Adhesive, preparation and use thereof

An adhesive and diluent technology, applied in the field of adhesives prepared from animal glue, can solve the problems of long drying time and curing time, poor resistance to normal temperature water of animal glue, restricting the application of animal glue, etc. Strong hydrolytic stability, good labeling effect and good stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

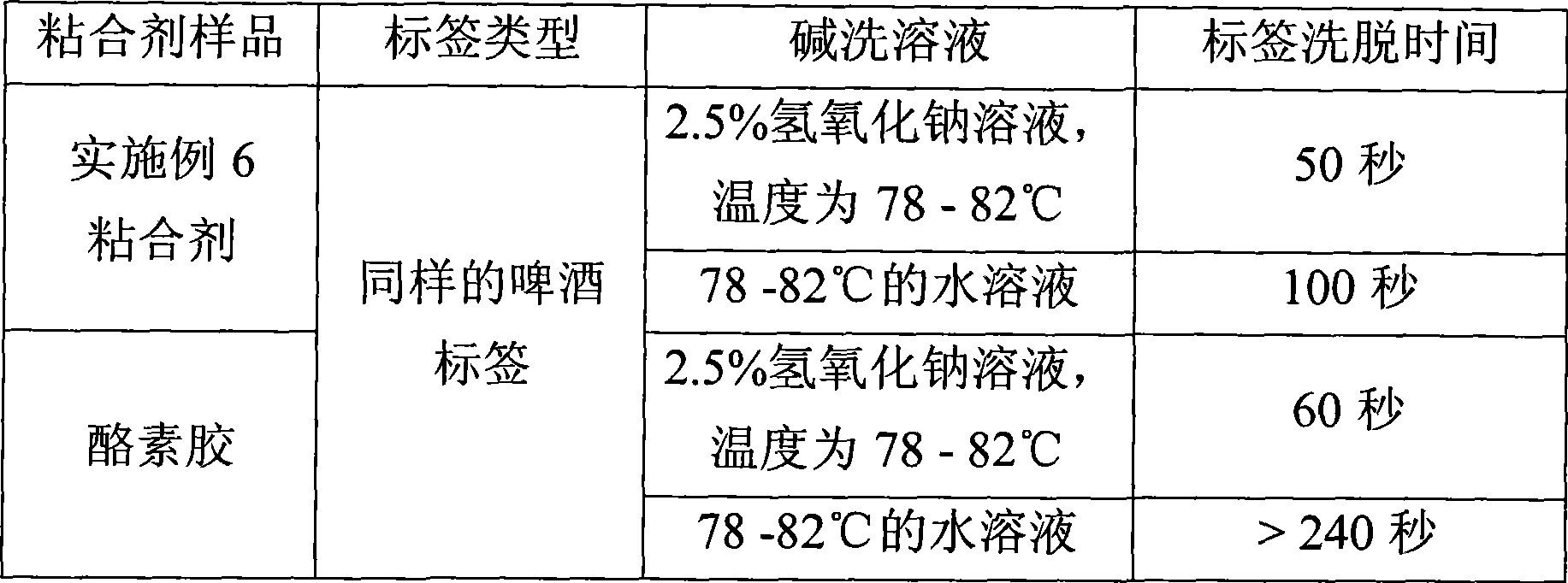

Image

Examples

Embodiment approach

[0036] Embodiments of the invention include:

[0037] 1. A water-based adhesive, which comprises components and weight percentages as follows:

[0038] Animal Glue 1-40%,

[0039] Emulsion 0-45%,

[0040] Starch 0-20%,

[0041] Thinner 5-40%,

[0042] Cross-linking agent 0-10%,

[0043] Thickener 0-5%,

[0044] Additives 0.001-2%, and

[0045] Water 20-50%.

[0046] 2. The water-based adhesive according to embodiment 1, wherein the weight percentage of the animal glue is 5-35%.

[0047] 3. The water-based adhesive according to embodiment 2, wherein the weight percentage of the animal glue is 8-18%.

[0048] 4. The water-based adhesive according to embodiment 1, wherein the weight percentage of the emulsion is 10-40%.

[0049] 5. The water-based adhesive according to Embodiment 4, wherein the weight percentage of the emulsion is 20-40%.

[0050] 6. The water-based adhesive according to Embodiment 1, wherein the weight percentage of the starch is 4-15%.

[0051] 7. Th...

Embodiment 1

[0100] The composition and content of the binder are as follows:

[0101] Glue 20%

[0102] Starch 10%

[0103] Acrylic Emulsion 30%

[0104] Urea 13%

[0105] Cross-linking agent 1%

[0106] Ammonia 2%

[0107] Water 23%

[0108] Other additives 1%

[0109] Among them, the animal glue is industrial gelatin, from Qinghai Gelatin Co., Ltd.;

[0110] The starch is corn starch, from National Starch Chemical Co., Ltd.;

[0111] The cross-linking agent is zinc oxide from Luoyang Lantian Chemical Factory;

[0112] Other additives refer to preservatives, defoamers and flavors. The preservative was ACTICIDE SPX from THOR company. The defoamer is BEVALOID series, from BEVALOID company.

[0113] The name of the acrylic emulsion is Neicryk BT-9, and its composition is an anionic acrylic emulsion from DSM Company,

[0114] Put 115 grams of water, 50 grams of starch, and 100 grams of animal glue in a stirring tank, and stir at high speed for half an hour. The temperature was rai...

Embodiment 2

[0117] The composition and content of the binder are as follows:

[0118] Glue 30%

[0119] Starch 7%

[0120] Urea 20%

[0121] Borax 2%

[0122] water 40%

[0123] Other additives 1%

[0124] Among them, the animal glue is industrial gelatin, from Qinghai Gelatin Co., Ltd.;

[0125] The starch was cornstarch from National Starch Chemicals;

[0126] The preservative in other additives is ACTICIDE SPX from THOR company, and the defoamer is BEVALOID series from BEVALOID company.

[0127] Put 200 grams of water and 35 grams of starch in a stirring tank and stir for half an hour. Put 100 grams of urea into it. After mixing evenly, heat to 40°C in a water bath. Add 150 grams of animal glue to form a uniformly swollen glue solution, add 10 grams of borax, and continue stirring for half an hour. Raise the temperature to 70°C and keep stirring for half an hour. Then cool down to 50°C, add 1 gram of preservative and 4 grams of defoamer. Lower the temperature to 30-35°C in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com