Online testing and labeling device for surface defect

A labeling and defect technology, applied in labeling machines, labels, packaging, etc., can solve problems such as poor anti-interference ability, poor discrimination accuracy, and slow labeling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

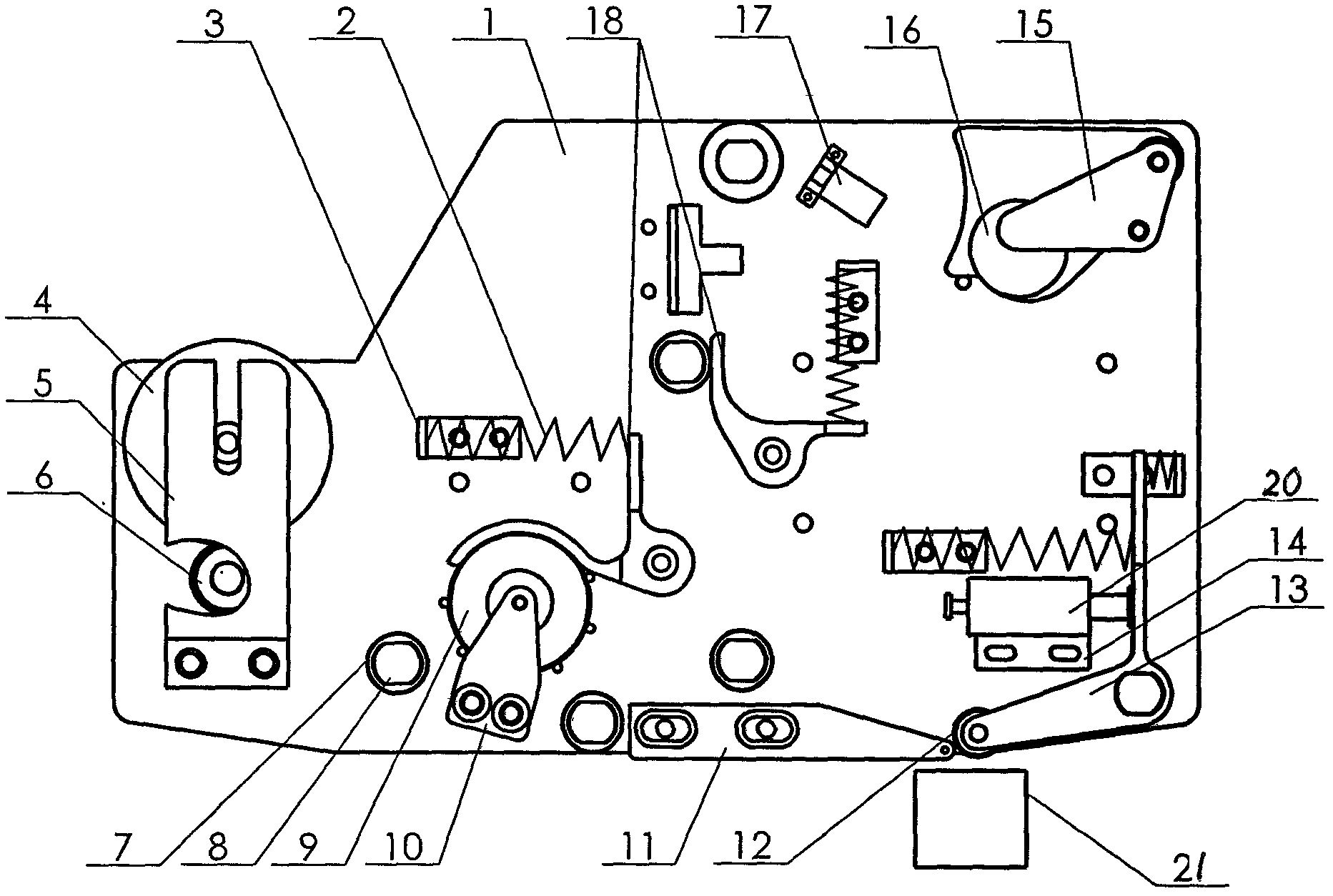

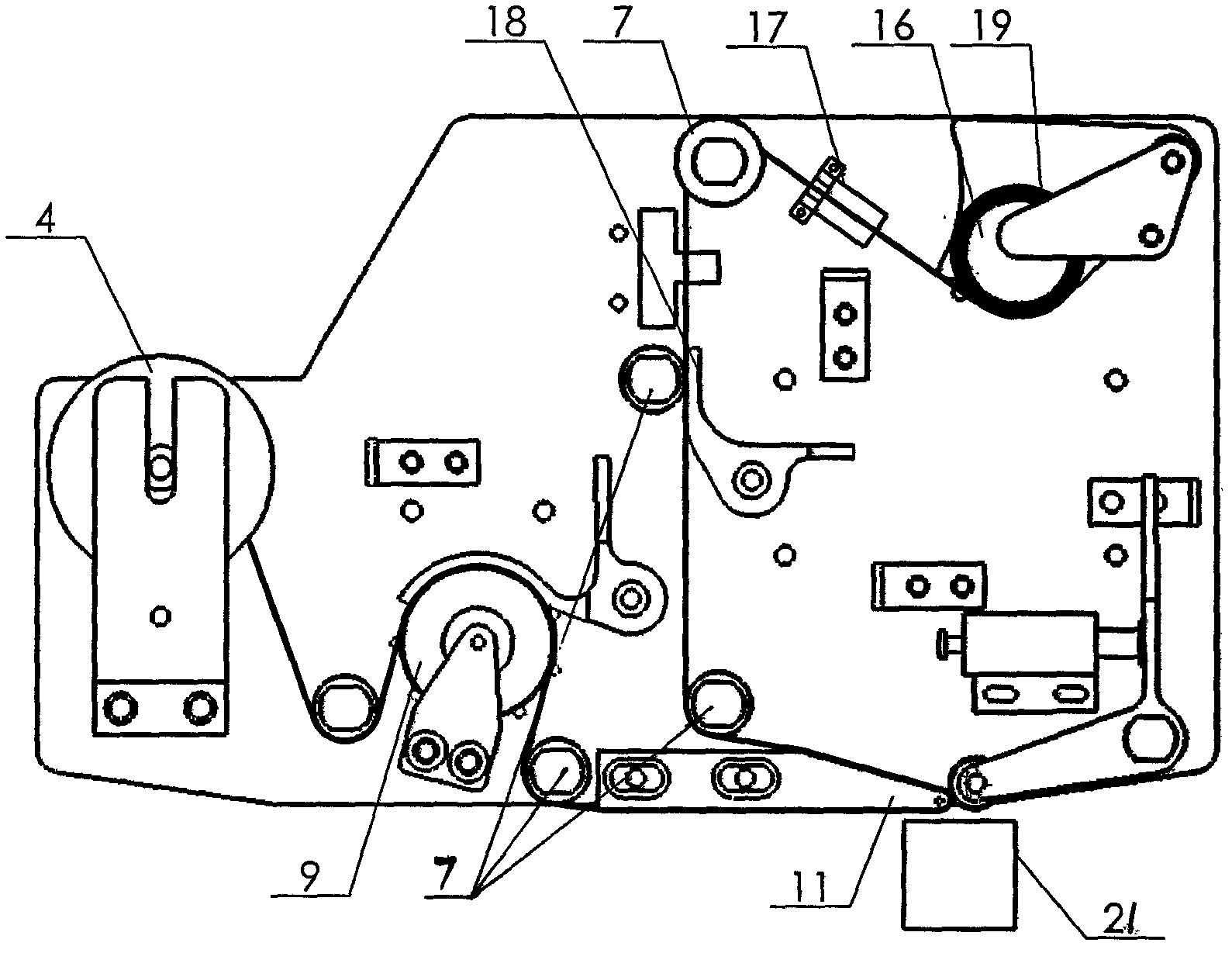

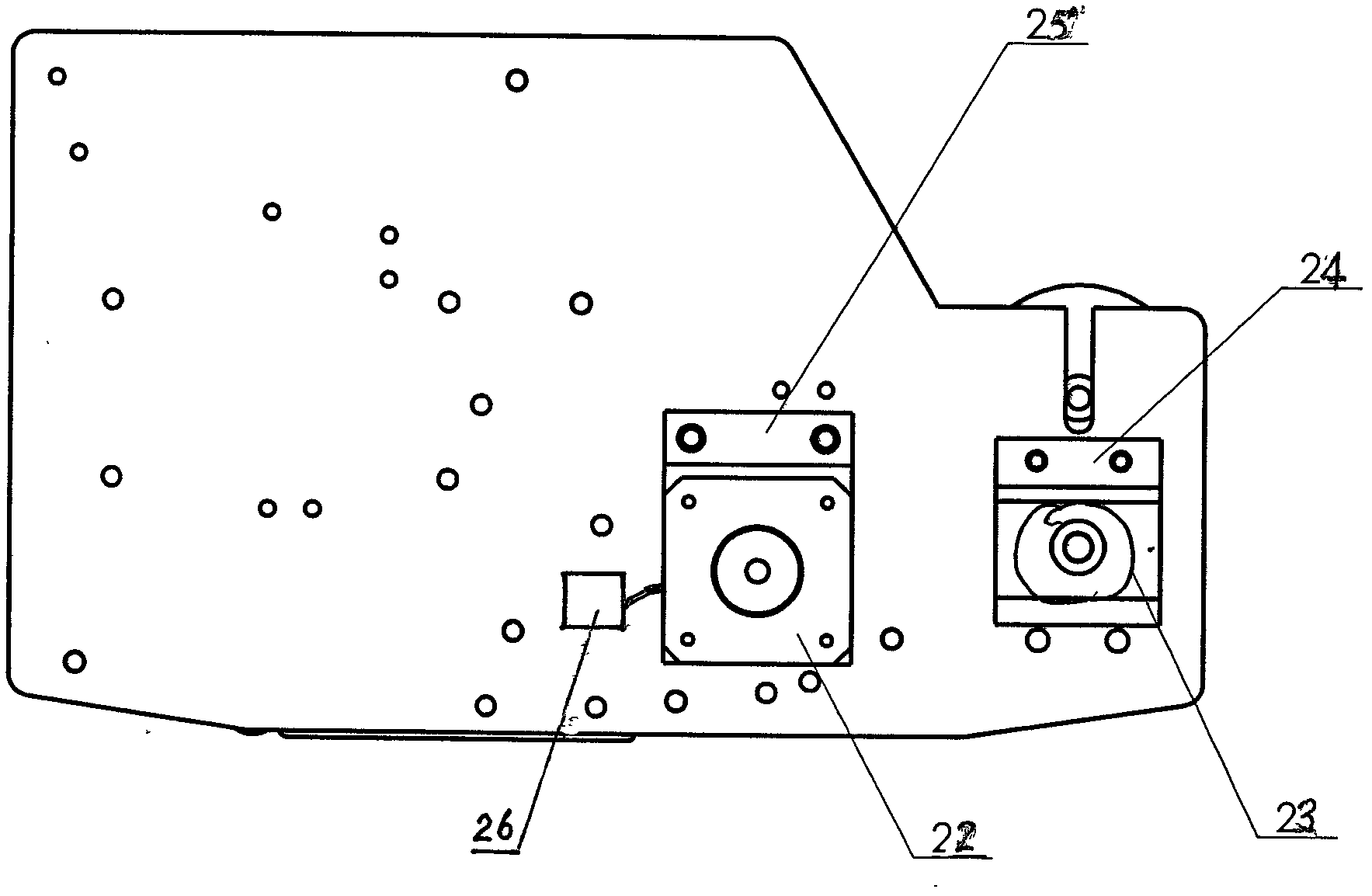

[0016] like figure 1 , image 3 As shown, the surface defect online detection and labeling device of the present invention consists of a base plate 1, a spring seat 3, a winding support 5, a bridge wheel 7, a driving wheel support 10, a corner seat 11, a press wheel seat 13, and a Roll seat 16, photoelectric cell 17, paper pressing device 18, label tape 19, stepper motor 22, reduction motor 23, reduction motor holder 24, stepper motor holder 25 are formed. The stepping motor 22 and the stepping motor seat 25, the reduction motor 23 and the reduction motor seat 24 are installed on the back side of the substrate 1, and on the stepping motor 22, a signal receiving device 26 is arranged for receiving the operation signal sent by the detection host; On the winding bracket 5, a winding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com