Patents

Literature

63results about How to "Fast labeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

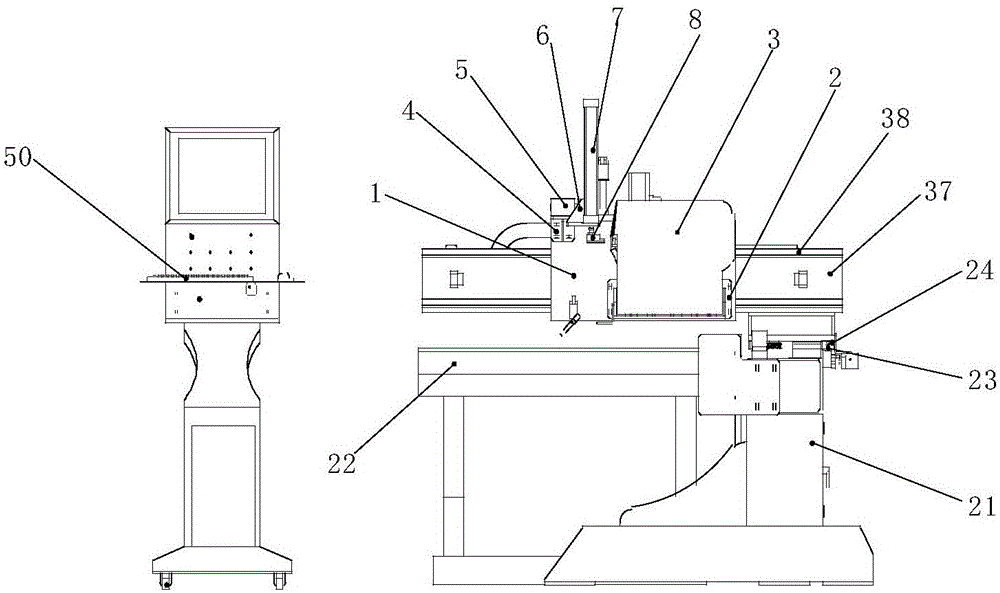

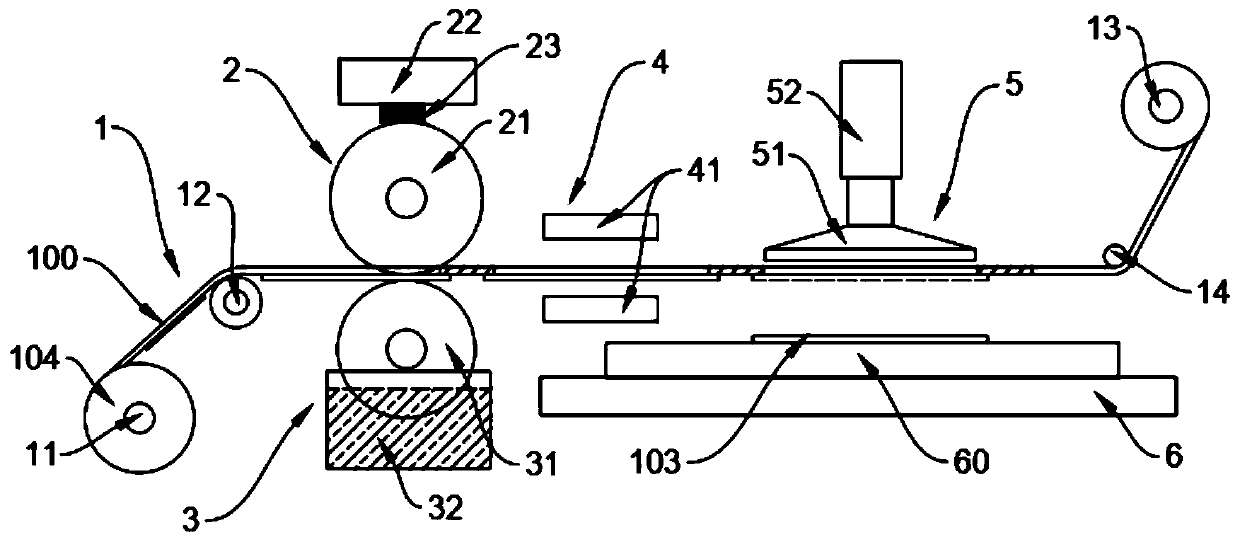

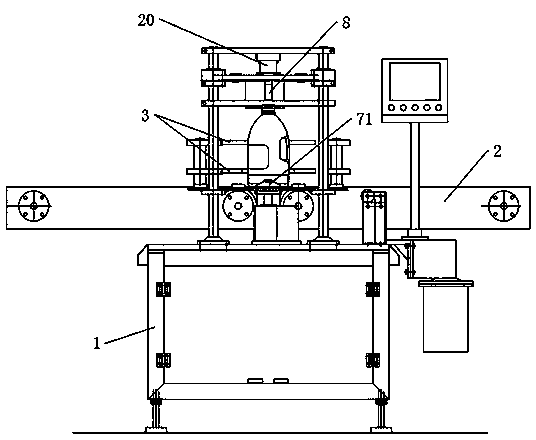

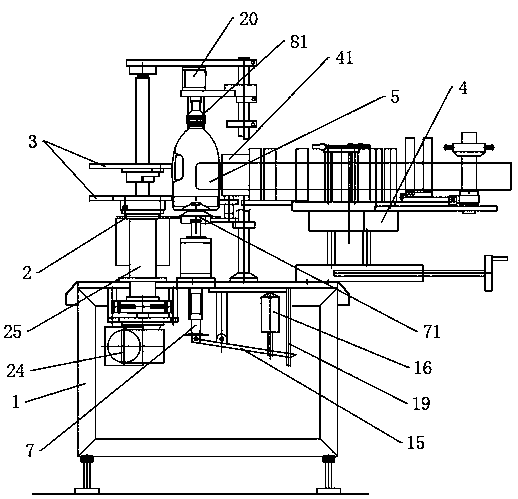

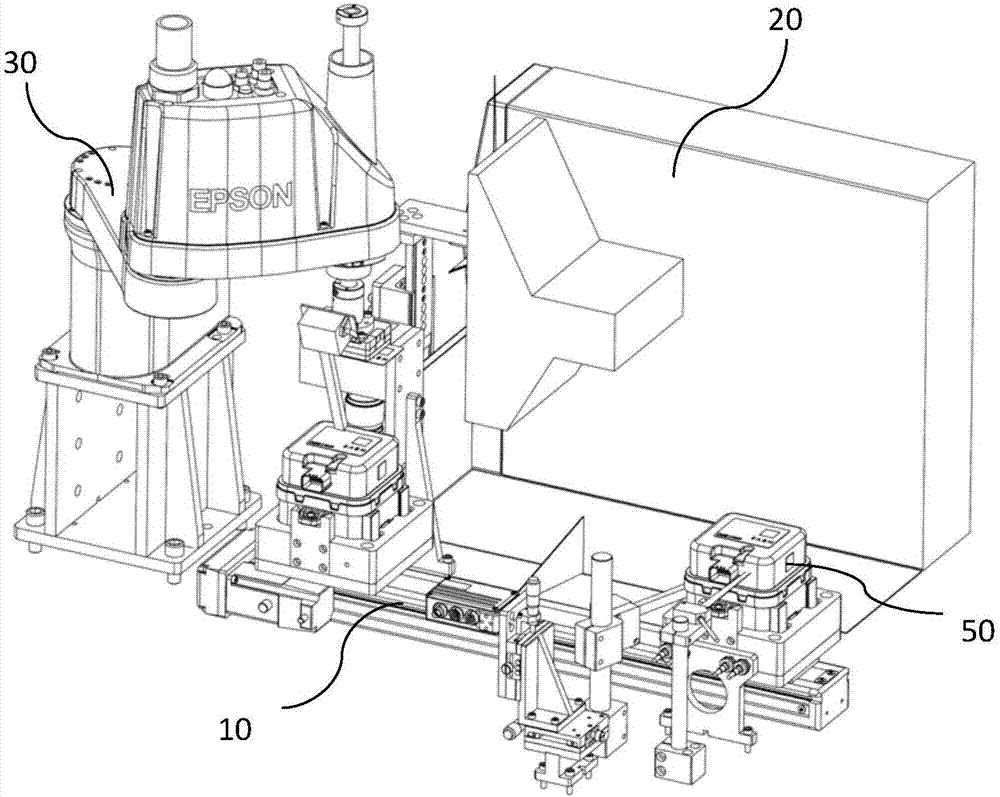

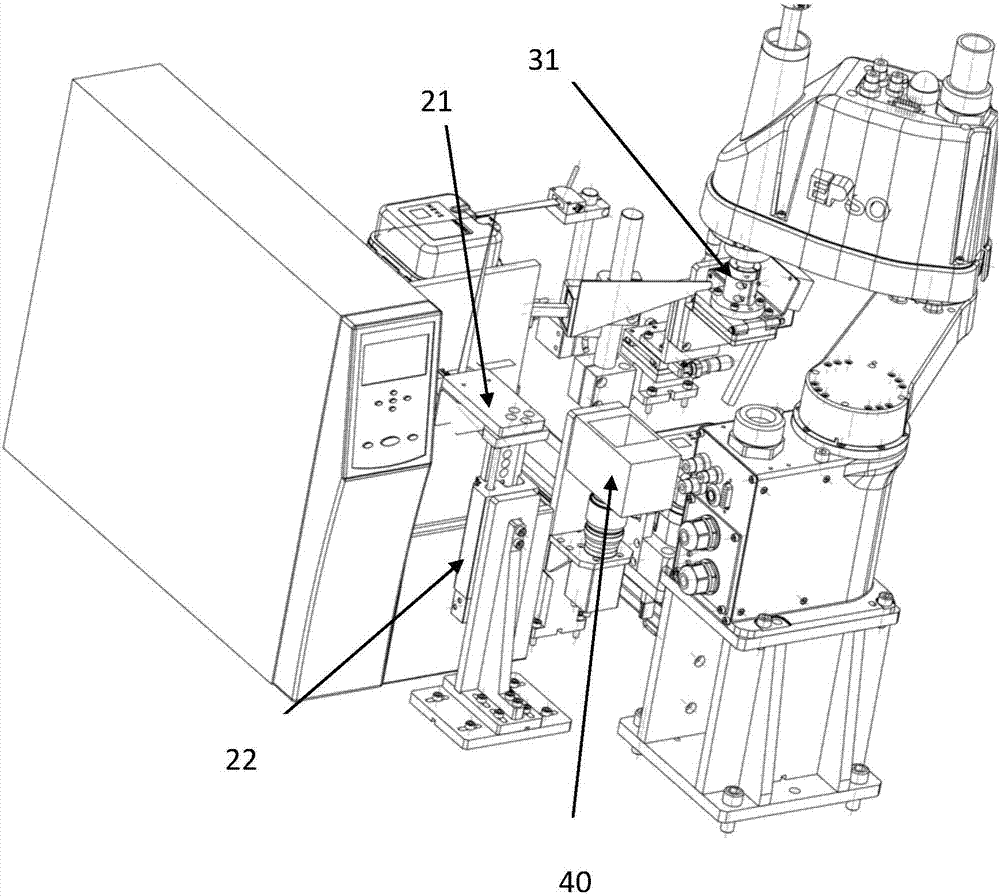

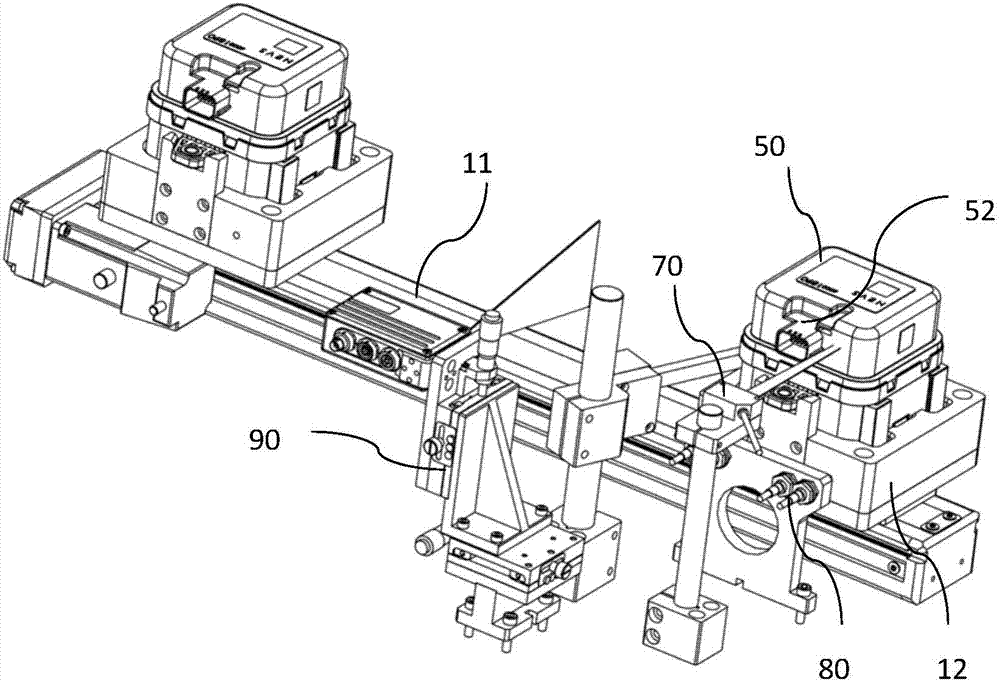

Automatic labeling machine and labeling method

ActiveCN107284780AHigh controllable precisionImprove detection accuracyLabelling machinesComputer graphics (images)Engineering

The invention discloses an automatic labeling machine and a labeling method. The labeling machine comprises a conveying module for conveying products from an identifying position to a labeling position, a label printing device, a robot and a CCD camera, wherein a slide table is arranged in a label outlet of the label printing device, and is provided with a horizontal support surface; a cylinder is connected below the slide table, and is acted on the slide table to move in the vertical direction; the robot comprises a vacuum label sucking head; the vacuum label sucking head moves between the label printing device and the labeling position; and the CCD camera is arranged below the vacuum label sucking head for acquiring images of labels absorbed on the vacuum label sucking head. The automatic labeling machine is high in control precision and detecting precision, generates no bubbles in labeling, and is fast in labeling.

Owner:苏州有泰精密自动化有限公司

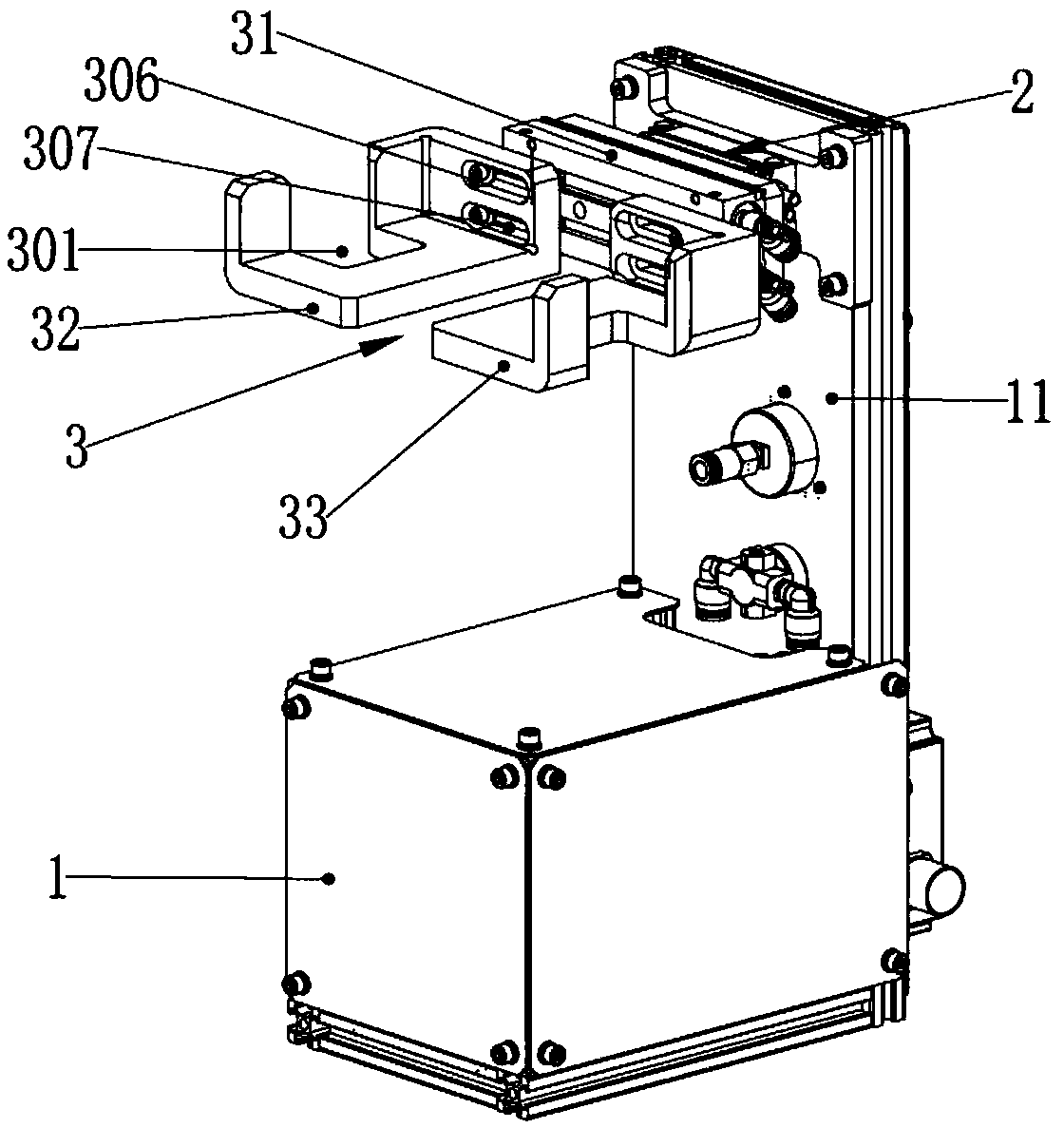

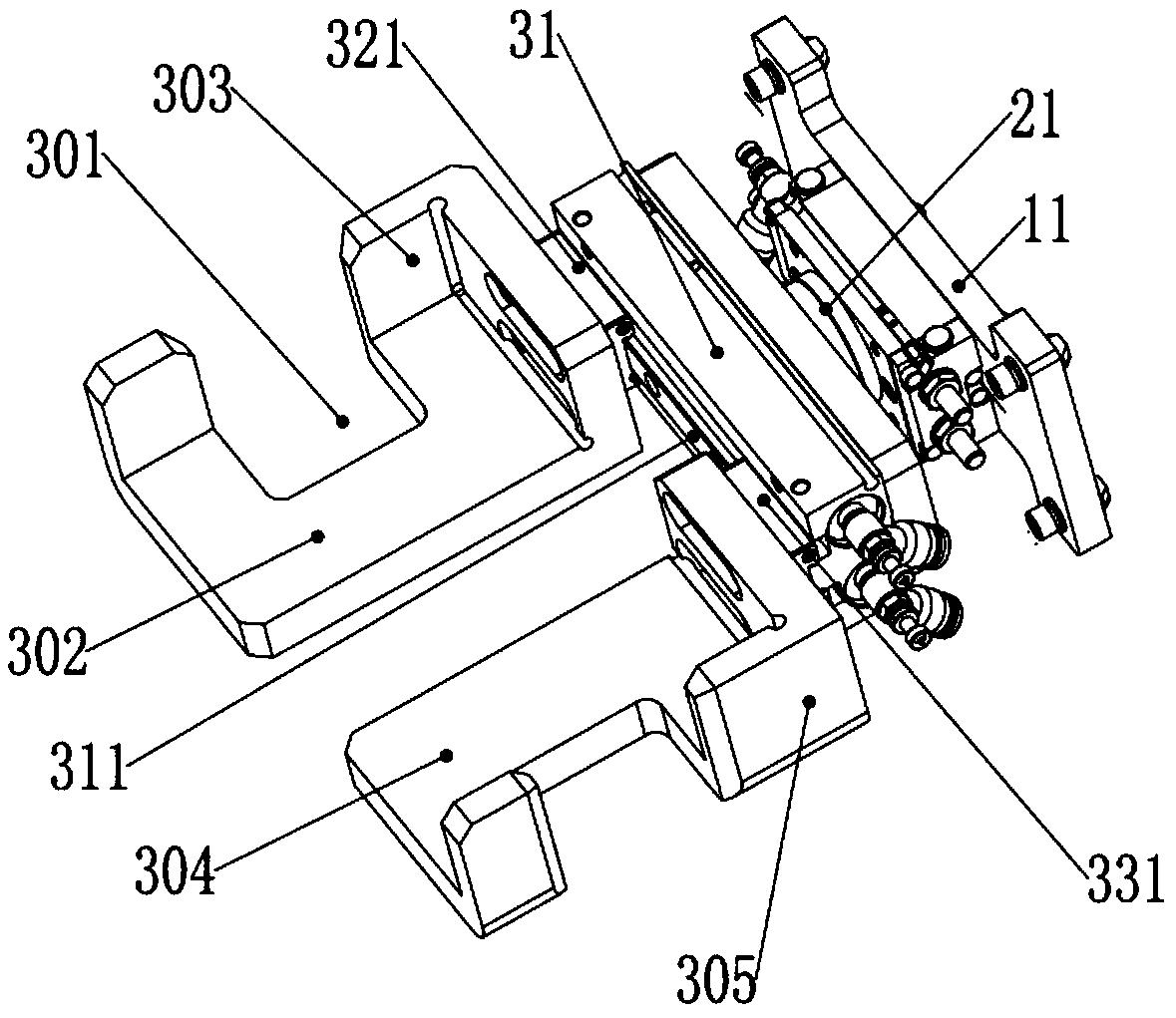

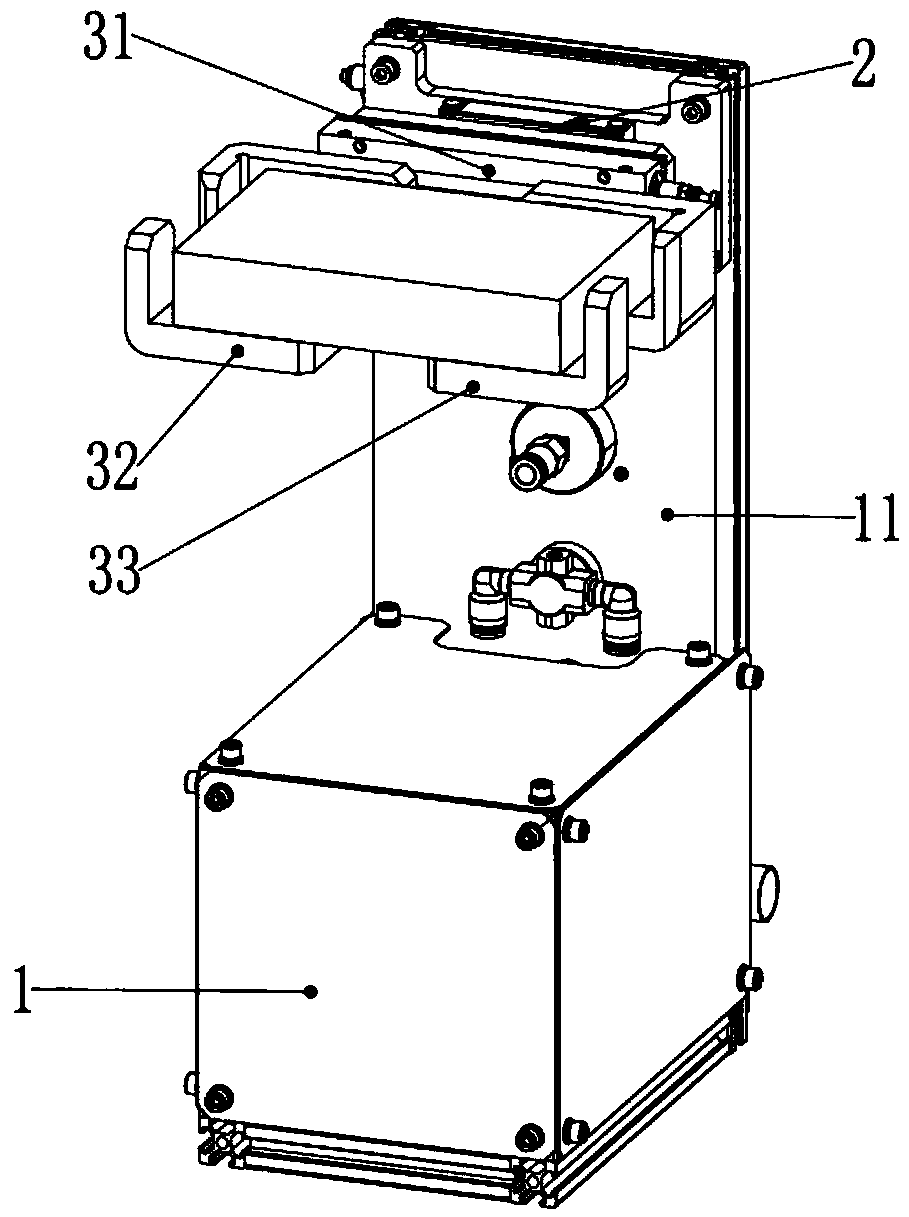

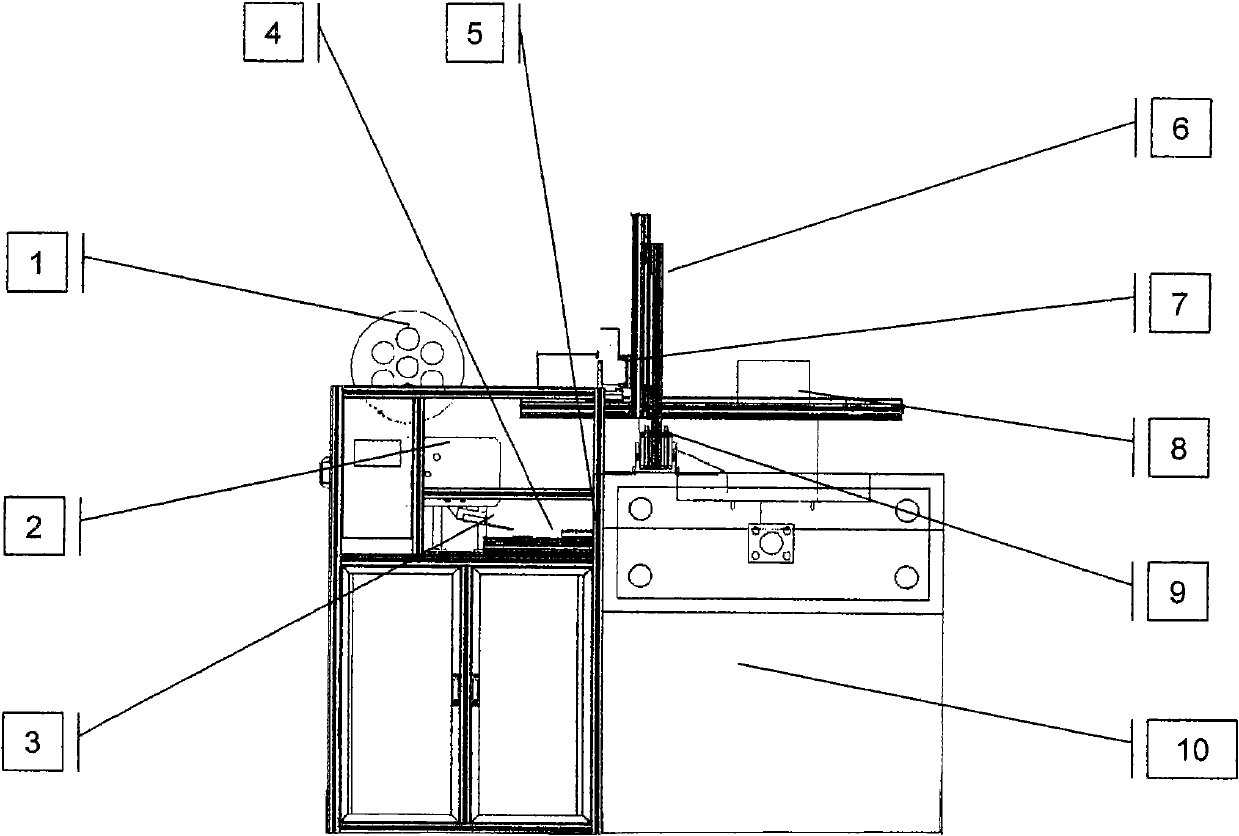

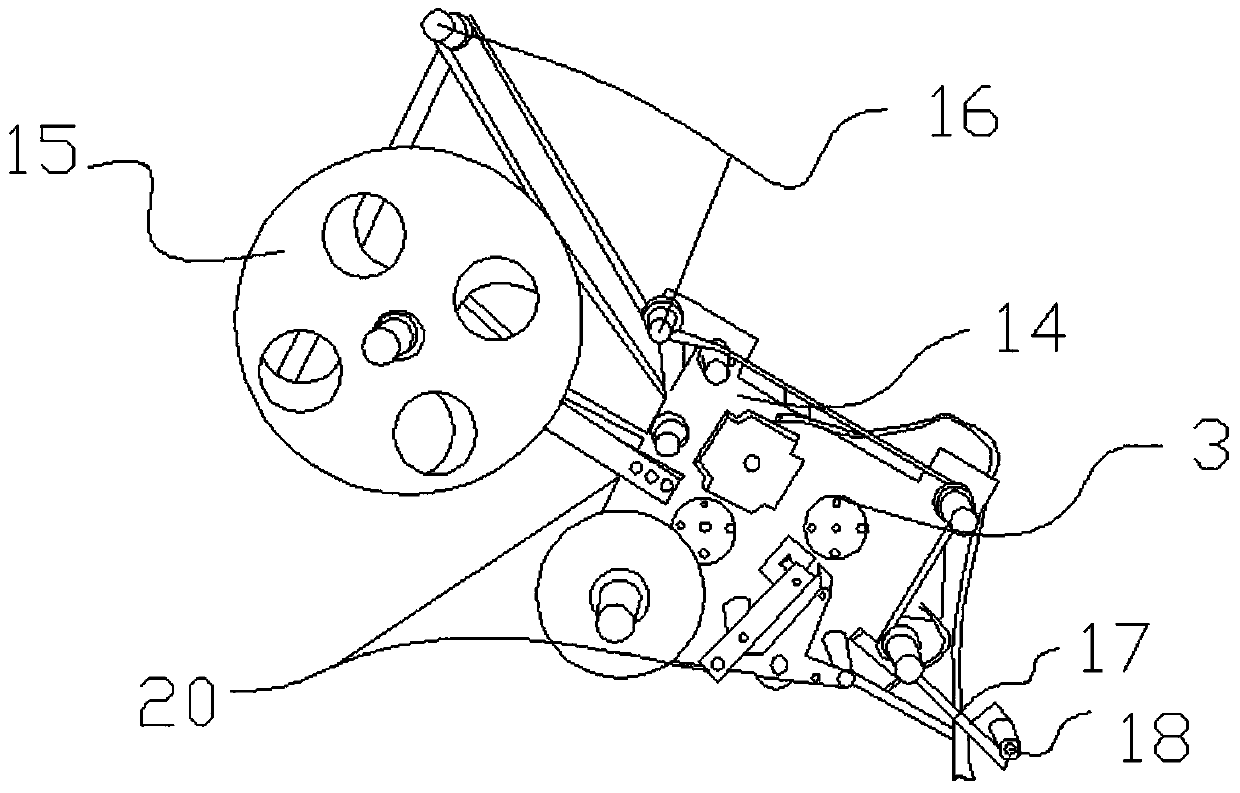

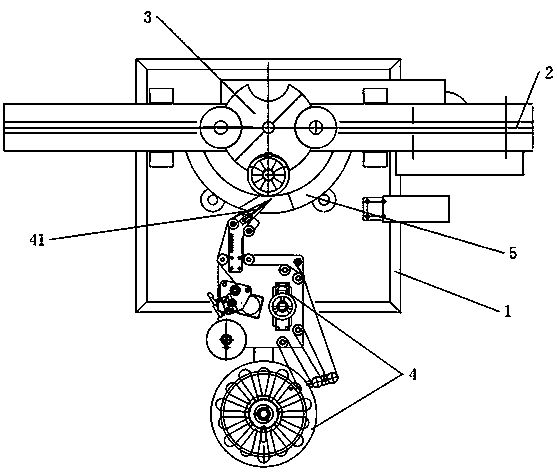

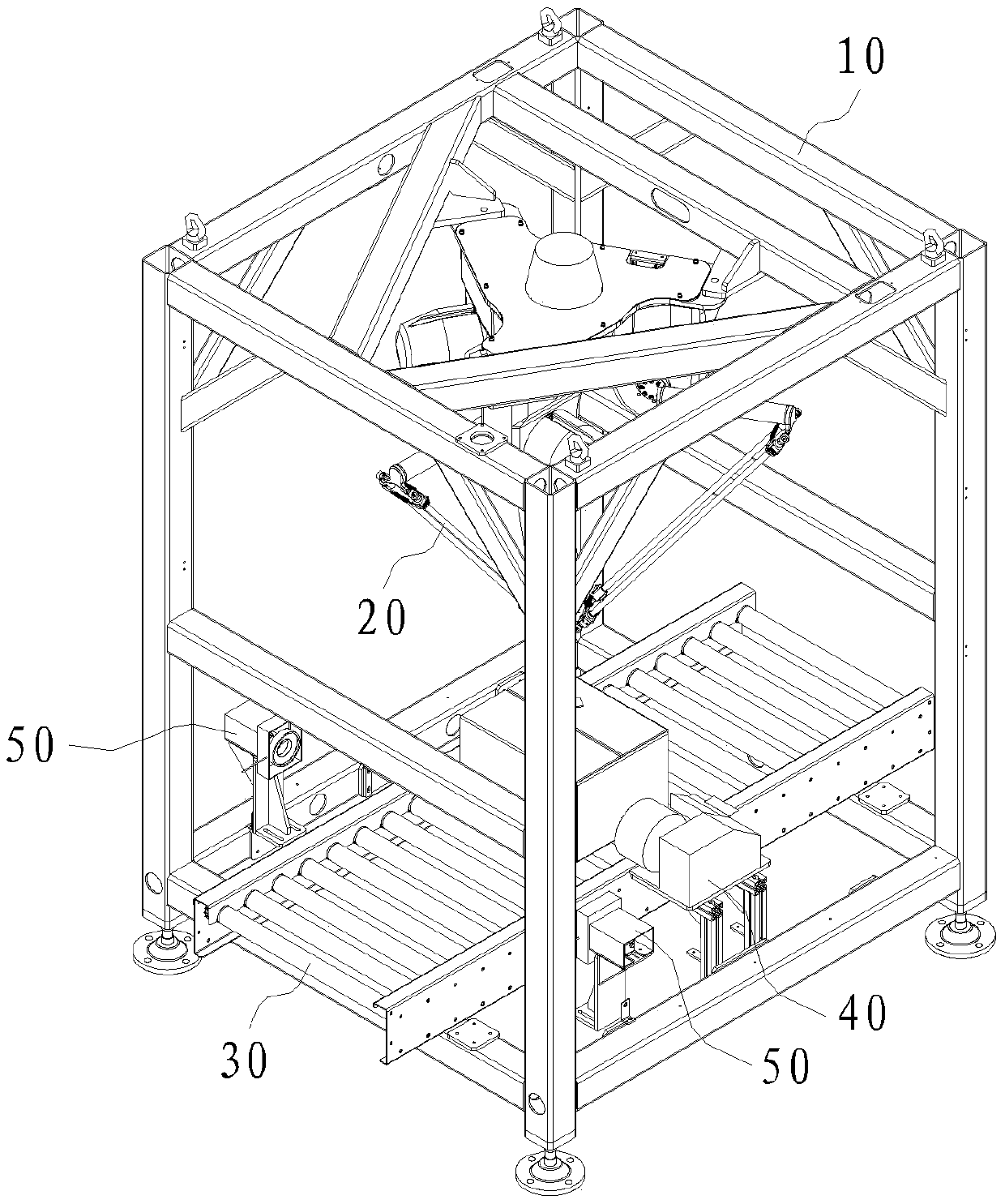

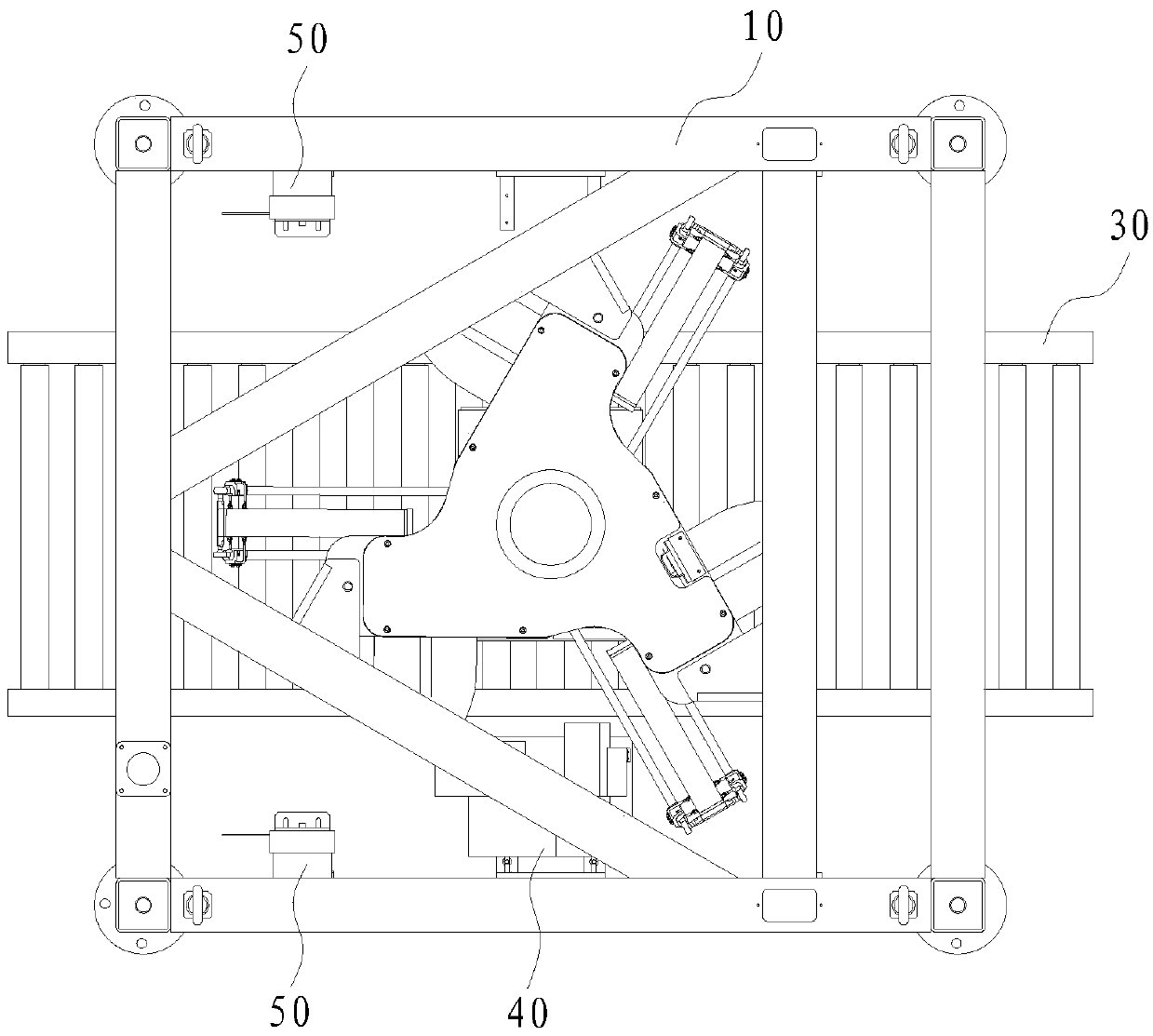

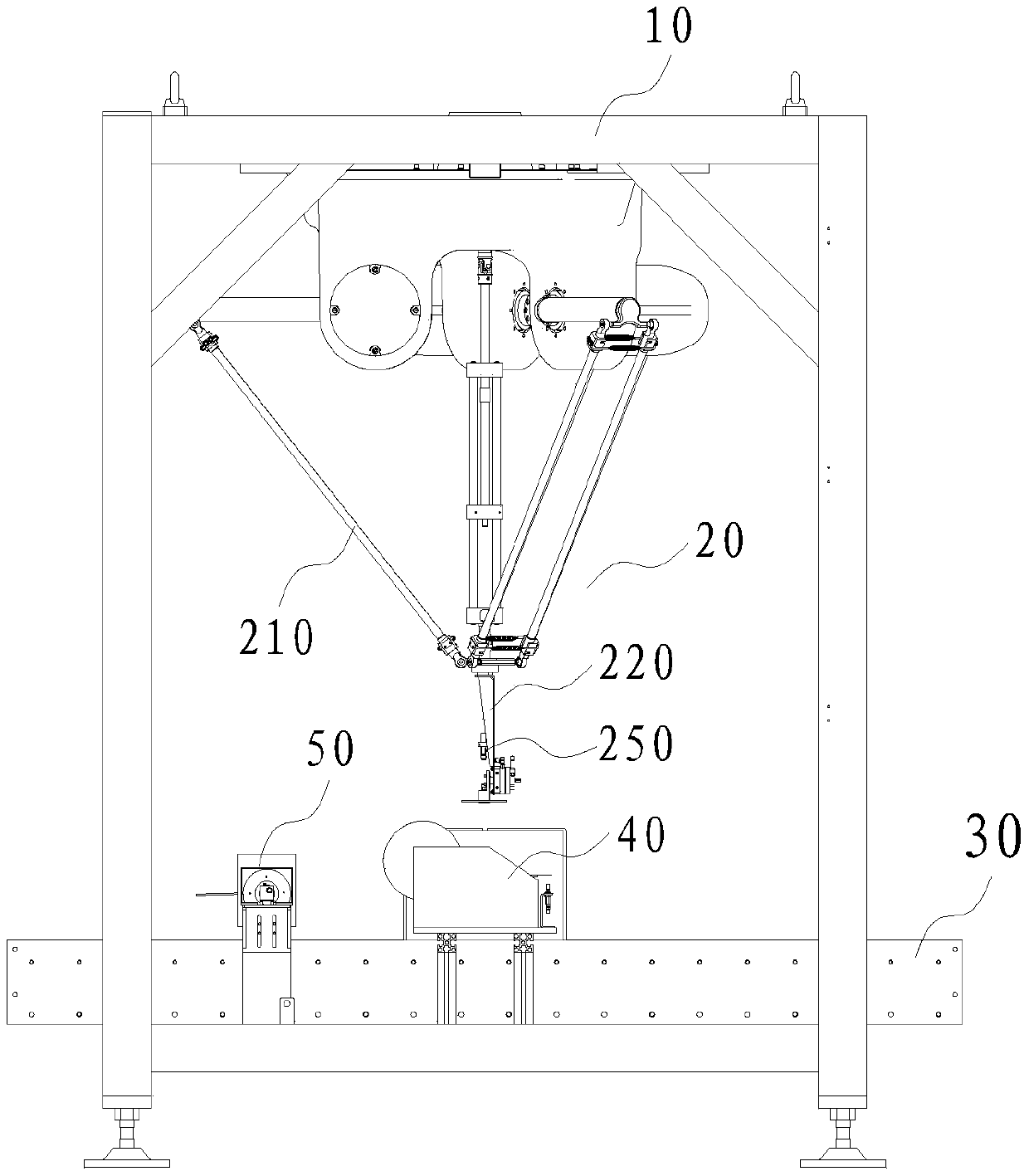

Labeling robot, labeling machine and labeling method of labeling machine

ActiveCN105501589AIncrease the level of automationIncrease productivityLabelling machinesCartonAutomation

The invention discloses a labeling robot, a labeling machine and a labeling method of the labeling machine. The label robot comprises a spider claw robot body, an installation support, a rotary support, a swing mechanism, a label taking mechanism and a controller, wherein the installation support is installed at the lower end of a rotary shaft of the spider claw robot body, the rotary support is installed at the lower end of the installation support in a rotary mode, the swing mechanism is connected with the rotary support, the label taking mechanism is installed on the rotary support, and the controller is electrically connected with the spider claw robot body, the swing mechanism and the label taking mechanism. According to the labeling robot, the labeling machine and the labeling method of the labeling machine, labeling of cartons in different specifications can be achieved, the automation degree is high, and production efficiency is high.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

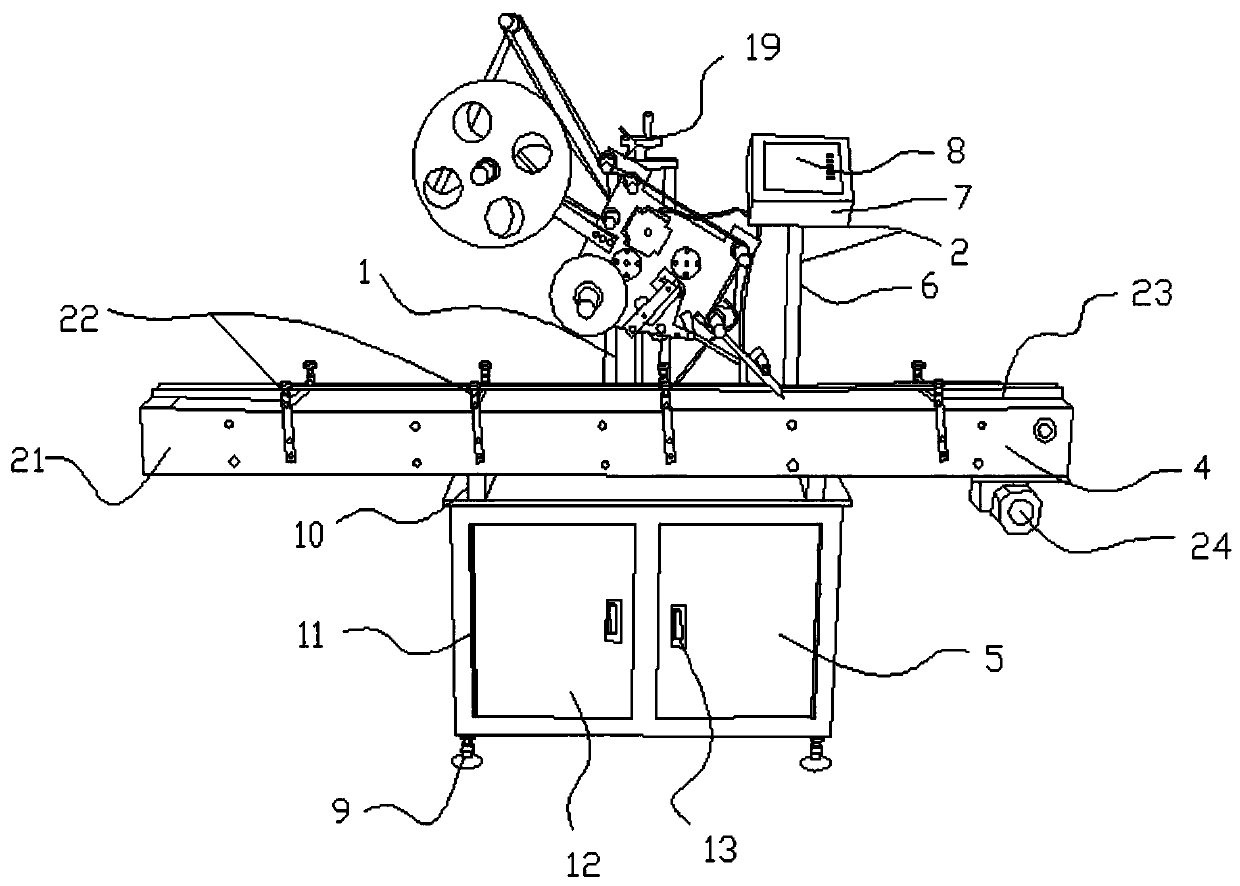

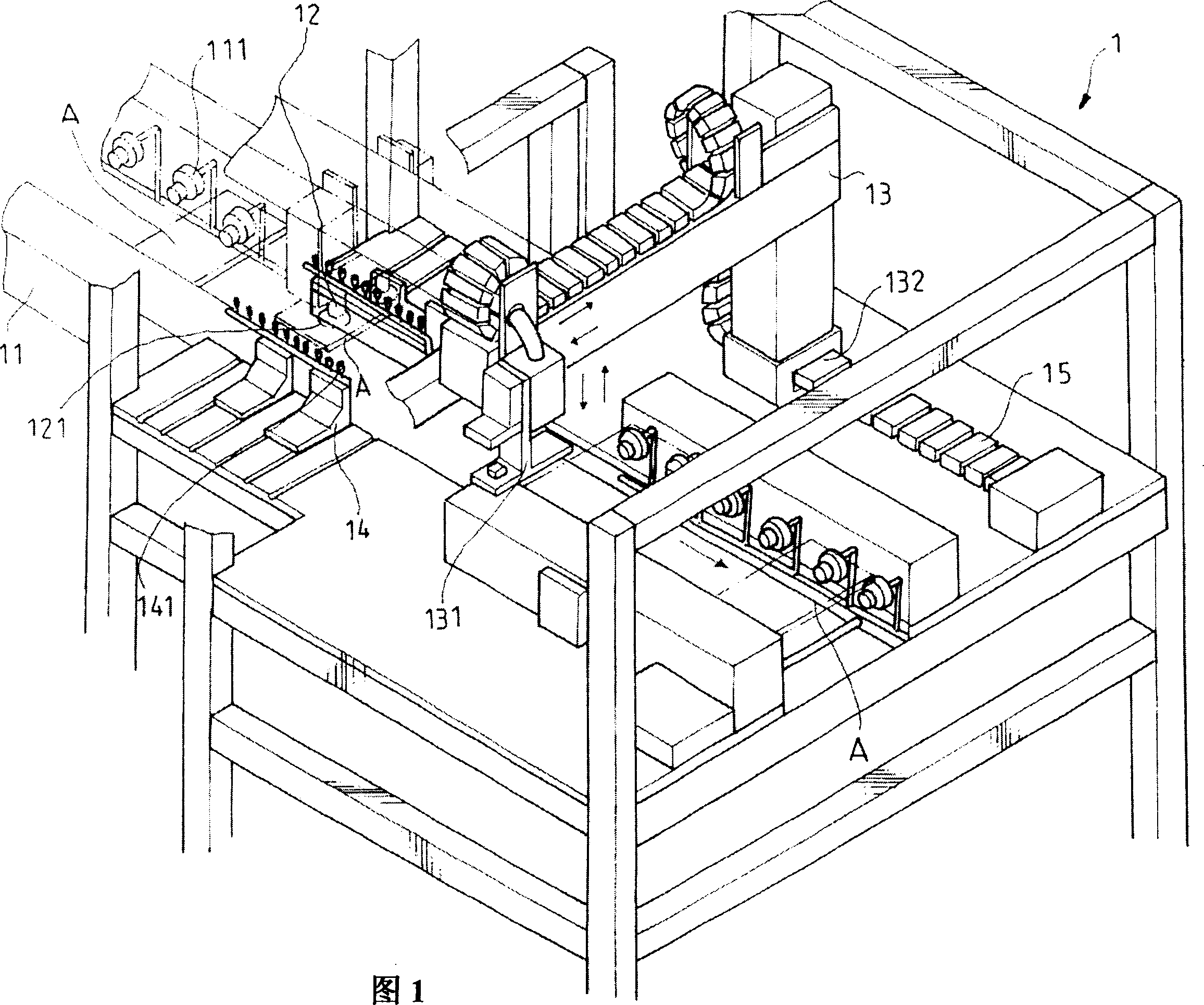

Working machine bench for displaying faceplate label busywork

InactiveCN101058349AFast labelingLabeling work is accurateLabelling flat rigid surfacesConveyor partsEngineeringSurface plate

The invention mainly relates to a working machine for display panel tagging, which comprises the panel bearing device, a displacement bearing device, an alignment platform and a tagging structure, the panel bearing device being able to contain complex panel and the isolating barricade board between adjacent display panel, being able to move away fromt eh working machine. The working platform has three sets of carrying device, using displacement display panel aligning the platform for tagging, moving the isolating barricade board to the material temporary storing zone and moving the tagged panel to the later processing machine. It is simple in working process, reduced in working space. It also prevents the bumping of production lines.

Owner:叶祺成 +1

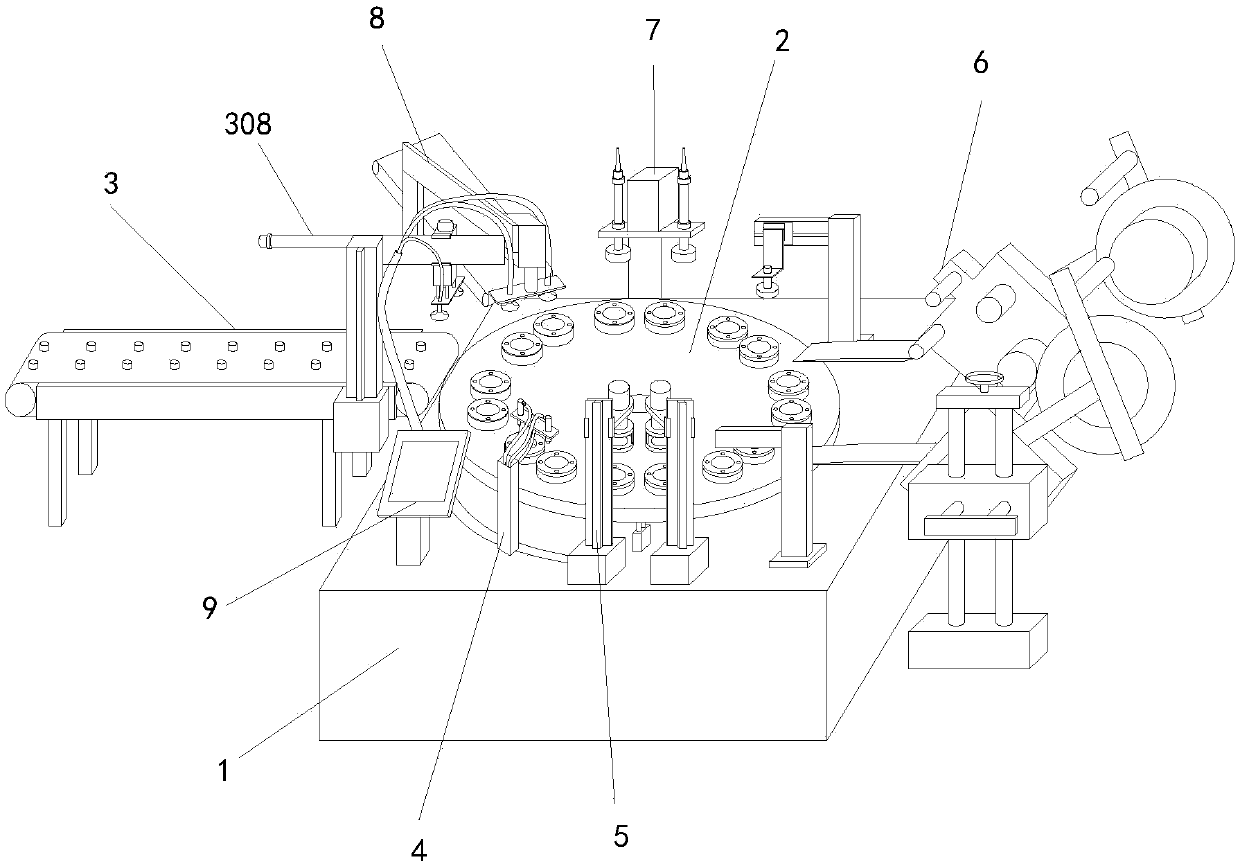

Automatic labeling machine

PendingCN109606882APrecise and beautiful labeling positionFast labelingCleaning using gasesConveyor partsEngineeringRotating disc

The invention discloses an automatic labeling machine. The automatic labeling machine comprises a base, a rotating motor is arranged in the base, a rotating disc is connected to the upper part of therotating motor through a rotating shaft, and a feed transfer device is arranged on the left side of the rotating disc. An ash cleaning device and two positioning devices are arranged on the right sideof the feed transfer device, two labeling devices are arranged on the right side of the rotating disc, and pressing devices are separately arranged on the right sides of the labeling devices. A discharge transfer device is arranged between the pressing devices and the feed transfer device, a control panel is fixedly mounted on the left lower part of the upper surface of the base, and placing rings are evenly and movably connected to the upper surface of the rotating disc along the circumference through fixed rings. According to the automatic labeling machine, the deficiency of the prior art is overcome, the design is reasonable, the structure is compact, the rotating disc is driven by a motor, so that the continuous and automatic labeling operation is realized, the control panel and a central processor perform the control and positioning labeling, so that the position of labeling is accurate and attractive, and the labeling speed is high.

Owner:上海洋明塑料科技有限公司

Biotinylation tag peptides

ActiveUS20110306096A1Fast purificationRapid mobilizationPeptide/protein ingredientsDepsipeptidesBiotinIn vivo

Biotinylation peptides are provided which can be fused with other peptides or proteins of interest using recombinant DNA techniques to provide efficient methods for biotinylating the resulting fusion proteins in vivo or in vitro.

Owner:PACIFIC BIOSCIENCES

Labeling machine

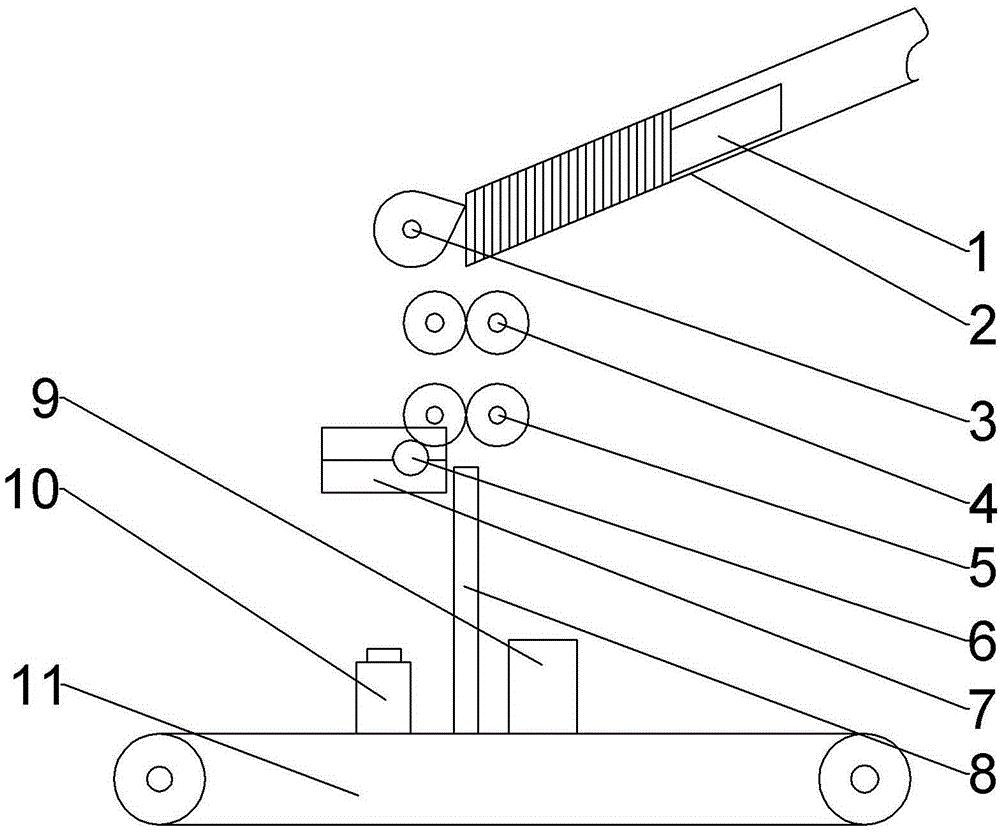

InactiveCN105173288AFast labelingSimple structureLabelling short rigid containersLabelling machinesEngineeringCoating

The invention relates to the field of packaging, and discloses a labeling machine. The labeling machine comprises a label supply unit, a label conveying unit and a labeling unit. The labeling machine is characterized in that the label supply mechanism comprises an inclined label box and label taking rollers arranged at a discharging port of the label box, and the label taking rollers are of a cam structure; the label conveying unit comprises two label pulling rollers which are arranged below the roller taking rollers and rotate in the opposite direction, a glue tank, a guide rail and two label coating rollers rotating in the opposite direction; the label coating rollers are arranged below the label pulling rollers, the glue tank is arranged on one sides of the label coating rollers, and glue in the glue tank is conveyed to the label coating rollers through a transition roller between the glue tank and the roller coating grooves; and the labeling mechanism comprises the guide rail vertically arranged below the label coating rollers, and a conveying belt arranged at the lower end of the guide rail. The labeling machine has the technical effects of being simple in structure and fast in labeling.

Owner:CHONGQING CHENGSHUO TECH

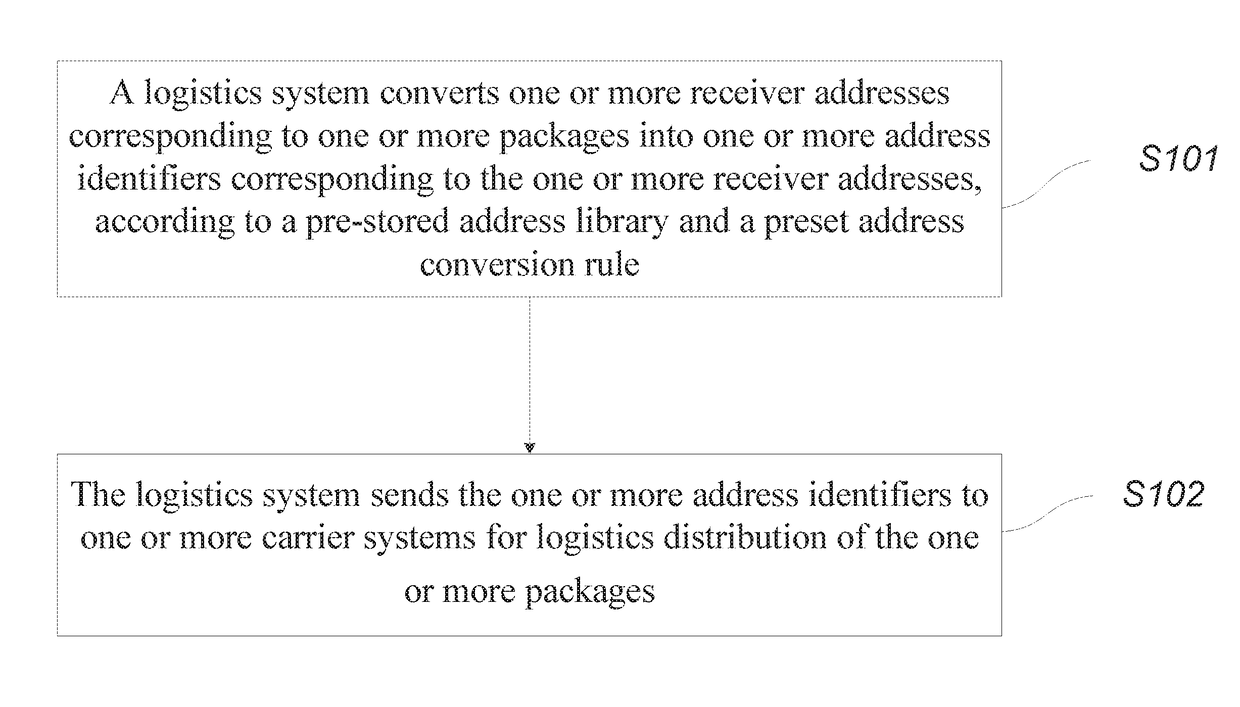

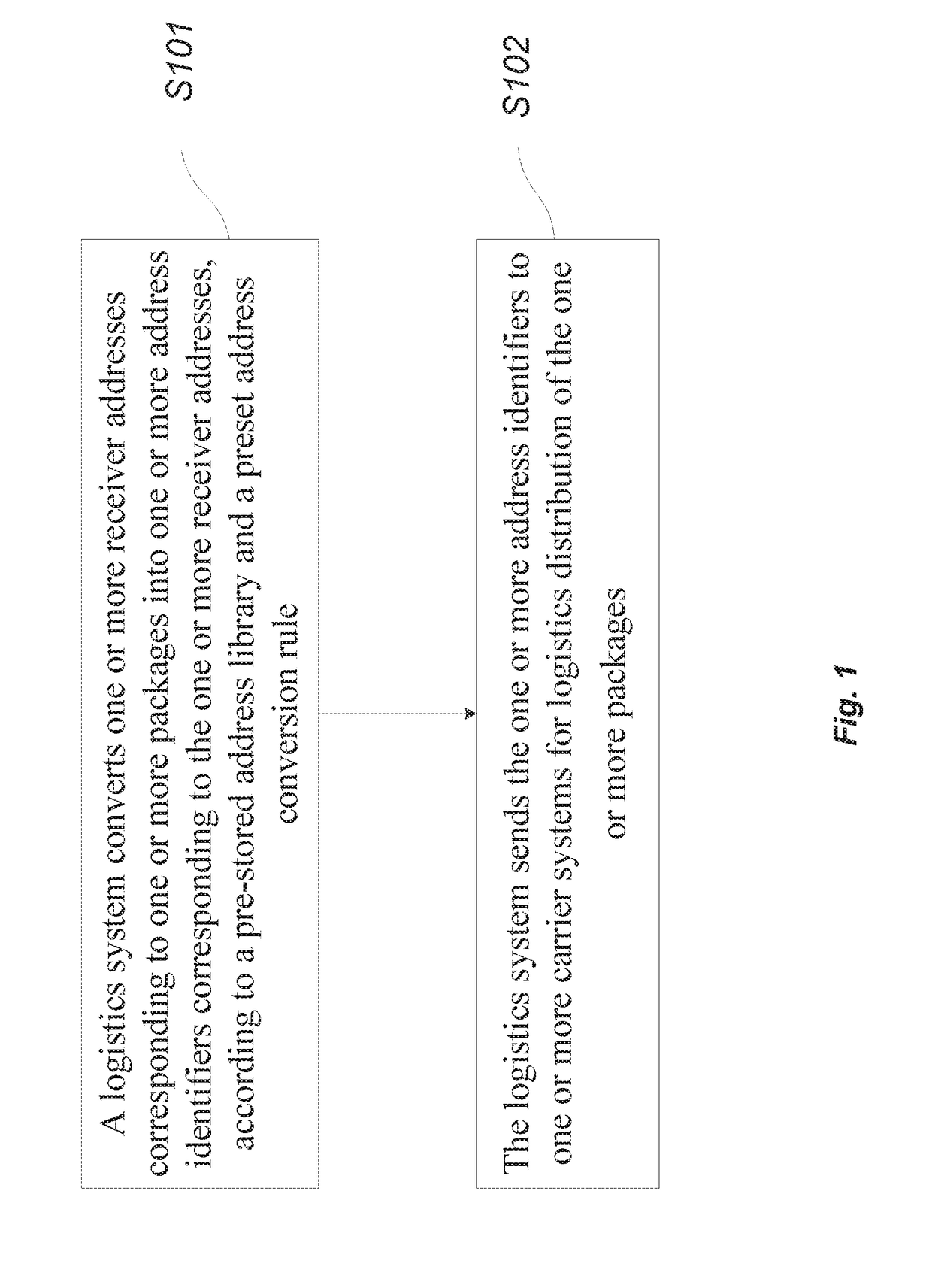

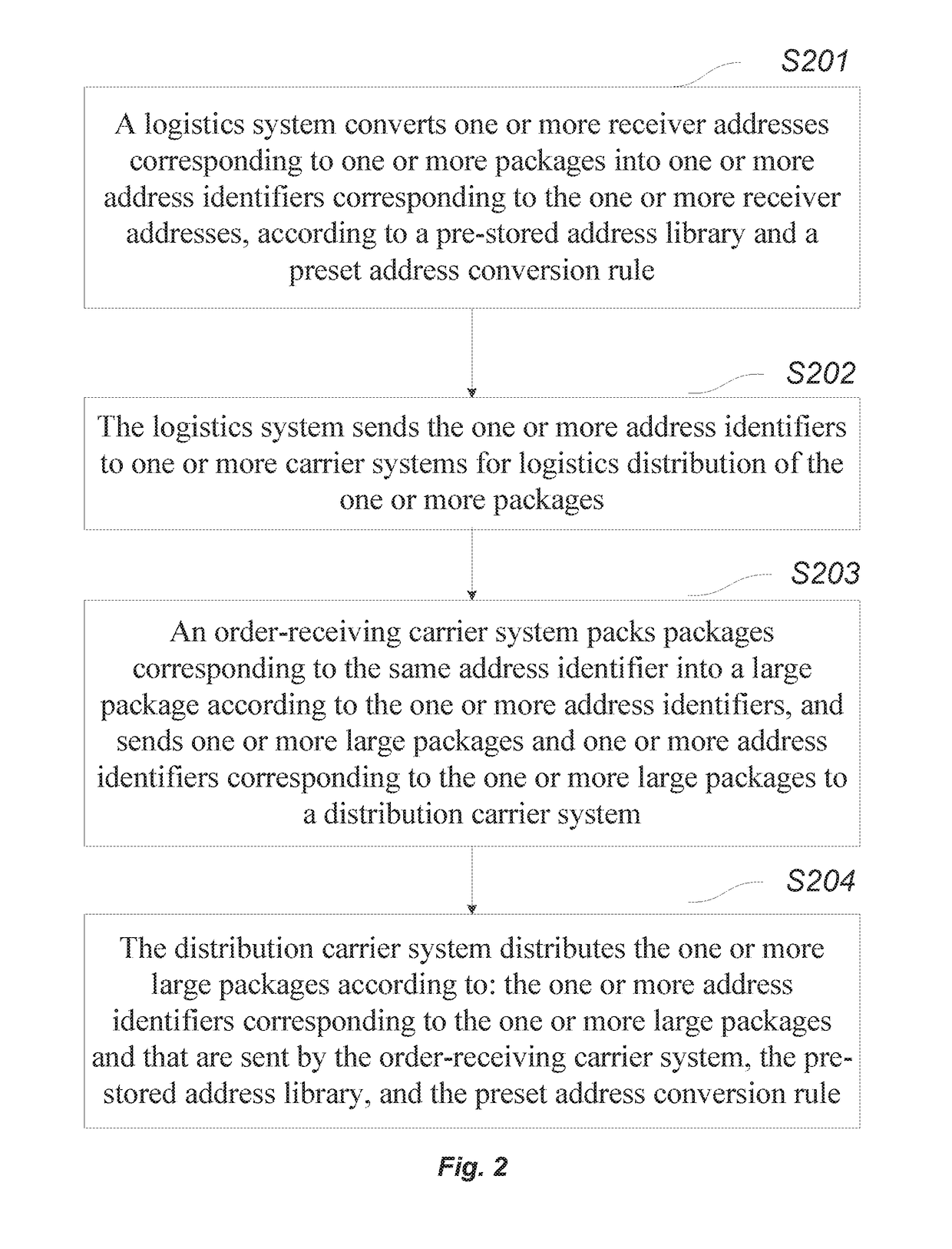

Logistics system and logistics distribution method and system

InactiveUS20170213183A1Improve the efficiency of logistics and distributionEasy to optimizeLogisticsLogistics managementDistribution method

A logistics distribution method is disclosed. The method may comprise converting, by a logistics system, one or more receiver addresses corresponding to one or more packages into one or more address identifiers corresponding to the one or more receiver addresses, according to a pre-stored address library and a preset address conversion rule. The method may further comprise sending, by the logistics system, the one or more address identifiers to one or more carrier systems for logistics distribution of the one or more packages.

Owner:CAINIAO SMART LOGISTICS HLDG LTD

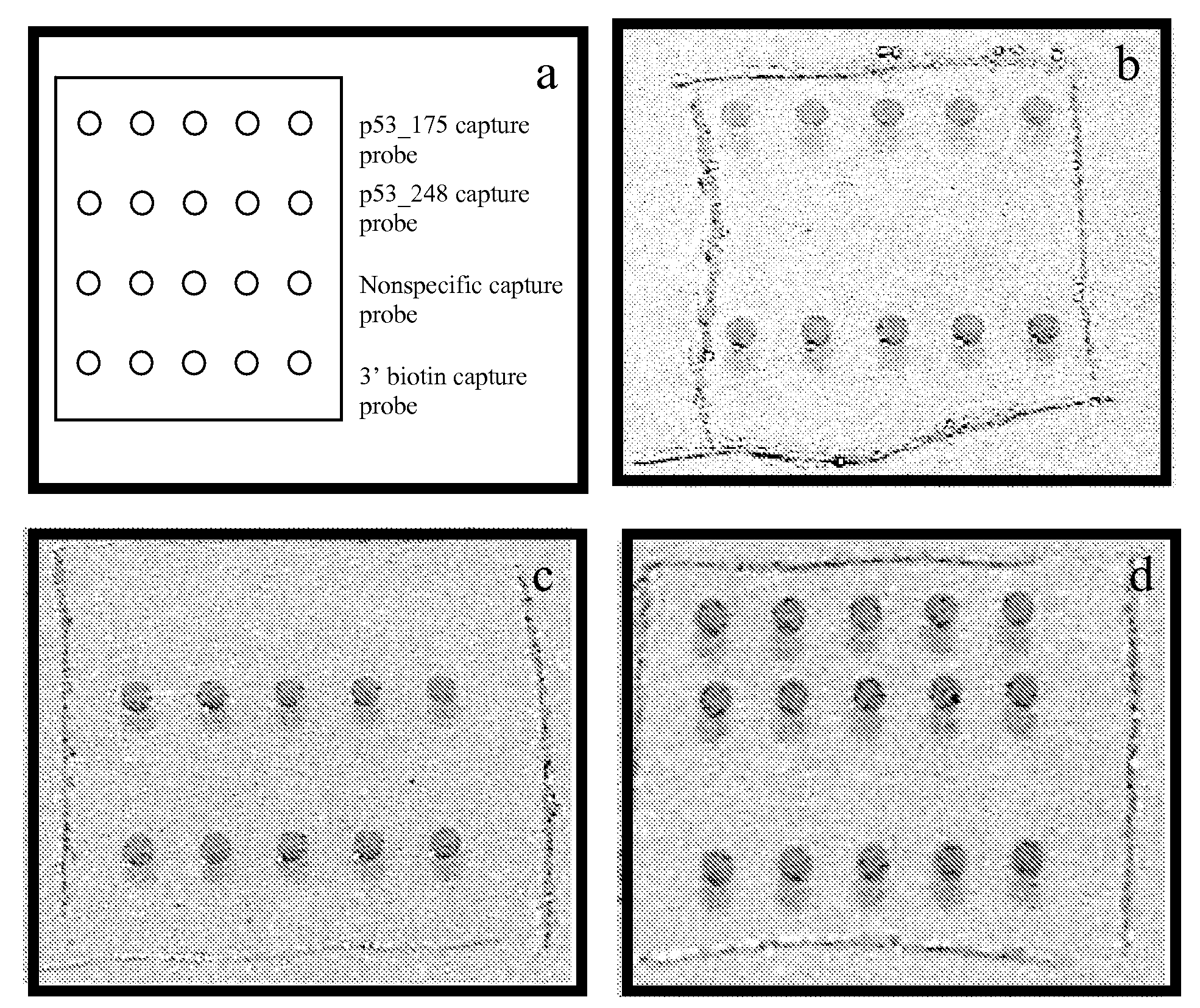

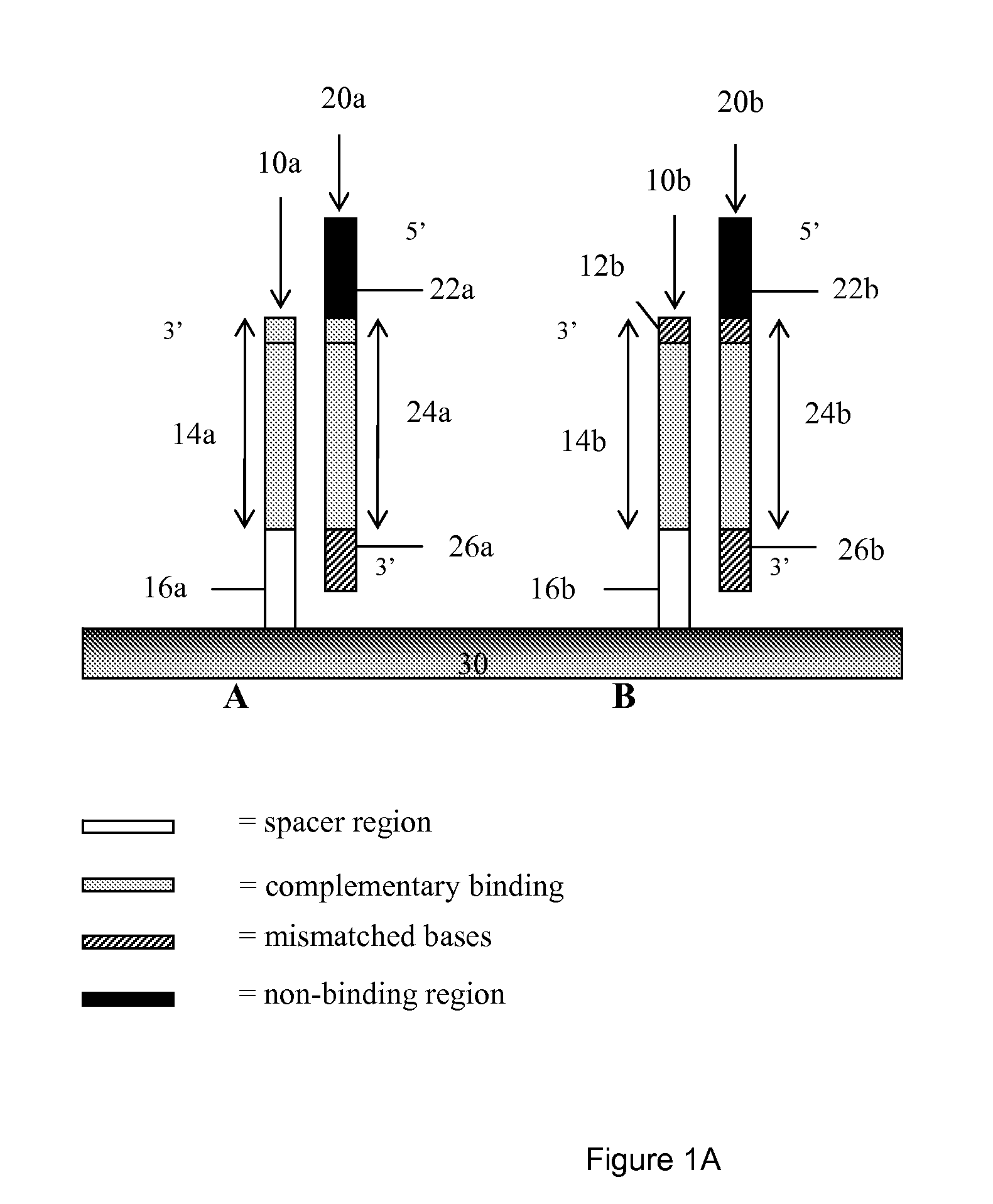

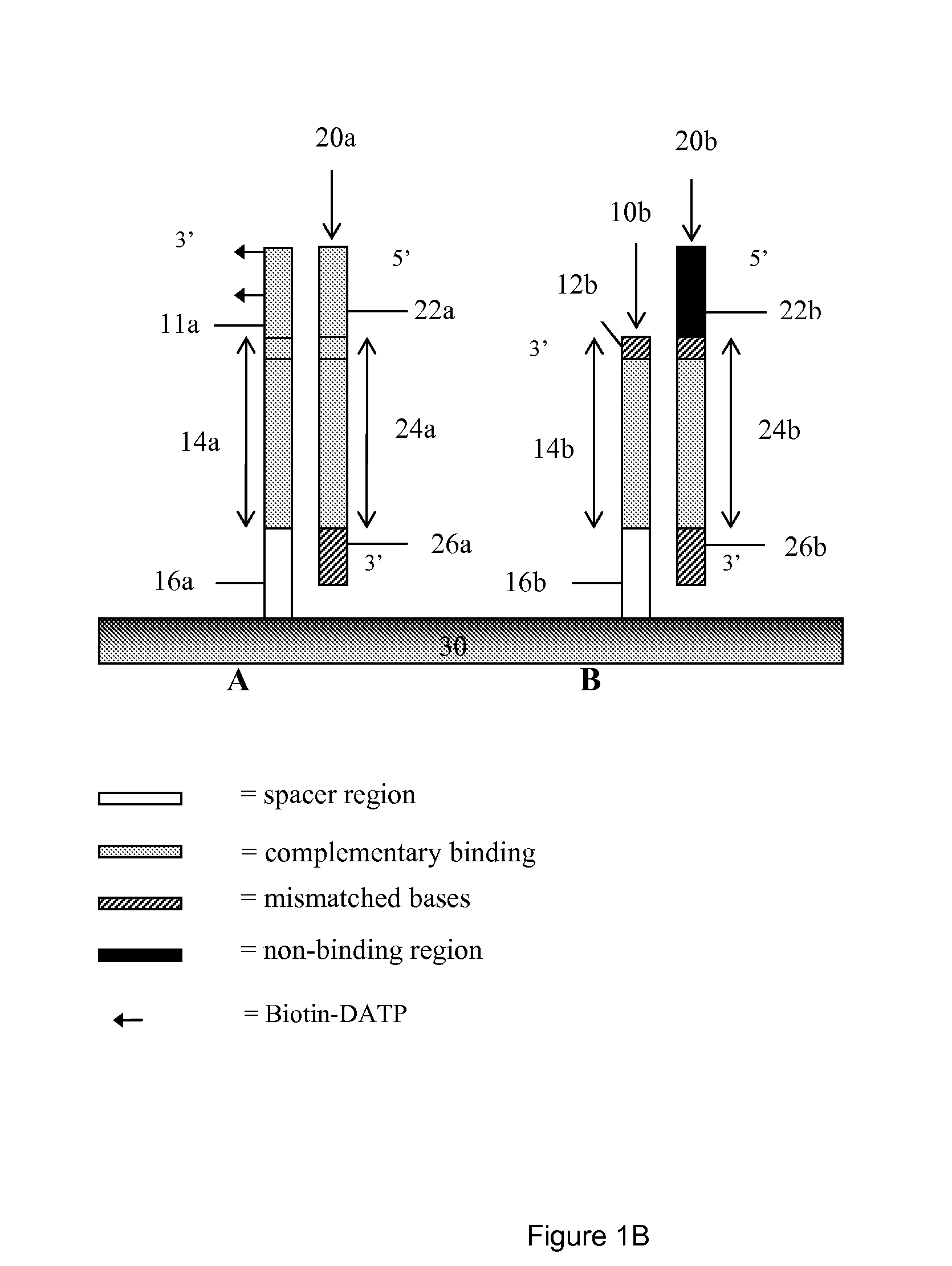

Detection of nucleic acid biomarkers using polymerization-based amplification

InactiveUS20090137405A1Easy to detectFast labelingMicrobiological testing/measurementLibrary member identificationSingle strandBiotin

The invention provides methods for highly-specific detection of hybridization of single stranded nucleic acids. The invention also provides methods for target identification which rely on this highly-specific hybridization detection. Targets suitable for detection include, but are not limited to, nucleic acid biomarkers. The methods of the invention can employ an on-chip, DNA polymerase-dependent labeling scheme termed primer extension (PEX) to couple biotinylated deoxyribonucleotide triphosphate (dNTP) molecules to nucleic acid hybrids bound to a solid substrate, allowing for subsequent recognition by biotin-binding-protein-labeled photoinitiators. Surface-initiated polymerization from these surface bound photoinitiators can lead to the formation of macroscale amounts of polymeric material, thereby amplifying the signal from the initial molecular recognition event.

Owner:UNIV OF COLORADO THE REGENTS OF

Medicine bottle labeling machine

PendingCN109455376AFast labelingAccurate labelingLabelling machinesLabelling short rigid containersMedicine bottlesLabelling machine

The invention discloses a medicine bottle labeling machine. The medicine bottle labeling machine comprises a frame, a main conveyor belt, a bottle dividing device, a chain righting device, a top beltpressing device and a labeling device, wherein the bottle dividing device, the chain righting device and the labeling device are arranged sequentially in the conveying direction of the main conveyor belt from front to back; the top belt pressing device is arranged between the chain righting device and the labeling device and right above the main conveyor belt; the labeling device comprises a labelfeeding device, a former and a label spreading device; the label feeding device, the former and the label spreading device are arranged sequentially in the conveying direction of the main conveyor belt from front to back; the former includes two forming plates side by side; the label spreading device includes two spreading rollers arranged side by side and relatively rotating; the two forming plates and the two spreading rollers are arranged above the main conveyor belt; and the gap between the two spreading rollers faces the gap between the two forming plates rightly. According to the medicine bottle labeling machine, the automatic labeling process of a medicine bottle can be completed, the labeling is fast and accurate, and the machine is suitable for the case where a label is attachedto one side or three sides of the medicine bottle.

Owner:GUANGDONG T&K PHARMA

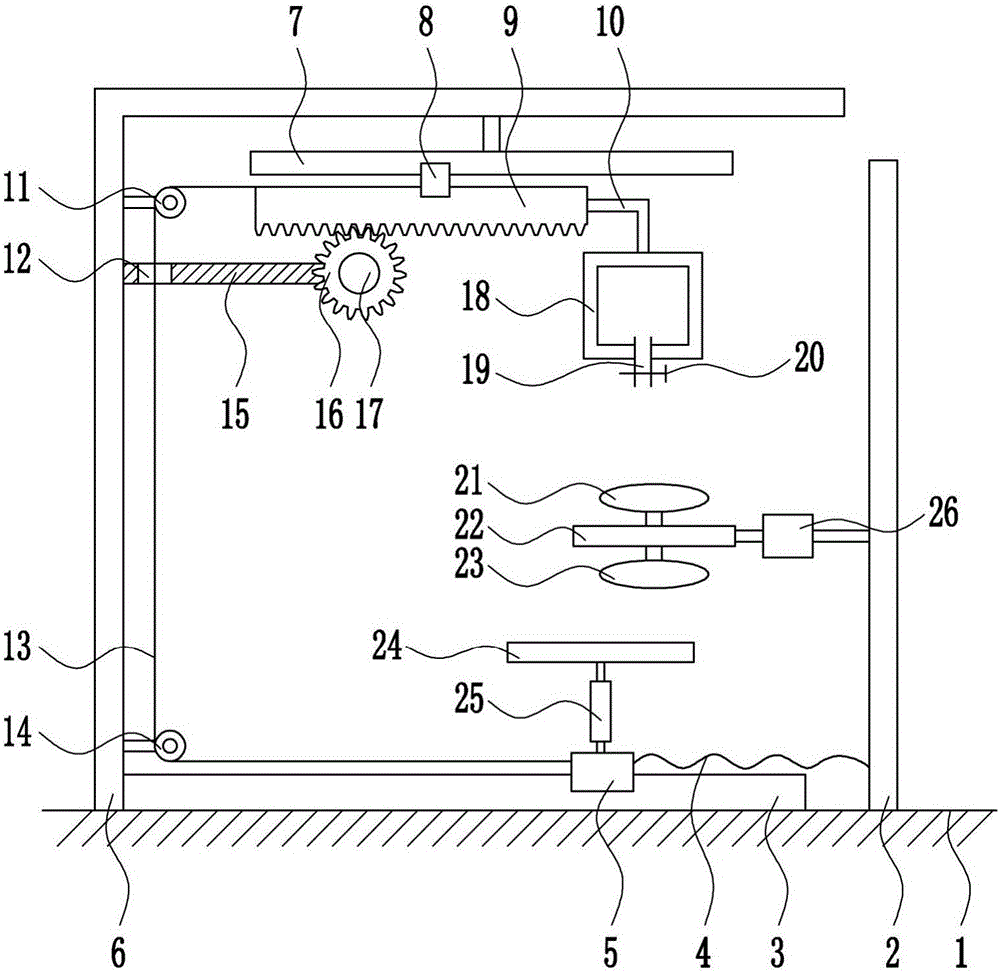

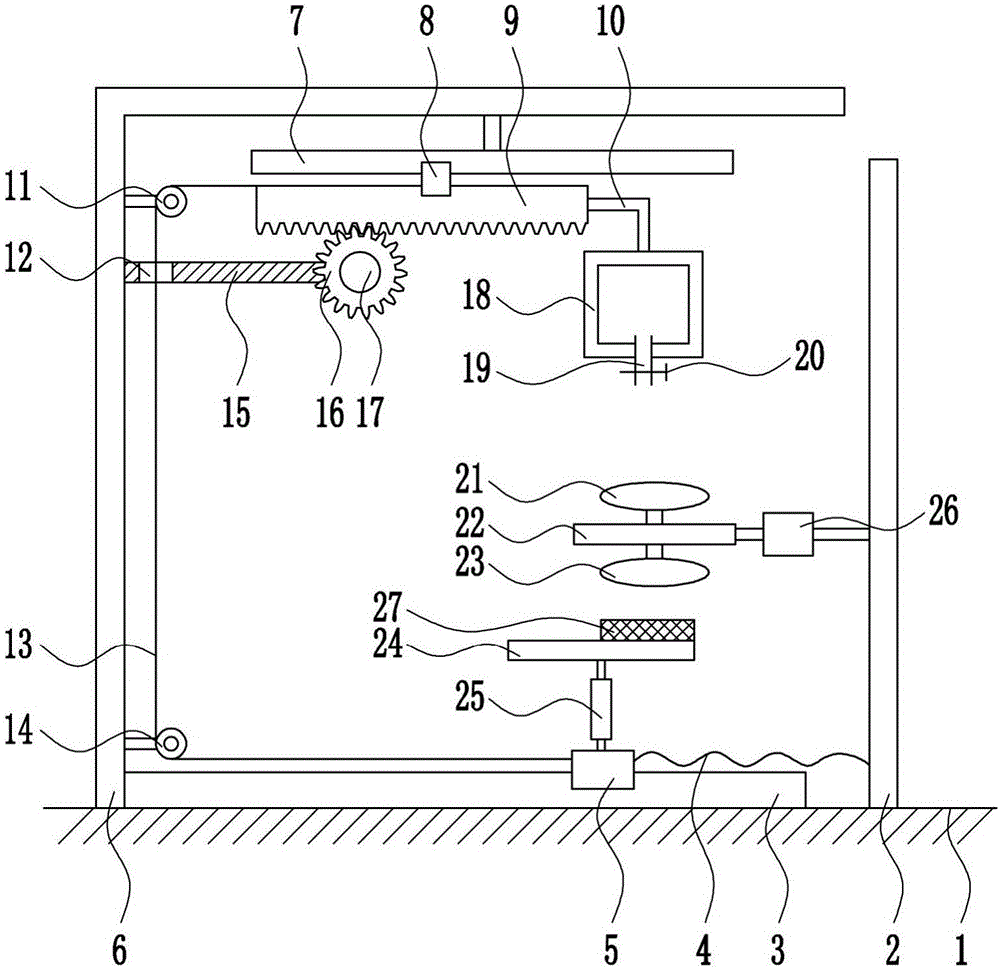

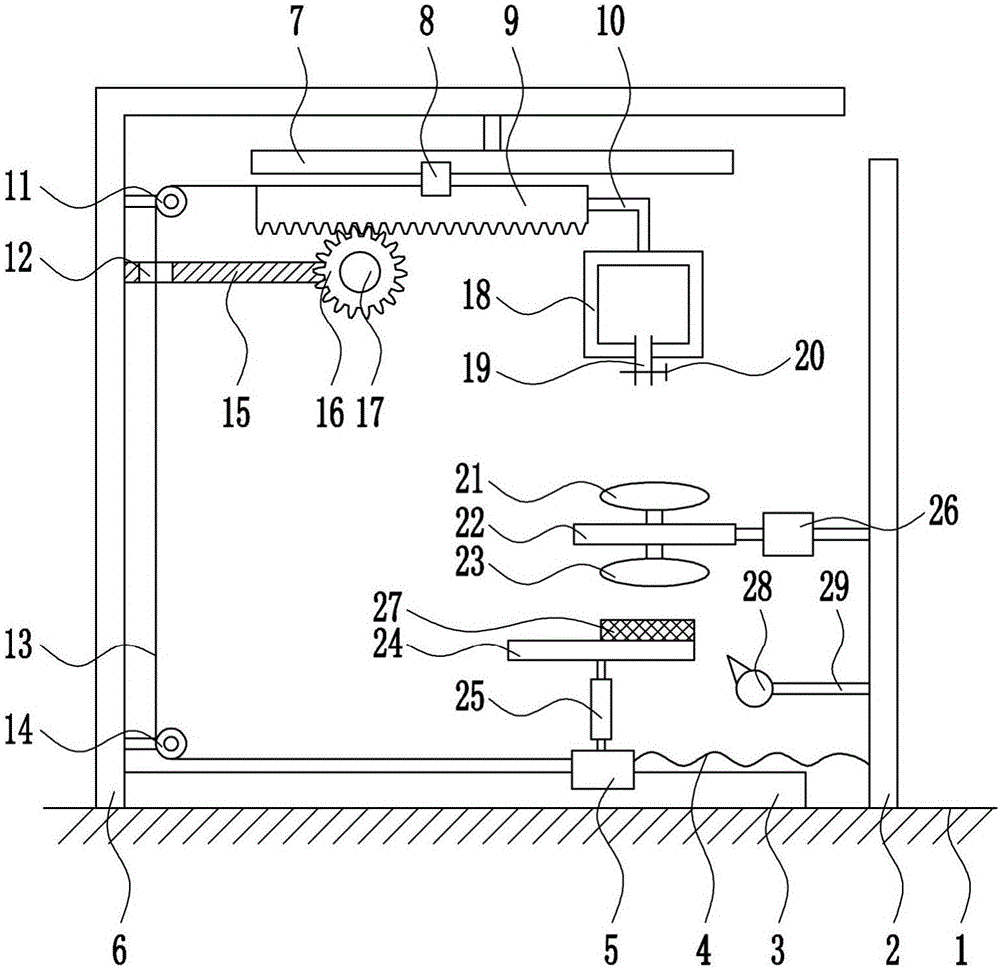

Quick shoe box labeling device

The invention relates to a labeling device, in particular to a quick shoe box labeling device. The quick shoe box labeling device is high in labeling speed, and comprises a right support, a first sliding rail, an elastic piece, a first sliding block, a left support, a second sliding rail, a second sliding block, a rack, a first connection rod, a first fixed pulley, a stay wire, a second fixed pulley, a second connection rod, a gear, a first motor, a box, a hard pipe, an electric control valve, a first electric suction cup, a fixing plate, a second electric suction cup, a containing plate, an electric push rod and a second motor. The left support, the first sliding rail and the right support are sequentially arranged on the ground from left to right. The first motor rotates to drive the box and the containing plate to move leftwards and rightwards, the second motor rotates to drive the fixing plate to rotate, and thus the effect of the high labeling speed is achieved.

Owner:浙江欣顺鞋业有限公司

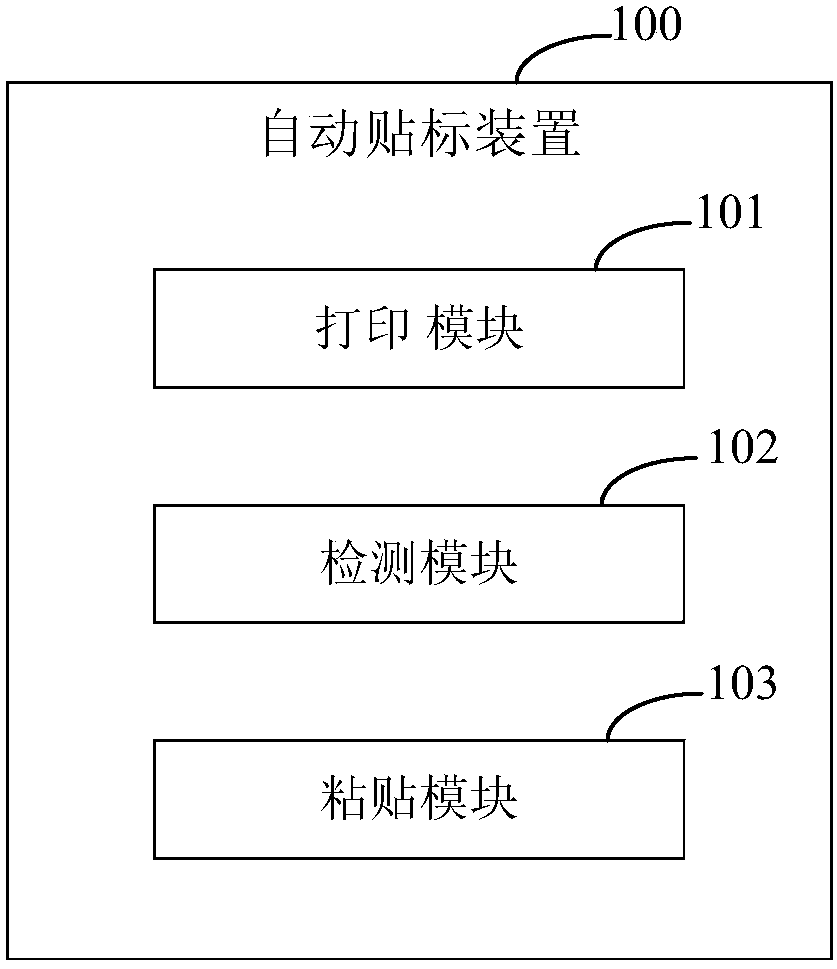

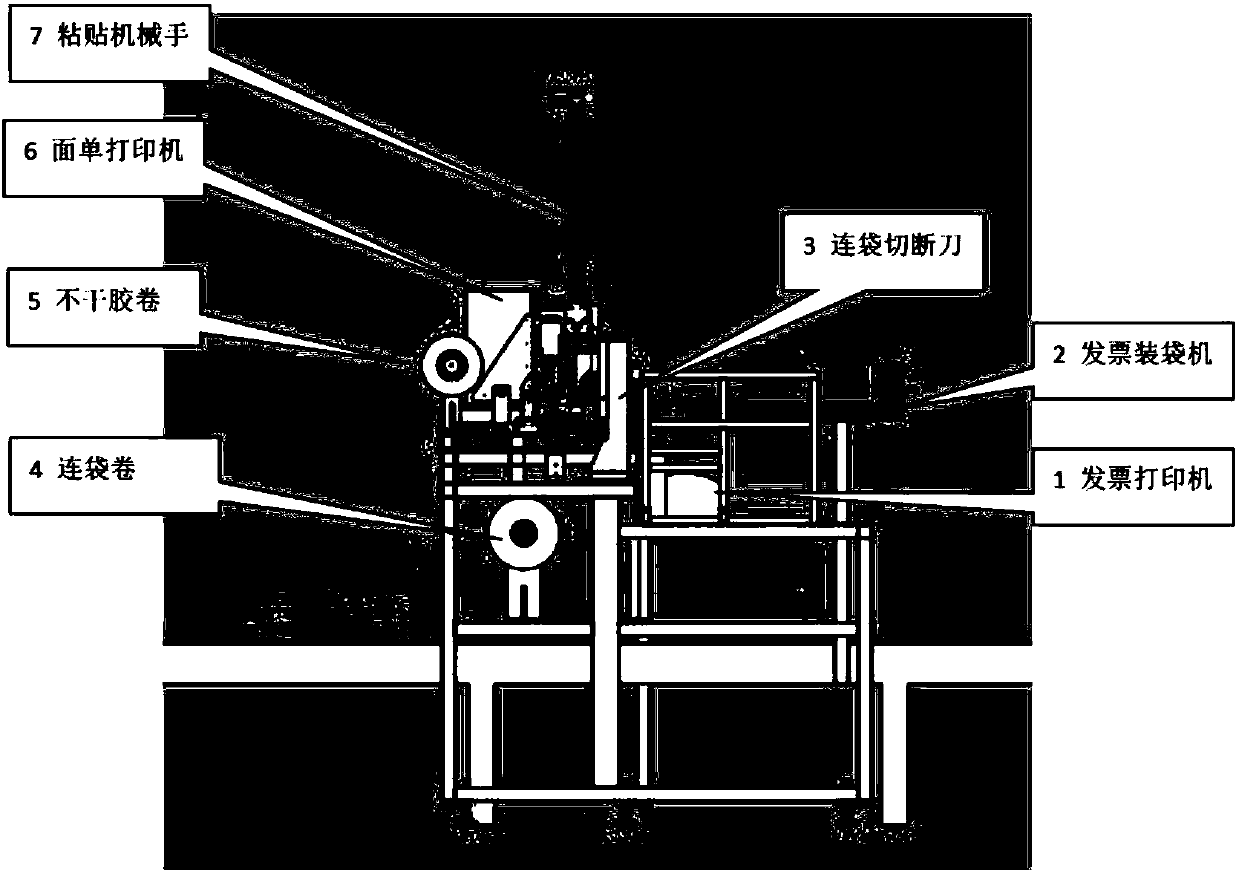

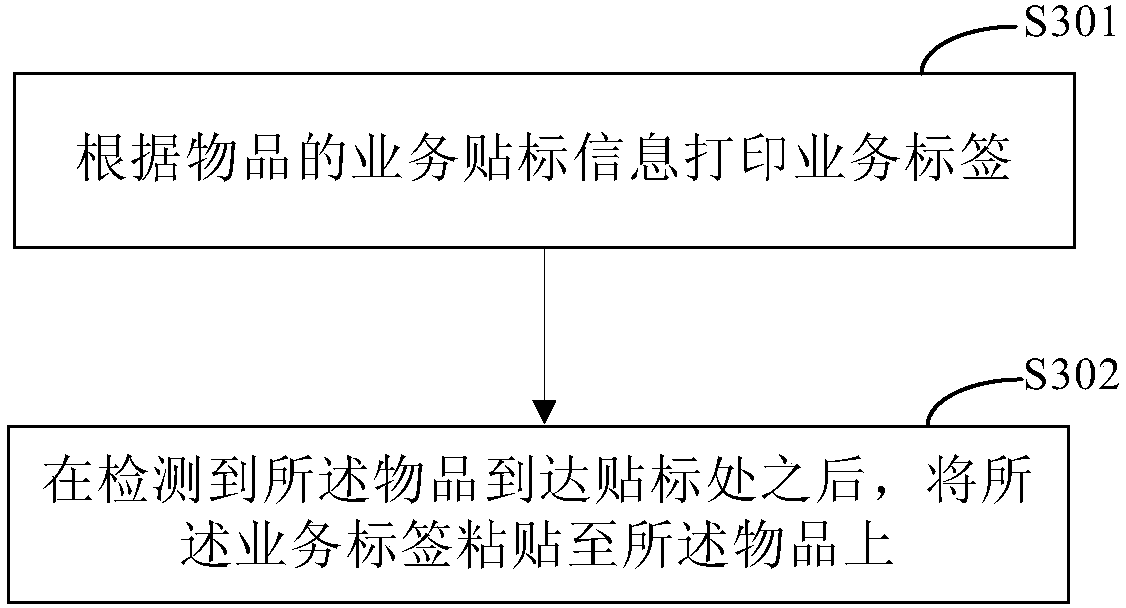

Automatic labeling device, method and system and labeling method using system

InactiveCN109902976ASolve technical problemsLoad shortcutLogisticsLabelling machinesComputer science

The embodiment of the invention provides an automatic labeling device, method, and system and a labeling method using the automatic labeling system, which can save the labor cost and solve the problems of manual mistaken labeling and less labeling of business labels. The automatic labeling device comprises a printing module, a detection module and a pasting module, wherein the printing module is used for printing business labels according to business labeling information of articles; The detection module is used for detecting whether the article reaches the labeling position; And the pasting module is used for pasting the business label to the article after the detection module detects that the article reaches the labeling position.

Owner:BEIJING JINGDONG ZHENSHI INFORMATION TECH CO LTD

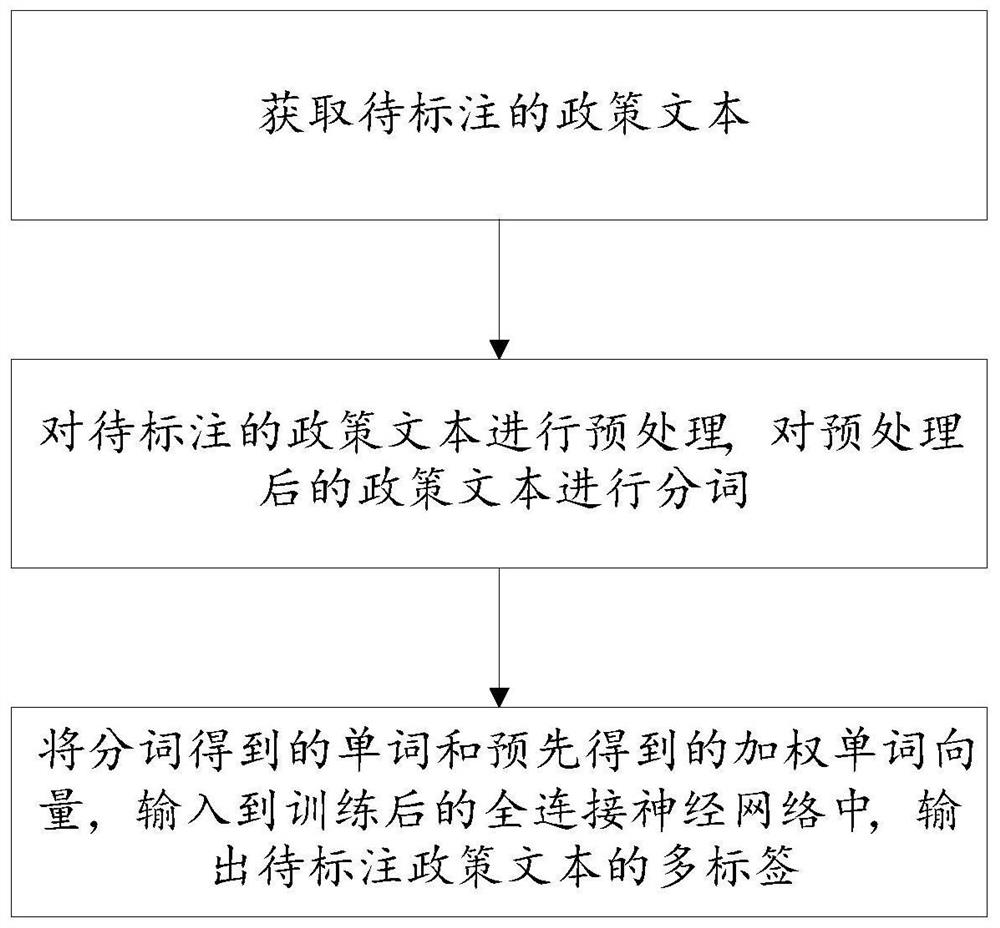

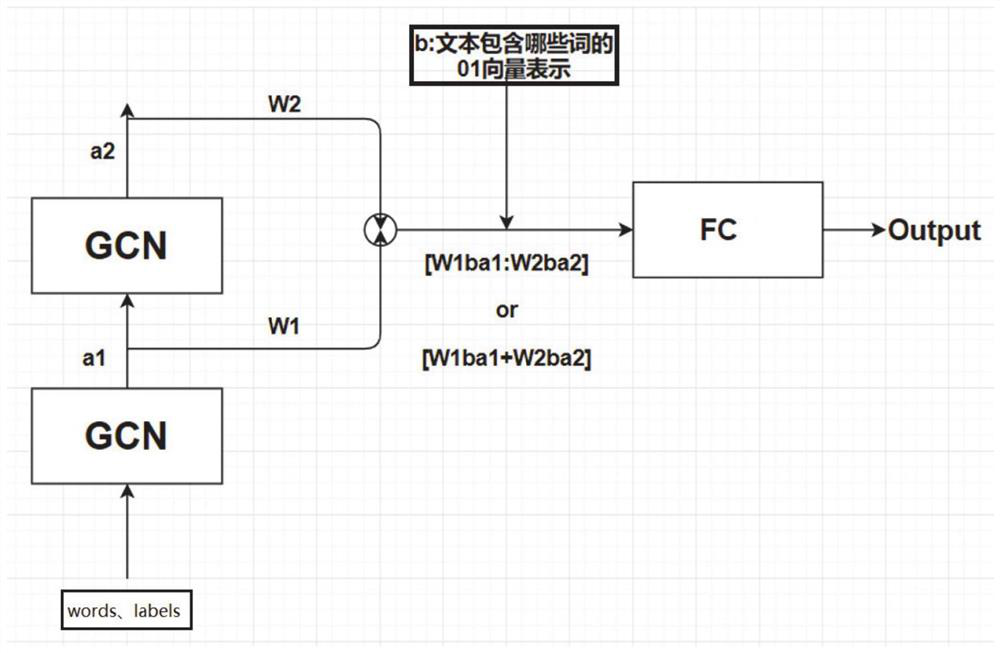

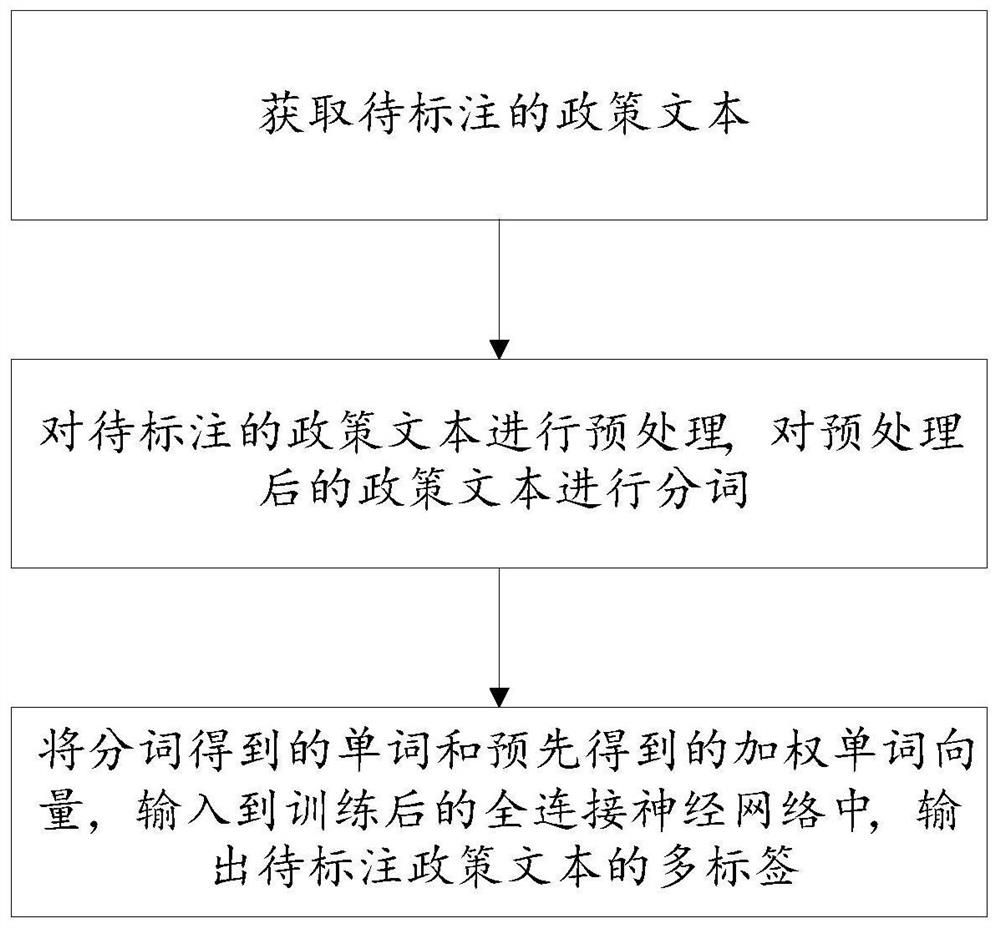

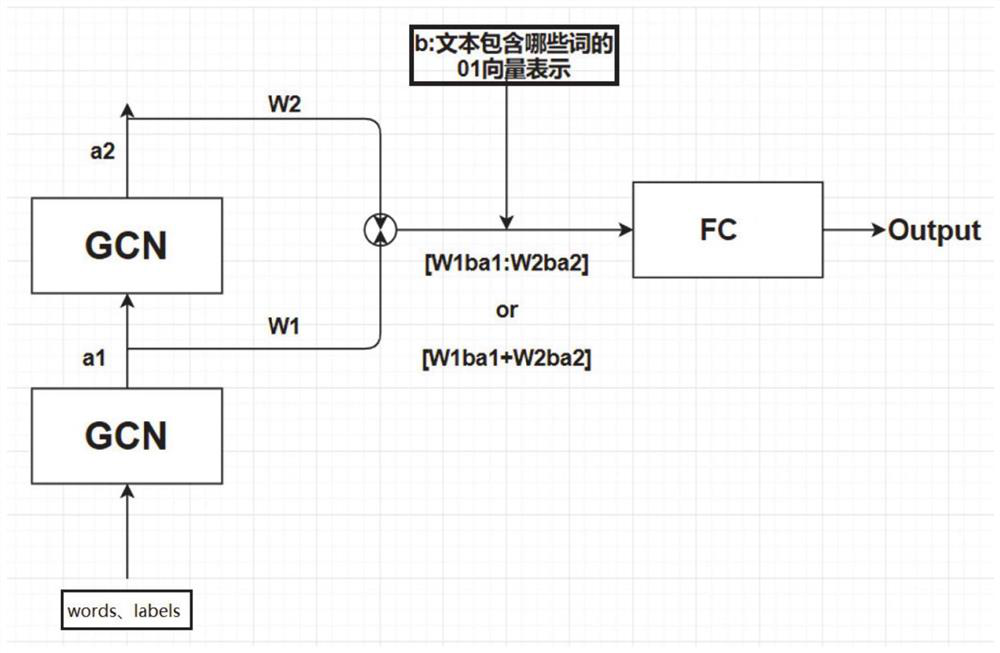

Policy text multi-label labeling method and system based on graph neural network

ActiveCN112906382AReduce labor costsErrors and omissionsNatural language data processingNeural learning methodsGraph neural networksArtificial intelligence

The invention discloses a policy text multi-label labeling method and system based on a graph neural network. The policy text multi-label labeling method comprises the steps of obtaining a policy text to be labeled; preprocessing the policy text to be labeled, and performing word segmentation on the preprocessed policy text; and inputting words obtained by word segmentation and weighted word vectors obtained in advance into the trained full-connection neural network, and outputting multiple labels of the policy text to be labeled. and in the efficient label labeling process, cheap computing resources are utilized, and a large amount of labor cost is reduced. Compared with manual work, more accurate label labeling is achieved, and mistakes and omissions of label labeling caused by the length of the file information are avoided. And timely policy file multi-label labeling is realized, and the label labeling of the required policy file is quickly carried out. The subjective difference is reduced, and the difference of a large number of labeled labels caused by different subjective judgment of different workers is avoided.

Owner:SHANDONG COMP SCI CENTNAT SUPERCOMP CENT IN JINAN +1

Synthesis of [18f]-labelled alkyl mesylates using fluorous spe separation

InactiveUS20110251432A1High reactivityFast labelingOrganic compound preparationSulfonic acid esters preparationCombinatorial chemistryAlkyl transfer

The invention relates to new processes for preparation of 18F-labelled alkylation reagents that can be used in the alkylation of amines that are suitable for use in labelling of Positron Emission Tomography (PET) radiotracers. (I)

Owner:GE HEALTHCARE LTD

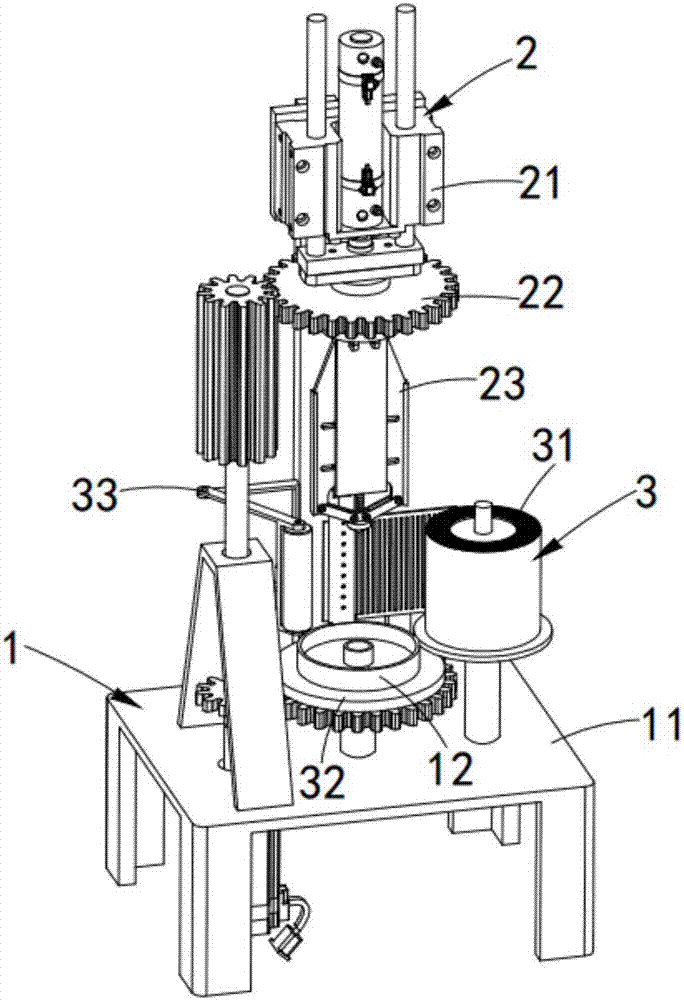

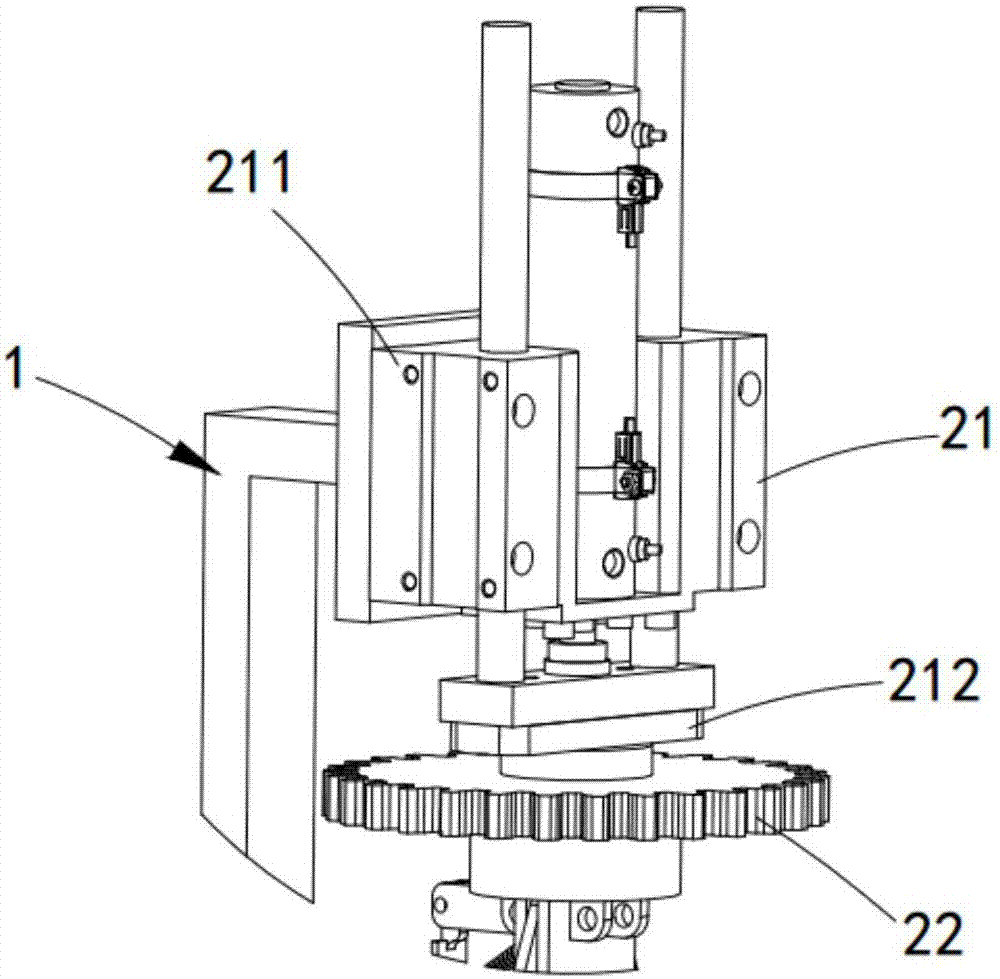

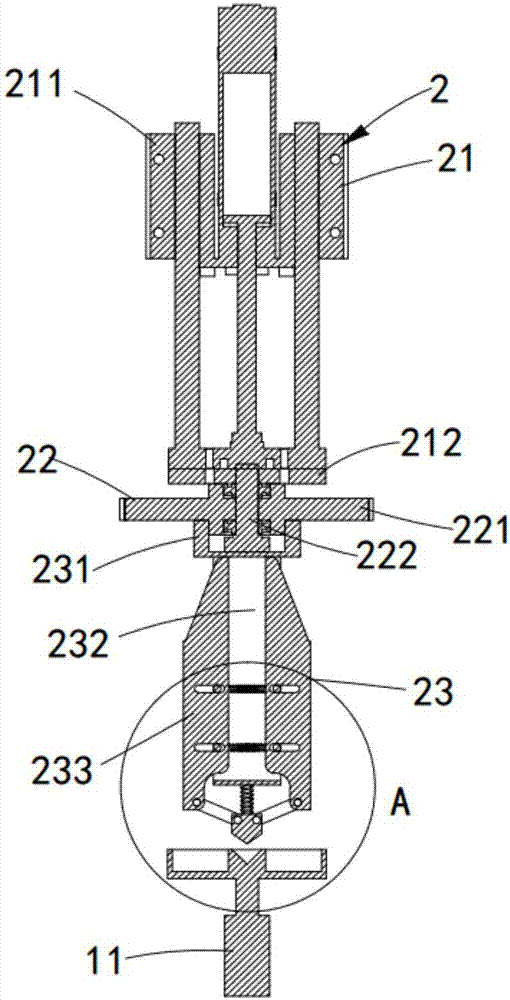

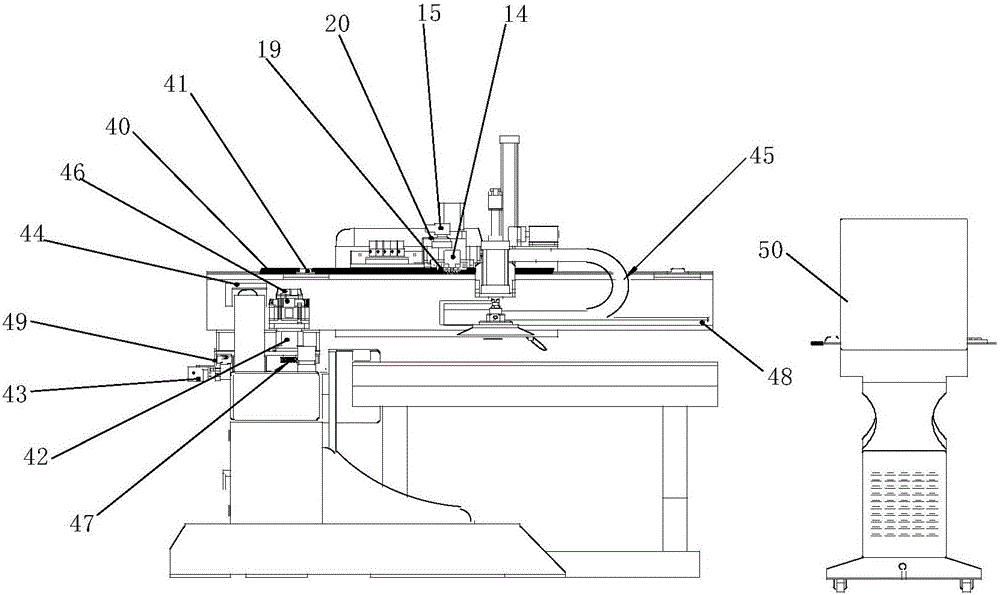

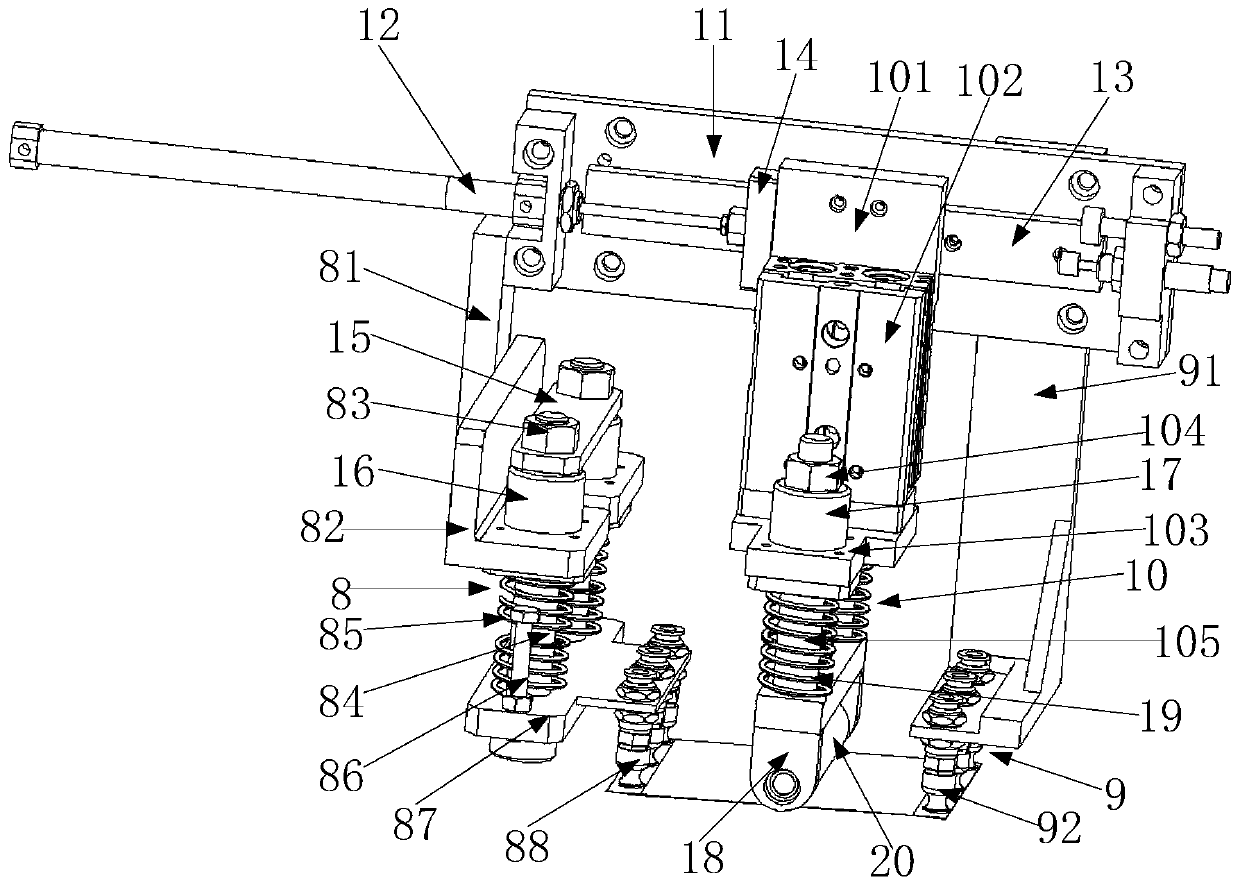

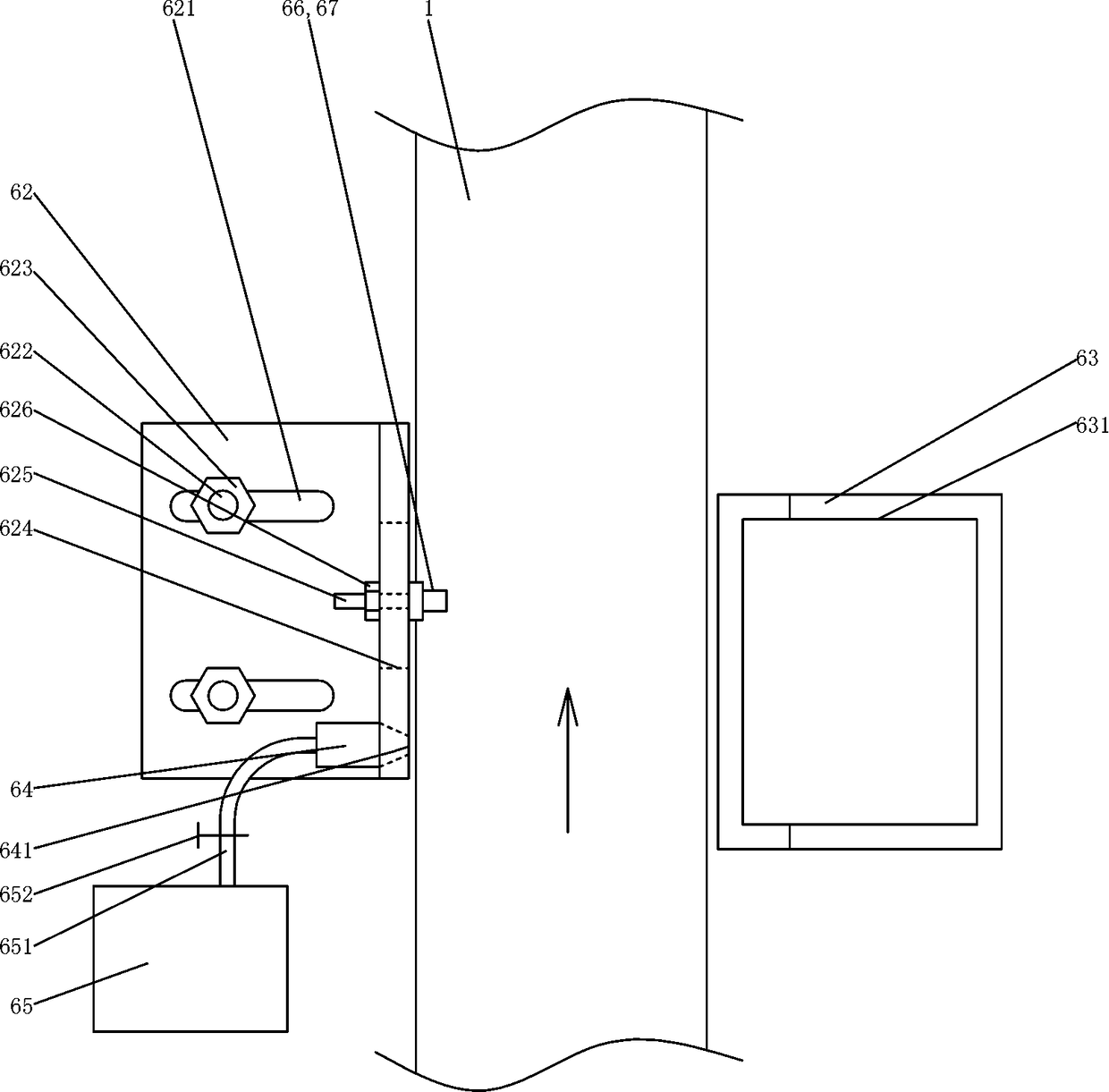

Dead head grinding and labeling device

ActiveCN106881450ASolve grinding problemsImprove grinding accuracyMoulding toolsFoundry mouldsEngineeringGrinding process

The invention discloses a dead head grinding and labeling device. The dead head grinding and labeling device comprises a rack, a grinding mechanism, labeling mechanisms and a drive mechanism. The grinding mechanism is arranged on the top of the rack, can ascend and descend up and down along the rack and automatically grinds the inner wall of a dead head placed on a dead head positioning base at the bottom of the rack; and in the grinding process, the width of a grinding cutter in the grinding mechanism can be changed along with the diameter changes of the inner wall of the dead head in the grinding process. Meanwhile, the labeling mechanisms are arranged on the two sides of the dead head positioning base and automatically label the outer wall of the dead head, the purpose of thorough grinding of the inner wall of the dead head is achieved, automatic dead head outer wall label paper labeling is achieved, the dead head inner wall grinding precision is improved, the dead head label pasting speed is increased, and labeling consistency is guaranteed.

Owner:长兴鼎峰铸材科技股份有限公司

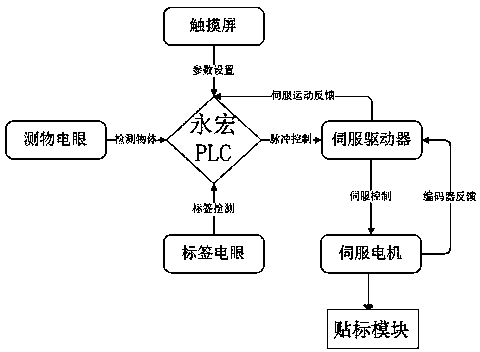

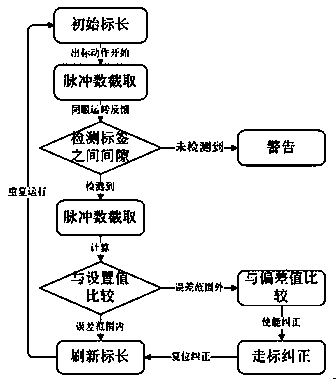

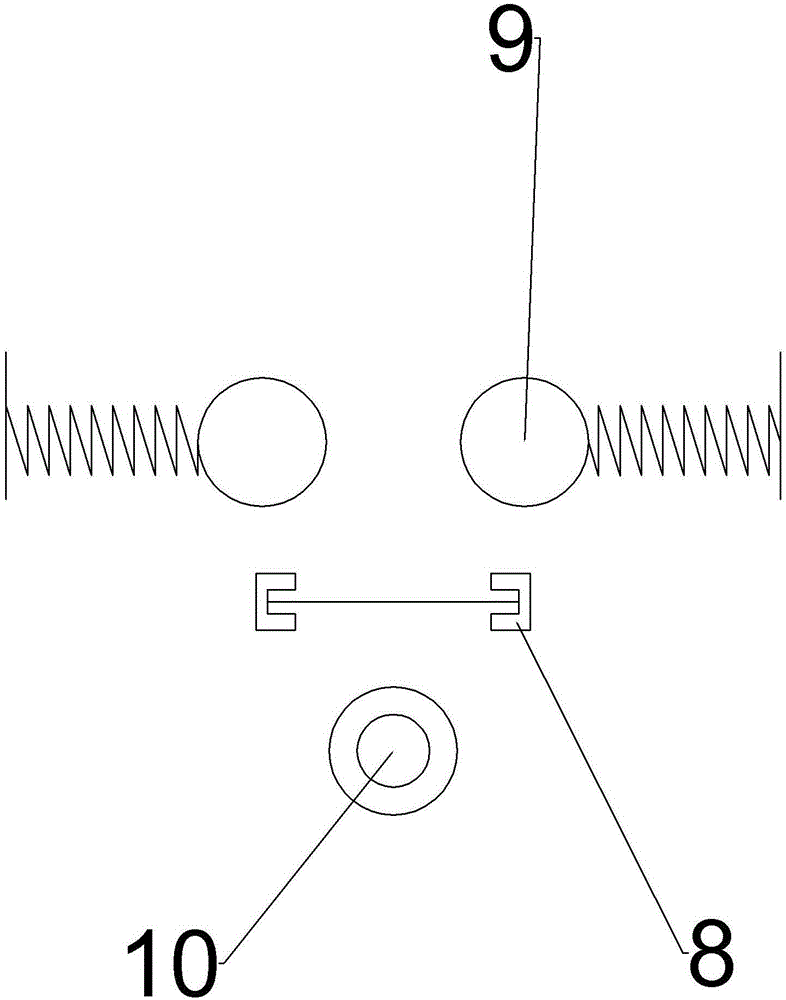

High-speed labeling machine capable of correcting label conveying and correcting method of machine

ActiveCN104354947APaste firmlyAvoid running unstableLabelling machinesProgrammable logic controllerInstability

The invention discloses a high-speed labeling machine capable of correcting label conveying and a correcting method of the machine. By taking a PLC (Programmable Logic Controller), a servo motor, a servo driver, an object measurement electric eye and a groove type optical label electric eye as main core parts, the continuous labeling operation is carried out; in view of instability of label conveying, each label is detected, calculated and finely adjusted; when the conveying deviation is mainly caused by slip of labels, the deviation value can be immediately loaded during conveying of next label by a system and the conveying distance is compensated, so that the labels are accurately conveyed.

Owner:ANHUI DOUBLE CRANE PHARMA

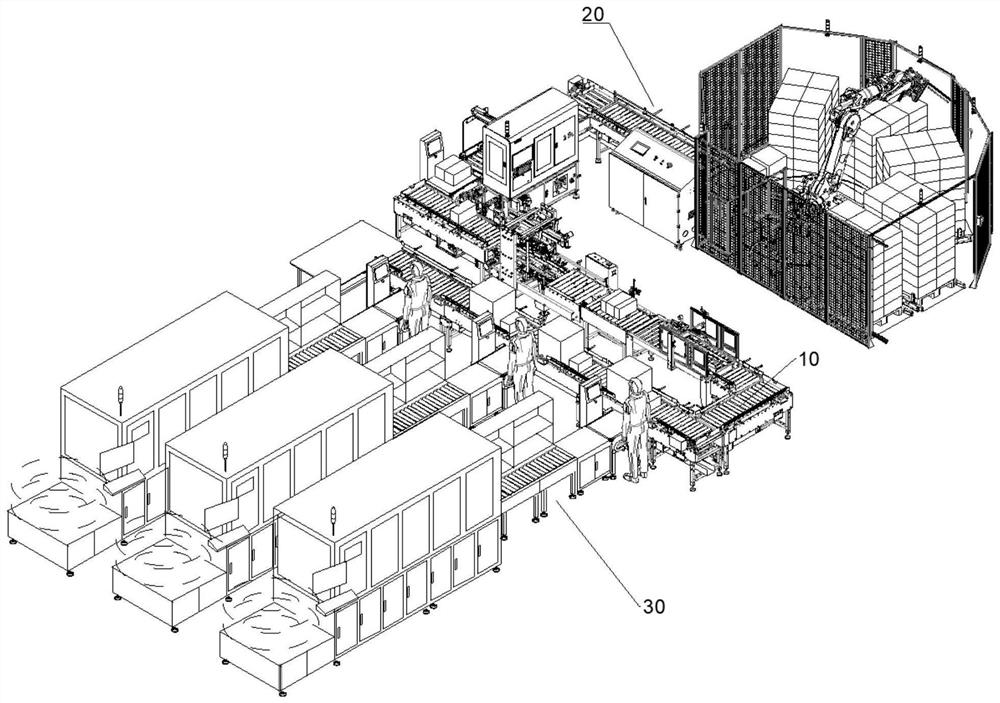

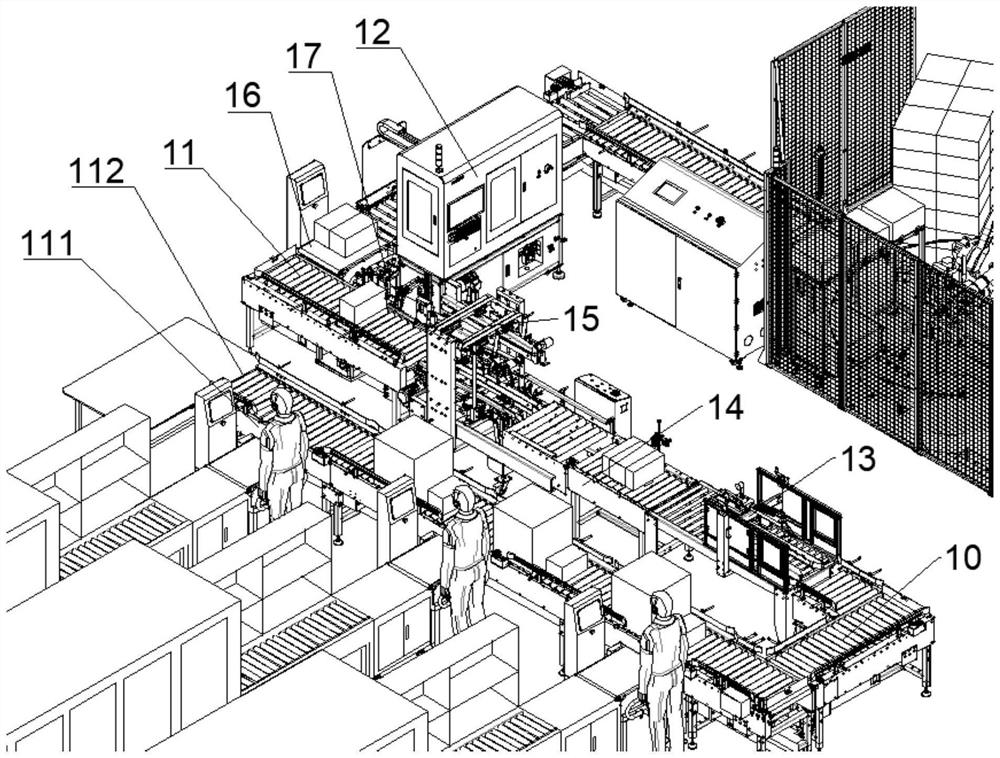

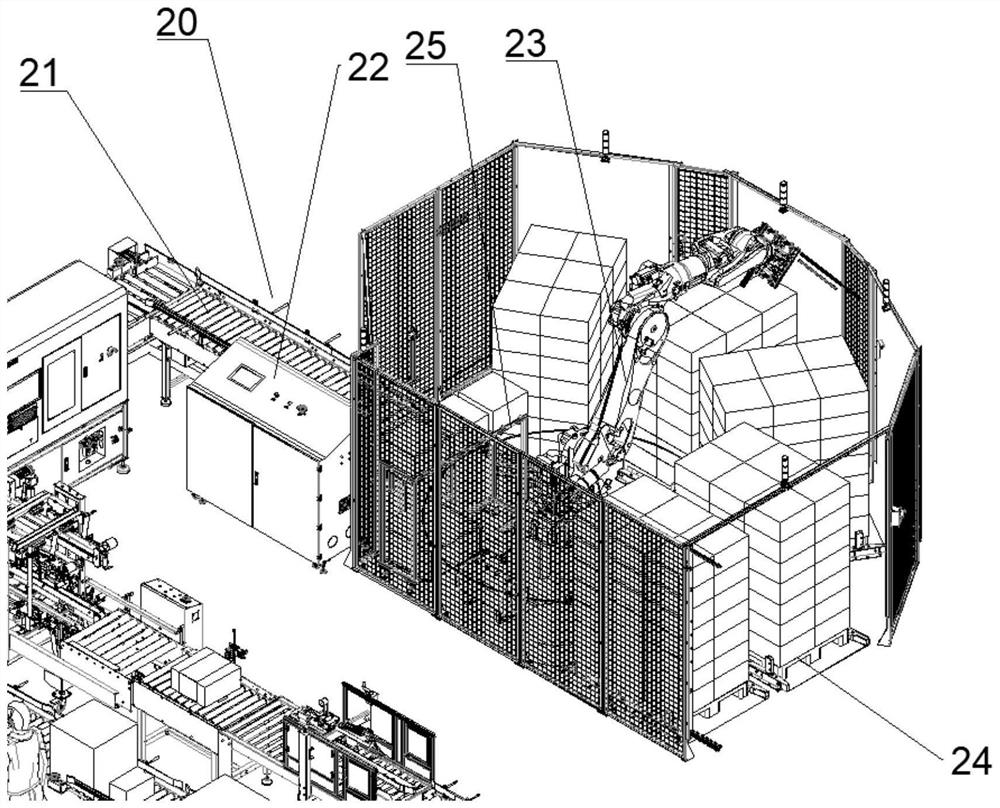

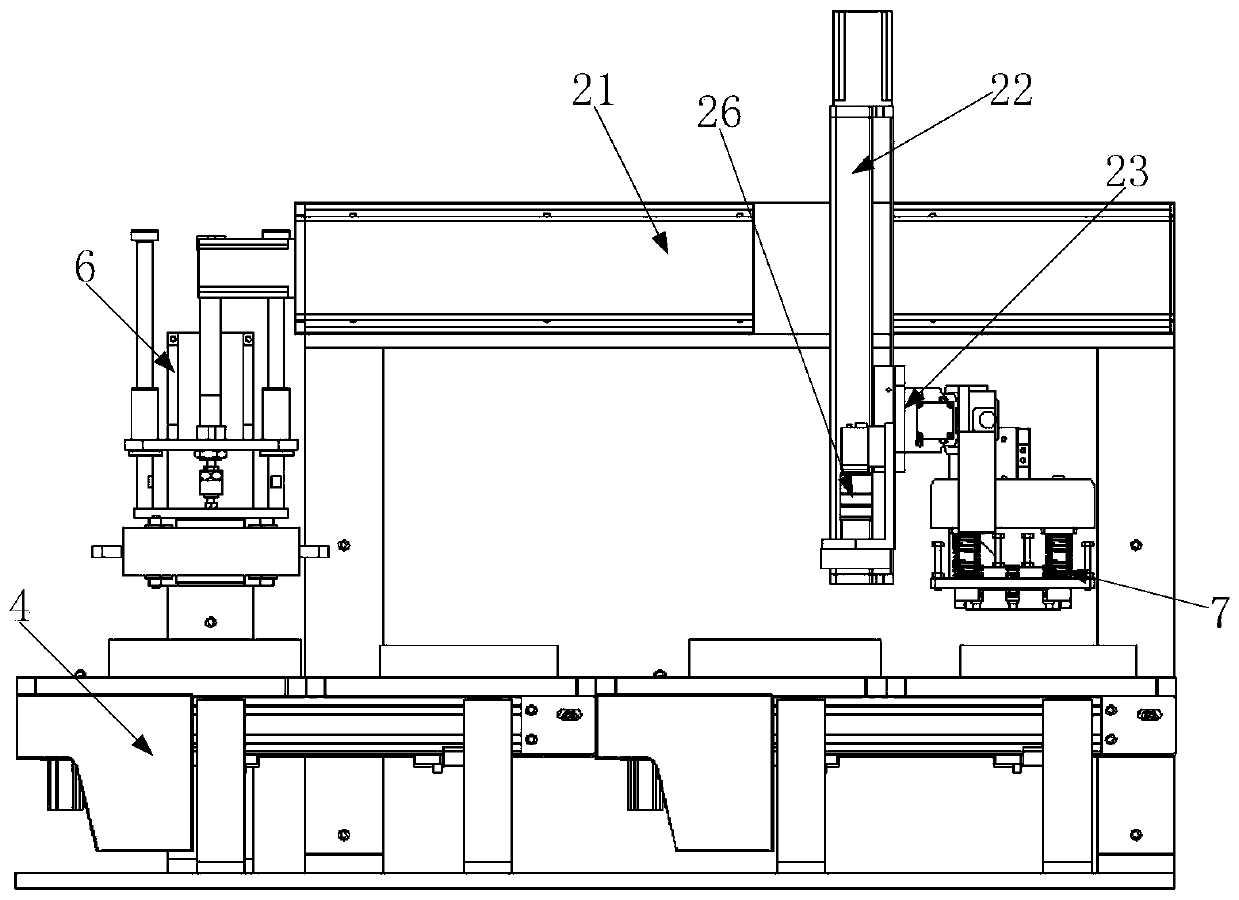

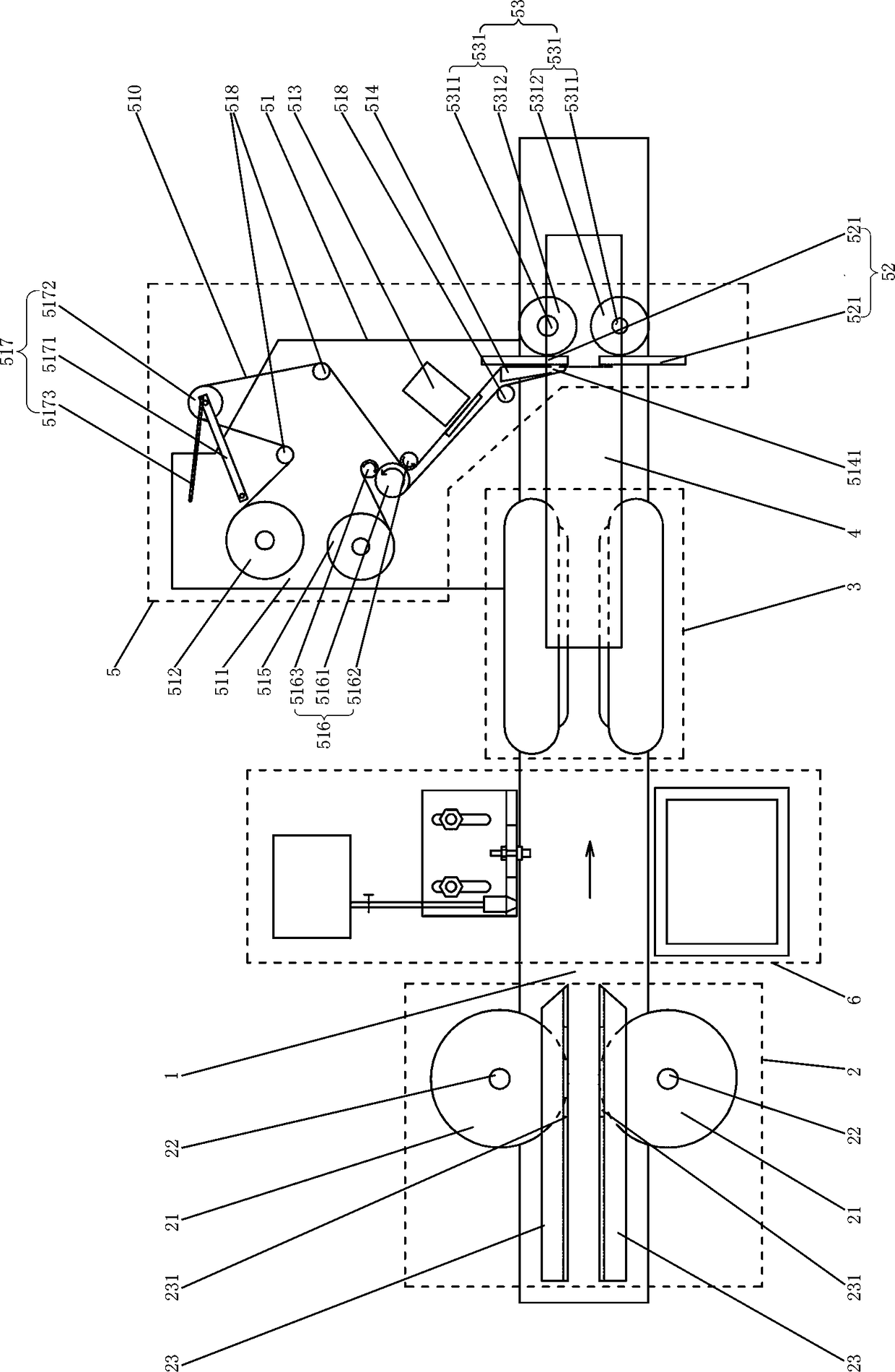

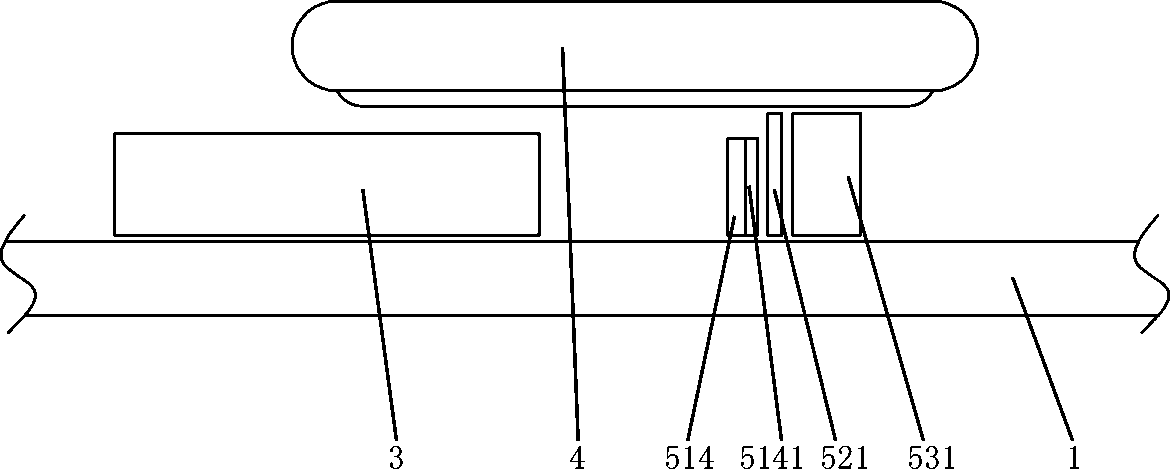

Automatic packaging, box sealing and stacking production line and control method thereof

ActiveCN114275265AQuick scanAutomate operationWrapper twisting/gatheringStacking articlesProcess engineeringManufacturing engineering

The invention relates to an automatic packaging, box sealing and stacking production line and a control method thereof.The automatic packaging, box sealing and stacking production line comprises an automatic packaging line, a box sealing line and a stacking line, the box sealing line comprises a first roller line, a box sealing control system, a box sealing mechanism, a first scanning mechanism, a first weighing mechanism and a printing and labeling mechanism, and the box sealing mechanism, the first scanning mechanism, the first weighing mechanism and the printing and labeling mechanism are arranged along the first roller line; the first scanning mechanism is used for scanning product information labels on the first packaging box and the second packaging box, and the box sealing control system drives the first weighing mechanism to weigh the second packaging box and sends a weighing result to the printing and labeling mechanism. The printing and labeling mechanism prints a weight label according to the weighing result and attaches the weight label to the second packaging box. The device and the method provided by the invention are compatible with a production line for manually assembling products while realizing automatic operation of the production line.

Owner:广东微容电子科技有限公司

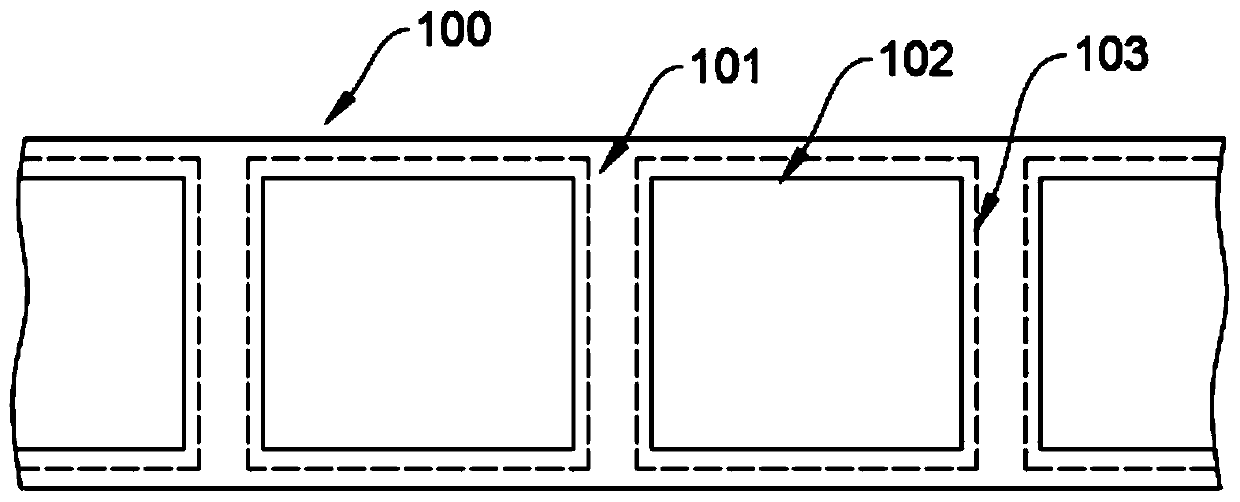

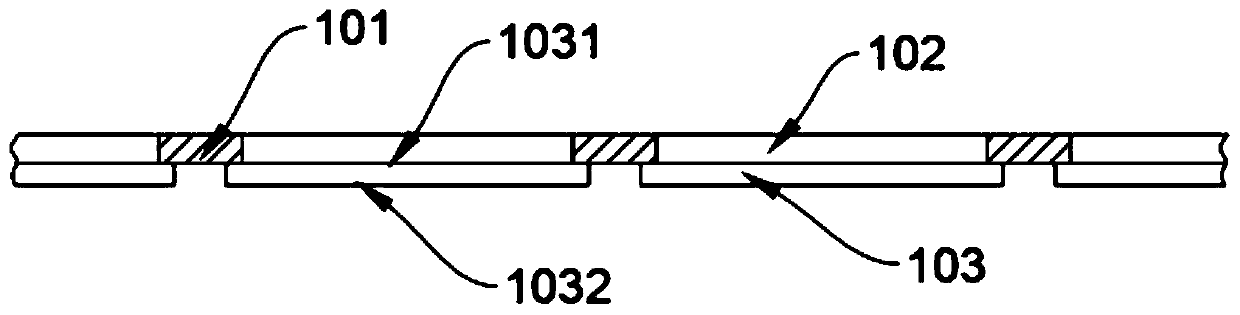

Color box position shifting machine

PendingCN109606879AMeet the labeling needs of different positionsFast labelingLabelling flat rigid surfacesLabelling machinesEngineeringMechanical engineering

The invention discloses a color box position shifting machine. The color box position shifting machine comprises a base, a turnover device and a clamping device; any side of the base is provided witha back plate extending upwardly, the turnover device is mounted on the plate surface of the back plate, the clamping device is connected with the turnover device, and the turnover device is used for rotating the clamping device; the clamping device comprises a clamping seat, a first clamping member and a second clamping member, the first clamping member and the second clamping member realize positioning and clamping of a color box through relative sliding, and the first clamping member and the second clamping member are both provided with labeling notches; and the clamping device further includes a driving device, and the driving device is used for driving sliding of the first clamping member and the second clamping member on the clamping seat. According to the color box position shiftingmachine, shifting of the color box at different angles can be realized, the labeling requirements of different positions are met, the labeling speed is improved, and the production efficiency of products is improved.

Owner:FOSHAN KINGPENG ROBOT TECH CO LTD

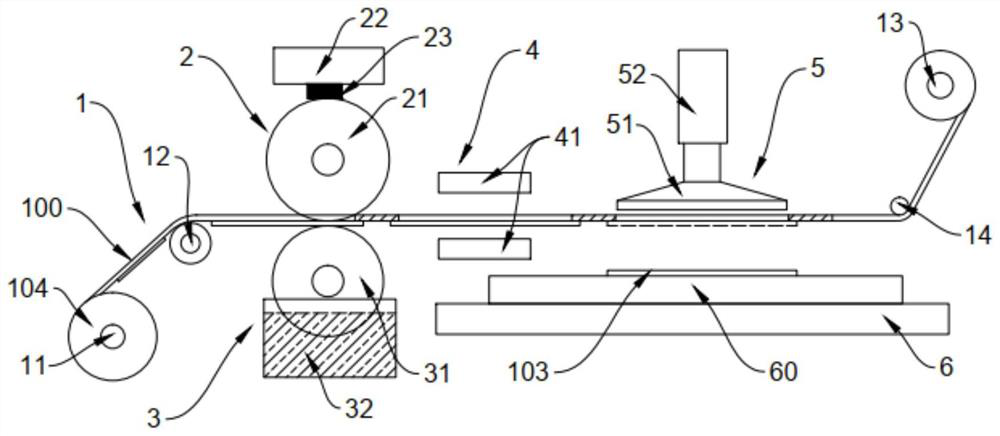

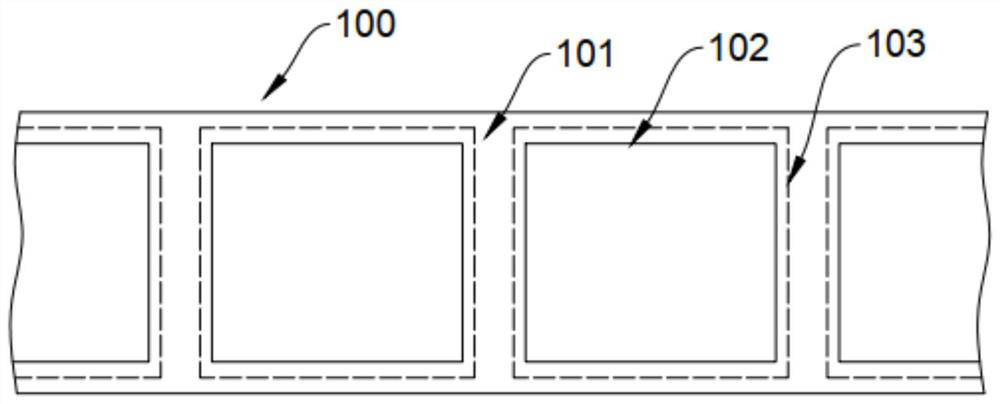

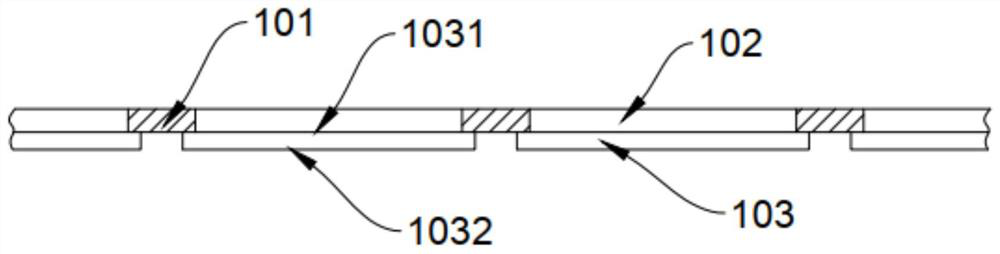

Injection molding machine with automatic label delivering system

The invention relates to the technical field of labeling devices, in particular to an injection molding machine with an automatic label transferring system. The injection molding machine comprises a label roll unwinding device, a label transferring device, a label transferring axis, a label vacuum adsorbing and transferring device, a label adsorption die cavity transferring device and a mechanical arm, wherein the lower part of the label roll unwinding device is jointed with the label transferring device; the label transferring device is in fit joint with the label transferring axis and the label vacuum adsorbing and transferring device; and the other end of the label transferring axis is jointed with the label adsorption die cavity transferring device which is in fit joint with the mechanical arm. Compared with the prior art, the injection molding machine is novel and simple in structure and convenient to operate, realizes labeling automation, has the advantages of low possibility of damaging the label, high labeling precision, quick labeling and the like, improves the working efficiency and realizes mechanical automation.

Owner:ATRA PLASTICS SHANGHAI

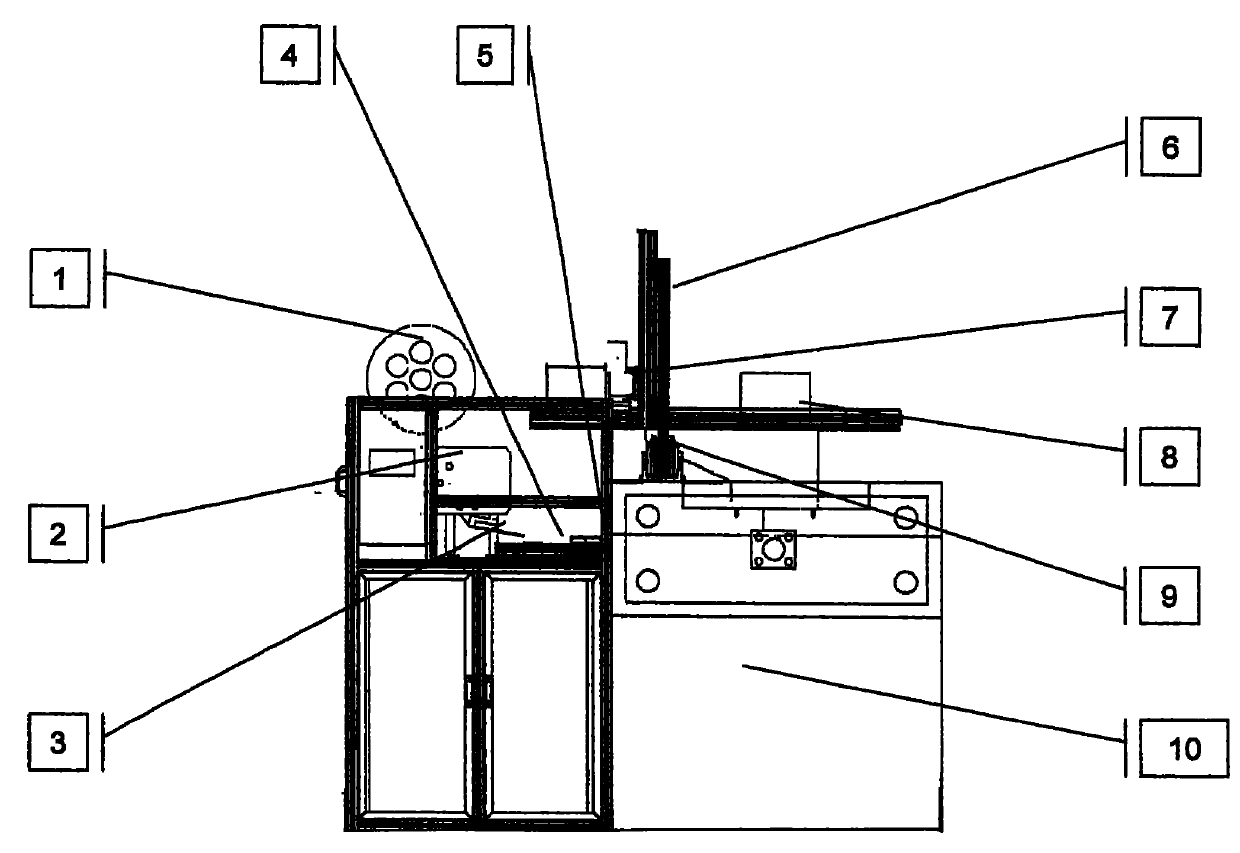

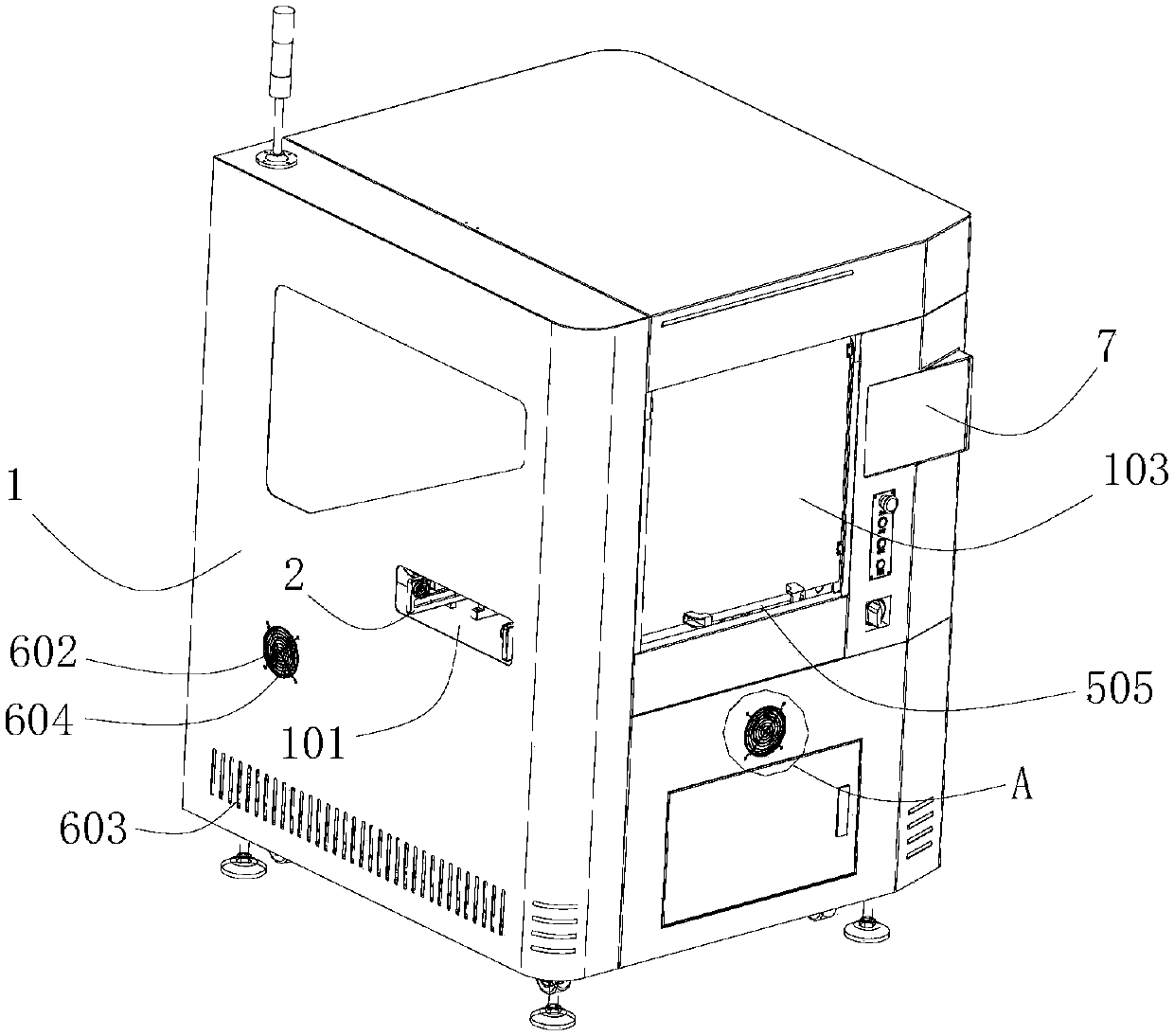

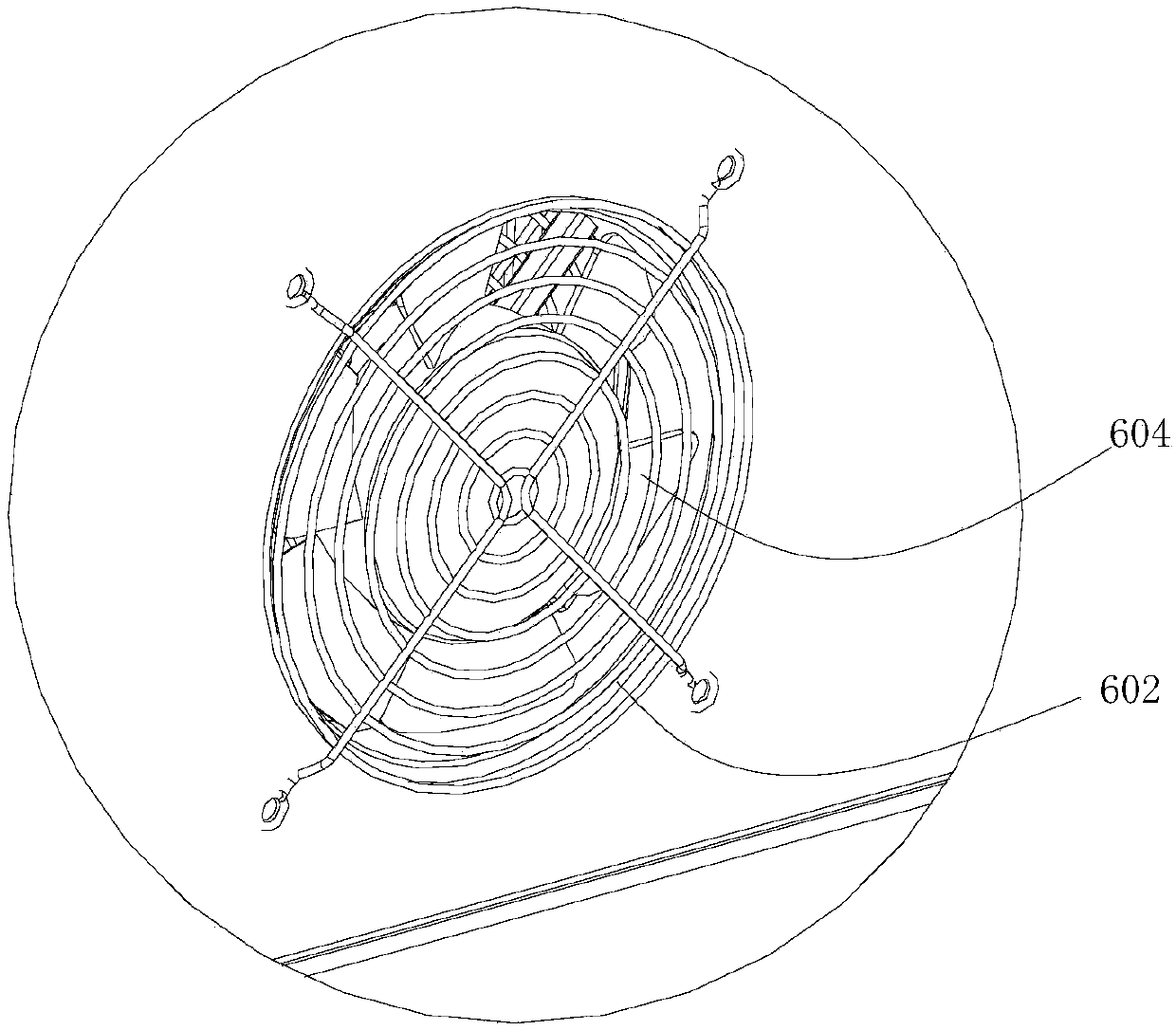

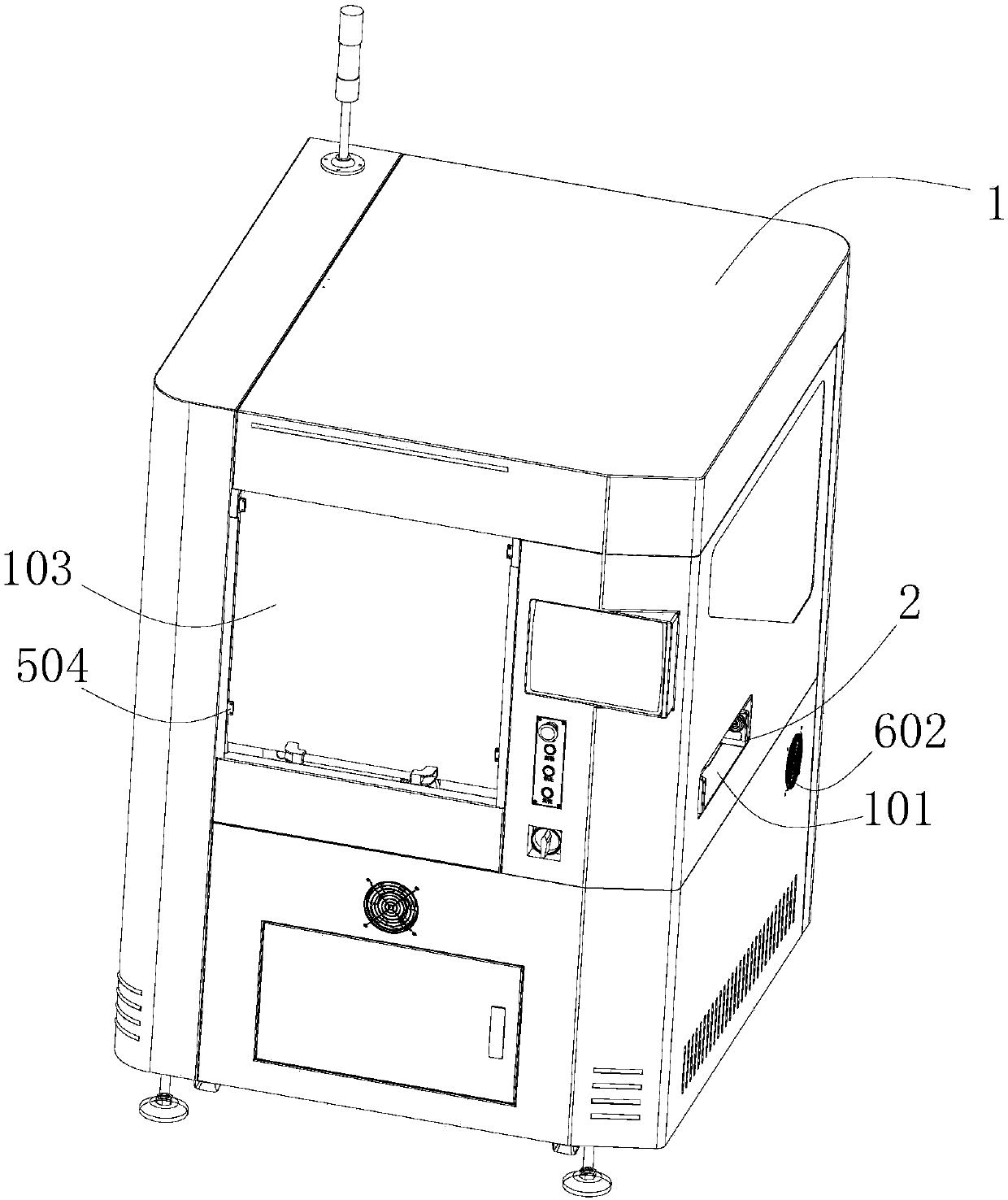

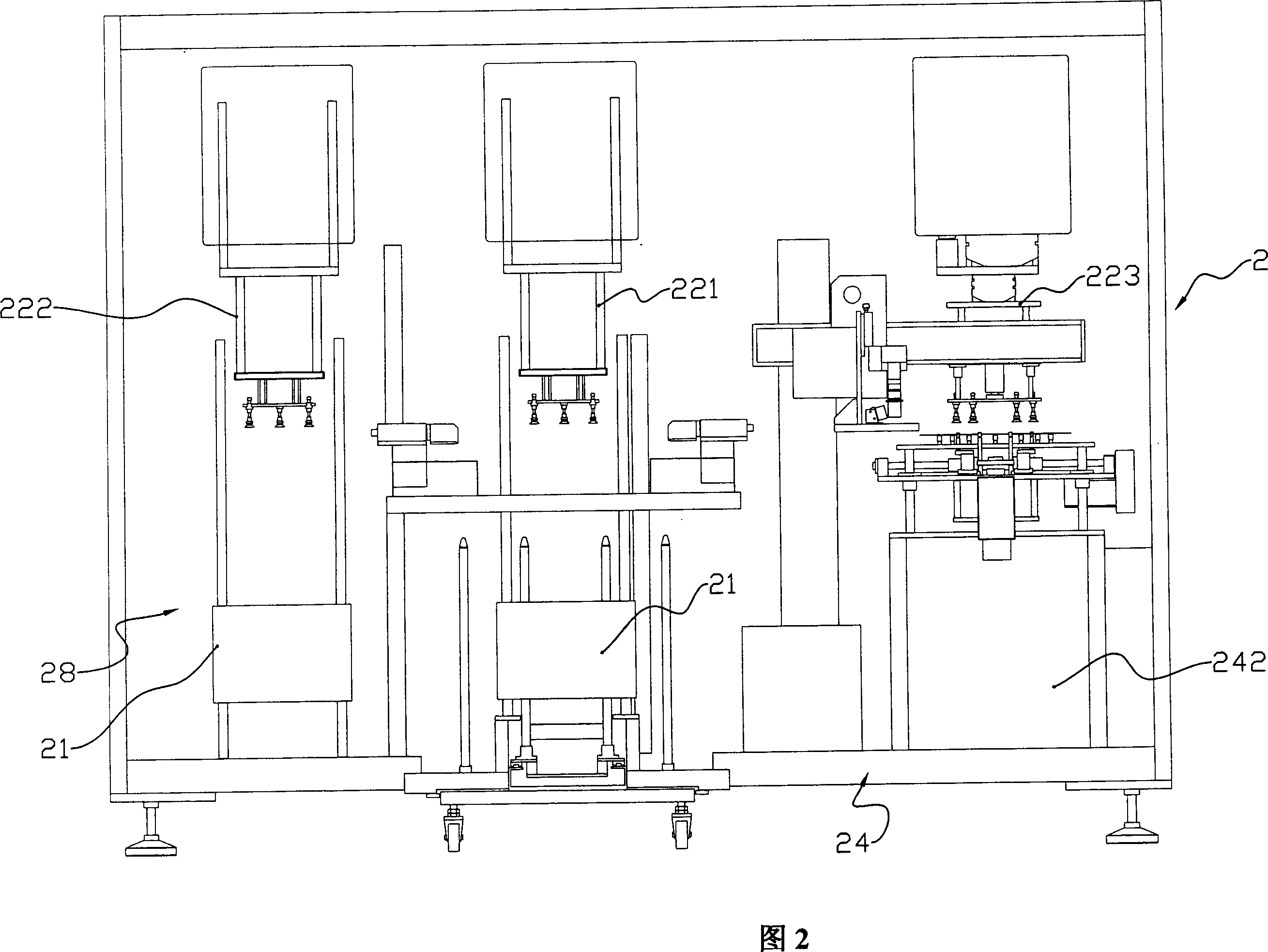

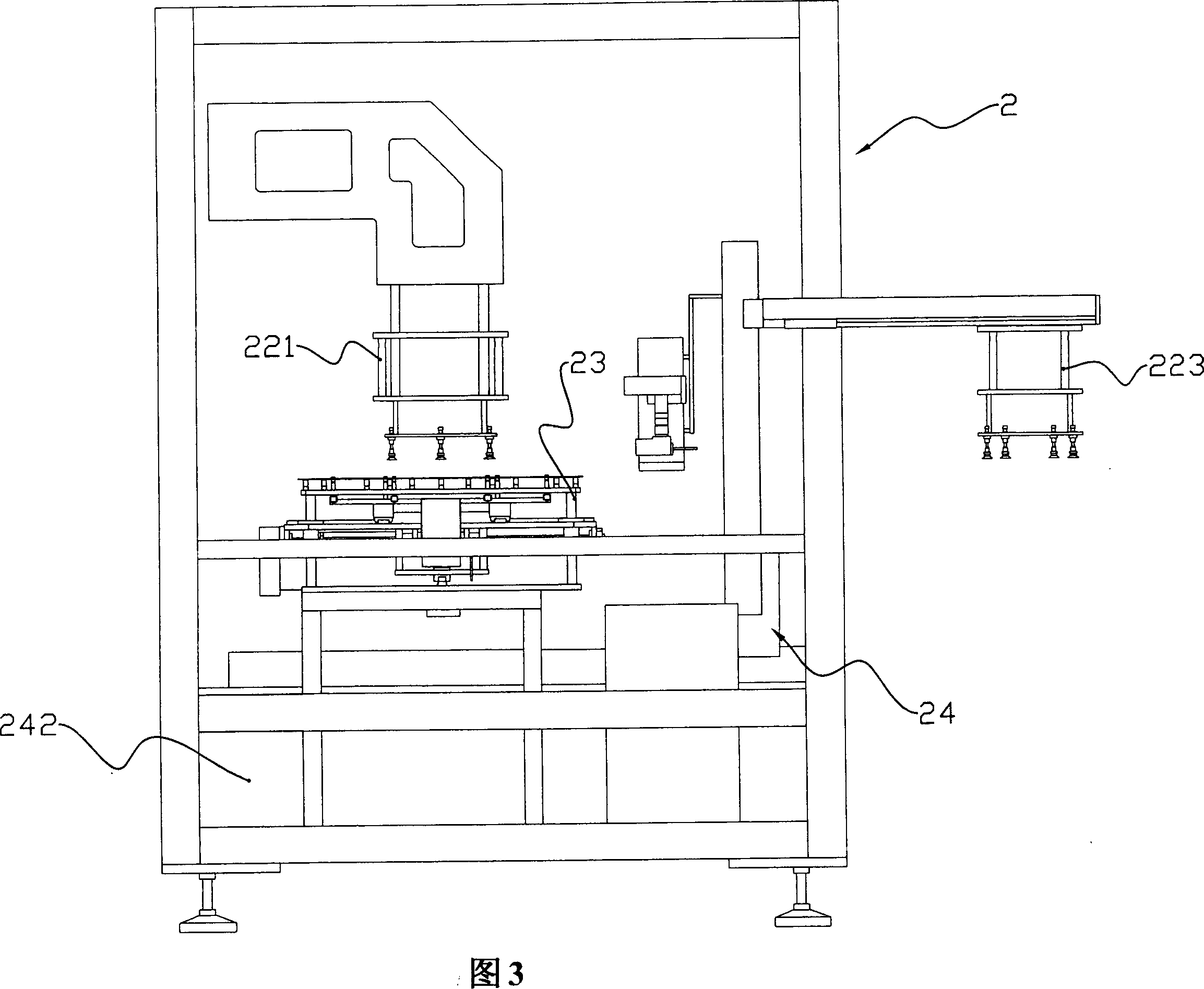

Automatic labelling machine

PendingCN107554905APrecise positioningWith modular designLabelling machinesProduction lineControl system

The invention discloses an automatic labelling machine and belongs to an intelligent robot. The automatic labelling machine comprises a labelling machine complete machine, wherein a circuit board inlet, a circuit board outlet and an observation door are arranged on side faces of the labelling machine complete machine; a conveyer for conveying a circuit board, a label feeding device for conveying label paper and a labelling device are arranged in the labelling machine complete machine; the labelling device takes out the label paper sent out by the label feeding device and pastes the label on the label paper onto the circuit board of the conveyer; the labelling machine complete machine is connected with a control system for setting a labelling position; and the control system is in communication connection with the label feeding device and the labelling device. According to the automatic labelling machine, the labelling device and the label feeding device are positioned on the side of the conveyer, so that the path that a labelling head moves to the label feeding device is short, and the labelling speed is high; the control system is accurate in positioning, high in labelling precision and safe to operate; and design of the observation door saves space, and the complete machine can use the circuit boards with different specifications and can be matched with other machines at willto construct the automatic labelling machine of a production line.

Owner:广东腾山机器人有限公司

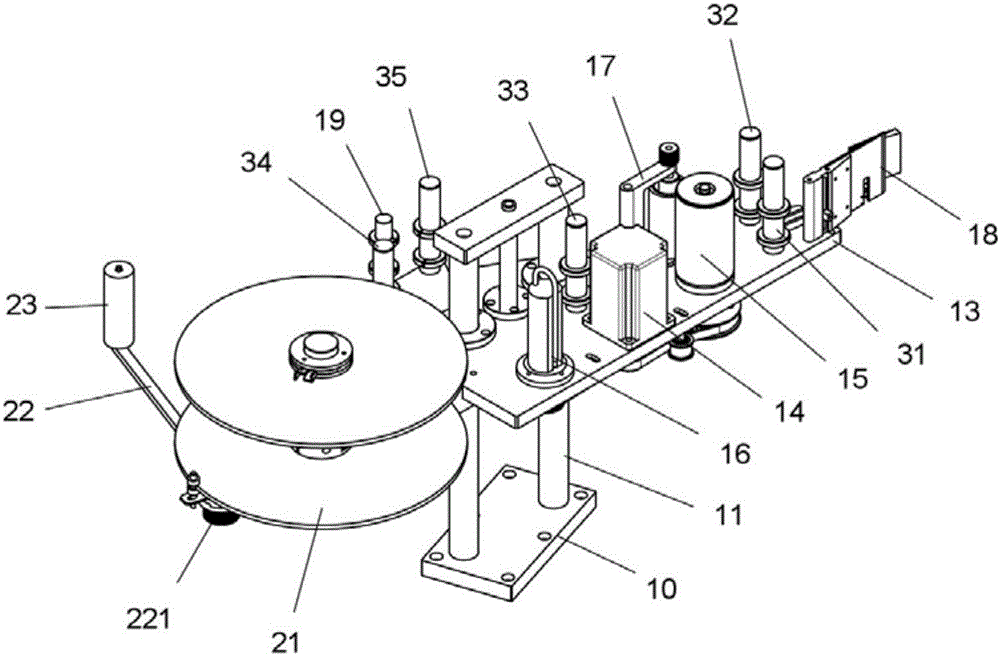

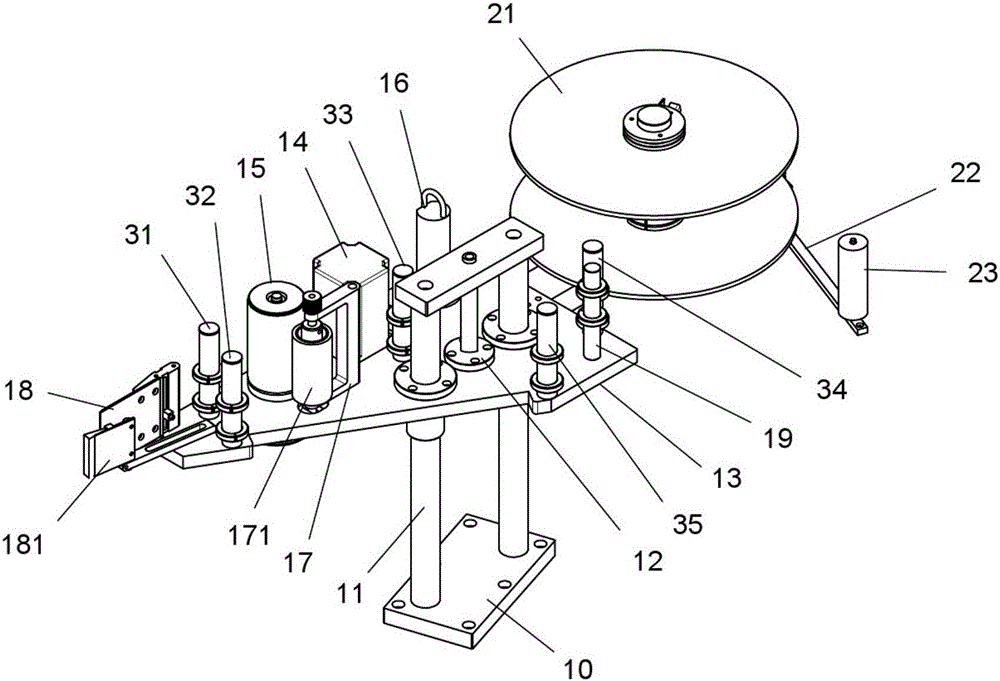

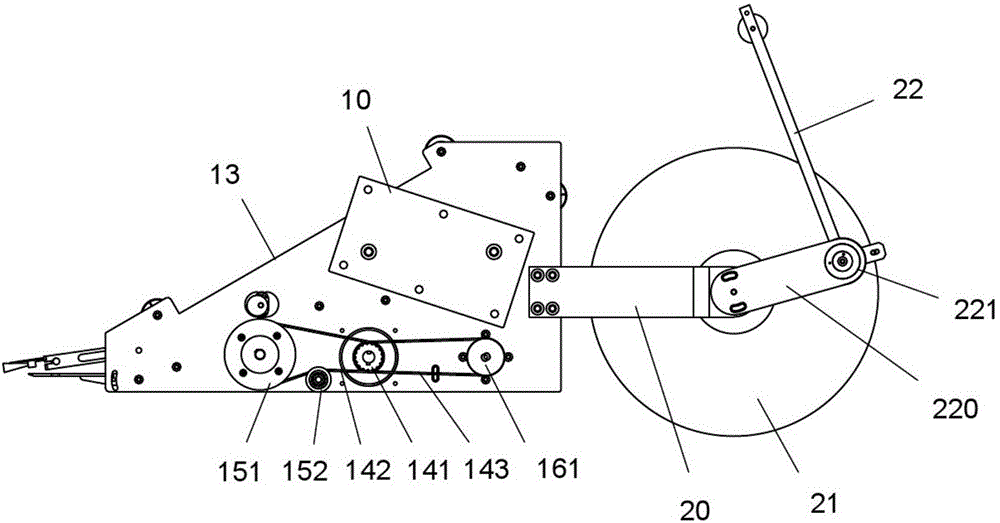

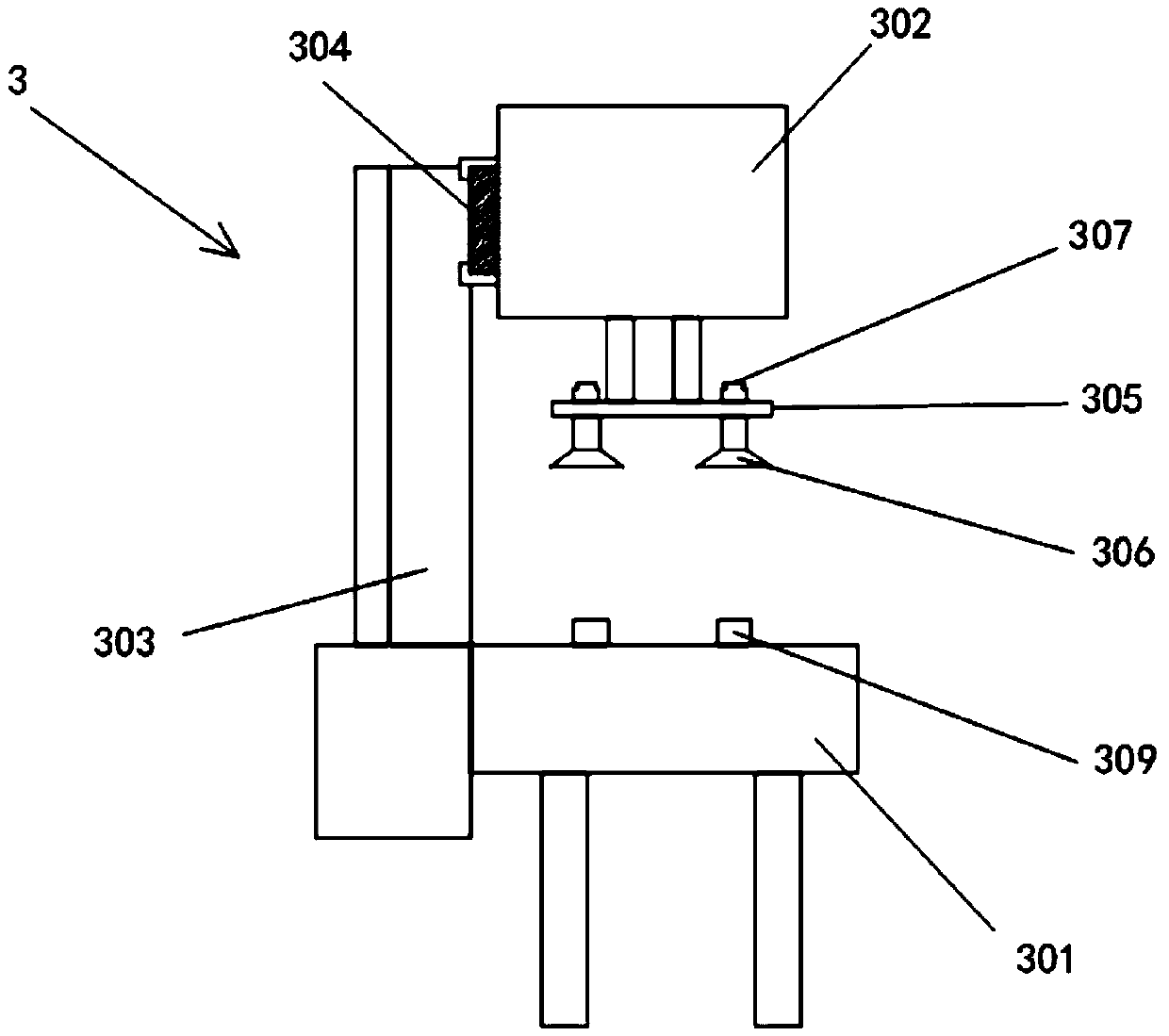

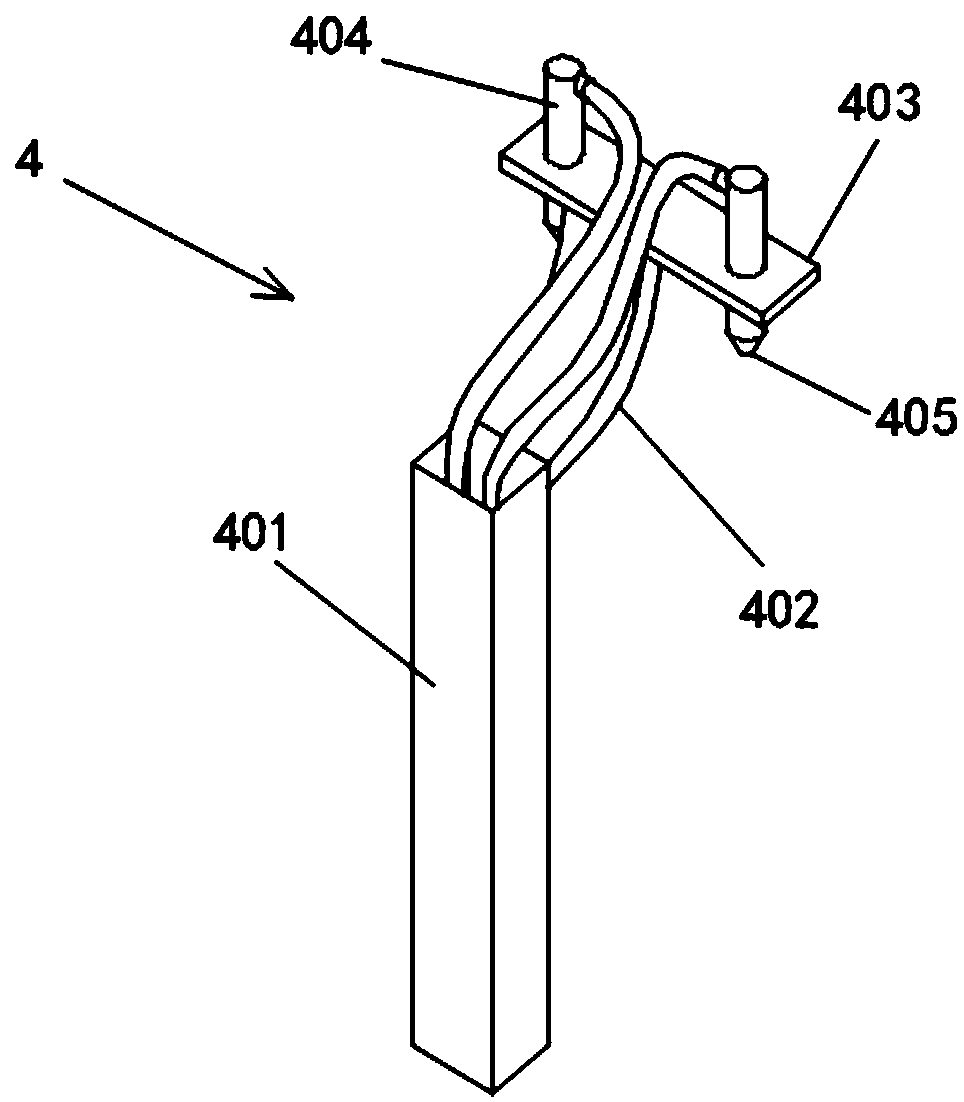

Labeling device used in pharmaceutical manufacturing process

InactiveCN106628473ASimple structureFast labelingLabelling machinesWebs handlingPharmaceutical manufacturingEngineering

The invention discloses a labeling device used in the pharmaceutical manufacturing process. The labeling device comprises a base. Stand columns are fixed to the upper portion of the base. A supporting plate is arranged on the stand columns. The upper ends of the stand columns are connected with a fixed beam. Telescopic cylinders are connected between the fixed beam and the supporting plate. One end of the supporting plate is provided with an unwinding device support. The unwinding device support is rotationally provided with an unwinding device through a rotary shaft. The lower portion of the rotary shaft is also rotatably connected with an extension plate. The end of the extension plate is provided with a pin shaft. A rotary rod is connected to the pin shaft. A torsional spring is arranged between the rotary rod and the pin shaft. A rotary roller is rotatably arranged at the upper end of the rotary rod. A sponge sleeve is arranged outside the rotary roller. The labeling device used in the pharmaceutical manufacturing process is simple in structure and capable of rapidly labeling medicine bottles. The labeling device conducts guiding and driving on labels through multiple vertical roller and driving roller assemblies, drives the labels to go into a label output head to complete labeling, and is high in automation degree and capable of meeting the requirement for the labeling speed.

Owner:HUZHOU NEW AOKE CHEM CO LTD

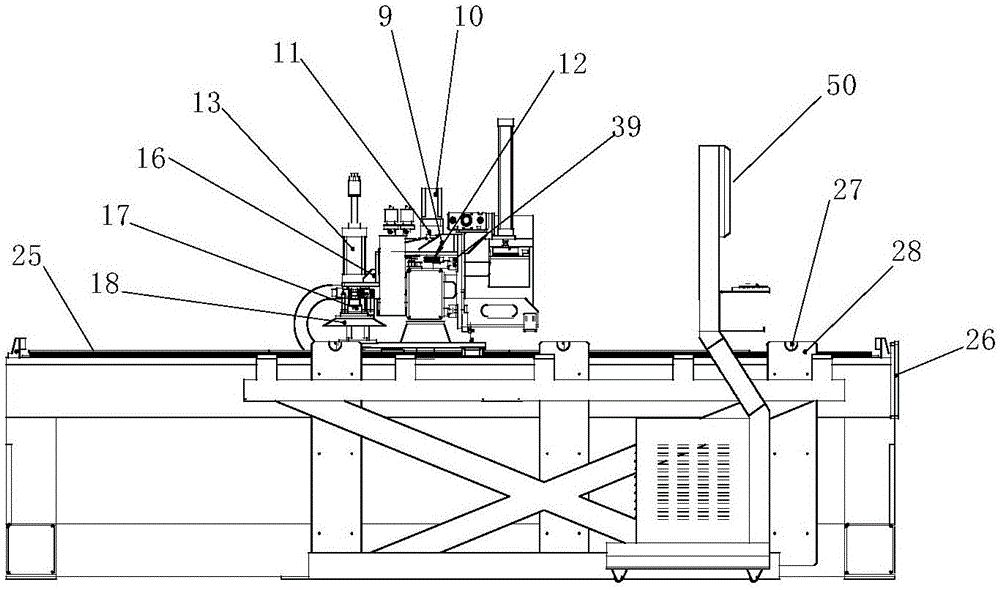

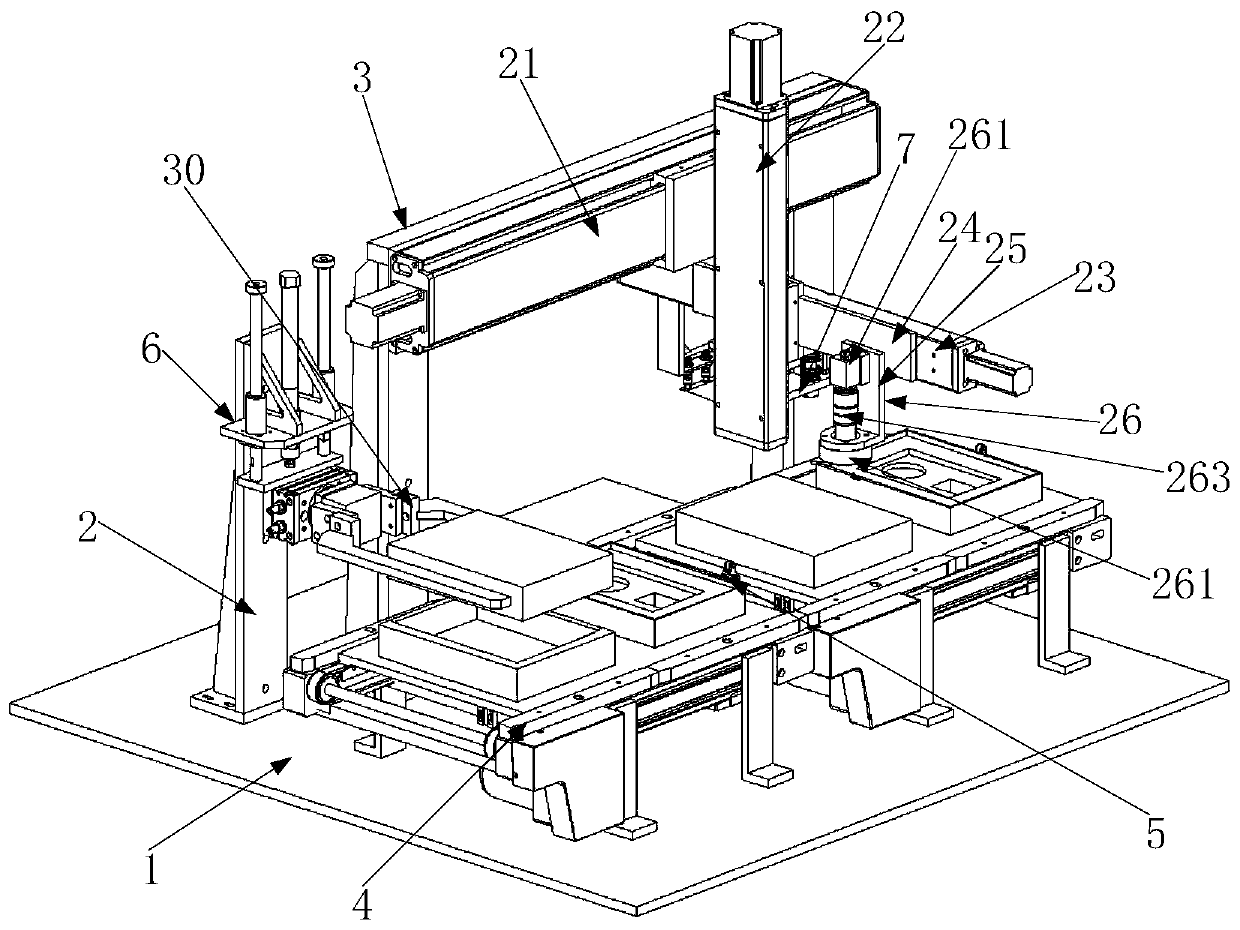

Carpentry labelling machine

The embodiment of the invention discloses a carpentry labelling machine. The carpentry labelling machine comprises a machine tool section, a cross beam section and a machine head section, wherein the cross beam section is in slidable connection with the machine tool section; the machine head section is in slidable connection with the cross beam section; the machine head section comprises a sliding plate, a printer support, a printer, a horizontal cylinder support, a horizontal cylinder, a vertical cylinder support, a vertical cylinder and an attraction block; the sliding plate is in slidable connection with the cross beam section; the printer is fixed on one end of the sliding plate through the printer support; the horizontal cylinder is fixed on the other end of the sliding plate through the horizontal cylinder support; the vertical cylinder is fixedly connected onto an outer side of the horizontal cylinder through the vertical cylinder support; and the attraction block is arranged at one end, close to the machine tool section, of a piston rod of the vertical cylinder. According to the carpentry labelling machine provided by the embodiment of the invention, the cross beam section is in slidable connection with the machine head section; and through the cooperation of the horizontal cylinder and the vertical cylinder, the attraction block does not need to reciprocate on a cross beam for fetching barcode labels, so that labelling speed of the carpentry labelling machine is improved.

Owner:济南品脉数控设备有限公司

Automatic bottle labeling machine

The invention discloses an automatic bottle labeling machine. The automatic bottle labeling machine comprises a machine frame, a control device, a labeling device, a transfer device and a power device; the control device is fixedly welded to the machine frame; the labeling device is fixedly welded to the upper portion of the machine frame; the transfer device is welded to the middle of the machineframe; the power device is fixedly welded to the lower portion of the machine frame; the control device comprises a controller supporting pillar, a controller and a touch screen; the controller supporting pillar is fixedly welded to the machine frame; the controller is connected with the machine frame through a wire in a penetrating mode and fixedly connected to the upper portion of the controller supporting pillar; and the touch screen is fixedly arranged on the controller. The automatic bottle labeling machine is provided with the controller and further provided with the touch screen so that operation is easy, and the labeling speed and precision are high.

Owner:陈超

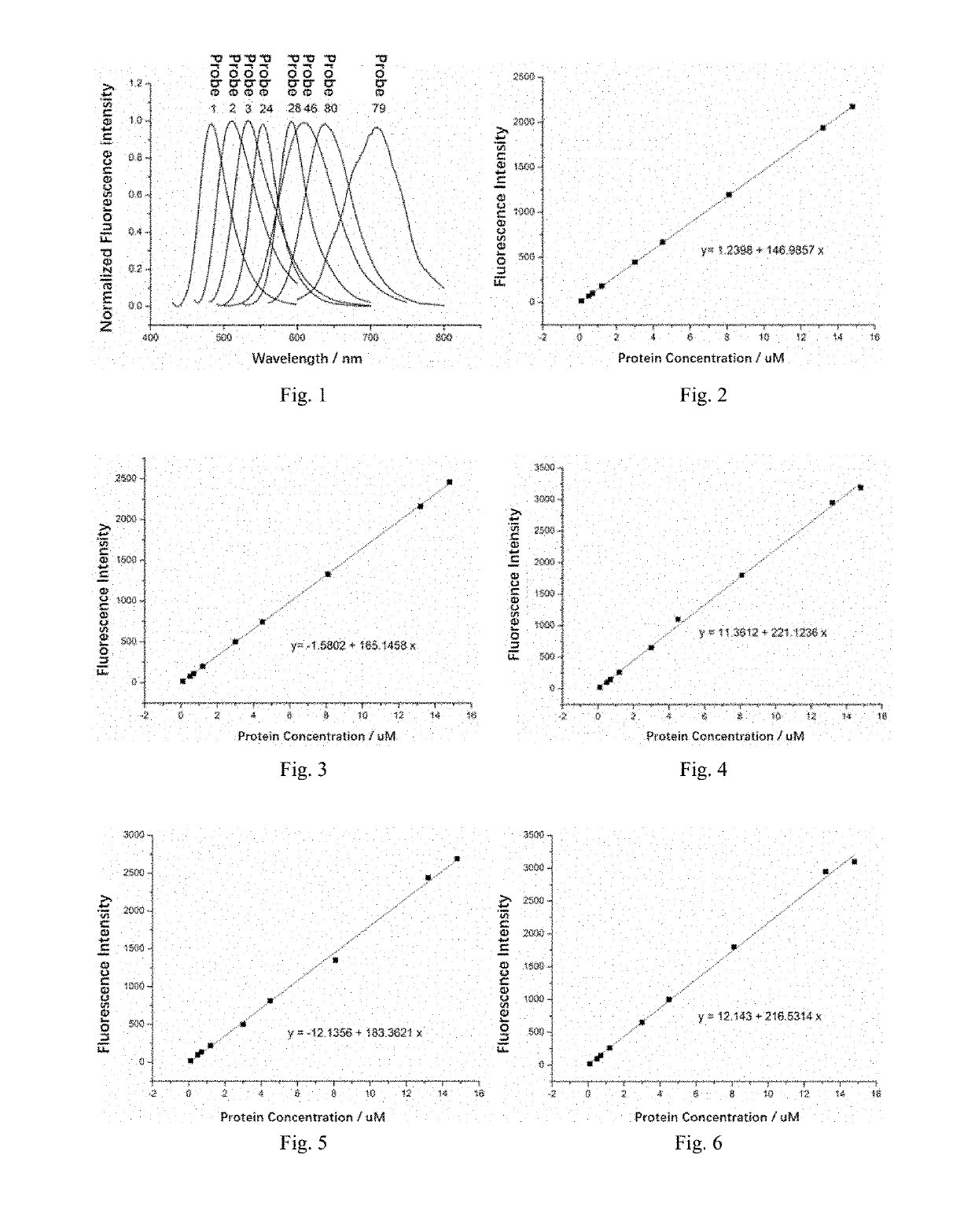

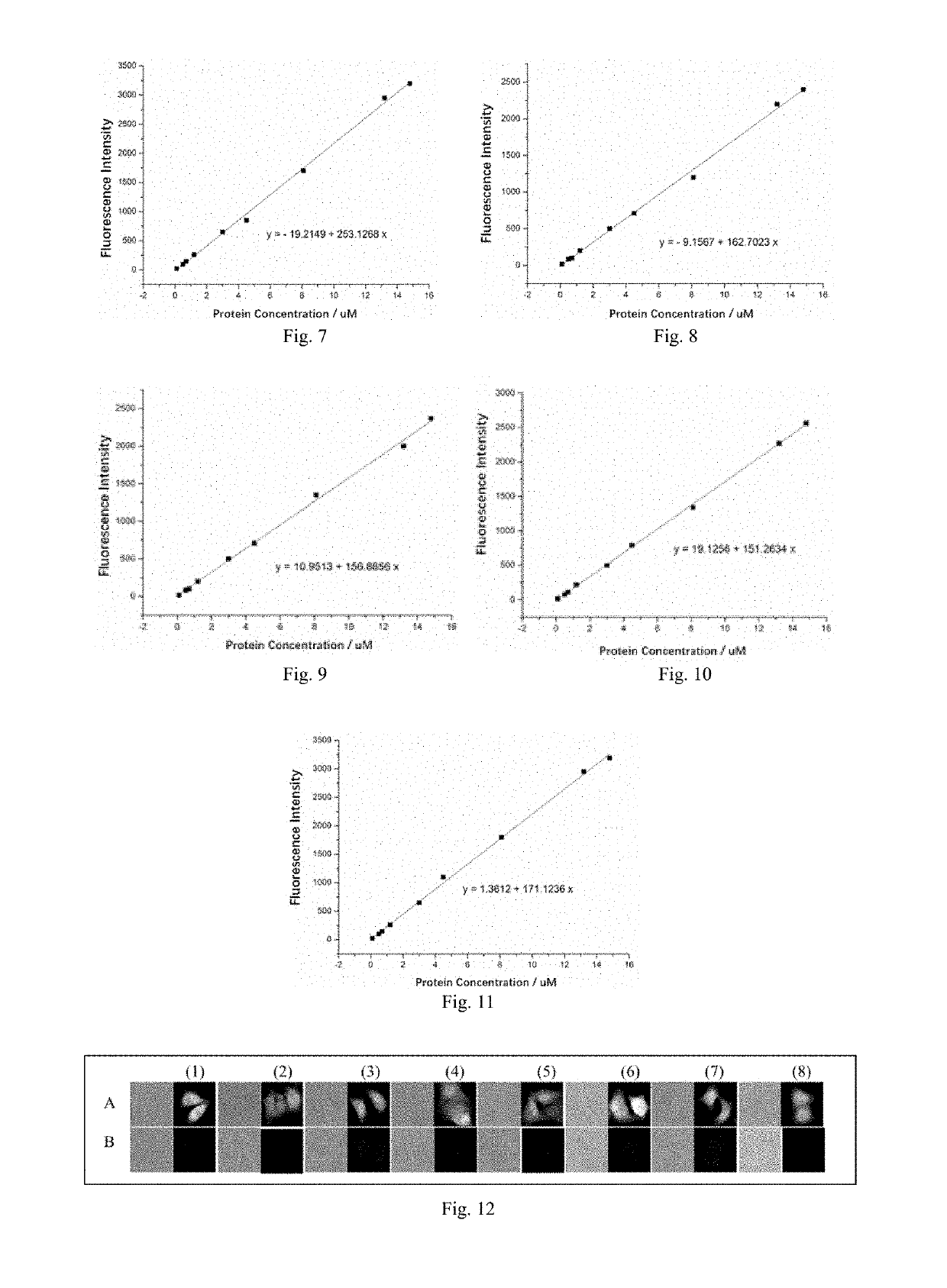

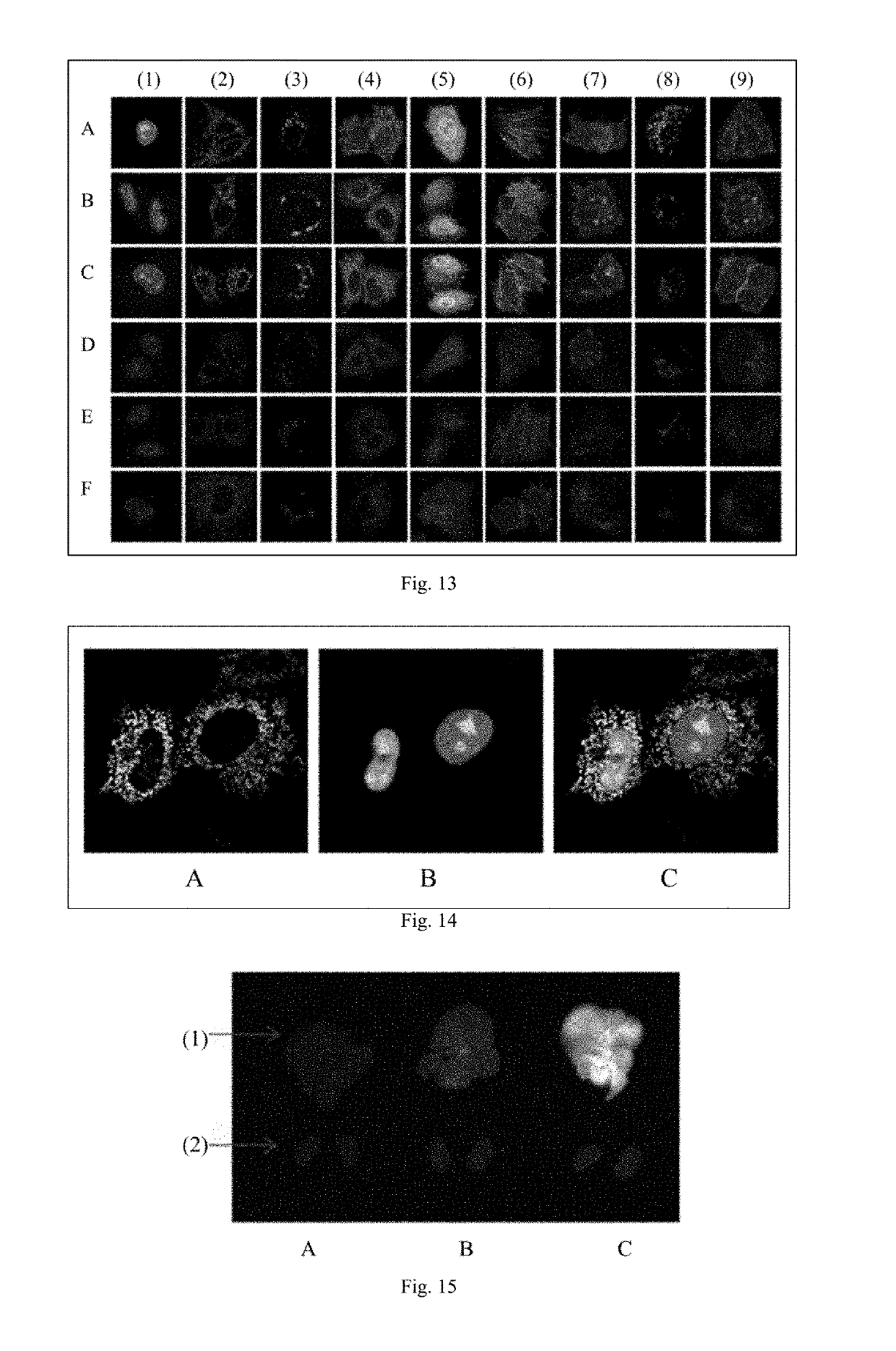

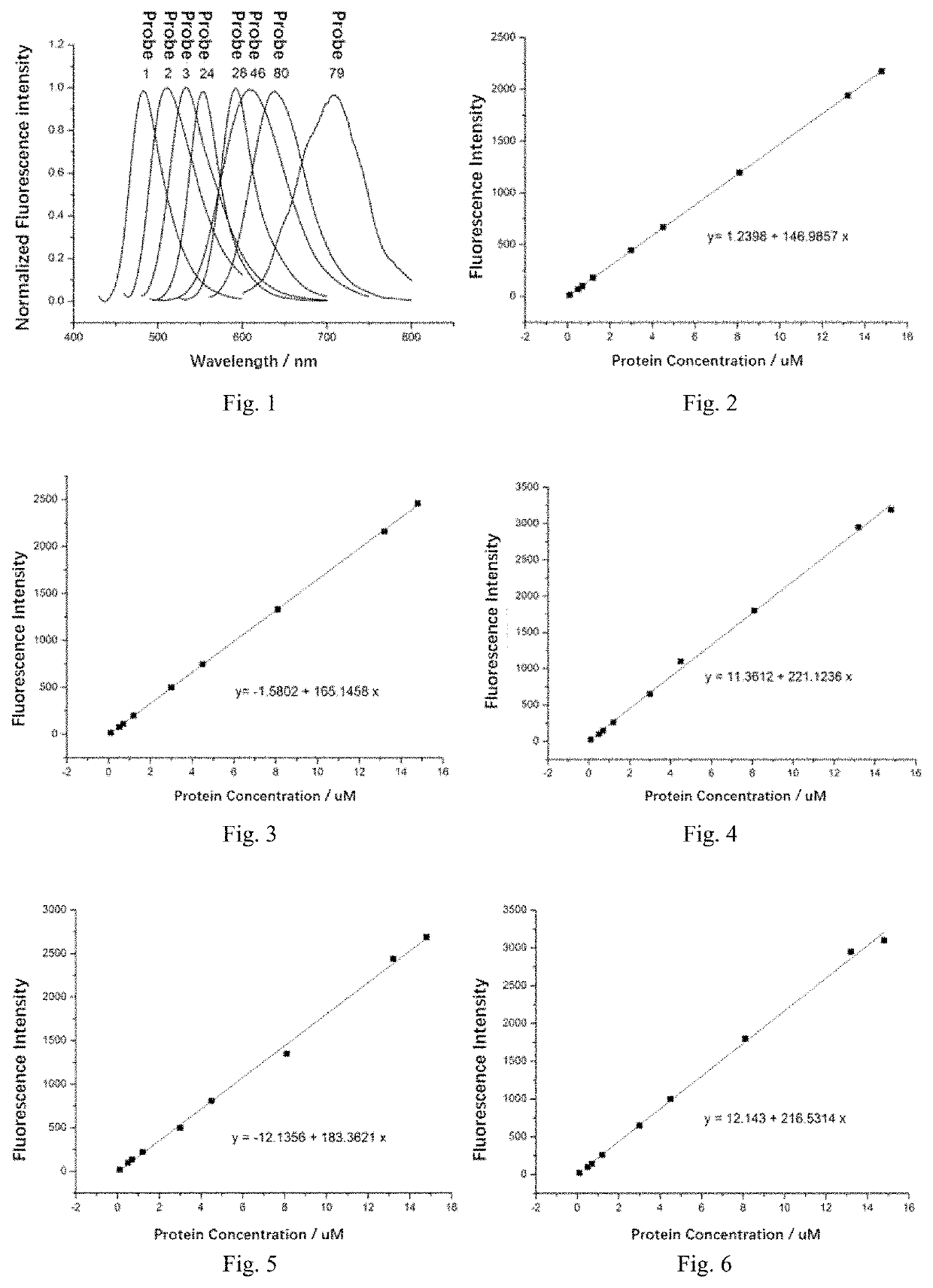

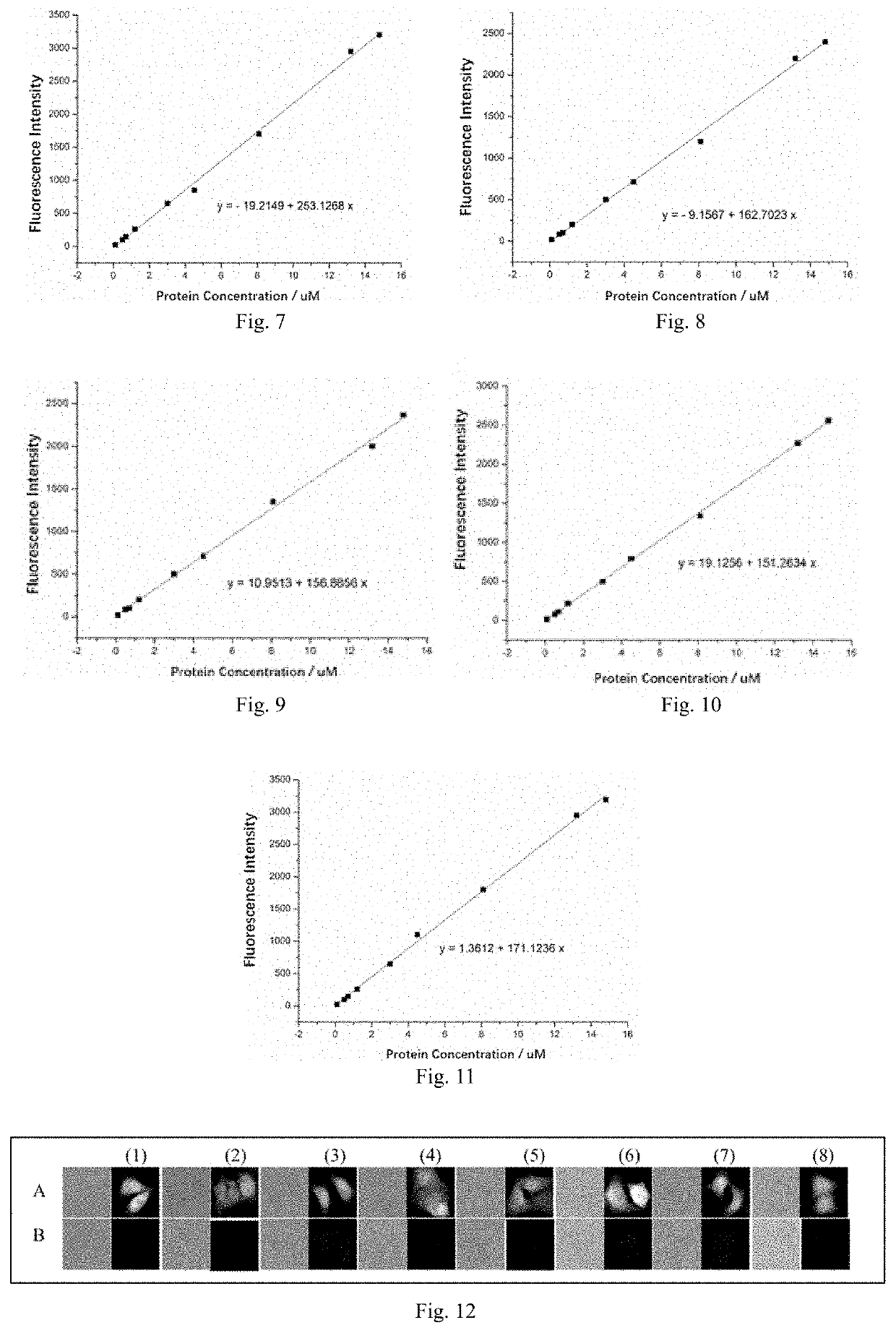

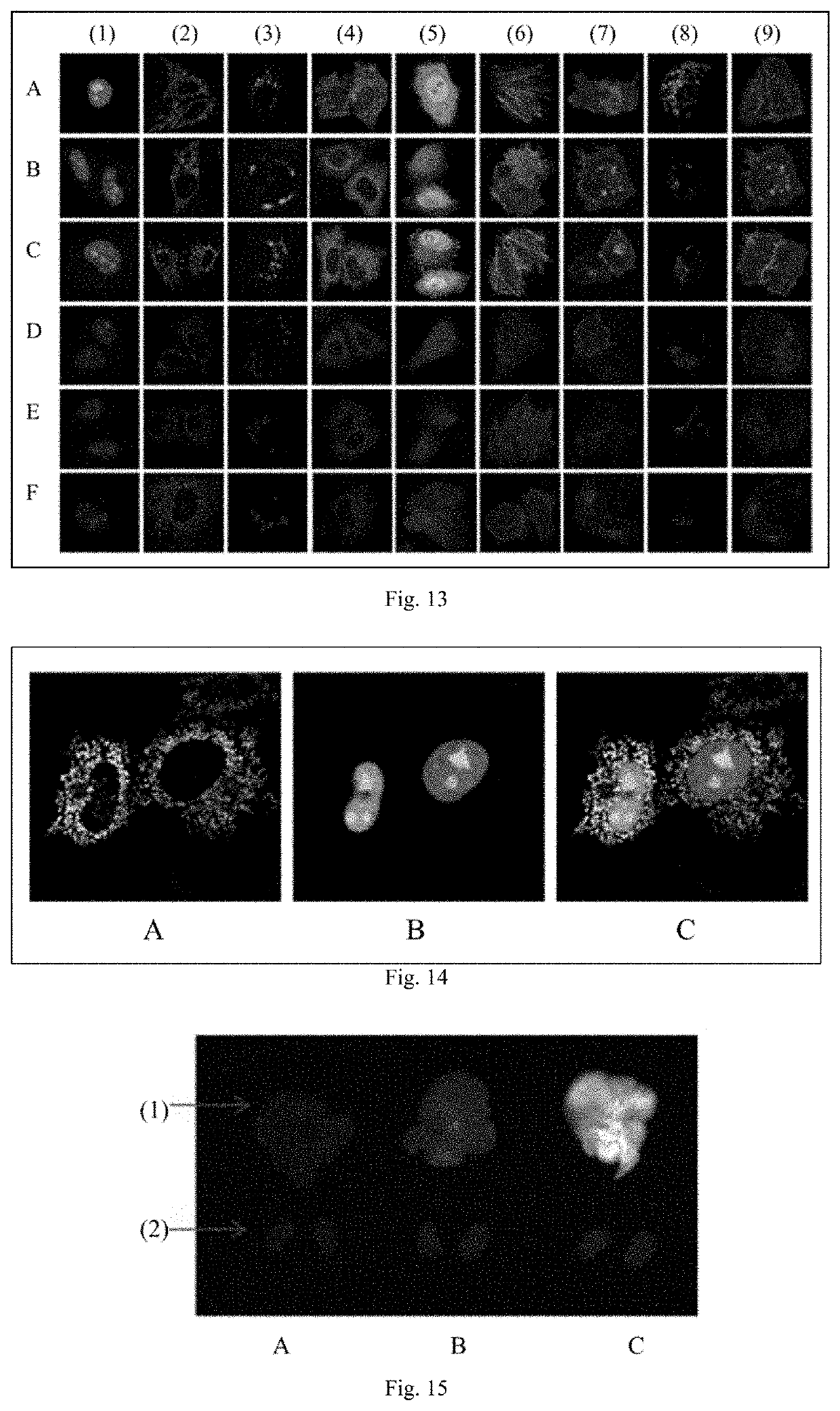

Fluorescent probe and preparation method and use thereof

ActiveUS20190187144A1Rapid contrast imagingRapid Quantitative DetectionSilicon organic compoundsBiological testingFluoProbesCell organisation

Provided are a fluorescent probe and a preparation process and the use thereof. The fluorescent probe is sensitive and specific to viscosity, and can be used for specific fluorescent labeling of proteins, and can also be used for quantification, detection or kinetic studies of proteins, and the imaging of cells, tissues and living bodies.

Owner:FLUORESCENT DIAGNOSIS (SHANGHAI) BIOTECH CO LTD

Infusion bag labeling machine and labeling method

The invention discloses an infusion bag labeling machine and a labeling method. The infusion bag labeling machine comprises a conveyor belt for conveying infusion bags and a labeling device arranged at the upper part of the conveyor belt; the labeling device comprises a label belt conveying mechanism for conveying label belts, a glue applying mechanism, an ink applying mechanism and a labeling mechanism; the label belts conveyed on the label belt conveying mechanism are applied with glue and ink simultaneously through the glue applying mechanism and the ink applying mechanism; the labeling mechanism pushes labels on the label belts to the infusion bags and sticks the labels on the infusion bags through pressing; and the infusion bag labeling machine and labeling method have the advantagesof being simple in device structure, low in failure rate, high in labeling efficiency, few in labeling operations, and simple in operation.

Owner:合肥中科创奥数字科技有限公司

Multi-label labeling method and system for policy text based on graph neural network

ActiveCN112906382BReduce labor costsErrors and omissionsNatural language data processingNeural learning methodsEngineeringGraph neural networks

The invention discloses a policy text multi-label tagging method and system based on a graph neural network, comprising: obtaining policy text to be tagged; preprocessing the policy text to be tagged, and performing word segmentation on the preprocessed policy text; The word and the pre-obtained weighted word vector are input into the trained fully connected neural network, and the multi-label of the policy text to be labeled is output. Efficient labeling process, using cheap computing resources, reduces a lot of labor costs. Compared with manual work, more accurate labeling is achieved, and labeling errors and omissions will not occur due to the length of document information. Timely multi-label labeling of policy documents, fast labeling of required policy documents. The subjective difference is reduced, and a large number of labeling differences will not be caused due to different subjective judgments of different workers.

Owner:SHANDONG COMP SCI CENTNAT SUPERCOMP CENT IN JINAN +1

Labeling machine and labeling method for infusion bag

Owner:合肥中科创奥数字科技有限公司

Labelling device

PendingCN110817025AHigh labeling accuracyFast labelingLabelling machinesLabelling machineEngineering

The invention belongs to the technical field of labelling, and provides a labelling device. The labelling device comprises a platform, and a first support, a second support and a conveying mechanism are arranged on the platform. The first support and the second support are both located on one side of the conveying mechanism. The first support is located on one side of the inlet end of the conveying mechanism, and blocking mechanisms are arranged in the middle of the conveying mechanism and at the outlet end of the conveying mechanism. A turnover mechanism is arranged on the first support, anda sliding module is arranged on the second support. A labelling mechanism is arranged on the sliding module, and comprises an adjusting mechanism arranged on the sliding module, a first label suctionmechanism arranged at one end of the adjusting mechanism, a second label suction mechanism arranged at the other end of the adjusting mechanism, and a label pressing mechanism arranged on the adjusting mechanism and located between the first label suction mechanism and the second label suction mechanism. The labelling device has the following advantages that the labelling precision is high, labelling can be fast carried out, the labor cost is reduced, the work efficiency is improved, and the product attractiveness is not influenced by the labelling effect.

Owner:SHENZHEN LIANSHUO AUTOMATION TECH

Barrel labeling machine

PendingCN110963139AFast labelingImprove labeling qualityLabelling short rigid containersLabelling machinesEngineeringStructural engineering

The invention discloses a barrel labeling machine. The barrel labeling machine comprises a labeling machine frame, a bottle body conveying chain is arranged on the labeling machine frame, the bottle body conveying chain is provided with a bottle inlet and outlet stirring wheel, a labeling station is arranged on the labeling machine frame, the labeling station is provided with a labeling arm, a bottle protecting plate is arranged on the labeling machine frame, the bottle protecting plate is arc-shaped, the bottle protecting plate is provided with a notch into which the labeling arm extends, thelabeling machine frame is connected to a barrel body driving rod which drives the barrel body to lift and drop and can drive the barrel body to rotate, a jacking head is arranged at the top of the barrel body driving rod, the barrel body lifting rod is driven to lift by a barrel body lifting power mechanism and is driven to rotate by a rotating power mechanism, a barrel body pressing rod capableof moving up and down and rotating is installed on the labeling machine frame, a barrel body pressing head right opposite to the jacking head is arranged at the bottom of the barrel body pressing rod,and a top jacking spring is arranged between the barrel body pressing rod and the labeling machine frame and can jack the barrel body pressing rod downwards. The barrel labeling machine can quickly perform automatic labeling on the barrel body, and has the advantages of being quick in labeling, high in labeling quality and high in labor efficiency.

Owner:潍坊现代科技发展有限公司

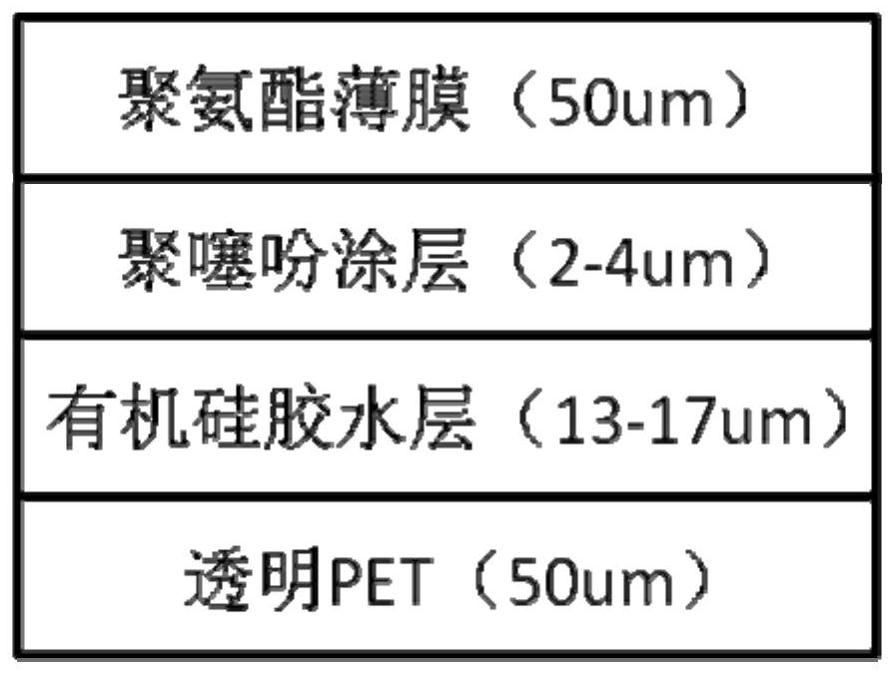

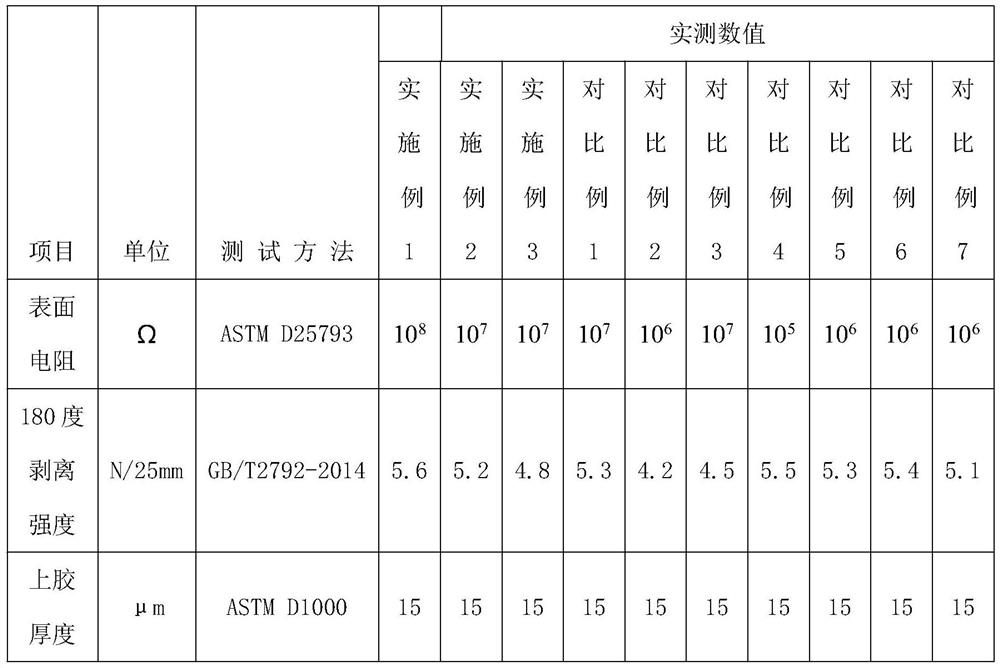

A kind of antistatic silica gel protective film and preparation method thereof

ActiveCN109016769BImprove securityFast labelingSynthetic resin layered productsCoatingsPolymer scienceCross linker

The invention provides an antistatic silica gel protective film. A base layer is a polyurethane film. The base layer is coated with a bottom polythiophene coating layer. The bottom layer is coated with an organic silica gel aqueous layer. Transparent PET is pasted to the organic silica gel aqueous layer. The organic silica gel aqueous layer comprises a low viscosity silicone resin, a high viscosity silicone resin, carbon nanotubes, anhydrous toluene, anhydrous ethyl ester, a crosslinking agent, a coupling agent and platinum. The aligned carbon nanotubes are used in the silica gel protective film, have good affinity with the organosilicone pressure sensitive adhesive, do not affect the solidification of the platinum, have good dispersibility and maintain a good antistatic effect. The bottompolythiophene coating can improve the antistatic effect of the glue.

Owner:深圳深汕特别合作区昌茂粘胶新材料有限公司

Fluorescent probe and preparation method and use thereof

ActiveUS11209437B2Sensitive to viscosityFast labelingSilicon organic compoundsBiological testingFluoProbesBiological body

Provided are a fluorescent probe and a preparation process and the use thereof. The fluorescent probe is sensitive and specific to viscosity, and can be used for specific fluorescent labeling of proteins, and can also be used for quantification, detection or kinetic studies of proteins, and the imaging of cells, tissues and living bodies.

Owner:FLUORESCENT DIAGNOSIS (SHANGHAI) BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthesis of [18f]-labelled alkyl mesylates using fluorous spe separation Synthesis of [18f]-labelled alkyl mesylates using fluorous spe separation](https://images-eureka.patsnap.com/patent_img/8b1fe457-f46d-4f6b-b43e-417c57023bae/US20110251432A1-20111013-C00001.png)

![Synthesis of [18f]-labelled alkyl mesylates using fluorous spe separation Synthesis of [18f]-labelled alkyl mesylates using fluorous spe separation](https://images-eureka.patsnap.com/patent_img/8b1fe457-f46d-4f6b-b43e-417c57023bae/US20110251432A1-20111013-C00002.png)

![Synthesis of [18f]-labelled alkyl mesylates using fluorous spe separation Synthesis of [18f]-labelled alkyl mesylates using fluorous spe separation](https://images-eureka.patsnap.com/patent_img/8b1fe457-f46d-4f6b-b43e-417c57023bae/US20110251432A1-20111013-C00003.png)