Patents

Literature

65results about How to "High labeling accuracy" patented technology

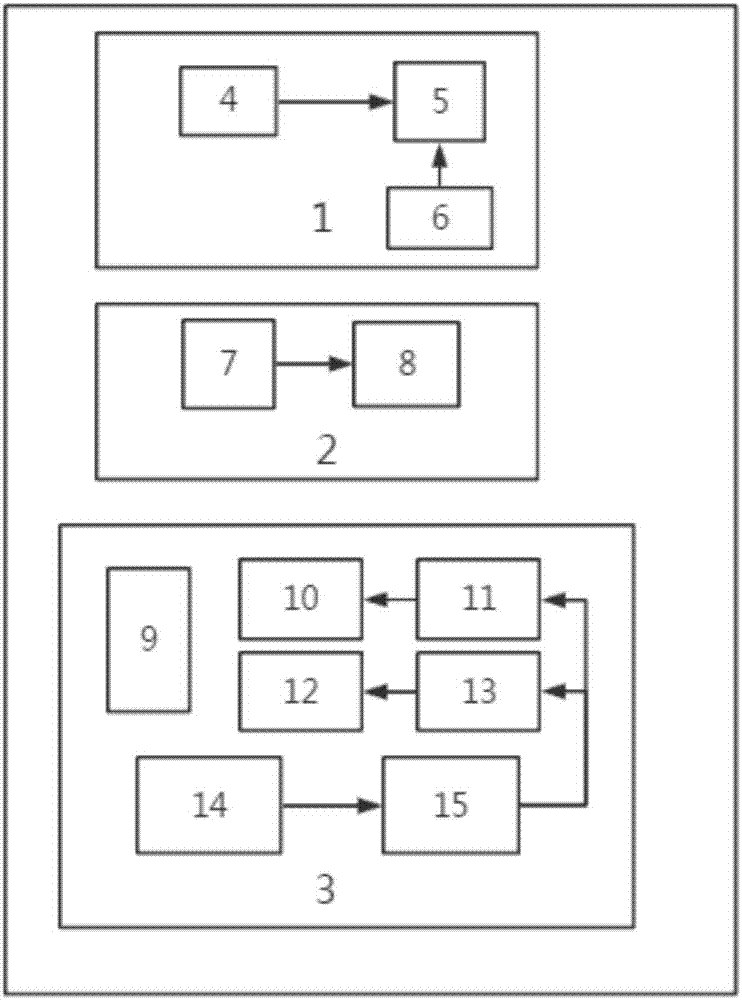

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

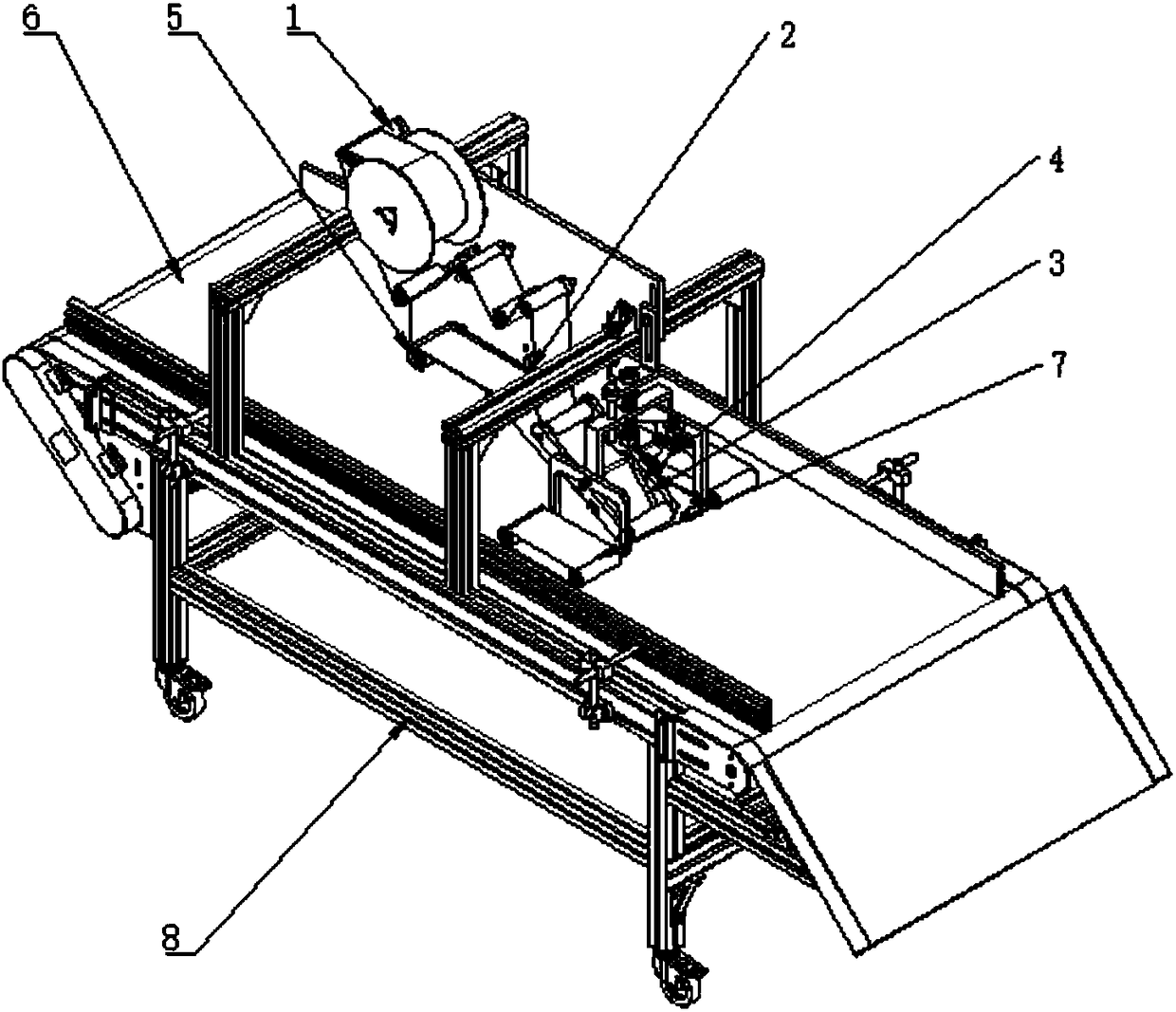

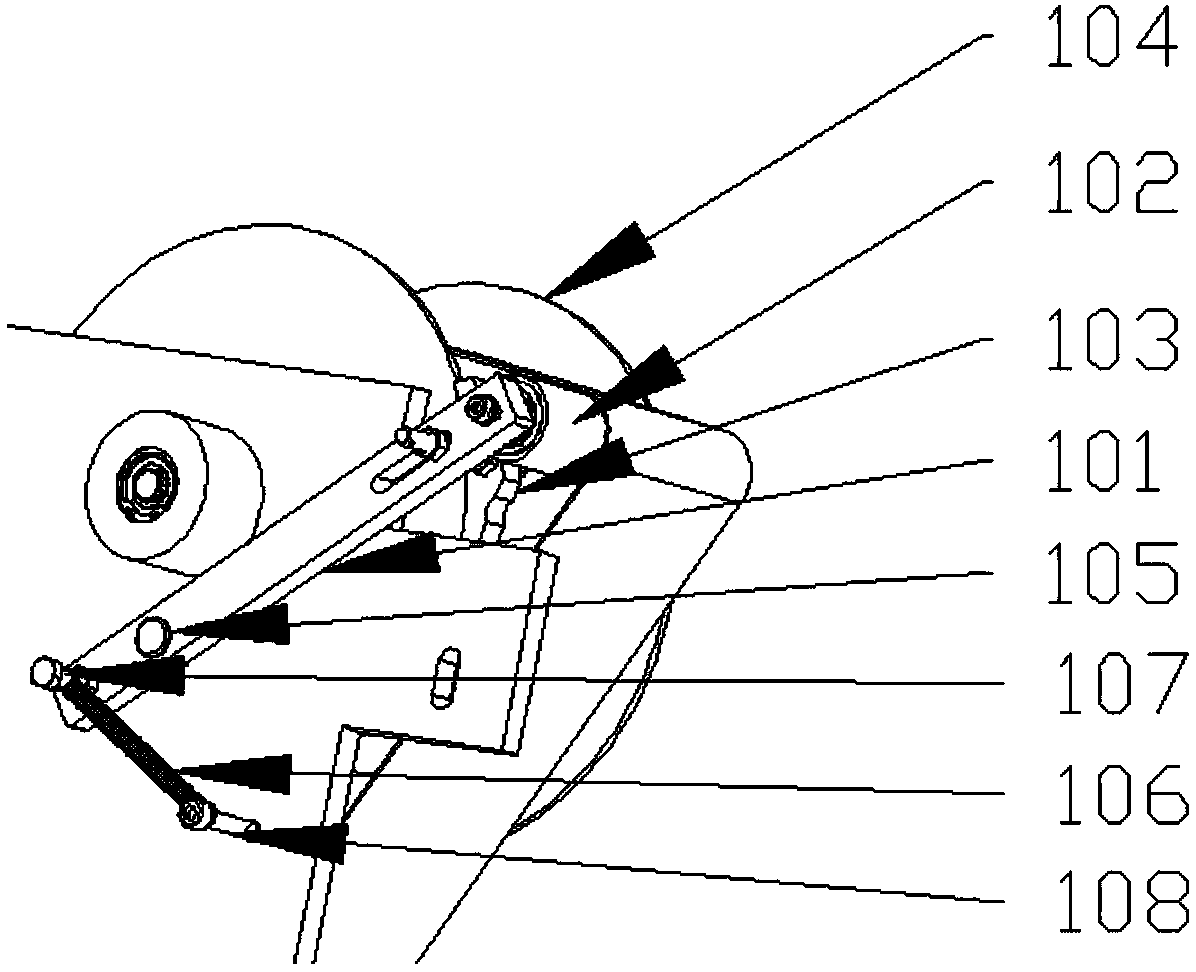

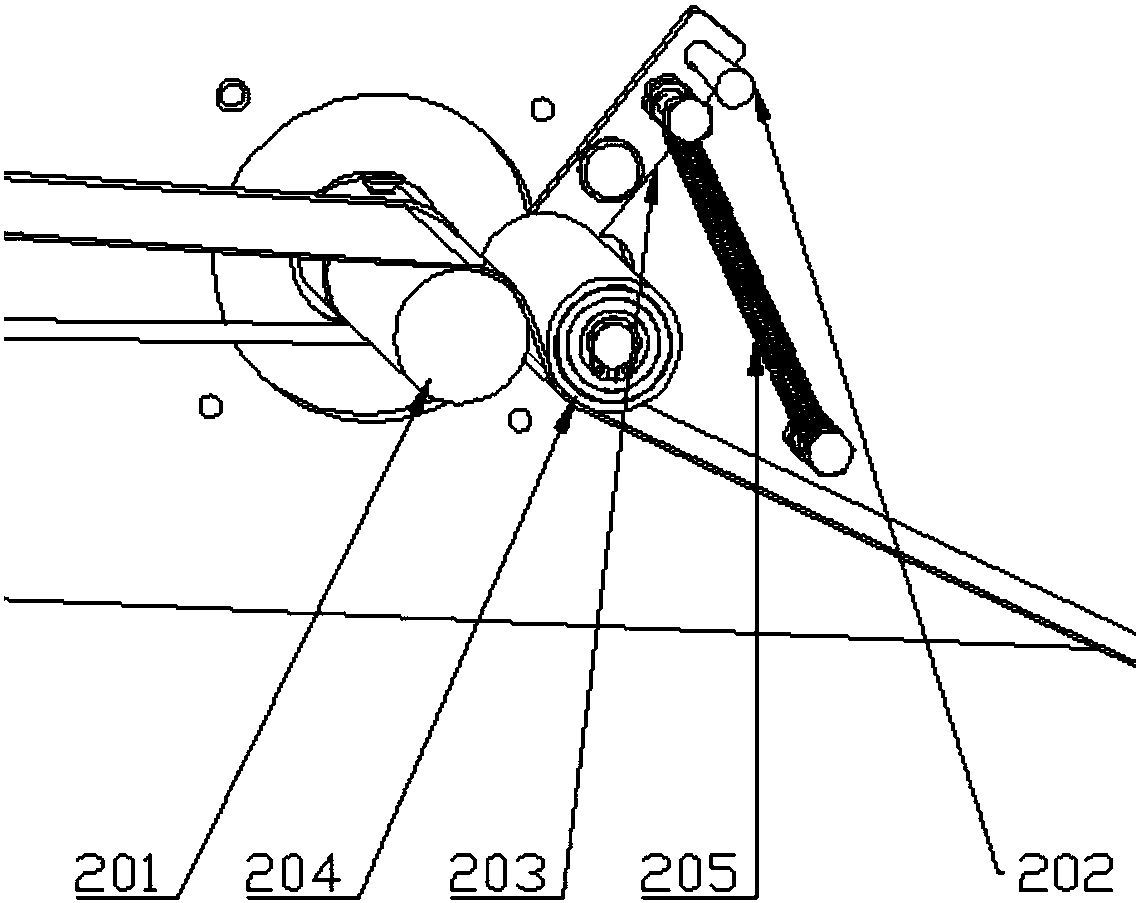

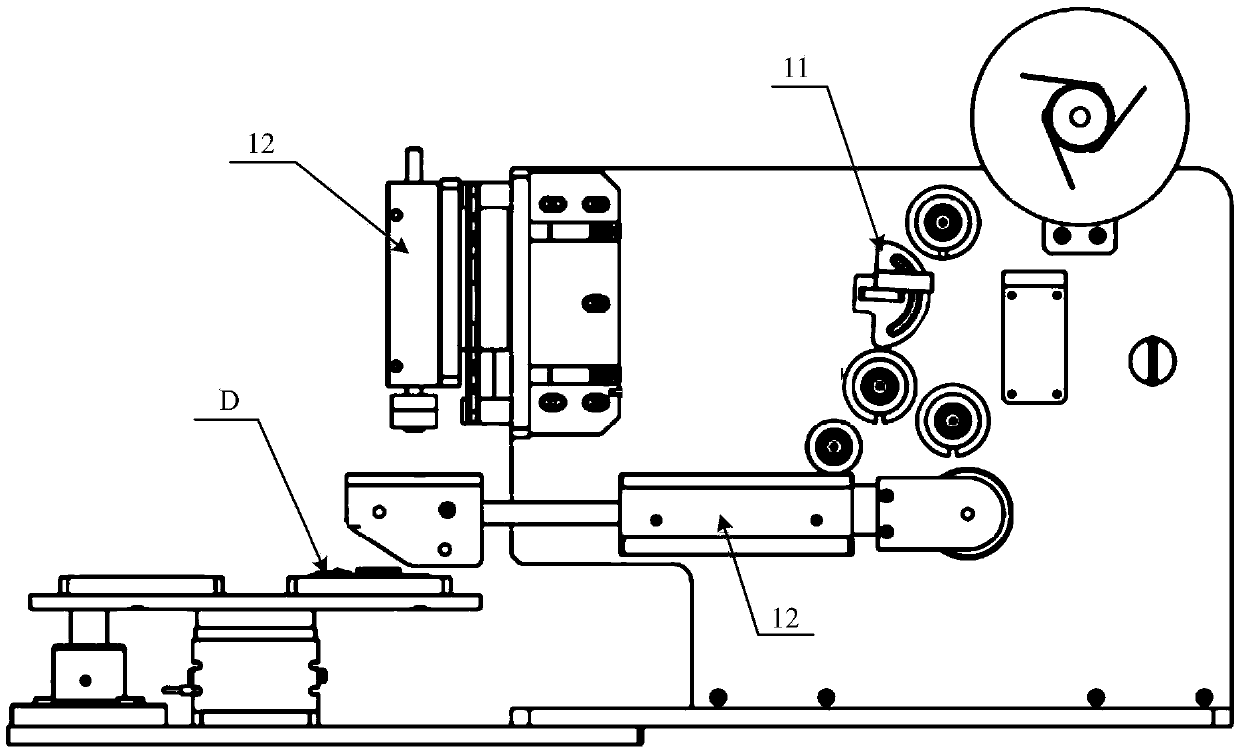

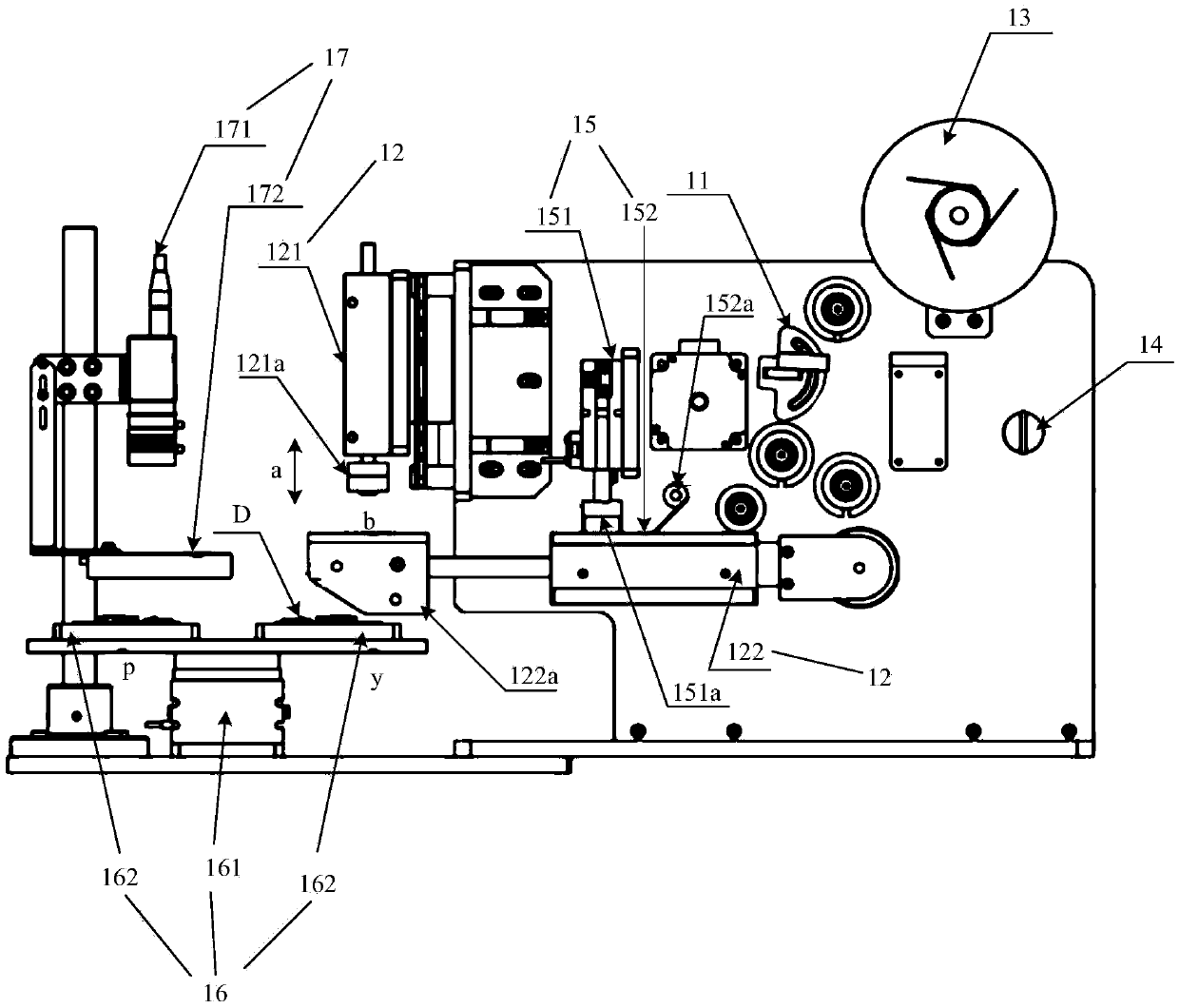

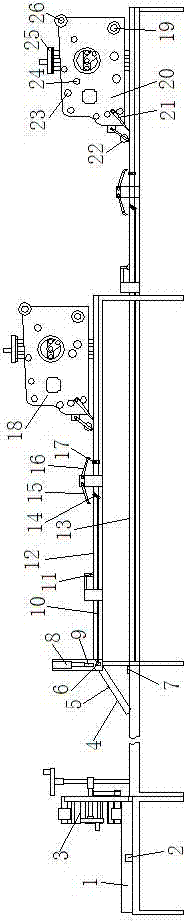

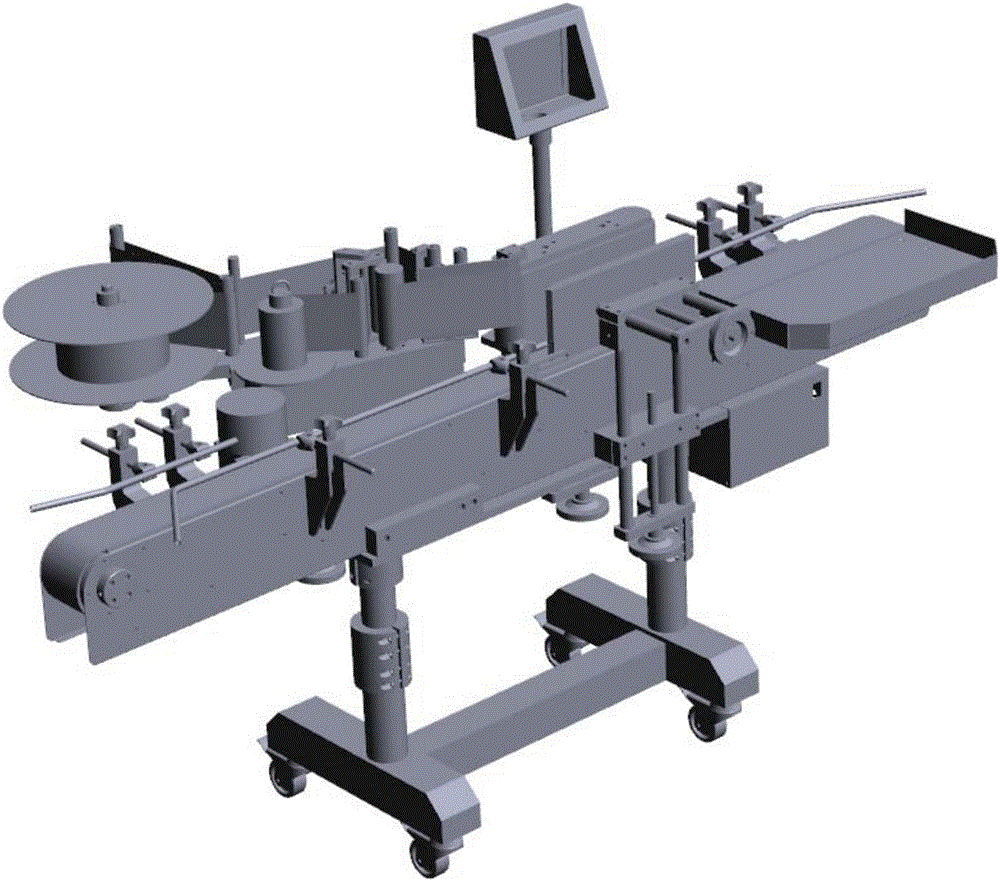

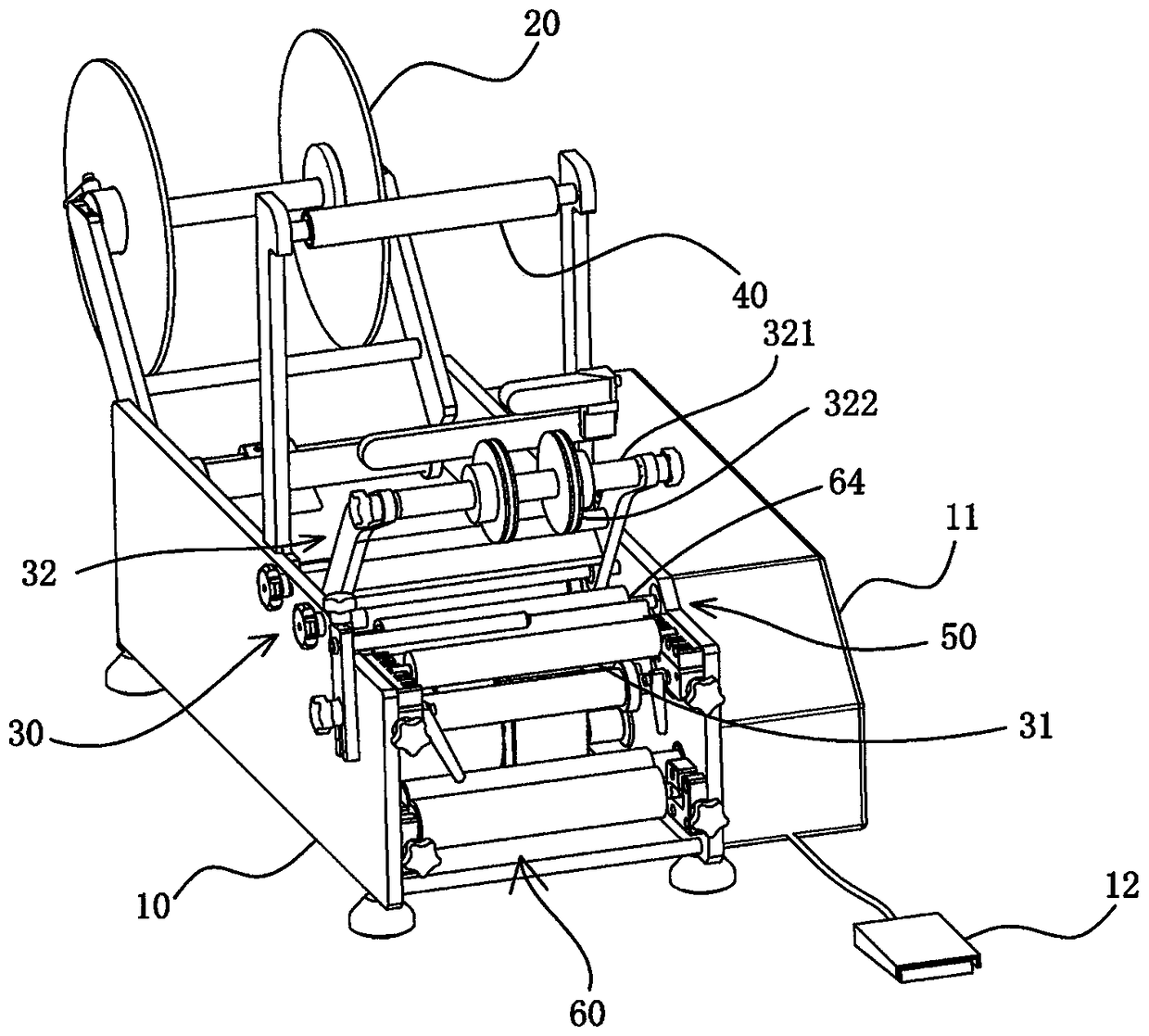

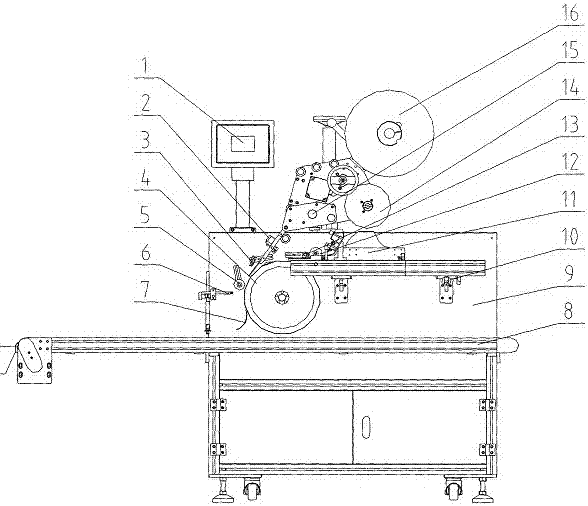

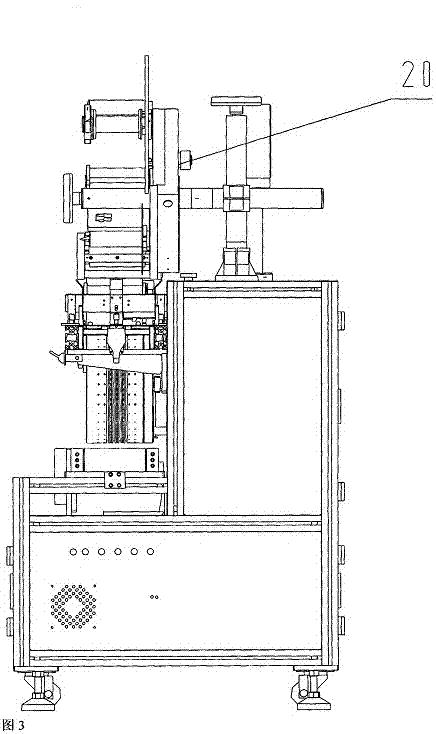

Souvenir bag labeling machine

ActiveCN108190164AAdapt to market demandEasy to installLabelling machinesWebs handlingPaper recyclingEngineering

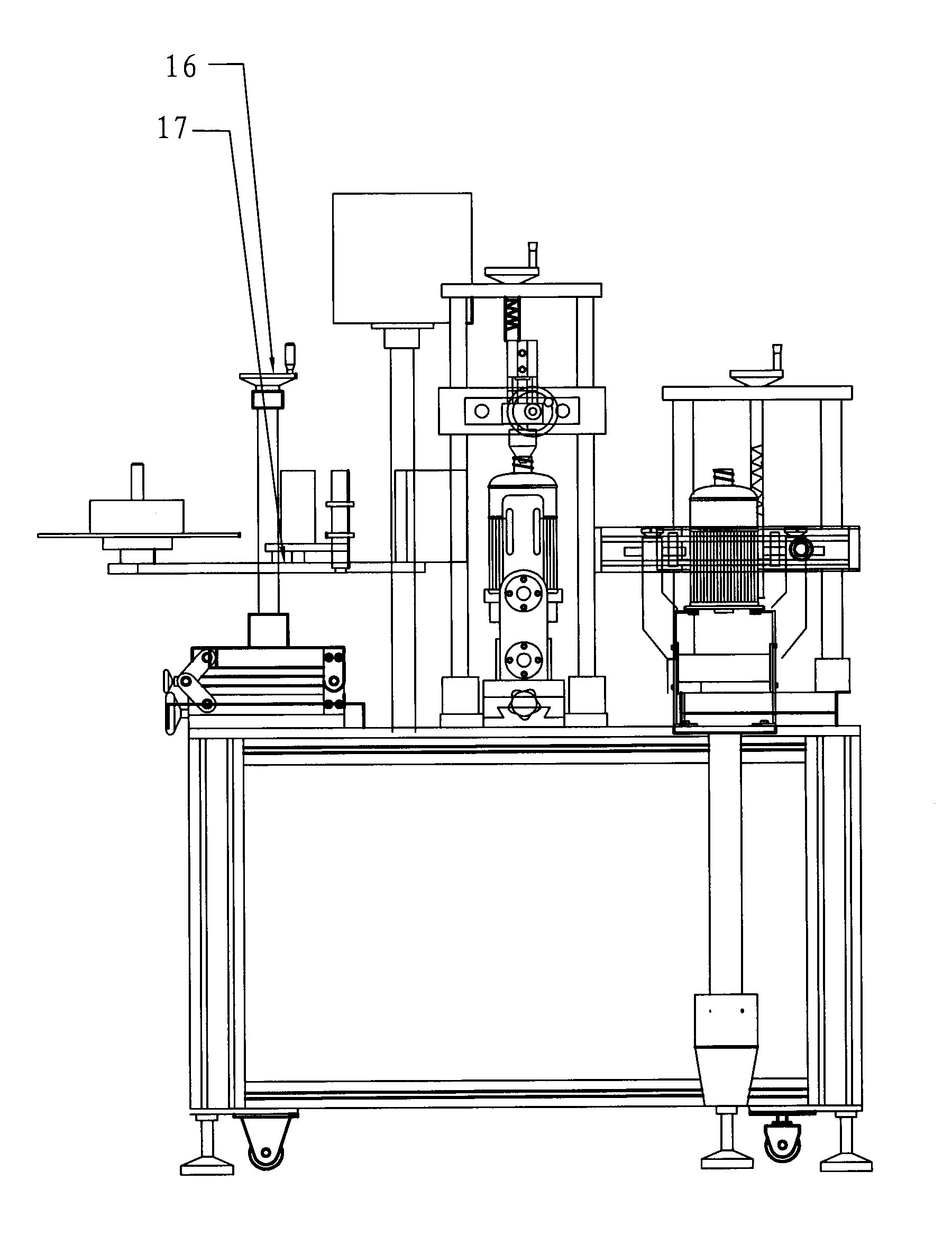

The invention relates to a souvenir bag labeling machine. A souvenir bag conveying device is mounted on a rack and provided with a photoelectric sensor. A braking mechanism is mounted on the souvenirbag conveying device, and a drawing mechanism is mounted blow the front portion of the braking mechanism. A label peeling mechanism and a pneumatic label covering mechanism are mounted below the frontportion of the drawing mechanism, and a label flattening roller is mounted at the front end of the pneumatic label covering mechanism. A souvenir bag compressing device is mounted between the label peeling mechanism and the souvenir bag conveying device, and a wax paper recycling mechanism is mounted below the drawing mechanism. Wax paper separated from a label is recycled and wound around a label rolling device of the wax paper recycling mechanism through a drawing shaft and a pressing roll of the drawing mechanism. According to the souvenir bag labeling machine, the labeling work of souvenir bags can be automatically completed, and a synchronous contact pasting method of a brush-pasting method is adopted for achieving the aim of reliable and efficient labeling; and the whole mechanism is high in movement speed, simple in structure and convenient to operate.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

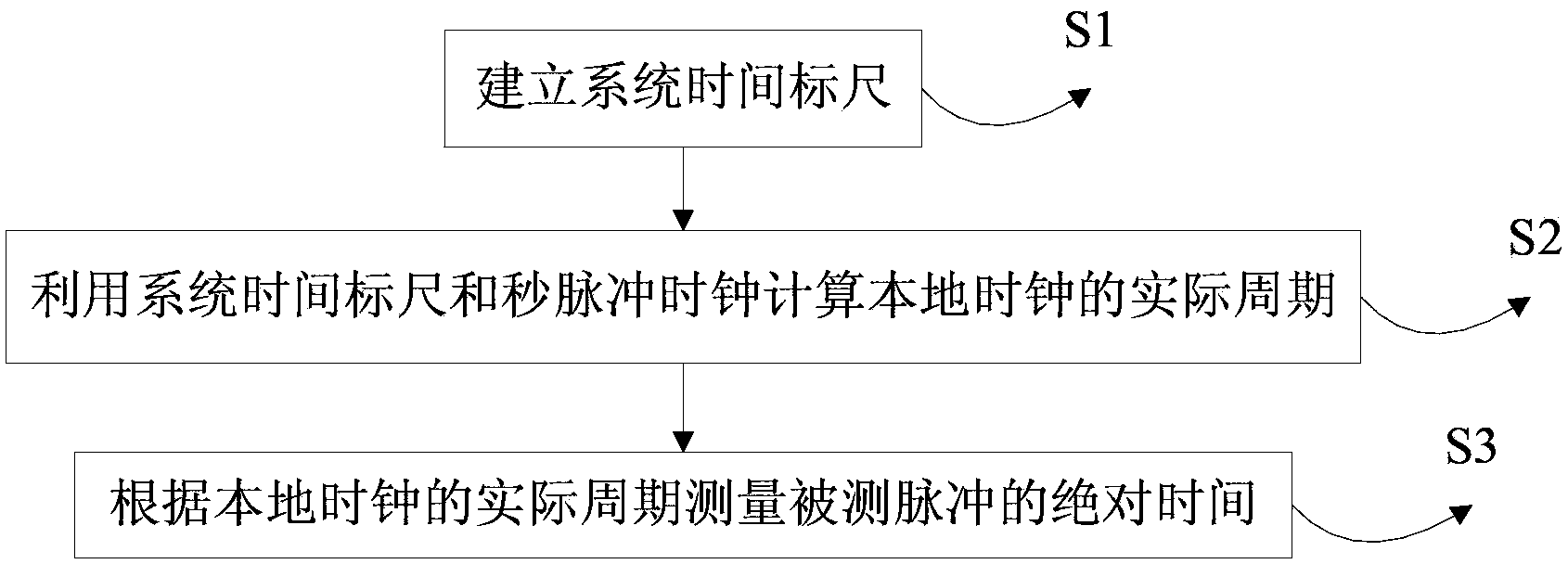

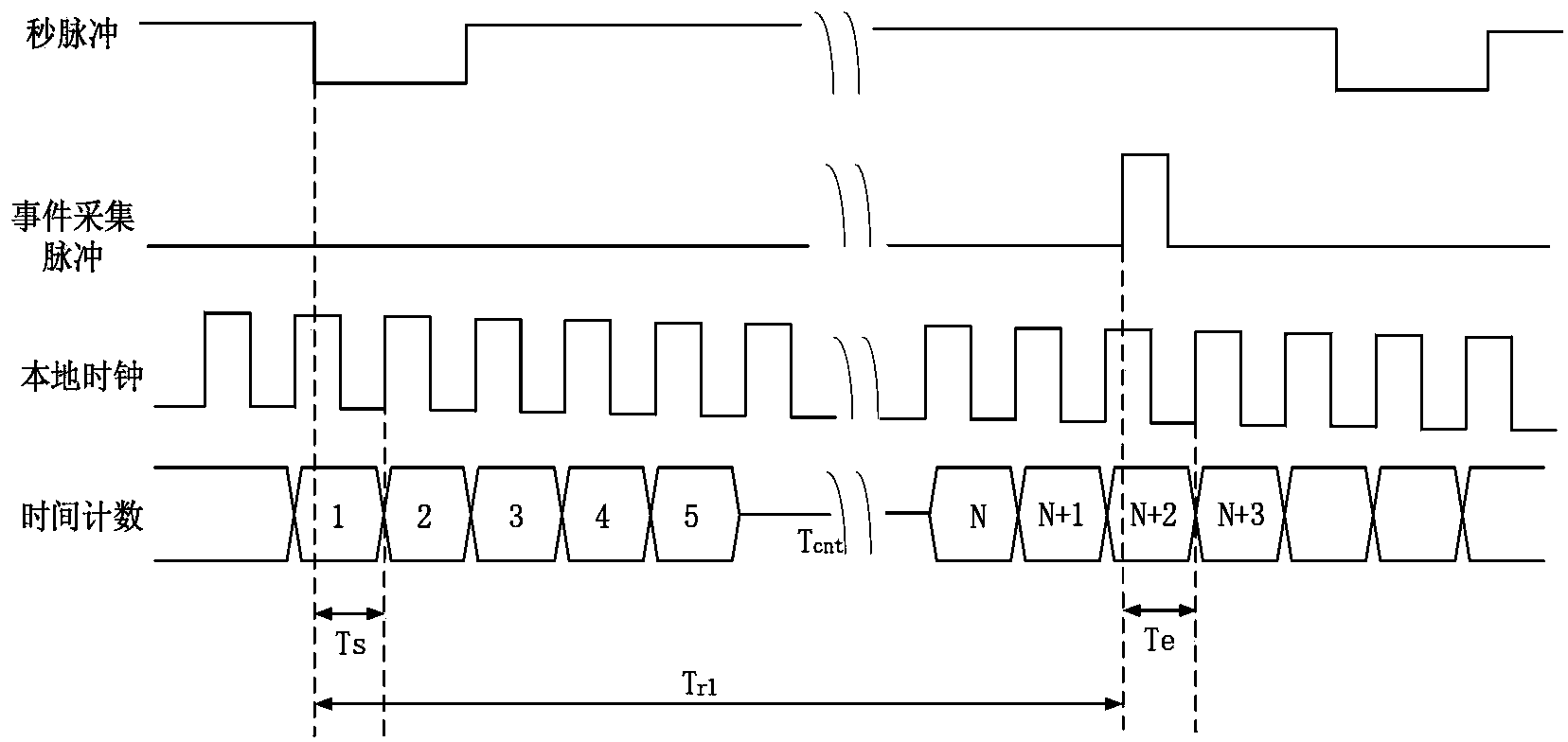

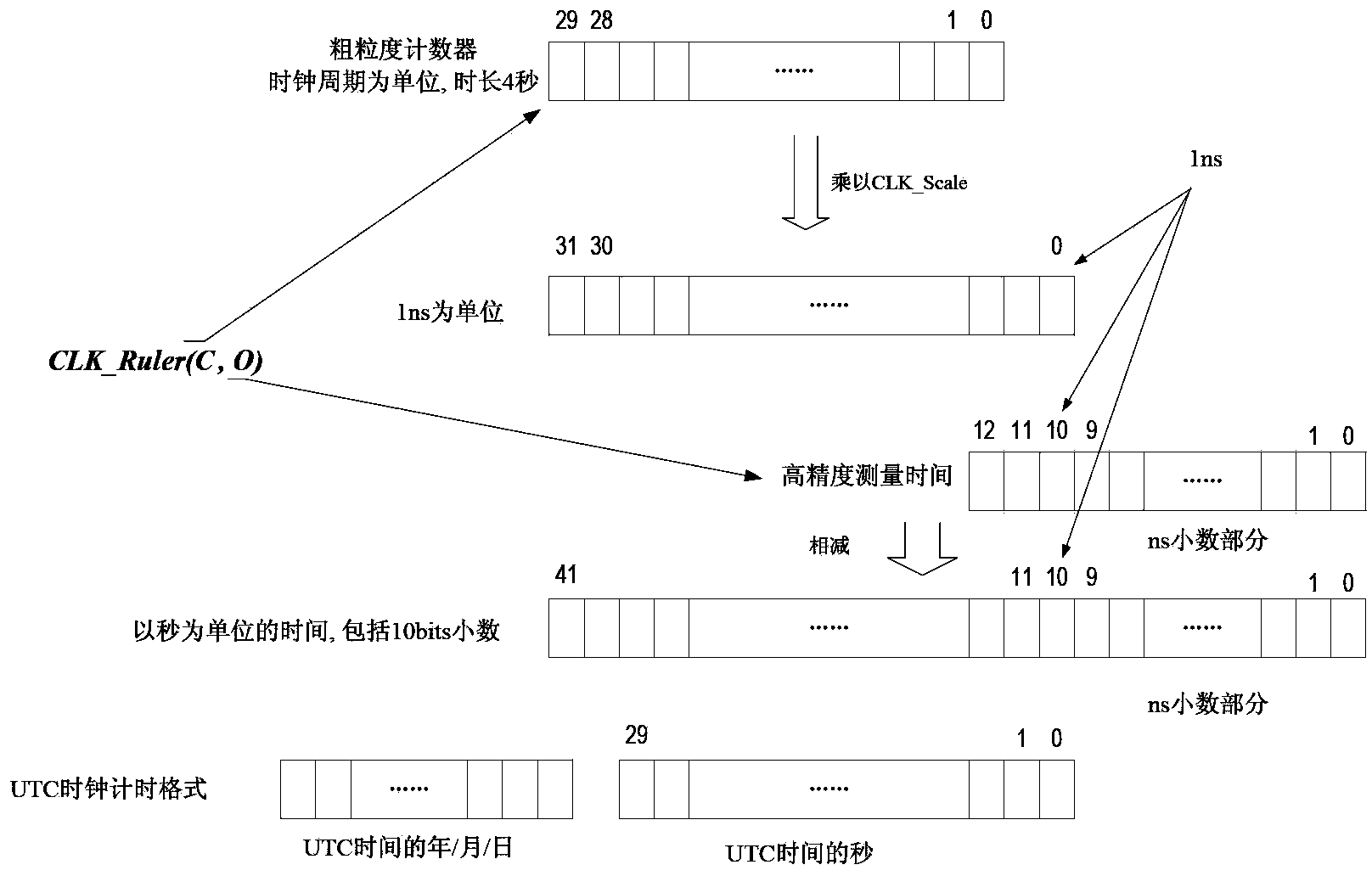

Time measuring method based on double-clock system

ActiveCN103383539AEliminate errorsHigh labeling accuracySynchronous motors for clocksSynchronisationProblem of timeSystem time

The invention provides a time measuring method based on a double-clock system. The method includes the steps: (1) building a system time scale, (2) calculating an actual cycle of a local clock by means of the system time scale and a second pulse clock, and (3) measuring absolute time of a pulse to be measured according to the actual cycle of the local clock. The time measuring method solves the inaccuracy problem of time in a unit smaller than second caused by non-synchronization and errors of the clock. The clock is corrected through the method that the local clock and the second pulse clock are used together to correct time, and by means of calculation of relation between the second pulse clock and the local clock, the relation between the pulse to be measured and the two clock systems is further calibrated in detail. Intrinsic time of the local clock is used for marking the absolute time of an event, relative errors between several kinds of time are eliminated, and the marking precision is extremely high.

Owner:NO 513 INST THE FIFTH INST OF CHINA AEROSPACE SCI & TECH

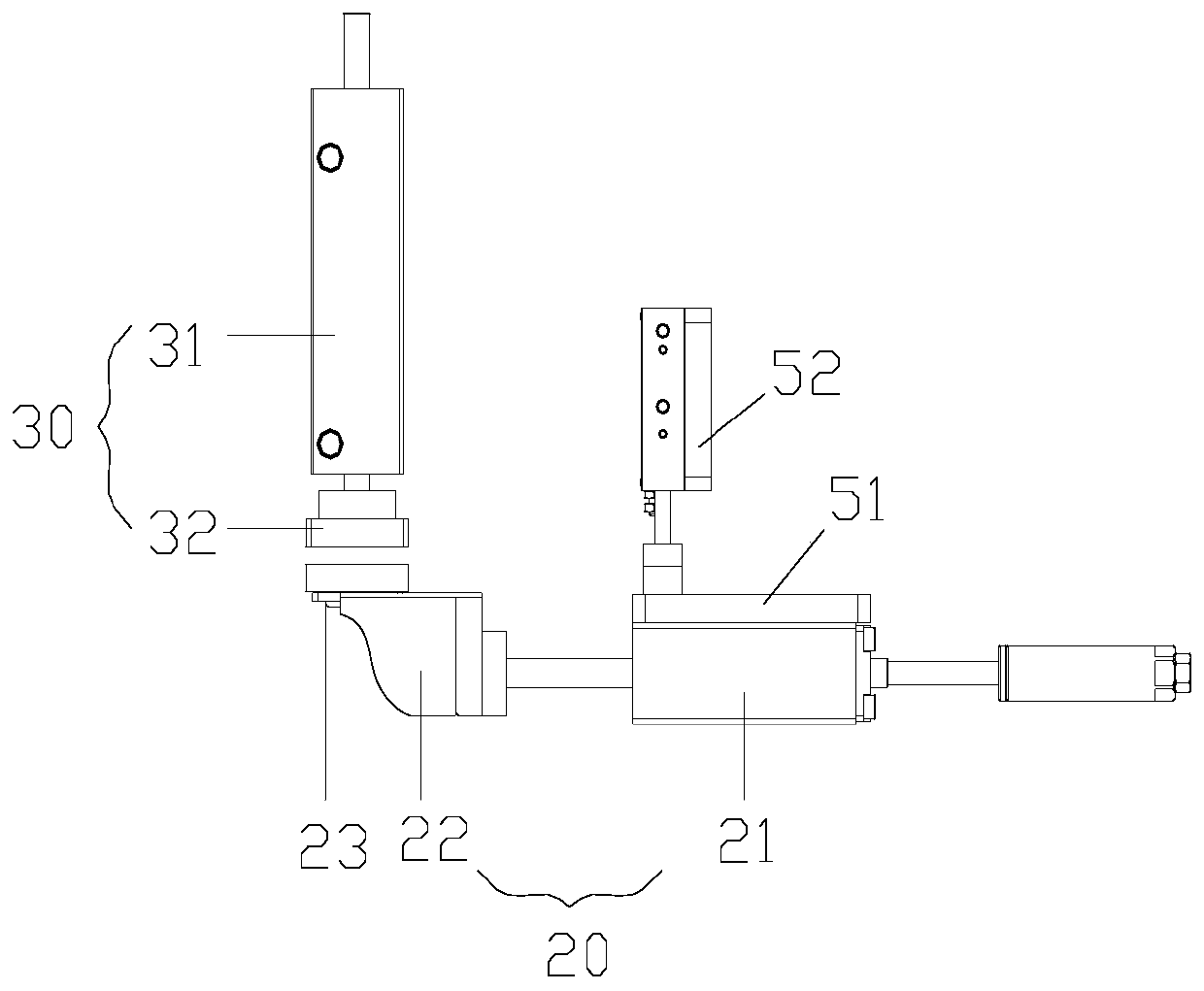

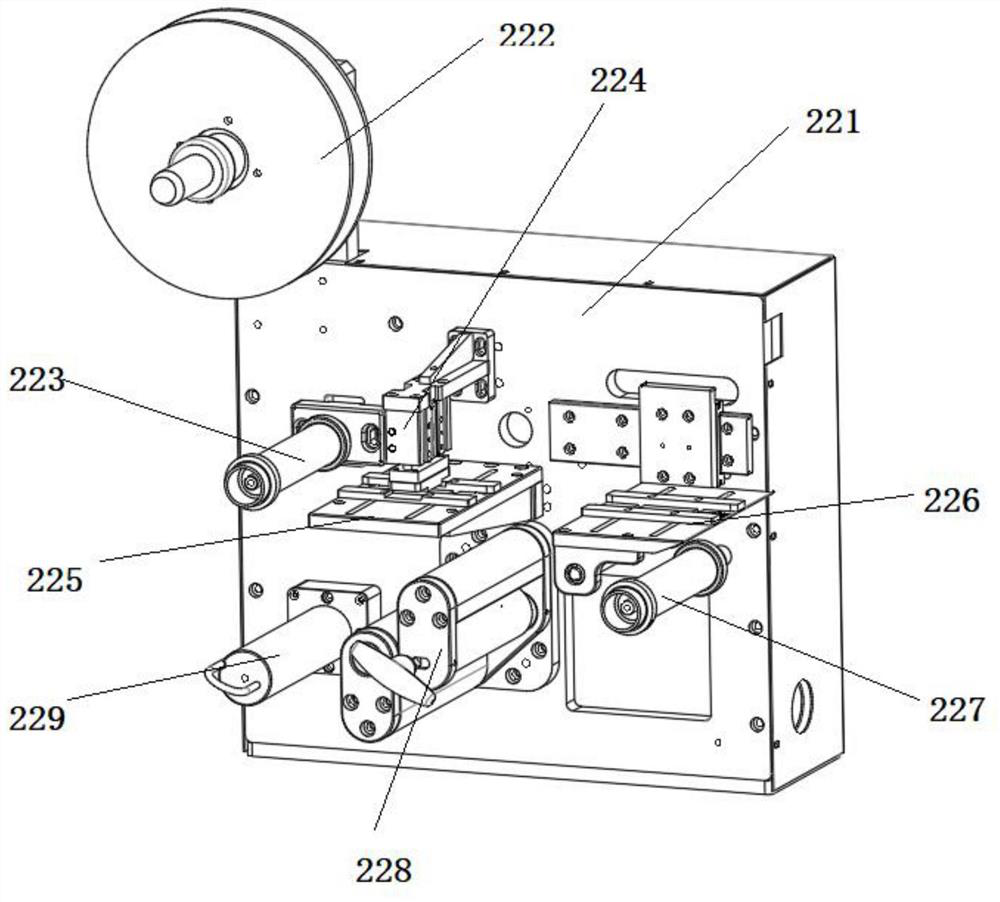

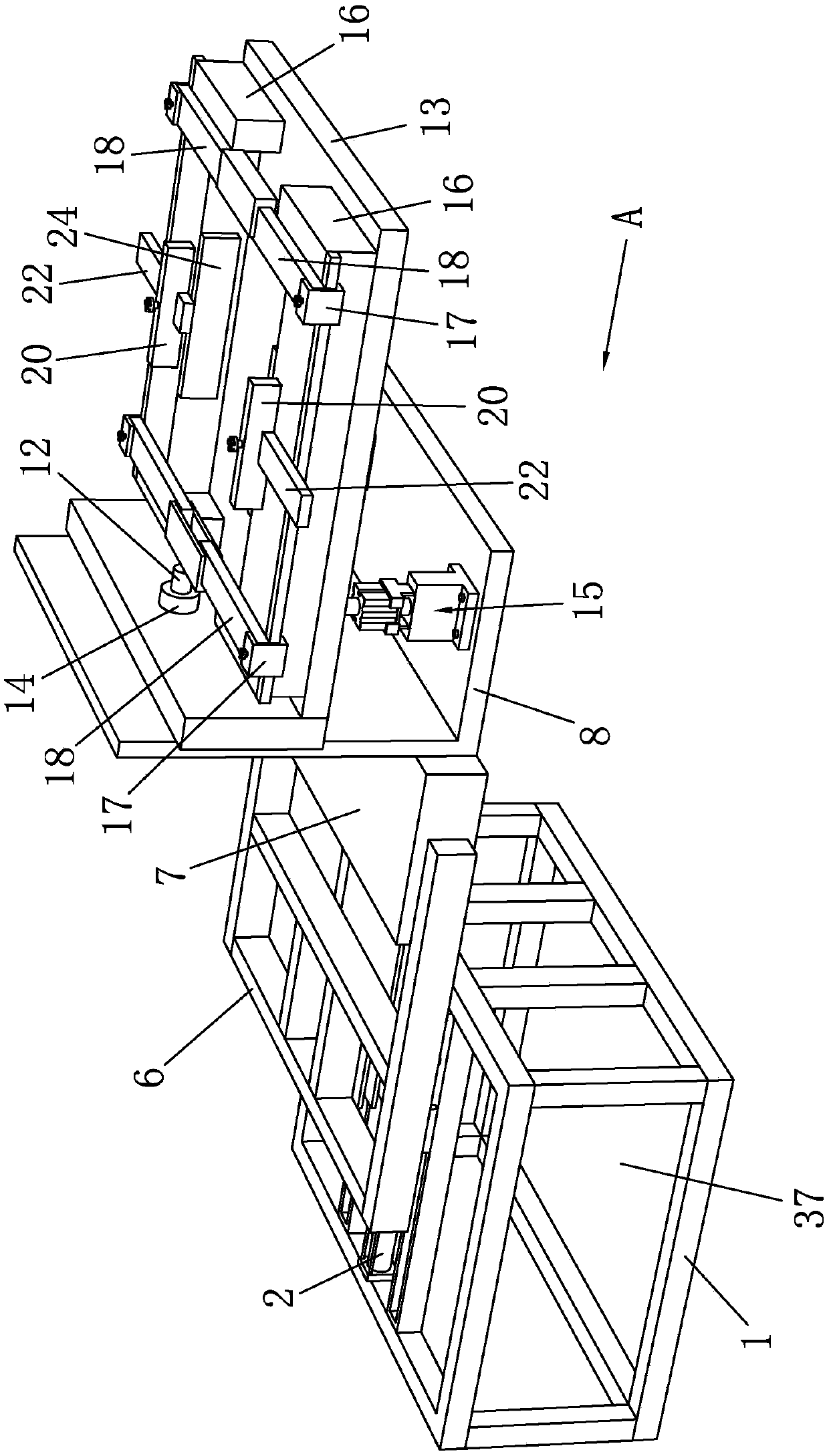

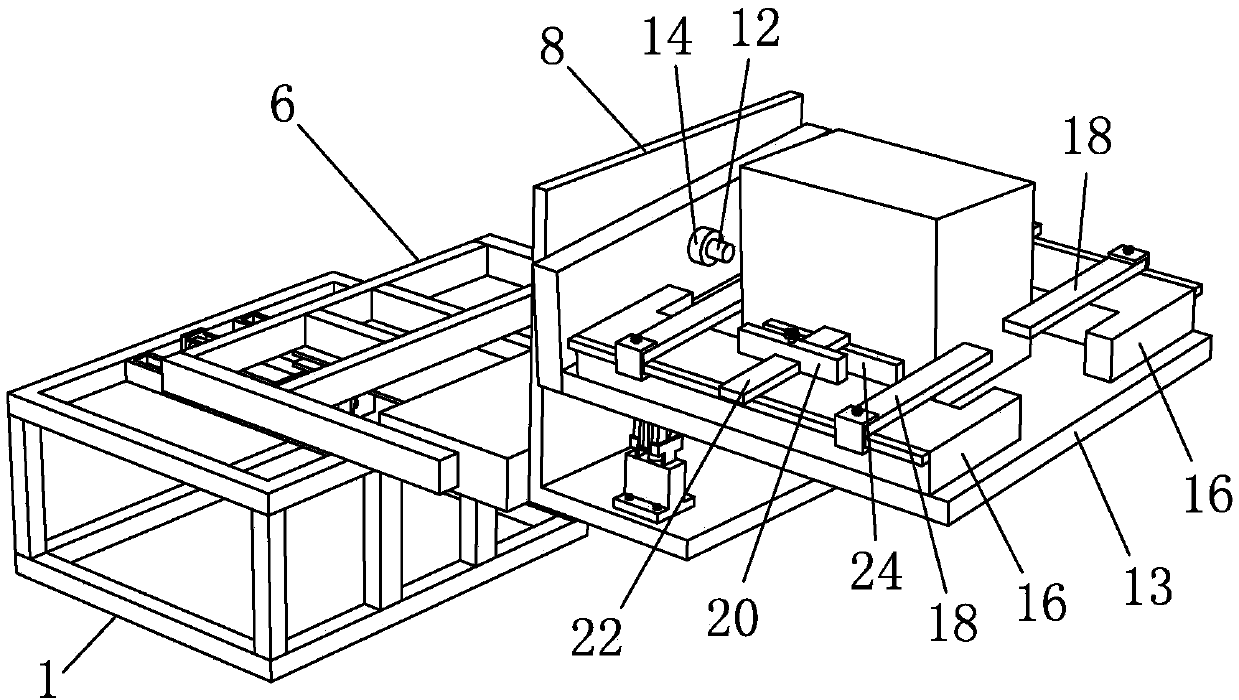

Labeling device

ActiveCN105366141AHigh precisionHigh labeling accuracyLamination ancillary operationsLaminationEngineeringMechanical engineering

The invention relates to a labeling device, and belongs to the technical field of labeling. The labeling device comprises a scale control assembly and a peeling assembly. The scale control assembly is used for obtaining material strips, controlling the length of the obtained material strips and then leading the material strips out. The peeling assembly is used for grabbing target labels on the material strips led out of the scale control assembly. The target labels are pasted to to-be-labled products located at the preset position, and labeled products are obtained. The scale control assembly is used for controlling the length of the led-out material strips every time the to-be-labeled products are labeled, and the precision that the peeling assembly grabs the labels and pastes the labels to the to-be-labeled products can be improved accordingly. The problem that in the prior art, the labeling precision is low is solved, and the effect of improving labeling precision is achieved.

Owner:BOE OPTICAL SCI & TECH +1

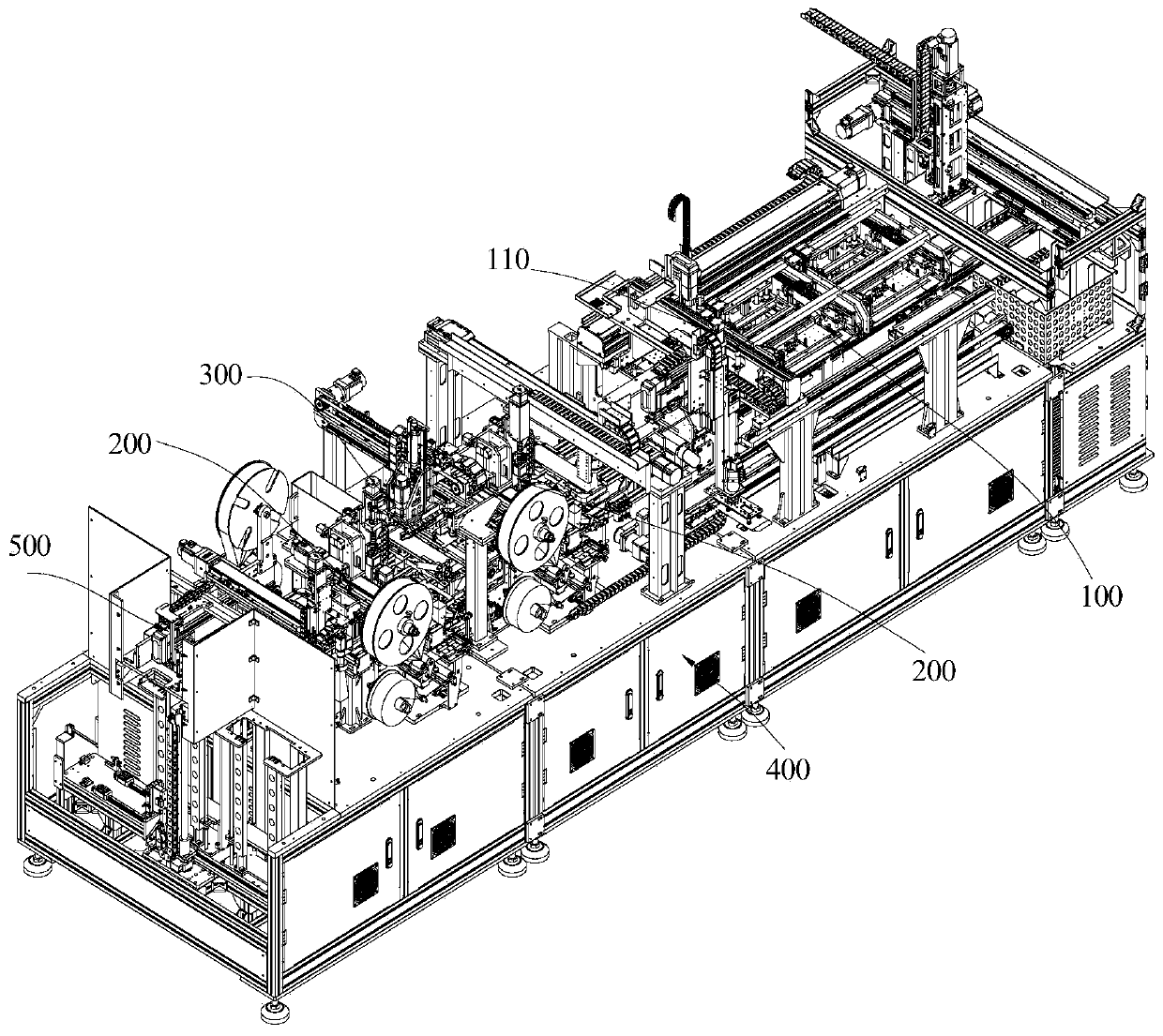

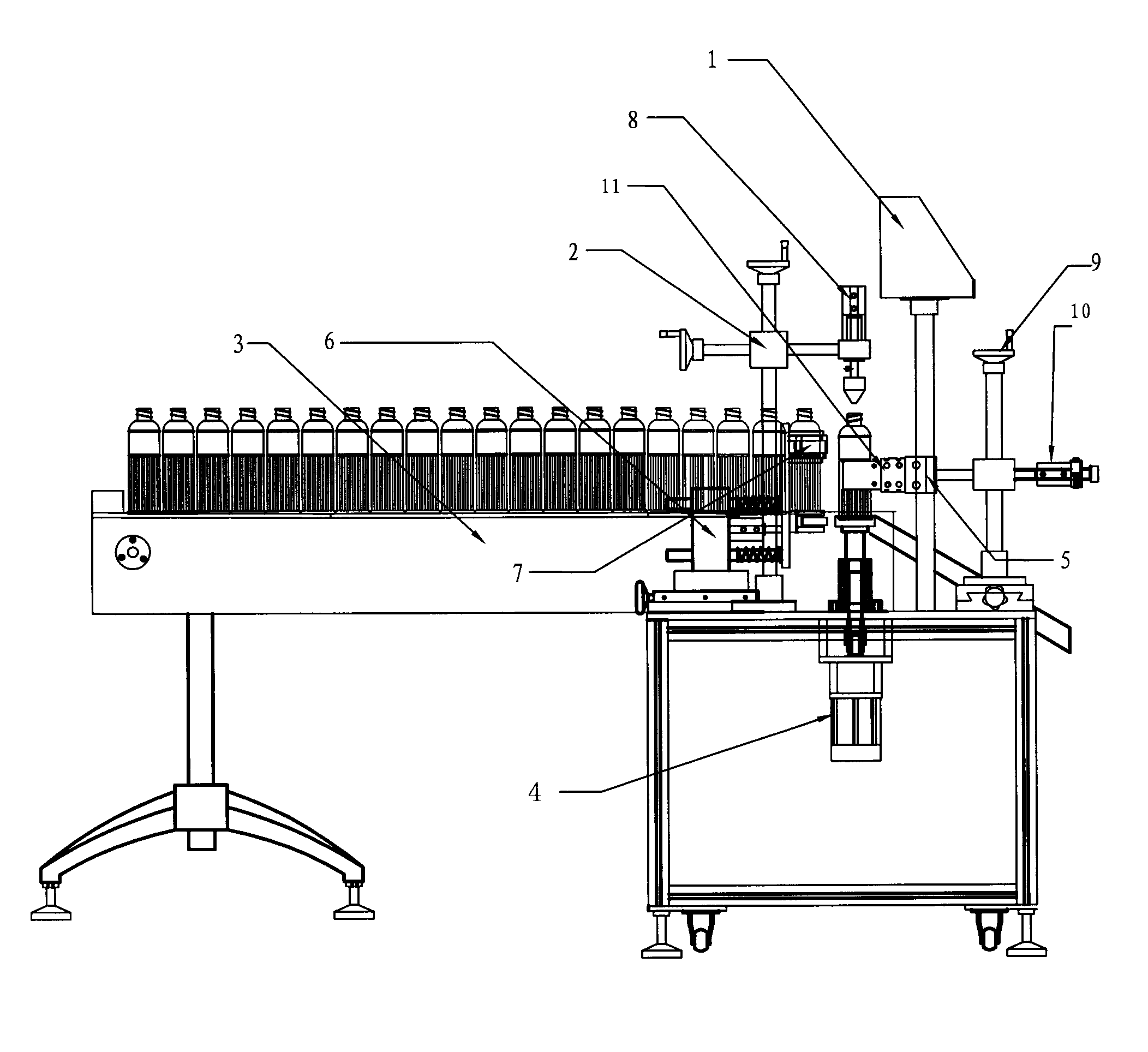

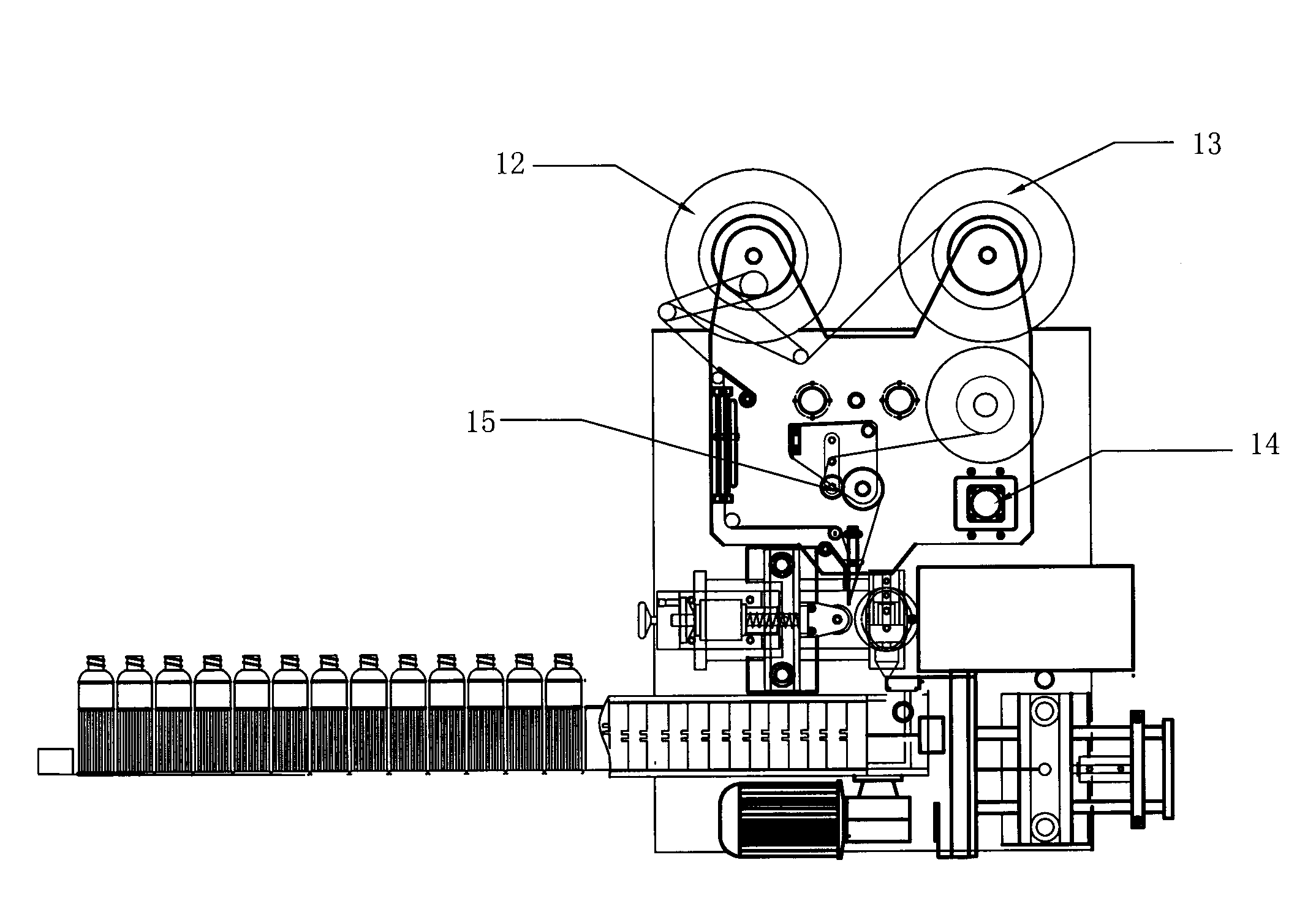

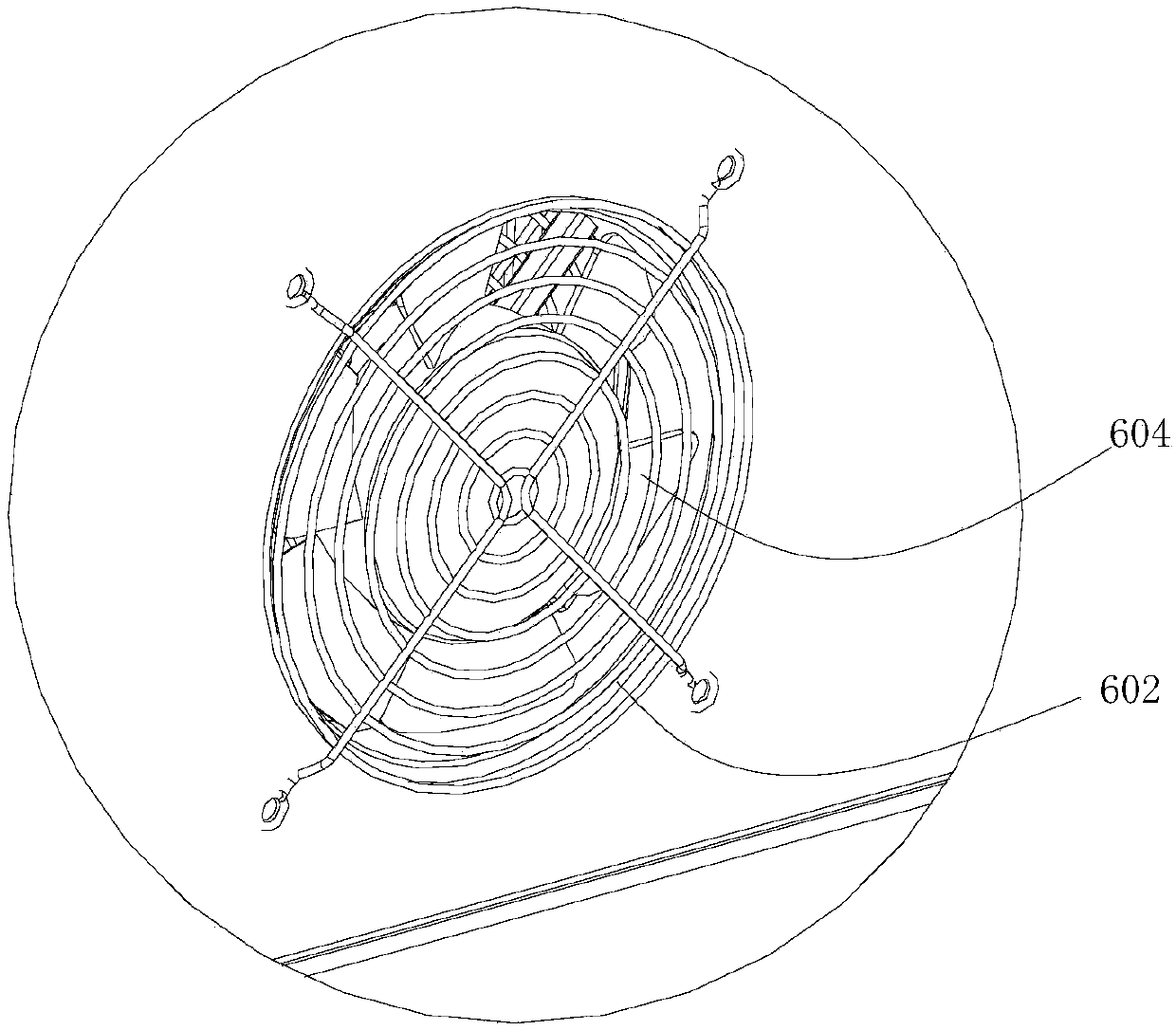

Full-automatic labelling system

ActiveCN104494982AHigh labeling accuracyImprove work efficiencyLabelling deformable materialsLabelling machinesWork performancePaper tape

The invention provides a full-automatic labelling system. The full-automatic labelling system comprises a paper tapes labelling part matched with a conveyor belt, wherein the paper tapes labelling part comprises a power device and a brand debatching mechanism driven by the power device; along the moving direction of the conveyor belt, and the front middle of the brand debatching mechanism is provided with a label brushing mechanism. Volumed brands are arranged on the brand debatching mechanism, the separation of the brands is realized by the brand debatching mechanism, and the half of each brand is pasted on one end of a textile, the other end of each brand extends out of the end of the textile, and the extension end of each brand is pasted on the other side of a spinning port under the action of the label brushing mechanism, so that the pasting of the paper tapes is finished. Compared with the manual operation in the prior art, the full-automatic labelling system has the advantages that the labelling precision and the working performance are high, the labor cost is lowered, and the labor intensity of operating workers is lowered.

Owner:HUAFANG

Labeling device and labeling method thereof

The invention provides a labeling device and a labeling method of the labeling device. The device comprises a rack, a product handling module fixed above the rack, and a label suction module fixed on the rack and located above the product handling module, wherein the product handling module is used for handling a product to be labeled to a preset labeling position; an automatic stripper is arranged on the rack; the label suction module is used for sucking a label from the automatic stripper and moving the sucked label to a place above the labeling position of the product handling module, and moves downwards to attach the label to the product to be labeled; and the product handling module is used for moving the labeled product away from the rack. With the adoption of the device and the method, two products can be labeled simultaneously and the labeling efficiency and labeling accuracy are greatly improved.

Owner:GOERTEK INC

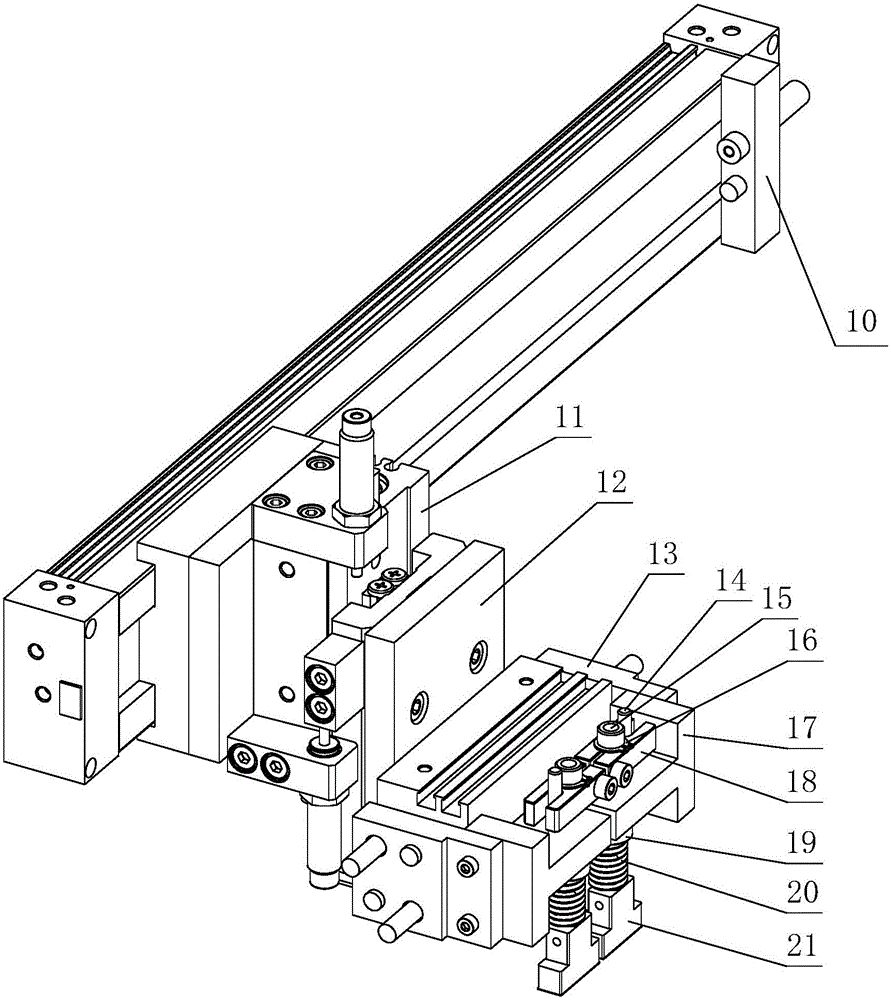

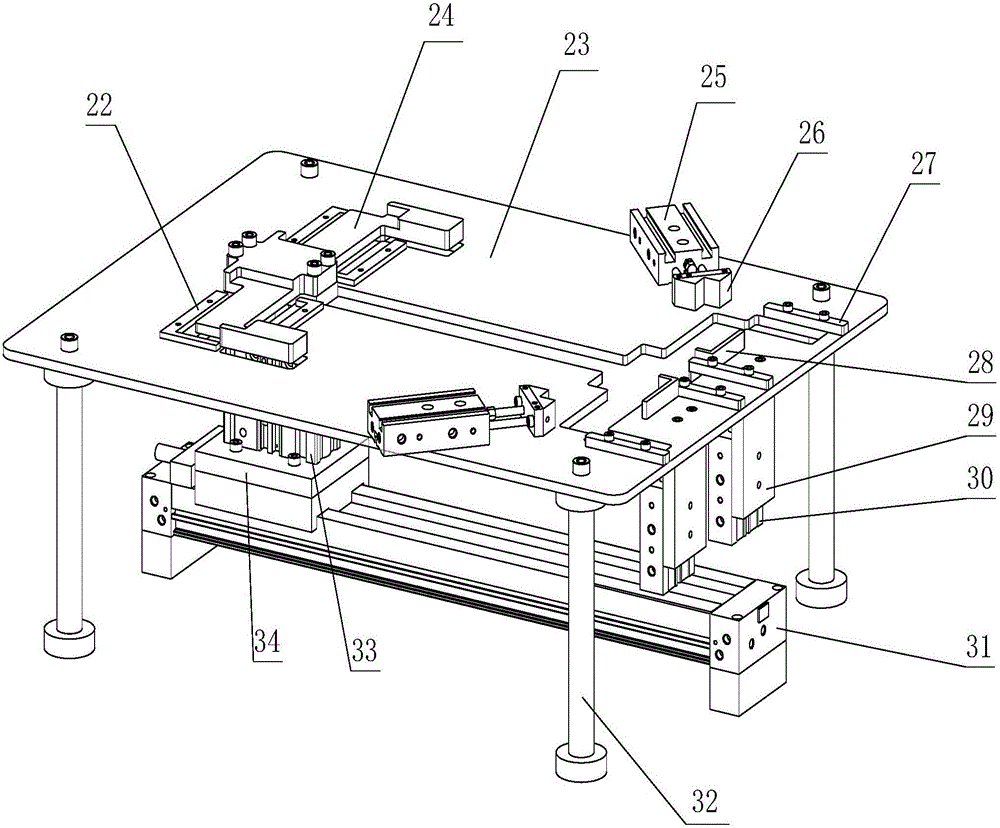

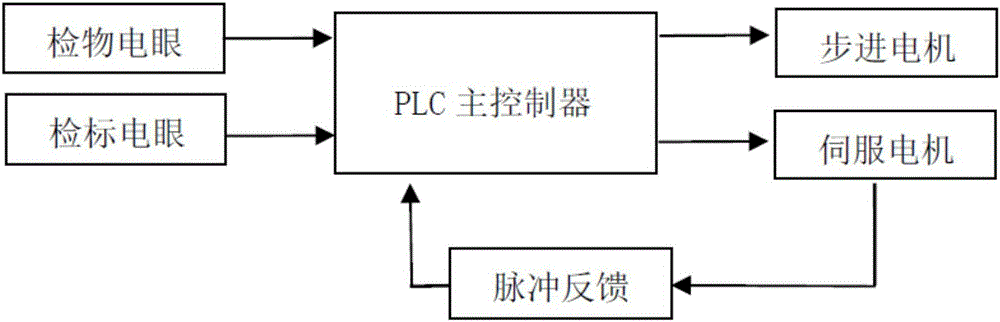

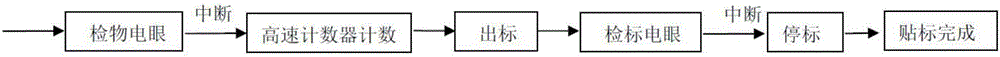

High-precision straight-line labeling machine

ActiveCN106184956AEfficient productionGuaranteed smooth productionLabelling machinesProduction lineElectric machinery

The invention discloses a high-precision straight-line labeling machine. The high-precision straight-line labeling machine comprises a labeling head, a conveying device, a label inspection electric eye and an object inspection electric eye. Drive power of the labeling head is obtained through a stepping motor. The drive power of the conveying device is obtained through a servo motor. The high-precision straight-line labeling machine further comprises a PLC master controller. The PLC master controller starts the servo motor. The conveying device drives a labeled object to move through the servo motor. When the object detection electric eye detects that the labeled object passes by, the PLC master controller enters an external interruption subroutine, a high-speed counter is triggered and reads the pulse number output through a pulse output port of the servo motor. After the high-speed counter counts to the target value, the PLC master controller starts the stepping motor, and the stepping motor continues to move; and after the label inspection electric eye detects the gap between labels, the stepping motor is controlled to move by an assigned distance and then stops, and therefore the labeling function is achieved. By means of the high-precision straight-line labeling machine, the labeling precision is increased, stepless speed regulation is achieved, the speed can be rapidly switched to be matched with the production speed of a whole production line, and the production line can be efficient and smooth.

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

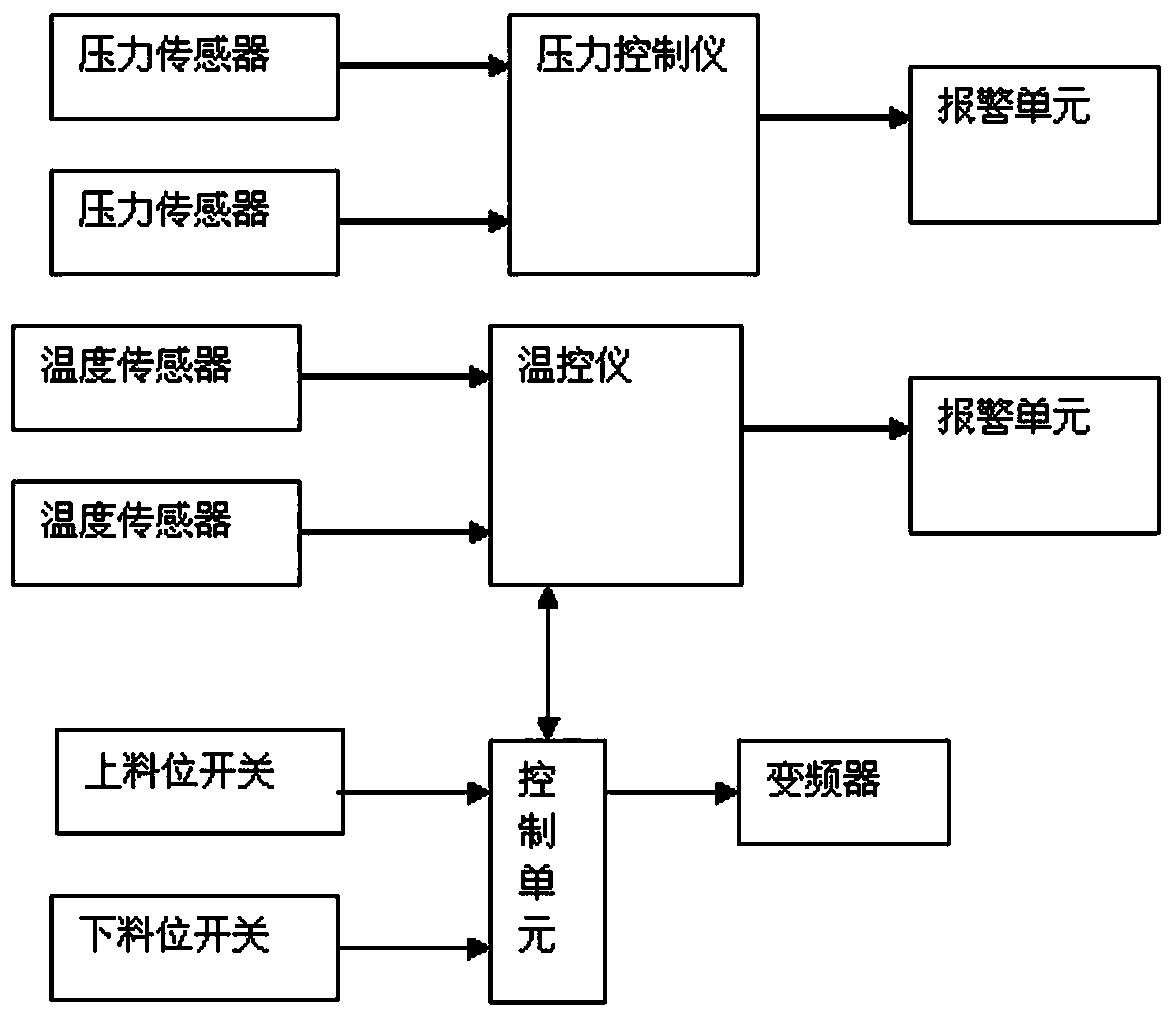

Full-automatic labeling and code printing equipment for hemodialysis concentrated liquid

The invention relates to full-automatic labeling and code printing equipment for hemodialysis concentrated liquid. The full-automatic labeling and code printing equipment is suitable for printing labels on packing barrels of the hemodialysis concentrated liquid through a label information printer and sticking the labels. The full-automatic labeling and code printing equipment comprises a machine frame, a labeling device, a code printer, a conveying device, a barrel correcting device and a label pressing device. The conveying device comprises a conveyer belt, a conveyer belt transmission motor, a conveyer belt driving wheel and a conveyer belt driven wheel. The labeling device and the code printer are installed on the upper portion of the machine frame. The labeling device comprises a label supporting disc, an anti-returning wheel, a main label feeding plate, a width adjusting wheel, a paper organizing roller, a knurling roller, a rubber roller, a label discharging plate, a paper collecting disc, a label pressing block, a placing cursor, a label pressing plate and a locking handle. The label placing motor is installed below a main label placing plate. The barrel correcting device comprises two barrel correcting motors, two barrel correcting belts and four barrel correcting belt wheels. The label pressing device comprises label pressing sponges and label pressing sponge adjusting hand wheels.

Owner:CHANGZHOU HUAYUE MINIMAL INVASIVE MEDICAL EQUIP CO LTD

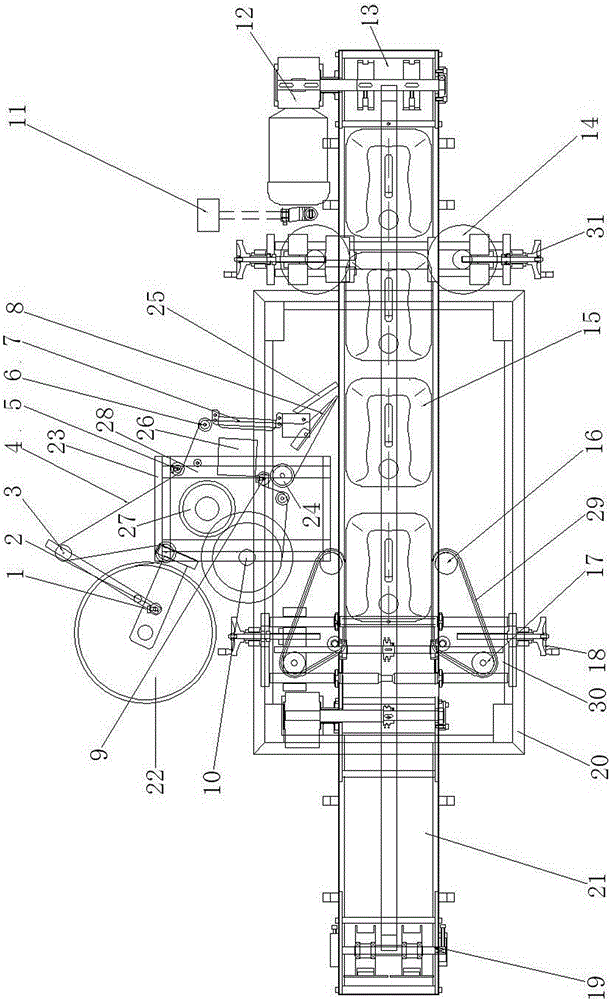

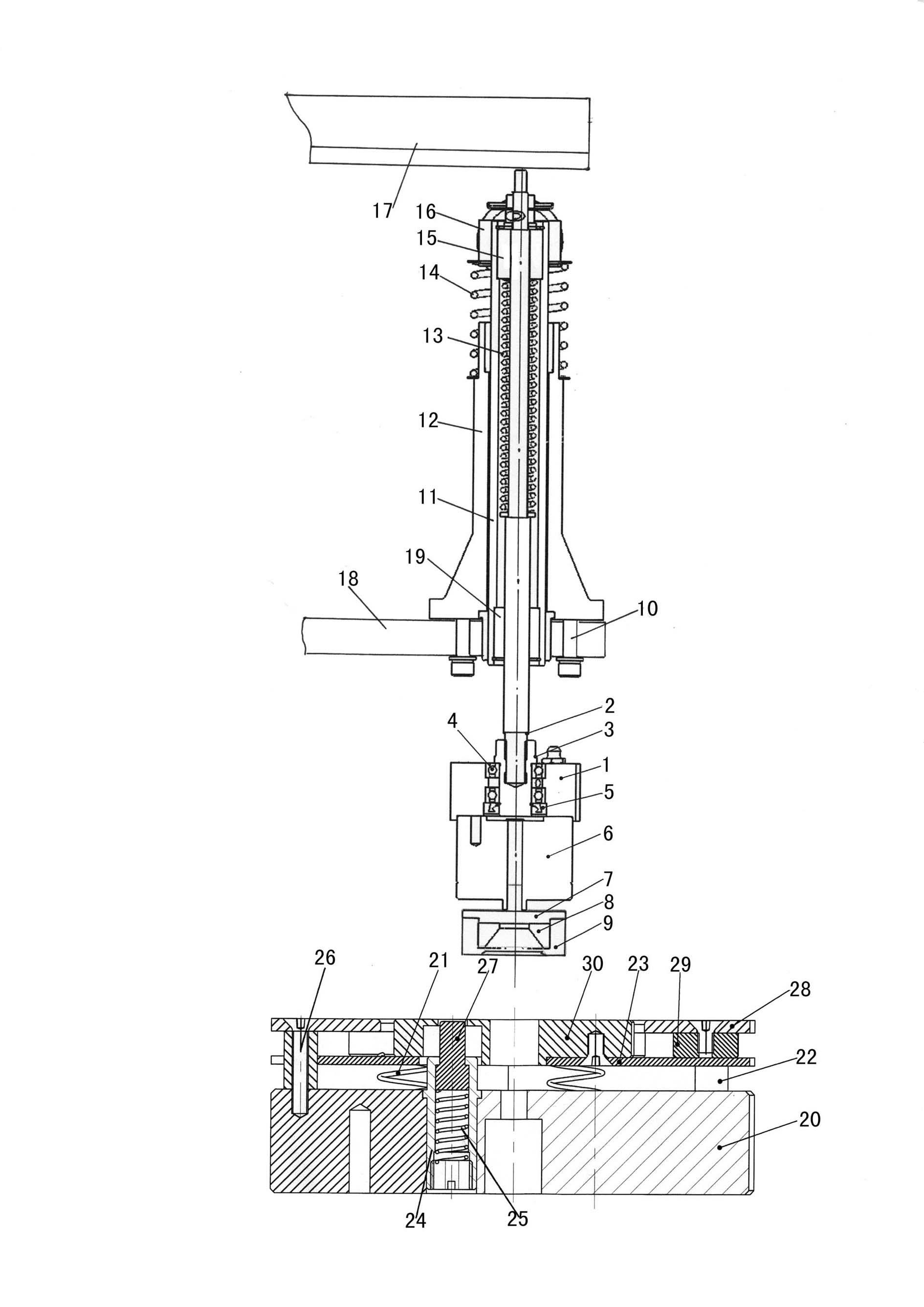

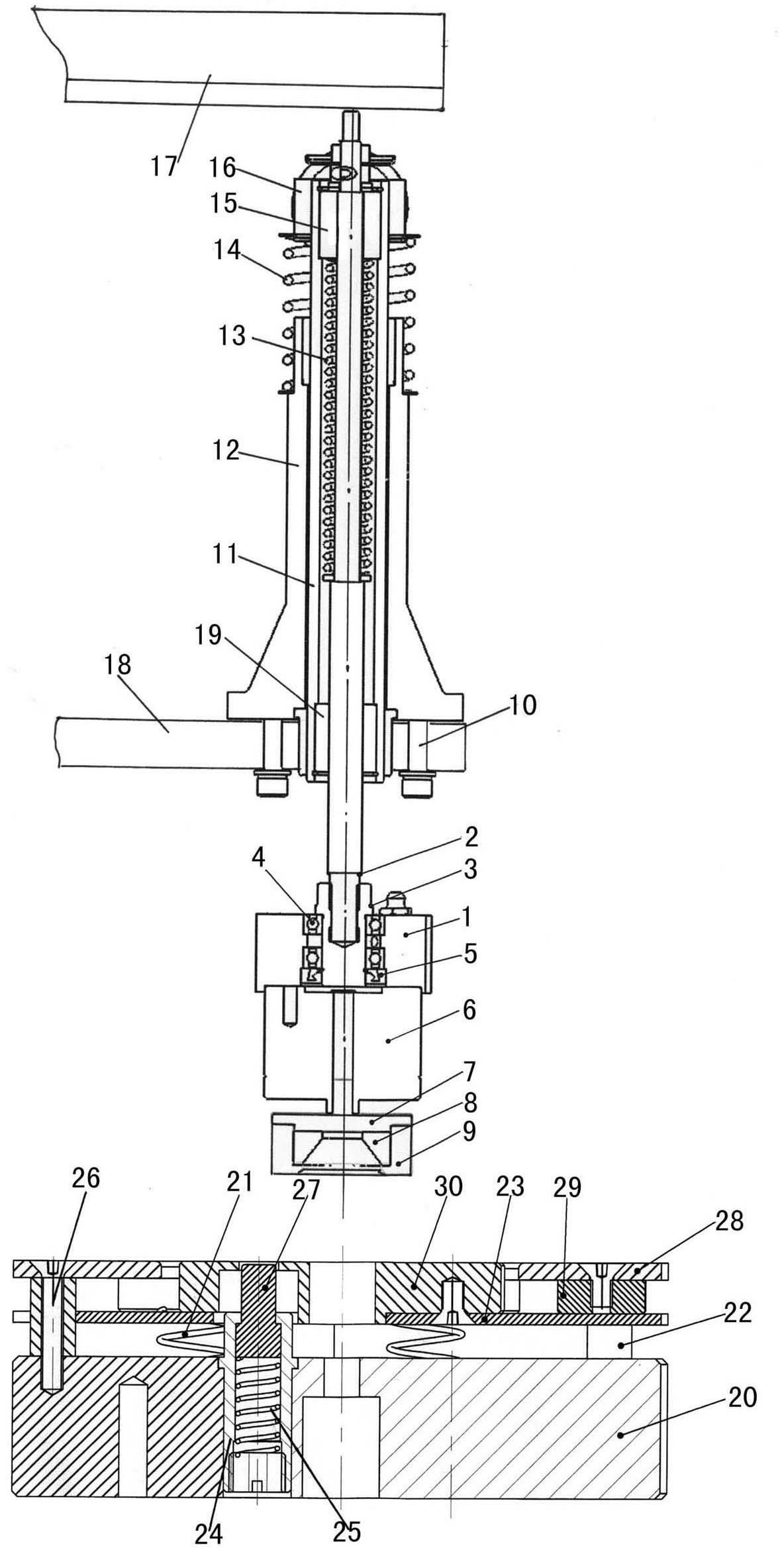

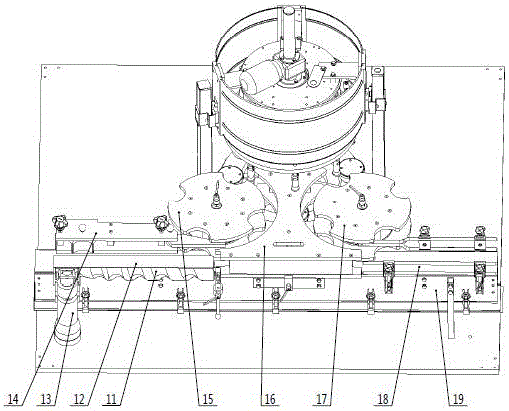

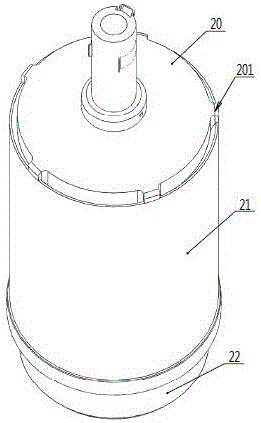

Container positioning apparatus of rotary labeler

ActiveCN102398706ADoes not affect appearanceNo harmLabelling machinesLabelling short rigid containersEngineeringFixed position

The invention discloses a container positioning apparatus of a rotary labeler. The container positioning apparatus comprises a bottle tray assembly and a bottle pressing rotary table arranged above the bottle tray assembly. The bottle tray assembly comprises an elevating elastic positioning apparatus. The container positioning apparatus also comprises a bottle pressing mechanism distributed on the bottle pressing rotary table arranged above and corresponding to the bottle tray assembly. A cam disk cooperating with the bottle pressing mechanism is independently and statically arranged above the bottle pressing mechanism. With the container positioning apparatus provided by the invention, labels can be labeled on fixed positions on the bottoms of plastic bottles. With the elevating elastic positioning apparatus, the appearance of the equipment is not influenced, and side surfaces of the plastic bottles are prevented from being damaged during the fixed-position labeling process. Therefore, bottle feeding and discharging processes are stable, a labeling precision is high, and high-speed labeling is realized. Also, the apparatus provided by the invention is advantaged in reasonable design structure, high cost performance, convenient operation, low maintenance cost, and adaptability of the transition of different bottle types.

Owner:秦皇岛中德实业有限公司

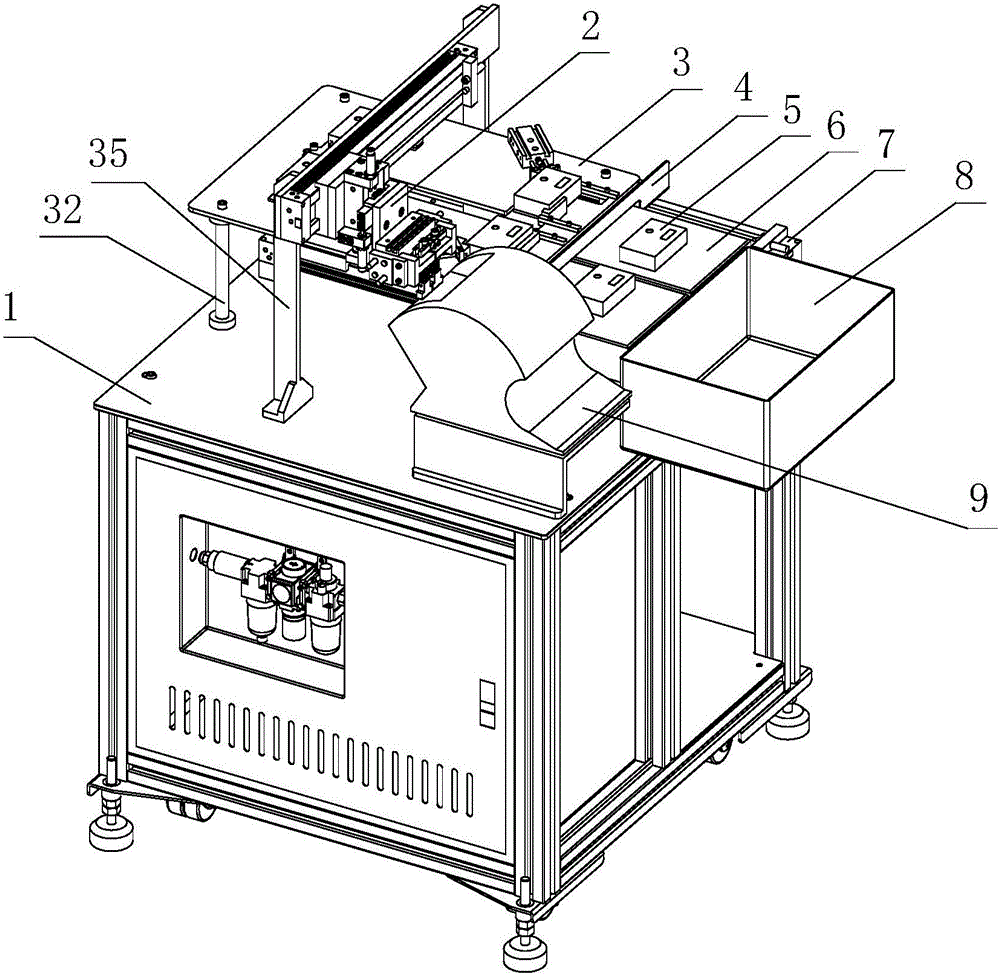

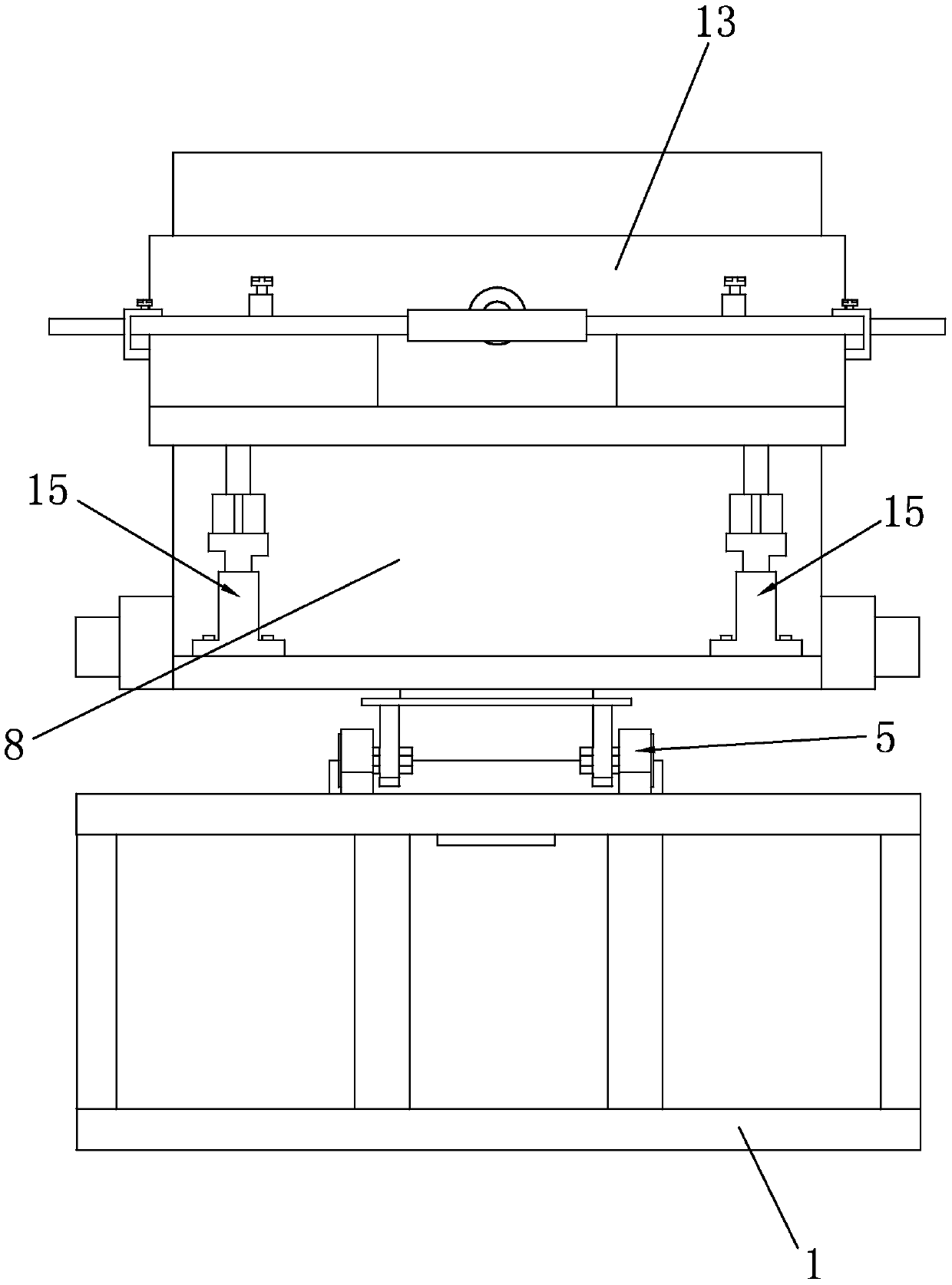

Automatic production line for paper box labeling and folding

ActiveCN111038809AHigh degree of automationReduce human interventionLabelling machinesProduction lineRobot hand

The invention discloses an automatic production line for paper box labeling and folding. The automatic production line comprises a machine body, wherein a labeling mechanism comprises a first workbench, a second workbench, a first workpiece transferring mechanism and a labeling mechanical arm; the first workbench is provided with a positioning assembly; the second workbench is provided with a label pressing mechanism; the label pressing mechanism comprises a label pressing roller, a first drive assembly and a second drive assembly; the label pressing roller is arranged above the second workbench; a box folding mechanism comprises a workpiece carrying plate assembly, a guide assembly and a second workpiece transferring mechanism; the workpiece carrying plate assembly comprises a workpiece carrying plate, a workpiece carrying plate drive mechanism and an overturning mechanism; the workpiece carrying plate is provided with a workpiece jig used for fixing a workpiece and used for driving the workpiece carrying plate to move to a forming station; the overturning mechanism is used for driving the workpiece to overturn after the workpiece carrying plate moves to the forming station; and the guide assembly is used for guiding the overturning mechanism to overturn after the workpiece carrying plate moves to the forming station. By means of the automatic production line, labeling and boxfolding can be automatically completed, and the production efficiency is improved.

Owner:ZHUHAI BOJAY ELECTRONICS

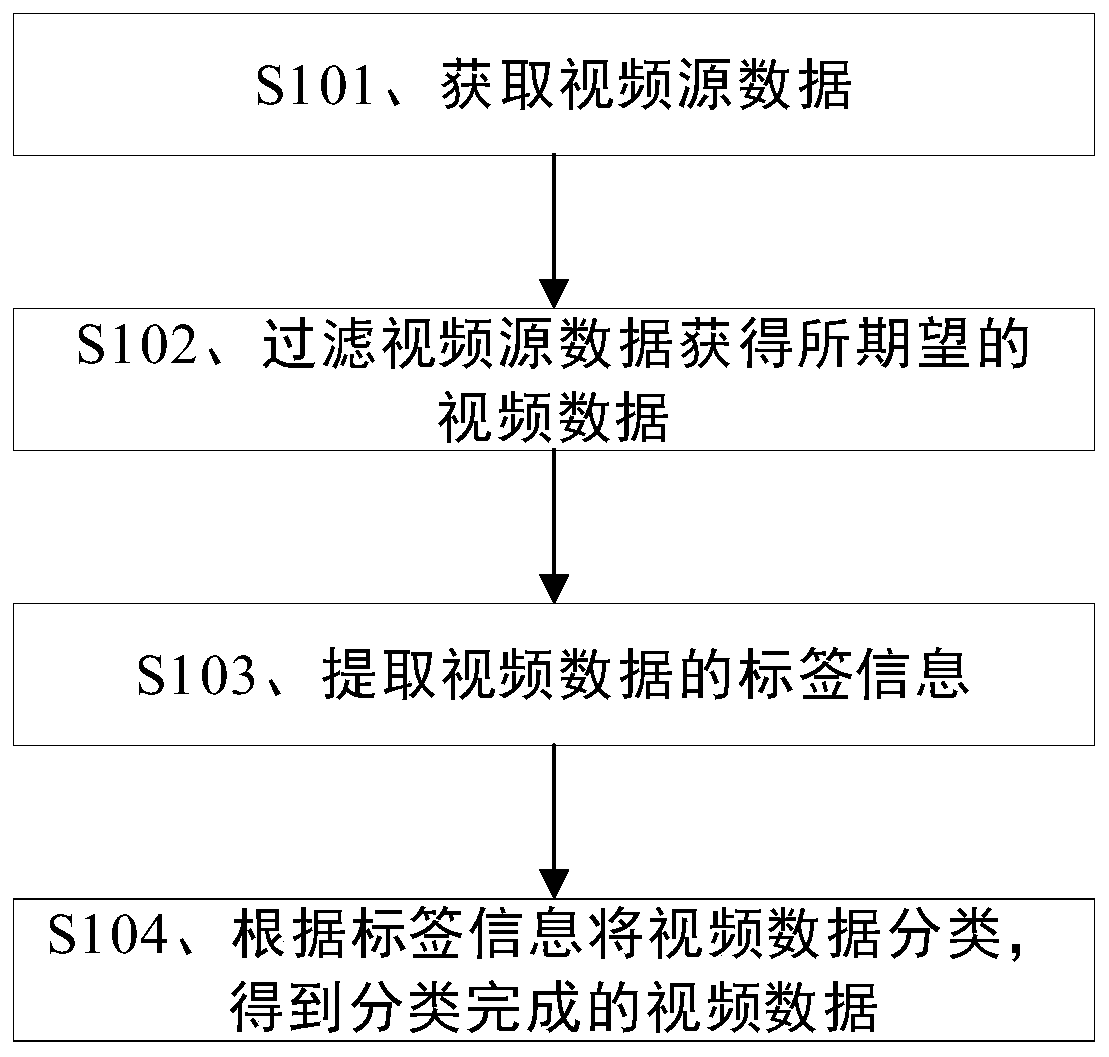

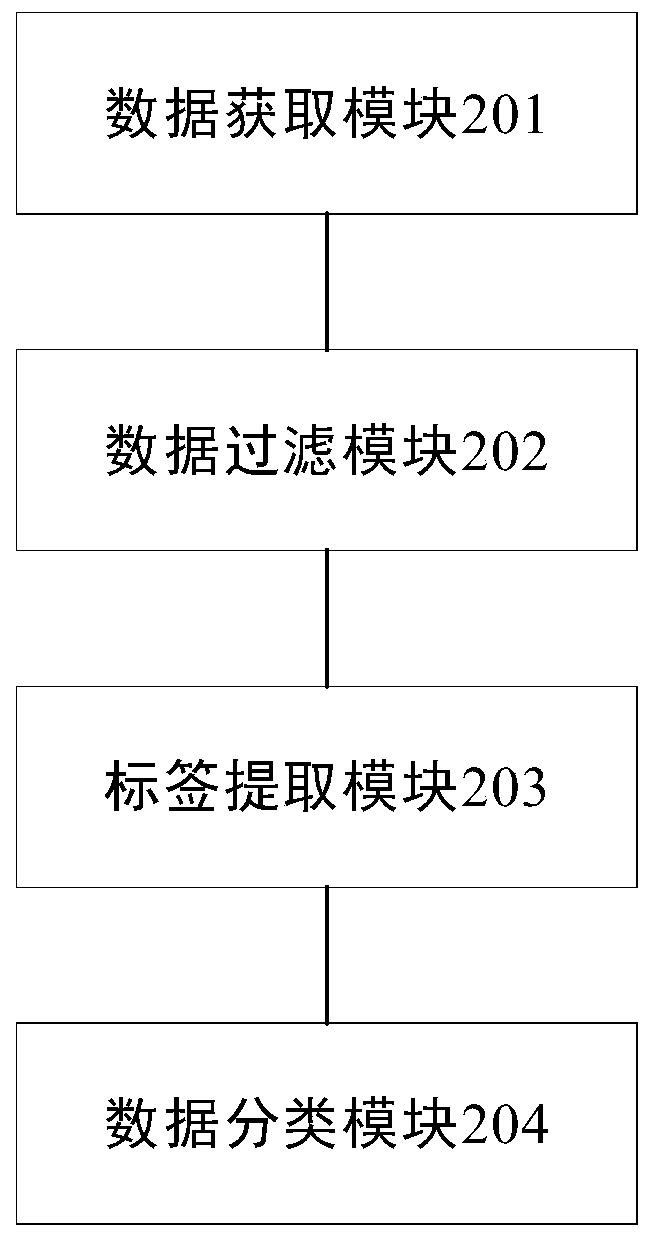

Video data processing method and device

PendingCN109840291AImprove experienceImprove processing efficiencyVideo data clustering/classificationSelective content distributionPattern recognitionSource data

The embodiment of the invention provides a video data processing method and device. The method comprises the steps of obtaining video source data; Filtering the video source data to obtain expected video data; Extracting label information of the video data; And classifying the video data according to the label information to obtain classified video data. According to the technical scheme, the process processing efficiency is high, the label accuracy is high, and good user experience can be guaranteed.

Owner:NETEASE MEDIA TECH BEIJING

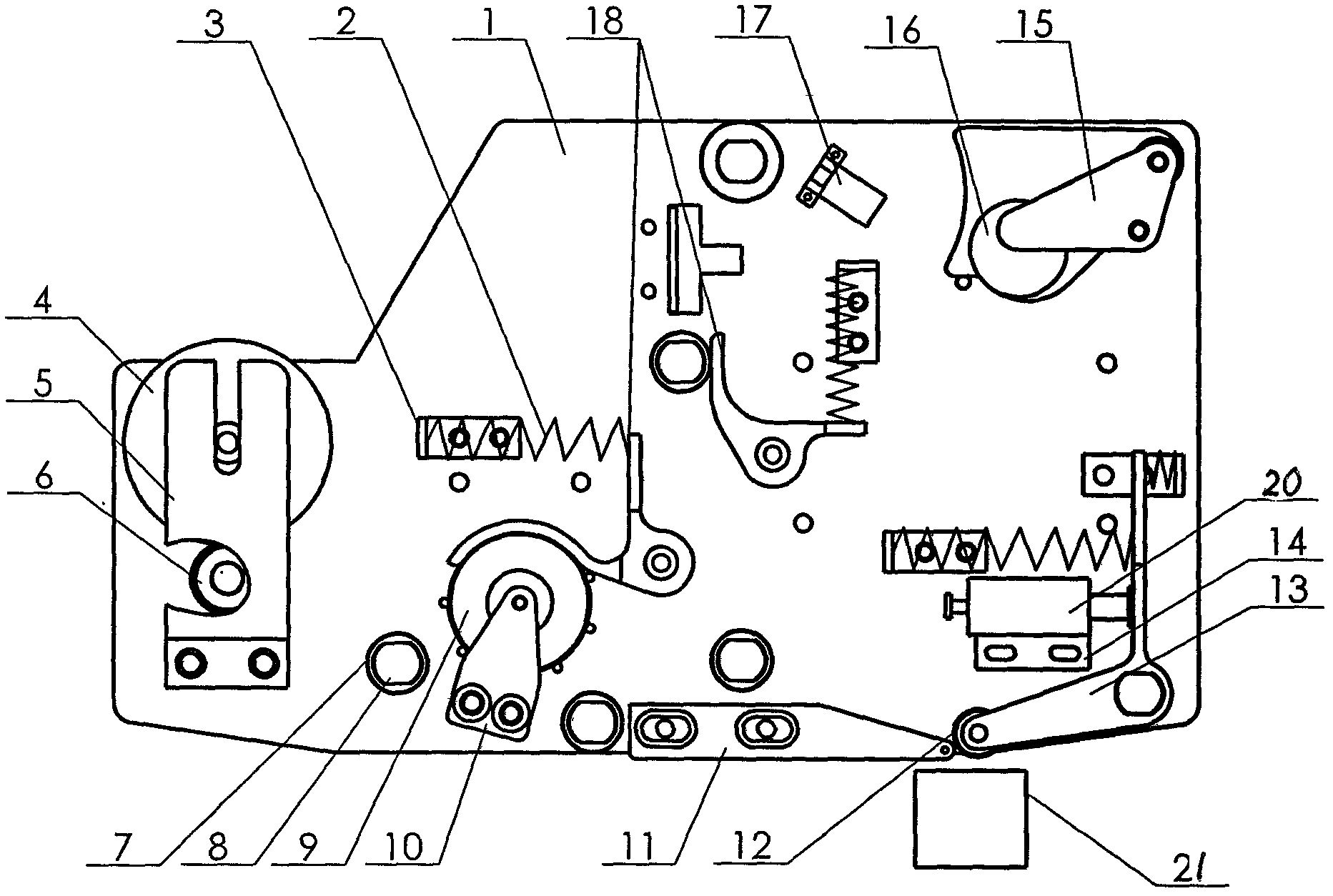

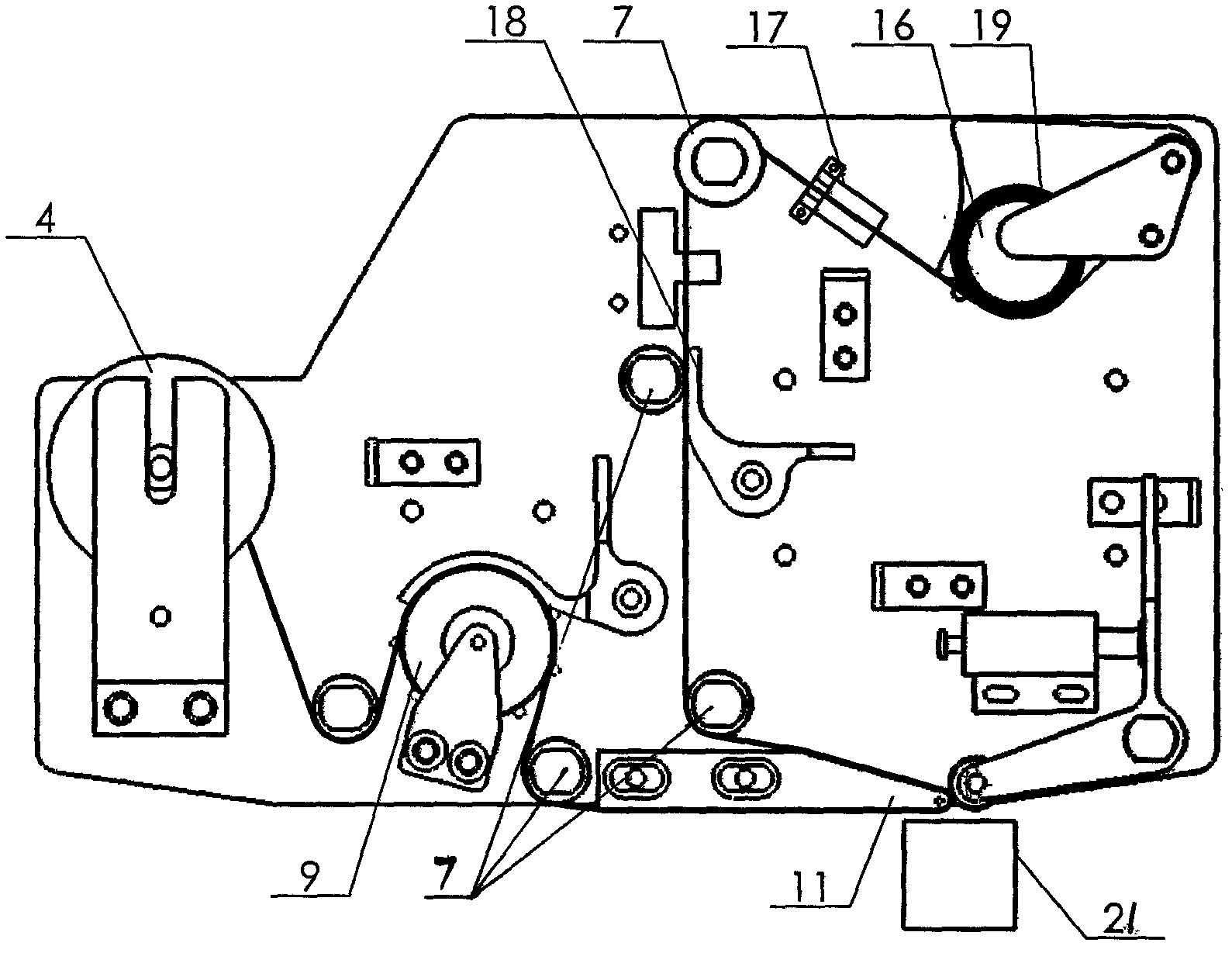

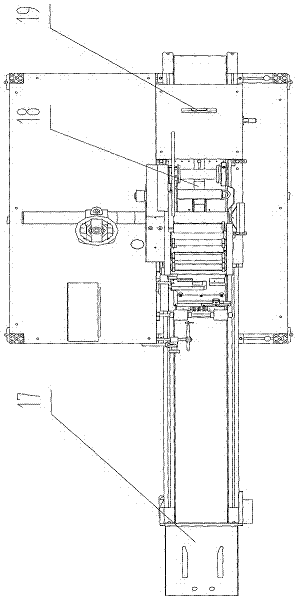

Online testing and labeling device for surface defect

The invention discloses an online and labeling device for a surface defect. The online testing and labeling device for the surface detect comprises a base plate, a winding bracket, an idler, a driving wheel bracket, a corner seat, a paper pressing wheel seat, an unwinding socket, a phototube, a paper pressing device, a labeling band, a stepper motor, a reducing motor, a reducing motor seat, a stepper motor seat and the like, wherein a signal receiving device used for receiving an operation signal transmitted from a testing host is arranged on the stepper motor; and the signal receiving device starts the stepper motor and drives each component of the labeling device to operate by receiving an operation command transmitted from the testing host, so that labeling operations can be finished accurately. The online testing and labeling deice for the surface defect has a small volume, light weight, and high labeling accuracy, and can be used for effectively preventing external noise and clutter interferences, and realizing continuous or discontinuous label paper labeling; therefore, the online testing and labeling device for the surface defect is particularly suitable to be used for labeling operations of online testing of the surface defect on a production line.

Owner:浙江双元科技股份有限公司

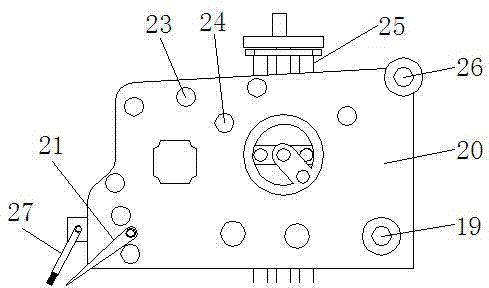

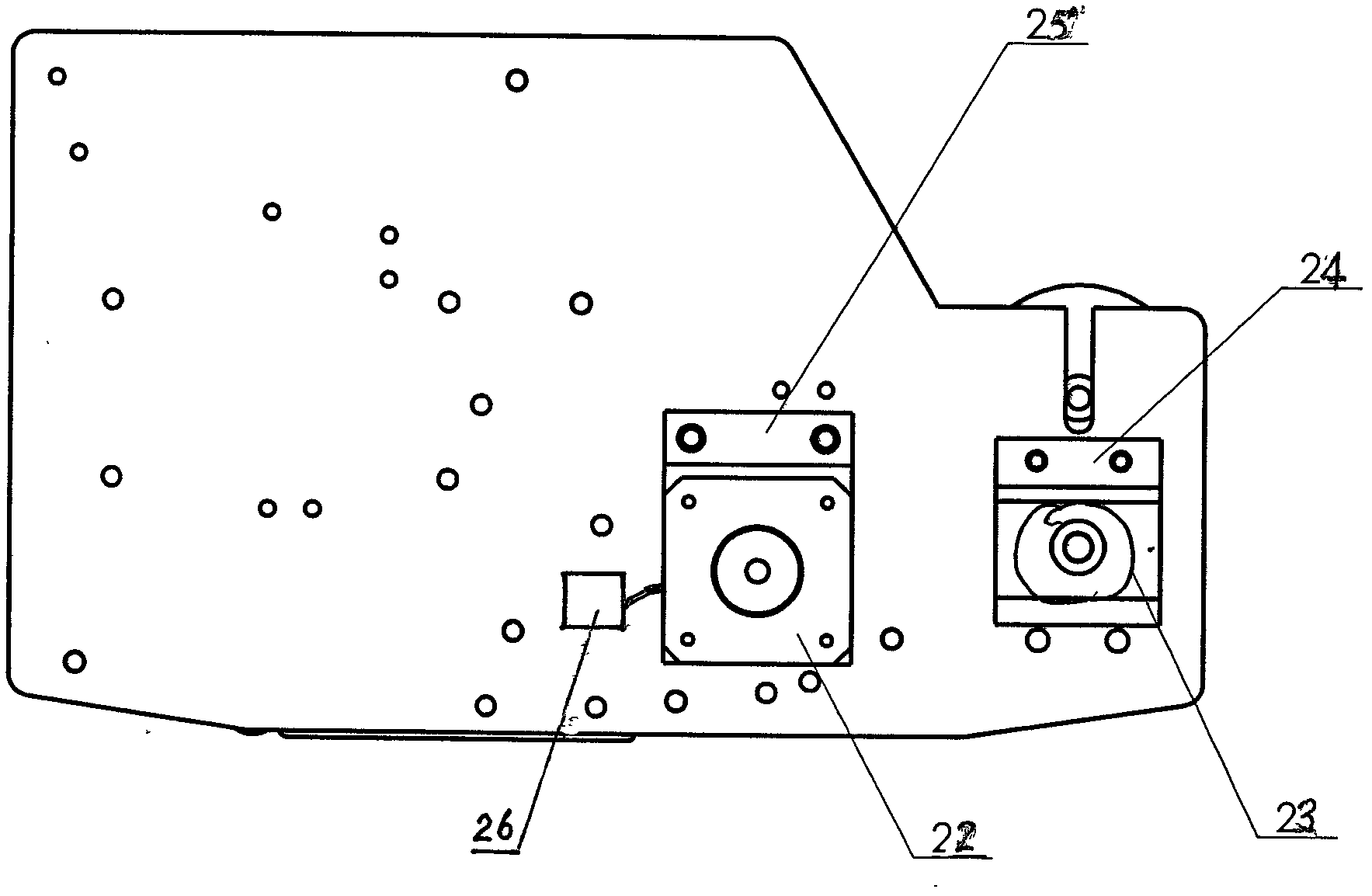

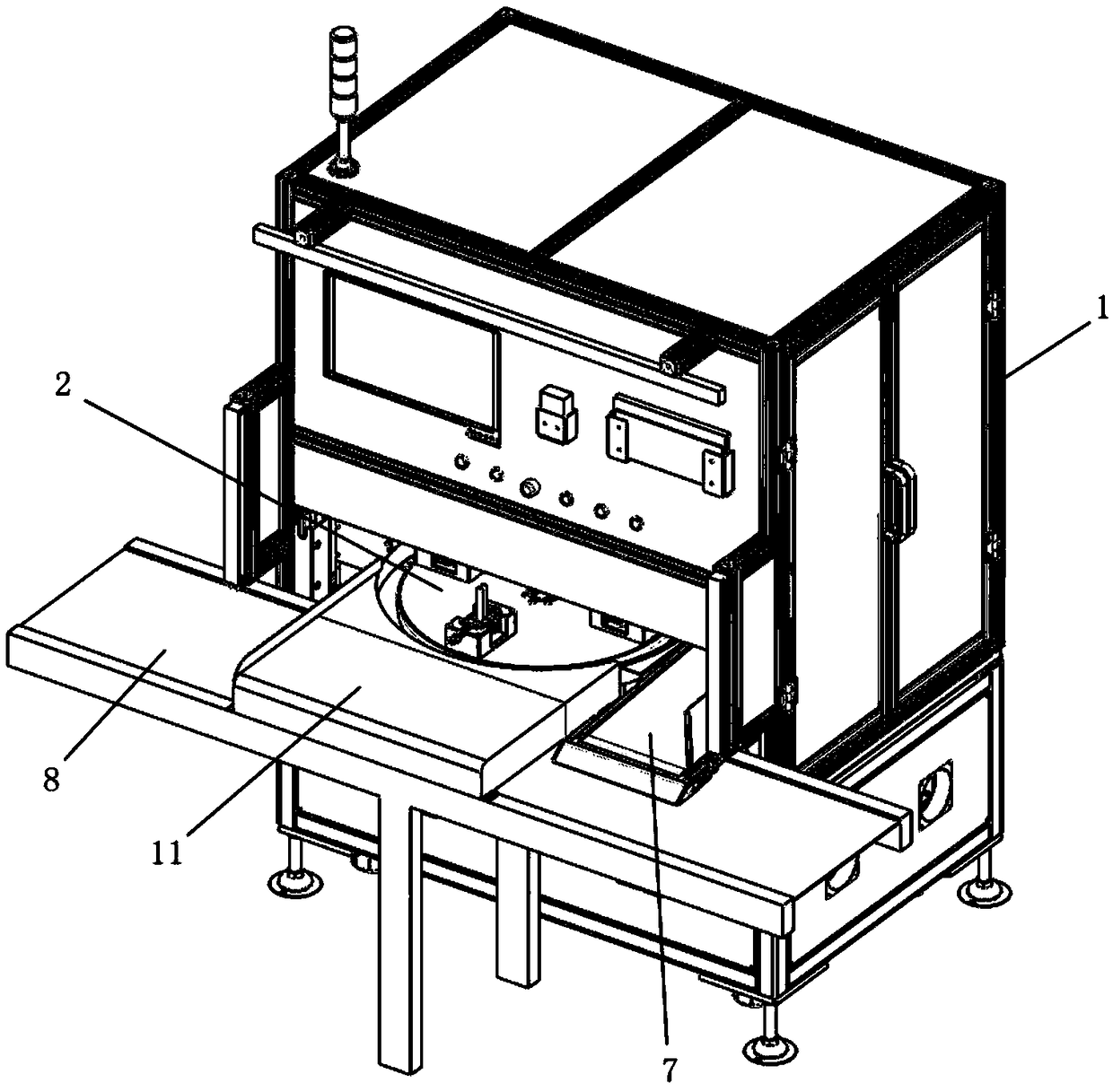

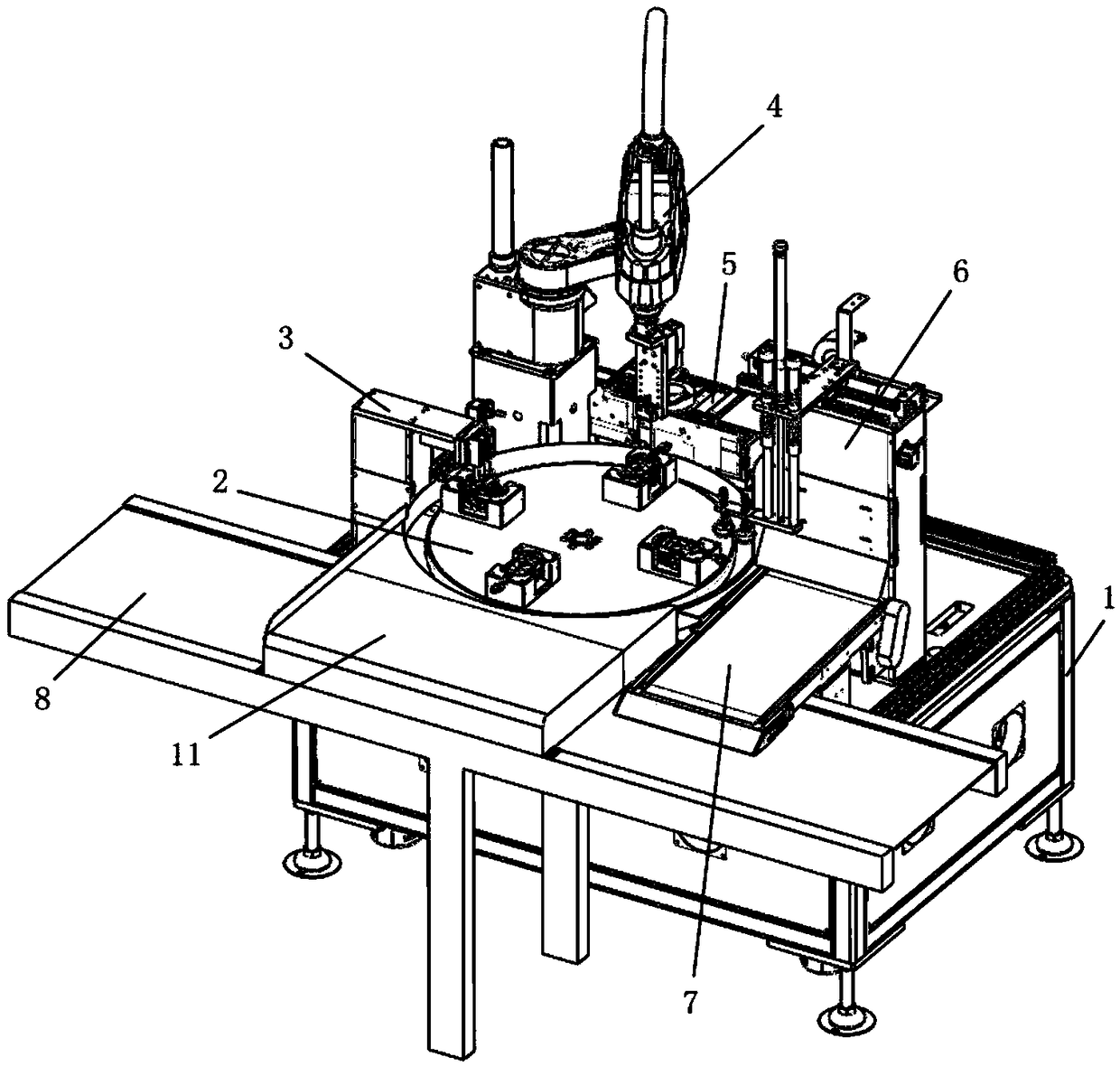

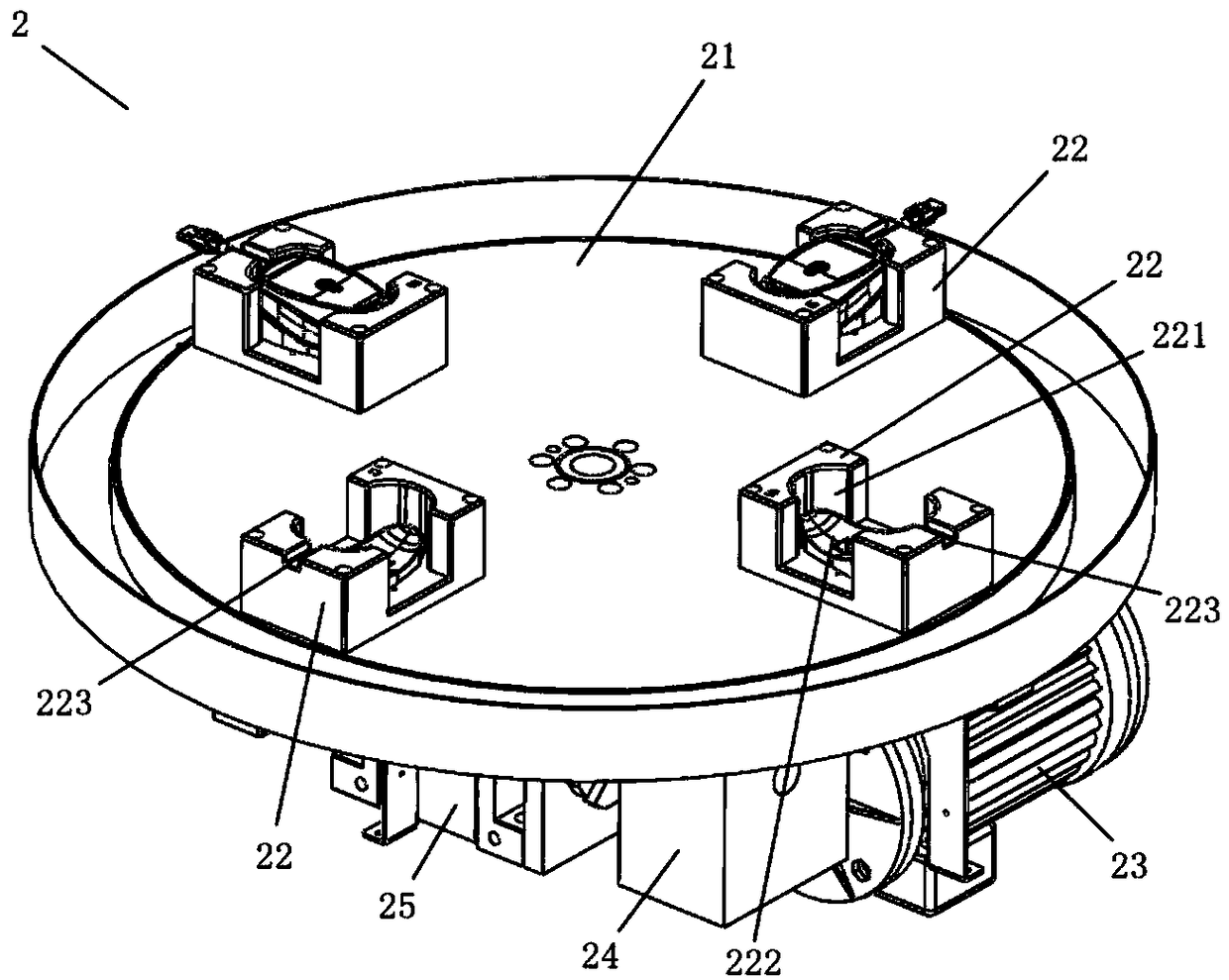

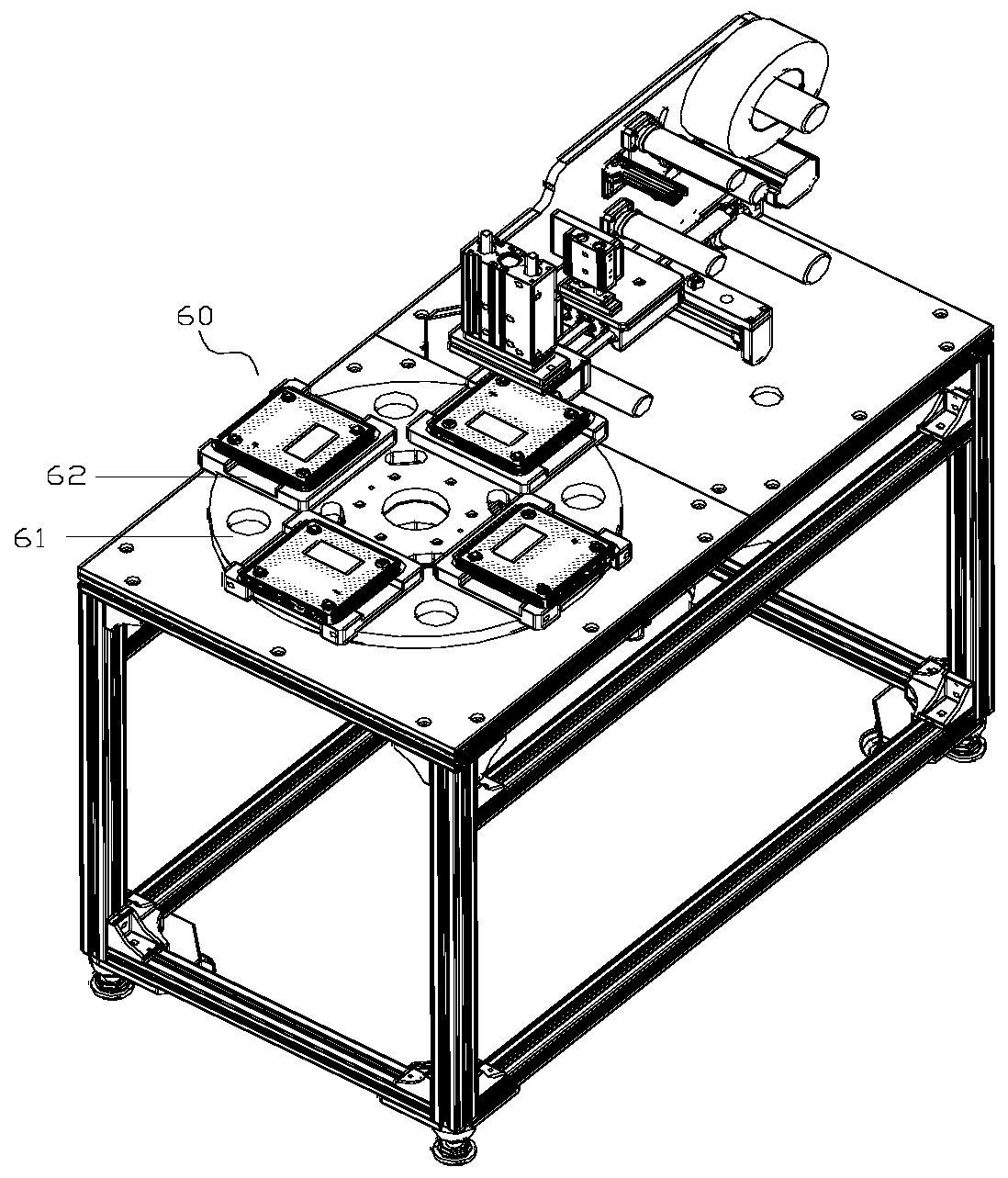

Mouse label sticking and inspection device

ActiveCN109204989AReduce manual labor intensityAvoid labeling position deviationPlastic recyclingLabelling flat rigid surfacesTransfer mechanismCcd camera

The invention relates to a mouse label sticking and inspection device including a framework. A label stripping machine is arranged in the framework. A rotary disc mechanism, a pressing mechanism, a sticking and inspection mechanism, a suction and transfer mechanism, a blanking line body, and a material feeding and discharging line body. The rotary disc mechanism is arranged on a platform at the middle of the framework, wherein the pressing mechanism, the sticking and inspection mechanism, the label stripping machine, the sticking and inspection mechanism and the blanking line body are clockwisely arranged around the rotary disc mechanism successively. The rotary disc mechanism includes a rotary disc and a motor, wherein the rotary disc is provided with a carrier. The pressing mechanism includes a pressing cylinder and a pressing plate. The sticking and inspection mechanism includes a mechanical arm, a CCD camera, and a suction head. The suction and transfer mechanism includes a positioning frame, a sliding frame, and a lifting board provided with a spring suction disk. The device is used for automatically sticking a label on a mouse and inspection, can reduce labor intensity and can guarantee product consistency.

Owner:苏州镭拓精工机械科技有限公司

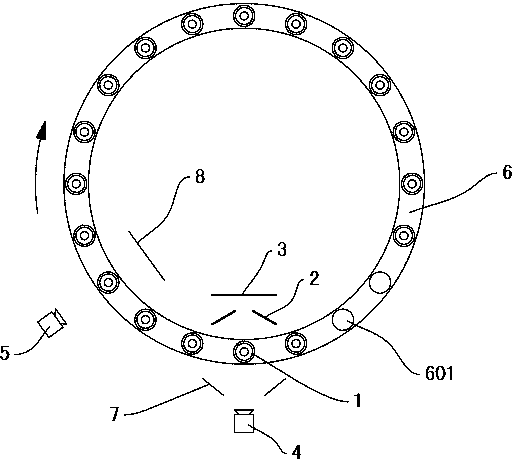

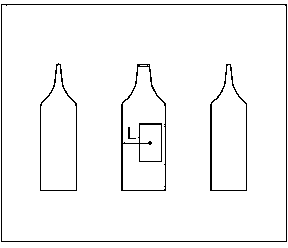

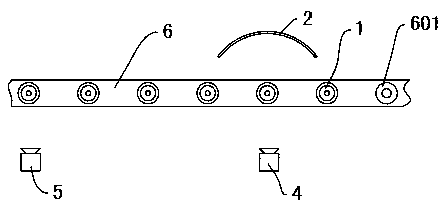

Container labeling position adjustment system and method for labeling container

InactiveCN104071403AReduce in quantityLow costLabelling machinesLabelling short rigid containersComputer visionMirror image

The invention relates to a container labeling position adjustment system and a method for labeling a container, and particularly relates to a device and a method for accurately labeling the surface of the container. Two reflective mirrors (2) are fixed on the other side of a transmission device (6), which is opposite to a first camera (4), the first camera (4) and the two reflective mirrors (2) respectively correspond to a range of 120 degrees on the circumference of the container (1), mirror images of the container (1) in the reflective mirrors (2) are positioned in an imaging range of the first camera (4), and an image of the whole surface of the container (1) can be collected by the first camera (4), so as to determine the position of a designator. The method for labeling the container comprises the following steps: calibrating the first camera (4) and a second camera (5) first, then performing coarse positioning by utilizing an image shot by the first camera (4), and finally, performing fine positioning by utilizing the second camera (5), so that one side of the designator of the container (1) and a to-be-pasted label are accurately positioned. The method has the advantages of low cost, high detection efficiency and the like.

Owner:北京创想智控科技有限公司

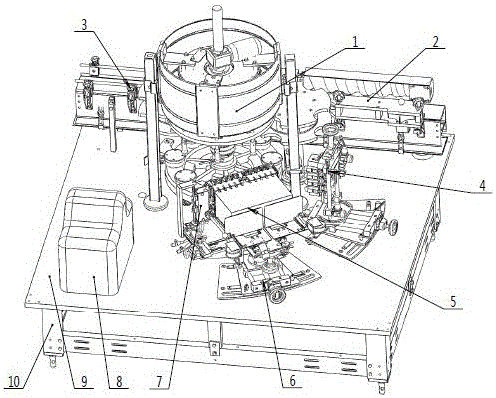

Thin-walled cylinder hot melt glue labeling machine

The invention discloses a thin-walled cylinder hot melt adhesive labeling machine. The thin-walled cylinder hot melt glue labeling machine comprises a bottle carrying and transferring table, a bottle feeding device, a glue spraying device, a split floating label bin, a glue scrapping device, a glue melting box and a bottle discharging device, wherein the bottle carrying and transferring table are installed in the center of the table surface of a rack, and the bottle feeding device, the glue spraying device, the split floating label bin, the glue scrapping device, the glue melting box and the bottle discharging device are located on the table surface of the rack and distributed on the periphery of the bottle carrying and transferring table. An adjustable label box is installed at the front end of a base plate in the split floating label bin, an auxiliary label feeding device is installed at the rear end of the base plate, elastic label pushing devices are symmetrically installed on the left side and the right side of the base plate correspondingly, and a rolling label feeding chain way is installed in the middle of the base plate. According to the thin-walled cylinder hot melt glue labeling machine, modularized design and a mechanical automatic production line of the composition structure are achieved, whole cylinder body labeling of labels with large diameters and widths of thin-walled paper cylinders, thin-walled metal cylinders and the like can be achieved, the replacing frequency of the labels can be greatly reduced through the label bin with a high capacity, operation of an operator is facilitated, production efficiency is greatly improved, the labeling quality and labeling precision are further improved, and production cost is maximally reduced.

Owner:莱州市同力机械有限公司

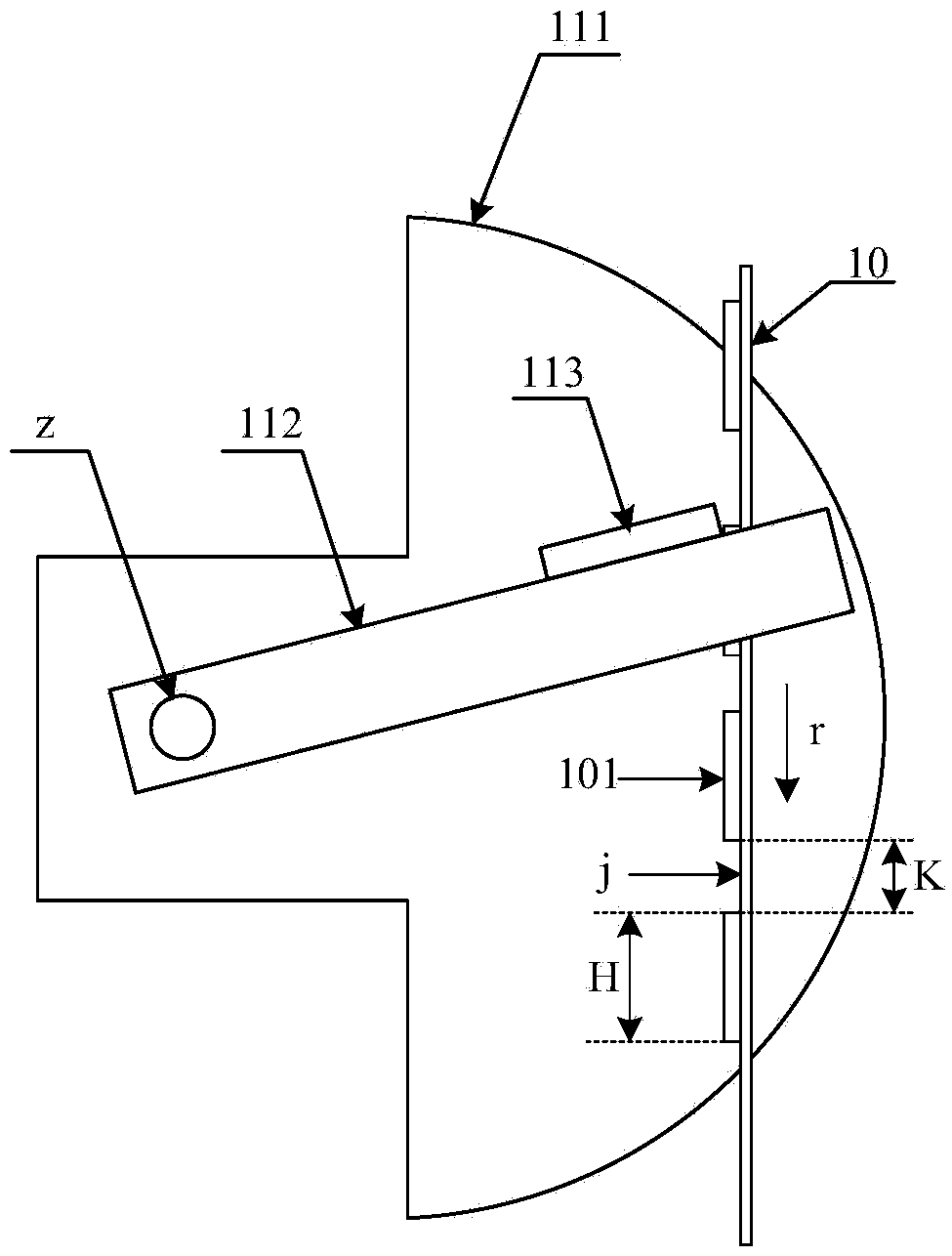

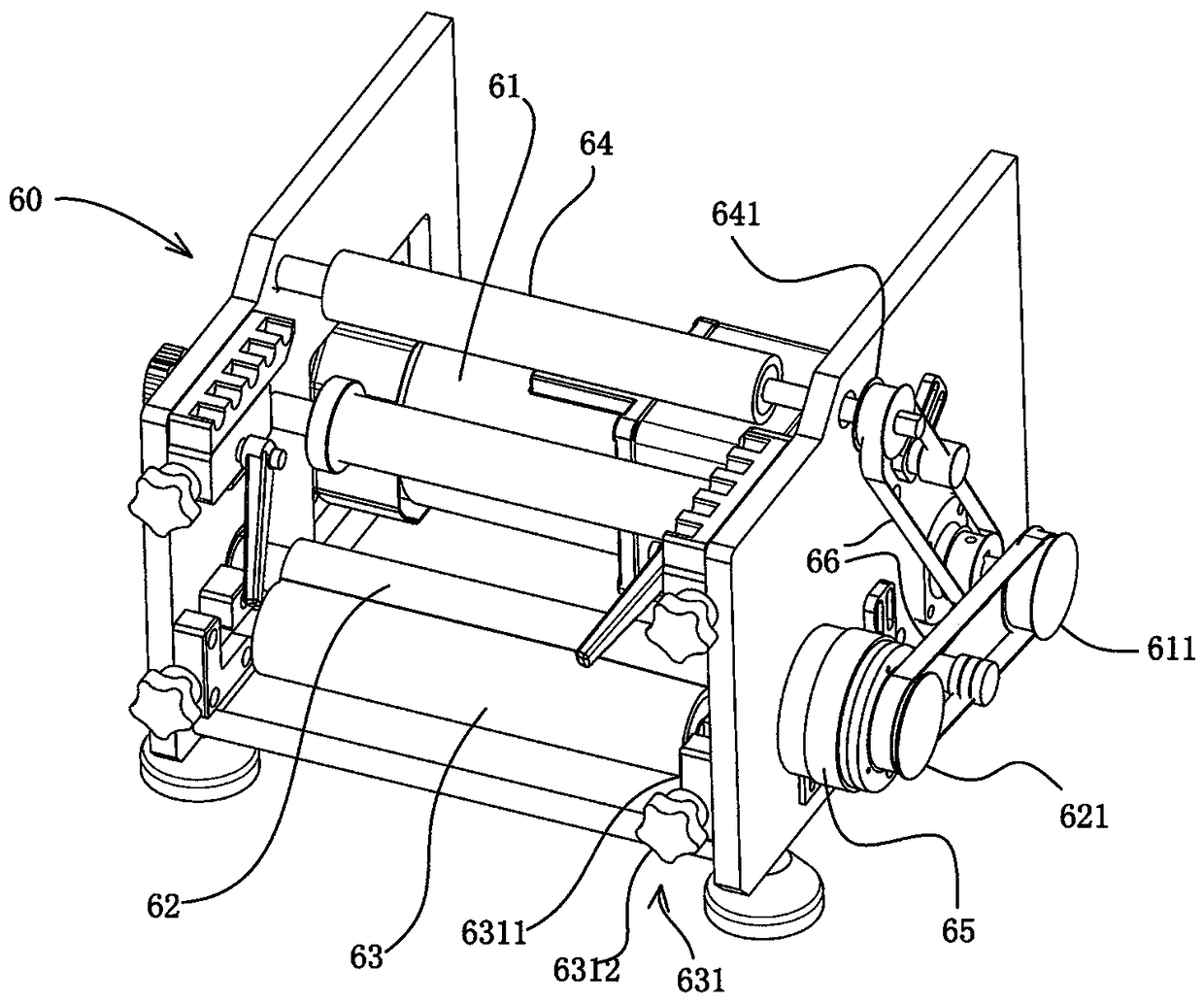

Copying labeling machine

InactiveCN102372103AHigh labeling accuracyHigh precisionLabelling machinesLabelling short rigid containersCopying mechanismElectric machinery

The invention, relating to the technical field of labeling machines, discloses a copying labeling machine, comprising a machine frame and a control cabinet, wherein, the control cabinet is arranged on the machine frame, the machine frame is provided with a feeding mechanism, the labeling machine is provided with a rotating actuating motor, one end of the feeding mechanism is provided with a top bottle mechanism, the other side of the top bottle mechanism is provided with a manipulator grabbing unit, the labeling machine is provided with a labeling copying mechanism, the labeling machine is provided with a pressing unit, and the pressing unit is provided with a membrane labeling system. The labeling machine can label round an oval-shaped bottle, a waist-round bottle and other abnormal-shaped bottles with high labeling precision.

Owner:东莞市祥搏机电设备有限公司

Injection molding machine with automatic label delivering system

The invention relates to the technical field of labeling devices, in particular to an injection molding machine with an automatic label transferring system. The injection molding machine comprises a label roll unwinding device, a label transferring device, a label transferring axis, a label vacuum adsorbing and transferring device, a label adsorption die cavity transferring device and a mechanical arm, wherein the lower part of the label roll unwinding device is jointed with the label transferring device; the label transferring device is in fit joint with the label transferring axis and the label vacuum adsorbing and transferring device; and the other end of the label transferring axis is jointed with the label adsorption die cavity transferring device which is in fit joint with the mechanical arm. Compared with the prior art, the injection molding machine is novel and simple in structure and convenient to operate, realizes labeling automation, has the advantages of low possibility of damaging the label, high labeling precision, quick labeling and the like, improves the working efficiency and realizes mechanical automation.

Owner:ATRA PLASTICS SHANGHAI

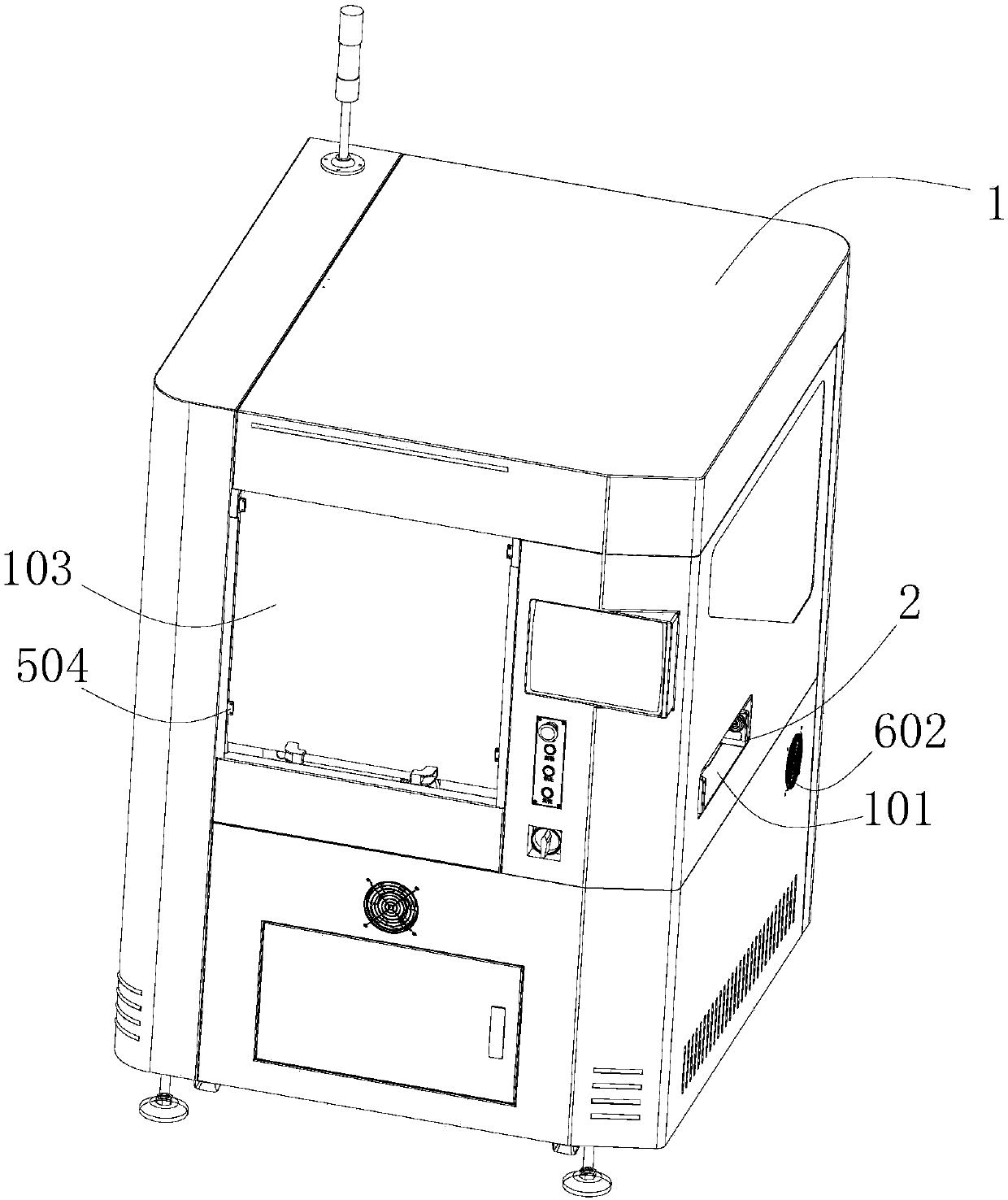

Automatic labelling machine

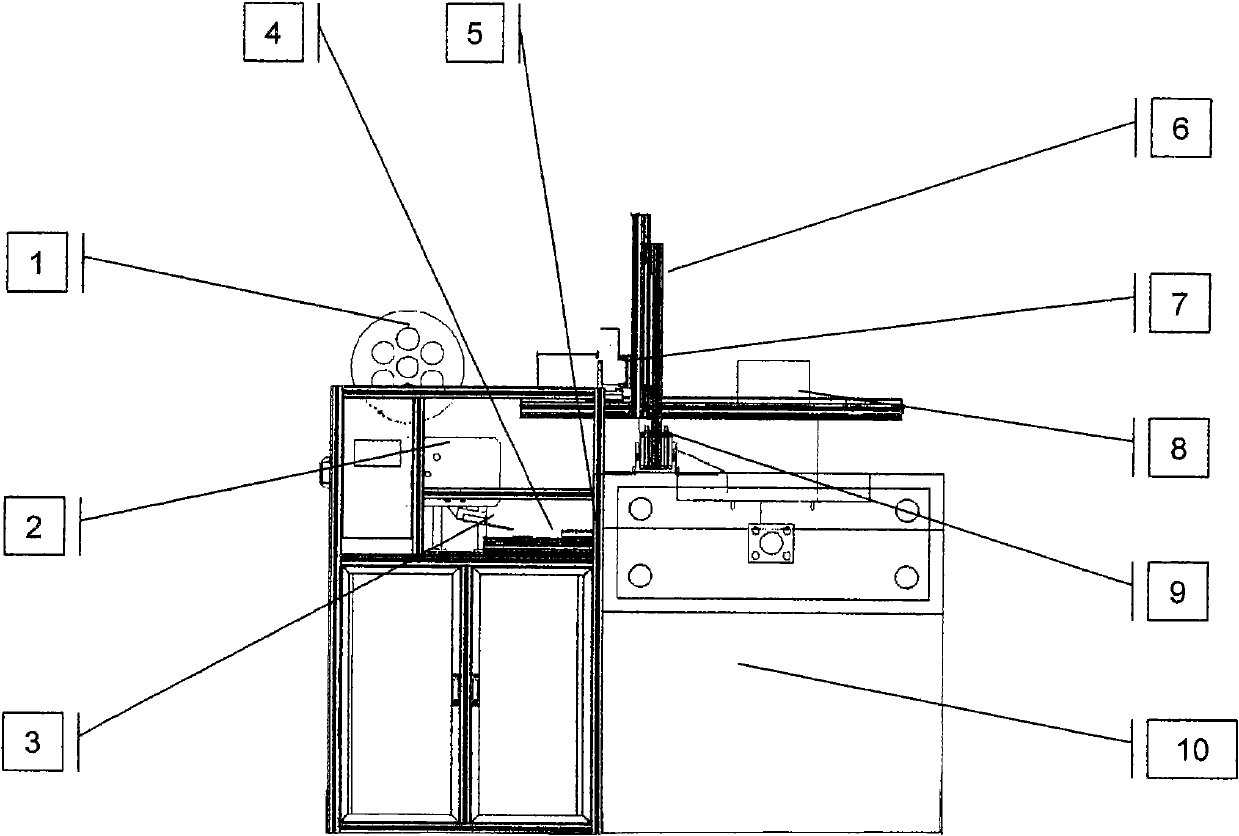

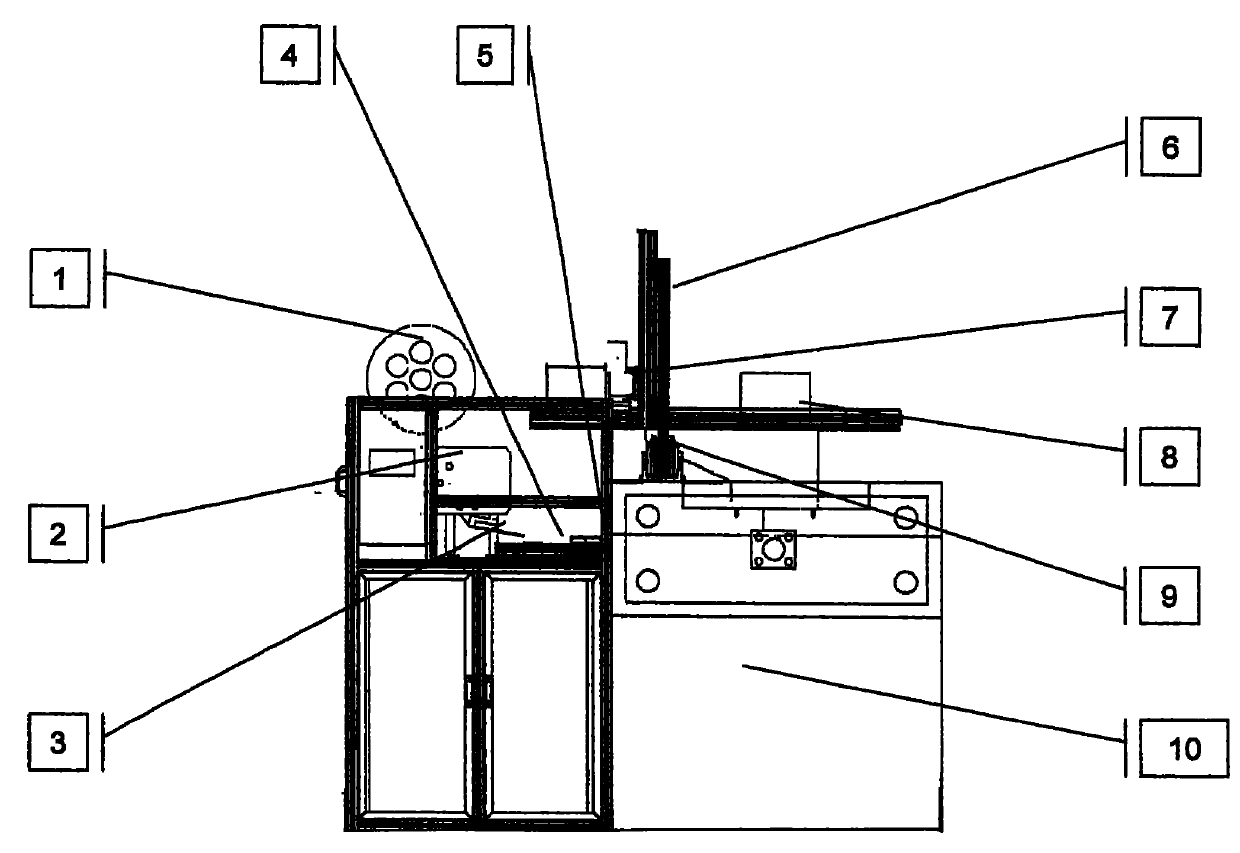

PendingCN107554905APrecise positioningWith modular designLabelling machinesProduction lineControl system

The invention discloses an automatic labelling machine and belongs to an intelligent robot. The automatic labelling machine comprises a labelling machine complete machine, wherein a circuit board inlet, a circuit board outlet and an observation door are arranged on side faces of the labelling machine complete machine; a conveyer for conveying a circuit board, a label feeding device for conveying label paper and a labelling device are arranged in the labelling machine complete machine; the labelling device takes out the label paper sent out by the label feeding device and pastes the label on the label paper onto the circuit board of the conveyer; the labelling machine complete machine is connected with a control system for setting a labelling position; and the control system is in communication connection with the label feeding device and the labelling device. According to the automatic labelling machine, the labelling device and the label feeding device are positioned on the side of the conveyer, so that the path that a labelling head moves to the label feeding device is short, and the labelling speed is high; the control system is accurate in positioning, high in labelling precision and safe to operate; and design of the observation door saves space, and the complete machine can use the circuit boards with different specifications and can be matched with other machines at willto construct the automatic labelling machine of a production line.

Owner:广东腾山机器人有限公司

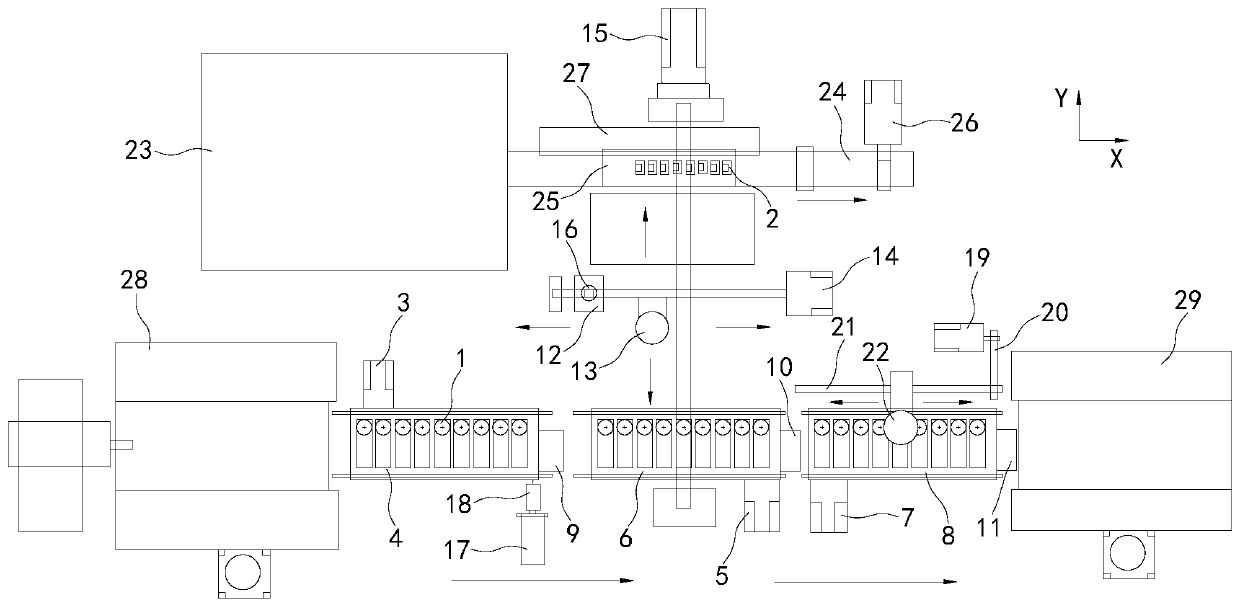

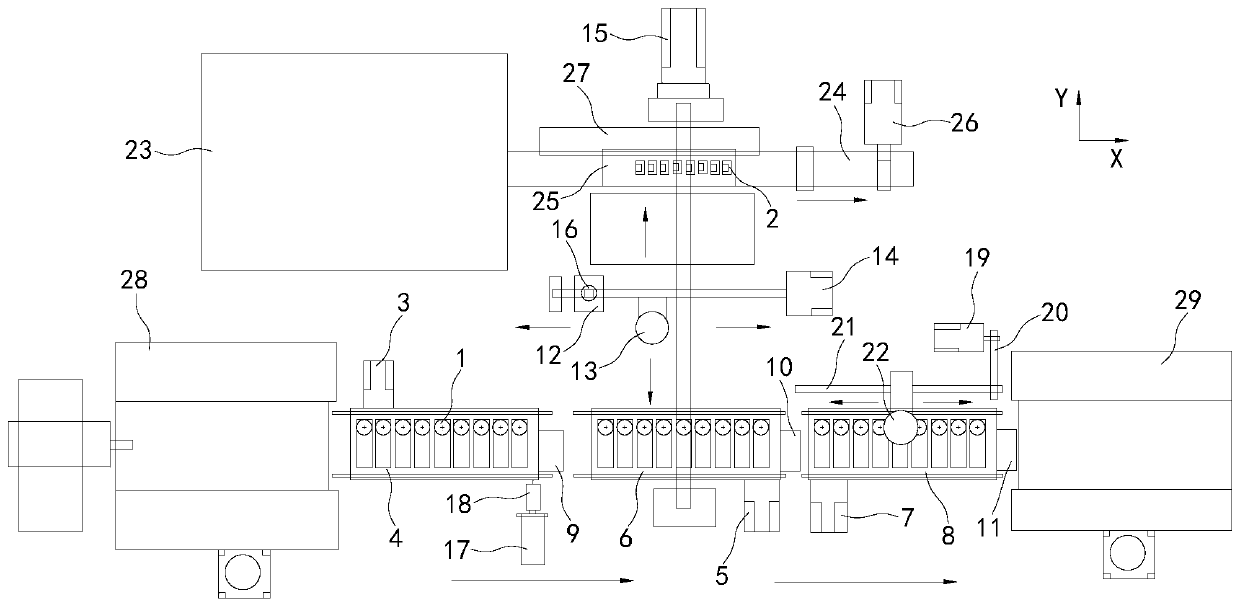

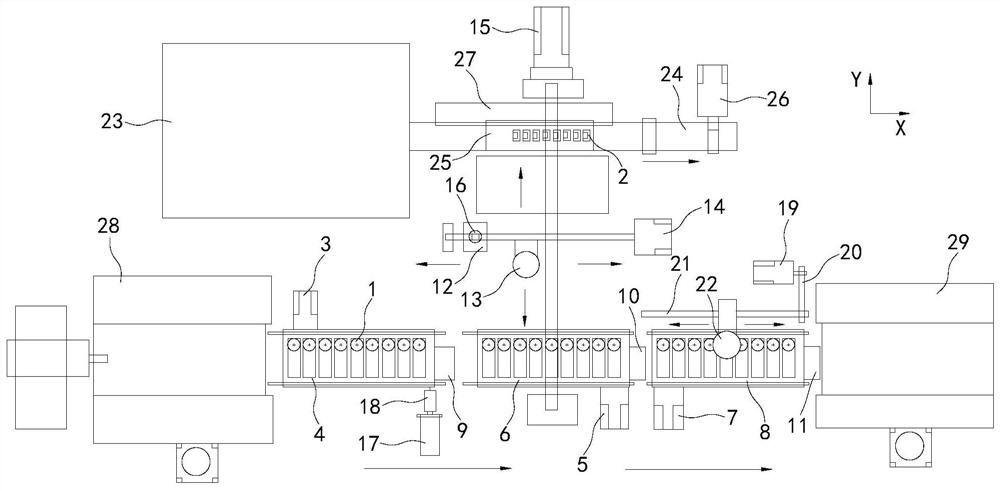

Full-automatic labeling equipment for electronic component based on visual deviation rectification

ActiveCN110002070AAvoid position deviationImprove efficiencyLabelling machinesAutomatic test equipmentVision based

The invention discloses full-automatic labeling equipment for an electronic component based on the visual deviation rectification. The full-automatic labeling equipment comprises a first transmissionmechanism, a second transmission mechanism, a third transmission mechanism and a labeling device, the first transmission mechanism, the second transmission mechanism and the third transmission mechanism are connected in sequence, the labeling device is located on the second transmission mechanism, a scanning assembly is arranged on the first transmission mechanism, a detecting assembly is arrangedon the third transmission mechanism, and the scanning assembly is in communication connection with the labeling device. The scanning assembly is used to obtain the master code on a circuit board, thelabeling device is used to label the code label corresponding to the master code on the circuit board, the visual deviation rectification is conducted on the label position and the positive and negative polarity through the labeling assembly, the automatic labeling of the circuit board is achieved, and the advantages of being high in efficiency and high in labeling precision are achieved.

Owner:SHENZHEN GRAND INNOSYS CORP

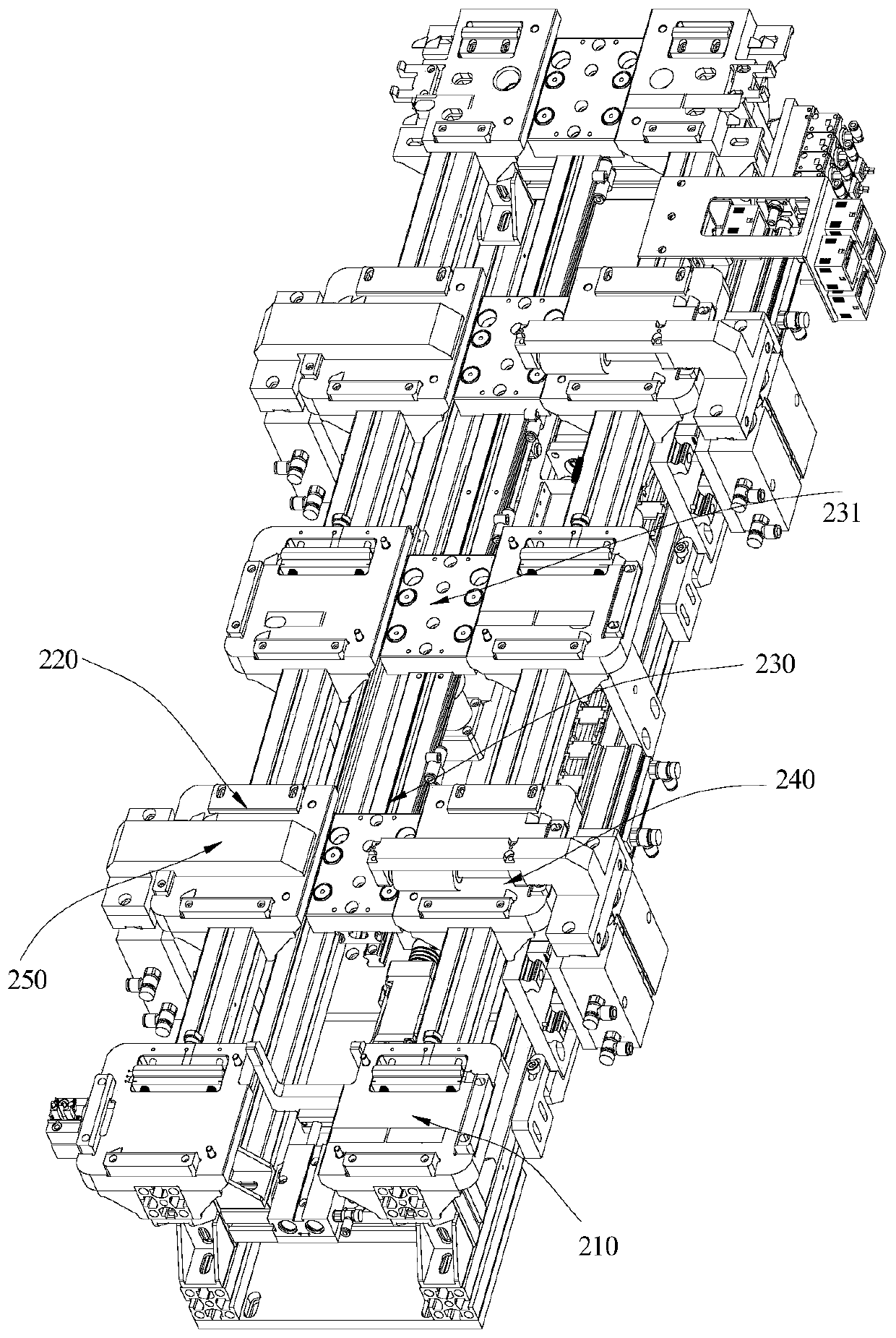

High-precision battery labeling structure

PendingCN109502122AEasy to identifyHigh labeling accuracyLabelling machinesEngineeringElectrical and Electronics engineering

The invention relates to the technical field of battery production, in particular to a high-precision battery labeling structure. The high-precision battery labeling structure comprises an unwinding assembly, a labeling assembly, a track assembly, and an attached platform assembly, wherein at least one pair of the unwinding assembly and the labeling assembly is symmetrically arranged on the two sides of the track assembly correspondingly; the unwinding assembly transports labeled roll films to the labeling assembly; the attached platform assembly is arranged on the track assembly; the labelingassembly includes an absorption rod for adsorbing labels; and the track assembly includes a circular track; and the attached platform assembly includes a base and a mounting block. When the base slides on the circular track, the mounting block keeps the direction of batteries at all times; when the base slides on the circular track to a labeling station, the base stops sliding; the absorption rodattaches the labels to the batteries; and after the completion, the base continues to slide. According to the high-precision battery labeling structure, the labeling on both sides of a battery in theworkflow is completed, the requirement of the various shape labels is met, the precision is high, the labor cost is reduced and the production efficiency is improved.

Owner:丰川泽精工机械无锡有限公司

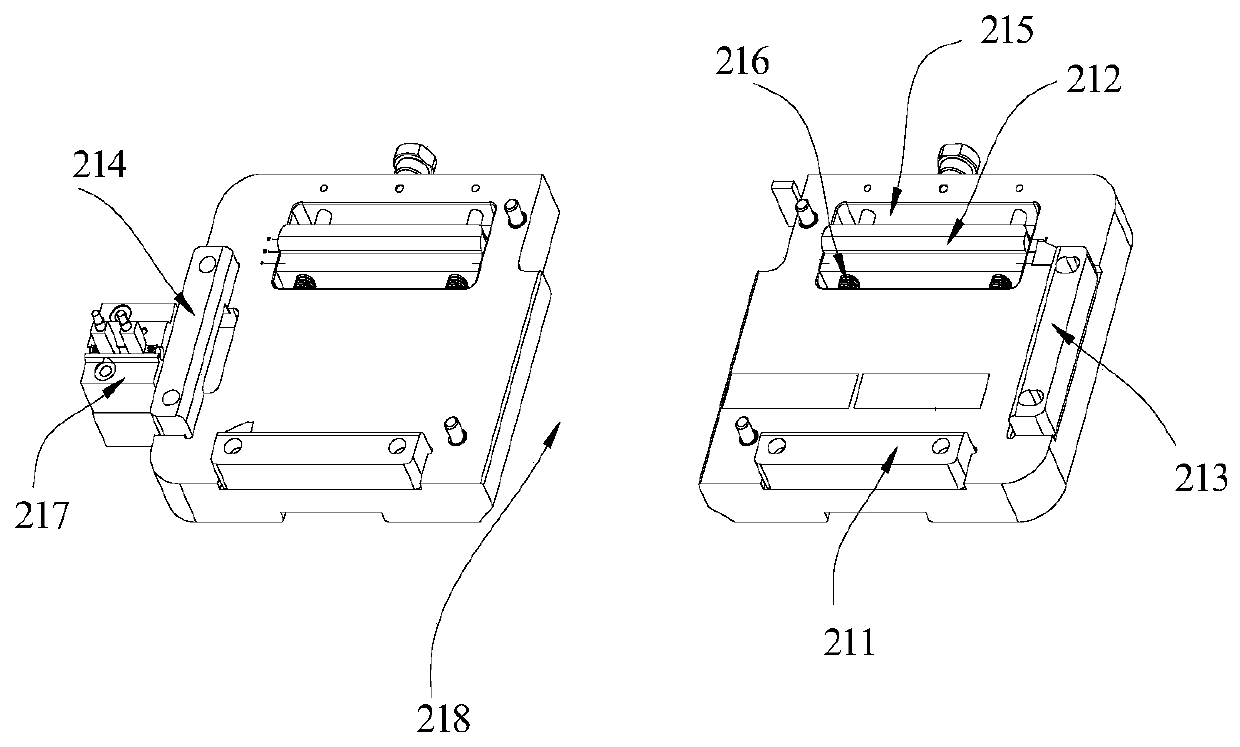

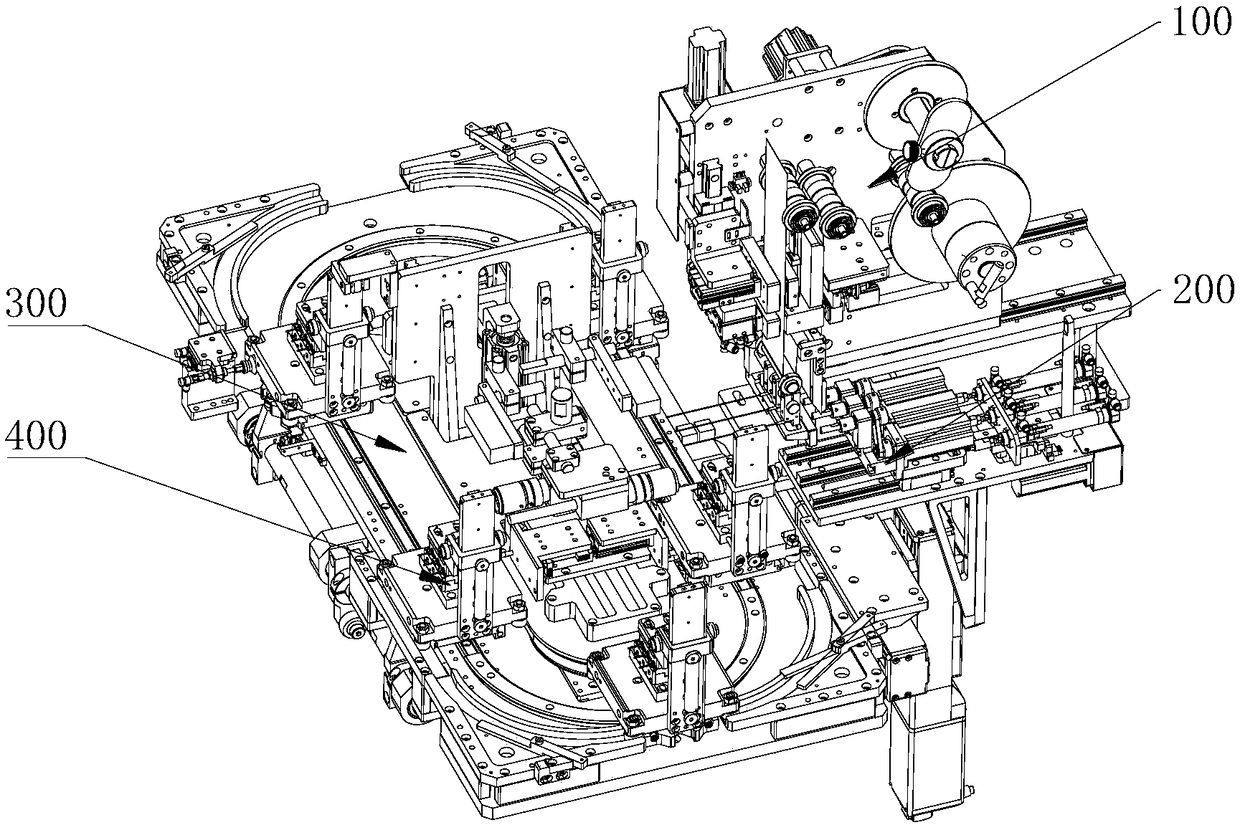

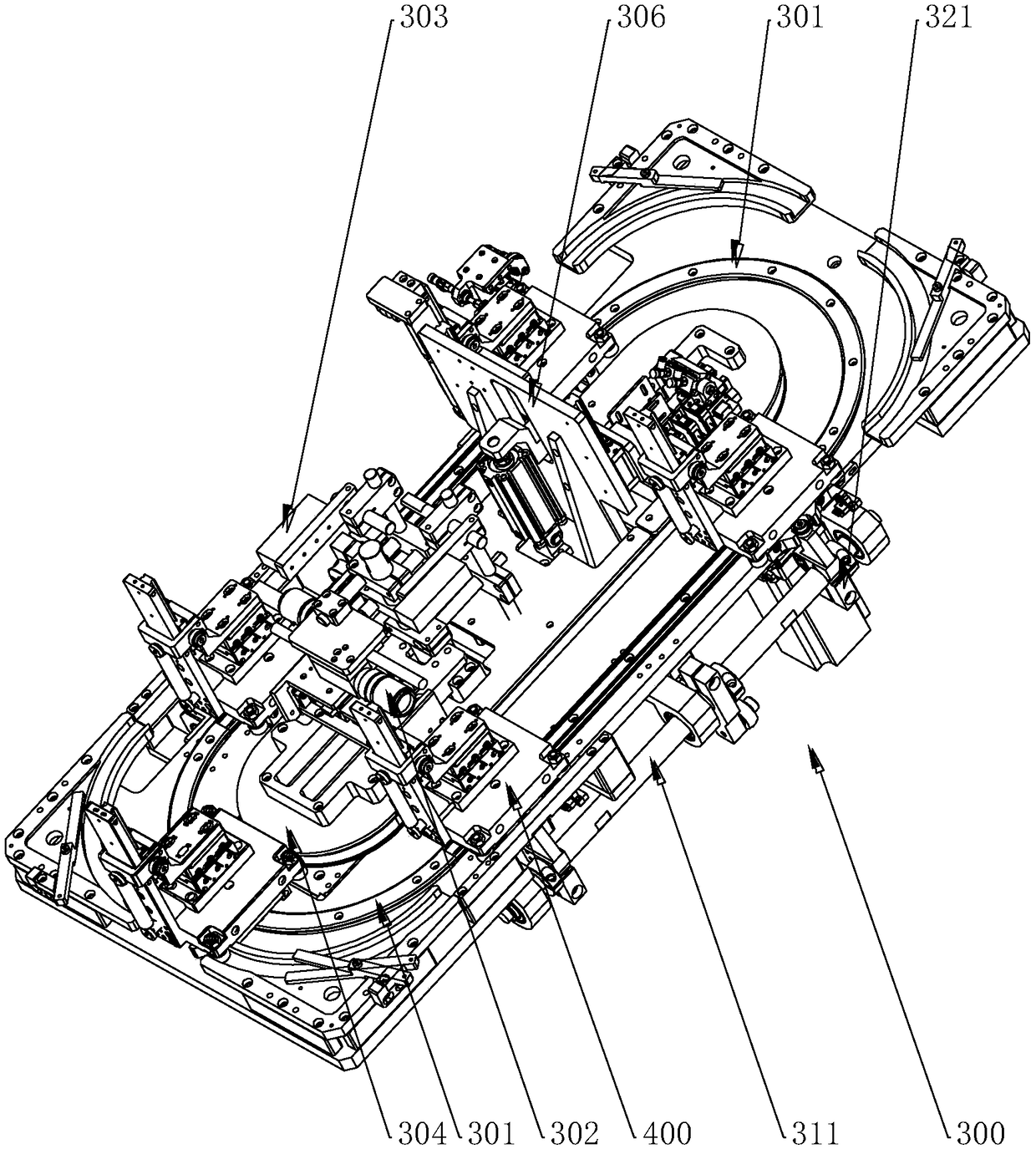

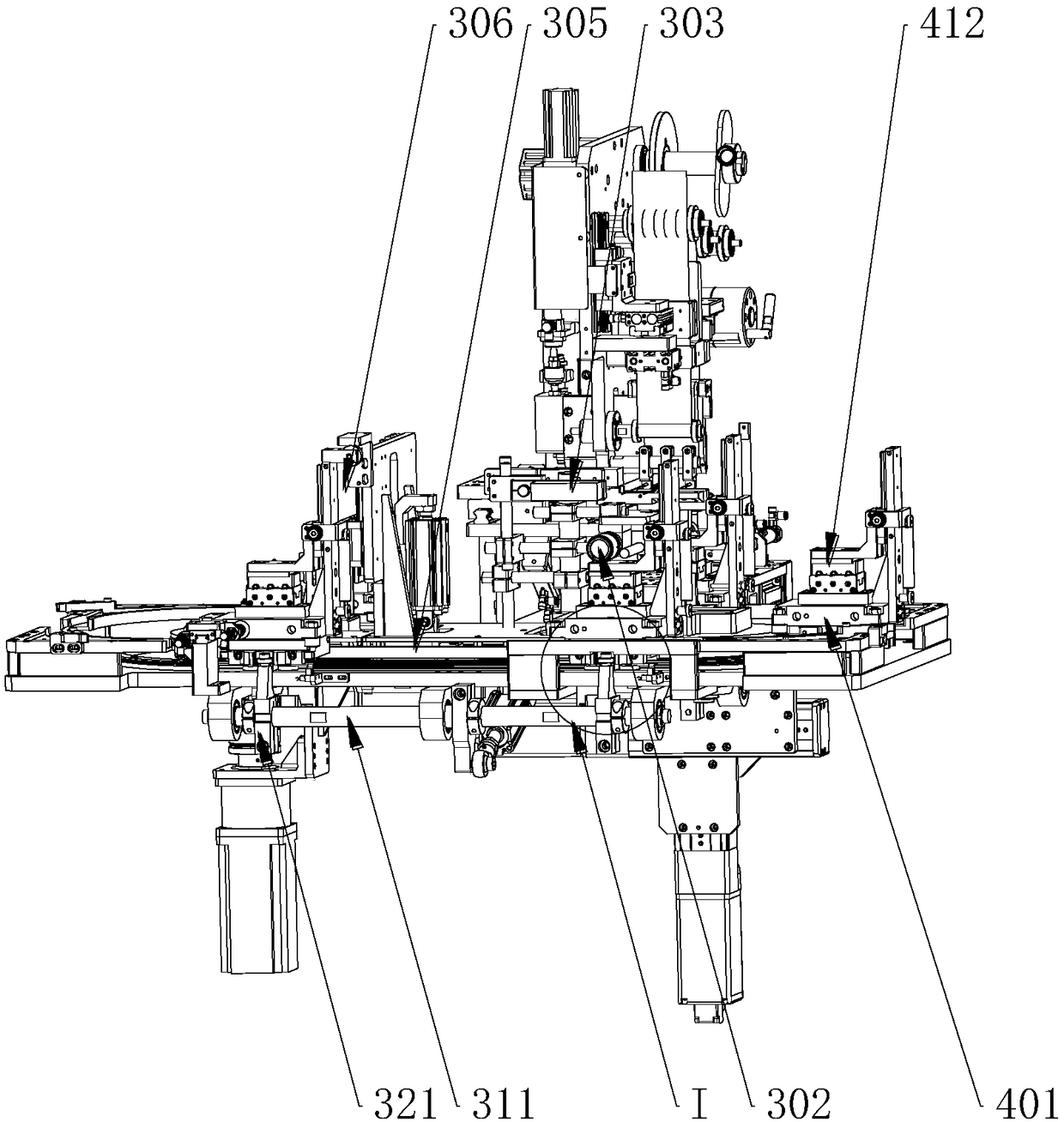

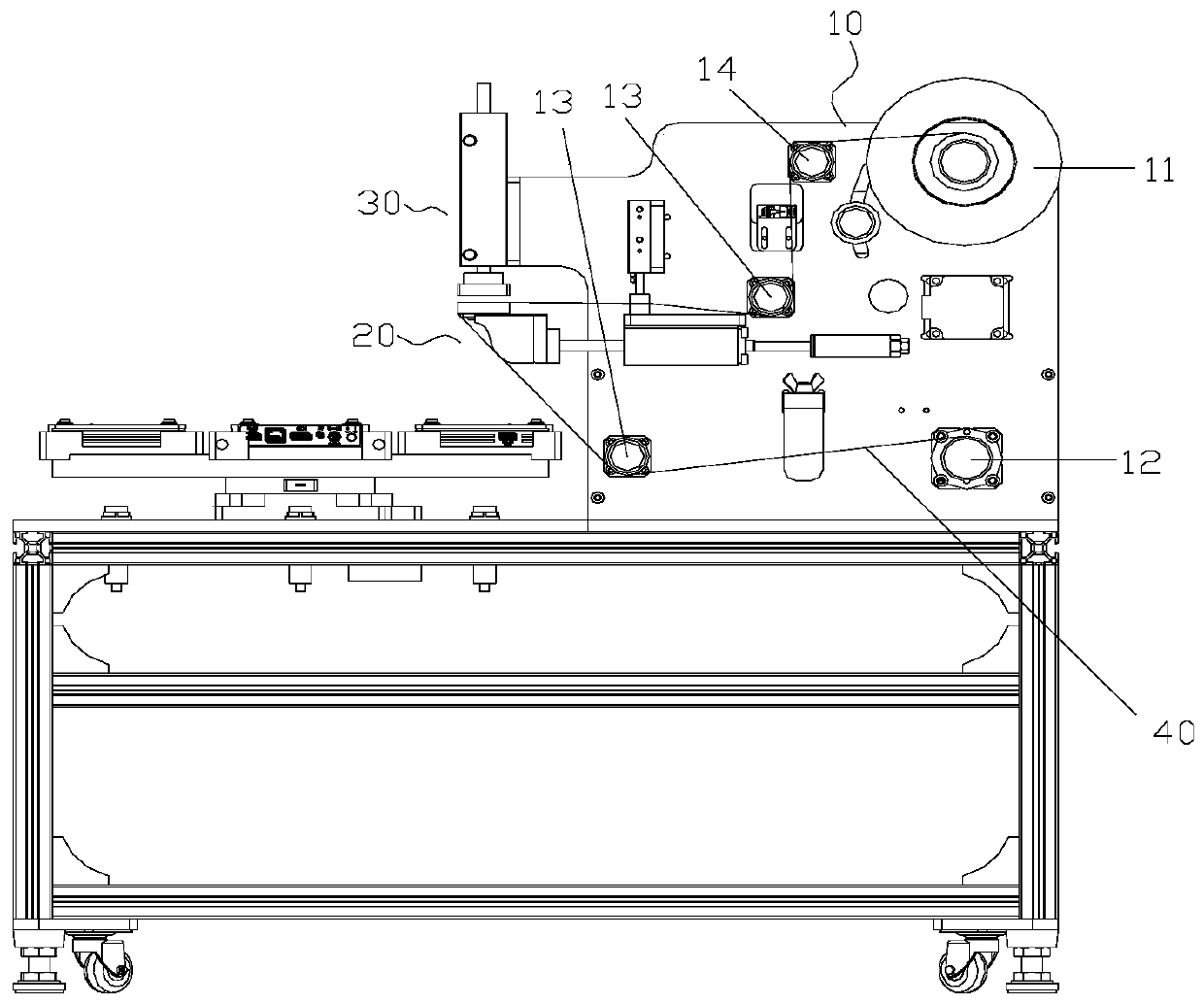

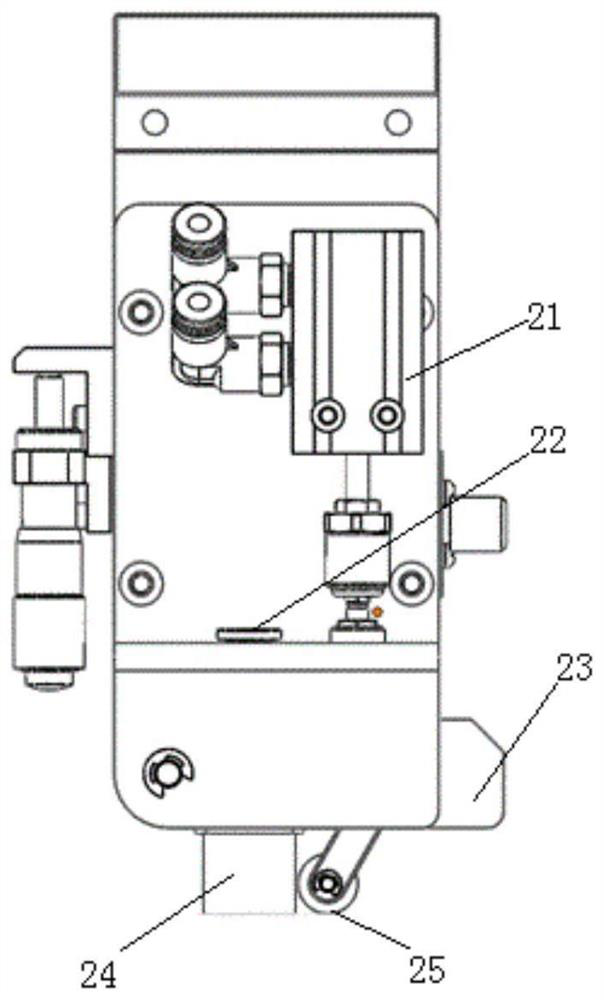

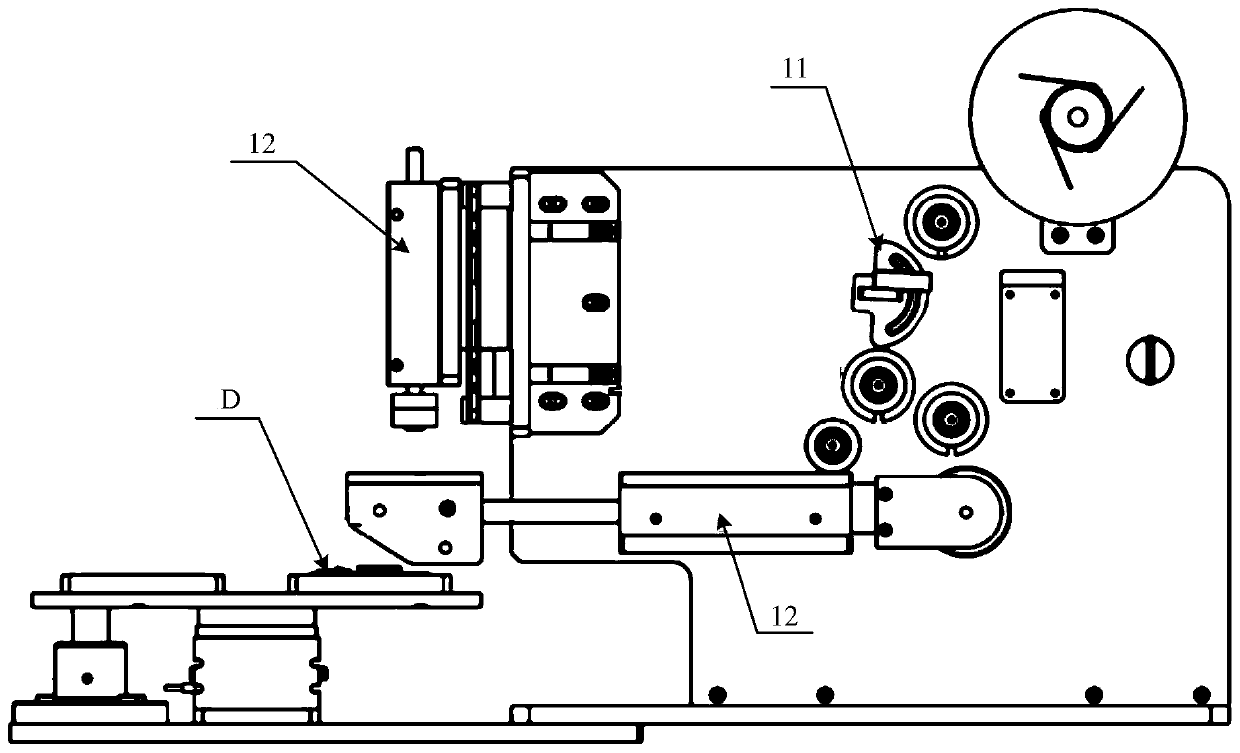

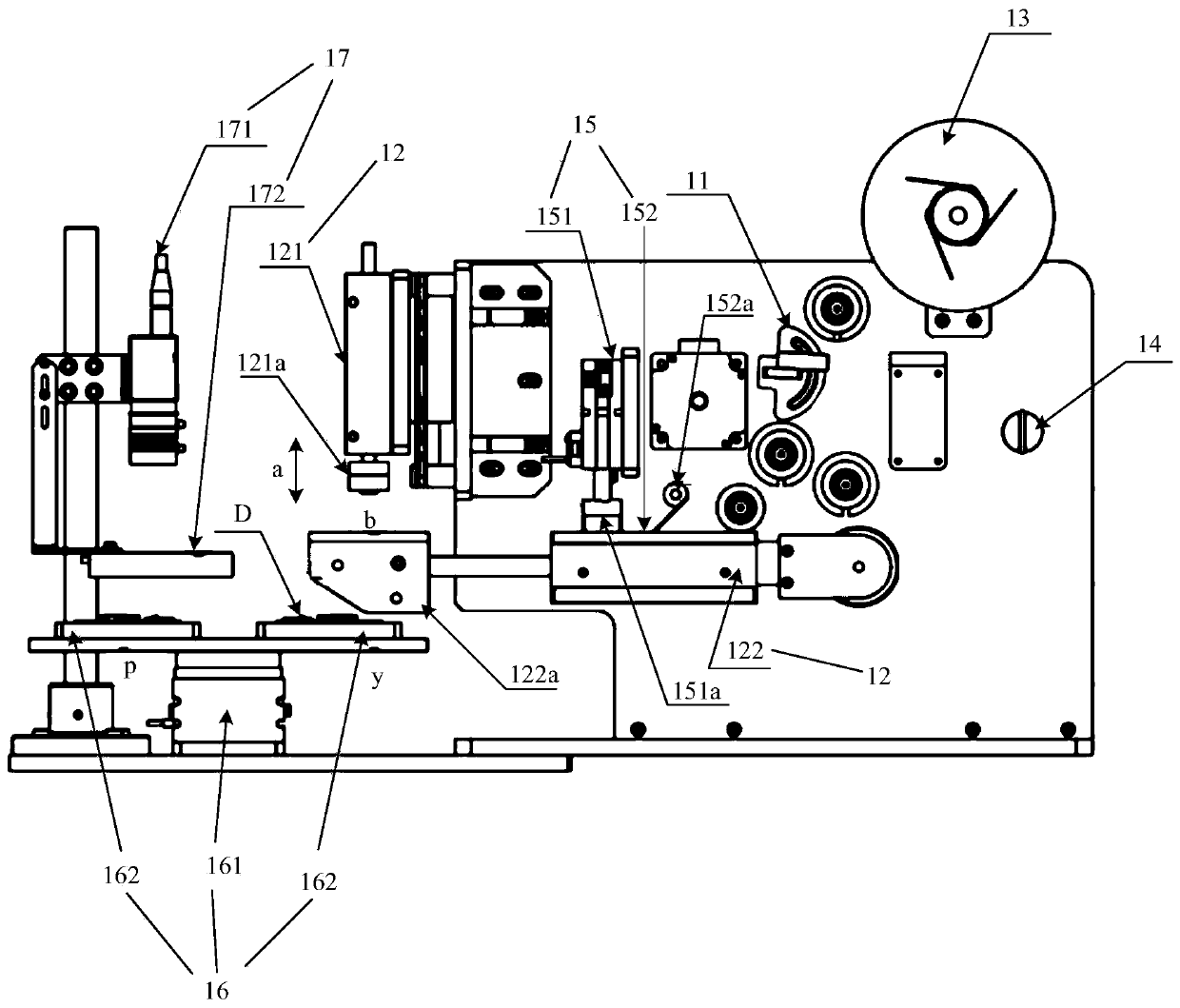

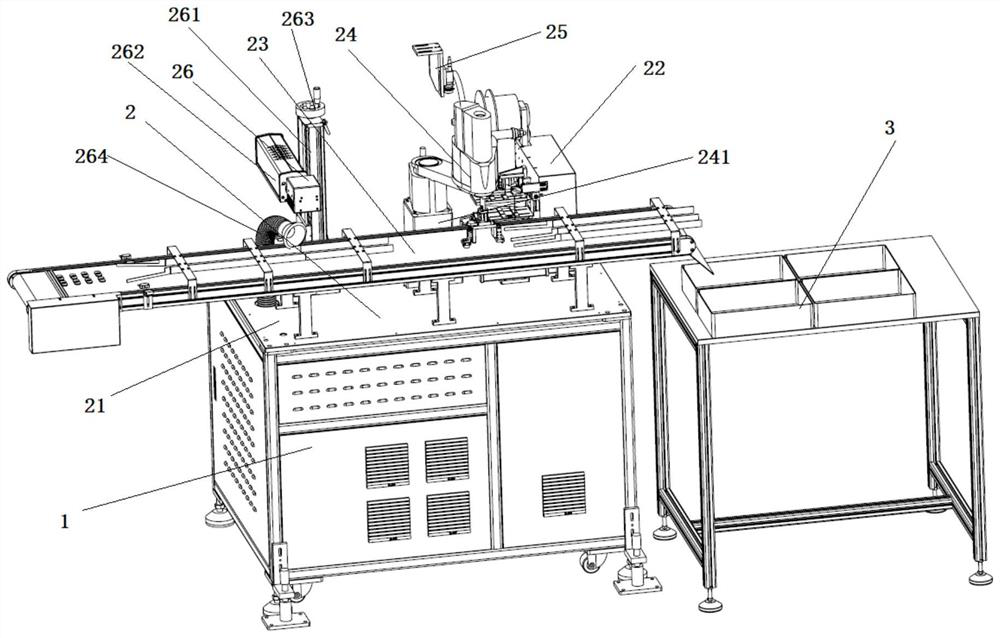

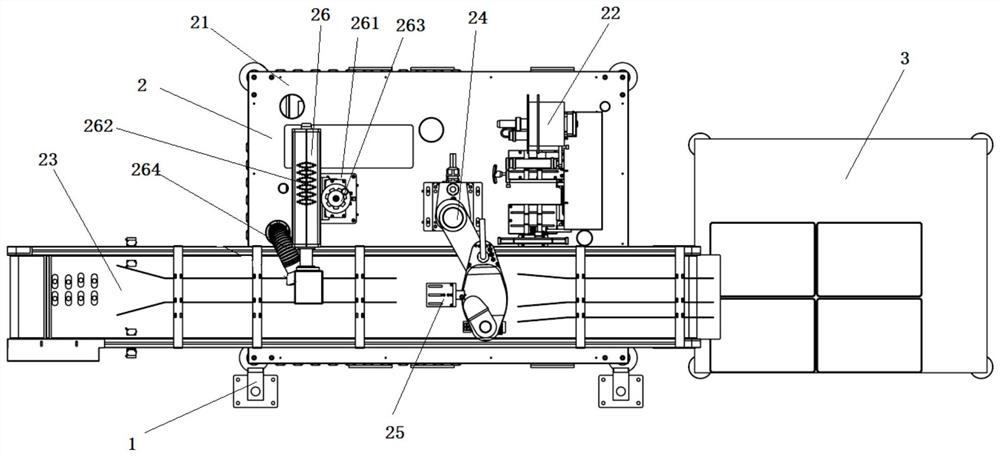

Suction labeling type automatic labeling structure, labeling method and set-top box labeling mechanism

PendingCN109760910AHigh labeling accuracyImprove efficiencyLabelling machinesLabelling machineEngineering

The invention relates to the technical field of labeling machines, in particular to a suction labeling type automatic labeling structure, a labeling method and a set-top box labeling mechanism. The automatic labeling structure is used for performing stripping and labeling on wound label rolls and is characterized by comprising a label conveying mechanism, a stripping mechanism and a labeling mechanism; the label conveying mechanism comprises a label roller, a label collecting roller, a pulling roller group and a guiding roller group; a label roll is arranged on the label roller; a pulled-out label tape winds around the pulling roller group and the guiding roller group sequentially and winds around the stripping mechanism for completion of stripping; the stripped label tape winds around thelabel collecting roller; the labeling mechanism sucks stripped labels at the stripping mechanism and moves to to-be-labeled positions. The invention aims to provide the suction labeling type automatic labeling structure, the labeling method and the set-top box labeling mechanism. With the adoption of the technical scheme, the technical problems of low labeling efficiency and precision and high cost of existing labeling manners are solved.

Owner:UNIONMANTECH

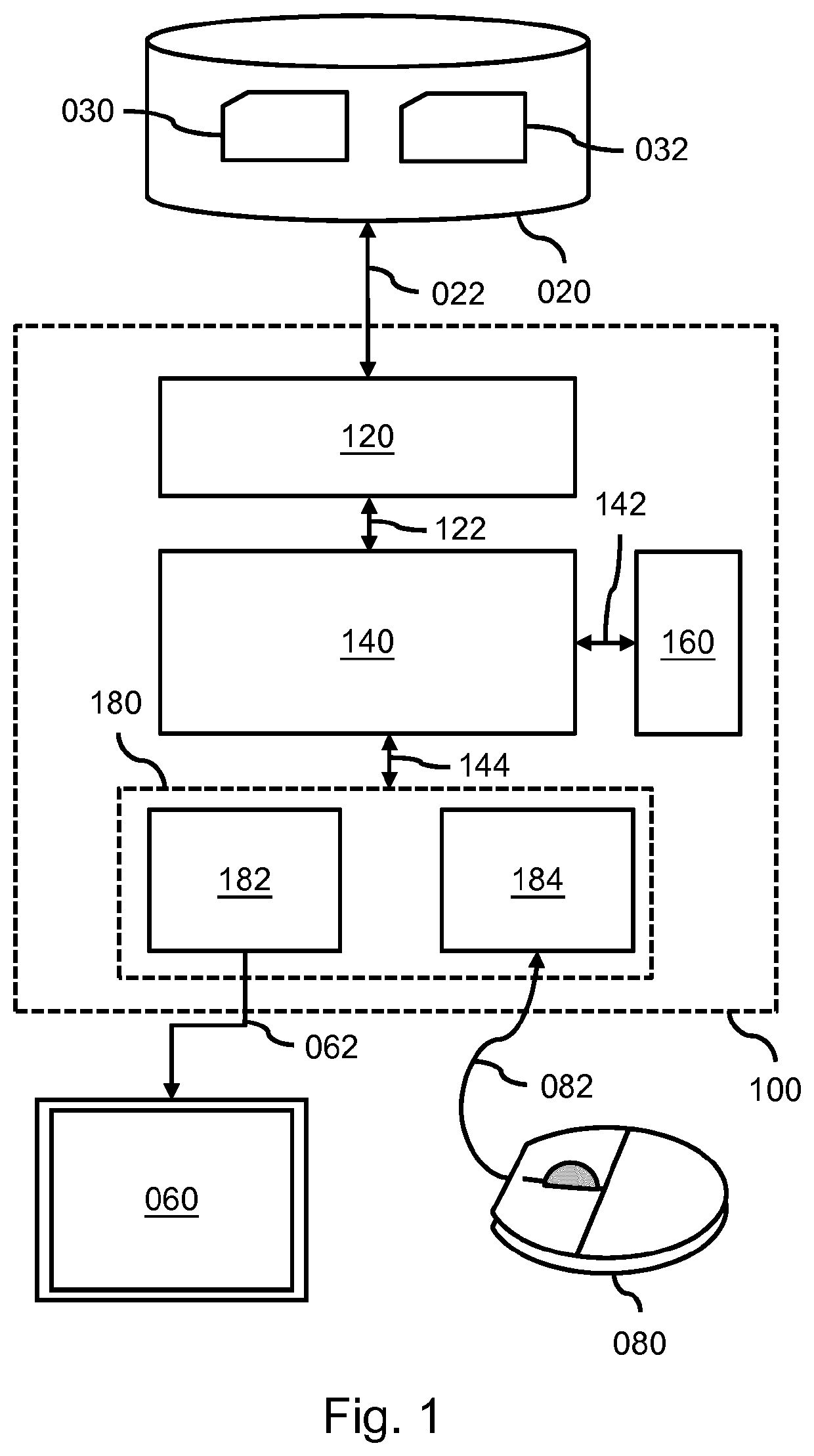

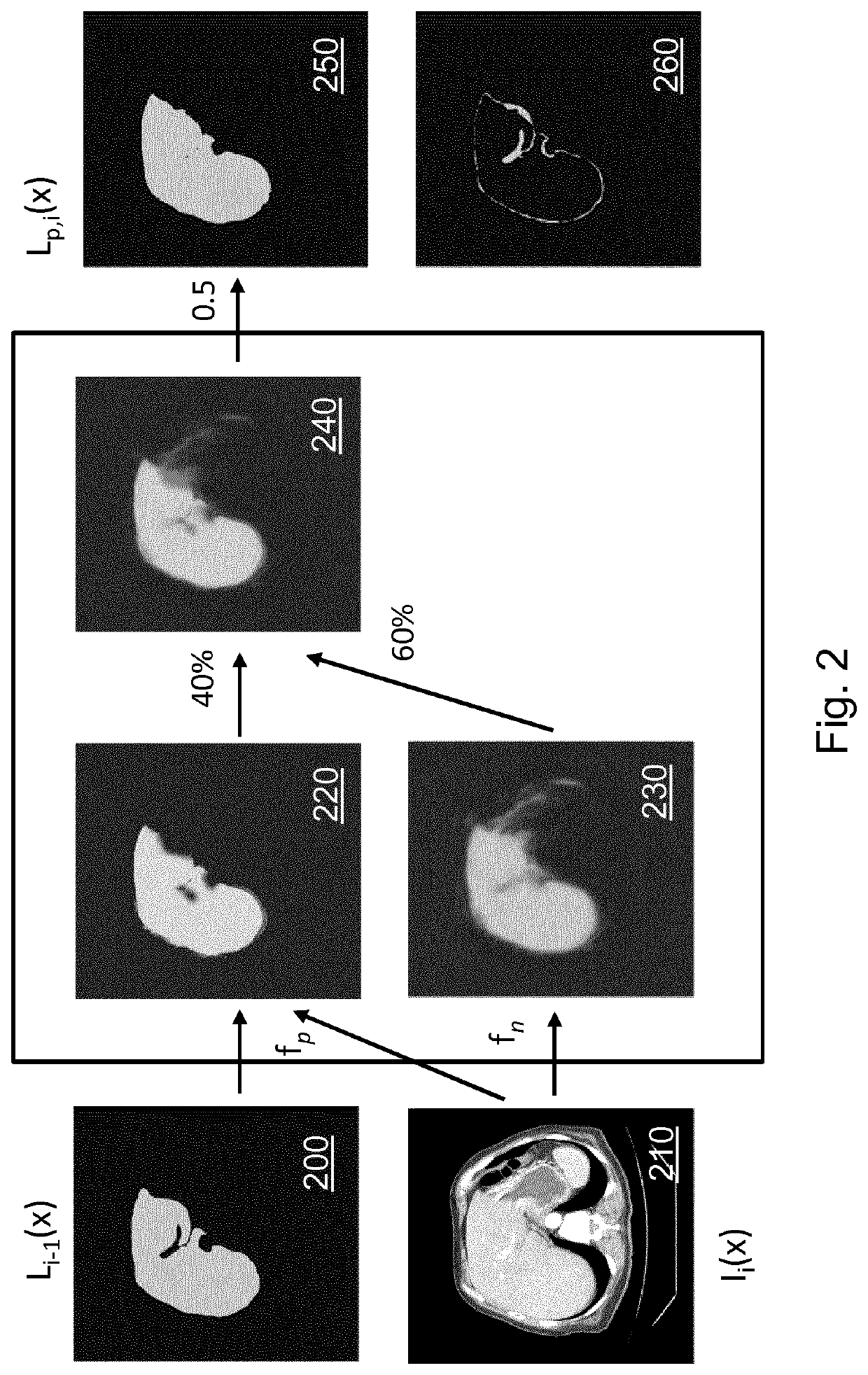

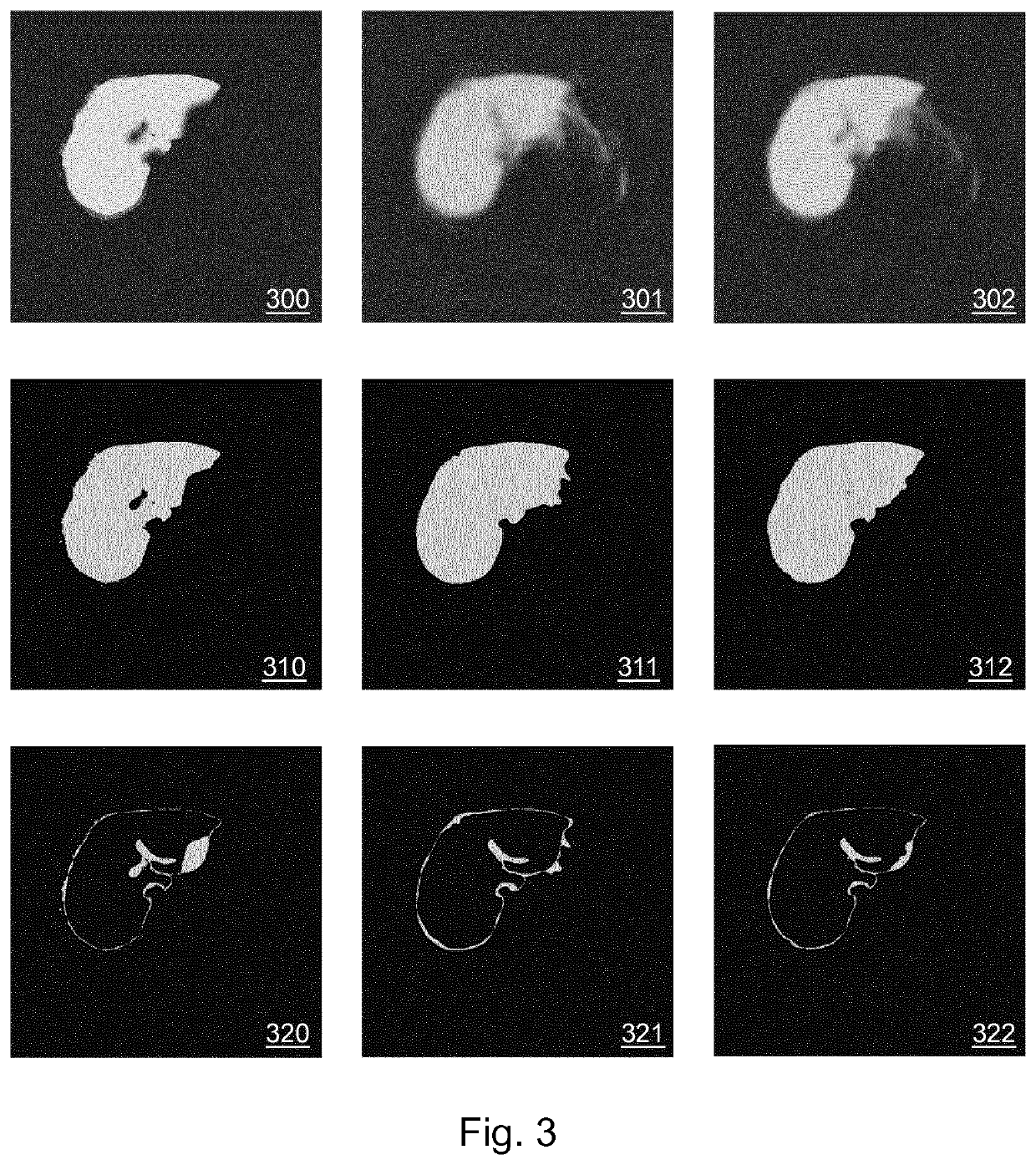

Interactive iterative image annotation

PendingUS20220019860A1Accurate labelingLess interaction timeMedical automated diagnosisMachine learningPattern recognitionUser verification

A system and computer-implemented method are provided for annotation of image data. A user is enabled to iteratively annotate the image data. An iteration of said iterative annotation comprises generating labels for a current image data part based on user-verified labels of a previous image data part, and enabling the user to verify and correct said generated labels to obtain user-verified labels for the current image data part. The labels for the current image data part are generated by combining respective outputs of a label propagation algorithm and a machine-learned classifier trained on user-verified labels and image data and applied to image data of the current image data part. The machine-learned classifier is retrained using the user-verified labels and the image data of the current image data part to obtain a retrained machine-learned classifier.

Owner:KONINKLJIJKE PHILIPS NV

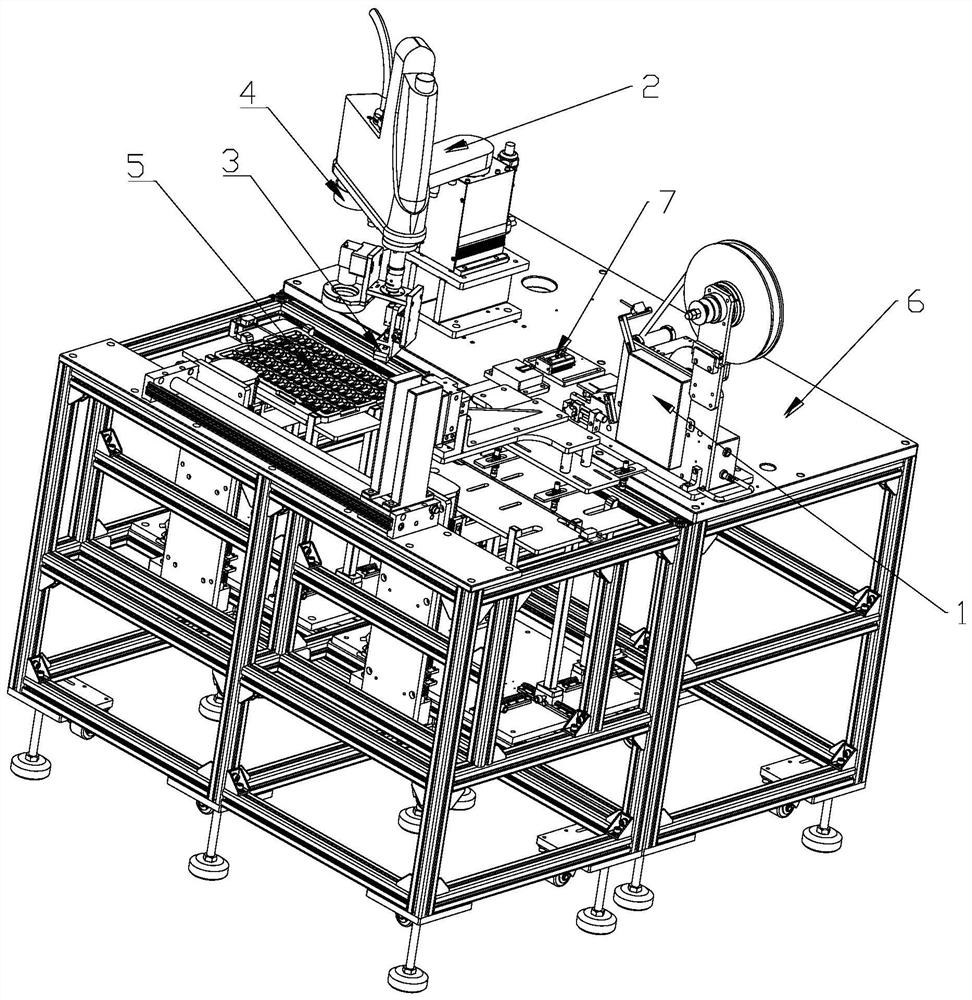

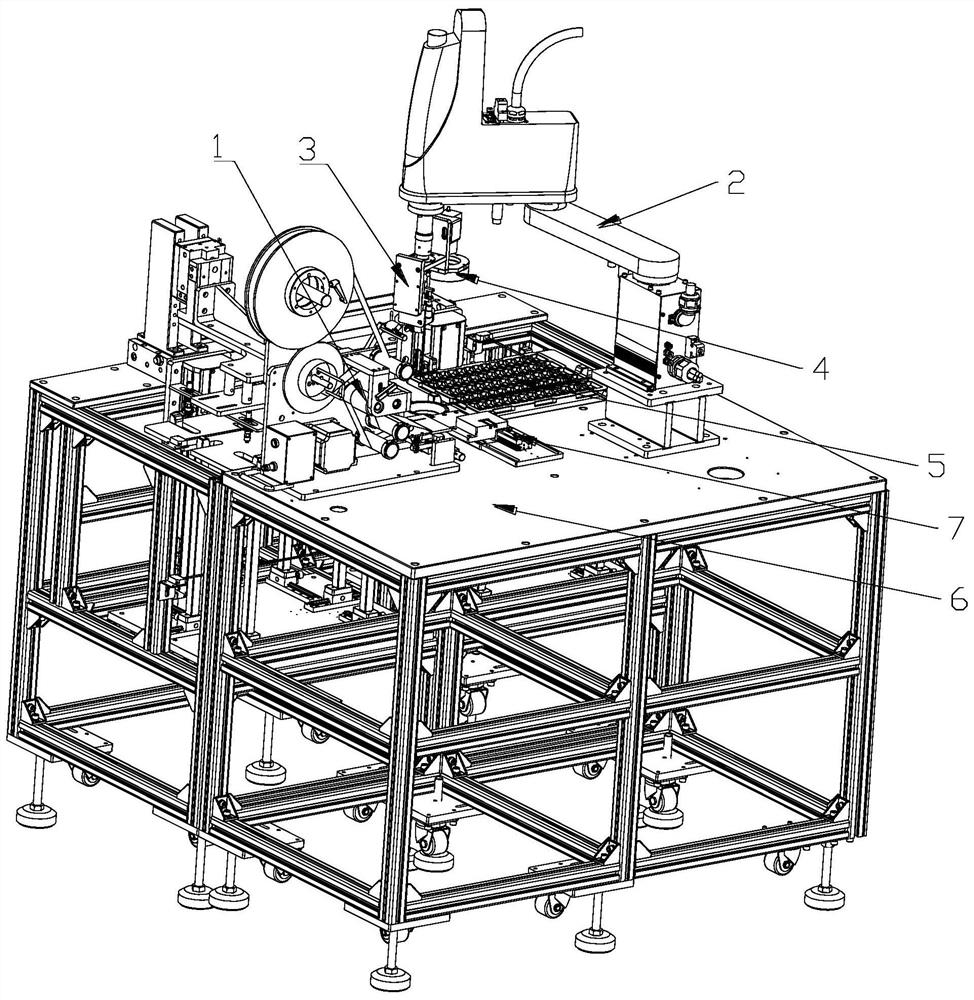

Automatic labeling system and method

InactiveCN111731622AHigh labeling accuracyMeet high precision labelingLabelling machinesLabelling machineSingle label

The invention belongs to the technical field of labeling, and particularly provides an automatic labeling system and method. The automatic labeling system comprises a label stripping machine and a machine arm, wherein the label stripping machine is used for stripping and separating single labels for later use. The system further comprises a labeling mechanism, a visual positioning module, a modulearranging and fixing clamp and a material placing module. The labeling mechanism is mounted at the tail end of the mechanical arm and used for sucking the labels through pressure and attaching the labels to surfaces of to-be-labeled products in a rolling manner; the visual positioning module is mounted at the tail end of the mechanical arm and used for image recognition and positioning of the to-be-labeled products; the material placing module is used for separately fixing the to-be-labeled products; and the module arranging and fixing clamp is used for fixing the single to-be-labeled products for labeling through the labeling mechanism. In the labeling process, due to plane label sucking, inclined step-by-step contact and rolling press-fit, the problem of bubbles generated by labeling can be avoided; and automatic labeling is achieved, manual work can be effectively replaced, and the labeling consistency is improved.

Owner:WUHAN HUAGONG GENUINE OPTICS TECH

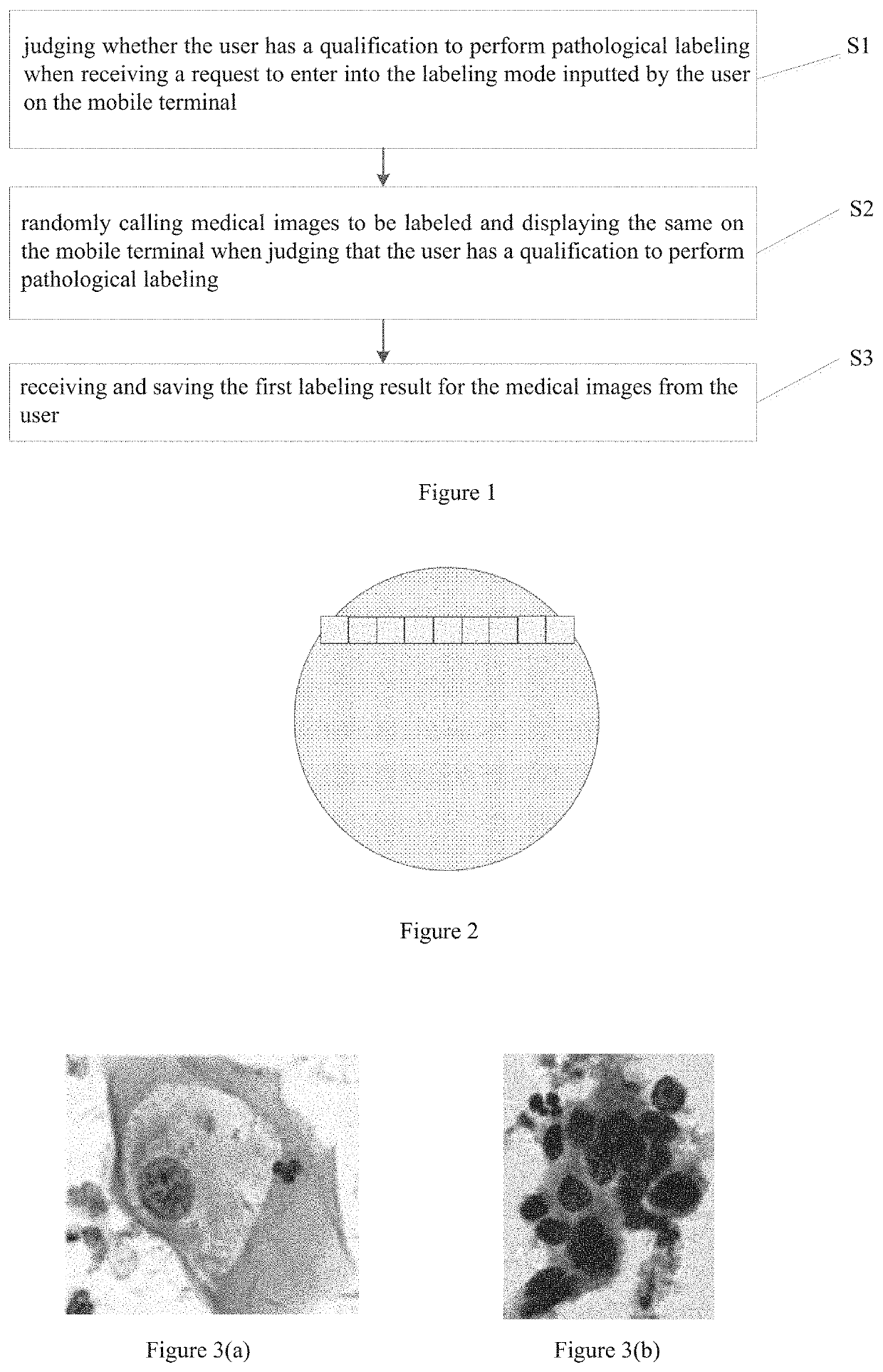

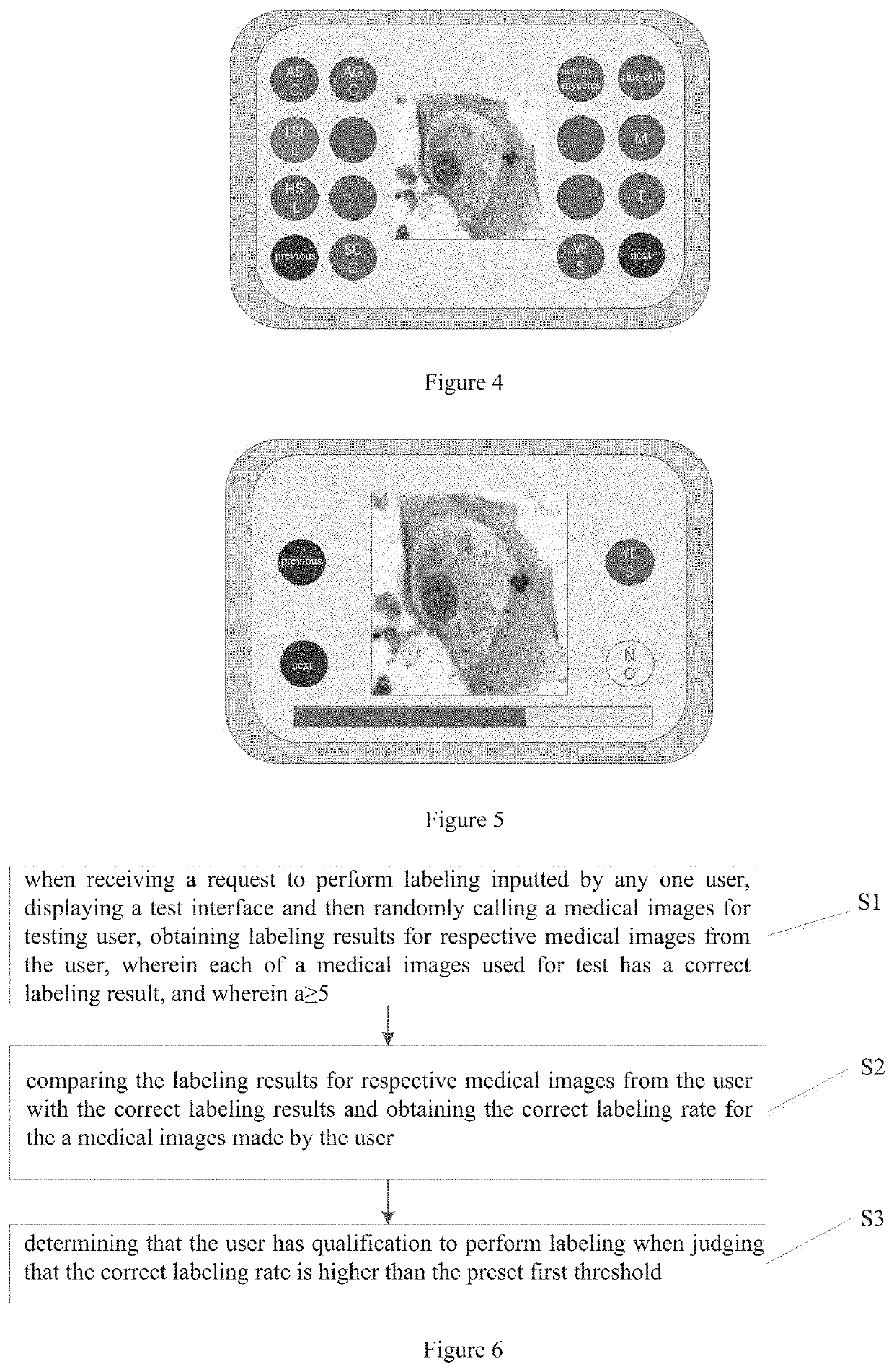

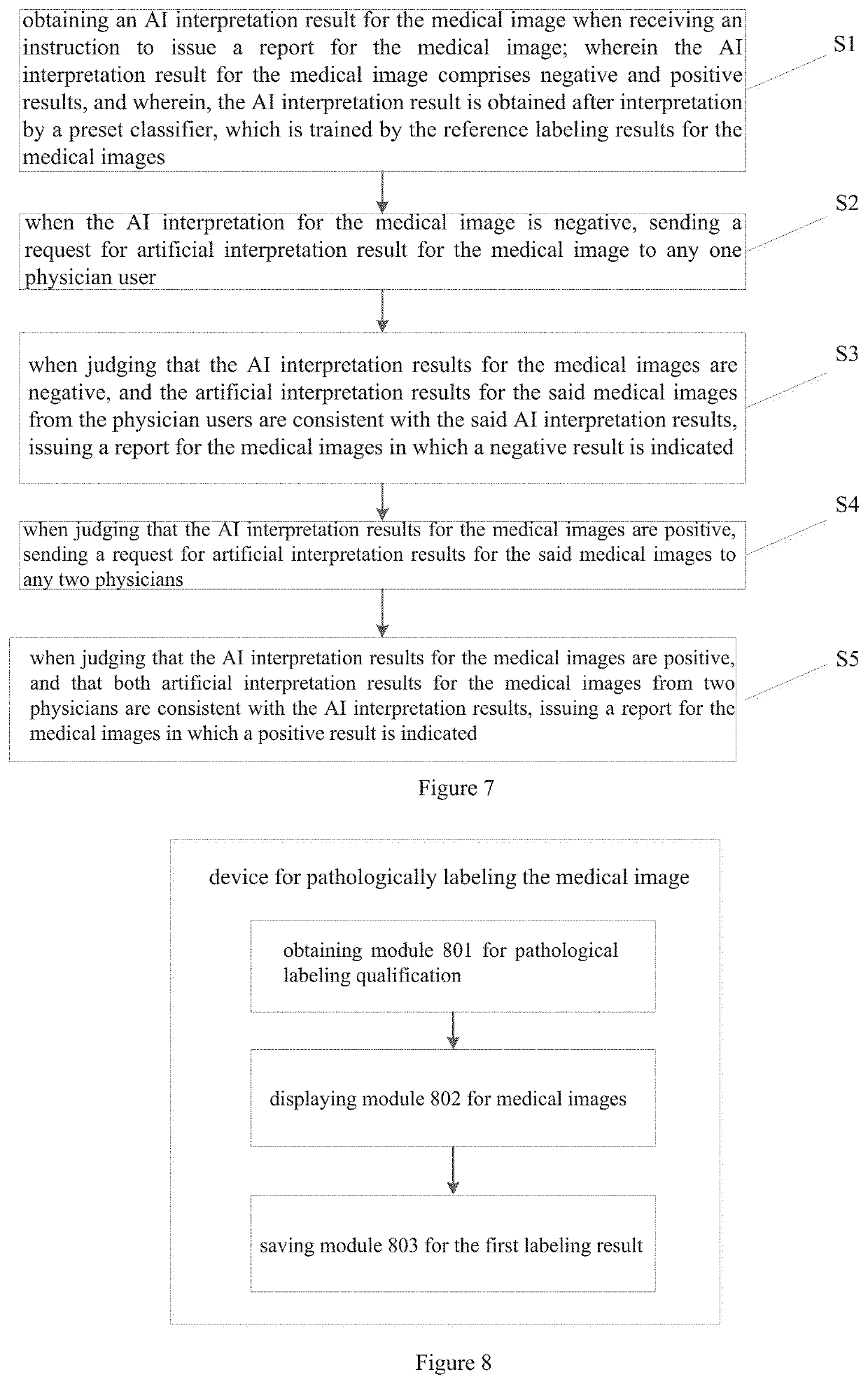

Methods and devices for pathologically labeling medical images, methods and devices for issuing reports based on medical images, and computer-readable storage media

ActiveUS20210035677A1Improve labeling efficiencyQuality improvementMedical imagesMachine learningComputer visionNuclear medicine

Disclosed herein are a method and a device for pathologically labeling medical images, which is capable of effectively solving the problem associated with limitations on working location of artificial labeling, enhancing labeling efficiency, and providing a huge number of learning samples with high quality with artificial intelligence.

Owner:GUANGZHOU KINGMED DIAGNOSTICS CENT

Round bottle labelling machine provided with plate pressing mechanism

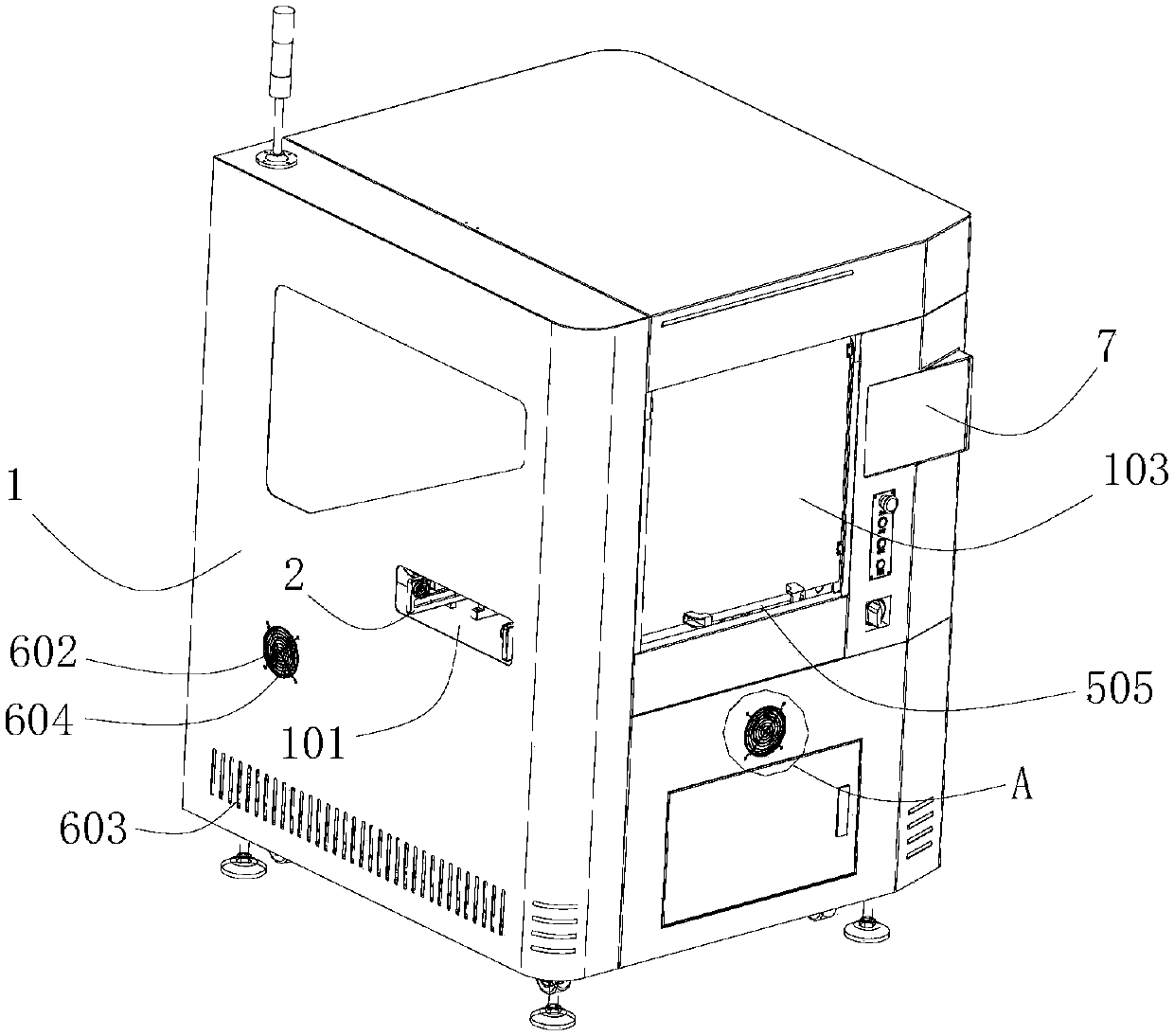

InactiveCN108082636AReasonable designCompact structureLabelling machinesLabelling short rigid containersEngineeringSingle label

The invention discloses a round bottle labelling machine provided with a plate pressing mechanism, and aims to solve the problems in the prior art that manual labelling is low in efficiency and poor in accuracy, and working efficiency is severely affected. The round bottle labelling machine comprises a machine box; a label conveying mechanism, a bottle supporting device which is used for clampinga round bottle to be labelled, a sensor used for detecting position of a label, a label stripping device used for attaching the label and a clutch traction device are arranged in the machine box; a control electric cabinet is arranged on a side surface of the machine box; and the clutch traction device comprises a motor, a traction driving gear shaft, a traction driven gear shaft, a driving shaftand a clutch. The round bottle labelling machine is reasonable in design, compact in structure and reasonable in space occupation; labelling precision and efficiency can be effectively improved; requirement of attaching of a single label or two labels can be met; and working efficiency is high.

Owner:沈阳星辉利包装机械有限公司

Labeling device

InactiveCN105366141BHigh precisionHigh labeling accuracyLamination ancillary operationsLaminationEngineeringScale control

Owner:BOE OPTICAL SCI & TECH +1

End cover labeling device

PendingCN111907852AIncrease productionHigh labeling accuracySortingLaser beam welding apparatusAssembly lineLabelling machine

The invention relates to an end cover labeling device, and belongs to the technical field of automatic labeling equipment. The end cover labeling device comprises a labeling cabinet, a labeling mechanism and a material receiving mechanism, the labeling mechanism comprises a labeling bottom plate, and an assembly line assembly is transversely installed on the surface of the labeling bottom plate and used for conveying an end cover to be labeled and conducting laser marking and labeling on the end cover to be labeled; and a laser marking assembly, a label stripping and pasting assembly and a label conveying assembly are sequentially arranged on the inner side of the assembly line assembly from left to right, a high-definition camera is further fixedly arranged right above the assembly line assembly, and the high-definition camera is electrically connected with the label stripping and pasting assembly. According to the end cover labeling device, by designing the label conveying assembly,the assembly line assembly, the label stripping and pasting assembly, the high-definition camera and the laser marking assembly and through cooperation of all components, automatic label taking and pasting in the whole process are achieved, the labeling precision is high, the automation degree is high, a large amount of manpower is saved, the film pasting work efficiency is improved, the company product yield is increased, and the end cover labeling device has a wide application prospect.

Owner:CHANGZHOU ANYI INTELLIGENT TECH

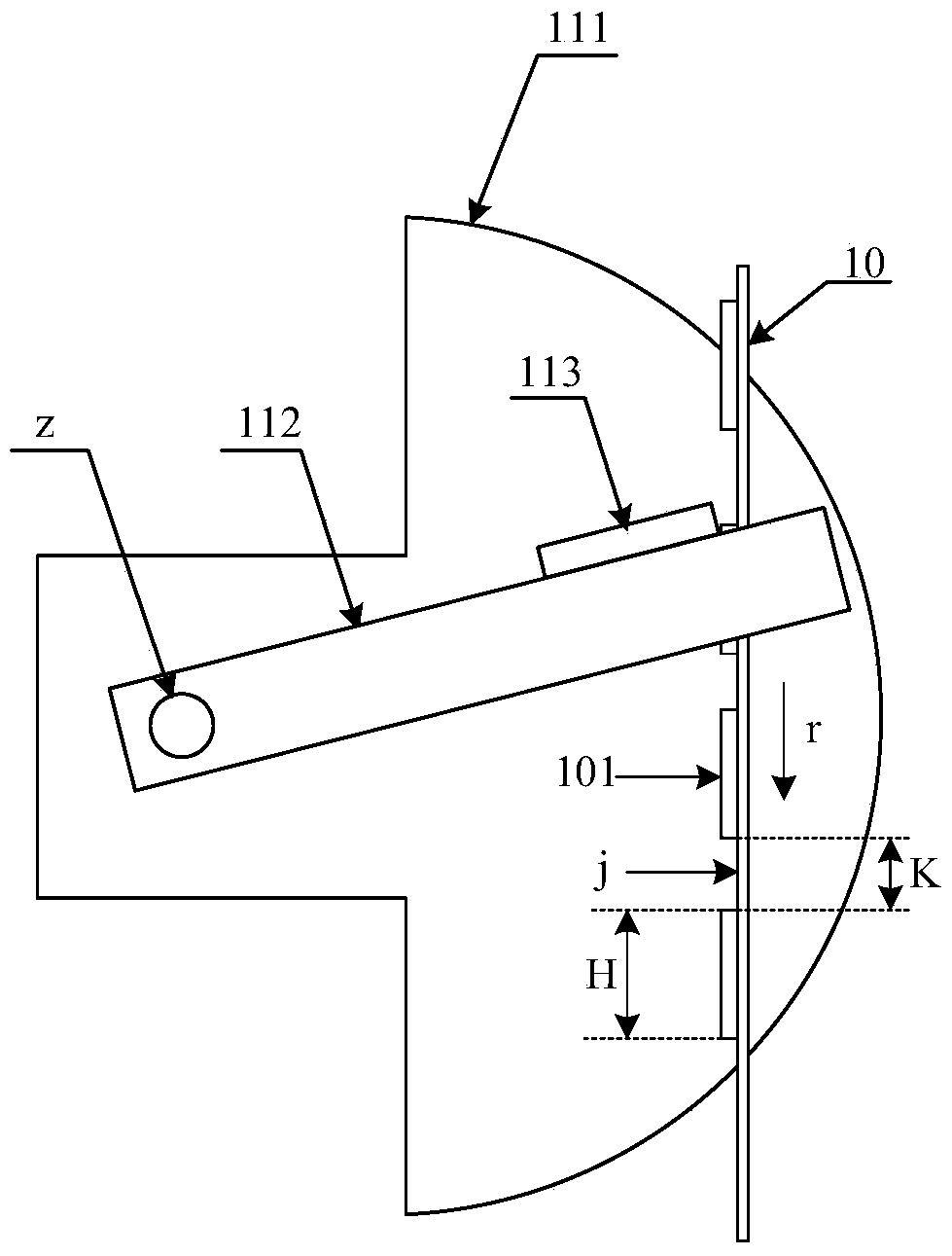

Method and device for marking contour of excavation roadway based on adjustment of laser light path

PendingCN107990847AEliminate labeling errorsMany solutionsUsing optical meansProjection distanceOptical path

The invention relates to a method and device for marking the contour of an excavation roadway based on adjustment of a laser light path and belongs to the technical field of auxiliary equipment for aheading machine. The device is called a laser marking device, and is essentially a laser light path adjusting device. The device includes a prismatic refractive light path adjusting module, a gratingdiffractive light path adjustment module and a galvanometer scanning light path adjustment module which are totally three function modules. A function of adjusting point laser to a continuous laser line can be achieved, the shortcoming that devices are various and difficult to recognize during multipoint laser transmission is overcome, and roadway contour marking accuracy is improved. The three function modules can be flexibly selected for different shapes of roadway contours, and the device is high in universality. A working mode of simultaneous use of multiple devices is adopted, a laser projection path is optimized, and the working safety is improved. A measurement feedback device in the galvanometer scanning light path adjustment module can be utilized to measure the projection distance and perform feedback to a control device to automatically adjust a projected laser pattern to eliminate errors and solve the real-time follow-up problem in tunneling work.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Positioning adjustment device for automatic labeling of carton

The invention discloses a positioning adjustment device for automatic labeling of a carton. The positioning adjustment device comprises a machine frame, and the machine frame is provided with a hydraulic oil cylinder and sliding rails. The sliding rails are slidably connected with a safety protection device, and an aluminum alloy frame is disposed at the top of the safety protection device. The aluminum alloy frame is provided with a leveling board in a welded mode, and the side surface of the leveling board is provided with an angle adjusting plate. The angle adjusting plate is provided witha rotary table, and the rotary table is provided with a pointer. The side surface of the rotary table is provided with a locking bar, and the locking bar is provided with a carton labeling table. Thetop surface of the carton labeling table is provided with two positioning plates, and the positioning plates are provided with U-shaped buckling blocks. The U-shaped buckling blocks are provided withfirst limiting plates, and the positioning plates are provided with guiding blocks. The guiding blocks are internally provided with moving rods, and the end portions of the moving rods are provided with second limiting plates. The positioning adjustment device aligns label paper with the labeling position of the carton up and down, improves the labeling precision, reduces the deviation of the labeling position, at the same time, ensures the good contact between the label paper and the top surface of the carton, improves the labeling quality, facilitates the batch labeling work of the carton, and improves labeling efficiency.

Owner:李佳麒

Labeling machine through vacuum drum

InactiveCN107487503AImprove work efficiencyImprove stabilityLabelling machinesArticle separationEngineeringMechanical engineering

A labeling machine through a vacuum drum is composed of a rack, a collecting conveying line, a paging mechanism, a vacuum adsorption part, a labeling mechanism and a corresponding control part and is characterized in that when paged by the paging mechanism and then adsorbed on a vacuum drum device, paper is saw by an object detection sensor during rotating and labeled by the labeling mechanism; and after being labeled, the paper is separated by a blanking device onto the collecting conveying line and conveyed into a collecting box by the conveying line. The labeling machine through the vacuum drum has the characteristics of being high in labeling precision and wide in application range.

Owner:高巍

A fully automatic labeling equipment for electronic components based on vision correction

ActiveCN110002070BAvoid position deviationImprove efficiencyLabelling machinesComputer hardwareElectrical polarity

The invention discloses a fully automatic labeling equipment for electronic components based on visual deviation correction, which includes a first transmission mechanism, a second transmission mechanism, a third transmission mechanism and a labeling device, the first transmission mechanism, the second transmission mechanism mechanism and the third transmission mechanism are connected sequentially, the labeling device is located on the second transmission mechanism, the first transmission mechanism is provided with a scanning component, the third transmission mechanism is provided with a detection component, and the The scanning component communicates with the labeling device, uses the scanning component to obtain the mother code on the circuit board, uses the labeling device to paste a character code label corresponding to the mother code on the circuit board, and then passes through the detection component The position and positive and negative polarity of the label after labeling are visually corrected and detected, and the automatic labeling of the circuit board is realized, which has the advantages of high efficiency and high labeling accuracy.

Owner:SHENZHEN GRAND INNOSYS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com