Production process and system of positive and negative electrode paste of lithium battery

A production process, positive and negative electrode technology, applied in the field of lithium battery positive and negative electrode slurry production process and system, can solve the problems of uneven contact between powder particles and binder, uneven mixing and dispersion of slurry, hard precipitation, etc. , to achieve the effects of increased productivity, reduced cost input, and improved dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

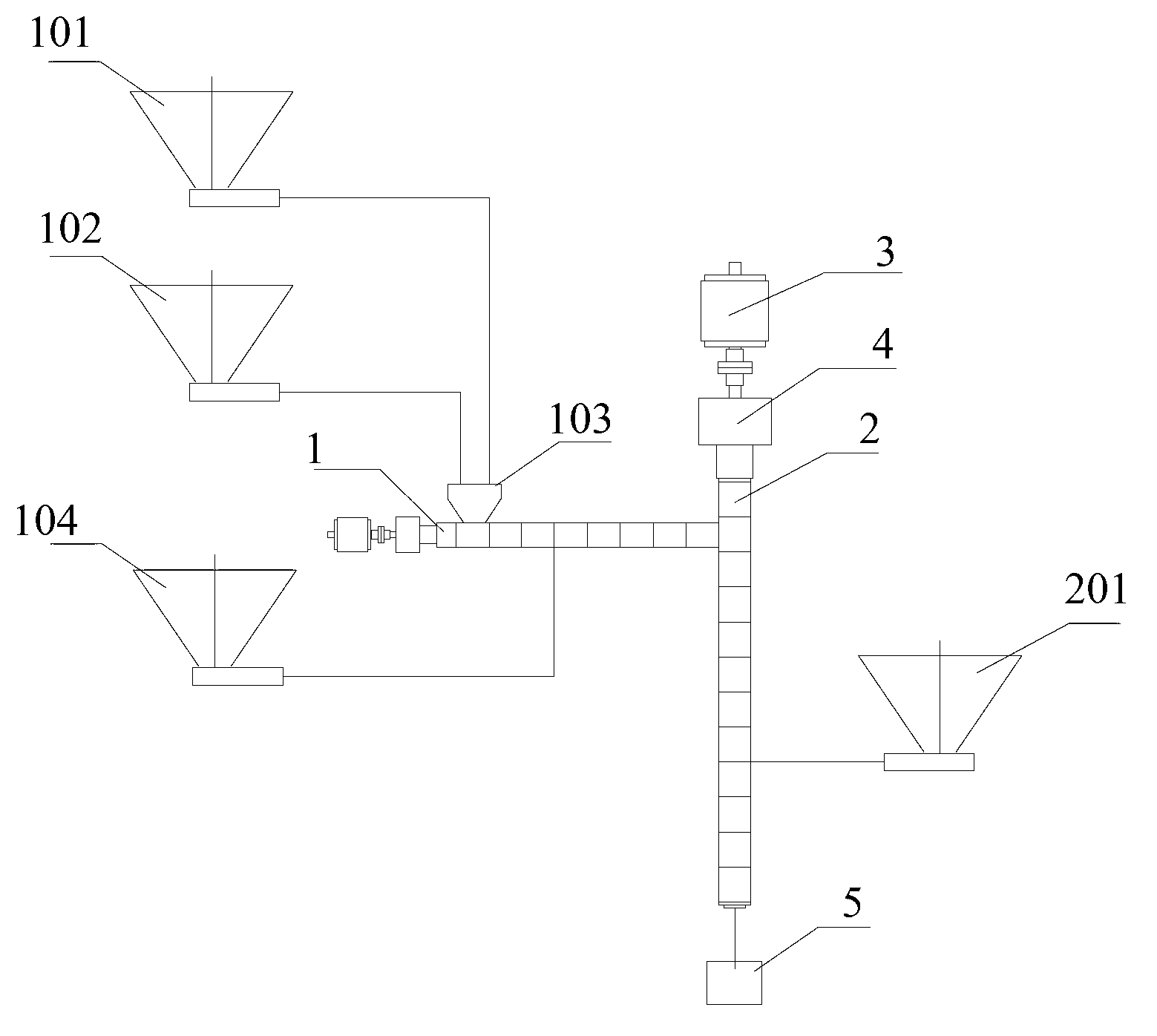

[0124] The production process for producing 500 kg of positive electrode slurry: lithium iron phosphate is added to the first-stage twin-screw extruder 1 through a quantitative continuous feeding device 102 at a flow rate of 311Kg / hour, and Ketjen carbon is passed through quantitatively at a flow rate of 7Kg / hour. The continuous feeding device 101 is added to the first-stage twin-screw extruder 1, nitrogen methyl pyrrolidone is added to the first-stage twin-screw extruder 1 through the quantitative continuous feeding device 104 at a flow rate of 91Kg / hour, and the positive electrode is obtained after being mixed. Basic material; then the positive electrode basic material is forcibly added to the second-stage twin-screw extruder, sheared and emulsified at a pressure of 2MPa, a shear rate of 10,000 times / min and a temperature of 40°C to obtain a positive primary product; Polyvinylidene fluoride and nitrogen methyl pyrrolidone are added to the second-stage twin-screw extruder thro...

Embodiment 2

[0126] The difference between this example and Example 1 is that lithium cobalt oxide is used instead of lithium iron phosphate, polyvinylidene fluoride and nitrogen methyl pyrrolidone mixture instead of nitrogen methyl pyrrolidone, under the pressure of 4MPa, the shear rate of 18000 times / min Production is carried out at a high speed and a temperature of 55° C., and the positive electrode slurry can be obtained after 1 hour of production.

Embodiment 3

[0128] The difference between this example and Example 1 is that lithium manganate is used instead of lithium iron phosphate, polyvinylidene fluoride and nitrogen methyl pyrrolidone instead of nitrogen methyl pyrrolidone, under 3MPa pressure, 19000 times / minute shear Speed and temperature of 50 ° C for production, after 1 hour of production, the positive electrode slurry can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com