Thin-walled cylinder hot melt glue labeling machine

A technology of thin-walled tubes and hot-melt adhesives, applied in labeling machines, labels, packaging, etc., can solve the problems of reducing the correct labeling rate, increasing production costs, and reducing production efficiency, so as to reduce the frequency of label replacement and reduce the glue The consumption of liquid and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

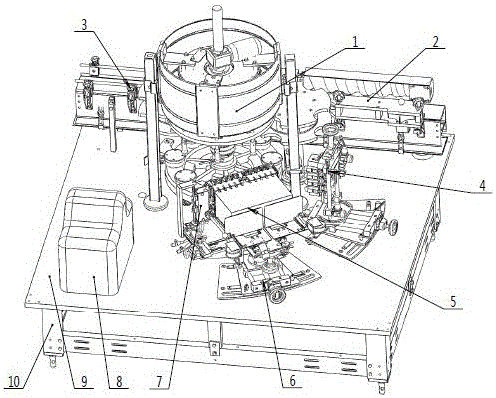

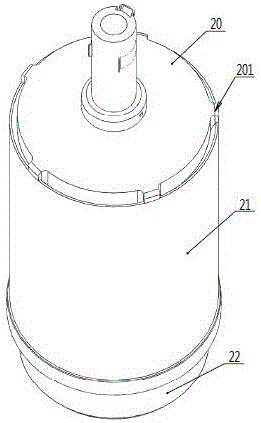

[0036] Such as figure 1 As shown, the thin-walled tube hot melt adhesive labeling machine of the present invention includes a bottle supporting turntable 1 arranged at the center of the frame table top, a bottle feeding device 2, a glue spraying device 4, The split floating standard warehouse 5 installed on the adjustable support 6, the rubber scraping device 7 installed on one side of the adjustable support 6, the melt box 8, the bottle output device 3, and also includes the frame 9 and the electrical control System 85, wherein:

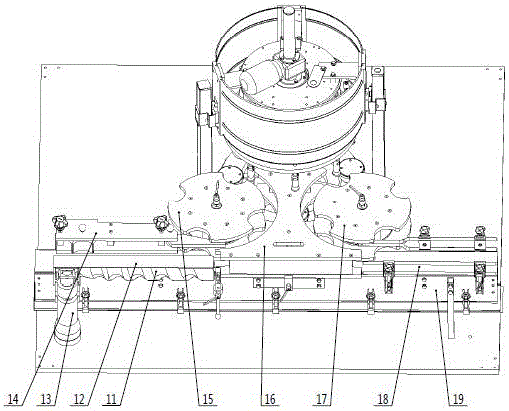

[0037] (1) Bottle inlet device and bottle outlet device: refer to figure 1 , figure 2 .

[0038] The bottle feeding device includes a bottle feeding screw 11, a protective cover 12, a screw support 13, a bottle stop device 14, a bottle feeding star wheel 15, a central guide plate 16, and a conveying cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com