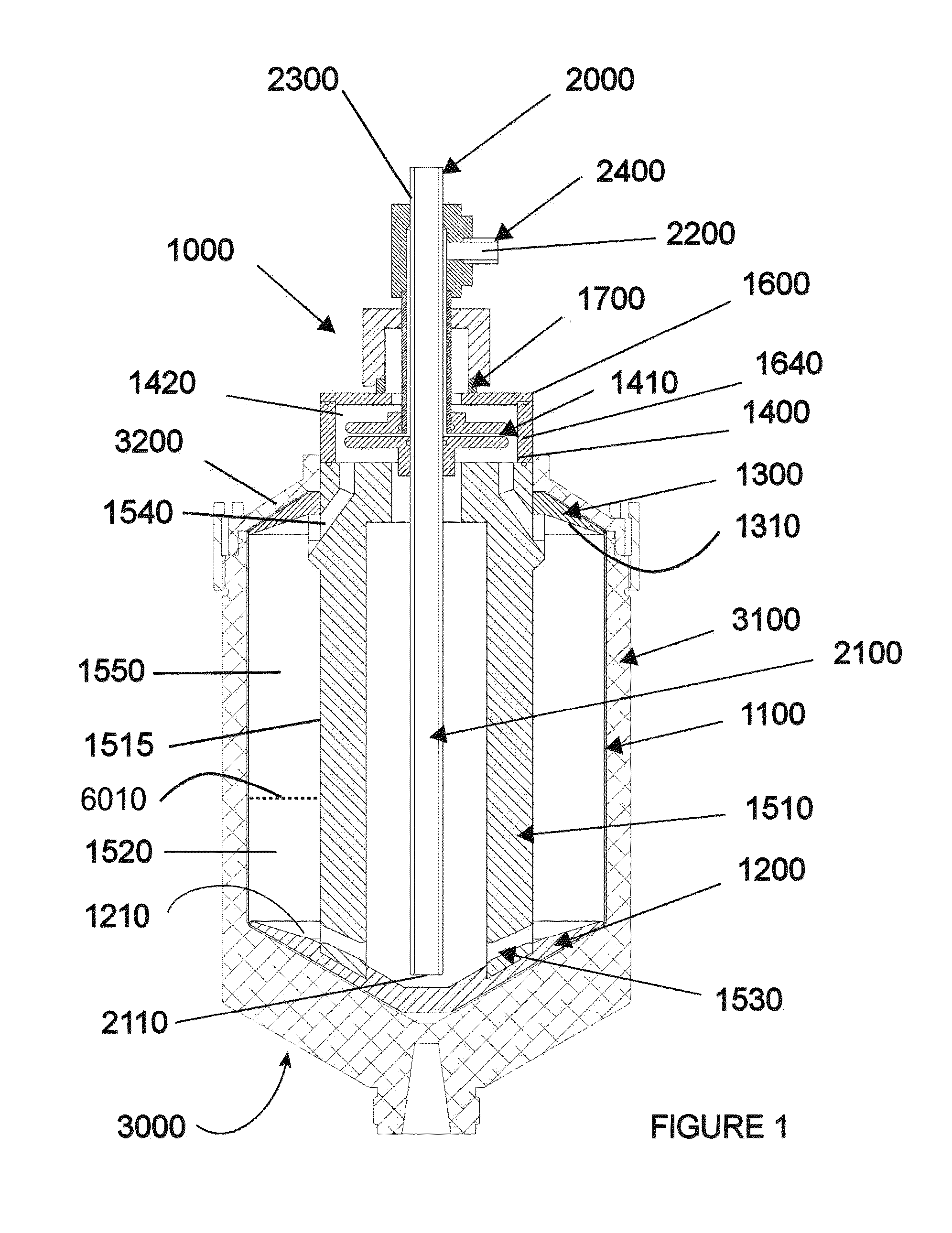

Single Use Centrifuge System for Highly Concentrated and/or Turbid Feeds

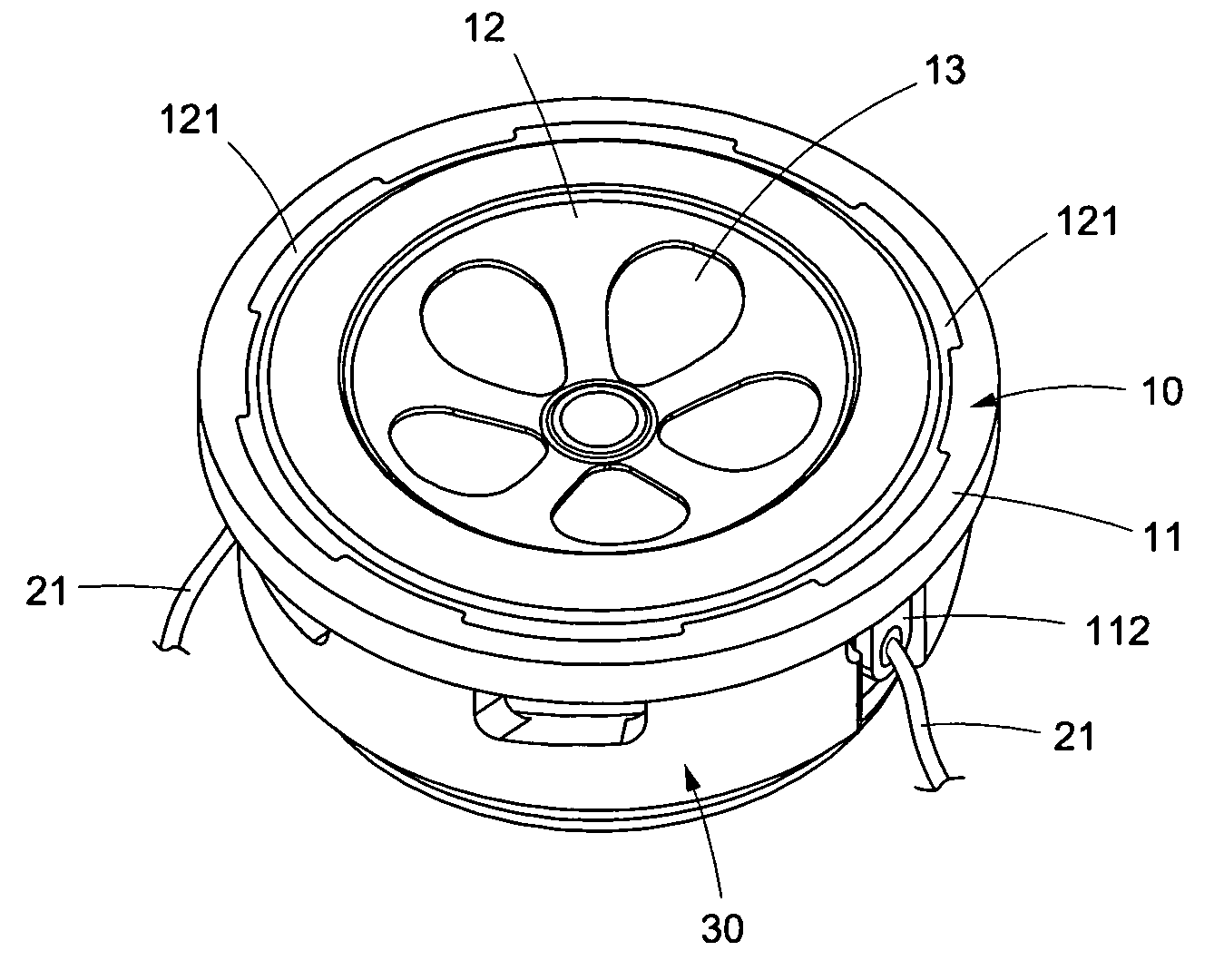

ActiveUS20130089917A1Angular velocity stabilityEfficient processingBioreactor/fermenter combinationsBiological substance pretreatmentsTurbidityAngular velocity

A method and apparatus for cell harvest of production scale quantities of cell cultures using single use components comprising a flexible membrane mounted on a rigid frame and is supported within a multiple use rigid centrifuge bowl, such single use components including a core with an increased diameter and an internal truncated cone shape in order to permit the system to maintain a sufficiently high angular velocity to create a settling velocity suited to efficiently processing highly concentrated cell culture streams. Features which minimize feed turbidity, and others which permit the continuous or semi-continuous discharge of cell concentrate, increase the overall production rate over the rate which can be achieved using current intermittent processing methods for large cell culture volumes. Injection of a diluent during the cell concentrate removal process permits more complete removal of viscous cell concentrates.

Owner:PNEUMATIC SCALE CORP

Electromagnetic vibrator and producing method

ActiveUS20100220888A1Reduce manufacturing costSimple methodDynamo-electric machinesTransducer casings/cabinets/supportsProduction rateCoupling

An electromagnetic vibrator includes an upper basin frame, an induction coil, and a lower basin frame, wherein the upper basin frame includes a supporting frame, a vibration sheet, and a suspension edge element. The vibration sheet and the suspension edge are integrally formed together via mold injecting, so as to achieve variety of style and colors of the speaker. The manufacturing method of the electromagnetic vibrator improves the traditional producing process of a speaker by minimizing the gluing procedure thereof. The machinery equipments replace the traditional manual process. The special coupling structure and unique process of the electromagnetic vibrator also reduce the amount of using glue, so that the manufacturing cost is minimized, the un-stability of manually operation process is minimized, the quality and production rate is enhanced, and the process is relatively more environmental friendly.

Owner:NINGBO SHENGYA ELECTRONICS

Wind turbine with mixers and ejectors

InactiveUS20090317231A1Improve productivityWind motor controlPump componentsHigh energyPopulated area

A Mixer / Ejector Wind Turbine (“MEWT”) system is disclosed which routinely exceeds the efficiencies of prior wind turbines. Unique ejector concepts are used to fluid-dynamically improve many operational characteristics of conventional wind turbines for potential power generation improvements of 50% and above. Applicants' preferred MEWT embodiment comprises: an aerodynamically contoured turbine shroud with an inlet; a ring of stator vanes; a ring of rotating blades (i.e., an impeller) in line with the stator vanes; and a mixer / ejector pump to increase the flow volume through the turbine while rapidly mixing the low energy turbine exit flow with high energy bypass wind flow. The MEWT can produce three or more time the power of its un-shrouded counterparts for the same frontal area, and can increase the productivity of wind farms by a factor of two or more. The same MEWT is safer and quieter providing improved wind turbine options for populated areas.

Owner:FLODESIGN WIND TURBINE

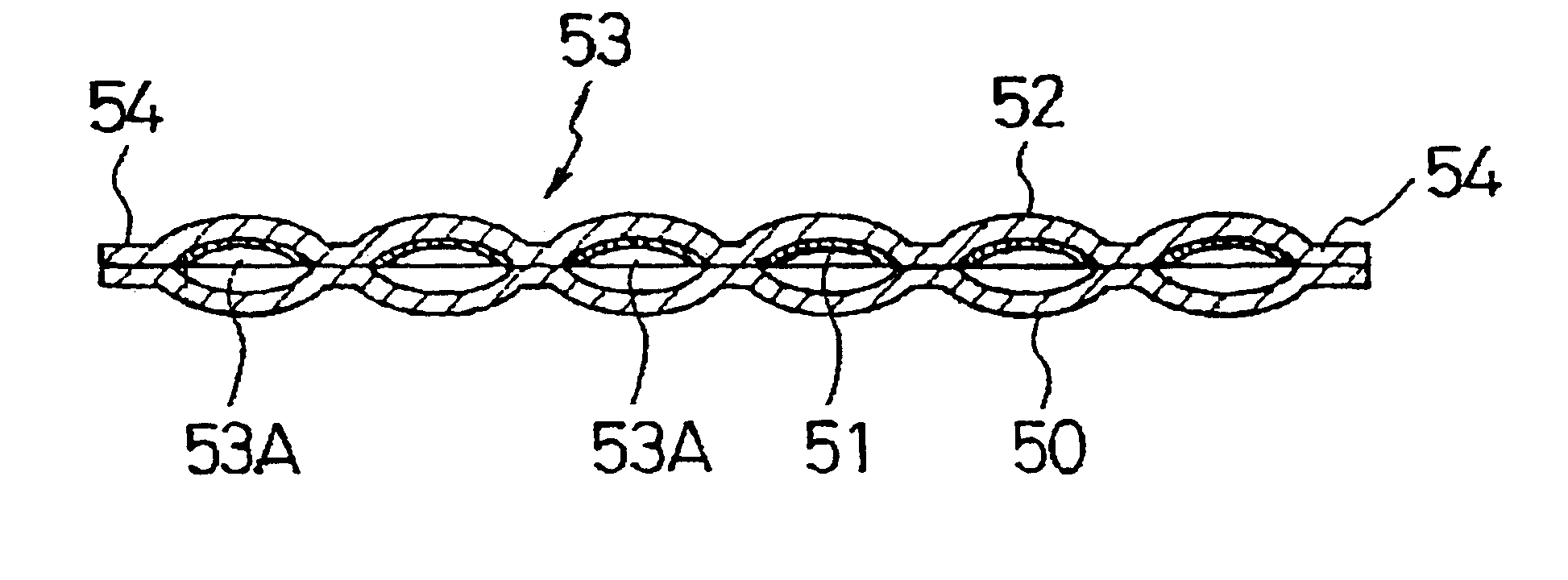

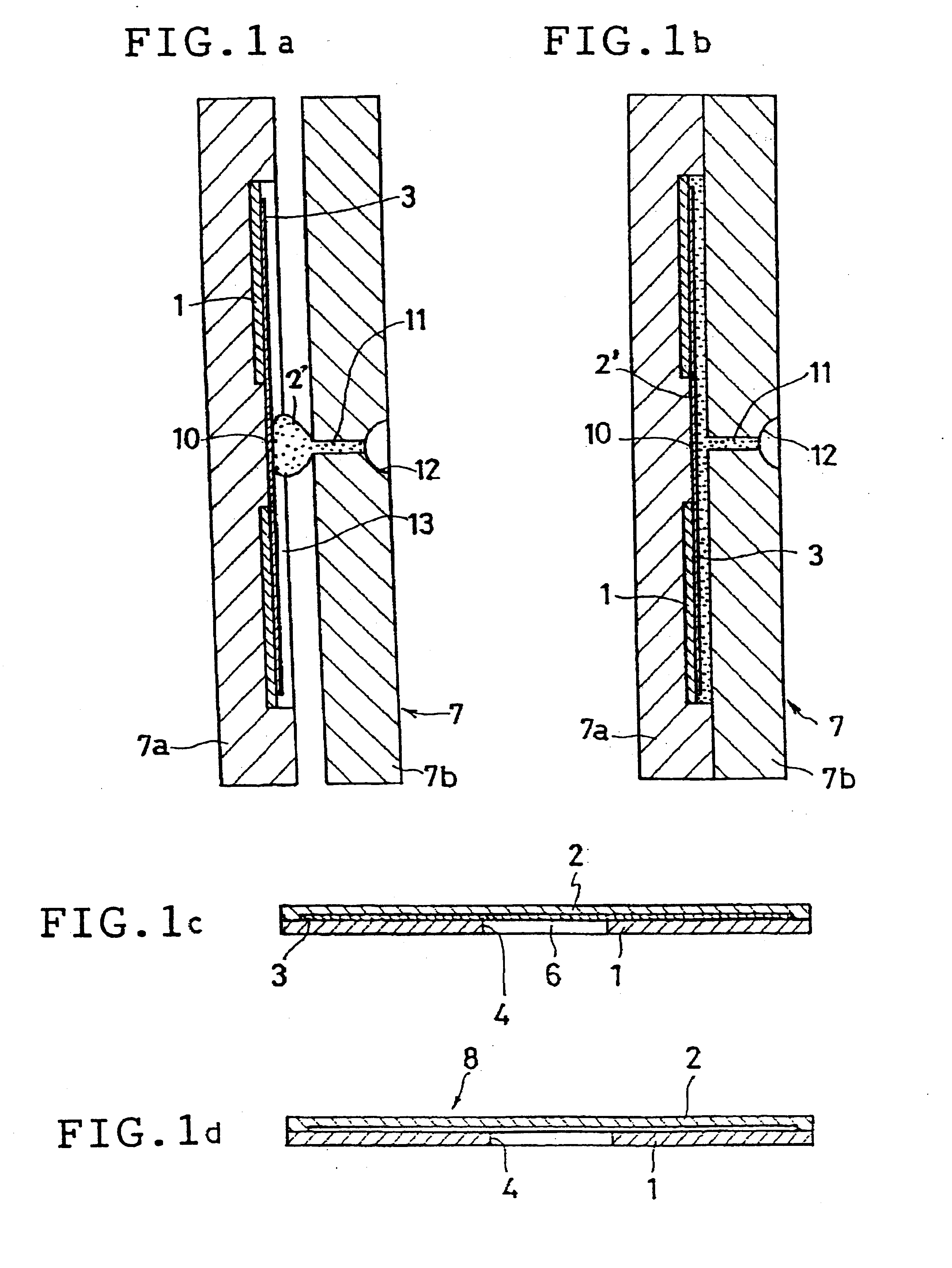

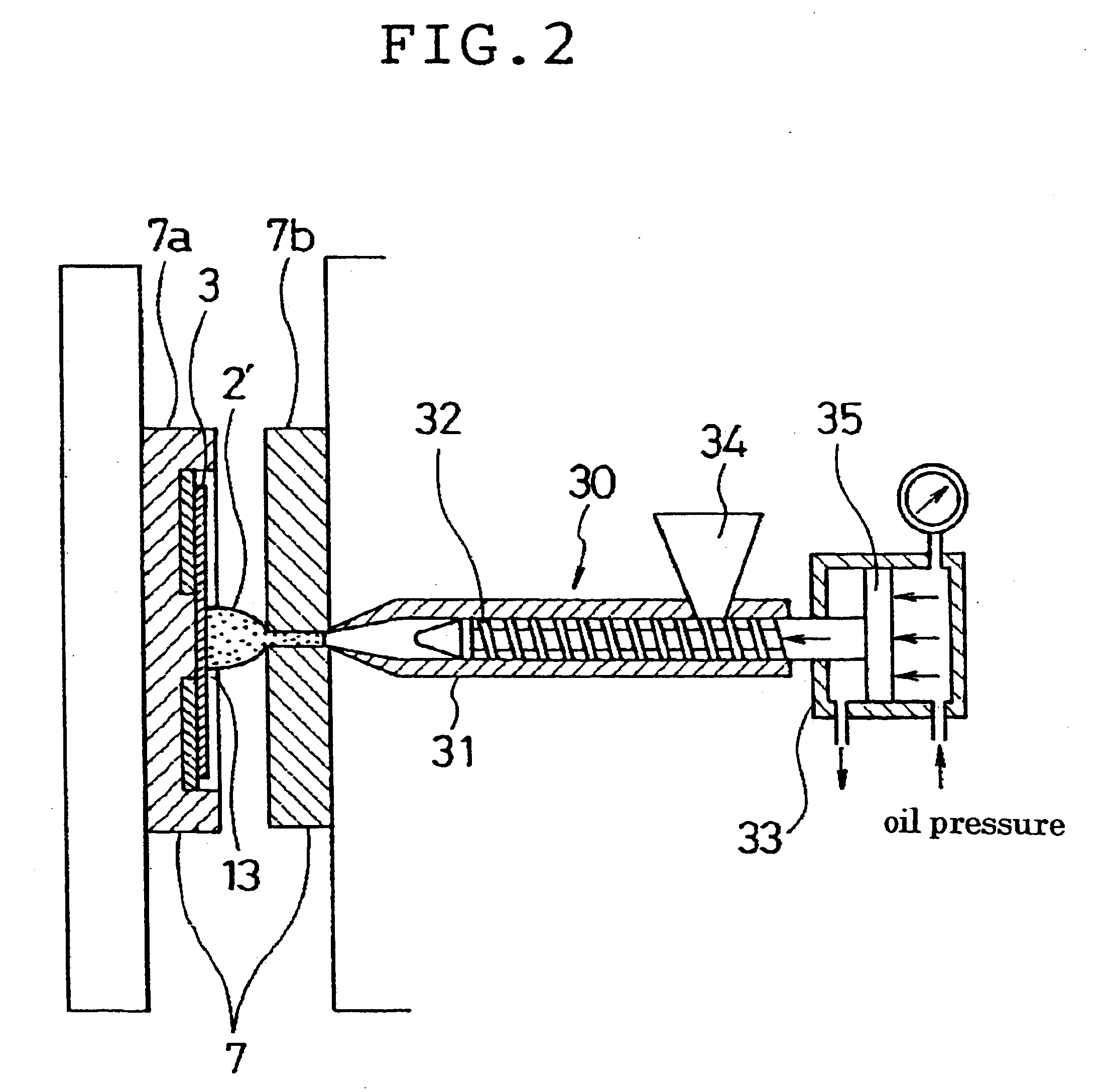

Resin bag and manufacturing method thereof

InactiveUS6413597B1High bonding strengthImprove productivityPedestrian/occupant safety arrangementSynthetic resin layered productsProduction rateEngineering

A method of manufacturing a resin bag whereby the peripheral edge of the bag such as a resin air baa is not bulky, the bonding strength is still sufficient, and the productivity is increased, is provided. A first resin sheet 1 and a heat-resisting sheet 3 are overlaid on each other and are disposed in a cavity 13 of a mold 7. The diameter of the heat-resisting sheet 3 is smaller than that of the first resin sheet 1 so that a portion of the sheet 1 is exposed outside the heat-resisting sheet 3. After injecting resin 2' into the cavity 13 through a sprue bush end 12, the resin 2'is pressed and expanded to mold a second resin sheet 2 and bond the sheet 2 to the sheet 1 at the peripheries thereof.

Owner:TAKATA CORPORATION

Production process and system of positive and negative electrode paste of lithium battery

ActiveCN103268931AQuality improvementImprove performanceElectrode manufacturing processesProduction rateMetallurgy

The invention discloses a production process and a production system of positive and negative electrode paste of a lithium battery. Positive and negative electrode materials are added to a first-order twin-screw extruder through a conveying device; then the materials are added to a second-order twin-screw extruder so as to be shorn and emulsified, and the consistency processing is performed; and finally, the materials are vacuum-degassed, cooled and shorn to obtain the positive and negative electrode paste. The dispersion degree of lithium ions in the paste is increased, the quality and performance of the battery in the subsequent production is effectively improved, the productivity is increased, and the cost input is reduced.

Owner:FOSHAN GOLD SILVER RIVER INTELLIGENT EQUIP CO LTD

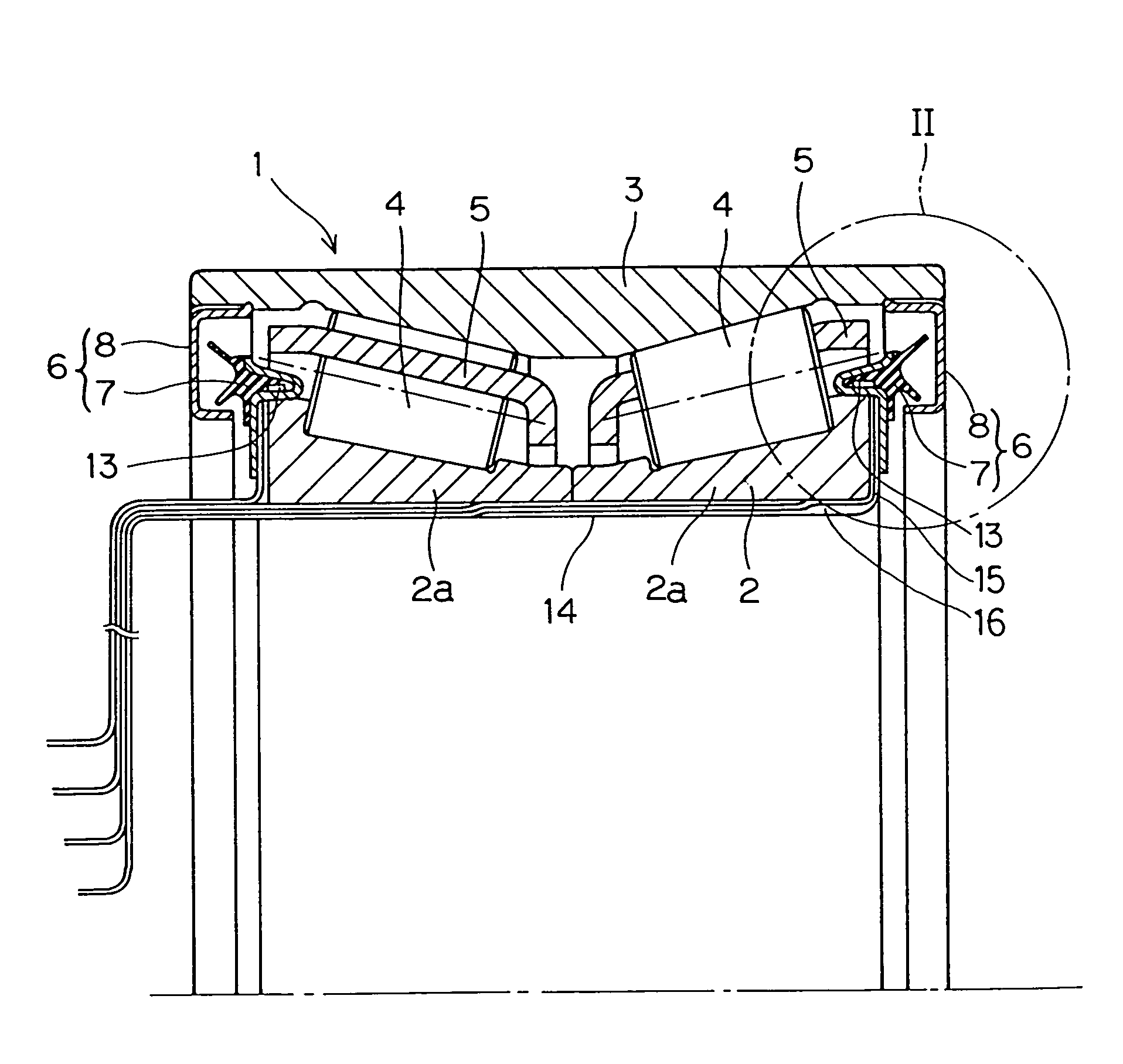

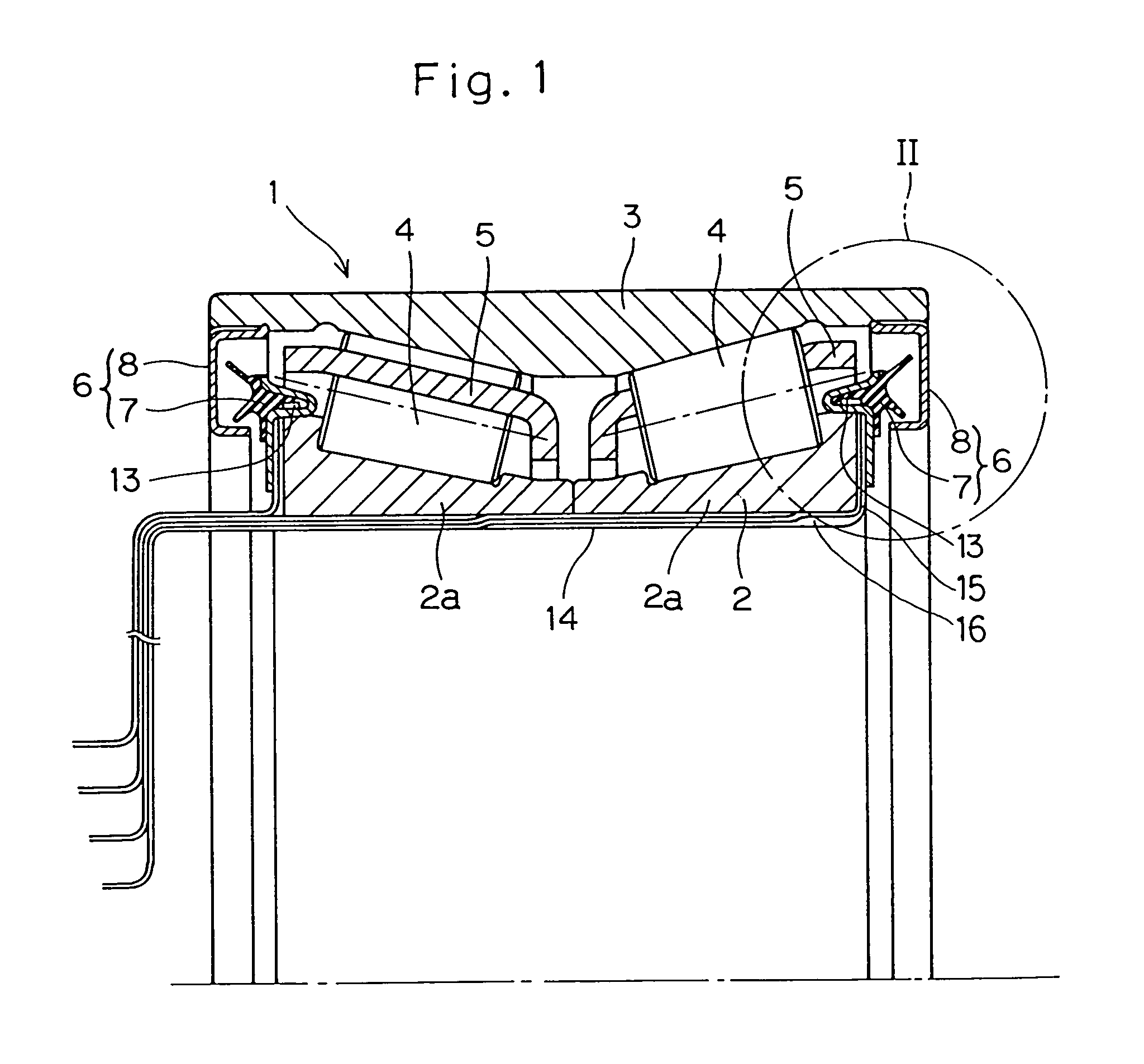

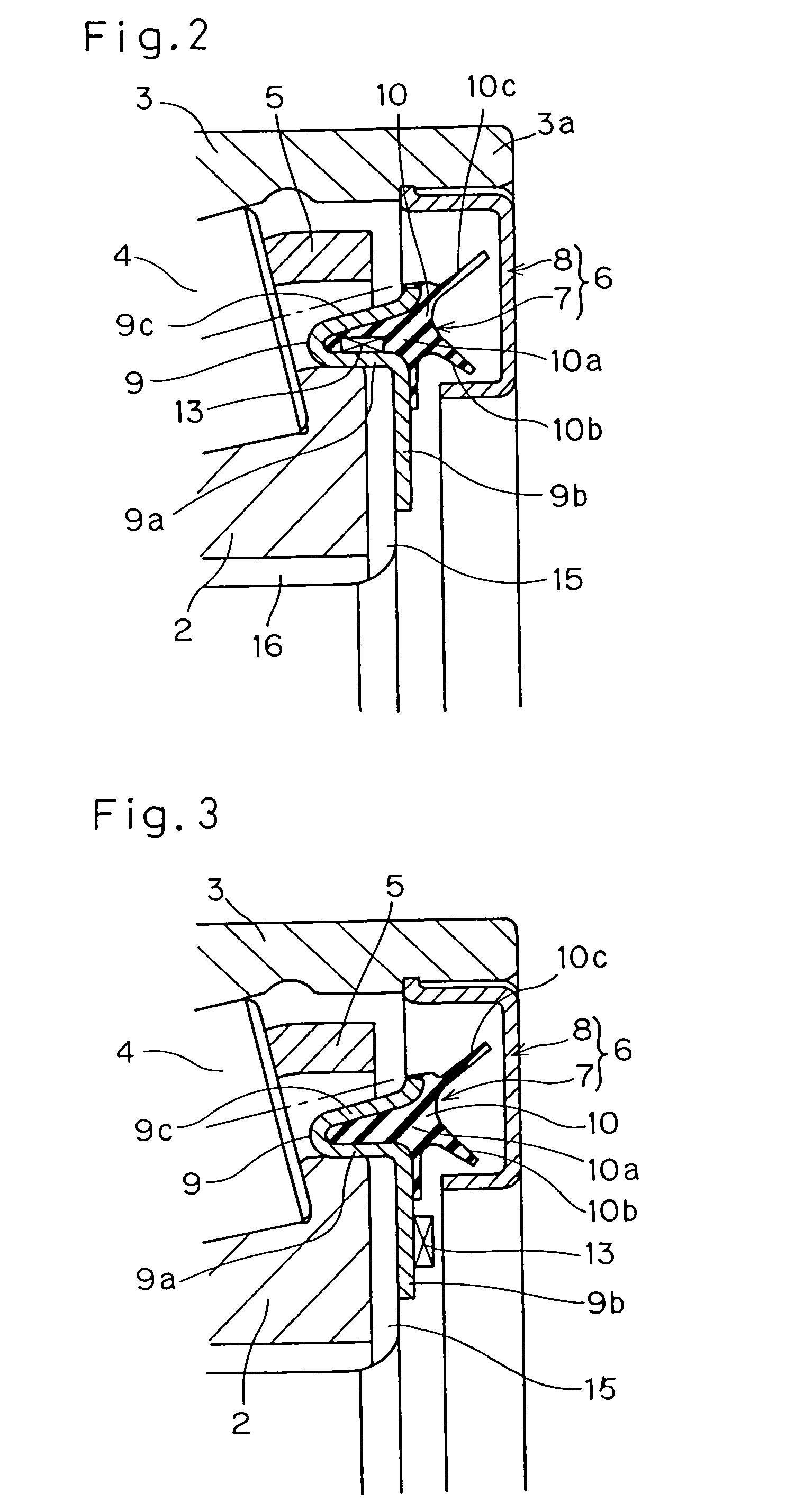

Bearing assembly with temperature sensor

InactiveUS7018105B2Improve detection accuracyReduce the number of partsThermometer detailsEngine sealsElectrical resistance and conductanceProduction rate

To provide a bearing assembly having a temperature sensor built therein, in which the accuracy of detection of the abnormal temperature is increased, the number of component parts is reduced and the productivity can be increased, a rolling bearing assembly (1) includes a sealing member (7) secured to a stationary bearing ring and a temperature sensor (13) is secured to the sealing member (7). The stationary bearing ring is an inner race (2) if the bearing assembly (1) is of an outer race rotating type. The sealing member (7) is made up of a core metal 9 and an elastic member (10) made of a rubber or resin. The temperature sensor (13) is fixed to the core metal (9) of the sealing member (7) either by means of an insert molding of the elastic member (10) or soldering after forming the sealing member (7). The temperature sensor (13) is in the form of a chip-type laminar thermistor.

Owner:SONY CORP +1

Process and mechanism to produce granulated organic-mineral fertilizer based on concentrated vinasse

InactiveUS20090133456A1Cheap manufacturingInexpensive to maintainClimate change adaptationBioloigcal waste fertilisersMicroorganismProduction rate

A process and mechanism to produce granulated organic-mineral fertilizer based on concentrated vinasse, comprising specific conditions of raw material preparation, volume and amounts of mixtures, humidity of the materials used in the mixture, homogenization, granulation, drying and packaging, relation on amount of the product intended to granulate versus length of the granulator cylinder, temperature of the gases for draying, speed of the gas for draying and relation on the length versus diameter of the dryer. To improve the fertilizer composition and its mixing with conventional fertilizers, the present invention uses other sub-products from the sugar cane mill and alcohol distillery industries to obtain organic-mineral fertilizers that replace conventional fertilizers, providing organic materials and microorganisms, required for the reactivation of the soil fertility and a superior approach by the plants, resulting in an increasing of the harvesting productivity and the use of smaller amounts compared with conventional fertilizers.

Owner:KIMEL DE COLOMBIA

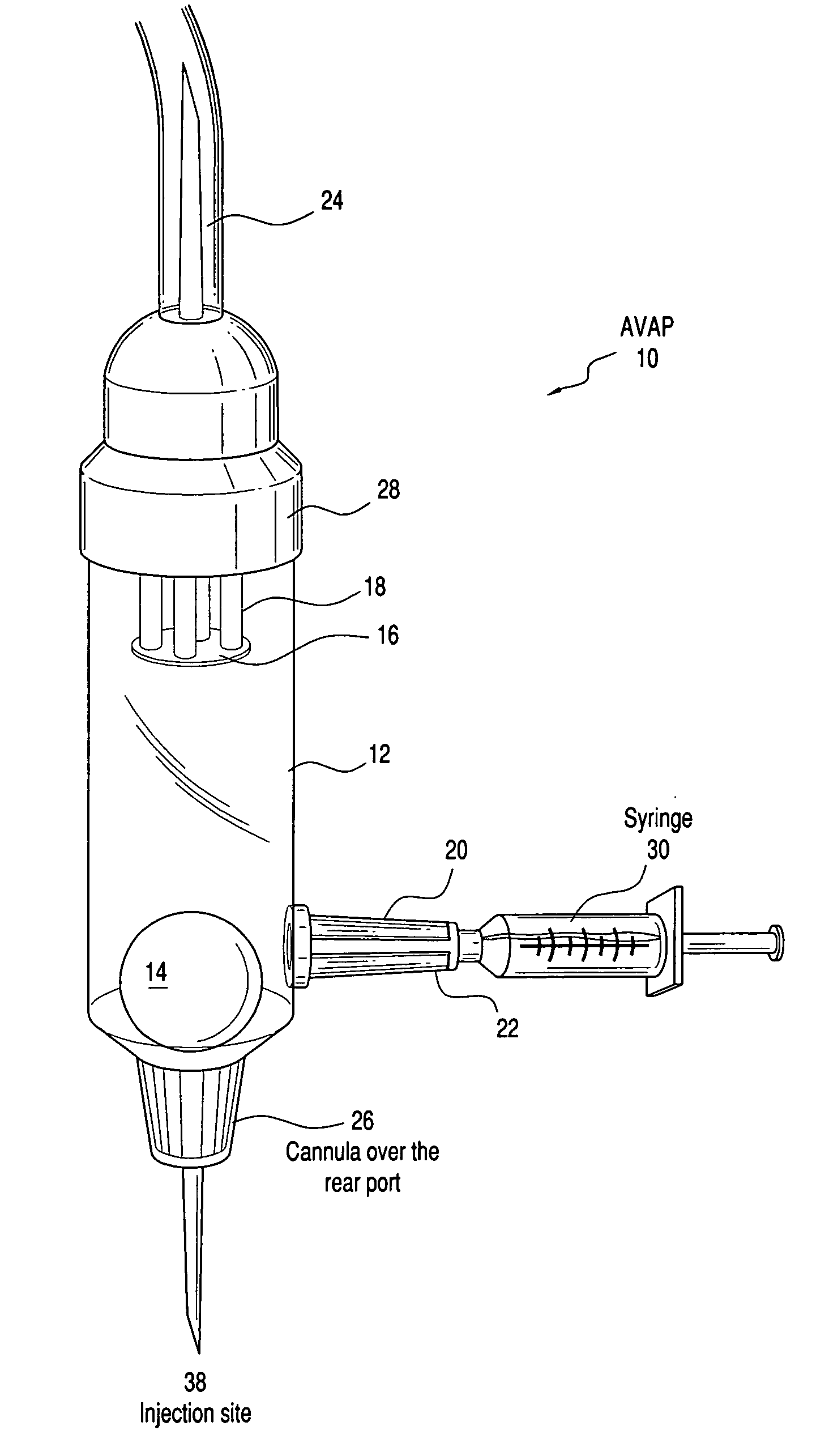

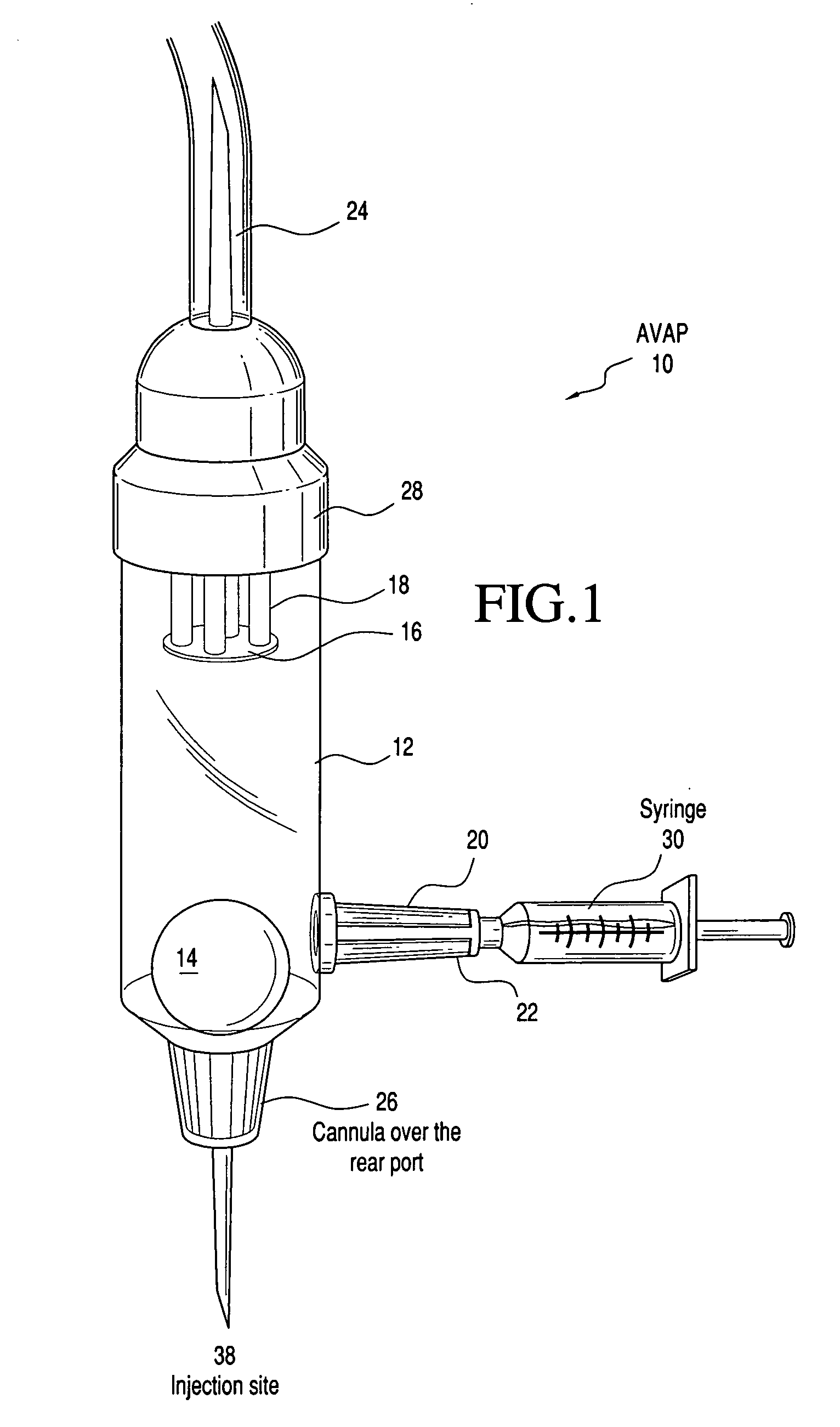

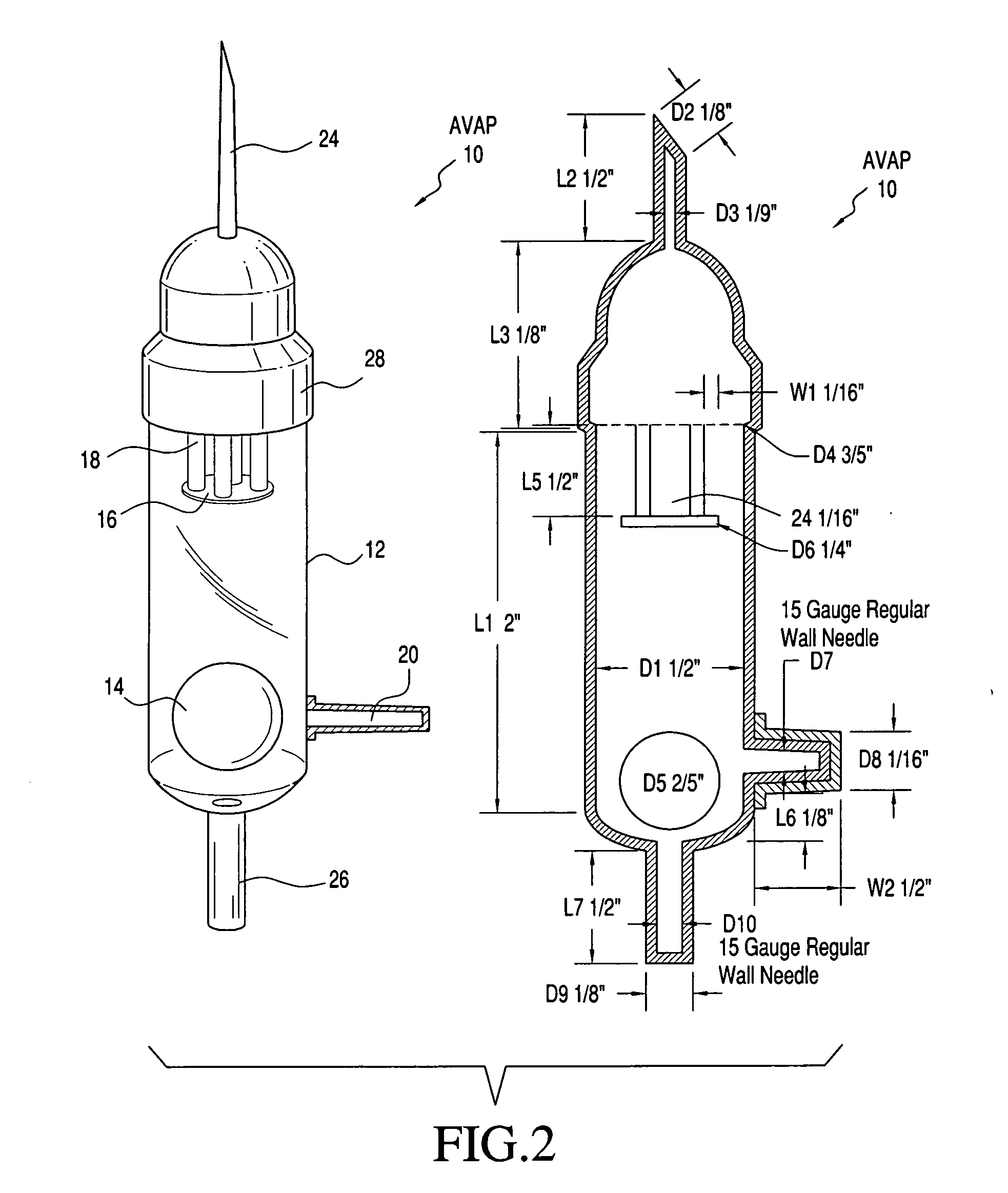

AVAP: air valve and port for intravenous (IV) tubing

InactiveUS20050283123A1Avoid blood circulationImprove productivityInfusion devicesProduction rateVein infusion

The invention provides an air valve for use in getting air out of intravenous (IV) tubing and preventing the air from intravenous (IV) tubing from entering healthcare patients' veins. In an illustrative embodiment the air valve is attached at one end to the intravenous (IV) tubing that hangs from an intravenous (IV) bag and at the other end to the injection site, where a needle is inserted into a patient's vein. The invention prevents any air from entering a healthcare patient's blood stream and causing air embolism, a potentially lethal complication caused by an accumulation of air bubbles in the blood stream that hinders the circulation of blood. The invention will also lead to increased productivity of intravenous (IV) drips since it allows for a seamless interchange of medications and solutions.

Owner:LYDE FELICIA C +1

Single use centrifuge system for highly concentrated and/or turbid feeds

ActiveUS9222067B2Efficient processingAngular velocity stabilityBioreactor/fermenter combinationsBiological substance pretreatmentsProduction rateMultiple use

A method and apparatus for cell harvest of production scale quantities of cell cultures using single use components comprising a flexible membrane mounted on a rigid frame and is supported within a multiple use rigid centrifuge bowl, such single use components including a core with an increased diameter and an internal truncated cone shape in order to permit the system to maintain a sufficiently high angular velocity to create a settling velocity suited to efficiently processing highly concentrated cell culture streams. Features which minimize feed turbidity, and others which permit the continuous or semi-continuous discharge of cell concentrate, increase the overall production rate over the rate which can be achieved using current intermittent processing methods for large cell culture volumes. Injection of a diluent during the cell concentrate removal process permits more complete removal of viscous cell concentrates.

Owner:PNEUMATIC SCALE CORP

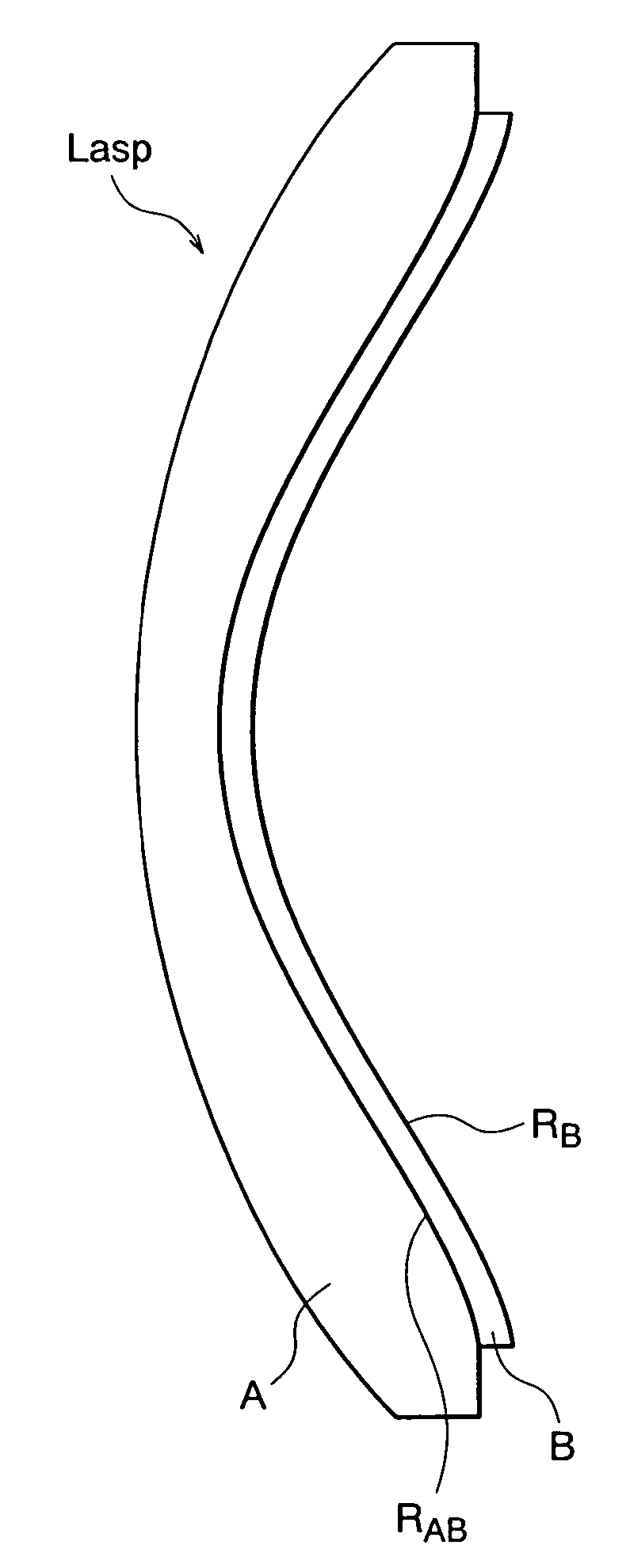

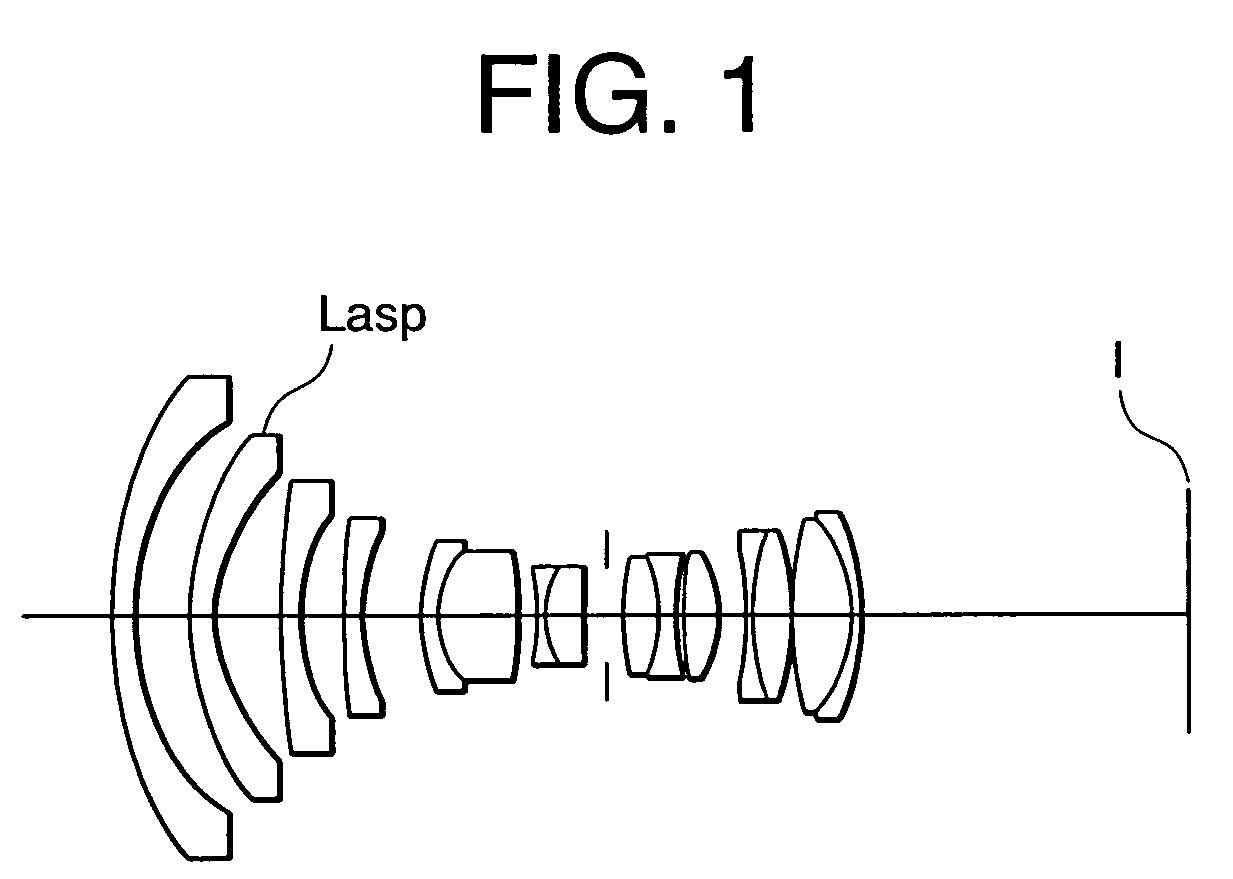

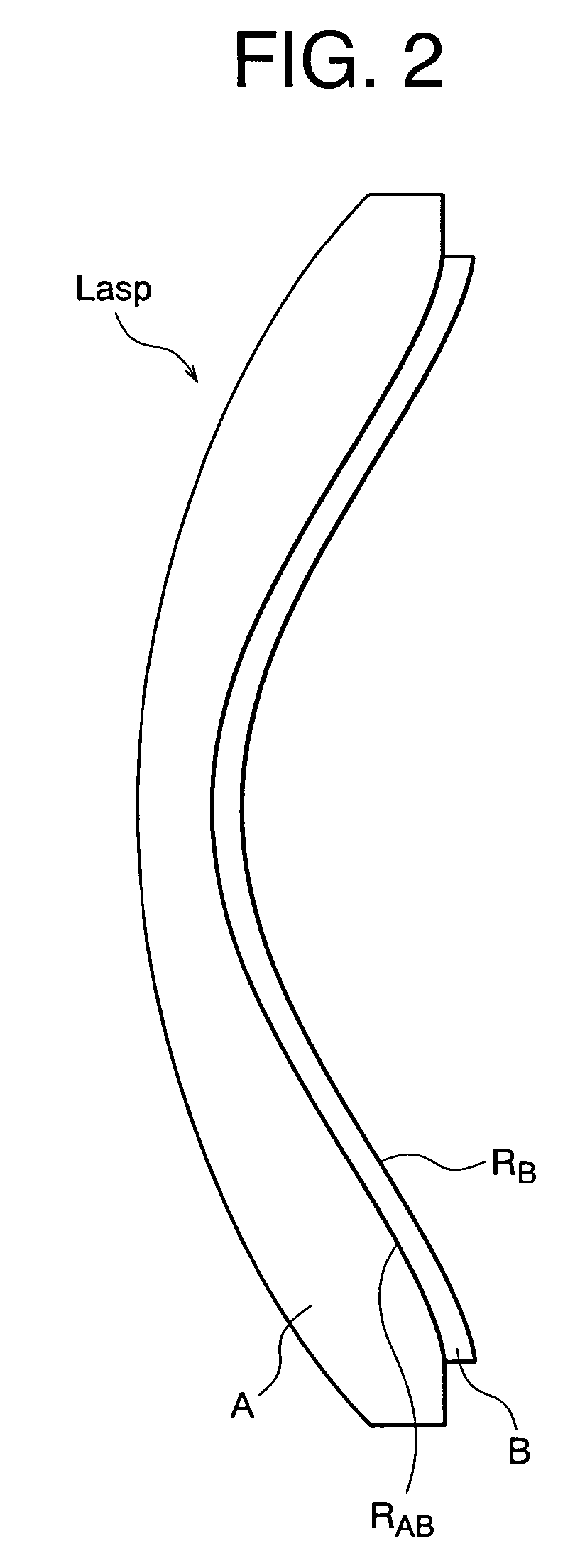

Aspherical lens and optical instrument using the same

ActiveUS7365916B2Compactness in dimensionLarge degree of freedom in designLensConditional expressionDegrees of freedom

Owner:NIKON CORP

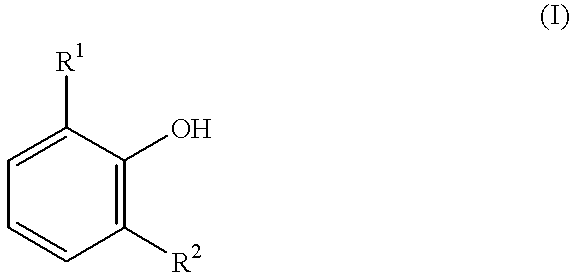

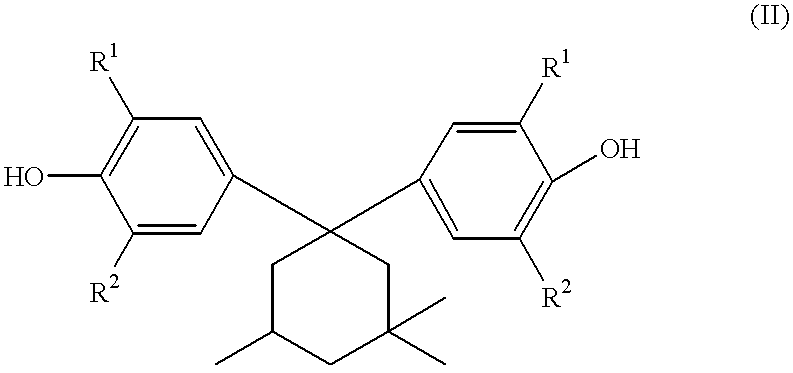

Process for producing 3, 3, 5-trimethylcyclohexylidenebisphenol

InactiveUS6284931B1Suppresses viscosity riseHigh yieldPhysical/chemical process catalystsOrganic compound preparationProduction rateBatch processing

A process for producing a 3,3,5-trimethylcyclohexylidenebisphenol, comprising pre-reacting a phenol (A), i.e., phenol whose 2- and 6-positions may be monosubstituted or disubstituted with an alkyl group having 1 to 4 carbon atoms, with 3,3,5-trimethylcyclohexanone (B) at a molar ratio ((A) / (B)) of 3 to 7 in the presence of an acid catalyst until 3,3,5-trimethylcyclohexanone (B) exhibits a degree of conversion of at least 90 mol %; adding the phenol (A) and / or an aromatic hydrocarbon (C) to the thus obtained reaction mixture; and post-reacting the resultant mixture. This process enables not only suppressing a rise of the viscosity of the reaction mixture but also obtaining the desired product at high yield. Therefore, this process is applicable to not only the productivity enhancement in batch processing but also a continuous reaction processing which has been regarded as being difficult.

Owner:HONSHU CHEM INDAL

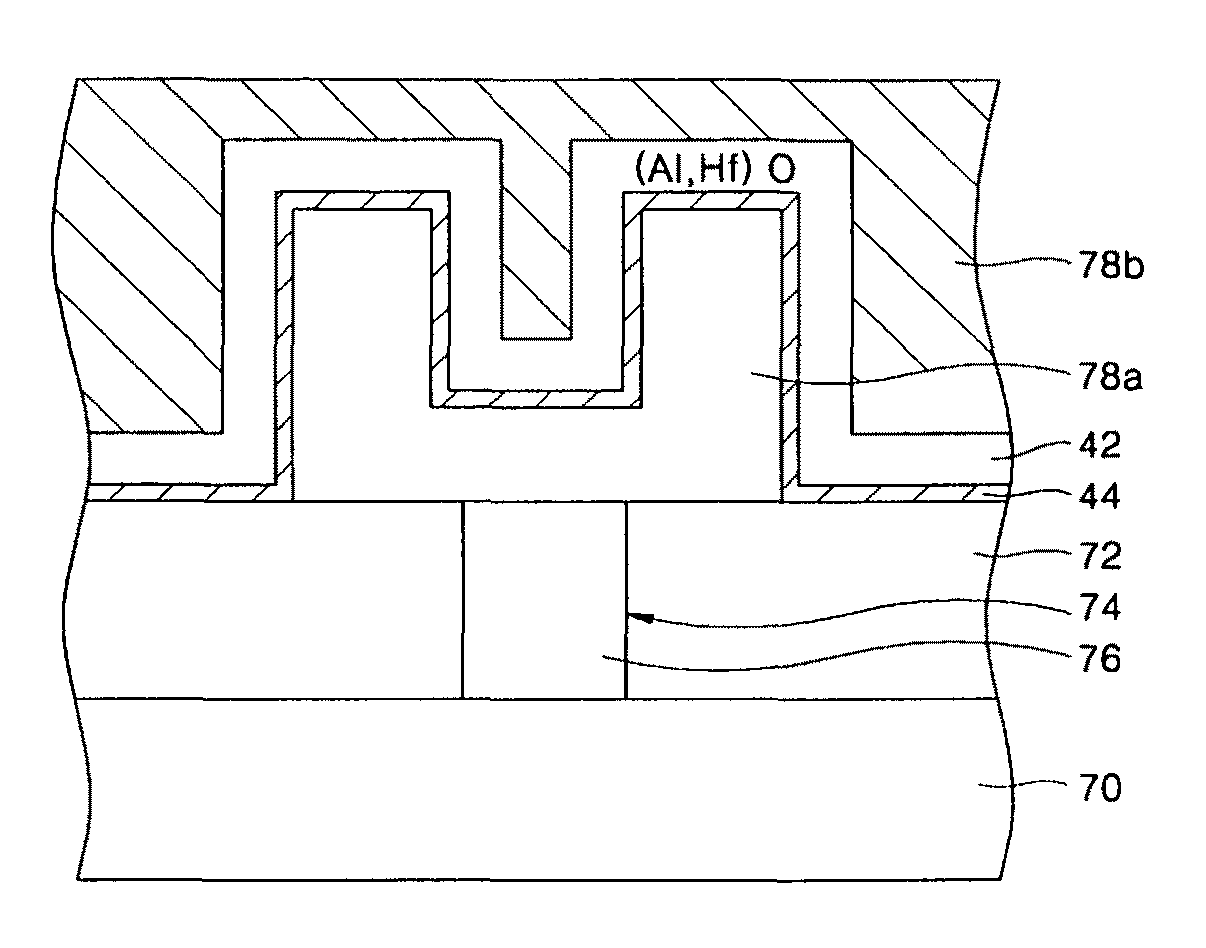

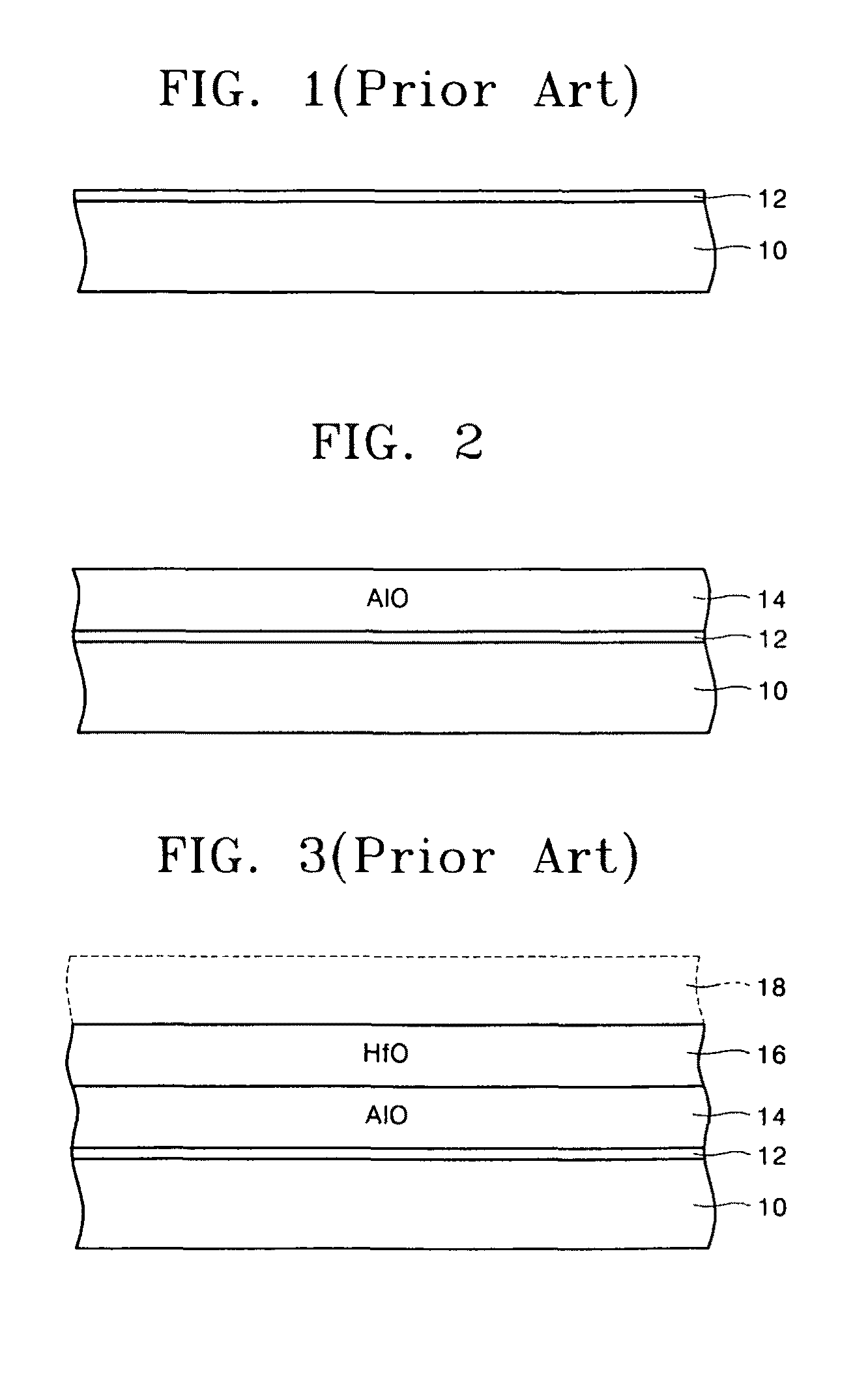

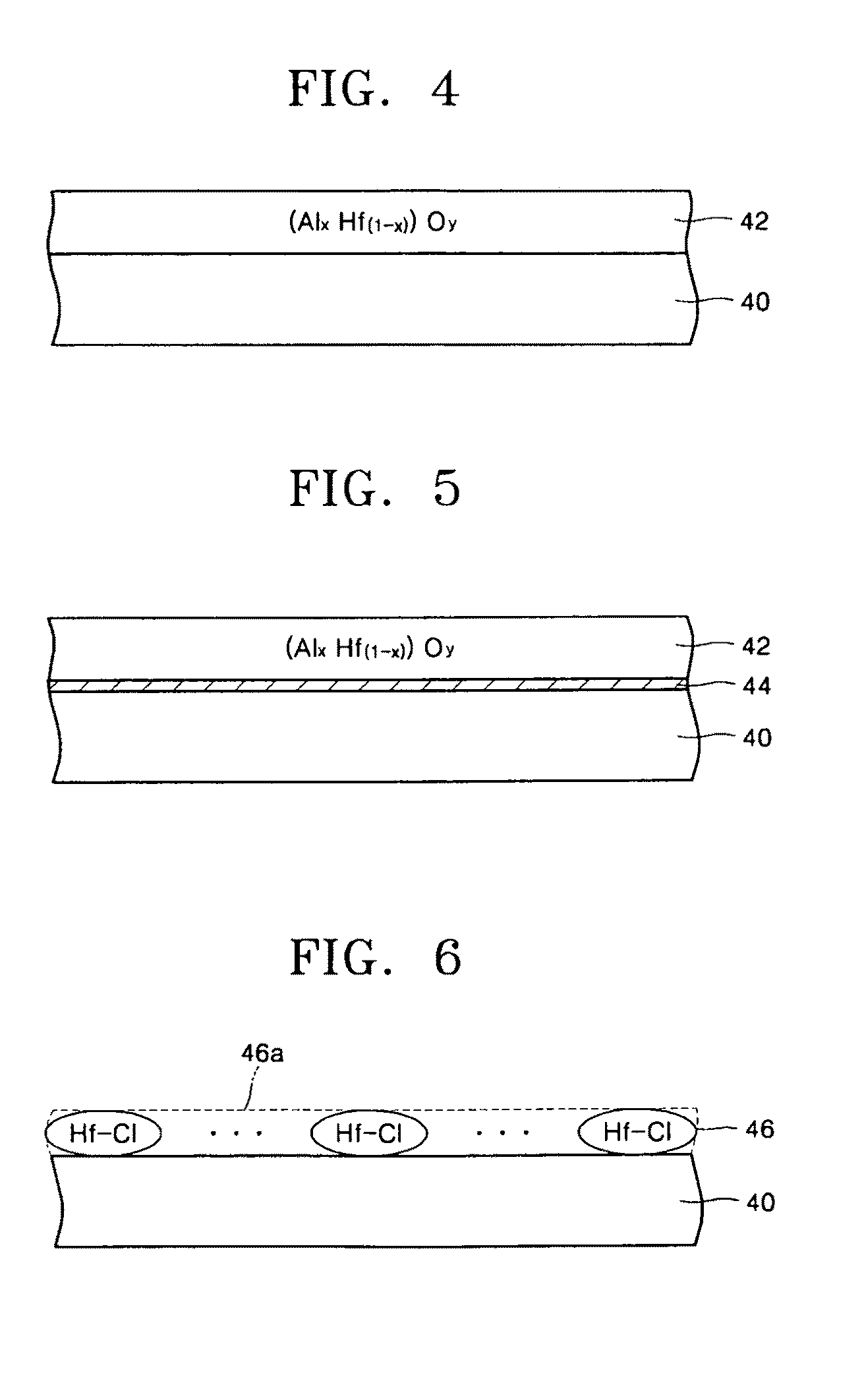

Method for manufacturing oxide film having high dielectric constant, capacitor having dielectric film formed using the method, and method for manufacturing the same

InactiveUS8143660B2Improve productivitySmall sizeTransistorSolid-state devicesProduction rateDielectric

Owner:SAMSUNG ELECTRONICS CO LTD

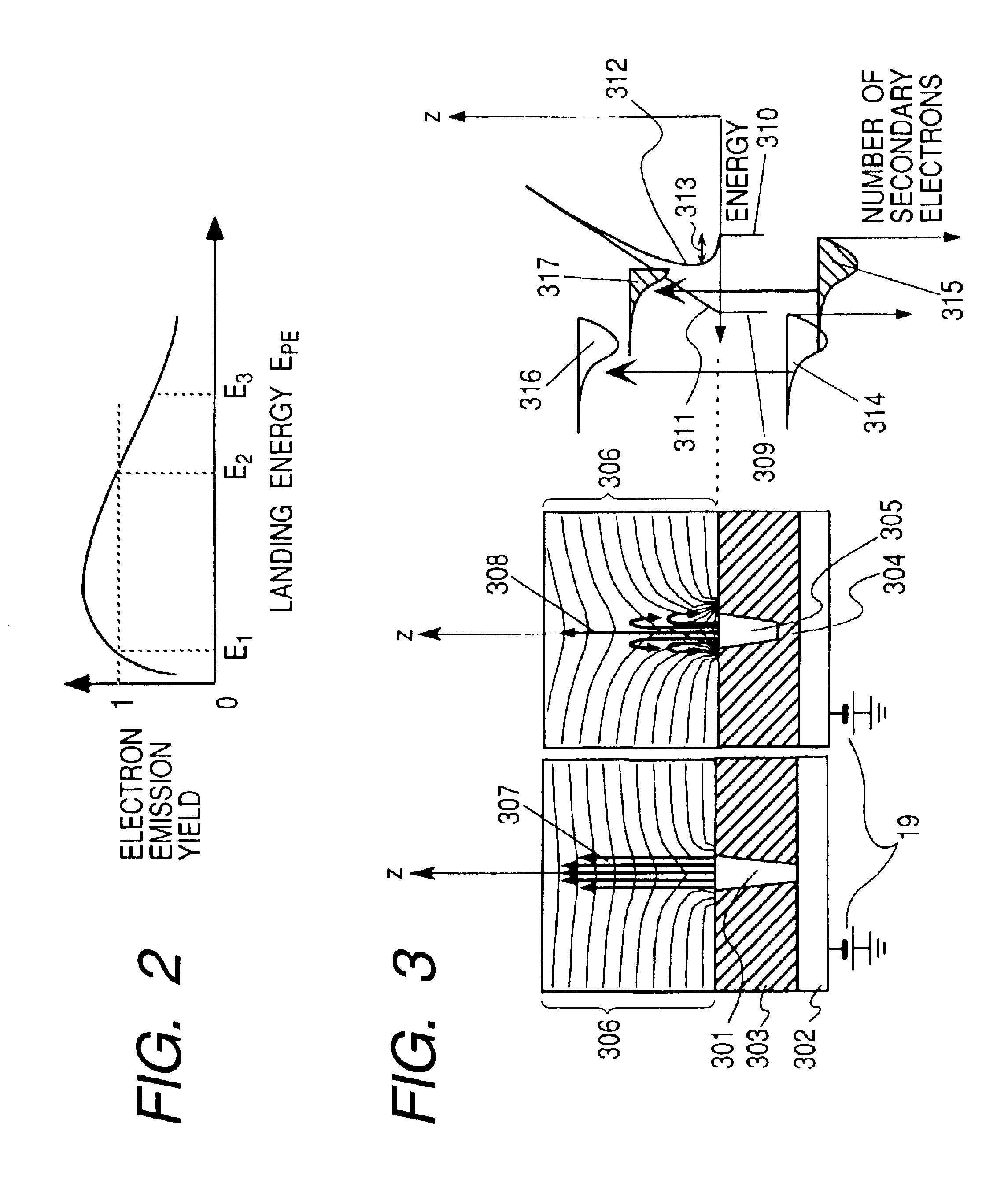

Wafer inspection method of charging wafer with a charged particle beam then measuring electric properties thereof, and inspection device based thereon

InactiveUS6853204B2Material analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementVoltage contrastElectric properties

A semiconductor defect inspection device and method for detecting defects of partially finished substrates (semiconductor wafers) for semiconductor devices is provided. The substrate surface is irradiated with a charged particle beam and a voltage contrast image is obtained while the charged voltage is controlled at a desired level, and the electric resistances of the irradiated area from the image are calculated to detect a defect and identify the type of defect. Further, the distribution of electric resistances on the whole surface of the substrate can be quickly worked out. The charged particle beam irradiation conditions are varied in order to bring the charged voltage of the area to a desired value. With this device / method, electric resistances of small portions at desired charged voltages and the corresponding electric resistances are measured in a non-contact manner to determine the type of defect. When this inspection method is applied to the PCB manufacturing process, defects can be detected and remedied at an early stage of the process. Consequently, in the semiconductor devices and other PCB related devices, the defect rate decreases and the productivity increase. Since the defect occurrence rate is reduced, the reliability of semiconductor devices is increased, and the efficiency in developing new products is improved.

Owner:HITACHI LTD

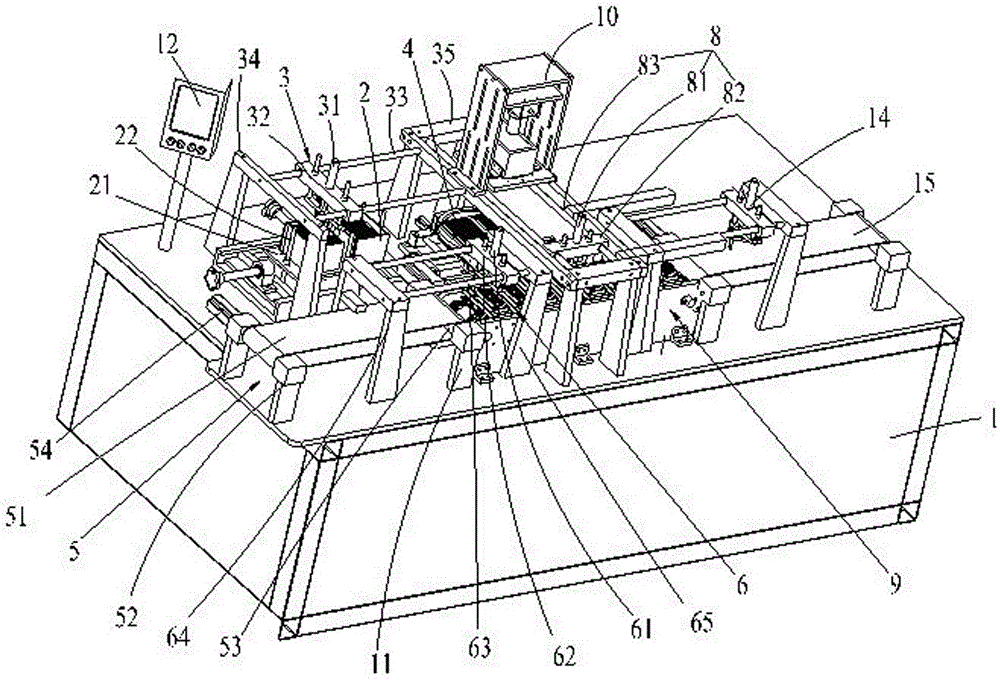

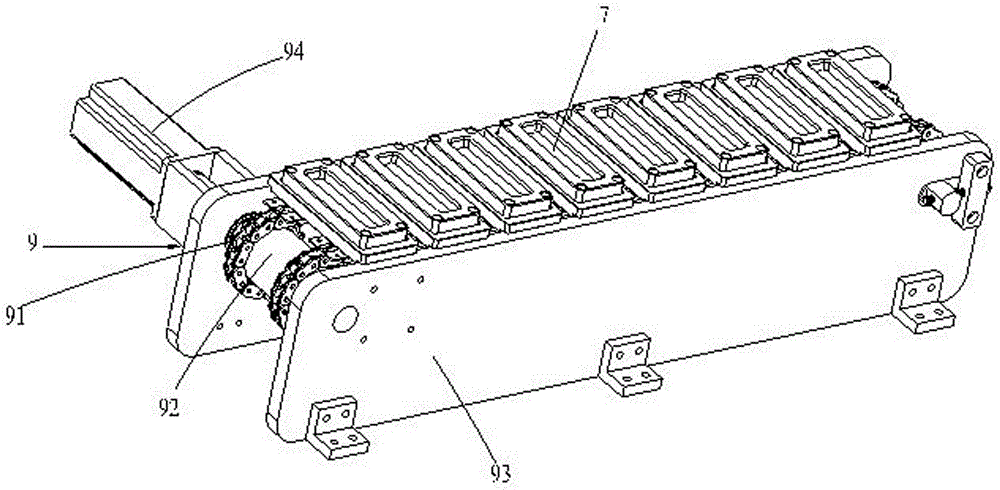

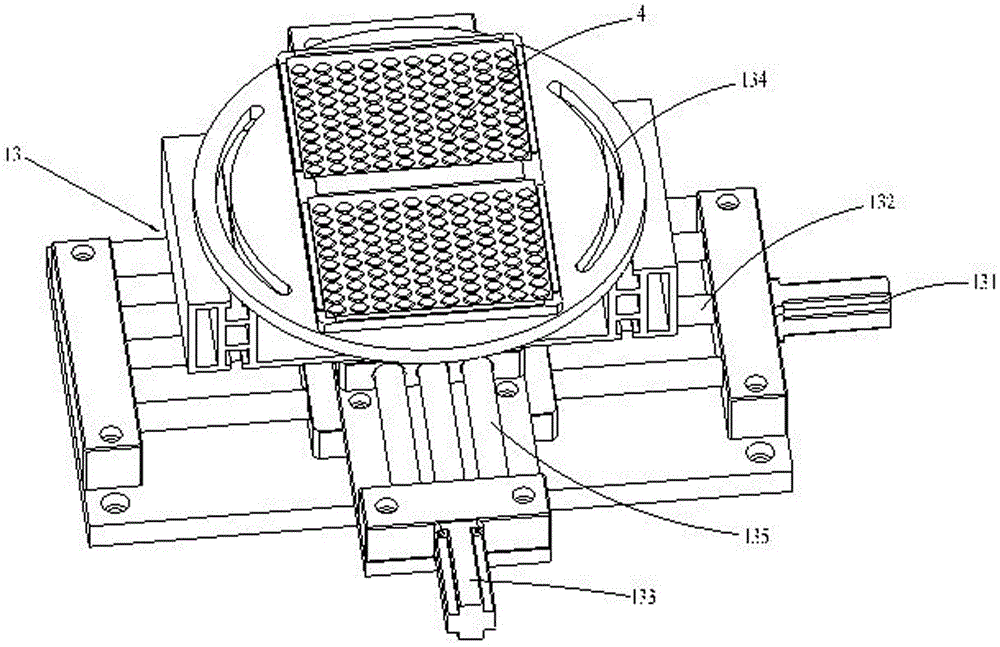

Full-automatic TSA (Transportation Security Administration) tag labeling machine

The invention belongs to the technical field of a tag labeling device, and particularly relates to a full-automatic TSA (Transportation Security Administration) tag labeling machine. The full-automatic TSA tag labeling machine comprises a stander, and a tag storage box, a tag sucker assembly, a tag adsorption and detection platform, a product storage conveyor belt, a product sucker assembly, a product positioning fixture assembly, a labeling sucker assembly, a product fixture transport system, a first vision system and a second vision system, which are respectively arranged on the stander. Compared with the prior art, the full-automatic TSA tag labeling machine has the following advantages: the labeling speed is high, error in labeling is avoided, firmness in labeling is realized, miss in labeling is avoided; moreover, after the tag is automatically labeled, the detection is not needed; meanwhile, the full-automatic TSA tag labeling machine can be connected with a full-automatic packaging machine, so that after the tag is labeled, a lock can be automatically sent into the packaging machine, the complete automation of labeling, detection and packaging can be realized, and the total productivity can be improved by 10 times or more.

Owner:DONGGUAN JINGYU IND

Process for preparing mefenamic acid

ActiveCN101475505AImprove productivityLow yieldOrganic chemistryOrganic compound preparationDimethylaniline N-oxideAnti-inflammatory analgesics

The invention belongs to the technical field of anti-inflammatory drug production, and relates to a method for preparing mefenamic acid. The method comprises: adding o-chlorobenzoic acid and 2,3-dimethylaniline into a system which is formed by a non-protonic polar solvent and a dehydrant, performing condensation reaction in the presence of an acid-binding agent, a catalyst and a phase-transfer catalyst, and obtaining mefenamic sodium; acidifying the mefenamic sodium and obtaining coarse mefenamic acid products; and refining the coarse mefenamic acid products in an organic solvent and water and obtaining finished mefenamic acid products. The method improves the production efficiency of the mefenamic acid and reduces the production cost of the mefenamic acid.

Owner:BAOJI TIANXIN PHARM CO LTD

Method and system for increasing well rate using well-capital-string perforation

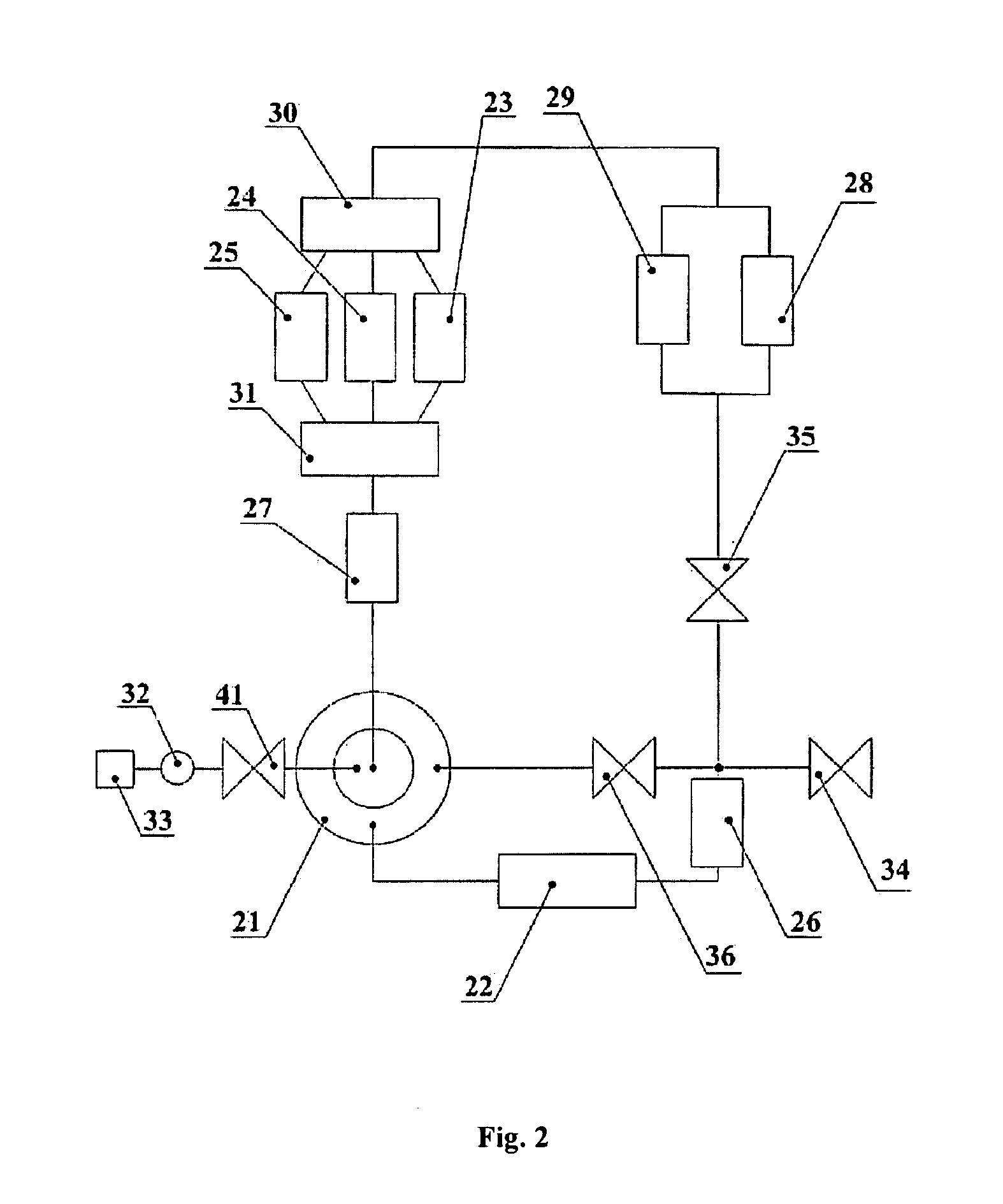

InactiveUS7568525B2Reduce laborReduce materialFluid removalVibration devicesProduction rateEngineering

The method of wells production rate increase which includes lowering the hydroperforator equipped with hydromonitor nozzles into the well on the pipe string; pumping liquid with abrasive material under pressure into the pipe string and hydroperforator; impacting the well elements and the stratum with the liquid with abrasive material via hydroperforator hydromonitor nozzles. When liquid with abrasive material impacts the well elements and the stratum, pressure is changed in the pipe string delivering the liquid with abrasive material. The difference is that pressure is changed over time so that pressure oscillations always include components with different frequencies, and in doing so, peak values (amplitudes) for at least some pressure oscillation components vary within the time interval Td, where Td≦Tv; Tv being the time of impact of the liquid with abrasive material on the well elements and the stratum via hydroperforator hydromonitor nozzles.

Owner:NORD SERVICE

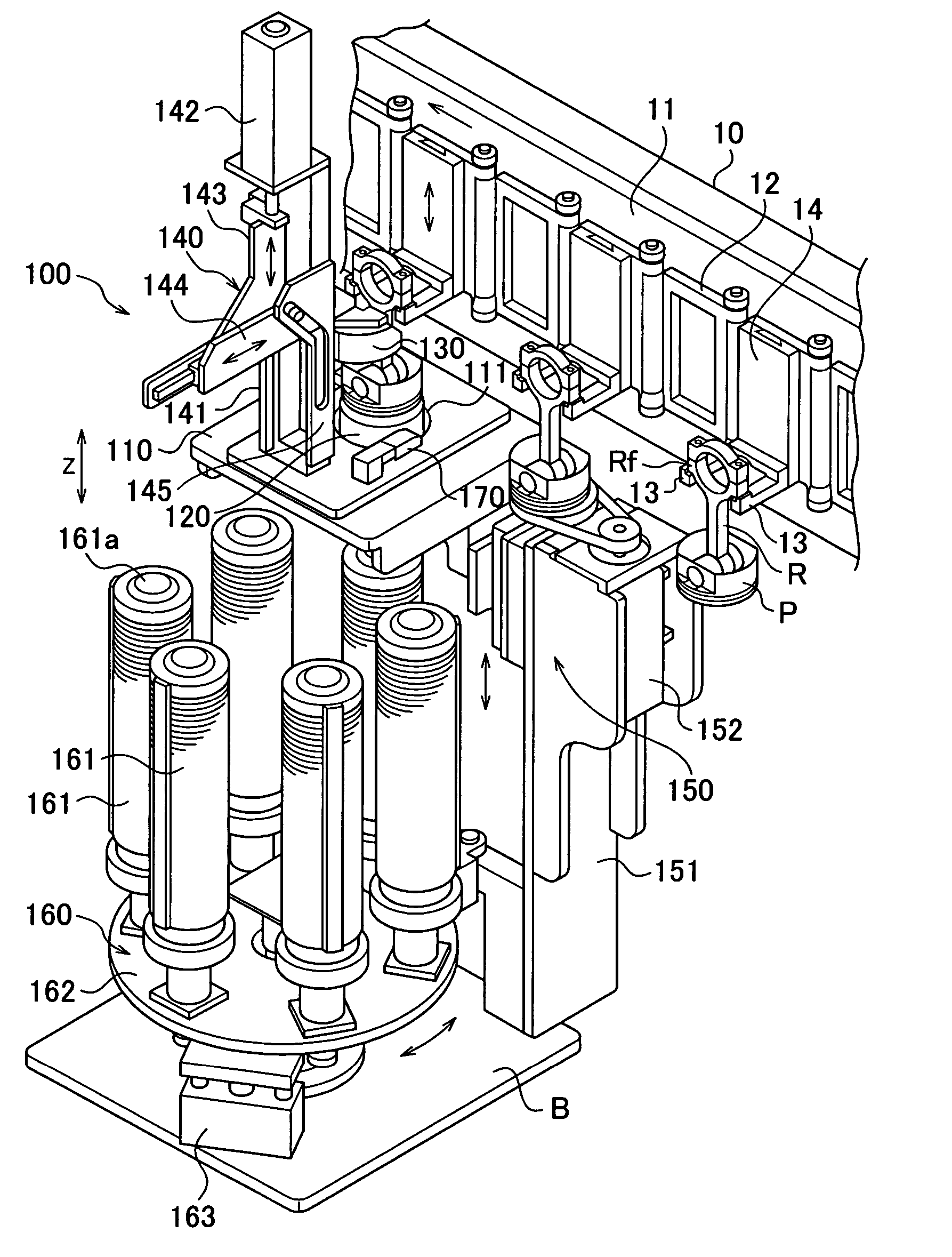

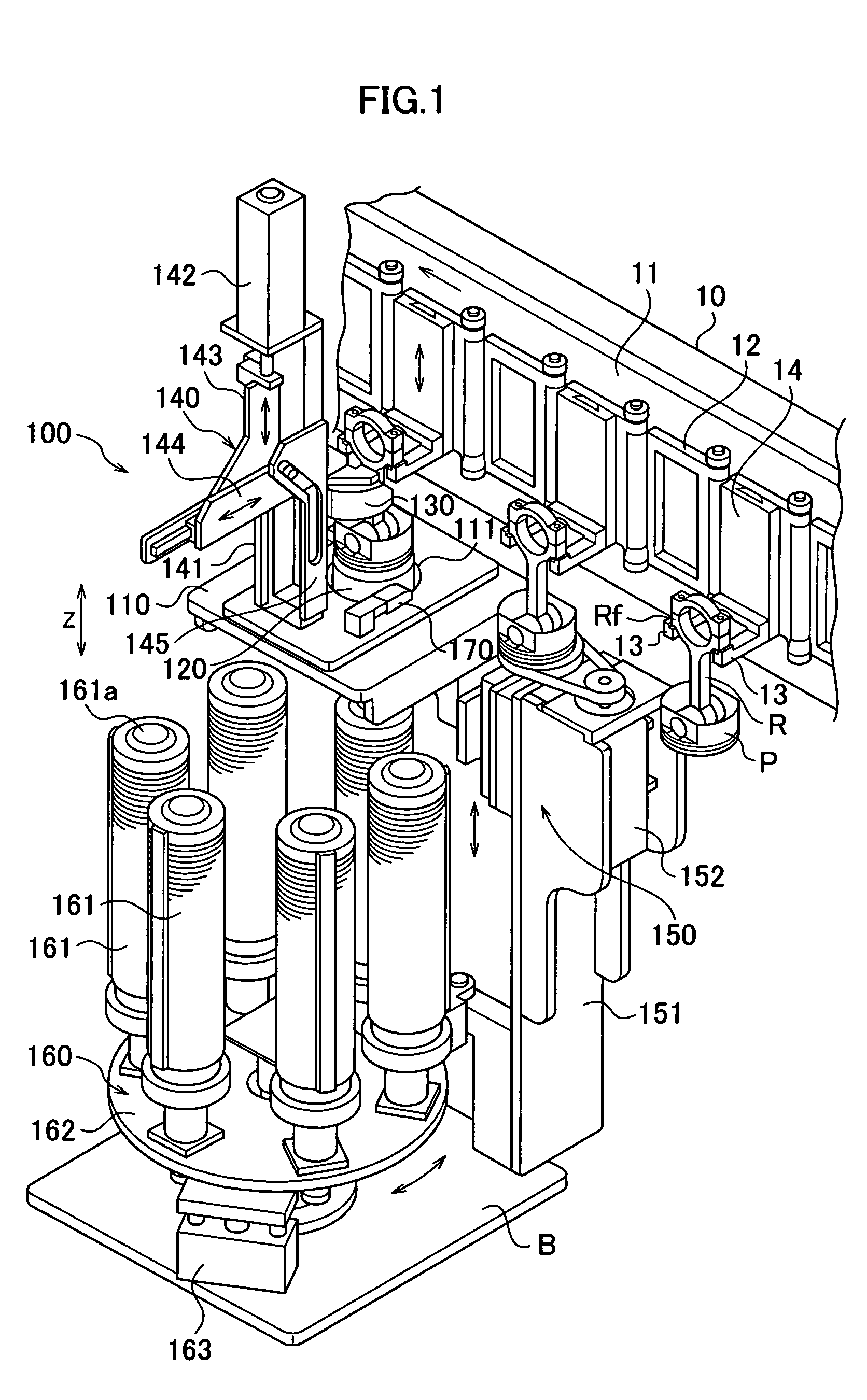

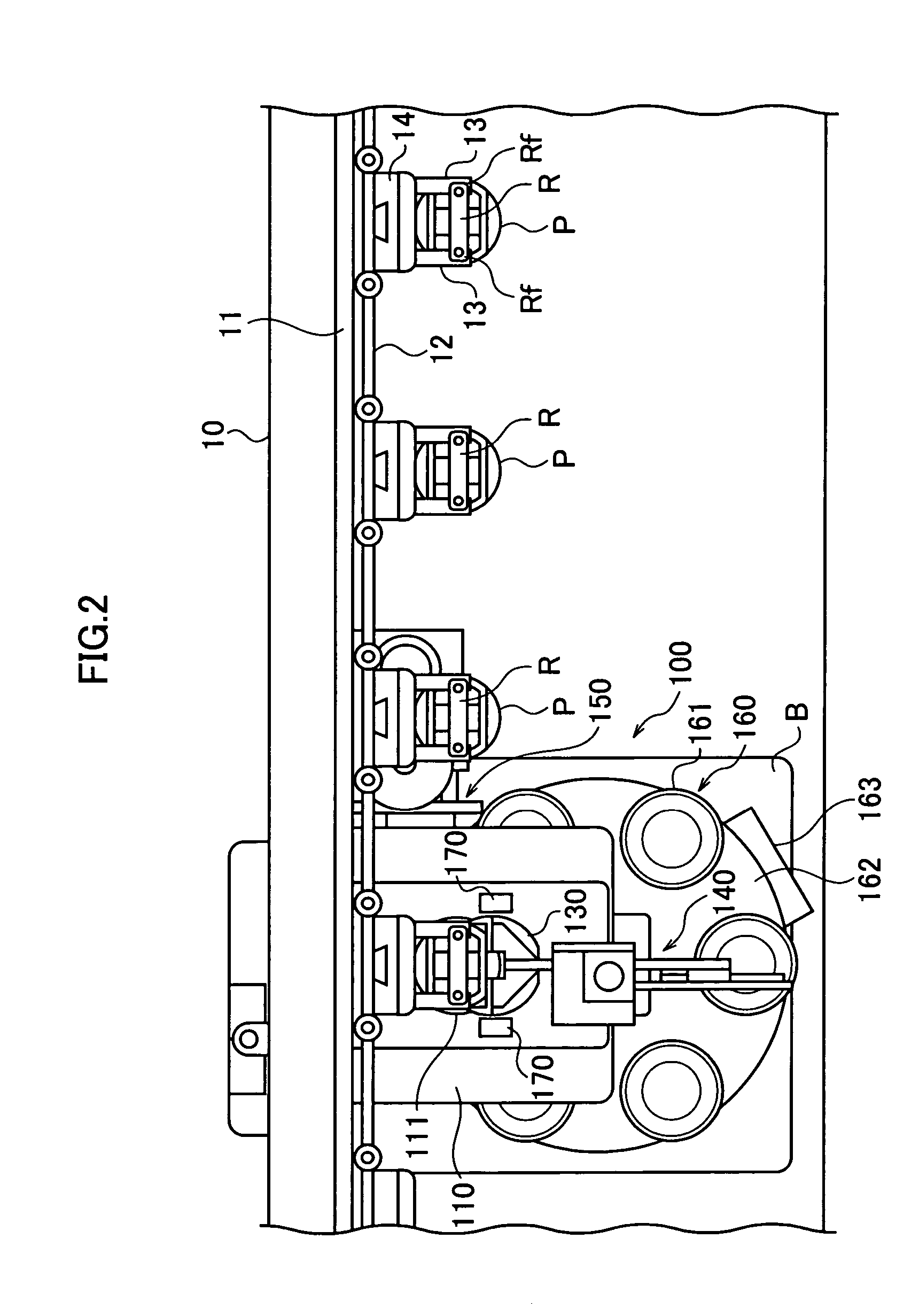

Device and method for installing piston ring

InactiveUS20060123610A1Ensure correct executionPrecise positioningAssembly machinesMetal working apparatusPiston ringEngineering

A piston-ring-installing device of the present invention includes a base (110) having a through-hole (111); a guide member (120) disposed in the through-hole and fixed to the base, for positioning a piston in the vertical direction while receiving a head of the piston suspended downwardly in the vertical direction, and guiding a piston ring while widening a diameter of the piston ring by an outer peripheral surface of the guide member; a piston pressing member (130) disposed above the base and supported movably toward a concave part (121b) of the guide member, and having a tapered inner wall surface (131) widened downwardly so as to come into contact with an edge of an upper end of the piston; a driving mechanism (140) disposed on the base, the driving mechanism driving the piston pressing member at least in the vertical direction; and a ring feeding mechanism (150) that feeds the piston ring placed on the guide member upwardly. Hence, a piston-ring installing operation is swiftly performed, and productivity is improved.

Owner:HIRATA & CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com