Labeling machine through vacuum drum

A technology of vacuum drum and labeling machine, which is applied in the directions of labeling machine, label, and object separation, can solve problems such as difficulty, insufficient vacuum suction, and inability to label, reduce labor costs, improve production efficiency, and has a wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

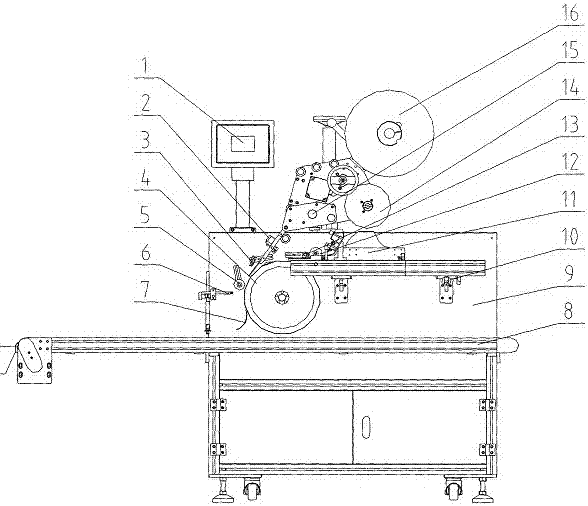

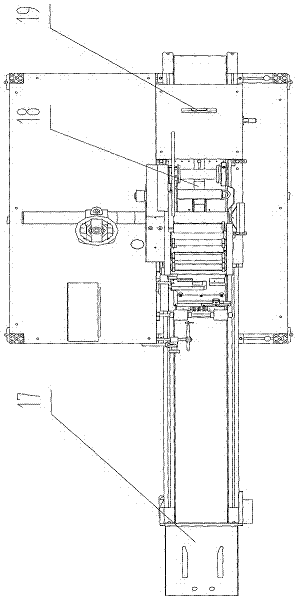

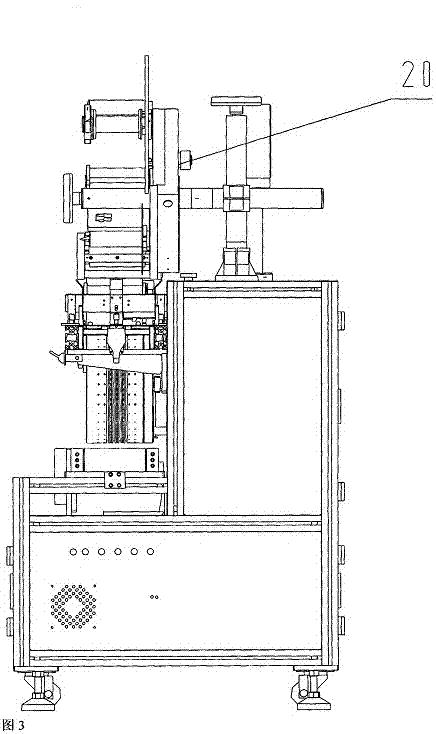

[0017] The vacuum drum paging and labeling machine of the present invention is realized in this way. First, open the man-machine interface (1) to start the machine, put the paper on the static electricity blowing hole (19), open the static electricity blowing valve (10) to eliminate static electricity, and then Put it in the paging baffle (11), the paging timing belt (18), rotates to drive forward movement, the upper dial back wheel (12) turns, and the paper sheets that are paginated move forward, and are transmitted by the paging guide synchronous wheel, and the upper part presses the label The wheel (12) presses it and transports it to the vacuum drum (4). Because the outer circumference of the vacuum drum (4) is full of vacuum holes, the paper is sucked and rotates with the vacuum drum (4). Seen by the sensor (6) of the object under test, the label feeding drive roller (15) rotates to pull the label, the clutch of the brake mechanism (20) is separated, the label feeding plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com