Automatic labelling machine

A labeling machine and labeling technology, applied in labeling machines, labels, packaging, etc., can solve problems such as circuit board shape is not fixed, labeling head positioning is not accurate, labeling speed is slow, etc., to achieve fast labeling speed, Space-saving and high-precision labeling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

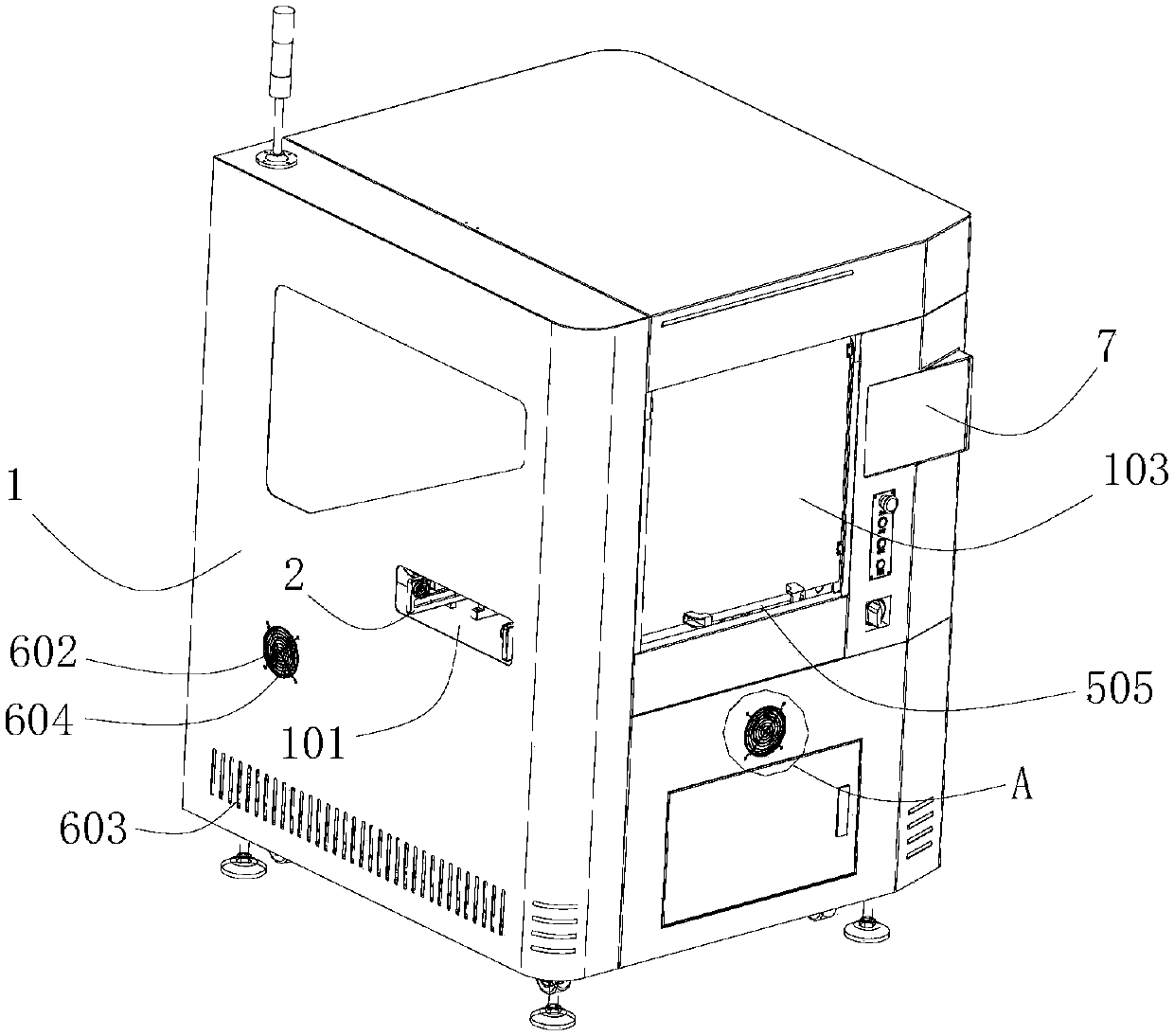

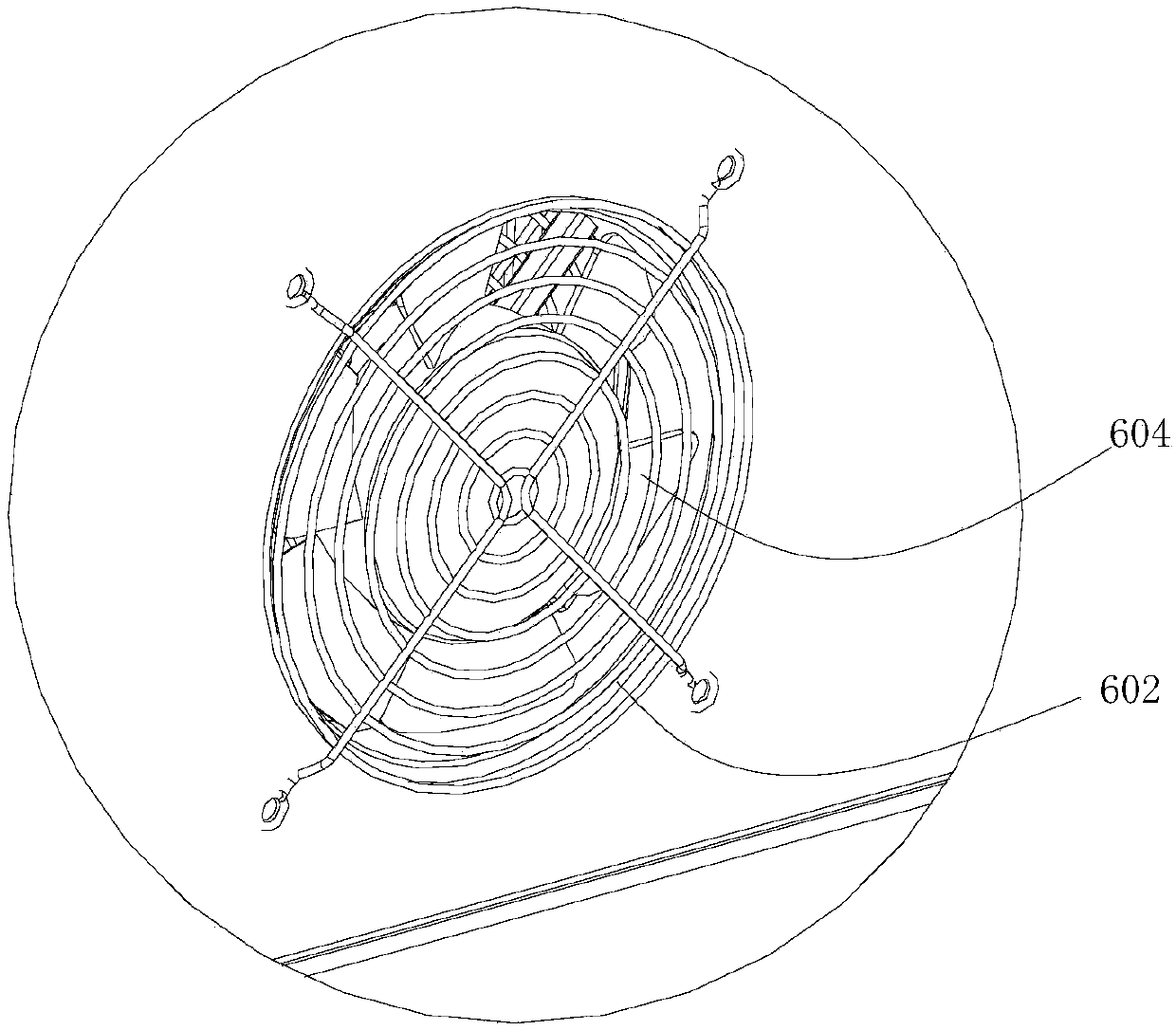

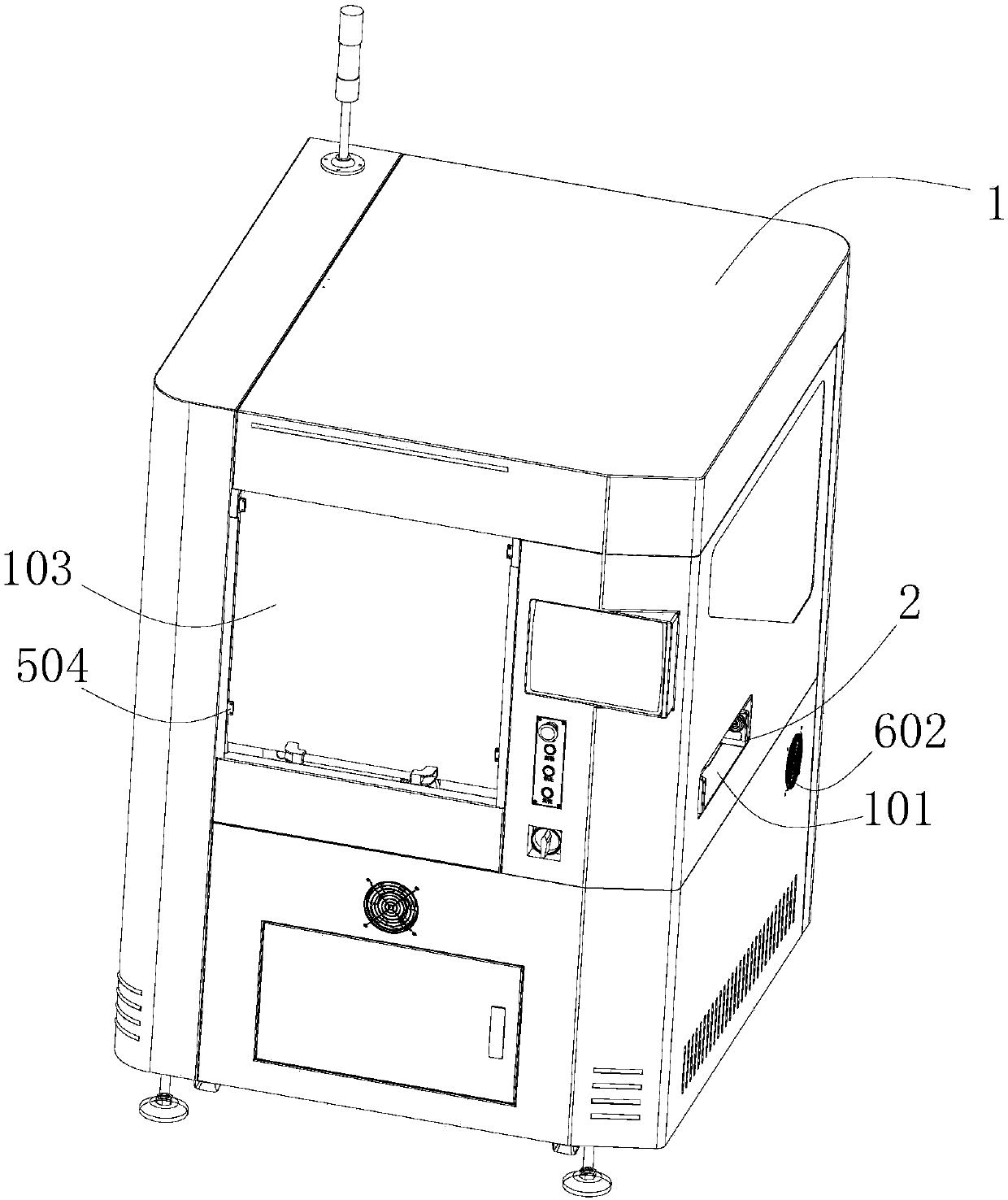

[0037] refer to Figure 1 to Figure 17 , is an automatic labeling machine, which includes a complete labeling machine 1, a group of opposite sides of the complete labeling machine 1 are respectively provided with a circuit board inlet 101 and a circuit board outlet 102, and a circuit board inlet 101 and a circuit board outlet 102 are located on different sides and the two positions are opposite; another group of opposite sides of the labeling machine 1 is respectively provided with observation doors 103; the inside of the labeling machine 1 is provided with a conveying device 2, The label feeding device 3 and the labeling device 4 for conveying the label paper 9; the labeling device 4 takes out the label paper 9 released by the label feeding device 3, and through its own rotation, pastes the label on the label paper 9 on the On the circuit board 8 on the conveying device 2; the labeling machine 1 is externally connected with a control system 7 for setting the labeling position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com