Removable hot-melt pressure-sensitive adhesive and preparation method

A hot-melt pressure-sensitive adhesive and pressure-sensitive adhesive technology, used in adhesives, film/sheet adhesives, adhesive additives, etc., can solve the problems of tearing off the rubber sleeve, large peeling force, and inability to open normally and repeatedly. , to achieve the effect of easy peeling, good die-cutting and good retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

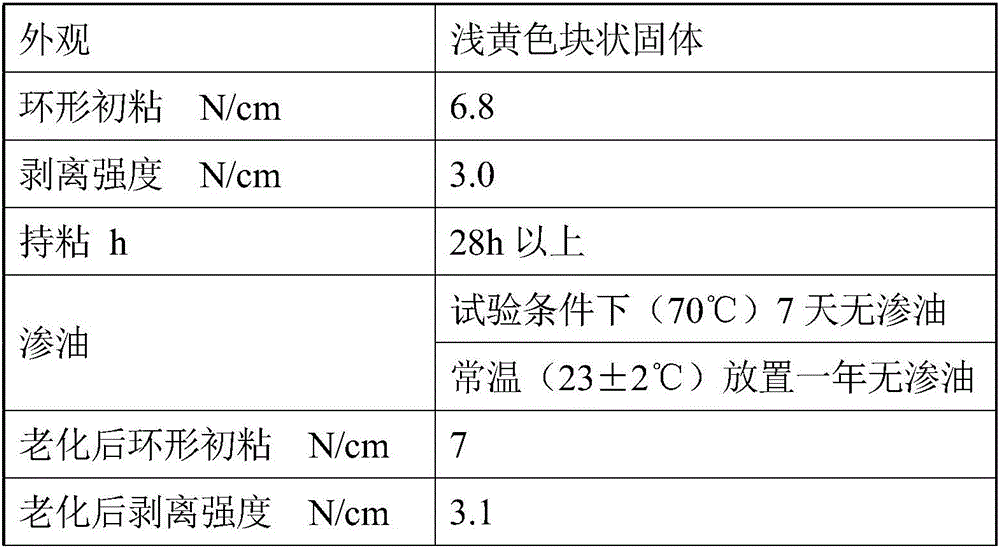

Examples

preparation example Construction

[0024] The preparation method of the above-mentioned hot-melt pressure-sensitive adhesive is carried out according to the following steps:

[0025] a. Weigh the components of the raw materials according to the formula, take dioctyl terephthalate, liquid petroleum resin, antioxidant 1076 and antioxidant 168 and put them into the reactor, heat and stir, and pour into the reactor while stirring Introduce nitrogen for protection to prevent aging and degradation of raw materials;

[0026] b. When the heating temperature reaches 135±5°C, slowly add SIS and 1 / 3 of the amount of C5 petroleum resin, and stir for 5 minutes; continue to stir and heat to 165±5°C, and keep the temperature at 25 rpm Stir for 120 minutes; keep the temperature range of 165±5°C because if the temperature is too low, it will cause incomplete melting and SIS agglomeration; if the temperature is too high, it will cause thermal oxidation and degradation at high temperature due to unsaturated double bonds in SIS ,...

Embodiment 1

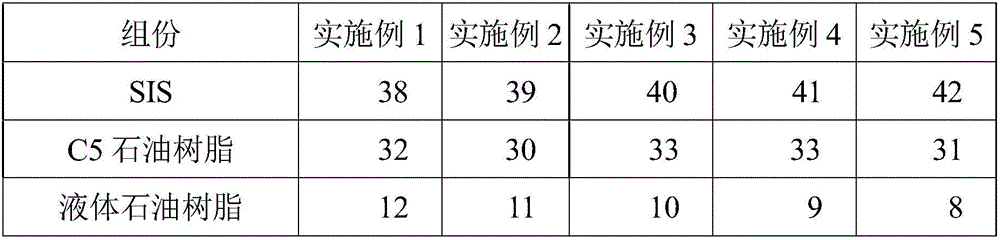

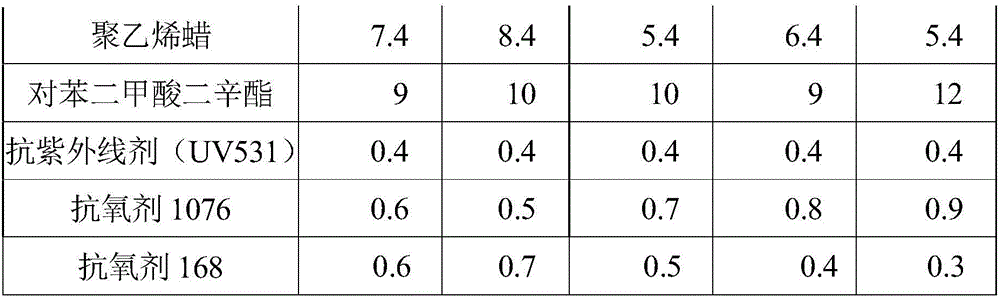

[0038] The hot-melt pressure-sensitive adhesive is prepared according to the following formula in units of parts by mass in kg.

[0039] Formulation list of table 1 hot-melt pressure-sensitive adhesive

[0040]

[0041]

[0042] The preparation method of hot melt pressure sensitive adhesive is as follows:

[0043] a. take each component by the proportioning ratio of embodiment 3, get dioctyl terephthalate (DOTP), liquid petroleum resin, antioxidant 1076 and antioxidant 168 and all drop in the reactor, stir and heat, At the same time, nitrogen protection was introduced.

[0044] b. When the heating temperature reaches 135°C, slowly add 1 / 3 part of C5 petroleum resin 3200, which is 11kg and all SIS 1105, and stir for 5 minutes; continue to stir and heat to 165°C, and stir with temperature control (25 rpm minutes) 120 minutes;

[0045] c. Add polyethylene wax and UV531 under the condition of temperature control and stirring, and add the remaining C5 petroleum resin in 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com