Patents

Literature

47results about How to "Good labeling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Adhesive, preparation and use thereof

InactiveCN101440269AGood initial adhesionLow freezing pointProtein waste adhesivesStarch adhesivesEnzymatic hydrolysisAdhesive

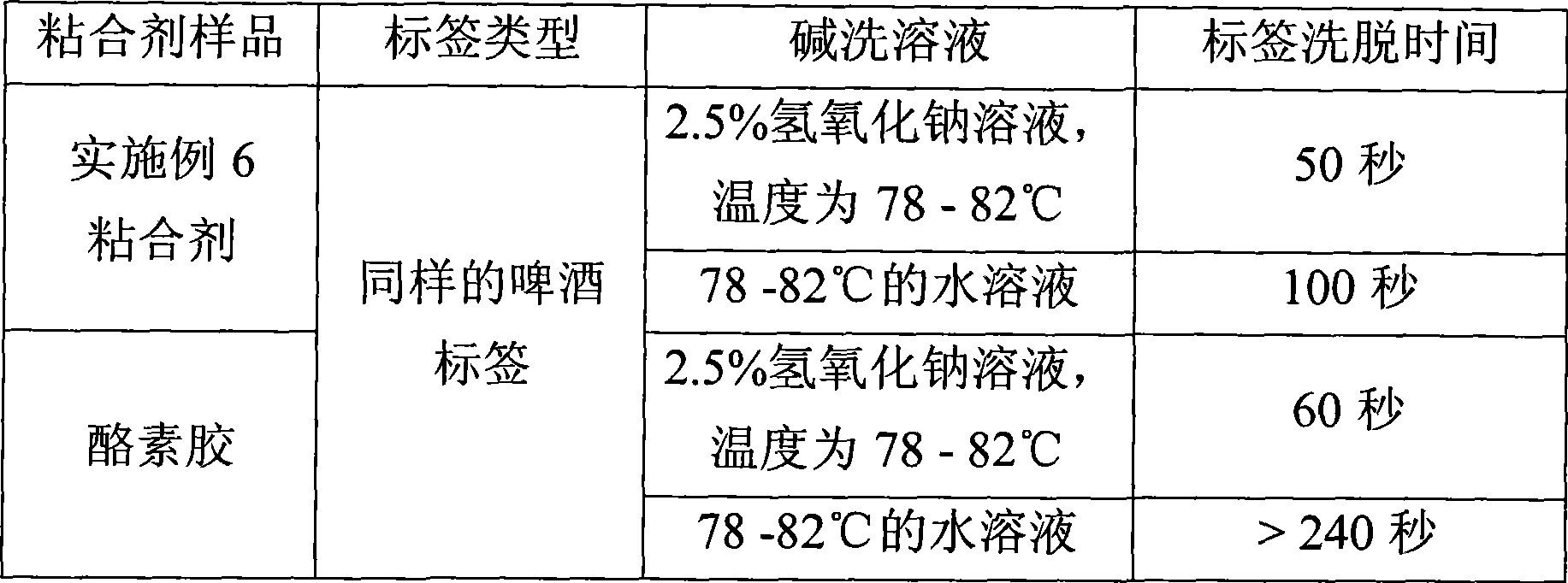

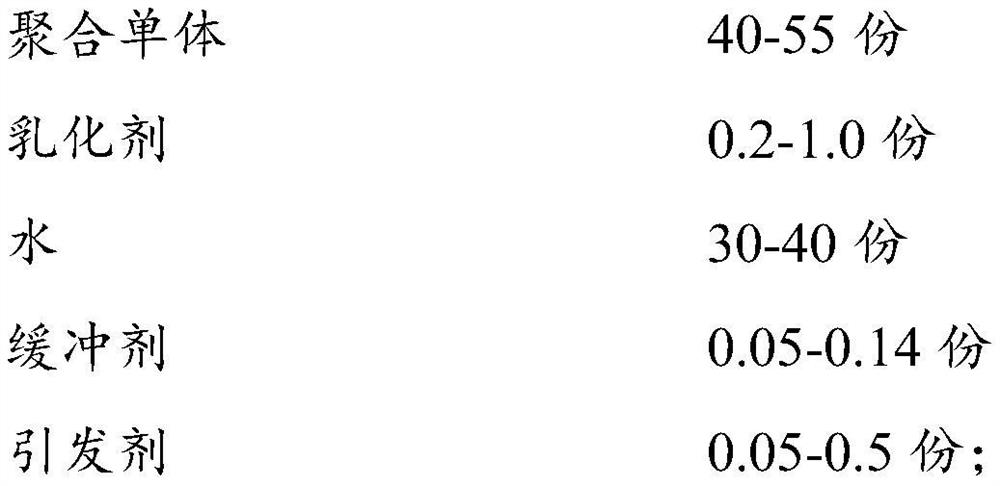

The invention provides an adhesive for labeling, which comprises 1 to 40 percent of animal glue, 0 to 45 percent of emulsion, 0 to 20 percent of starch, 5 to 40 percent of diluting agent, 0 to 10 percent of cross-linking agent, 0 to 5 percent of thickening agent, 0.001 to 2 percent of additive, and 20 to 50 percent of water. The adhesive has the advantages of good initial adhesion, low solidification point, good water resistance, strong enzyme hydrolysis resistant stability, elution in non-alkaline high temperature water and so on, well meets the requirements of improving production speed, improving the qualification rate of the production and recovering containers at present, and is particularly used for labeling beer bottles.

Owner:HENKEL KGAA

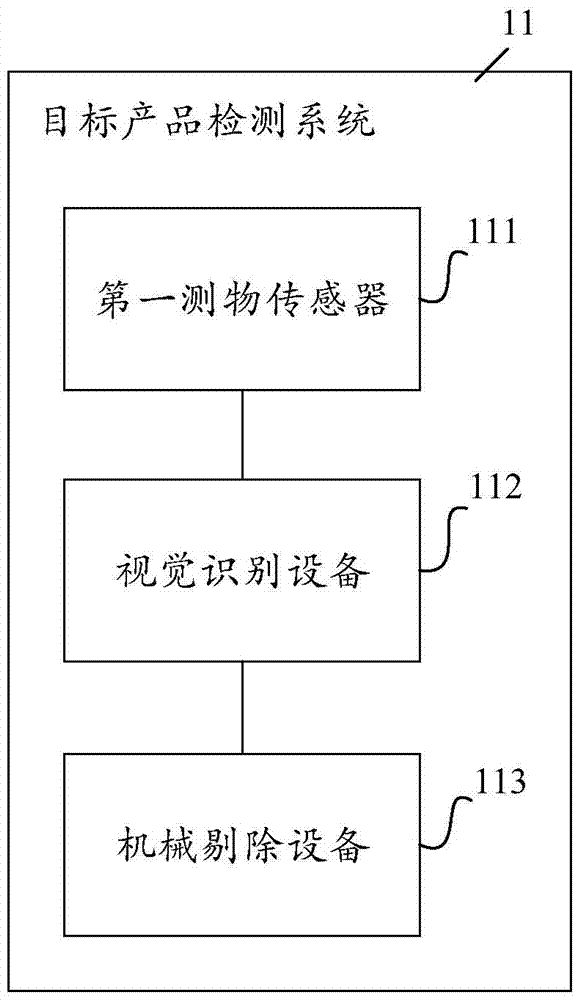

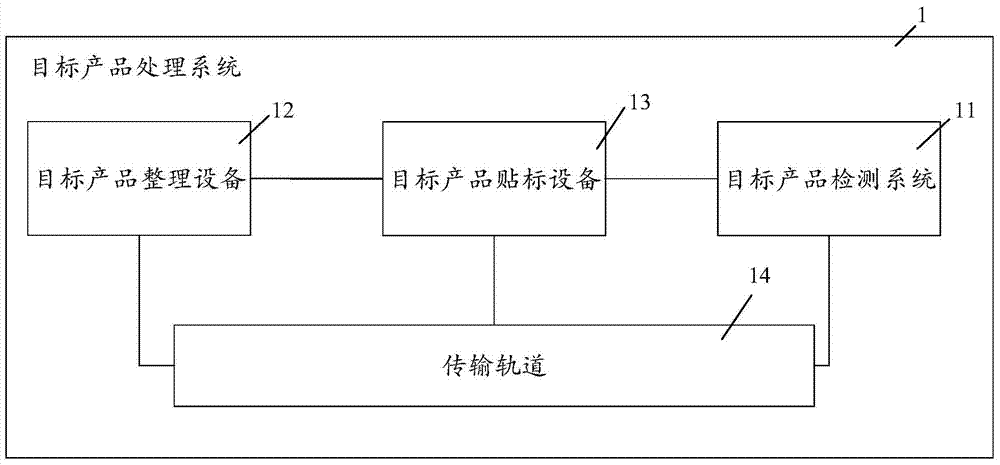

Target product detection system, detection method thereof, and target product processing system

ActiveCN104772289ASolve the problem of culling impreciseAffect work efficiencySortingSensing by electromagnetic radiationHandling systemComputer science

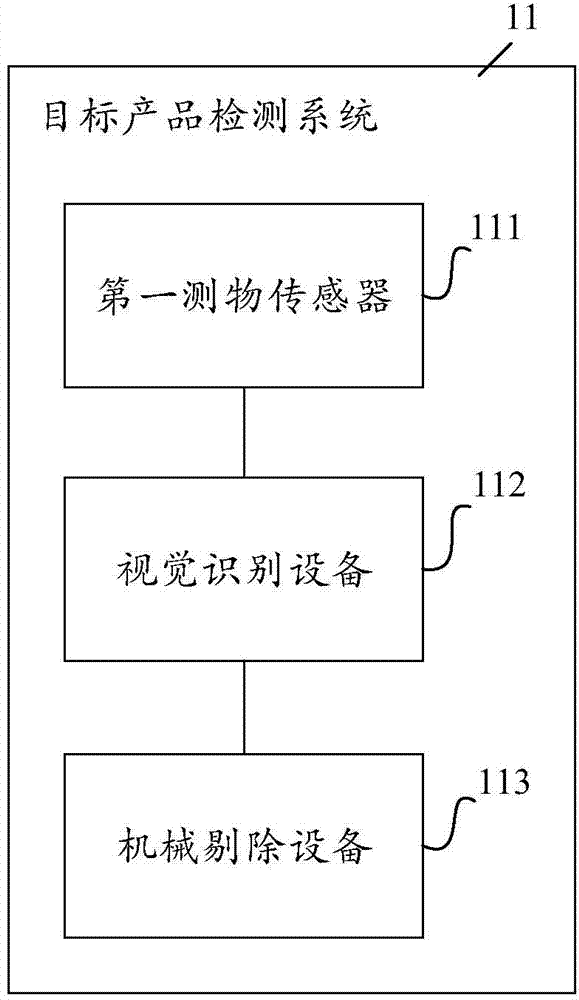

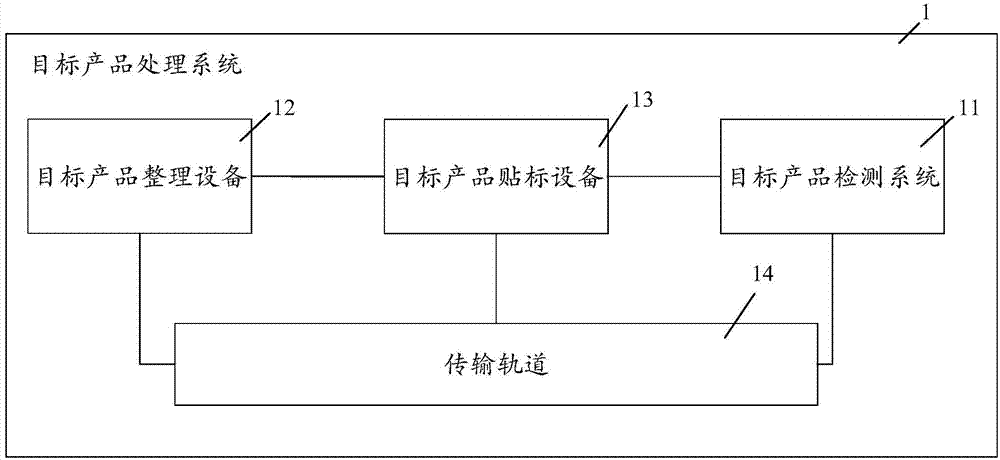

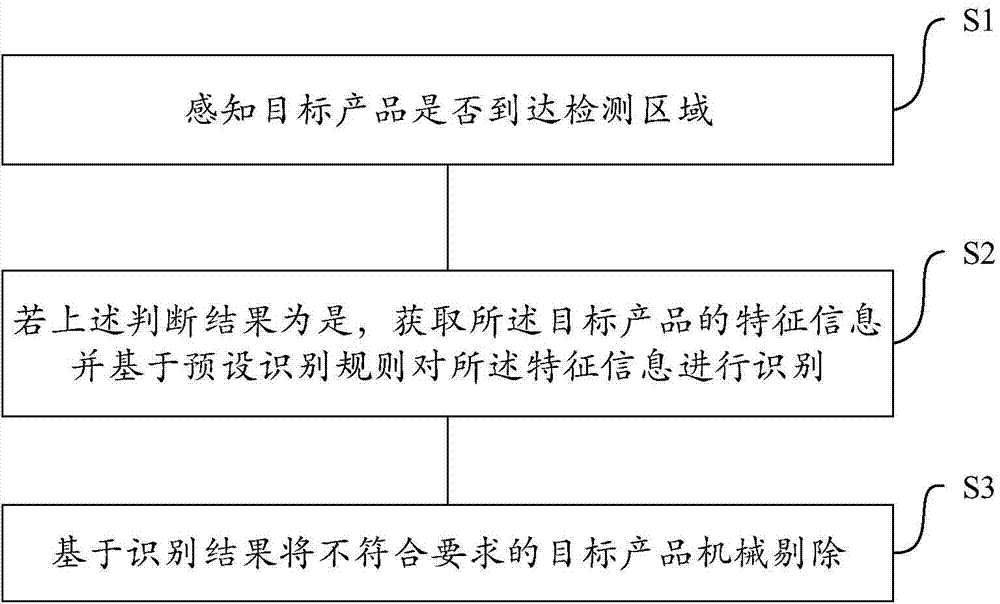

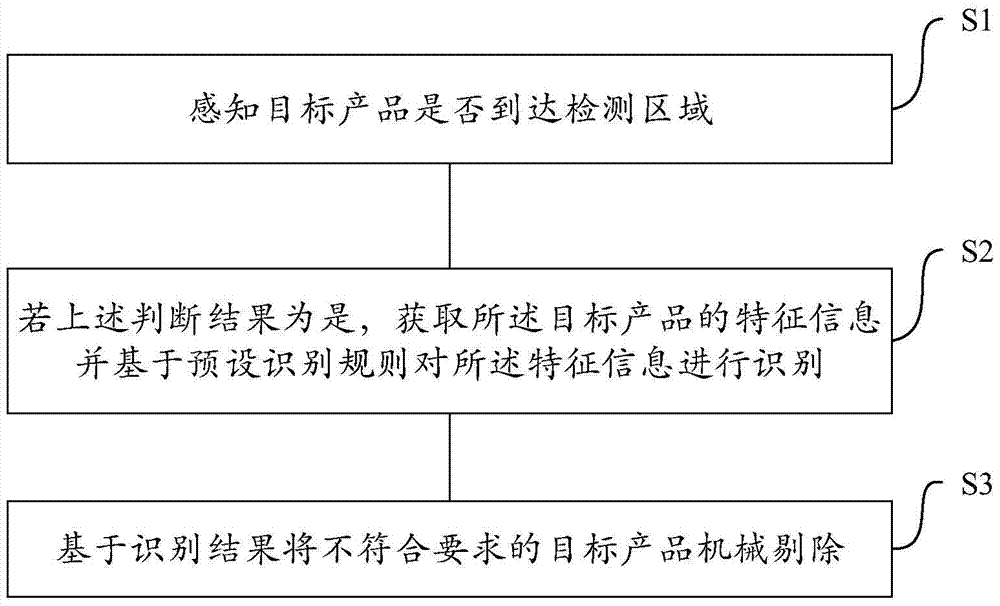

The invention discloses a target product detection system, a detection method thereof, and a target product processing system. The target product detection system comprises a first product detection sensor used for perceiving that whether a target product reaches a detection area or not, a visual identification device used for acquiring characteristic information of the target product and identifying the characteristic information based on a preset identification rule when the first product detection sensor perceives that the target product reaches the detection area, and a mechanical rejecting device used for mechanically rejecting undesirable target products according to the identification result of the visual identification device. The above technical scheme solves the problems of lack of identification examination of labels on products and inaccurate rejection of substandard products in the prior art.

Owner:SHANGHAI TY TECH

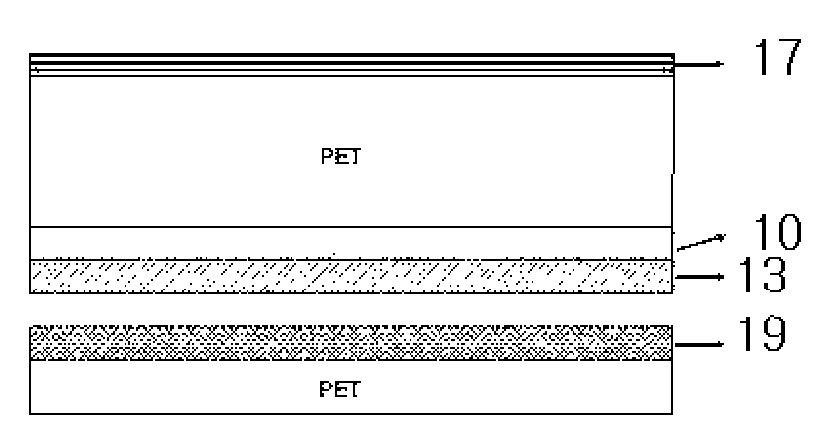

Antismudge, water repellent, and antistatic pressure-sensitive or adhesive tape for protection

InactiveUS20090317634A1Effective preventionImprove antistatic performanceFilm/foil adhesivesConductive materialWater useConductive polymer

Disclosed is an antistatic pressure-sensitive or adhesive tape for protection. More particularly, this invention relates to an antistatic protective tape, in which, upon antistatic treatment using a conductive polymer on the exposed surface of the tape opposite the surface having an adhesive, water repellency able to increase the contact angle with respect to water so as to easily remove water drops in a water-using process and antismudge performance able to prevent the generation of smudges due to oil or to easily remove generated smudges may be imparted together, unlike conventional protective films. Further, the invention provides an antistatic composition, in which antistatic treatment using the conductive polymer and water repellent and antismudge treatment are not separately performed but are performed at the same time, so that these properties may be simultaneously exhibited in a single layer, thus decreasing the complexity of the process by one or more steps, and also provides a protective tape using the same.

Owner:SUH KWANG SUCK

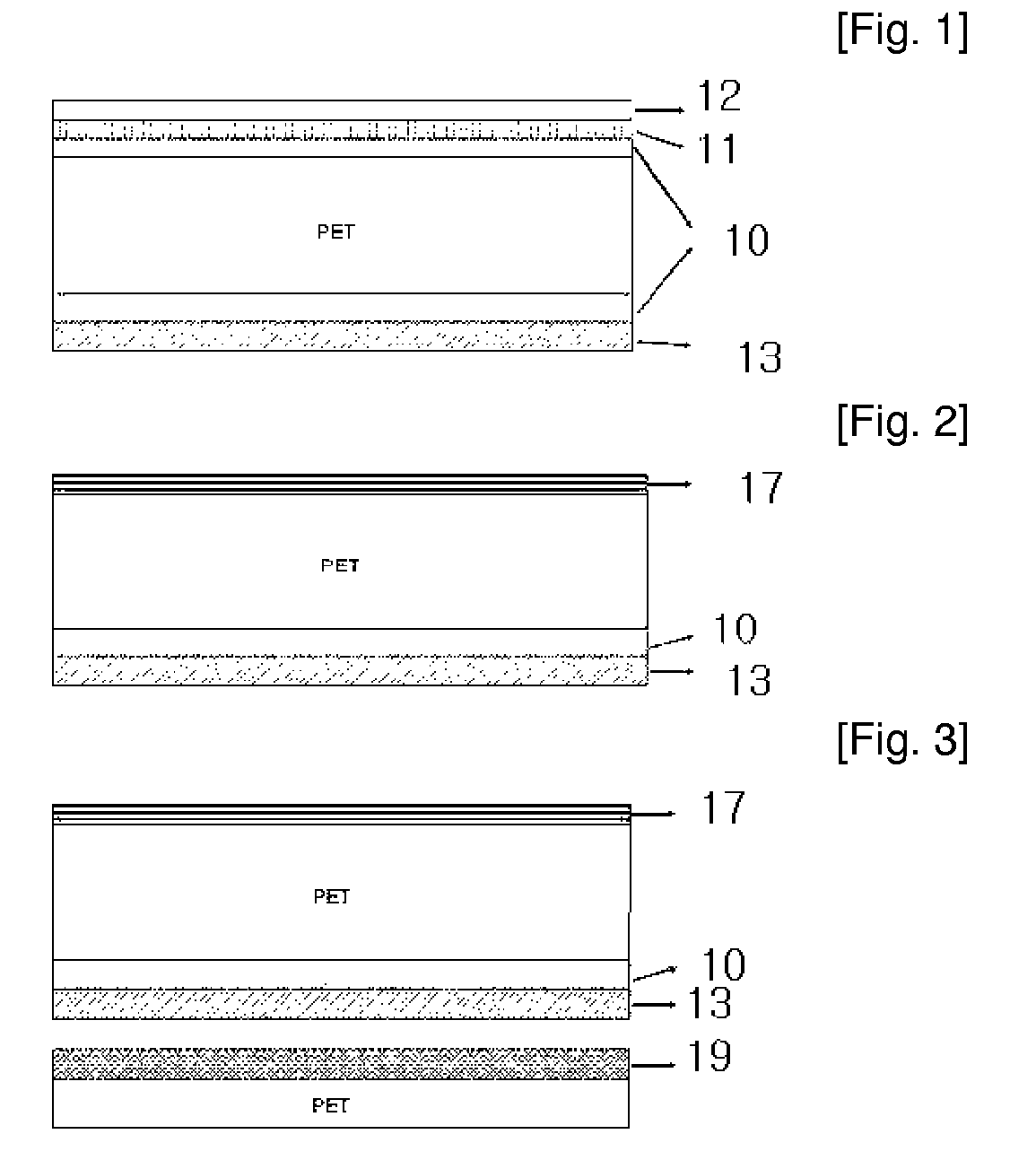

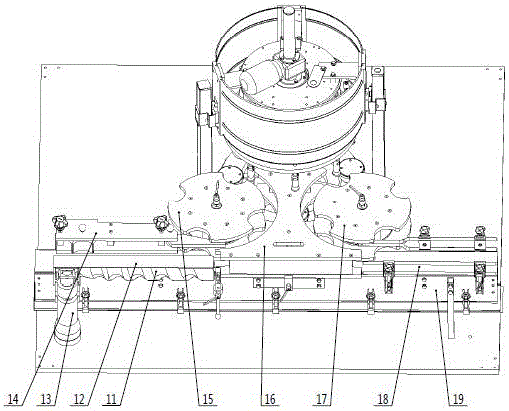

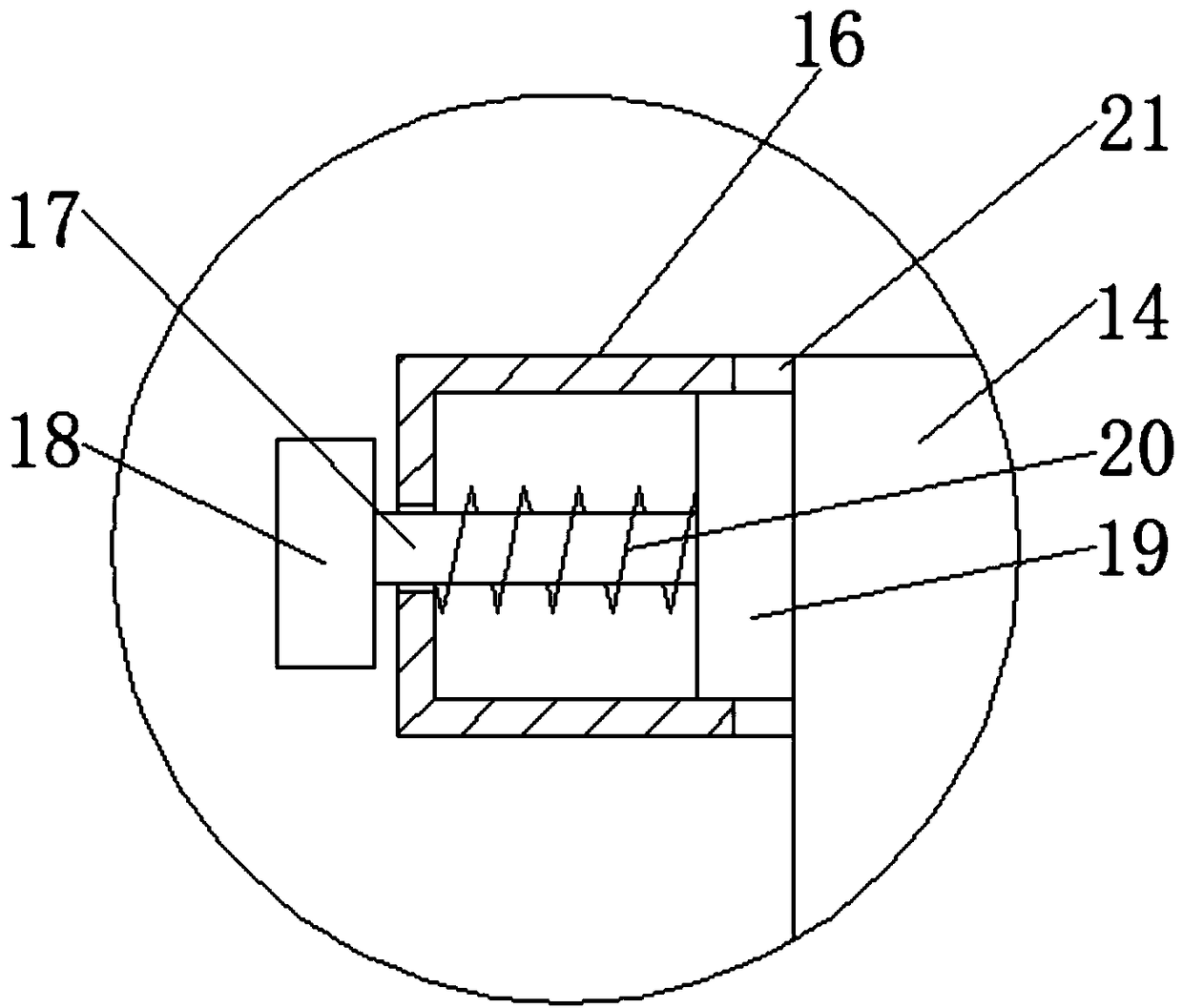

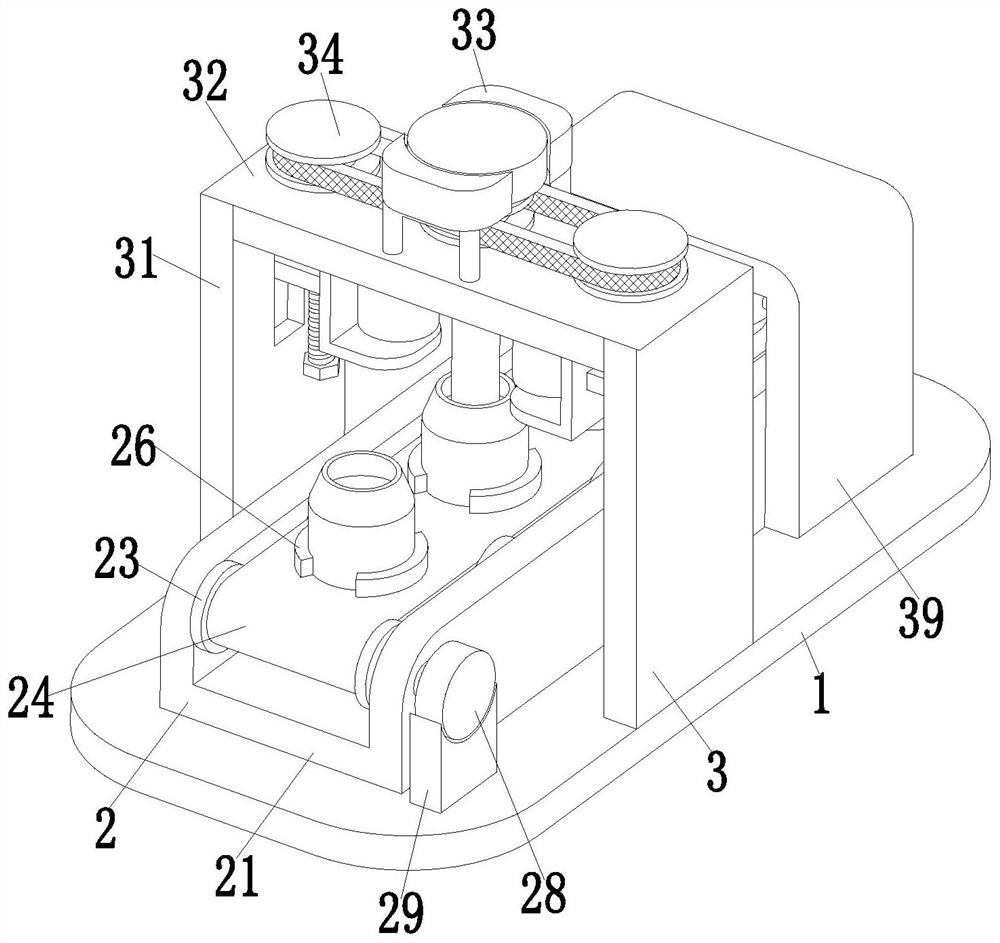

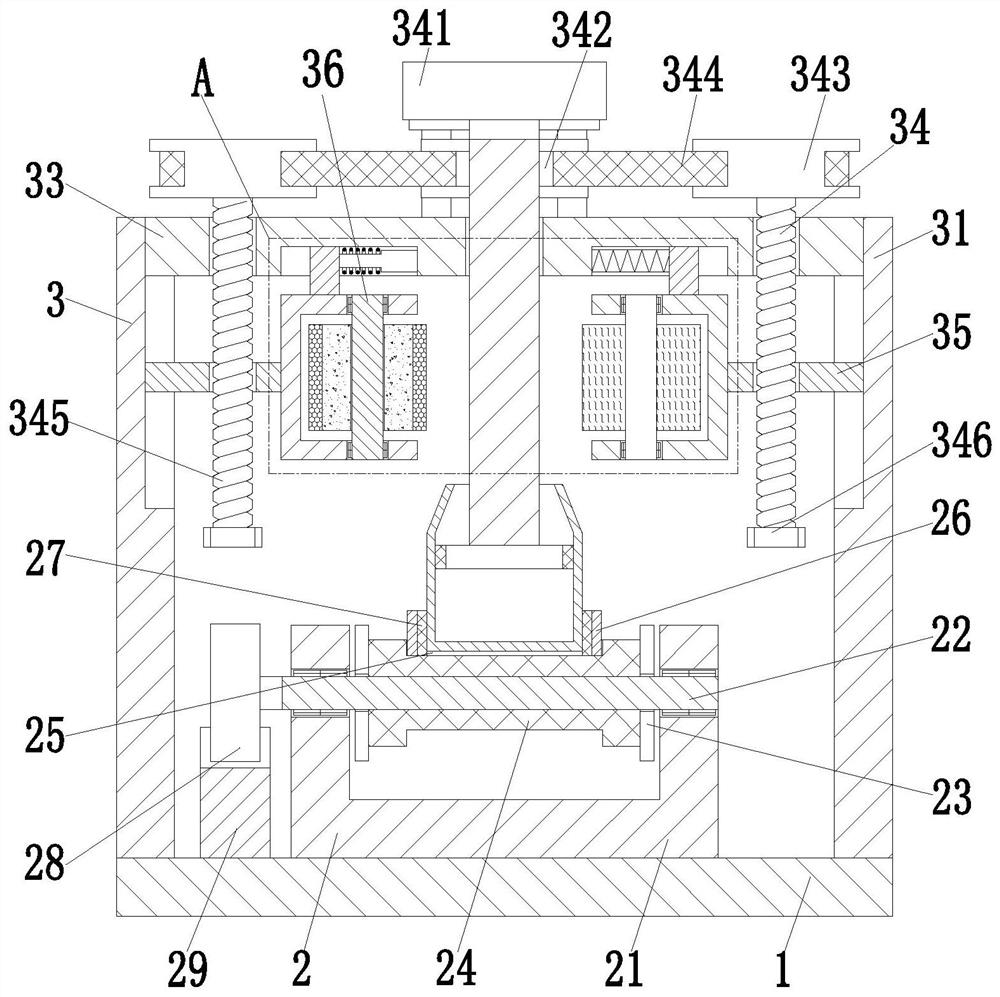

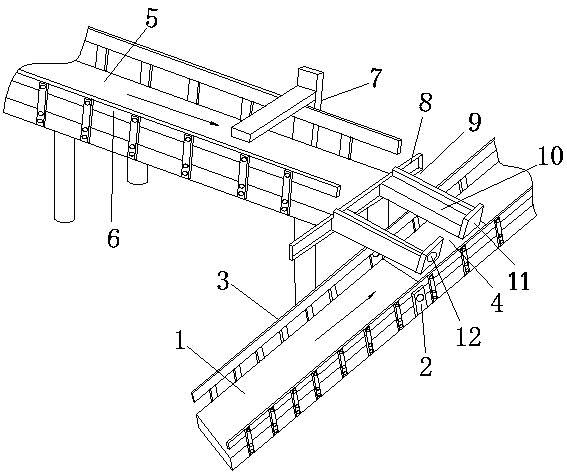

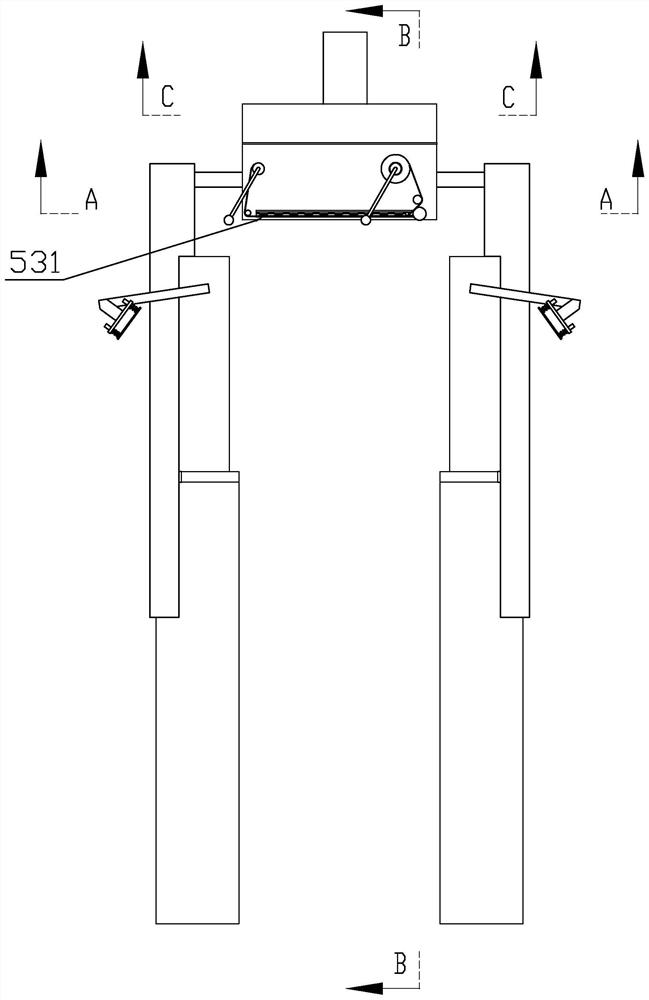

Labelling device of corrugated cartons

The invention discloses a labelling device of corrugated cartons. The labelling device comprises a transporting table. A conveying belt is mounted on the transporting table. Baffles are fixedly mounted on the upper end face of the conveying belt at equal distance. The cartons are placed between the adjacent baffles. A first treatment table and a second treatment table are erected above the left end and the right end of the transporting table correspondingly. Two sets of bearing pedestals are symmetrically mounted in the first treatment table. A rotating shaft is rotationally arranged between the two sets of bearing pedestals. A flattening roller is connected to the rotating shaft in a sleeving manner. According to the labelling device of the corrugated cartons, through circumferential motion of a rocking arm, a connecting block clamped in a fork rod converts torque into rotating action force, the connecting block and a rotating rod do reciprocating motion with the rotating angle being90 degrees, through transmission of a crank connecting rod structure, an L-shaped mechanical arm can do reciprocating motion with the rotating angle being 90 degrees, and therefore three sets of suction cups are used for absorbing labels, the labels are pasted to the surfaces of the corrugated cartons, the labelling device is suitable for different work conditions, and better application prospectsare brought.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

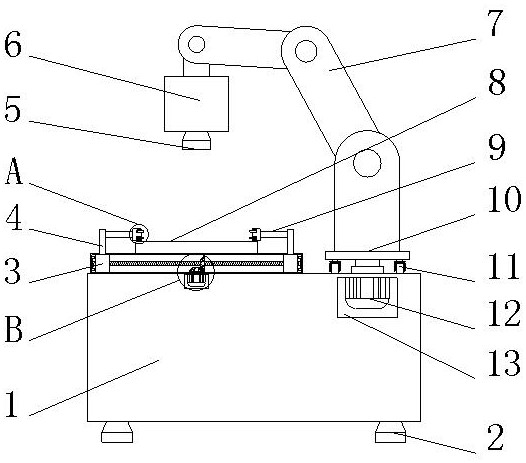

Automatic labelling method and device

The invention provides automatic labelling method and device. The device comprises a label sucking module unit and a control unit, wherein the label absorbing module unit comprises one or more label sucking components; each label sucking component comprises a labelling head and a pressure detection sensor; the control unit is set to be used for receiving a labelling pressure real-time value sent by the pressure sensor; according to the received labelling pressure real-time value, a motion execution unit drives the label sucking module unit so as to enable the label sucking components in the label sucking module unit to move to the preset position; and the label sucking components are used for executing the corresponding labeling operation corresponding to the preset position after moving to the preset positions. Through detecting the pressure, the pressure of the labelling head acted on a labelling object product is always accurately controlled within a pressure value range allowable by the labelling object product, so that the occurrence of the phenomenon that the product is damaged due to over pressure is avoided.

Owner:ZTE CORP

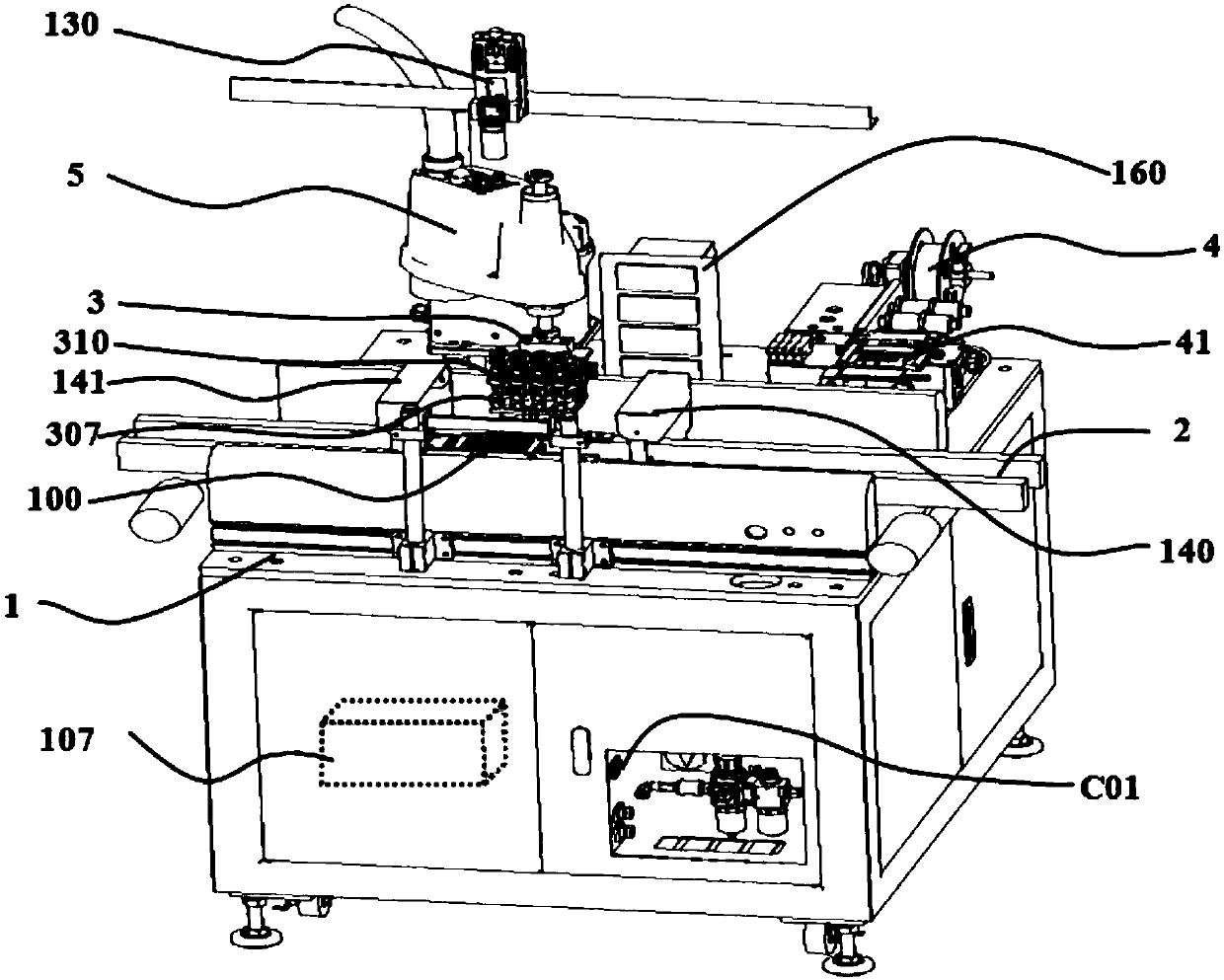

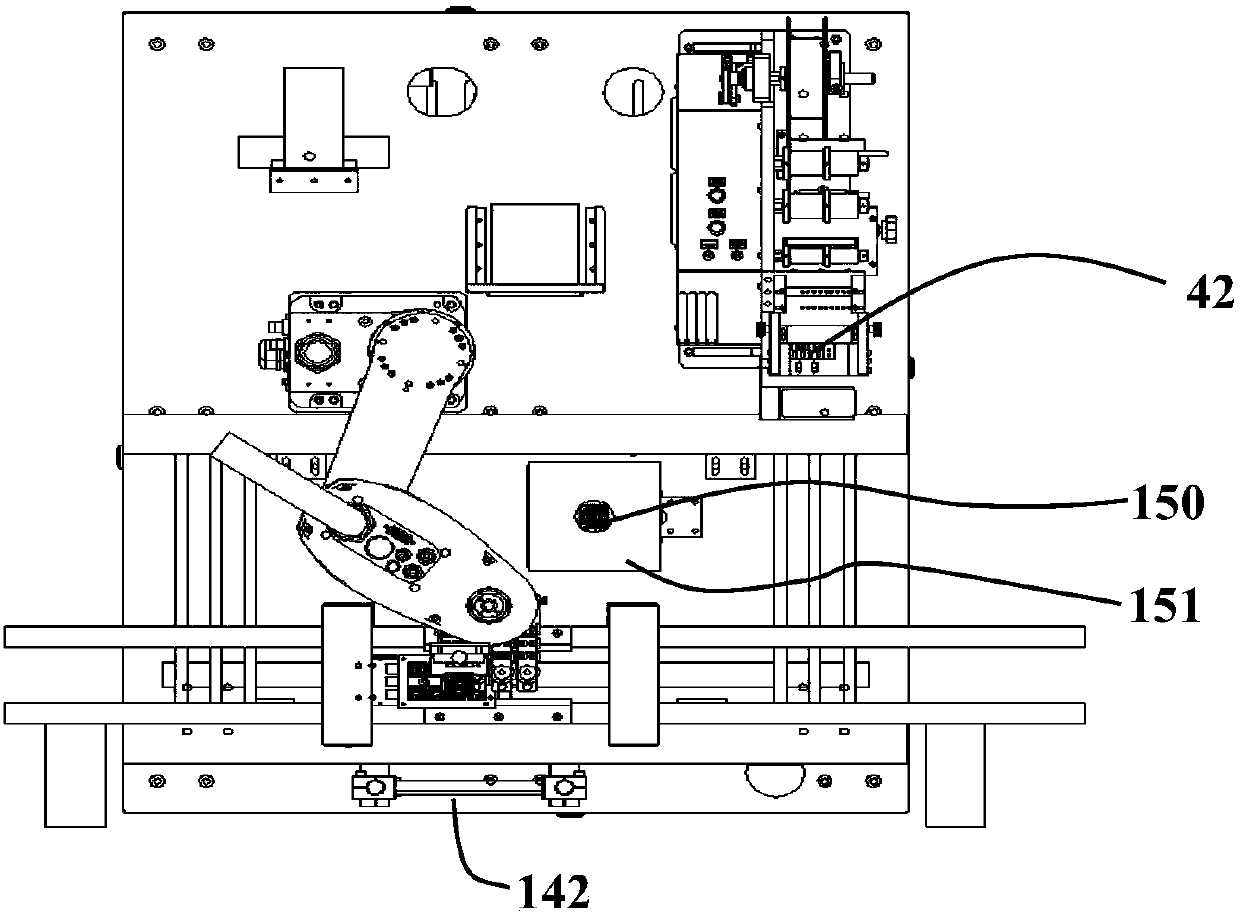

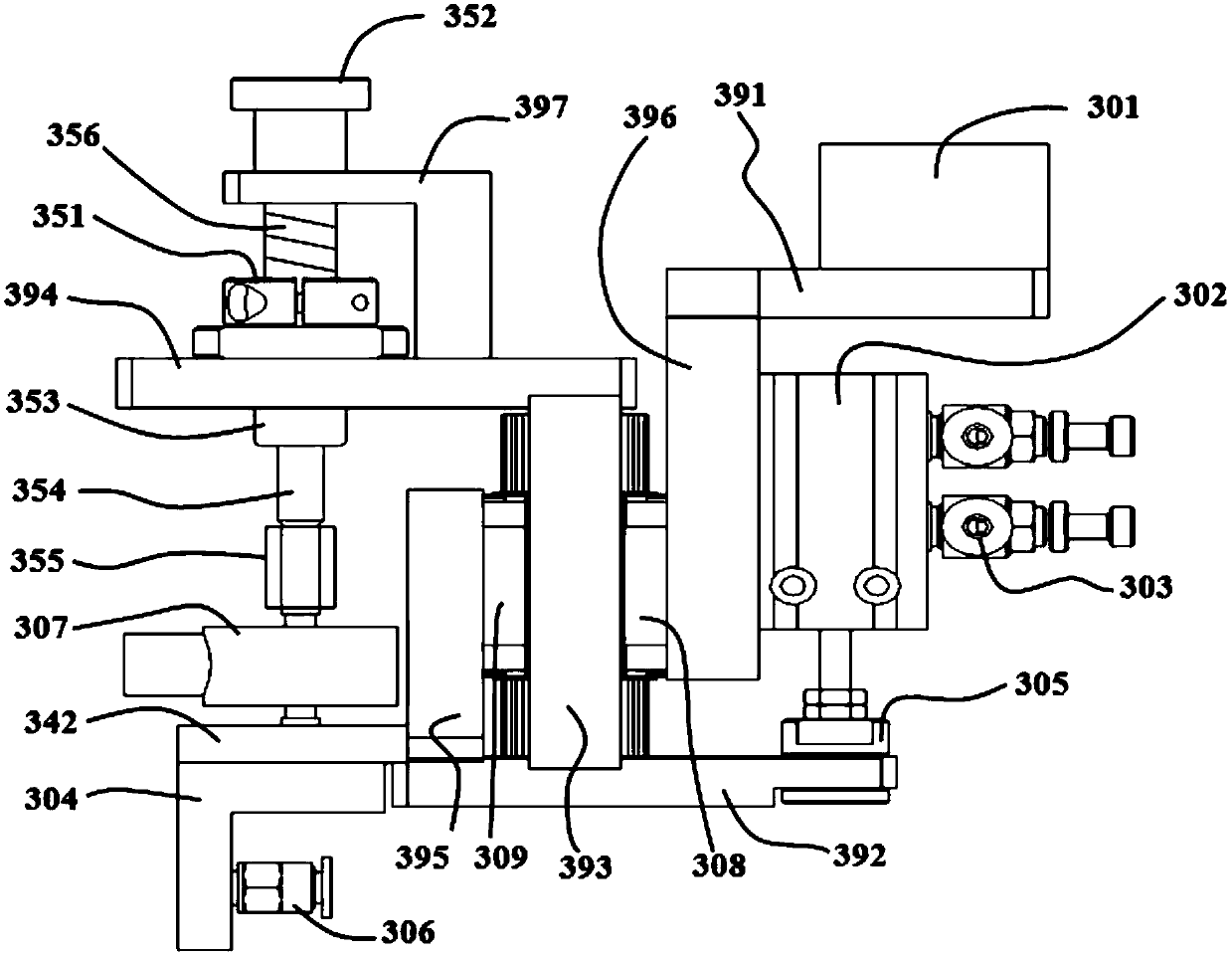

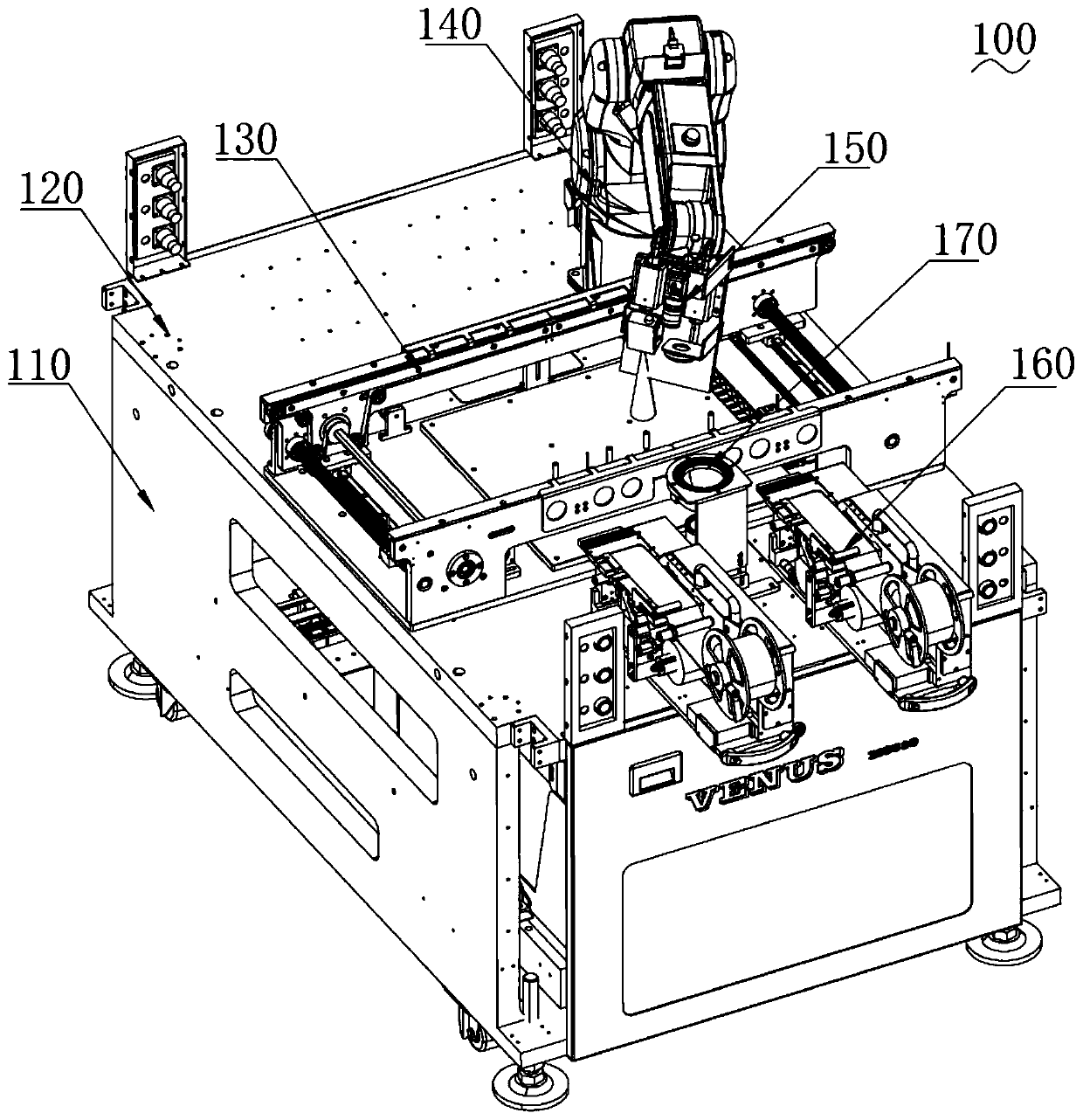

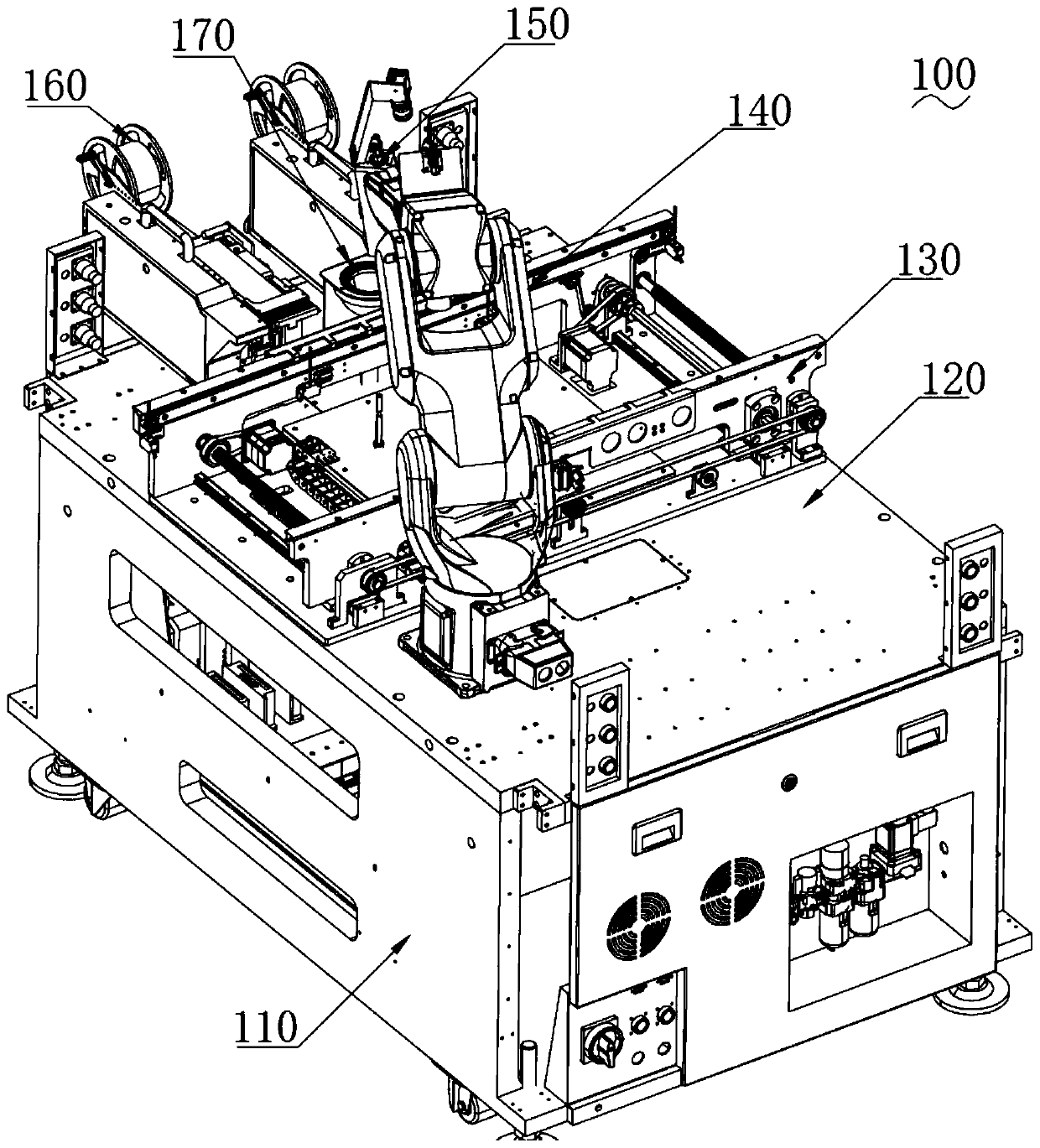

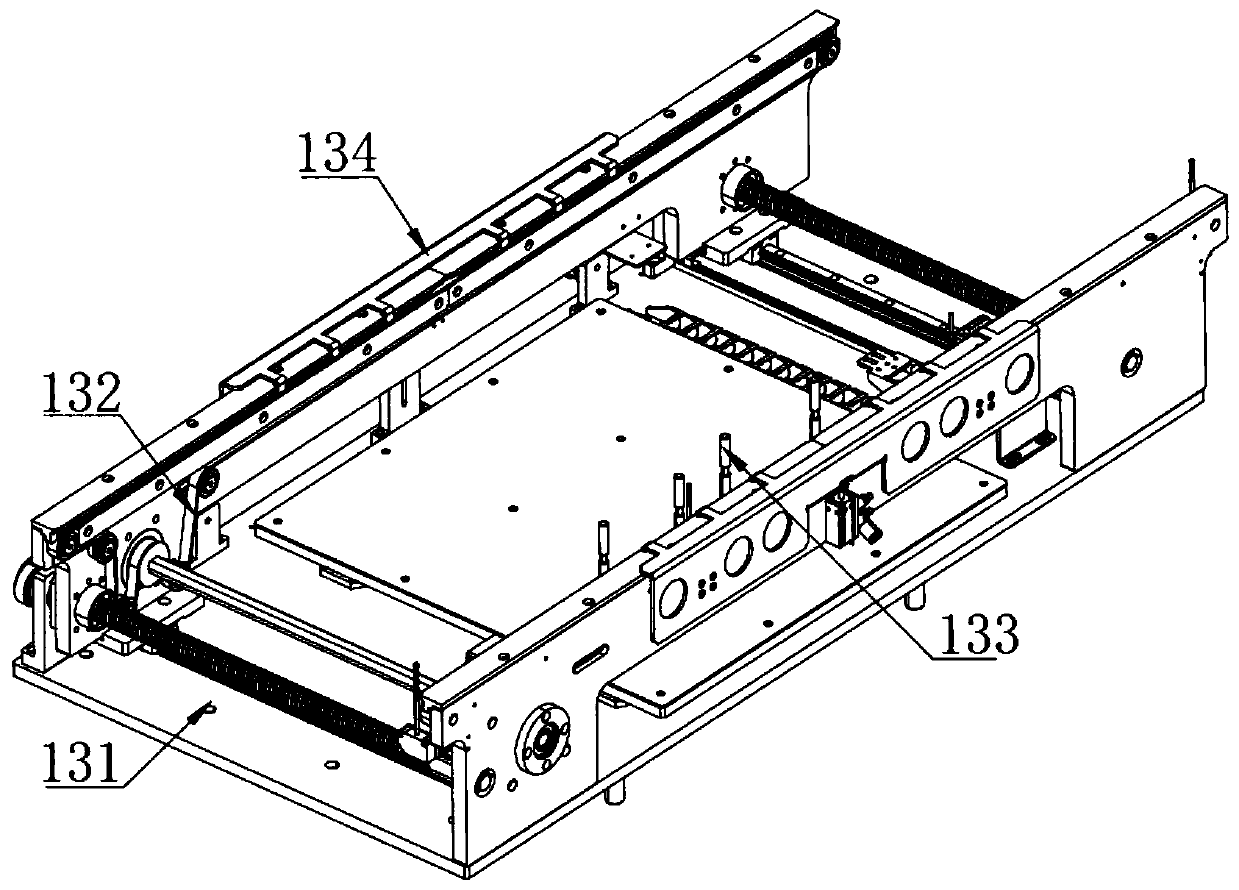

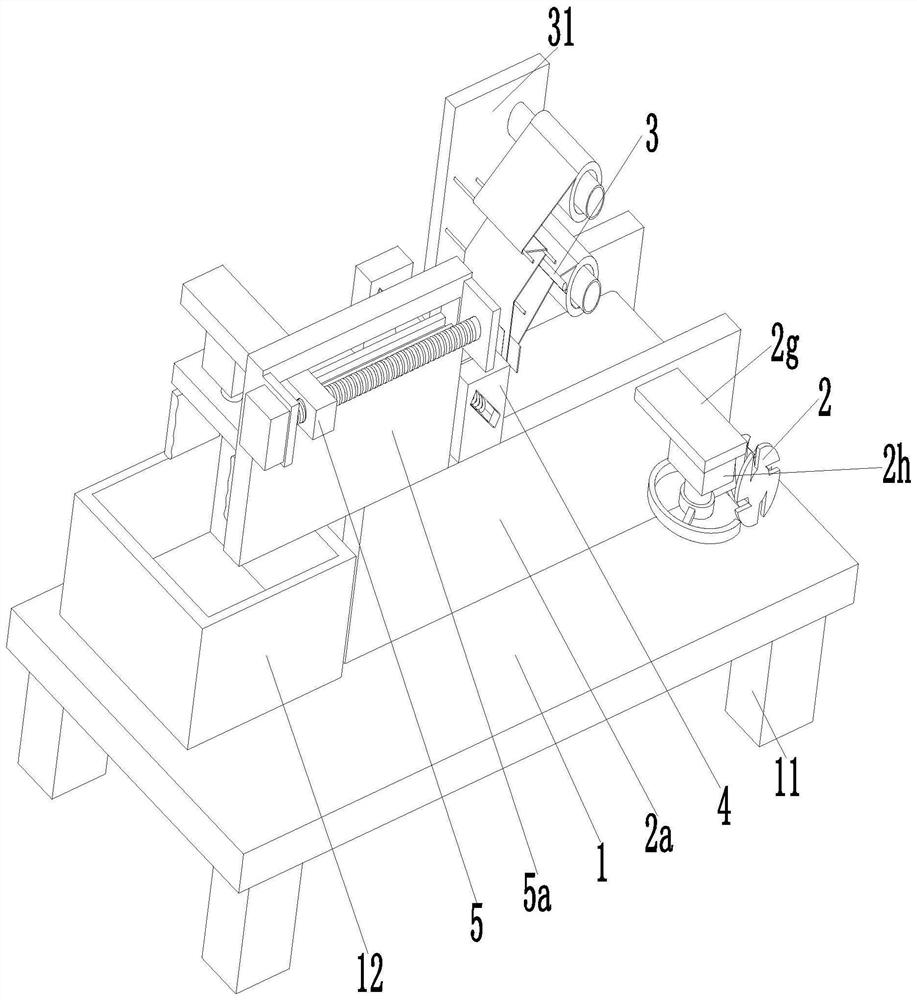

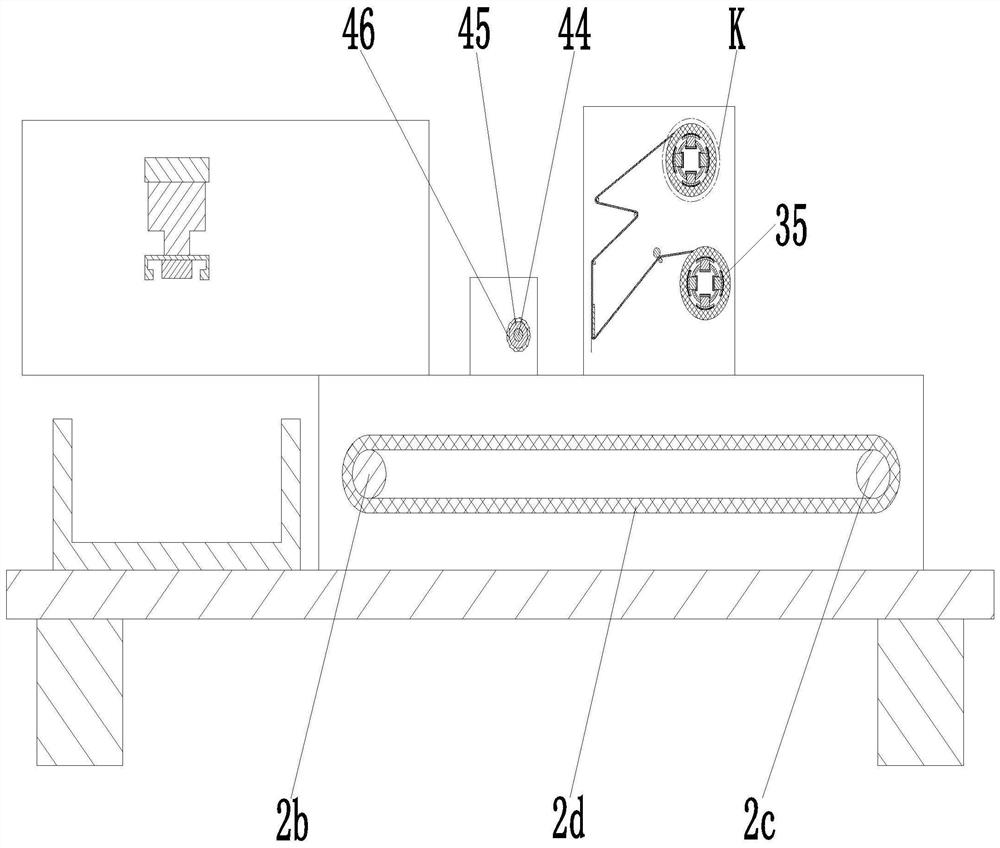

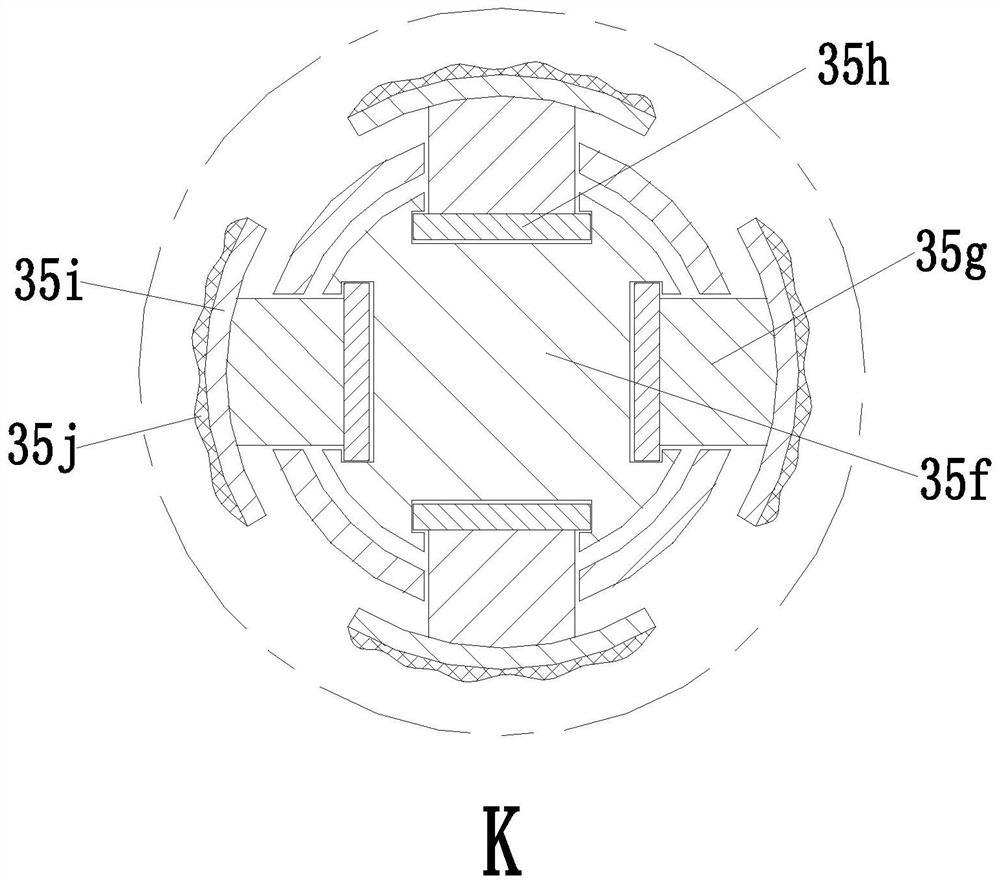

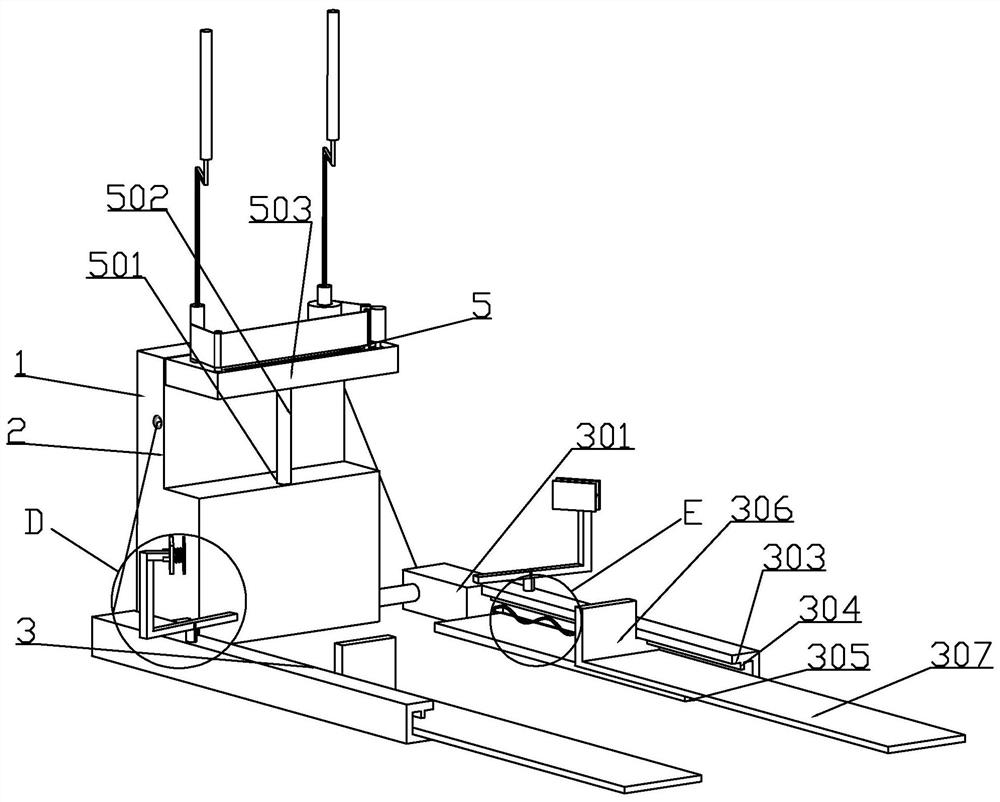

Multi-station labeling device based on mechanical arm

PendingCN109703850AImprove work efficiencySave manpower and material resourcesLabelling machinesMaterial resourcesEngineering

The invention relates to the technical field of automatic equipment, in particular to a multi-station labeling device based on a mechanical arm. The multi-station labeling device comprises a rack, a workbench arranged on the surface of the rack, a conveying device transversely arranged on the workbench, a robot arranged on the side, provided with the conveying device, of the workbench, a labelingdevice arranged at the driving end of the robot, and label unwinding devices arranged on the worktable and used for label discharging, wherein at least two groups of label unwinding devices are arranged, and the robot drives the labeling device to take labels on the label unwinding devices and attach the labels to products conveyed by the conveying device. According to the multi-station labeling device, the products are labeled through the robot in the automatic conveying mode, manual operation control is not needed, automatic material taking and labeling is achieved, working efficiency is high, automation degree is high, manpower and material resources are saved and labeling effect is good.

Owner:广东钮铂尔科技有限公司

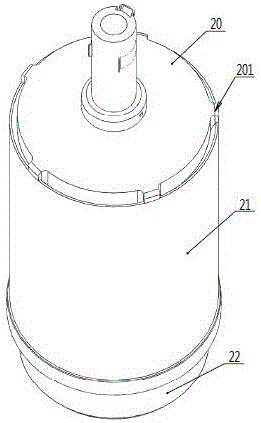

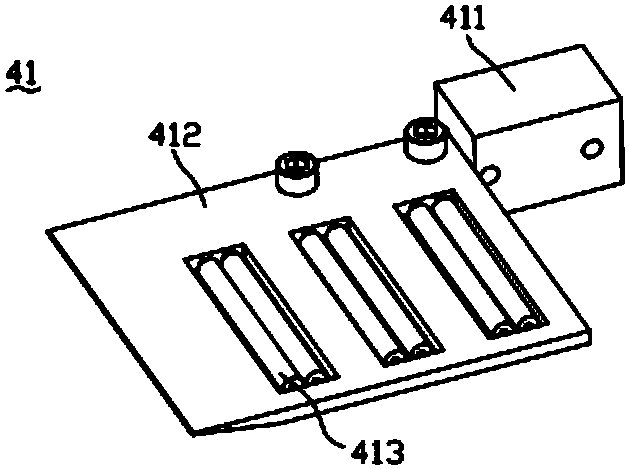

Thin-walled cylinder hot melt glue labeling machine

The invention discloses a thin-walled cylinder hot melt adhesive labeling machine. The thin-walled cylinder hot melt glue labeling machine comprises a bottle carrying and transferring table, a bottle feeding device, a glue spraying device, a split floating label bin, a glue scrapping device, a glue melting box and a bottle discharging device, wherein the bottle carrying and transferring table are installed in the center of the table surface of a rack, and the bottle feeding device, the glue spraying device, the split floating label bin, the glue scrapping device, the glue melting box and the bottle discharging device are located on the table surface of the rack and distributed on the periphery of the bottle carrying and transferring table. An adjustable label box is installed at the front end of a base plate in the split floating label bin, an auxiliary label feeding device is installed at the rear end of the base plate, elastic label pushing devices are symmetrically installed on the left side and the right side of the base plate correspondingly, and a rolling label feeding chain way is installed in the middle of the base plate. According to the thin-walled cylinder hot melt glue labeling machine, modularized design and a mechanical automatic production line of the composition structure are achieved, whole cylinder body labeling of labels with large diameters and widths of thin-walled paper cylinders, thin-walled metal cylinders and the like can be achieved, the replacing frequency of the labels can be greatly reduced through the label bin with a high capacity, operation of an operator is facilitated, production efficiency is greatly improved, the labeling quality and labeling precision are further improved, and production cost is maximally reduced.

Owner:莱州市同力机械有限公司

Horizontal multi-joint visual labeling robot

InactiveCN113562280AImprove stabilityGood labeling effectProgramme-controlled manipulatorArmsPhysical medicine and rehabilitationGear wheel

The invention discloses a horizontal multi-joint visual labeling robot which comprises a robot body. A fixed plate is fixedly connected to the left side of the upper surface of the robot body, a second motor groove is formed in the left side of the upper end of the front face of the robot body, a second servo motor is fixedly connected to the middle end of the top of the second motor groove, the output end of the second servo motor penetrates through the middle end of the bottom of an inner cavity of the fixed plate and is fixedly connected with a first gear, the middle end of the right side of the inner cavity of the fixed plate is movably connected with a screw, the right side of the outer surface of the screw is fixedly connected with a second gear, the first gear is engaged with the second gear, and the left side and the right side of the outer surface of the screw are in threaded connection with sliding blocks. According to the horizontal multi-joint visual labeling robot, a second pulley, the first gear, the second gear and the second servo motor are arranged, so that the aim of the good labeling effect is achieved, and the problems that an existing horizontal multi-joint visual labeling robot cannot adjust a to-be-labeled object, consequently, skewing is prone to happening to labeling during work, and the labeling effect is affected are solved.

Owner:深圳市星谊技术有限公司

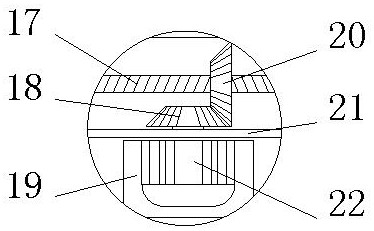

Labelling machine with good labelling effect for huangjiu

InactiveCN109229691ASolve the problem of poor labeling effectImprove work efficiencyLabelling machinesGear wheelArchitectural engineering

The invention discloses a labelling machine with good labelling effect for huangjiu. The labelling machine comprises a box, wherein the back surface of the box is fixedly connected with a motor case;the bottom of an inner chamber of the motor case is fixedly connected with a motor; an output shaft of the motor penetrates an inner chamber of the box and is fixedly connected with a gear; the innerchamber of the box is fixedly connected with a fixing rod; the front surface of the fixing rod is movably connected with a connecting rod through a rotating shaft. Under cooperative use of the box, the motor, the gear, the fixing rod, the connecting rod, a specially shaped toothed plate, a limit rod, a slide plate, a first spring, a fixed box and a clamp plate, the problem of poor labelling effectof the conventional labelling machine for huangjiu is solved, the labelling machine for huangjiu has good labelling effect, is simple to operate in a huangjiu production process, is convenient to useand is more precise during labeling of huangjiu, working efficiency of the labelling machine for huangjiu is increased greatly, and production efficiency of huangjiu is increased.

Owner:湖州老绍坊酒业有限公司

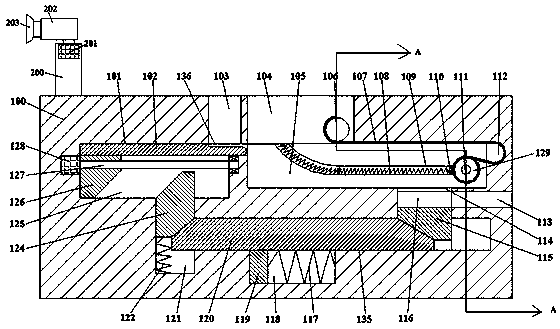

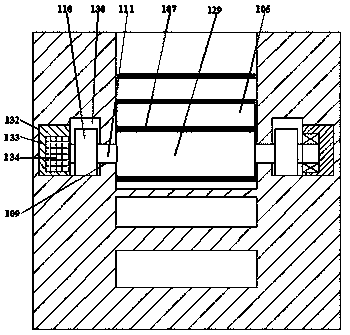

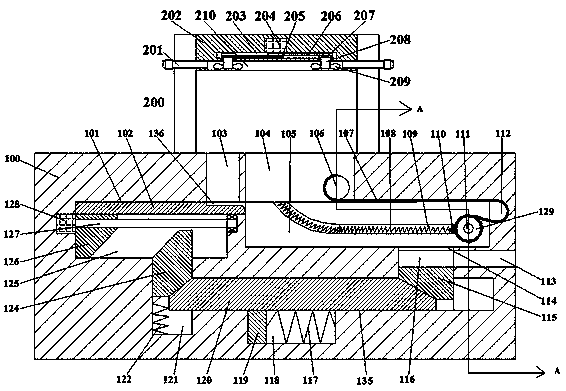

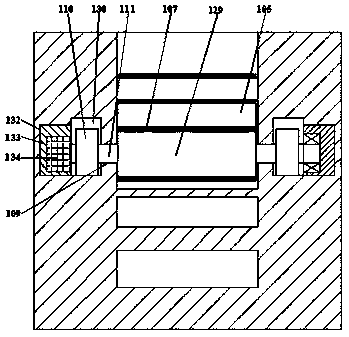

Automatic bottle labeling device

InactiveCN108341114AEasy maintenancePromote repairLabelling machinesLabelling short rigid containersEngineeringBottle

The invention discloses an automatic bottle labeling device comprising a machine seat and a labeling cavity formed in the machine seat. The top inner wall of the labeling cavity is internally providedwith a finished-product outlet slot in a penetrated manner. The front inner wall and the rear inner wall of the labeling cavity are internally provided with symmetrical sliding rail slots in a communicating manner, the inner walls of the sliding rail slots are internally provided with symmetrical gear installation slots in a communicating manner, and the inner walls of the gear installation slotsare internally provided with symmetrical first sliding slots in a communicating manner. The left end inner wall of the labeling cavity is internally provided with a second sliding slot in a communicating manner, the right end inner wall of the labeling cavity is internally provided with a bottle placement slot in a communicating manner, the bottom inner wall of the second sliding slot is internally provided with a third sliding slot in a communicating manner, the bottom inner wall of the third sliding slot is internally provided with a fourth sliding slot in a communicating manner, the rightend inner wall of the fourth sliding slot is internally provided with a fifth sliding slot in a communicating manner, the bottom inner wall of the labeling cavity is internally provided with a sixth sliding slot in a communicating manner, and the fifth sliding slot penetrates through the sixth sliding slot. The automatic bottle labeling device is simple in structure and convenient to operate, moveand carry.

Owner:傅丽秋

Printing ink and adhesive sticker label therewith

Printing ink includes following components, by mass, 3-8 parts of a white pigment, 81-90 parts of gloss oil, 1-5 parts of a primary photo-initiator, 2-6 parts of first organic silicon and 4-10 parts of a first levelling agent. In the printing ink, because the gloss oil is added in a high ratio, the printing ink is good in smoothness and is high in adhesion force, so that the printing ink is free of excessive adhesive when an adhesive sticker label is torn away even under a high temperature condition. In addition, the printing ink enables the adhesive sticker label to be recycled conveniently, is easy to prepare and is low in preparation cost.

Owner:赛维精密科技(广东)有限公司

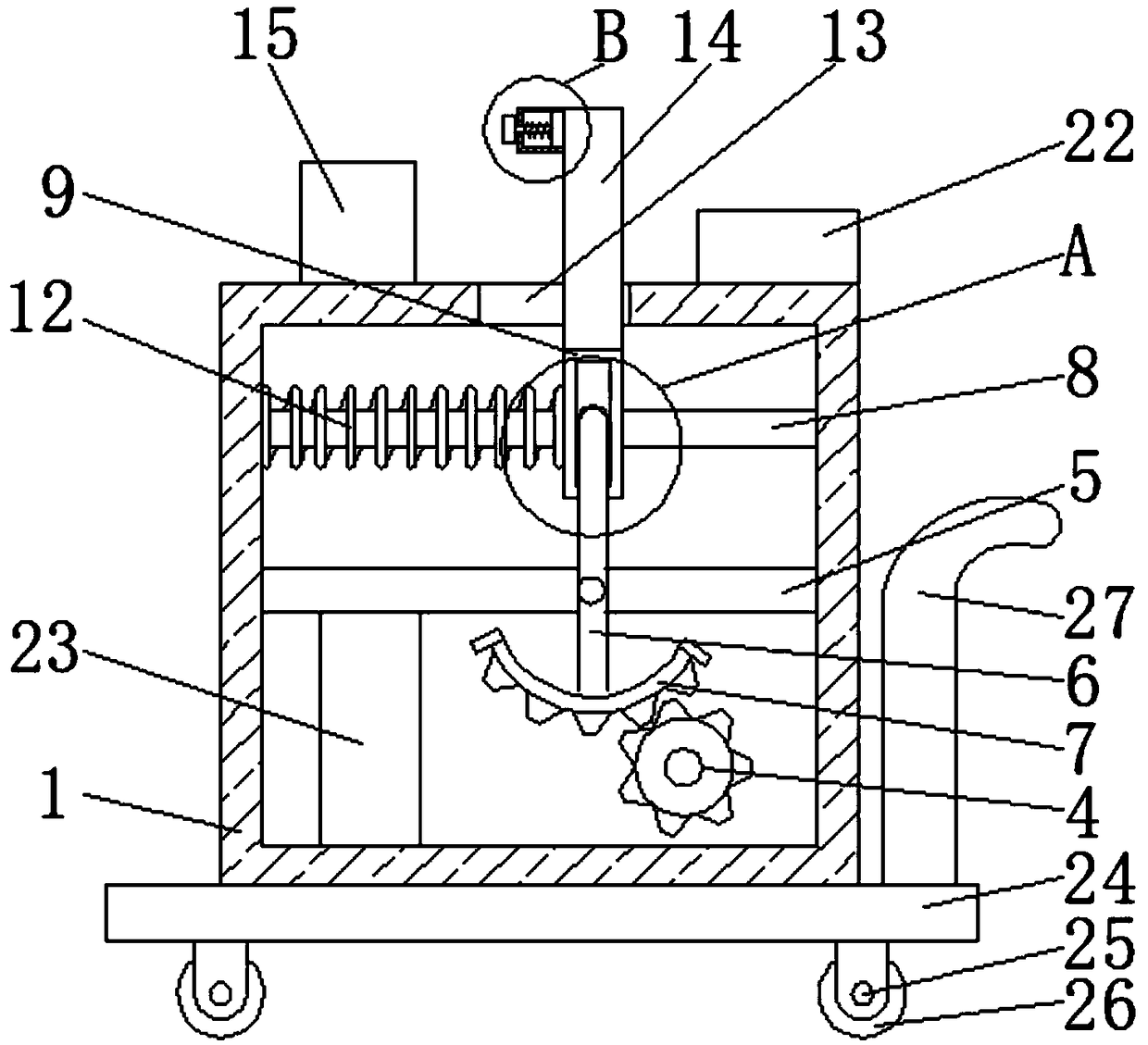

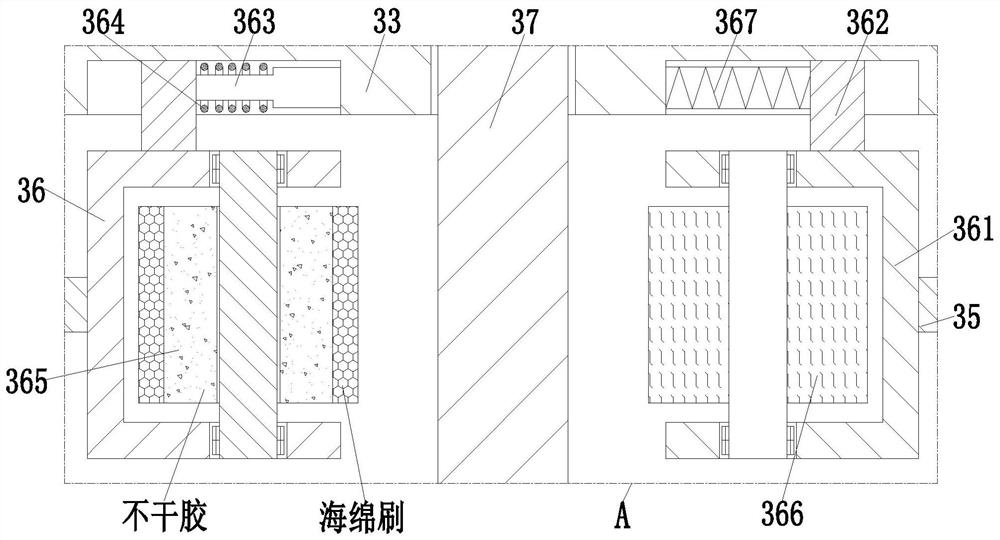

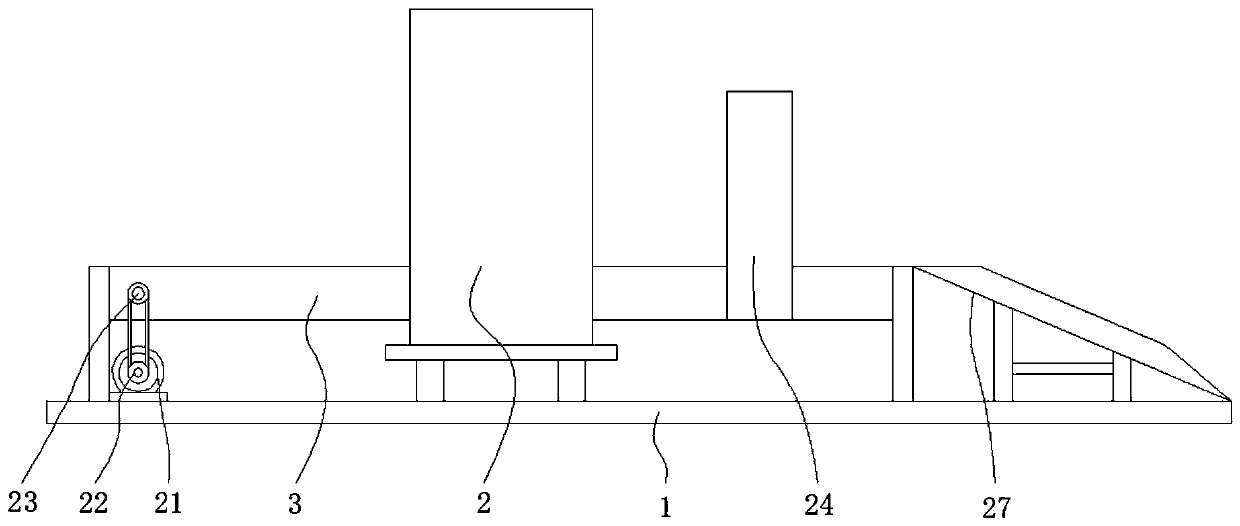

Intelligent labeling system for logistics labels

InactiveCN112173329ALow efficiencyGood labeling effectLabelling machinesLogistics managementProcess engineering

The invention relates to an intelligent labeling system for logistics labels. The system involves a bottom plate, a conveying mechanism, a labeling mechanism, a smoothing mechanism and a material taking mechanism, wherein the conveying mechanism is arranged on the bottom plate, the labeling mechanism is arranged at the right end of the conveying mechanism, the smoothing mechanism is arranged in the middle of the conveying mechanism, and the material taking mechanism is arranged at the left end of the conveying mechanism. The system can solve the following problems existing in existing logistics packaging box labeling that firstly, traditional manual labeling needs label stripping, position approval, labeling and other procedures, so that the procedures are numerous, much time is consumed for manual labeling, and the labeling efficiency is reduced; and during manual labeling, many errors are caused by human factors, so that the positions of the labels of logistics packaging boxes are different, and the subsequent use is influenced; and secondly, during traditional machine labeling, the phenomenon of unstable labeling is prone to occur; and the system can realize an intelligent labeling function, and has the advantages that the labeling effect is good, the working efficiency is high and the like.

Owner:深圳市兴耀扬科技有限公司

Intelligent labeling device for bottles

InactiveCN108341113AEasy maintenancePromote repairLabelling machinesLabelling short rigid containersEngineeringBottle

The invention discloses an intelligent labeling device for bottles. The intelligent labeling device for the bottles comprises a machine base and a labeling cavity arranged in the machine base, and a finished product outlet groove is internally formed in the inner wall of the top of the labeling cavity in a penetrating mode, and the front inner wall and the rear inner wall of the labeling cavity internally communicate with symmetric sliding rail grooves; the inner walls of the sliding rail grooves internally communicate with gear mounting grooves which are symmetric, and the inner walls of thegear mounting grooves internally communicate with first sliding grooves which are symmetric; the inner wall of the left end of the labeling cavity internally communicate with a second sliding groove,and a bottle placing groove is internally formed in the inner wall of the right end of the labeling cavity in a communicating mode; the inner wall of the bottom of the second sliding groove internallycommunicates with a third sliding groove, and a fourth sliding groove is internally formed in the inner wall of the bottom of the third sliding groove in a communicating mode; a fifth sliding grooveis internally formed in the inner wall of the right end of the fourth sliding groove, and a sixth sliding groove is internally formed in the inner wall of the bottom of the labeling cavity; and the fifth sliding groove penetrates through the sixth sliding groove. The intelligent labeling device for the bottles is convenient to operate and convenient to move and carry.

Owner:傅丽秋

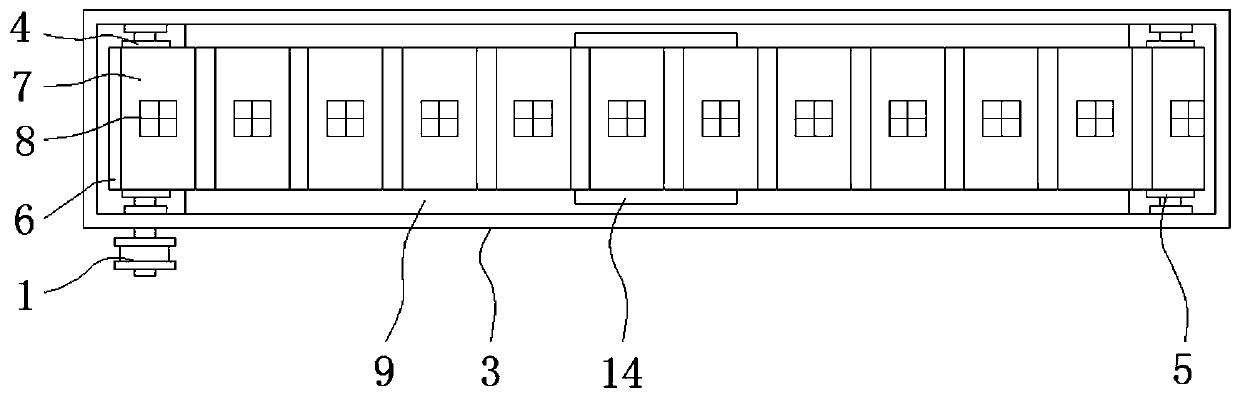

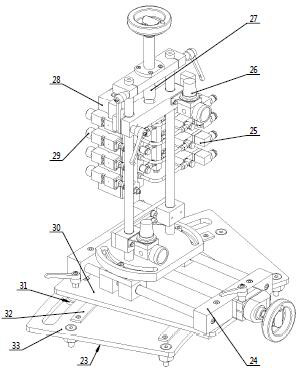

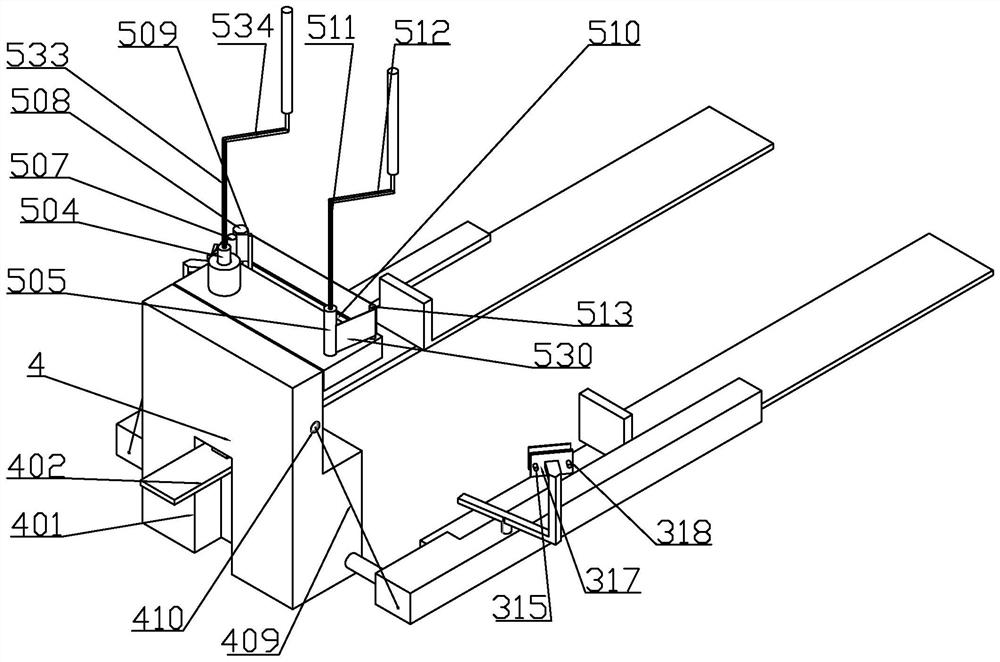

Intelligent labeling equipment and method for logistics base stations

InactiveCN112849623AMeet the needs of assembly line conveying and labelingImprove labeling efficiencyLabelling machinesLogistics managementProcess engineering

The invention relates to intelligent labeling equipment and method for logistics base stations. The intelligent labeling equipment comprises a bottom plate, a conveying device and a labeling device, the conveying device is arranged in the middle of the upper end face of the bottom plate, the labeling device is arranged above the conveying device, and the labeling device is installed on the bottom plate. By means of the intelligent labeling equipment, the problems that existing labeling equipment cannot meet the assembly line labeling requirement of products and is low in labeling efficiency can be solved, and the problems that the existing labeling equipment cannot label products with the cambered surfaces, cannot thoroughly attach labels to the products, is poor in applicability and cannot tightly press the labels after the labels are pasted, consequently the fitting degree between the labels and the products is not high, the products easily fall in the transportation process, the confusion or loss of goods is easily caused, and direct economic losses are easily caused are solved.

Owner:王小友

Labeling equipment for transmitting cosmetic bottles by utilizing gravity principle

InactiveCN112896691AAvoid sticking togetherTightly bondedLabelling machinesMechanical engineeringCosmetics

The invention relates to the related technical field of cosmetics, and discloses labeling equipment for transmitting cosmetic bottles by utilizing the gravity principle. The labeling equipment comprises a lower bin, and a supporting plate is fixedly connected to the upper portion of the lower bin. Conical wheels rotate to enable labels to be laid step by step, a labeling device extrudes the laid labels, the labels are prevented from being bonded together, the labels can be tightly attached to the cosmetic bottles, a second moving rod moves upwards to push the cosmetic bottles out of a device table, manual transfer is avoided, and the working efficiency is improved. The containing table moves downwards to cause rightward movement of a first moving rod to hinder rotation of a stop rod and pause rotation of a third connecting rod, so that the situation that a push block pushes the cosmetic bottles out of the containing table in the labeling process of the labeling device is avoided, smooth labeling work is guaranteed, the motion state of the first connecting rod is not affected by a second connecting rod all the time, the second connecting rod can rotate along with the first connecting rod and can also keep static, the relevance between the structures is increased, the two hands are liberated, and the operation is more convenient.

Owner:HUNAN UNIV OF TECH

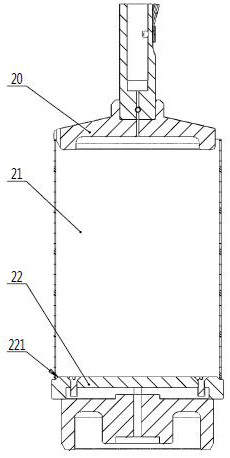

Automatic bucket cover installing production line

InactiveCN105502246AHigh degree of automationImprove job stabilityFlanged caps applicationLabelling machinesShort durationEngineering

The invention discloses an automatic bucket cover installing production line comprising a bucket body conveying track, a bucket cover conveying track and a bucket cover installing mechanism, wherein the bucket body conveying track and the bucket cover conveying track are vertical; the bucket cover conveying track is positioned above the bucket conveying track; the bucket cover installing mechanism is arranged at the tail end of the bucket cover conveying track; the bucket body conveying track is correspondingly arranged below the bucket cover installing mechanism; a bucket body conveying stopping station is arranged on a position, below the bucket cover installing mechanism, of the bucket body conveying track; the bucket cover installing mechanism is arranged correspondingly right above the bucket body conveying stopping station; when a bucket body is conveyed to the bucket body conveying stopping state along the bucket body conveying track, the conveying of the bucket body conveying track is stopped for short duration, at the same time, the bucket cover installing mechanism is loosened, a bucket cover falls on to the bucket body from the position above the bucket body, the bucket body conveying track starts continuously, and a next cover pressing step is performed. The automatic bucket cover installing production line is simple in structure, easy and convenient to operate, good in oil bucket labelling effect, and high in production efficiency.

Owner:GUANGXI LIUGONG PREMIUM GRADE LUBRICATING OIL

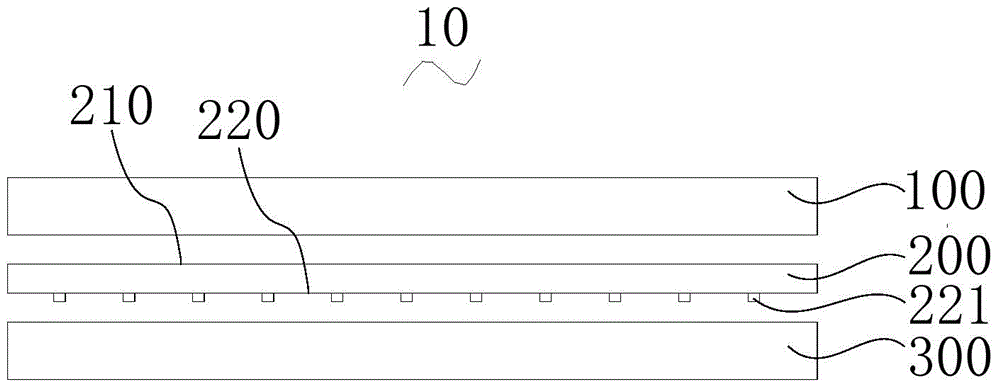

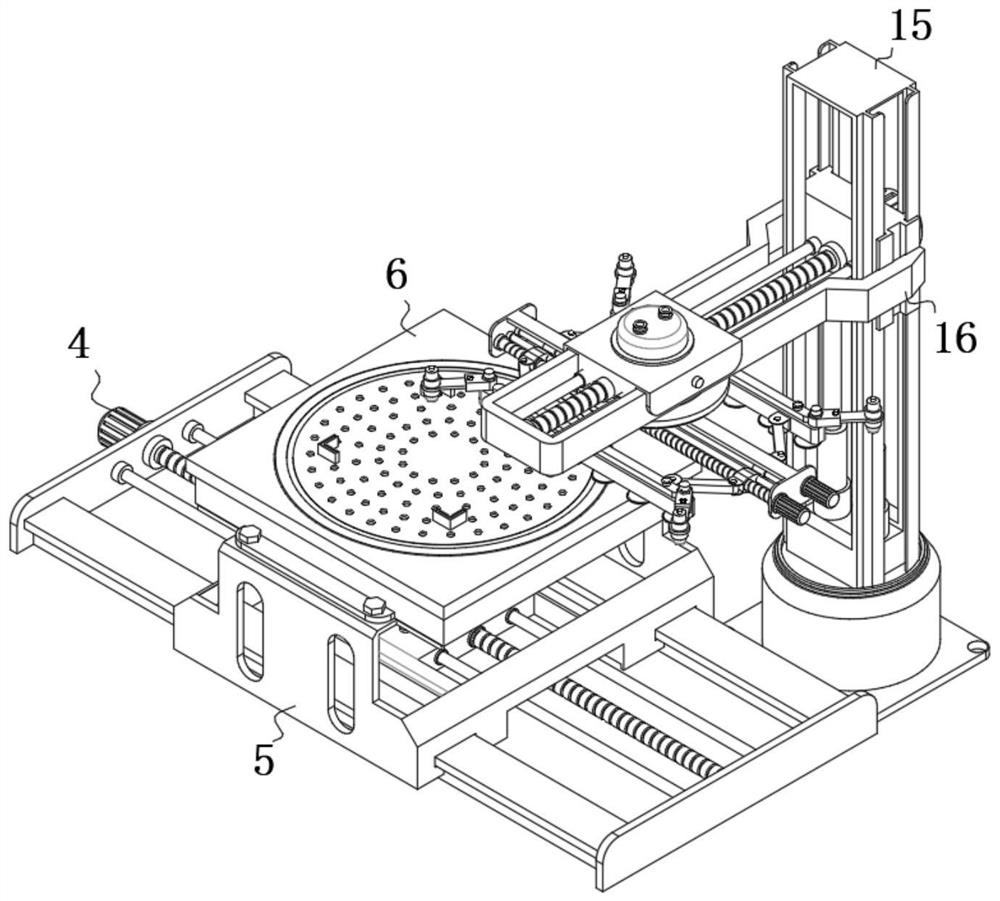

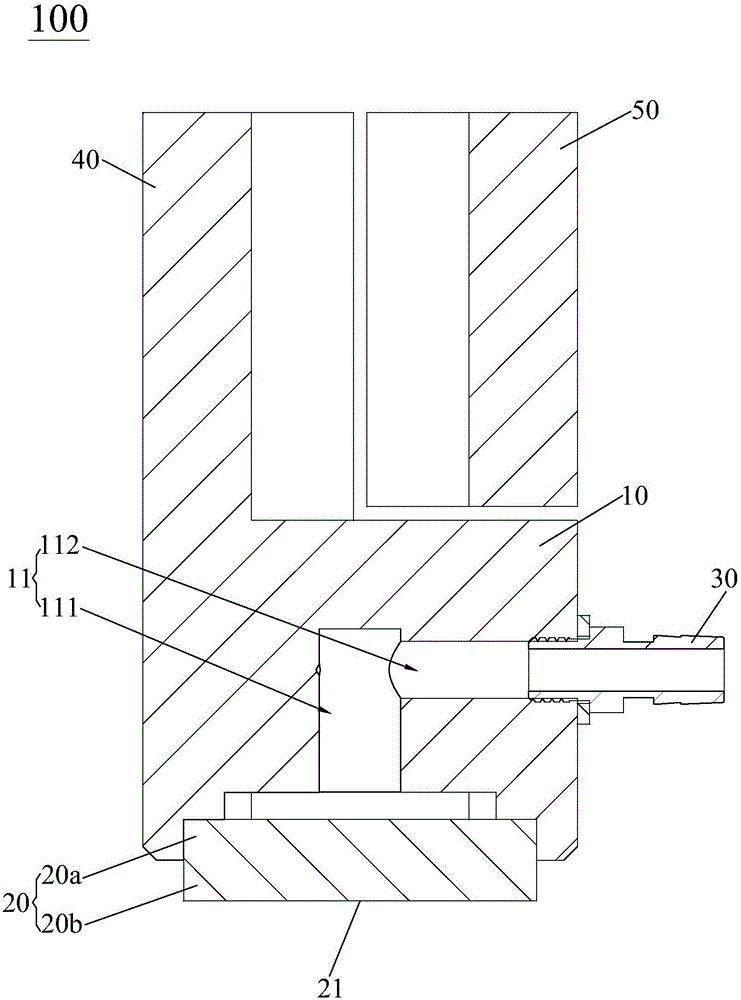

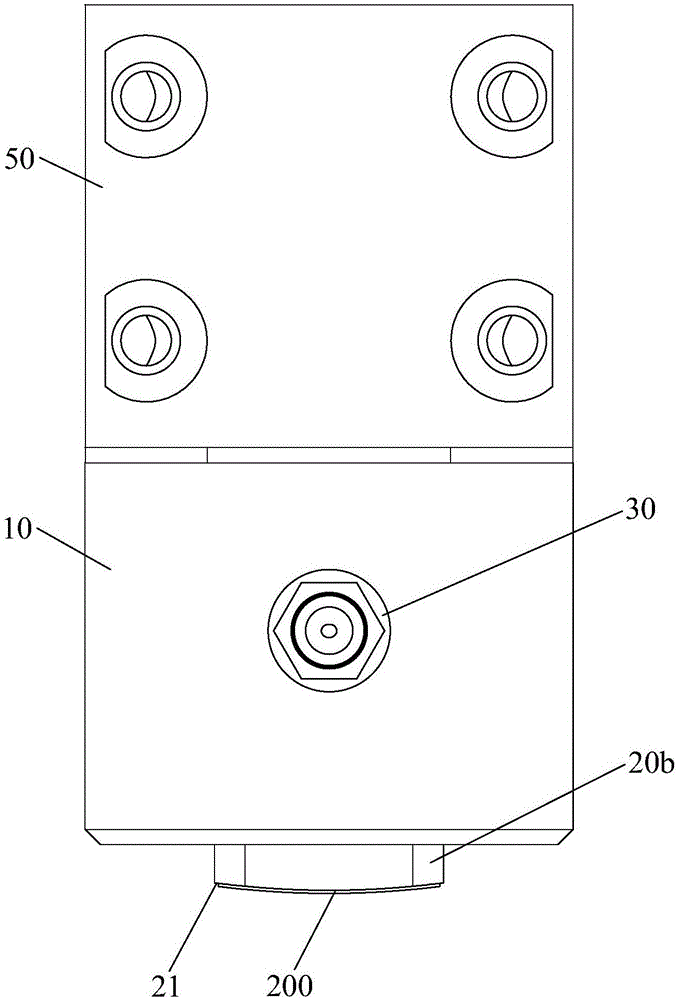

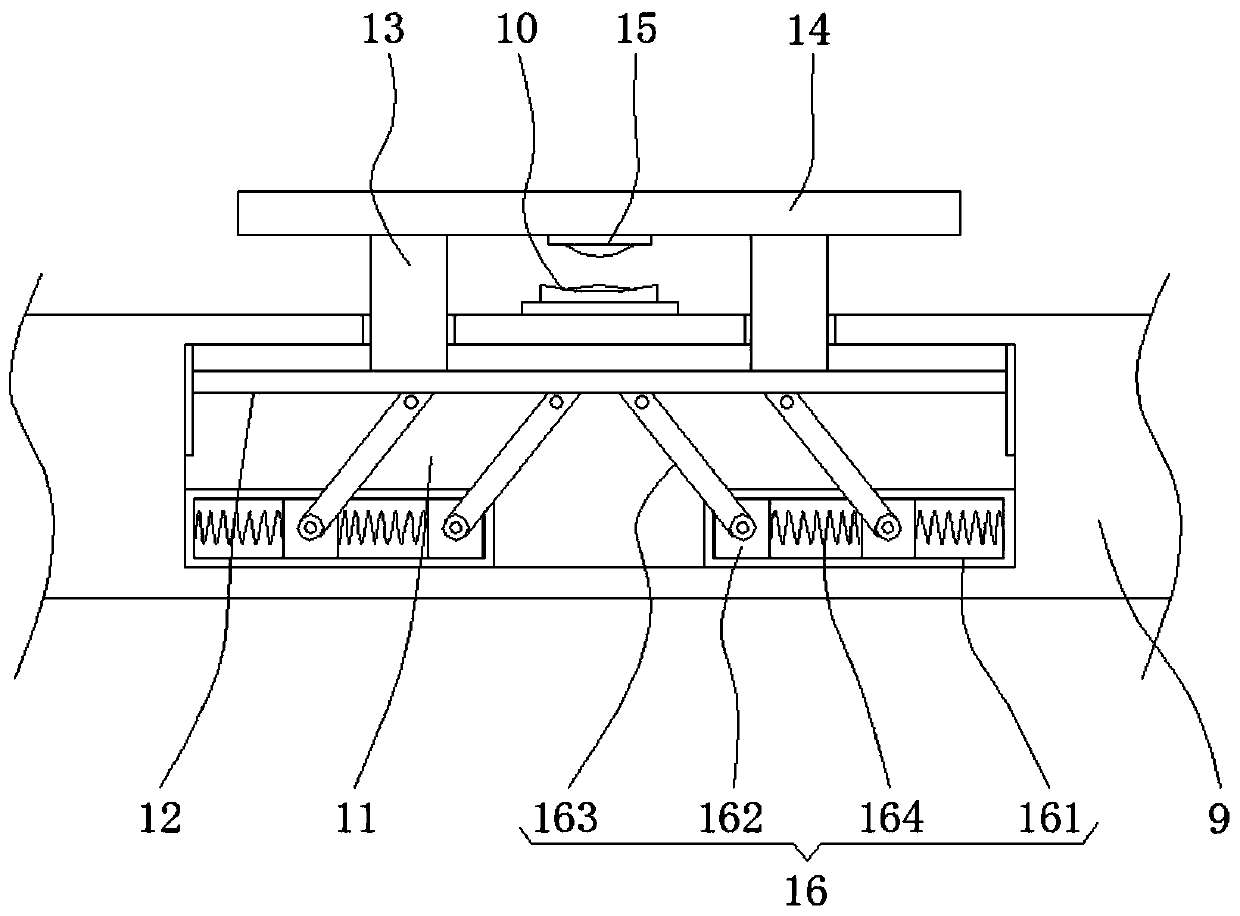

Pressure control attachment mechanism of automatic equipment

InactiveCN111891517AHigh positioning accuracyGood labeling effectMeasurement devicesCharacter and pattern recognitionControl engineeringIndustrial engineering

The invention discloses a pressure control attachment mechanism of automatic equipment, and relates to the technical field of automatic equipment. The mechanism includes a carrying module and an attachment module, the carrying module includes a base, an X-axis driving assembly is fixedly mounted in the base, a support framework is connected with the surface of the X-axis driving assembly, a carrying framework is mounted on the surface of the support framework through a connecting part, a bearing table is connected with the inner wall of the carrying framework in a rotating mode through a bearing, a group of negative pressure vacuum suction holes distributed in a circumferential array mode are formed in the surface of the bearing table, and a negative pressure generating chamber is fixedlyarranged in the bearing table. According to the mechanism, through the design of the carrying module and the attachment module, label attaching operation of an OLED face plate can be automatically finished in an automatic operation mode, and through the match of a positioning standard line and a positioning label in a CCD alignment camera, the mechanism can achieve positioning alignment of a labelattaching mechanism and work pieces to be subjected to label attaching through a mode of four-point positioning and image identification during work.

Owner:马鞍山威莎自动化设备科技有限公司

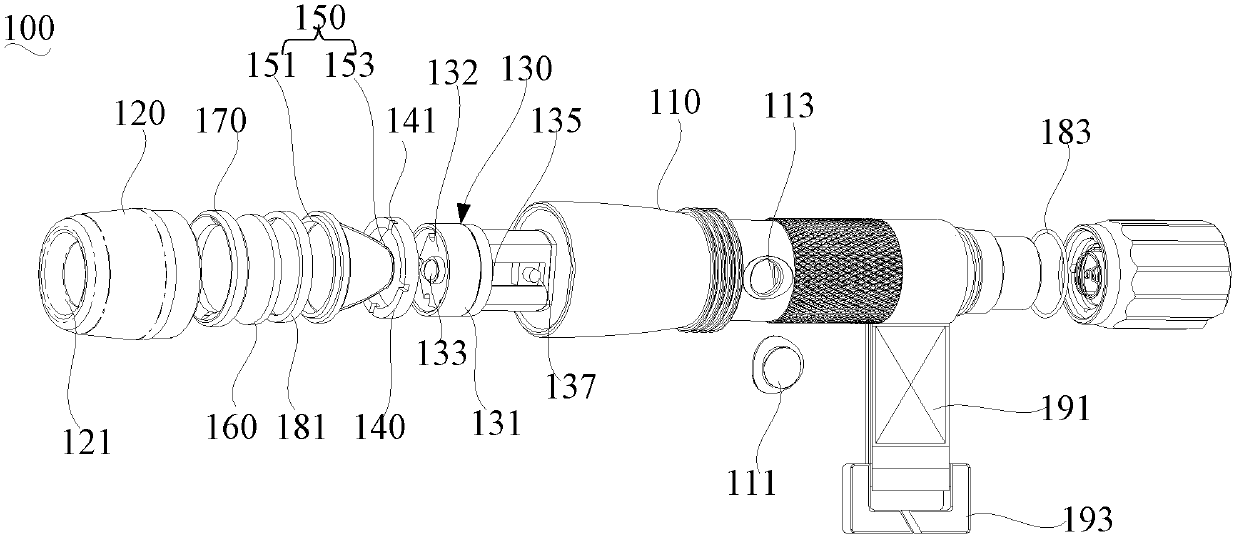

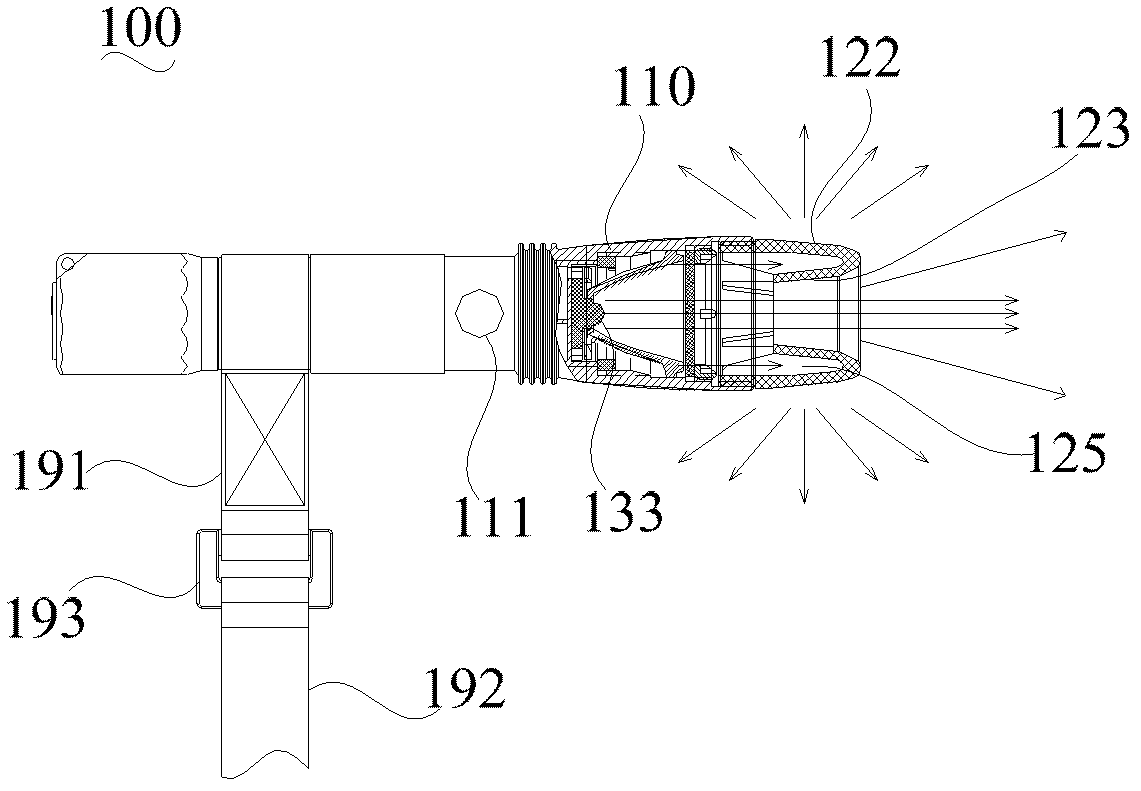

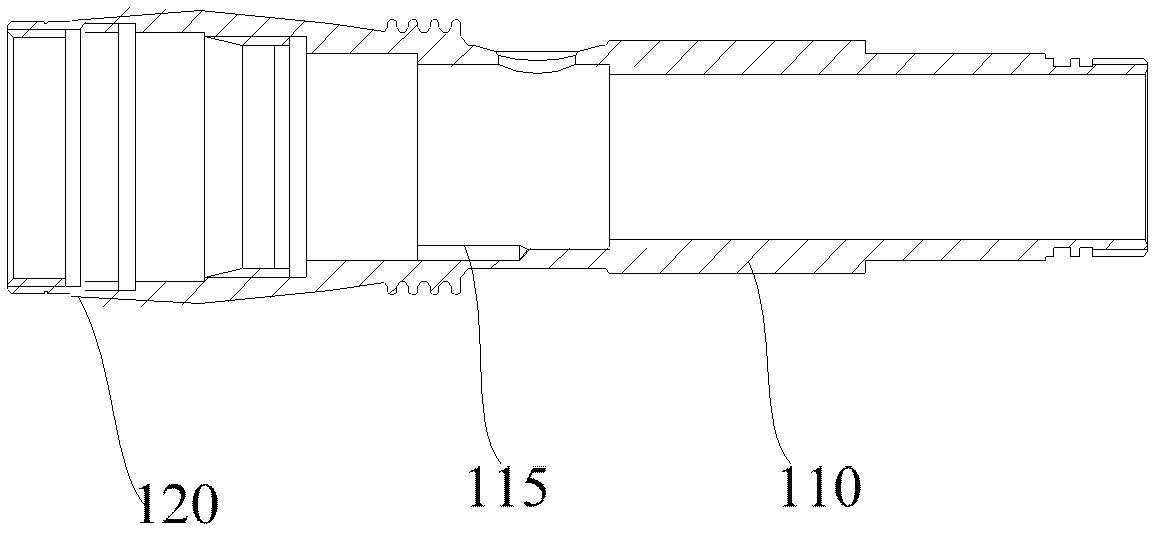

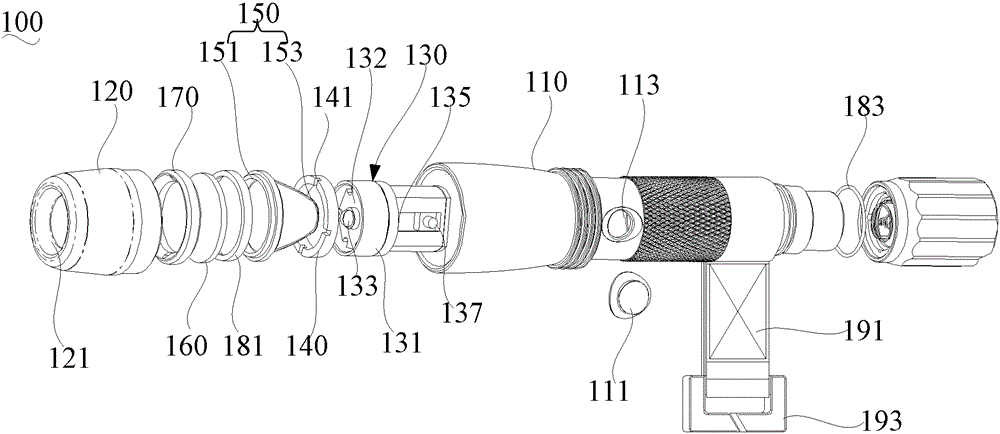

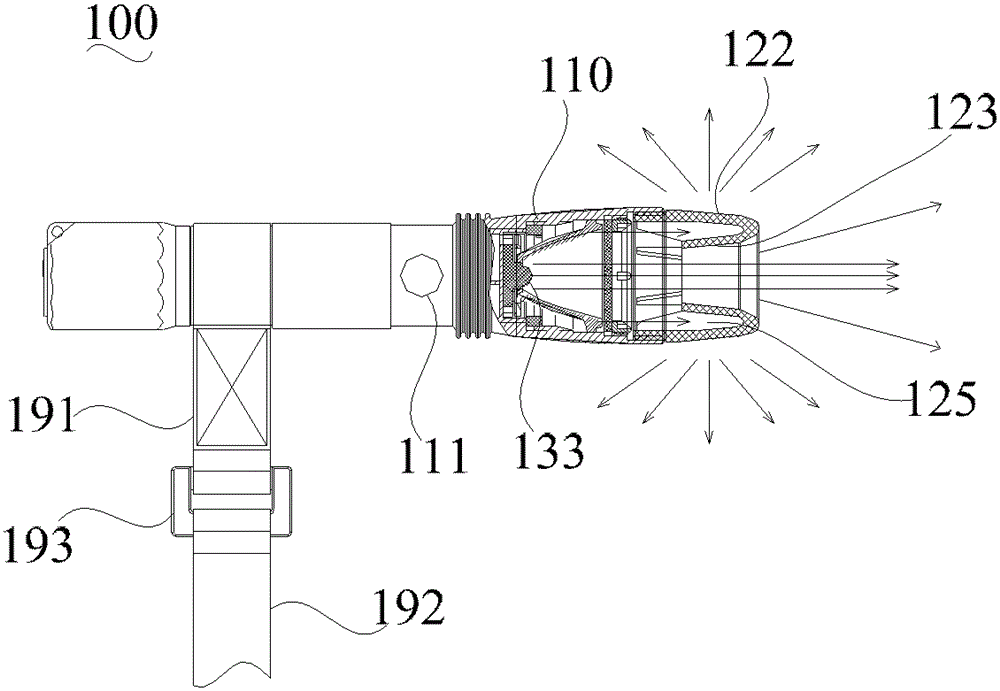

Flashlight

InactiveCN103375685AGood labeling effectIncrease reflectionLighting applicationsPoint-like light sourceLight sourceEngineering

A flashlight comprises a light tube, a base contained in the light tube, a base plate contained in the base, a light-emitting diode (LED) light source arranged on the base plate, a reflector provided with the large opening end and the small opening end and a light transmitting cover. The small opening end is connected with the base plate, and the LED light source is contained in the small opening end. A light hole is formed in the light transmitting cover, and the light transmitting cover is connected with one end of the light tube away from the light hole and contains the reflector. Light emitted by the LED light source is reflected by the reflector and emitted through the large opening end, and a part of the light penetrates the light hole of the light transmitting over to be emitted to light the front and achieve a lighting effect. The other part of the light penetrates the lateral wall of the light transmitting cover to be emitted, an observer on the side can observe the flashlight, and a marker indication signal effect is achieved. The flashlight can achieve a lighting effect and provide a marker indication signal.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

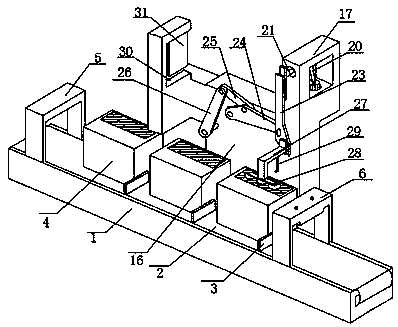

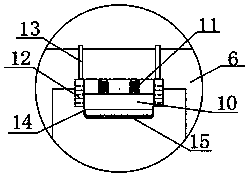

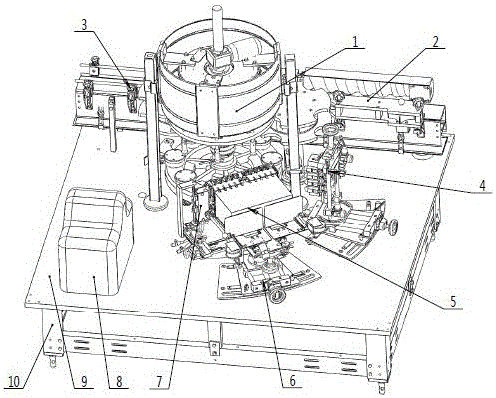

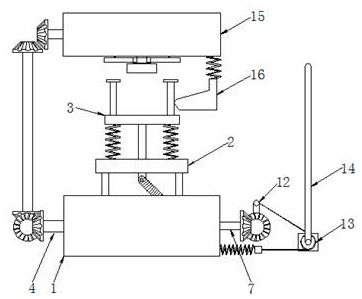

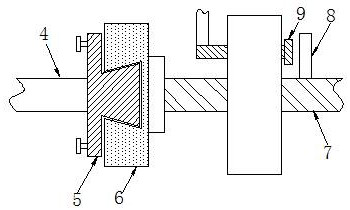

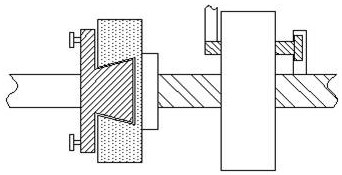

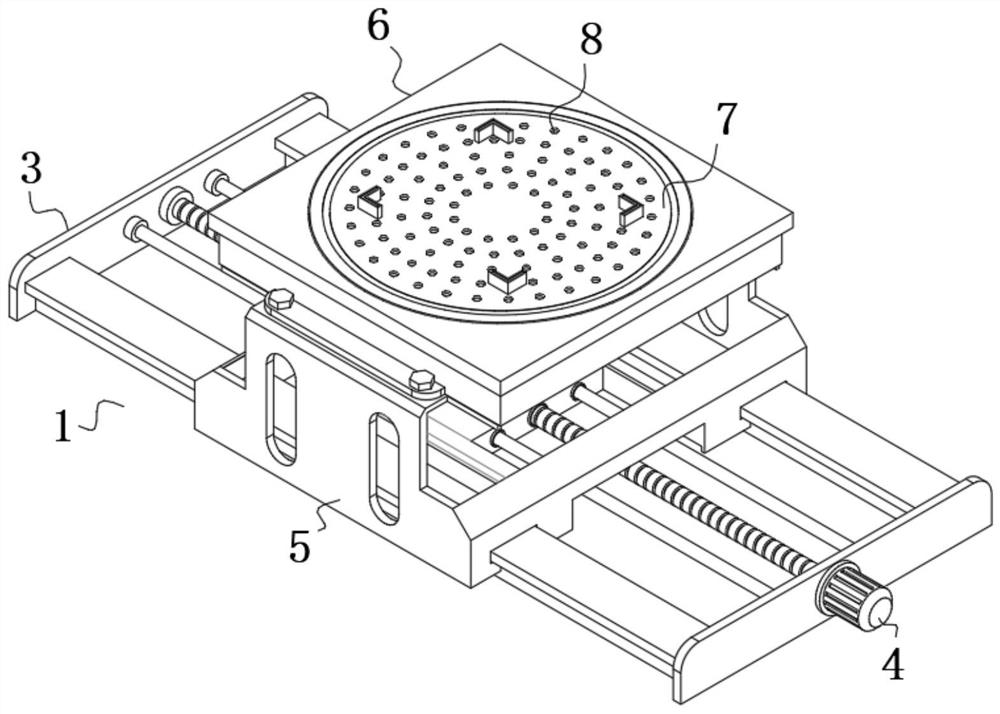

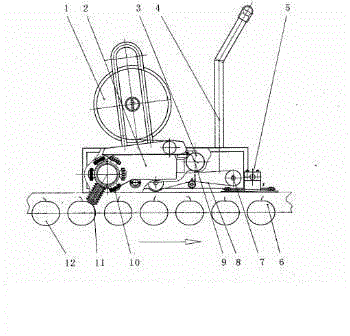

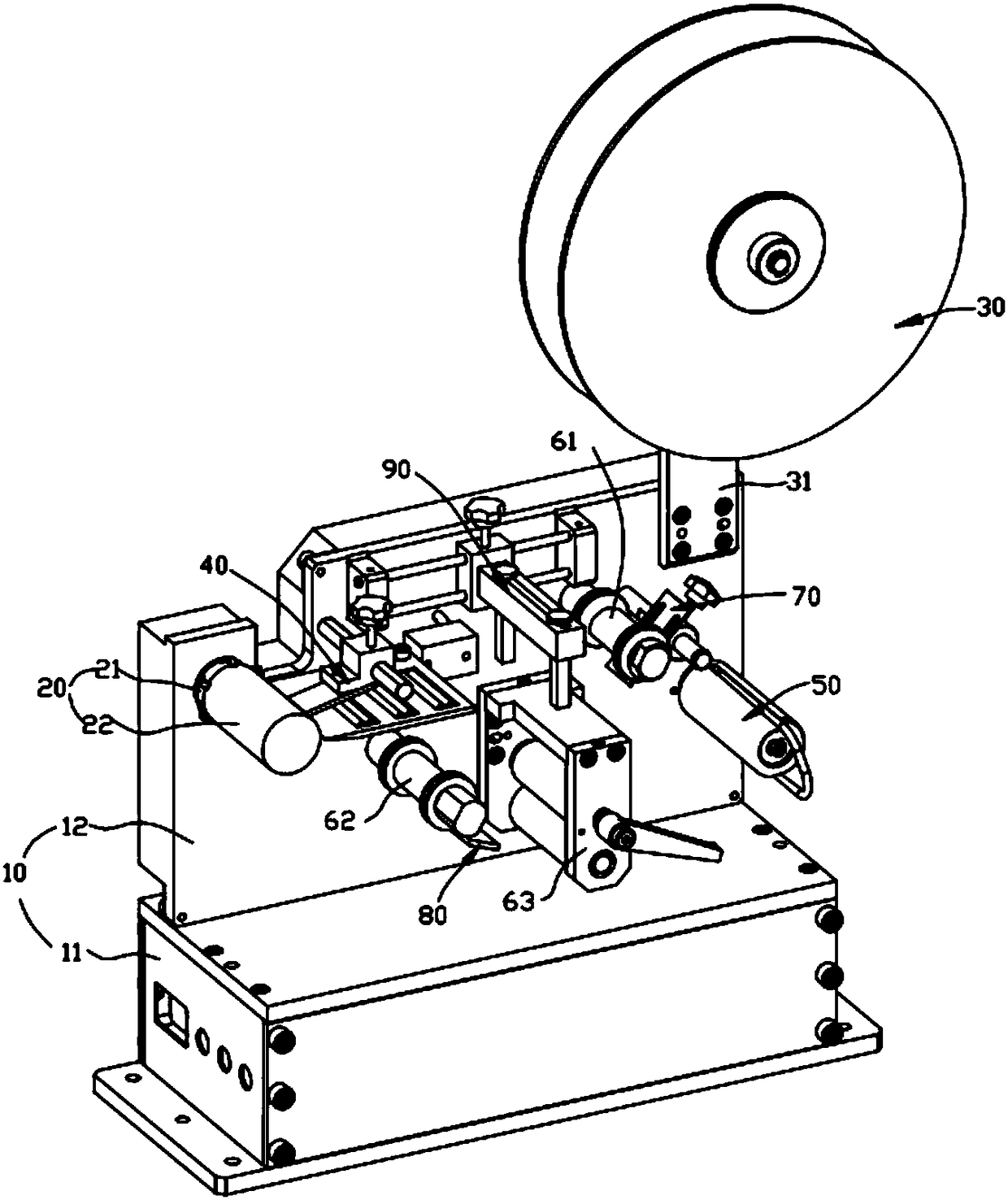

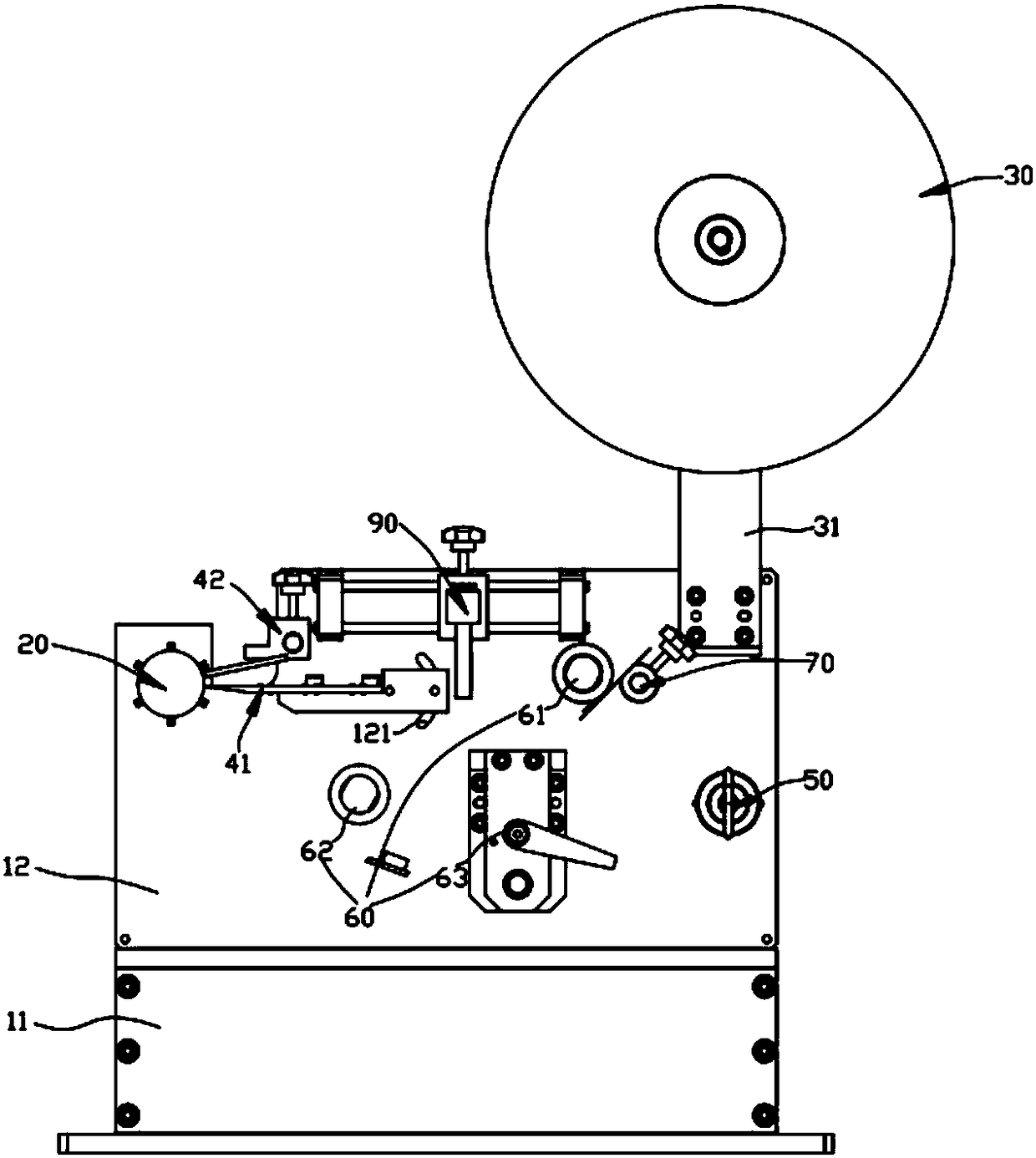

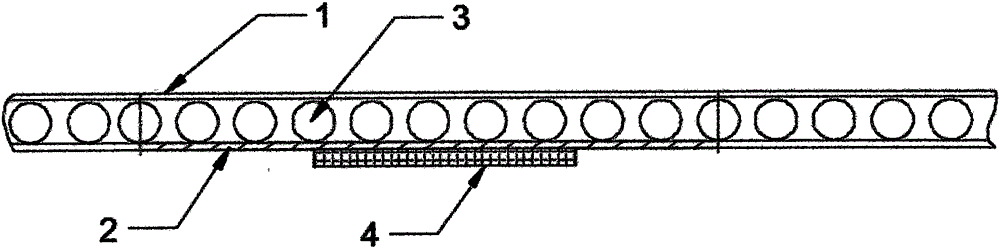

Automatic fruit labeler

InactiveCN104691877ASimple structureImprove labeling efficiencyLabelling machinesEngineeringProduction quality

The invention discloses an automatic fruit labeler. The automatic fruit labeler is characterized by mainly comprising a labeling head assembly 1, a transmission case assembly 2, a label sucking paper tube assembly 3, a labeler handle 4, a labeler fixed hinge 5, a frame 6, a main motor 7, a toothed driving belt 8, label bottom paper 9, a rotary labeling head 10, stretching air bags 11, fruit 12, etc., wherein the labeling head assembly 1 is connected with the transmission case assembly 2, the label sucking paper tube assembly 3 is connected with the transmission case assembly 2, the labeler handle 4 is fixedly mounted on the frame 6, connection of the labelers is realized through the labeler fixed hinge 5, the main motor 7 drives the toothed driving belt 8 to rotate, and the labeling head is equipped with a plurality of the telescopic pneumatic air bags 11. The automatic fruit labeler provided by the invention has the advantages of simple structure, low production cost, high efficiency, capacity of ensuring production quality, convenience and practicality.

Owner:杨光

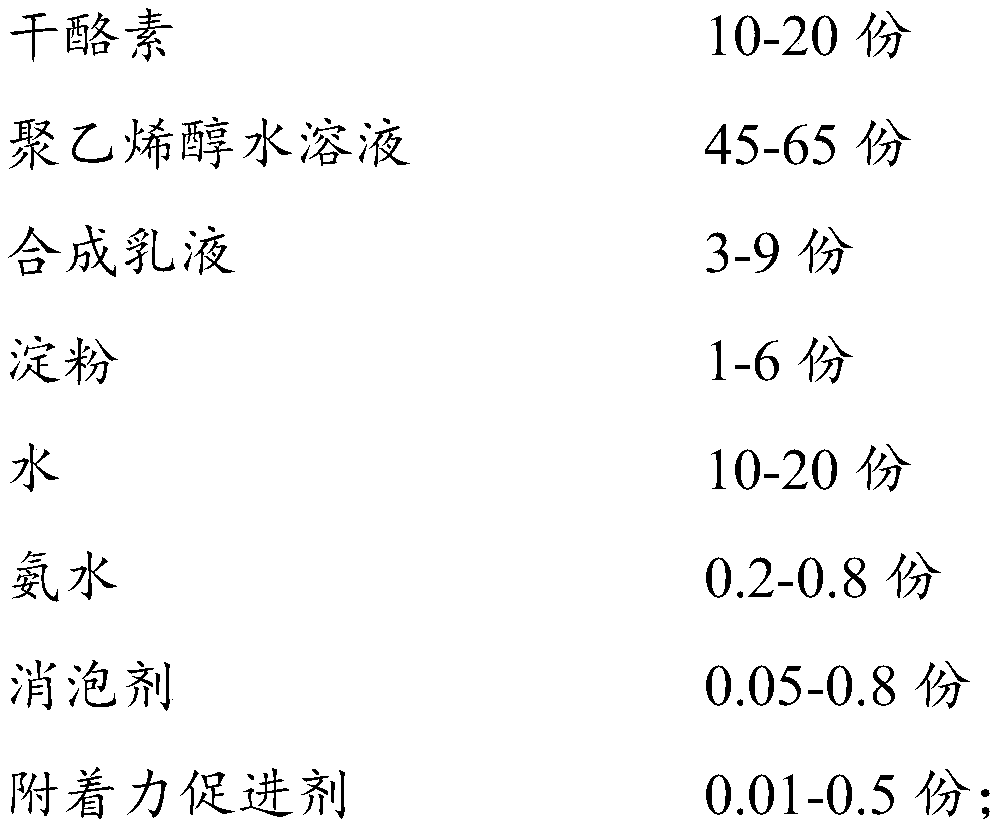

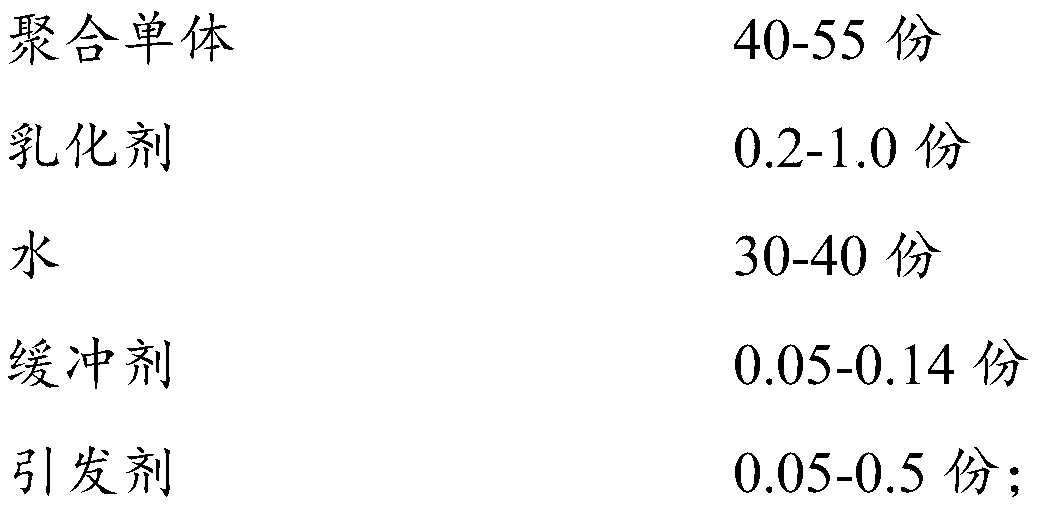

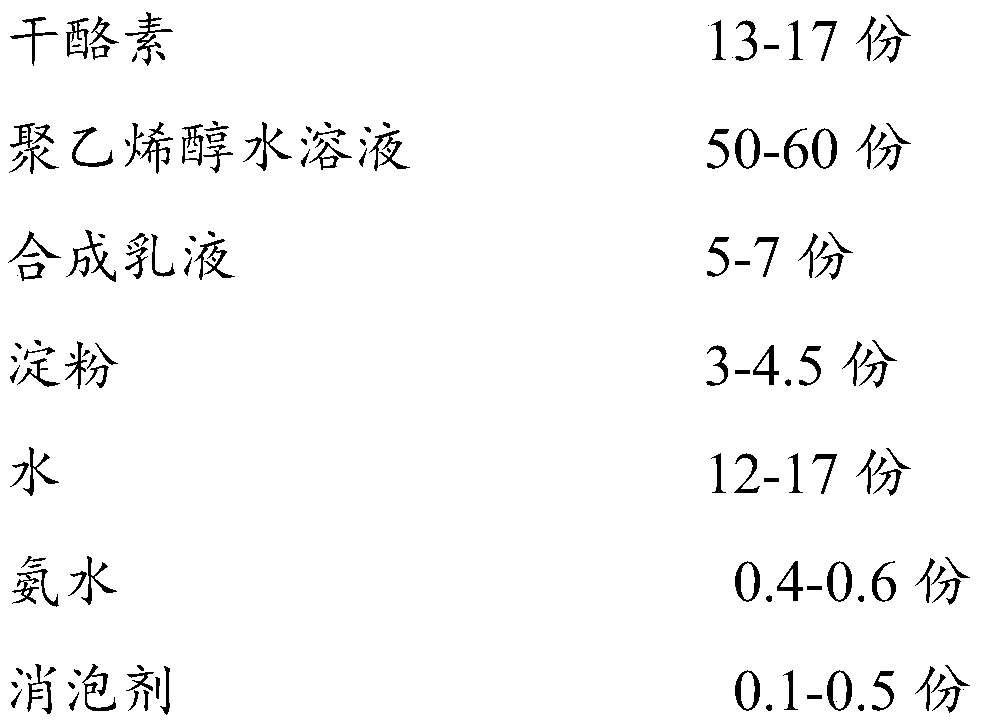

Labeling adhesive for glass bottles and preparation method thereof

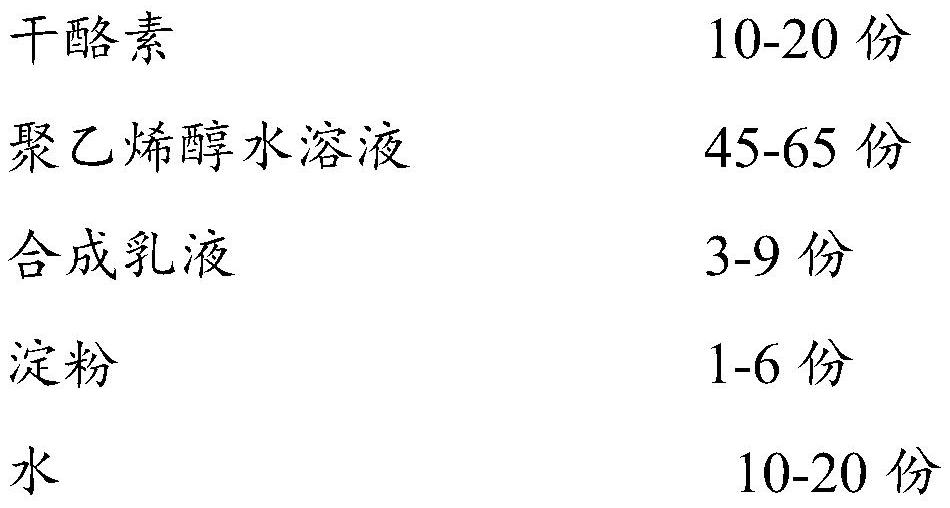

ActiveCN111471430AReduce manufacturing costGood storage stabilityStarch derivtive adhesivesMacromolecular adhesive additivesPolymer scienceMeth-

The invention relates to a labeling adhesive for glass bottles and a preparation method of the labeling adhesive. The labeling adhesive is prepared from the following raw materials in parts by weight:10-20 parts of casein, 45-65 parts of a polyvinyl alcohol aqueous solution, 3-9 parts of a synthetic emulsion, 1-6 parts of starch, 10-20 parts of water, 0.2-0.8 part of ammonia water, 0.05-0.8 partof a defoaming agent and 0.01-0.5 part of an adhesion promoter. The mass percent of polyvinyl alcohol in the polyvinyl alcohol aqueous solution is 10-30%. The synthetic emulsion is prepared from the following raw materials: a polymeric monomer, an emulsifier, water, a pH regulator, a buffer agent, an initiator and an alkali. The polymeric monomer is at least one selected from butyl acrylate, styrene, methyl methacrylate, hydroxyethyl acrylate and N-hydroxymethyl acrylamide. When used for rapid labeling of glass bottles, the labeling adhesive also has a good labeling effect, does not cause wiredrawing in the labeling process, and is short in drying time and free of corner warping.

Owner:中山金诚粘合剂有限公司 +1

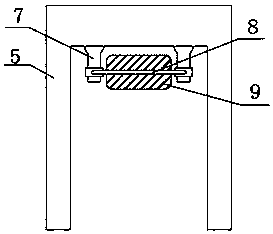

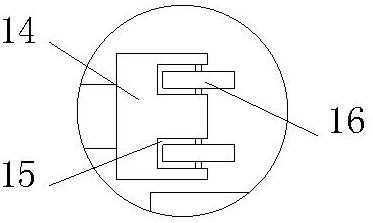

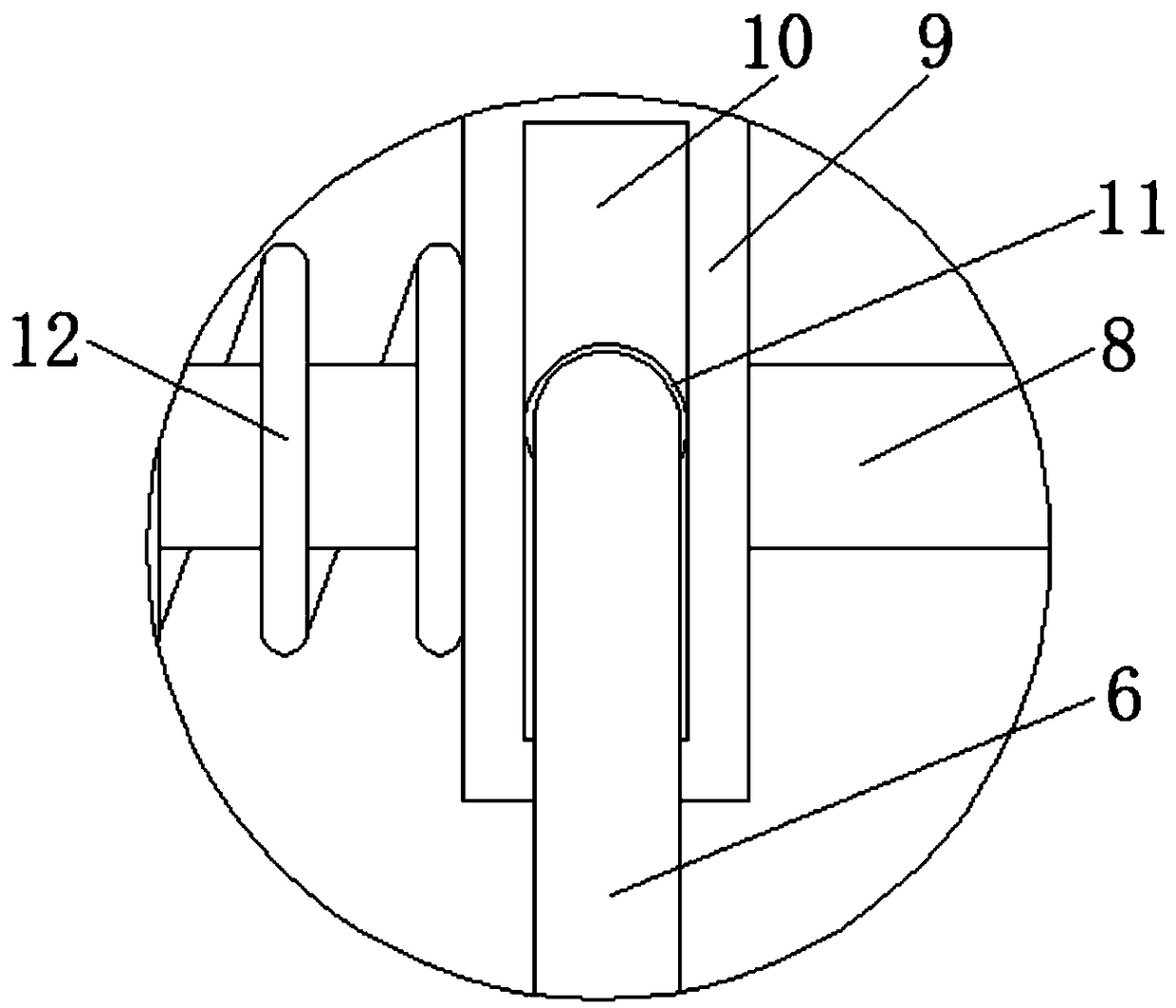

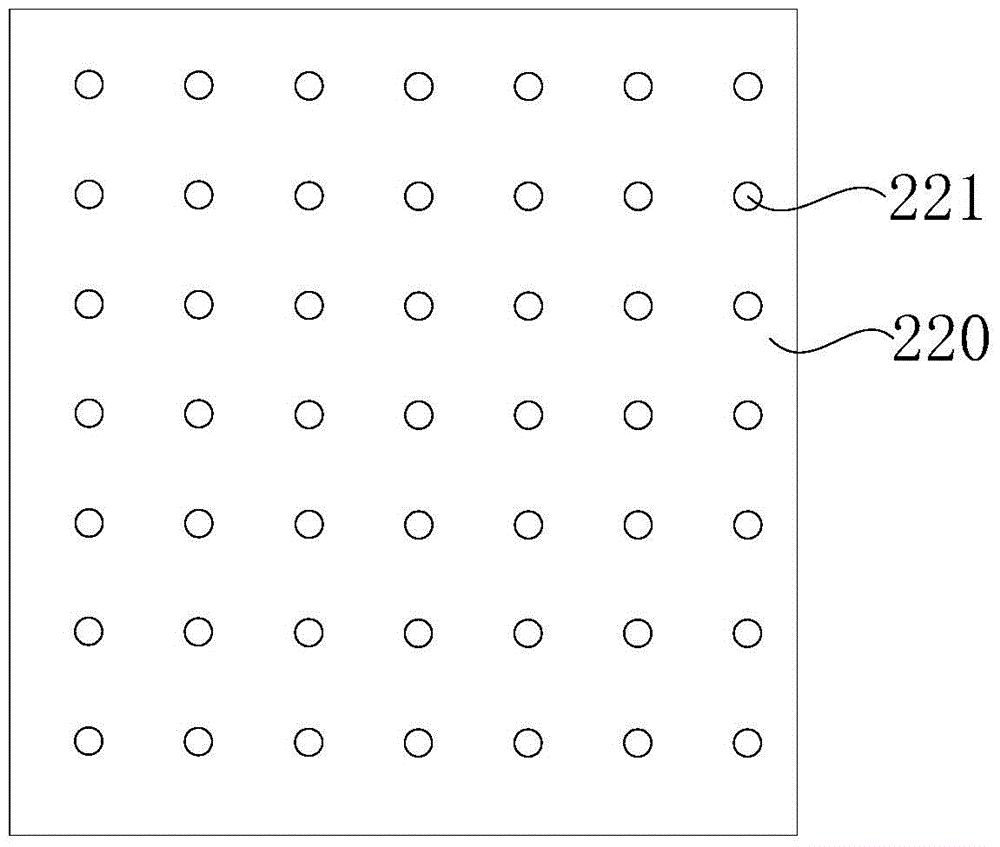

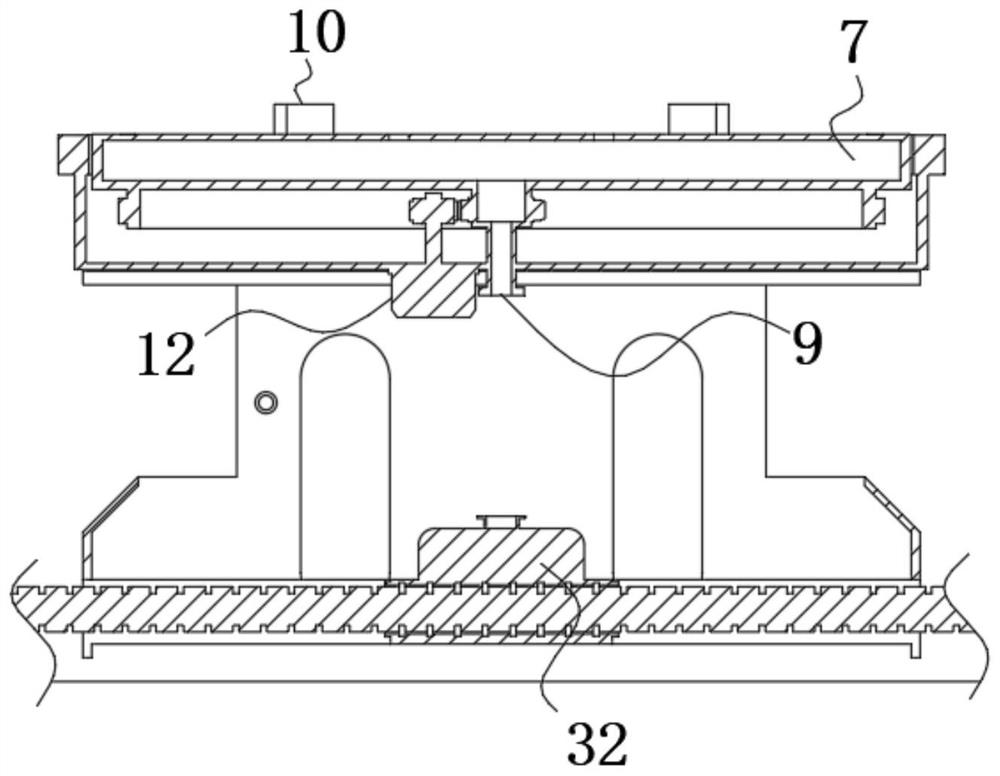

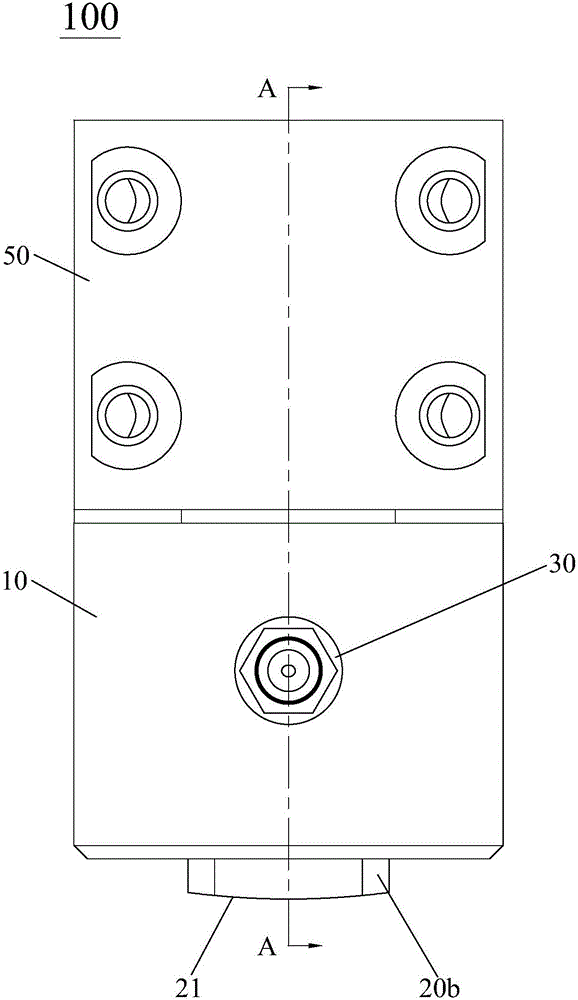

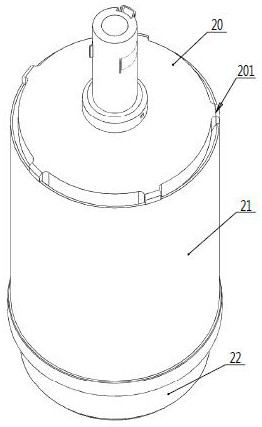

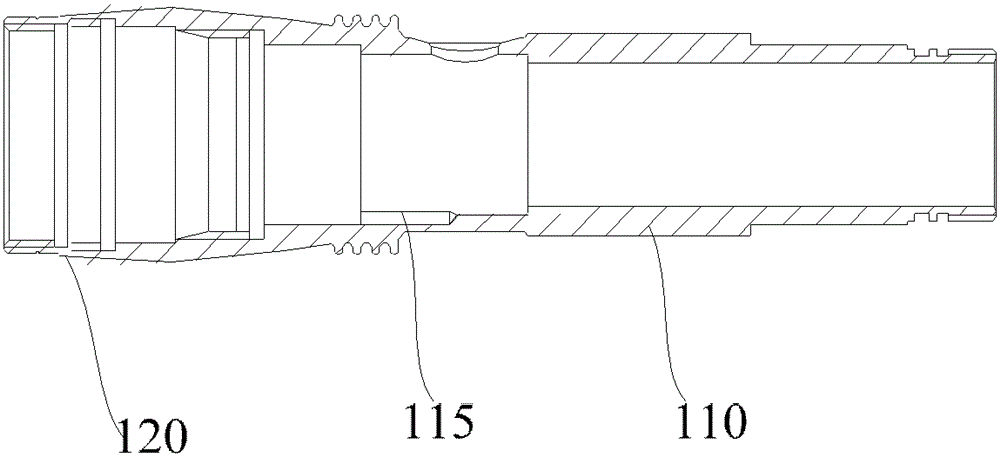

Flexible and elastic vacuum labeling head

PendingCN107176356ASolve the bubble problemImprove labeling effectLabelling machinesPhysicsEngineering

The invention discloses a flexible and elastic vacuum labeling head. The flexible and elastic vacuum labeling head comprises a frame body and an adsorbing and labeling head with the flexibility and the elasticity; the frame body is provided with a vacuum channel used for communicating with an external vacuum generating device; the adsorbing and labeling head comprises an installing end used for being connected with the frame body in an embedded and assembled mode, an adsorbing and labeling end used for conducting adsorbing and labeling and a vacuum hole used for enabling the adsorbing and labeling end and the vacuum channel to communicate with each other, the installing end is embedded into the frame body in a sealing mode, the adsorbing and labeling end stretches out of the frame body, the end face of the adsorbing and labeling end is an outwards-convex arc-shaped face, the vacuum generating device adsorbs a label to the arc-shaped face by means of the vacuum channel and the vacuum hole, line contact between the arc-shaped face and an object is changed into surface contact through extrusion between the arc-shaped face and the object in the laminating process, and then gas generated in the laminating process is exhausted. According to the flexible and elastic vacuum labeling head, the bubble problem generated in the labeling process is solved, the labeling effect is improved, and the labeling quality is guaranteed.

Owner:DONGGUAN SANNIAN INTELLIGENT TECH CO LTD

A medicine bottle labeling machine

ActiveCN106347802BLegibleEasy to viewLabelling short rigid containersLabelling machinesMedicine bottlesElectrical and Electronics engineering

The invention discloses a medicine bottle labeling machine. The medicine bottle labeling machine comprises a machine cabinet, a loading unit, a label disk, a labeling unit, a recovery unit, an intermediate transfer unit, a first monitoring unit and a second monitoring unit, wherein the machine cabinet comprises a base table and a mounting panel; the loading unit comprises a pneumatic claw which is used for grabbing medicine bottles and a first driving device which is used for driving the pneumatic claw to rotate; the label disk is mounted on the mounting panel and is of a turntable structure which is used for storing a label tape, and the label tape comprises base paper and a plurality of labels which are stuck to the base paper; the labeling unit is of a mechanism which is used for sticking the labels on the label tape to external cylindrical surfaces of the medicine bottles; the recovery unit is used for recovering the base paper; the intermediate transfer unit is used for assisting the label tape in moving; the first monitoring unit is used for monitoring labels passing through a first pull roll unit; the second monitoring unit is used for monitoring the base paper. According to the medicine bottle labeling machine, the repeated and omitted sticking of the labels can be avoided, and the reliability of labeling is effectively improved.

Owner:嘉兴日昌汽车配件股份有限公司

Labeling machine for logistics

PendingCN110758864AAvoid random placementImprove the effect of labelingLabelling flat rigid surfacesLabelling machinesLabelling machineManufacturing engineering

The invention provides a labeling machine for logistics. The labeling machine for logistics comprises a bottom plate, a movable frame and a conveying frame, wherein the bottom of the movable frame isfixed at the top of the bottom plate through a supporting base; the two sides of the conveying frame are fixed on the two sides of the top of the bottom plate through supporting plates; and one side of the conveying frame runs through the movable frame and extends to the other side of the movable frame. According to the labeling machine for logistics, which is provided by the invention, a placingarea and a center area are provided; so the position of a box body needing to be labeled is effectively guided, the labeling effect is further improved, random placing by workers is avoided and the labeling effect is improved; furthermore, a camera is provided and can monitor the labeling position, so the workers can control equipment according to monitoring information, a large amount of precision instruments are not needed and the production cost of the equipment is reduced.

Owner:安徽华源物流有限责任公司

Labeling adhesive for glass bottles and preparation method thereof

ActiveCN111471430BReduce manufacturing costGood storage stabilityStarch derivtive adhesivesMacromolecular adhesive additivesPolymer scienceMeth-

The invention relates to a labeling glue for glass bottles and a preparation method thereof. In parts by weight, the labeling glue is prepared from raw materials comprising the following components: 10-20 parts of casein, 45-65 parts of polyvinyl alcohol aqueous solution, 3-9 parts of synthetic emulsion, 1-6 parts of starch, 10 parts of water -20 parts, 0.2-0.8 parts of ammonia water, 0.05-0.8 parts of defoamer, 0.01-0.5 parts of adhesion promoter; the mass percentage of polyvinyl alcohol in the polyvinyl alcohol aqueous solution is 10-30%; the synthetic emulsion Prepared from raw materials including the following components: polymerized monomers, emulsifiers, water, pH regulators, buffers, initiators, alkalis; the polymerized monomers are selected from butyl acrylate, styrene, methyl methacrylate At least one of ester, hydroxyethyl acrylate and N-methylol acrylamide. It also has a good labeling effect when it is used for quick labeling of glass bottles. The labeling process does not draw, the drying time is fast, and the corners are not warped.

Owner:中山金诚粘合剂有限公司 +1

Adhesive, preparation and use thereof

InactiveCN101440269BGood initial adhesionLow freezing pointProtein waste adhesivesStarch adhesivesEnzymatic hydrolysisEmulsion

The present invention provides an adhesive for labeling. The adhesive comprises 1-40% animal glue, 0-45% emulsion, 0-20% starch, 5-40% diluting agent, 0-10% cross-linking agent, 0-5% thickening agent, 0.001-2% additive and 20-50% water. The adhesive of the present invention has the advantages of good primary adhesion, low solidifying point, good waterproof property, high stability against enzymatic hydrolysis and washability in elevated temperature water without alkali. It commendably meets the demands of speeding the manufacture rate, improving the manufacture qualified rate and recovering of containers, and specially suits for labeling of beer bottles.

Owner:HENKEL KGAA

Thin Wall Cylinder Hot Melt Adhesive Labeling Machine

ActiveCN106672364BImprove labeling efficiencyGood labeling effectLabelling machinesEngineeringHot melt

The invention discloses a thin-walled cylinder hot-melt adhesive labeling machine, which comprises a bottle-supporting turntable arranged at the center of a rack table, and a bottle feeding device and a glue-spraying device located on the rack table and distributed around the bottle-supporting turntable , a split floating standard bin, a glue scraping device, a glue melting box and a bottle discharge device; wherein: the front end of the chassis in the split floating standard bin is provided with an adjustable standard box, and the rear end of the chassis is provided with an auxiliary feeder A marking device is provided, the left and right sides of the chassis are symmetrically provided with elastic marking devices, and the middle of the chassis is provided with a rolling standard feeding chain track. The invention realizes the modular design of the composition structure and the automatic mechanical production line, and can realize the full-body labeling of the labels with larger diameter and larger width such as thin wallpaper drums and thin-walled metal drums, and the large-capacity label bin can greatly reduce the The frequency of changing labels is convenient for the operator, greatly improves the production efficiency, further improves the labeling quality and labeling accuracy, and minimizes the production cost.

Owner:莱州市同力机械有限公司

torch

InactiveCN103375685BGood labeling effectIncrease reflectionLighting applicationsLighting support devicesEngineeringFlashlight

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Internal quickly pressure-boosting method for bear or carbonated beverages after being sealed

InactiveCN105352669AIncrease internal pressureIncrease hardnessFluid-tightness measurement using fluid/vacuumCarbonated drinkBottle neck

The invention discloses an internal quickly pressure-boosting method for bear or carbonated beverages after being sealed. The method comprises the following steps: serially adding a metal guide rail to a present production line single-line conveying unit; adjusting the angle and forming an inclined angle between a vertical running plane of a bottle with a horizontal line; inclining and causing one side of the bottle to be adhered to one side of the metal guide rail while advancing; arranging a high frequency oscillation generator on the other side of the metal guide rail; generating high frequency oscillation through the high frequency oscillation generator; transferring the high frequency oscillation to the bottle through the metal guide rail; by utilizing the physical characteristics that the internal pressure boosting is caused after the bear or carbonated beverages are shaken, quickly expanding the gas in the bear or carbonated beverages under the condition of high frequency oscillation, thereby quickly boosting the internal pressure. According to the internal quickly pressure-boosting method for the bear or carbonated beverages after being sealed, the internal pressure quick boosting is online finished under the condition that the production efficiency is not influenced; the quick increasing for the surface hardness of the bottle is acquired, so that the labeling effect is conveniently increased; the accumulation for internal foams on the bottle neck part is quickened, so that a firm basis for judging and checking the poorly sealed wine end products is supplied.

Owner:T LINE TECH CO LTD

Portable carton labeling device and using method thereof

InactiveCN112340168APrevent faces from being misalignedPrevent poor labeling effectLabelling machinesClassical mechanicsCarton

The invention belongs to the field of carton labeling, and particularly relates to a portable carton labeling device. The portable carton labeling device comprises a mounting plate, wherein two firstsliding grooves are formed in the lower portion in a mounting block in a bilateral symmetry mode, and a first sliding rod is arranged in each first sliding groove in a reciprocating sliding mode; twocarton pulling assemblies, wherein the two carton pulling assemblies can pull cartons towards the mounting plate and enable the positions of the cartons to be aligned after the cartons are placed in ;a driving assembly, wherein the driving assembly is arranged on the side, opposite to the carton pulling assemblies, of the mounting plate and provides driving force for the carton pulling assemblies; and a labeling assembly, wherein the labeling assembly is arranged on the side, facing the carton pulling assemblies, of the mounting plate, and after the cartons are pulled to designated positionsby the carton pulling assemblies to be aligned, the side faces of the cartons are labeled. The labor can be saved, the situation that the position deviates during manual labeling can be avoided, and label paper can be prevented from rolling up during labeling.

Owner:董玲玲

A kind of detection method of target product

ActiveCN104772289BSolve the problem of culling impreciseAffect work efficiencySortingSensing by electromagnetic radiationPattern recognitionProduct testing

Owner:SHANGHAI TY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com