Patents

Literature

63results about "Labelling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

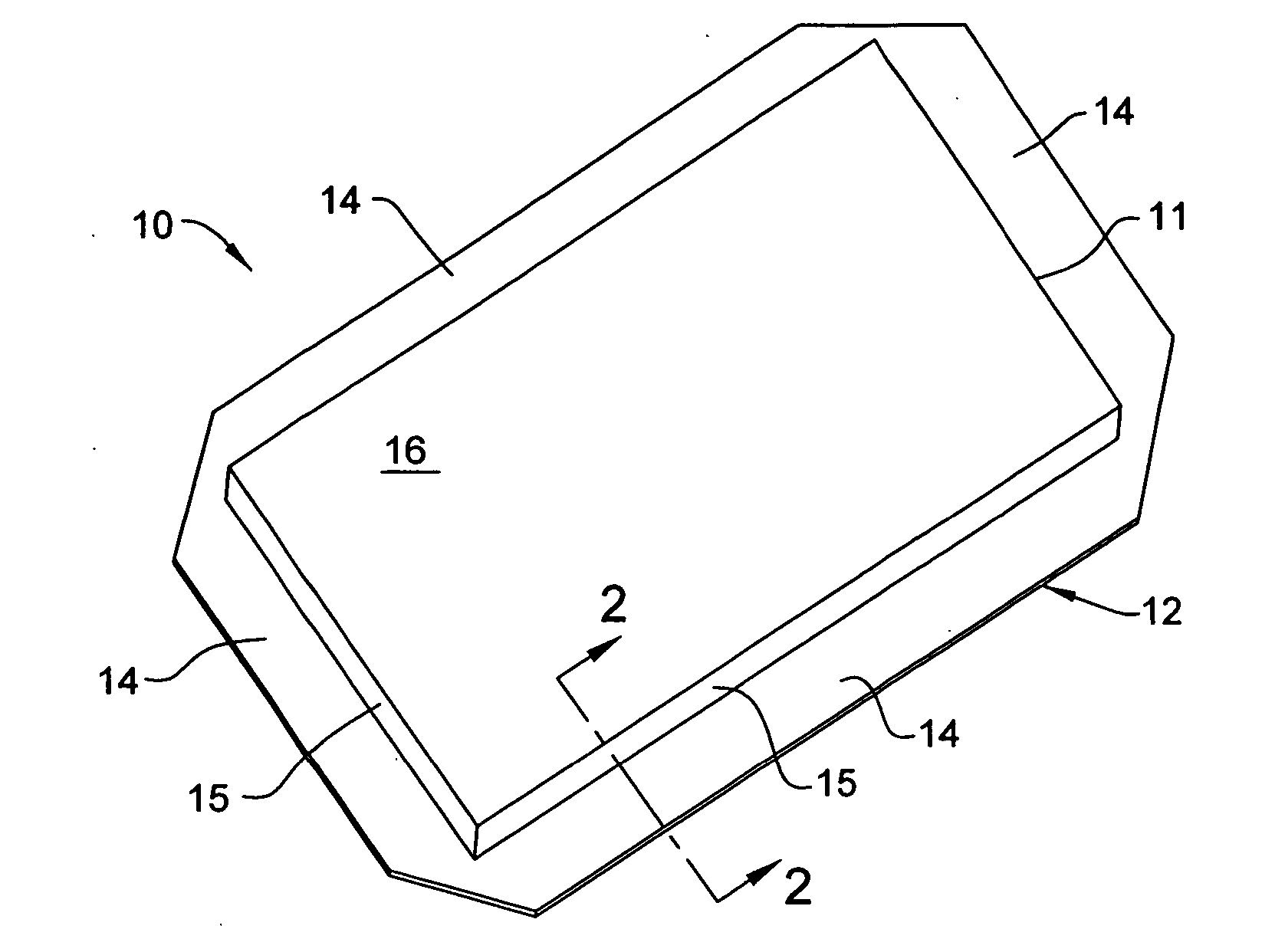

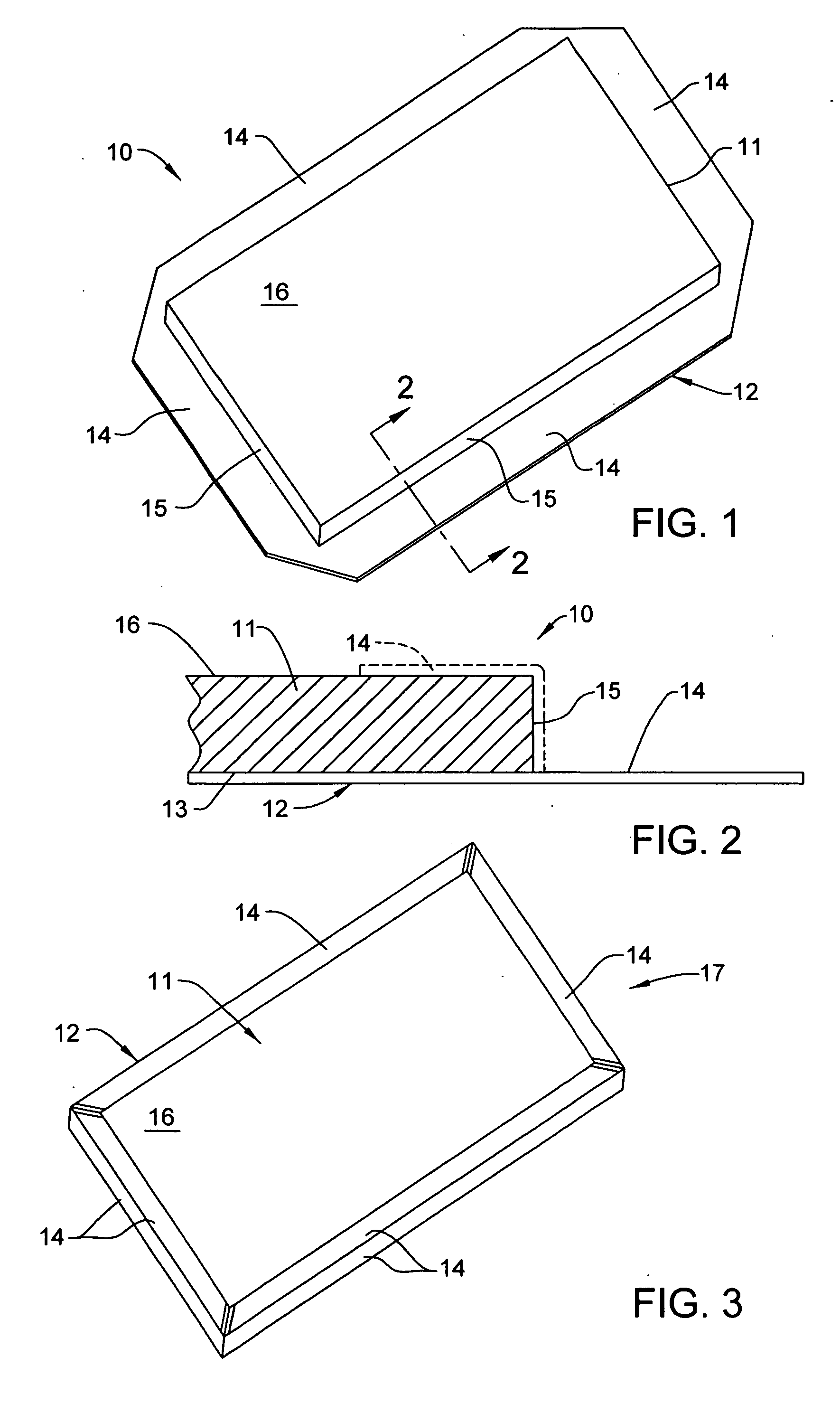

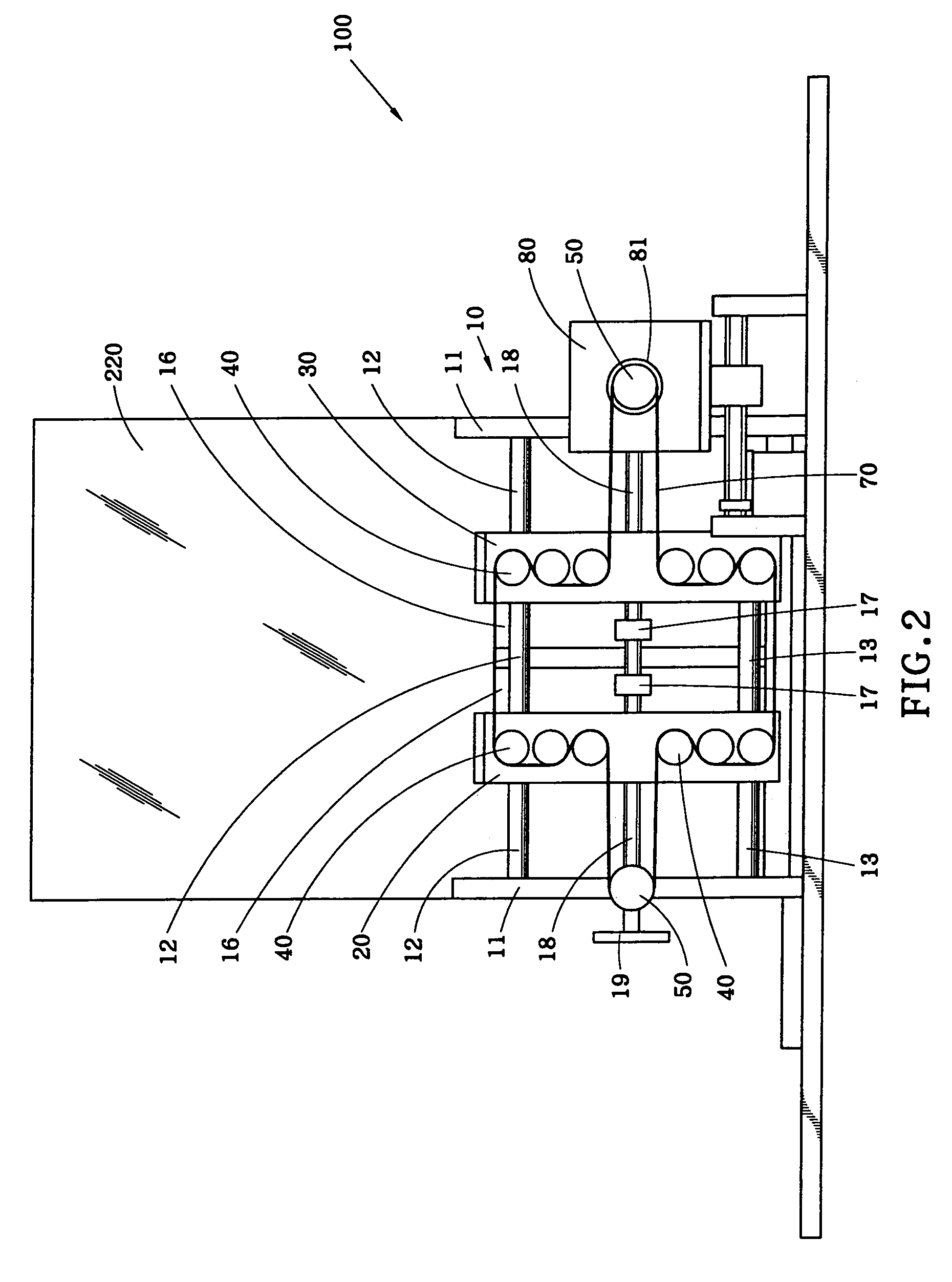

Process and apparatus for edge wrapping upholstered articles

ActiveUS20070214625A1Smooth and uniform transferenceUpholstery manufactureUpholstery auxillary devicesManufactured apparatusEngineering

A manufacturing apparatus and process to effect substantial automatic wrapping of the edges of a covered article, namely, the wrapping of cover sheet flaps around the edges of a substrate and the adhesive securement of the cover sheet flaps to the back side of the substrate, to form an upholstered article such as a pad or panel in a highly automated process which eliminates significant manual manipulations.

Owner:HAWORTH SPA

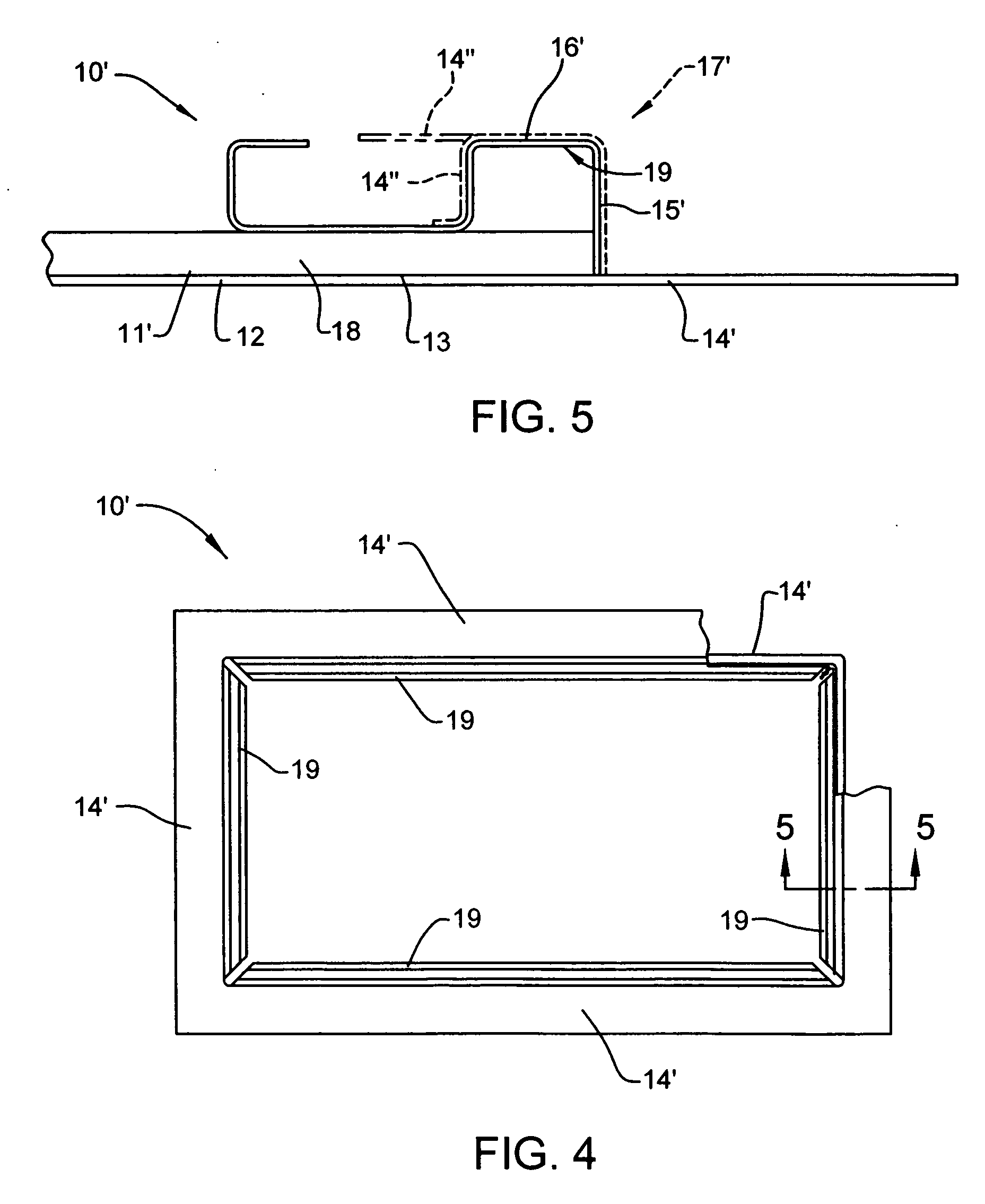

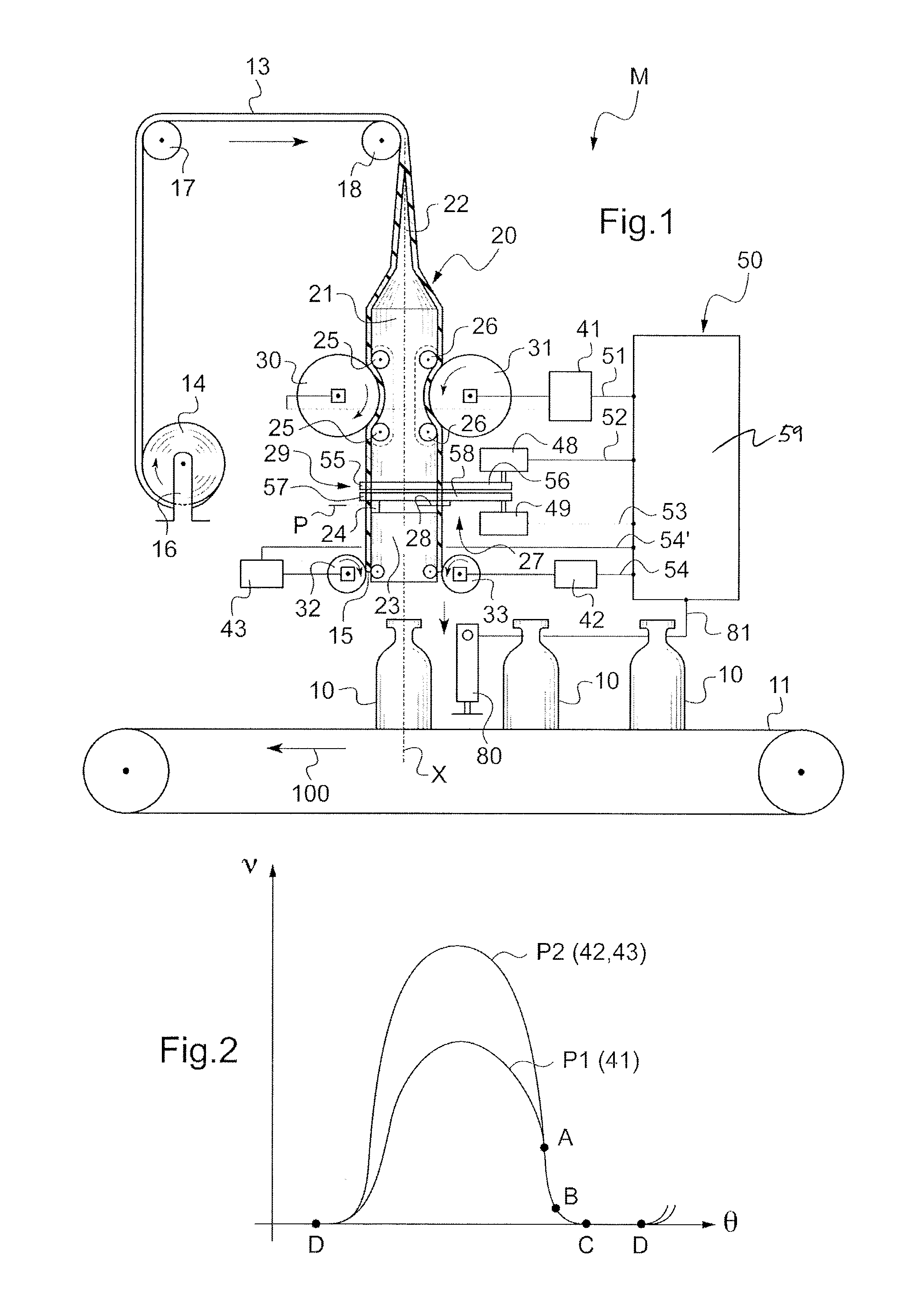

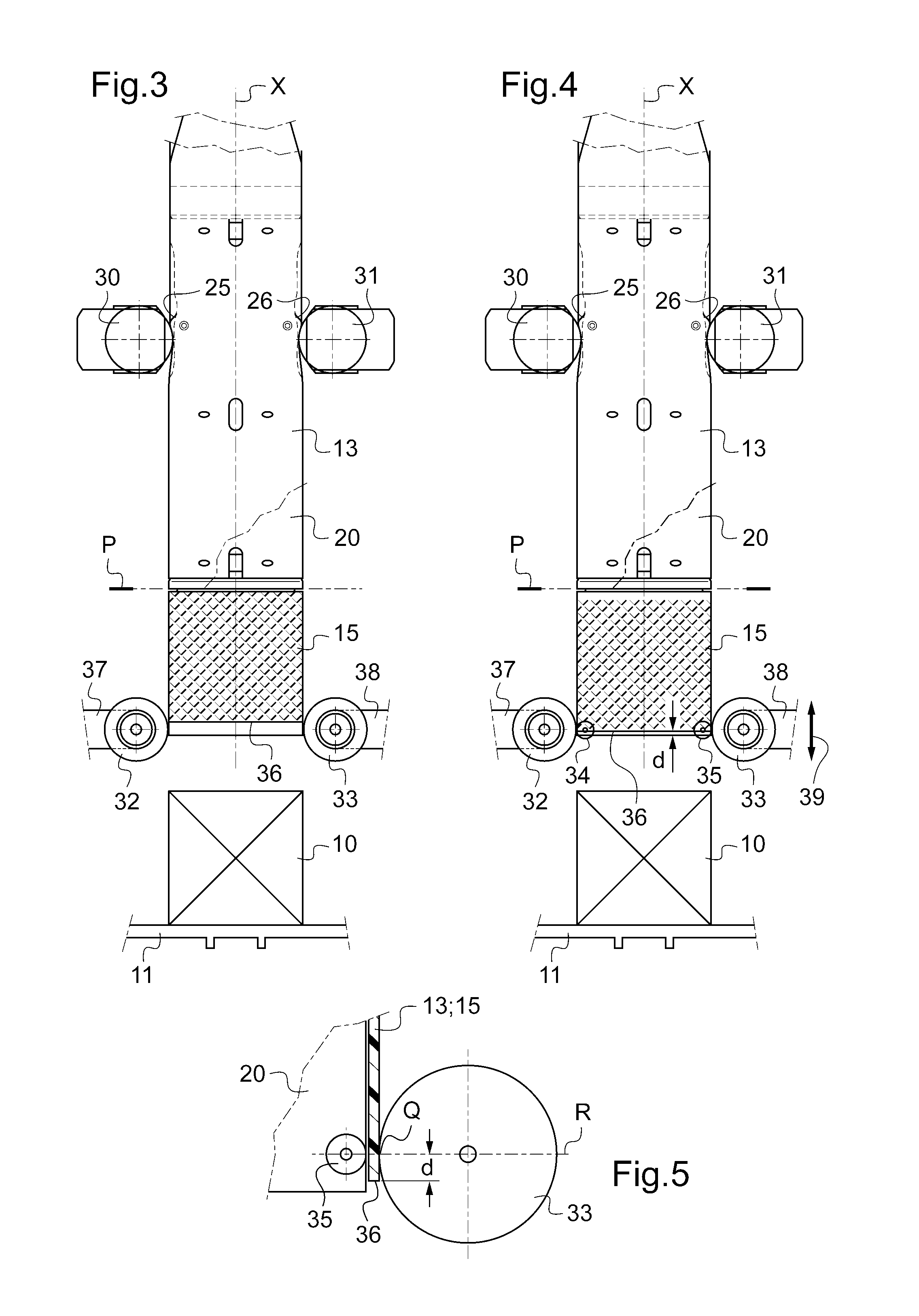

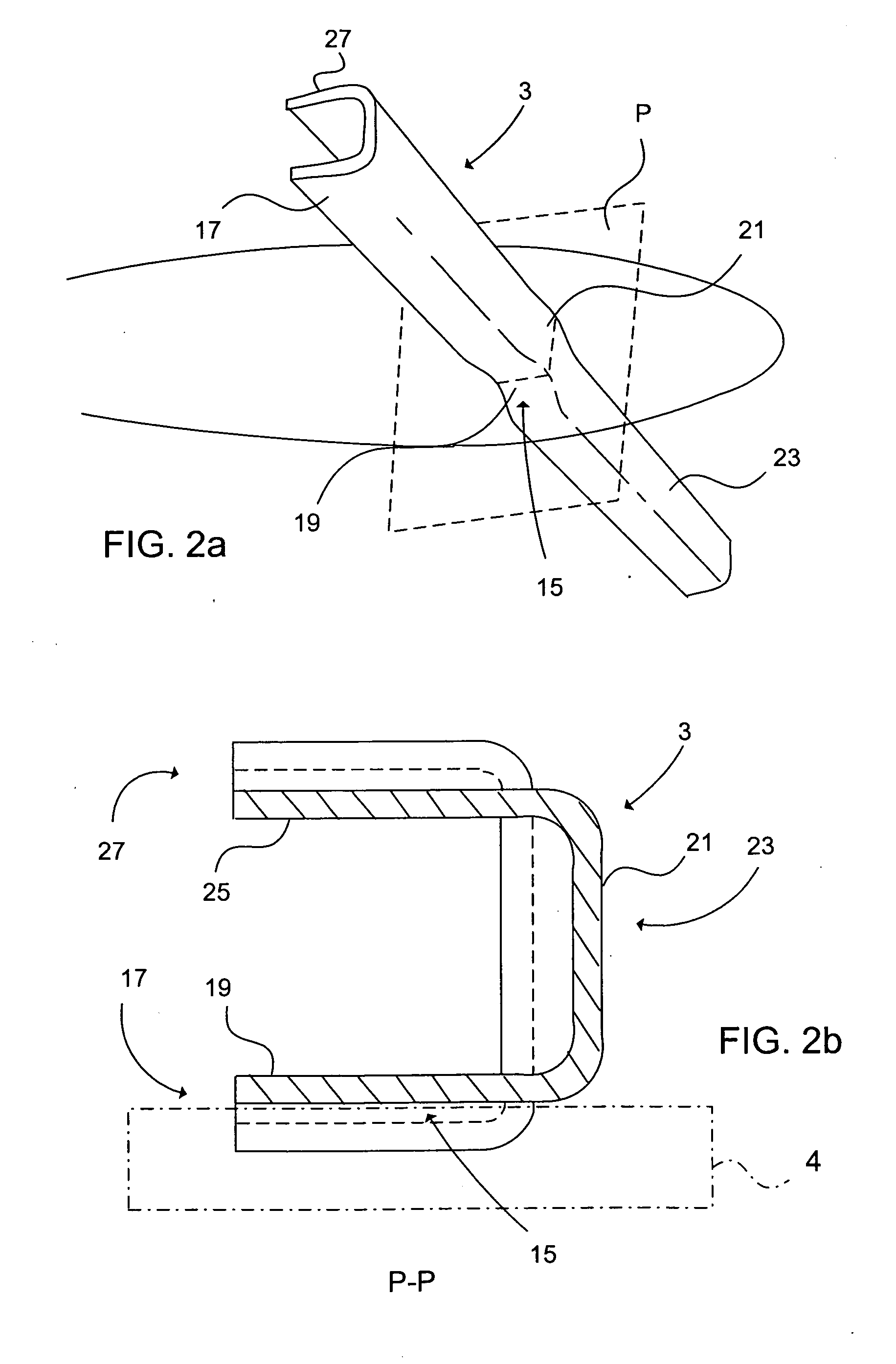

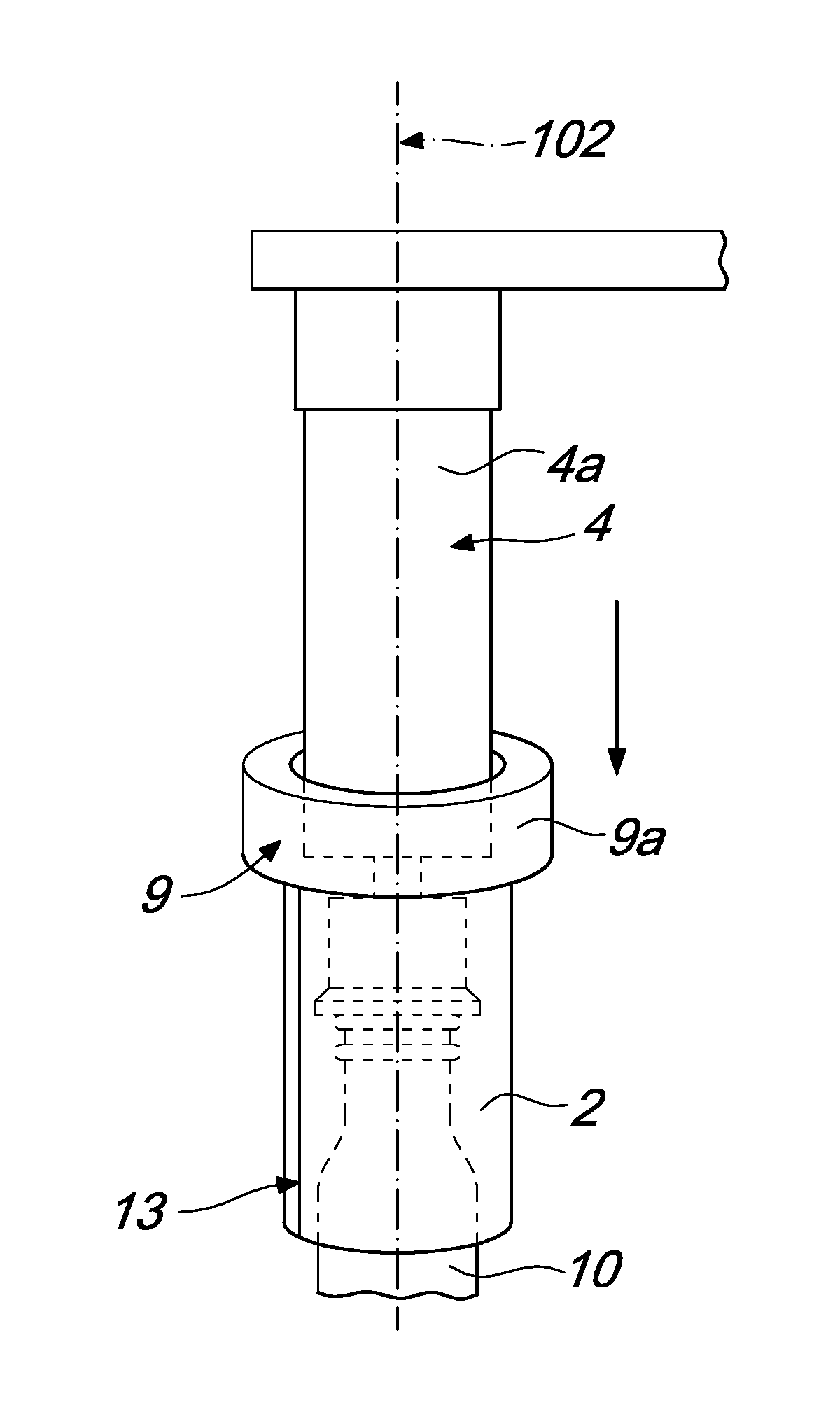

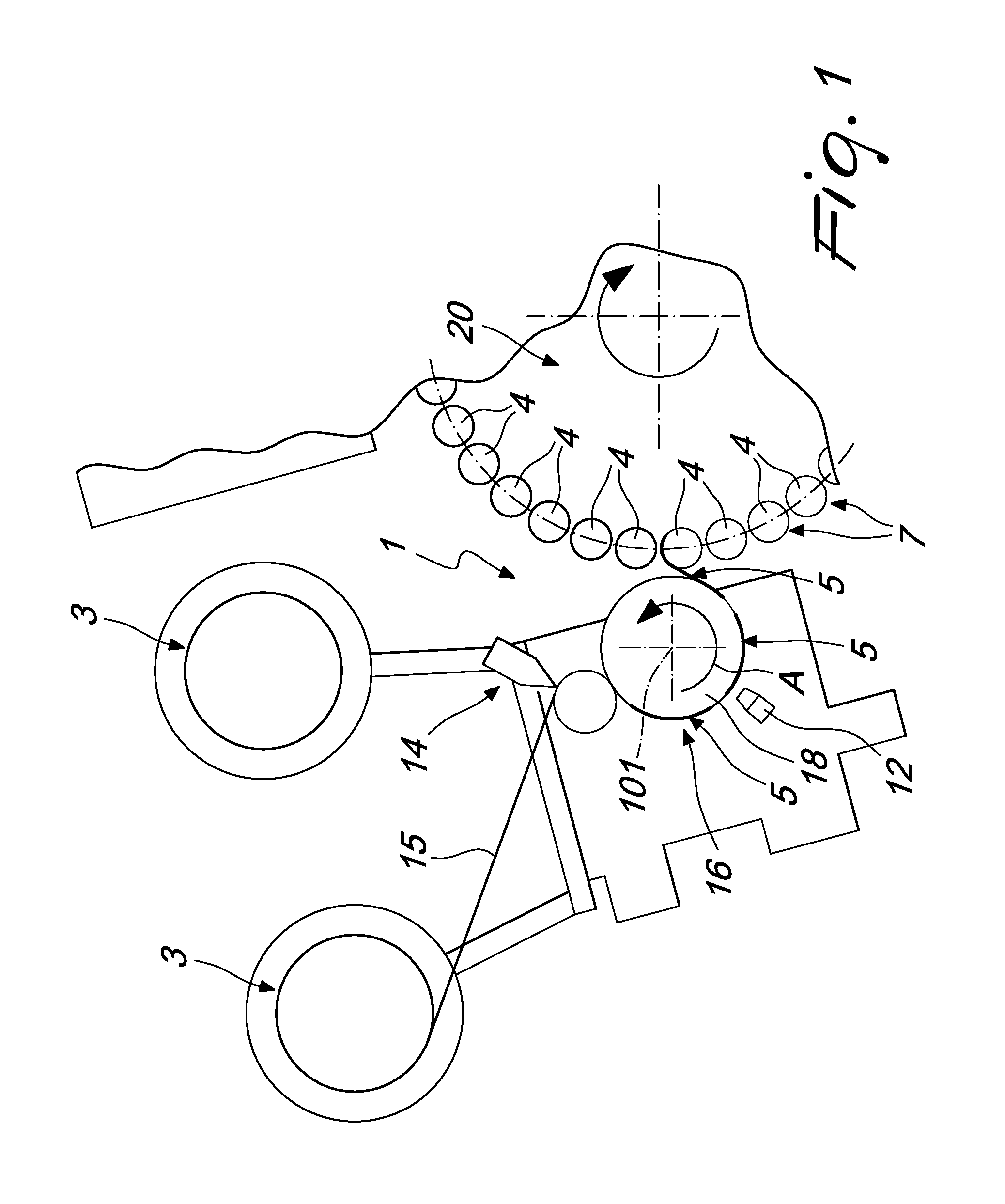

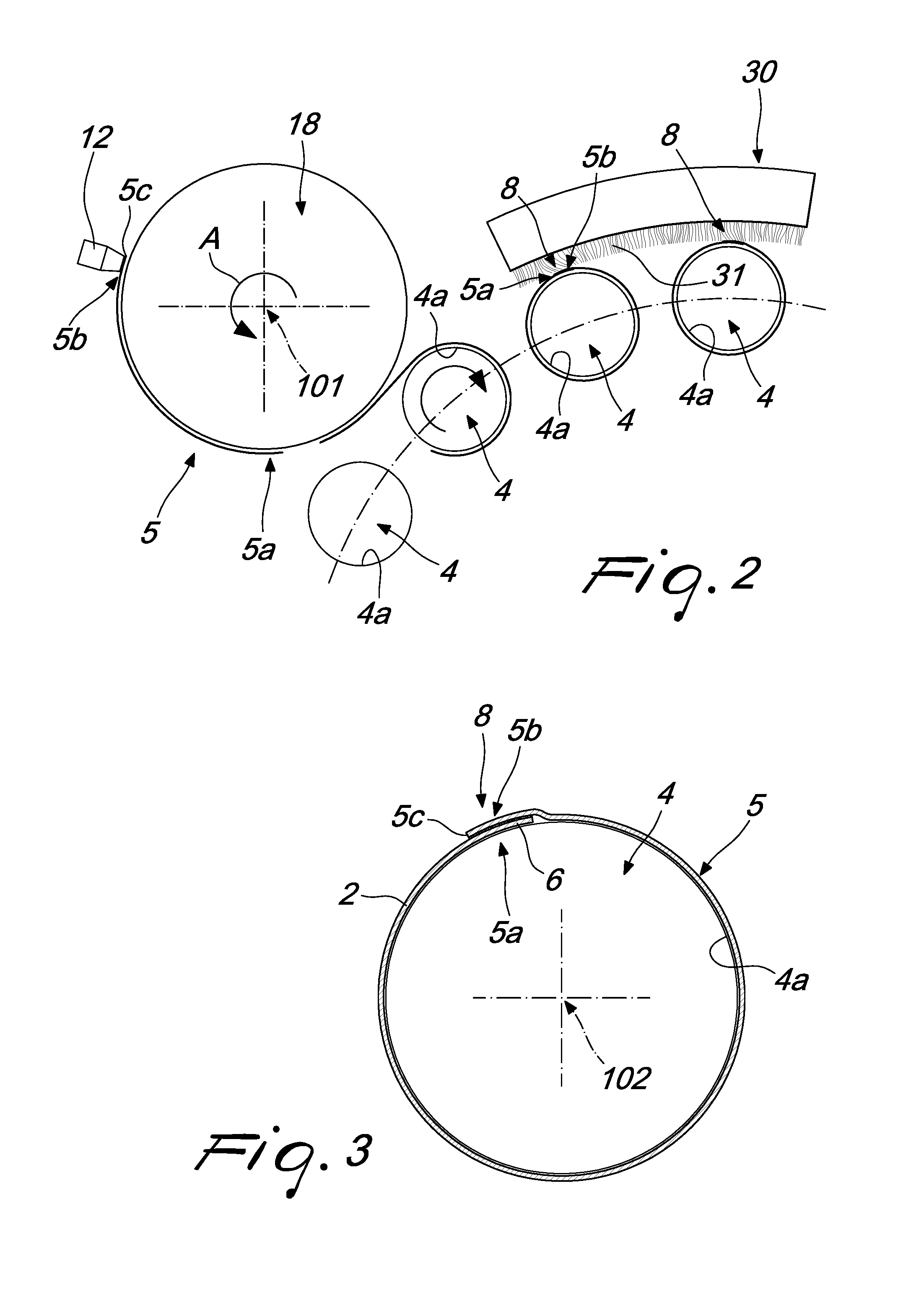

Device for placing sleeves on traveling articles

ActiveUS20100037556A1Eliminate riskRegular cut edgeWrappers shrinkageWrapping material feeding apparatusTangential contactEngineering

The invention relates to a device for placing sleeves on traveling articles, said sleeves being cut from a continuous sheath passing over a sheath-opening shaper, first outer wheels serving to advance the sheath along the shaper, and second outer wheels being provided downstream from cutter means for the purpose of ejecting the cut-off sheath segment, said wheels being driven in rotation by associated electric motors controlled synchronously by a virtual-shaft common electronic programmer. In accordance with the invention, the programmer is arranged to determine a continuous profile of speed variation for the associated electric motors, said profiles being bell-shaped and having a common end segment in which the profiles coincide, this corresponding to the motors having identical speeds, the length of the common end segment being selected so that the sheath is advanced beyond the point of tangential contact with the second wheels so that said sheath is pinched by said second wheels prior to being held stationary for the cutting and ejection pass.

Owner:SLEEVER INT

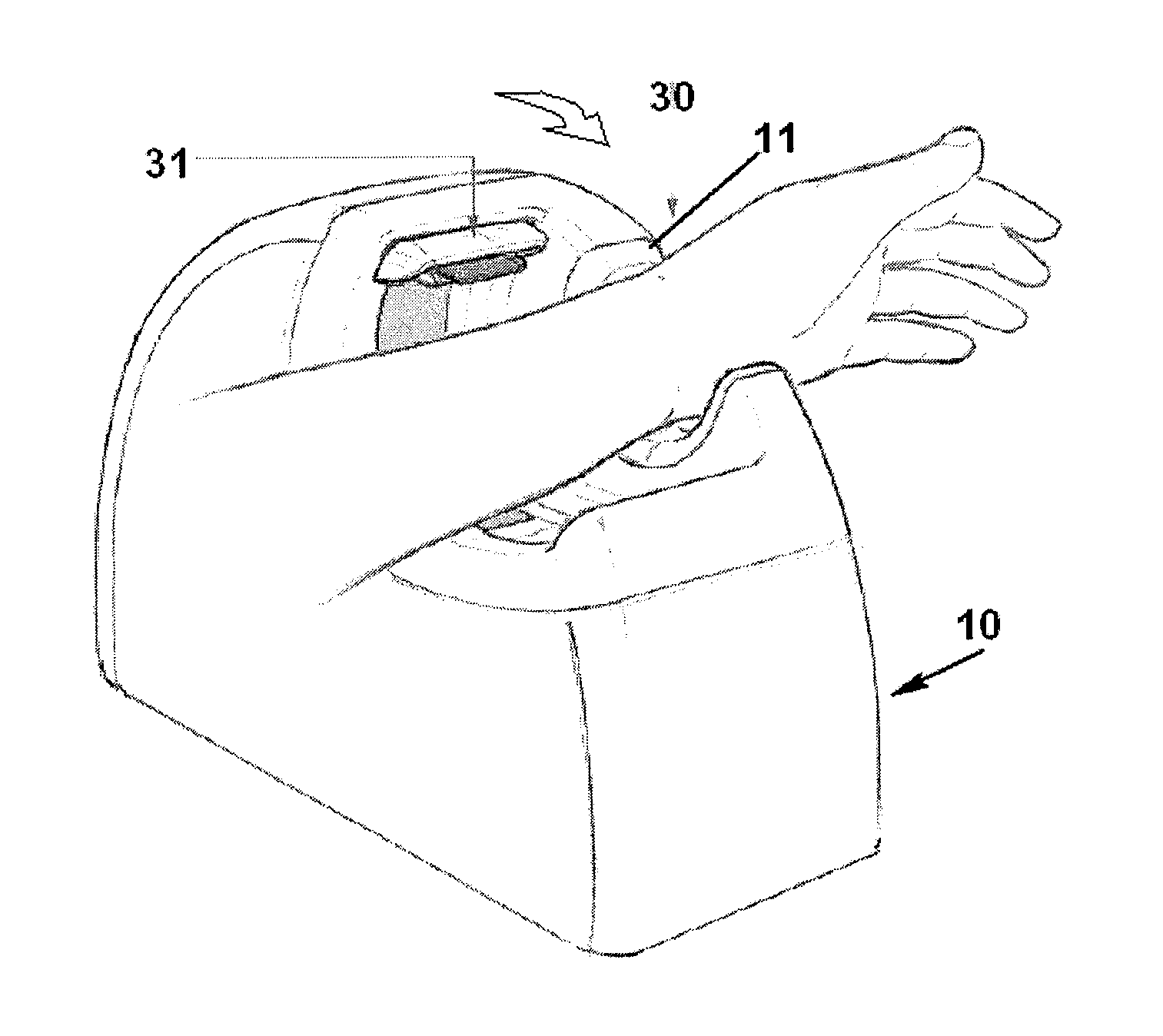

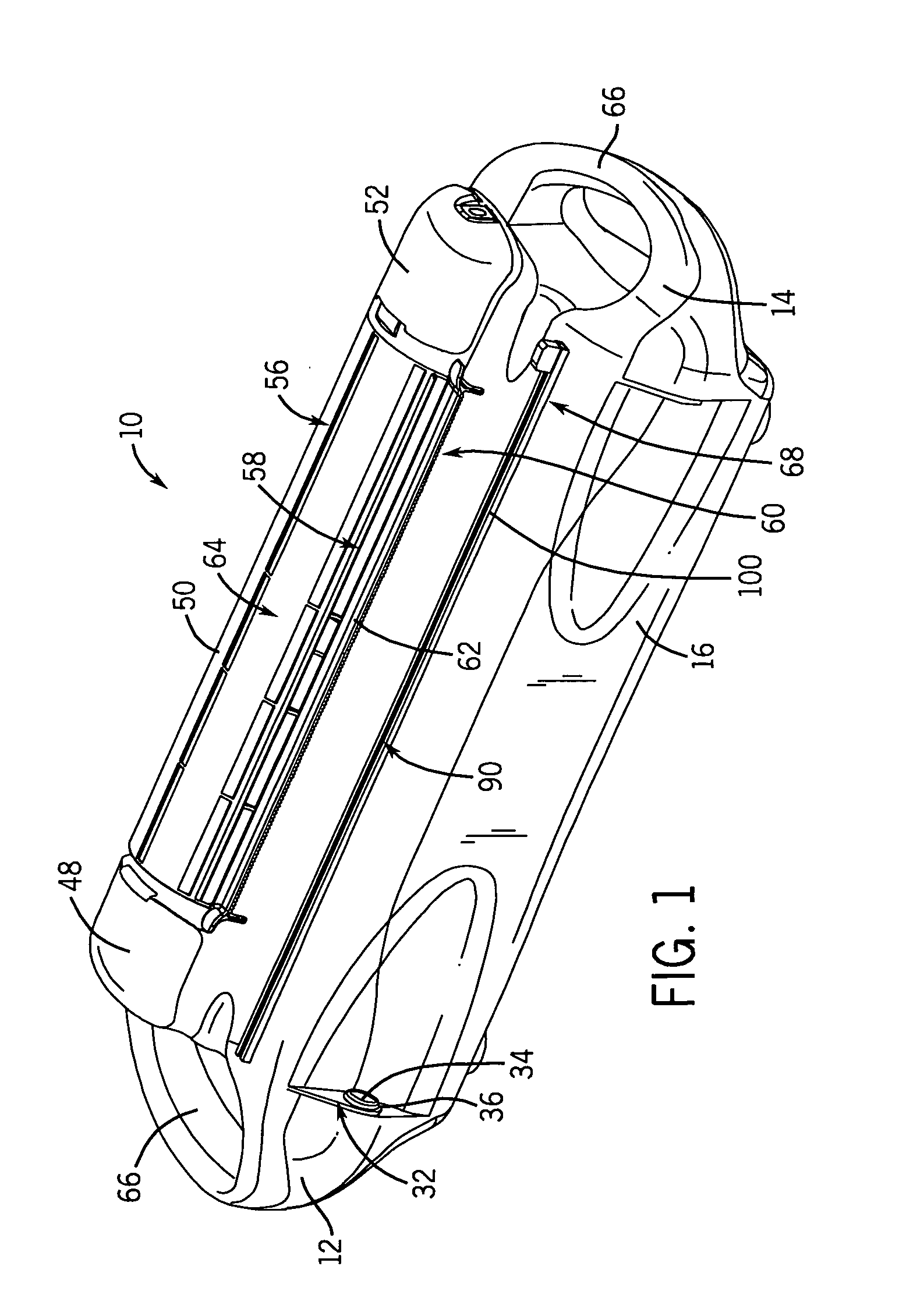

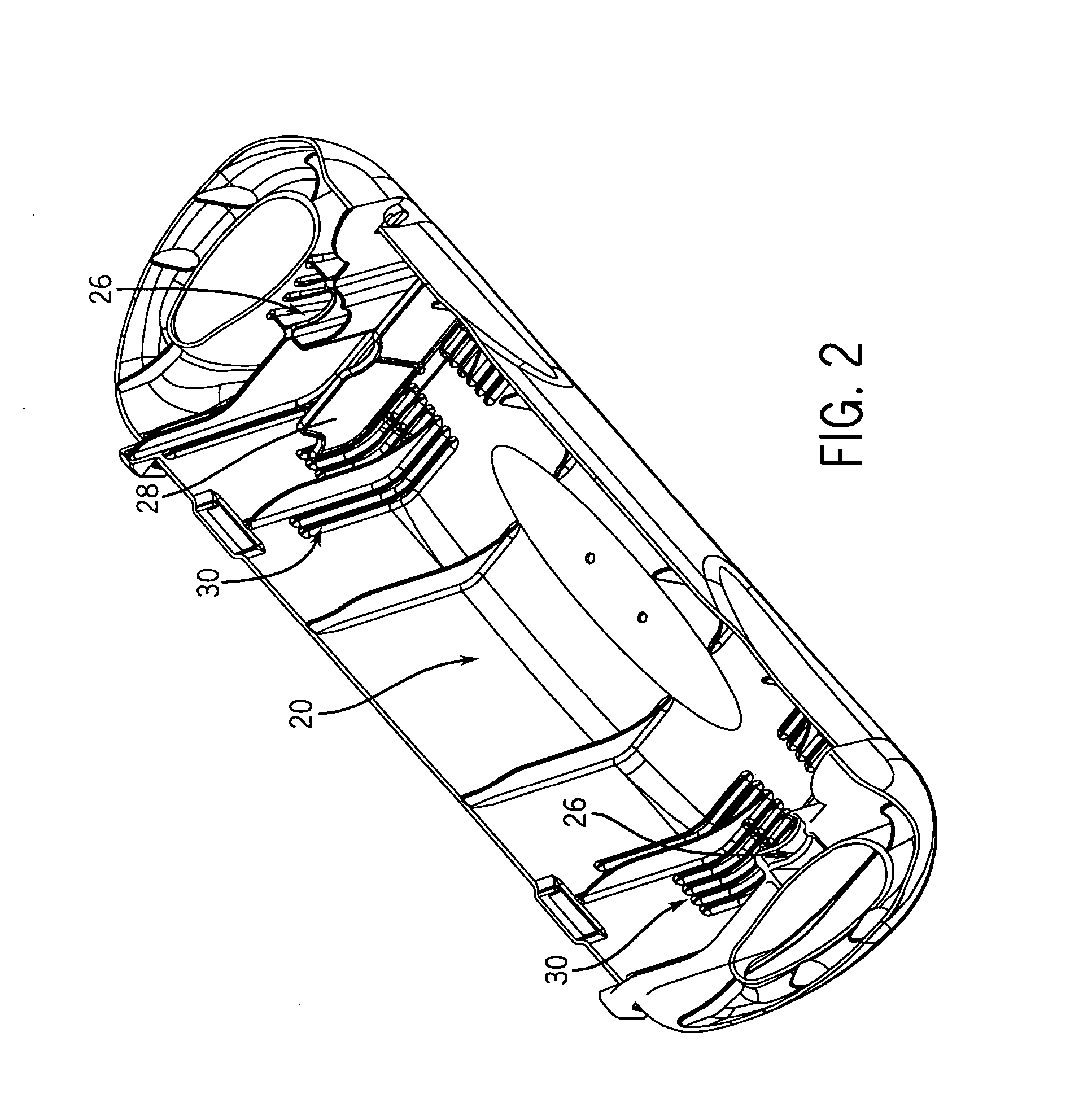

Wristband applicator

Owner:RFID N PRINT

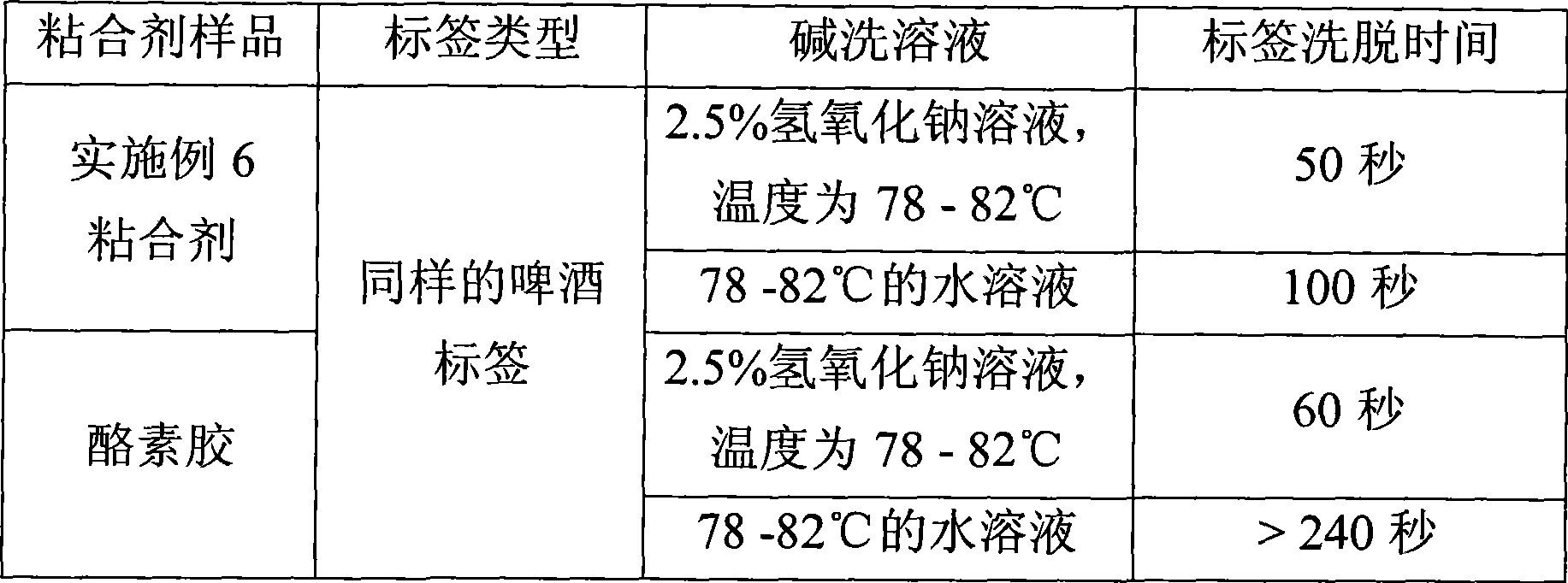

Adhesive, preparation and use thereof

InactiveCN101440269AGood initial adhesionLow freezing pointProtein waste adhesivesStarch adhesivesEnzymatic hydrolysisAdhesive

The invention provides an adhesive for labeling, which comprises 1 to 40 percent of animal glue, 0 to 45 percent of emulsion, 0 to 20 percent of starch, 5 to 40 percent of diluting agent, 0 to 10 percent of cross-linking agent, 0 to 5 percent of thickening agent, 0.001 to 2 percent of additive, and 20 to 50 percent of water. The adhesive has the advantages of good initial adhesion, low solidification point, good water resistance, strong enzyme hydrolysis resistant stability, elution in non-alkaline high temperature water and so on, well meets the requirements of improving production speed, improving the qualification rate of the production and recovering containers at present, and is particularly used for labeling beer bottles.

Owner:HENKEL KGAA

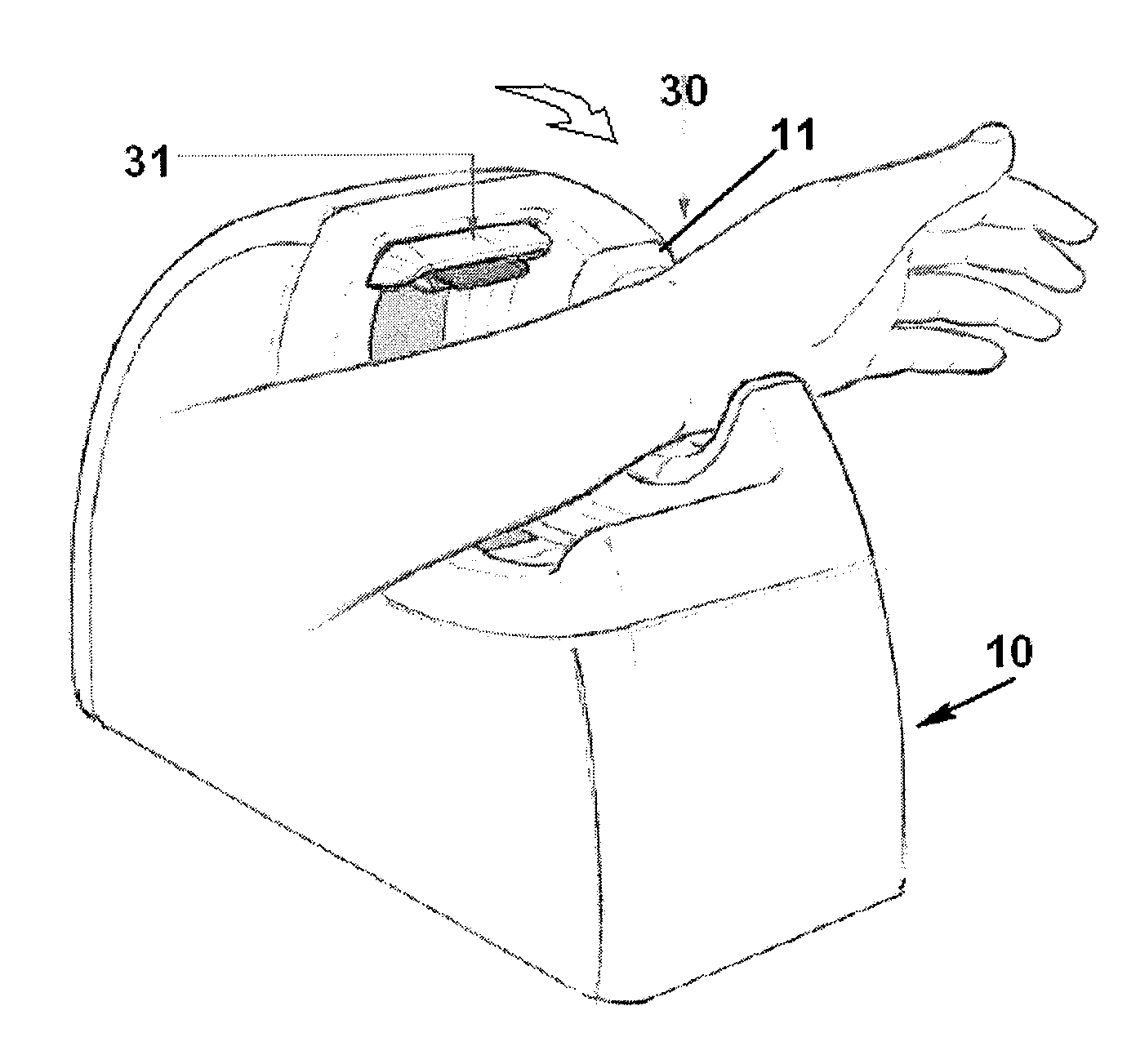

Wristband applicator

The present invention concerns apparatus for efficiently dispensing and applying a wristband identification bracelet that is meant for attachment around an extremity of an animal or person. The apparatus is provided with a supply of identity bands that are adapted to become a bracelet by having a first portion of the band affixed to a second portion to form a continuous loop around the extremity. The extremity is positioned within a receptacle in the apparatus, permitting the identification band to be wrapped closely around the extremity by the band fixing mechanism of the apparatus. The identification band is fixed to itself to form a bracelet, so as to prevent its removal from the extremity without damaging the integrity of the bracelet. The identification bracelet comprises an integral RFID inlay component, and particularly an RFID component whereby all of the RFID circuit is realised in low cost fully printed silicon ink TFT semiconductor form as opposed to a conventional integrated circuit (IC) chip used in prior art RFID inlays.

Owner:RFID N PRINT

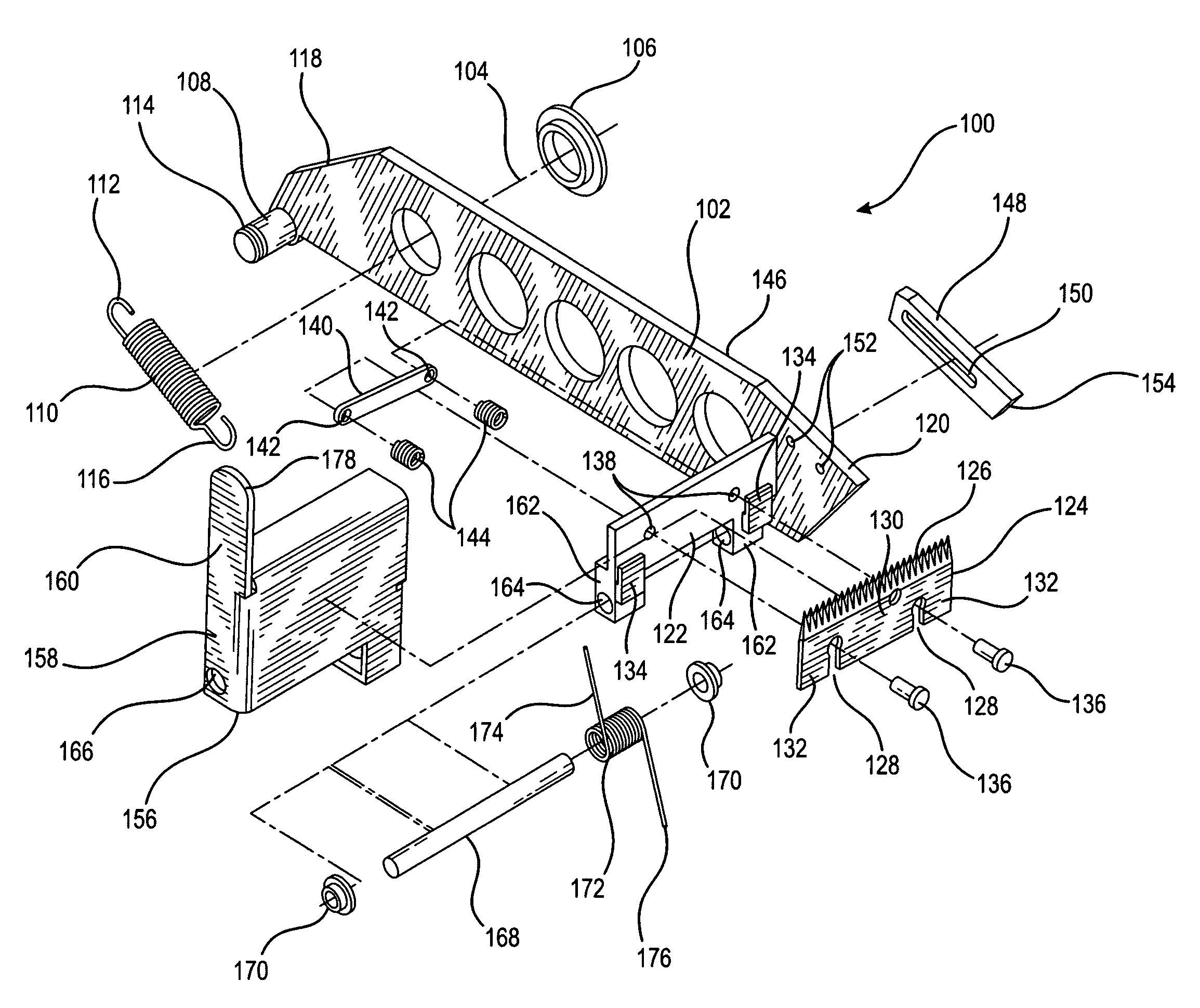

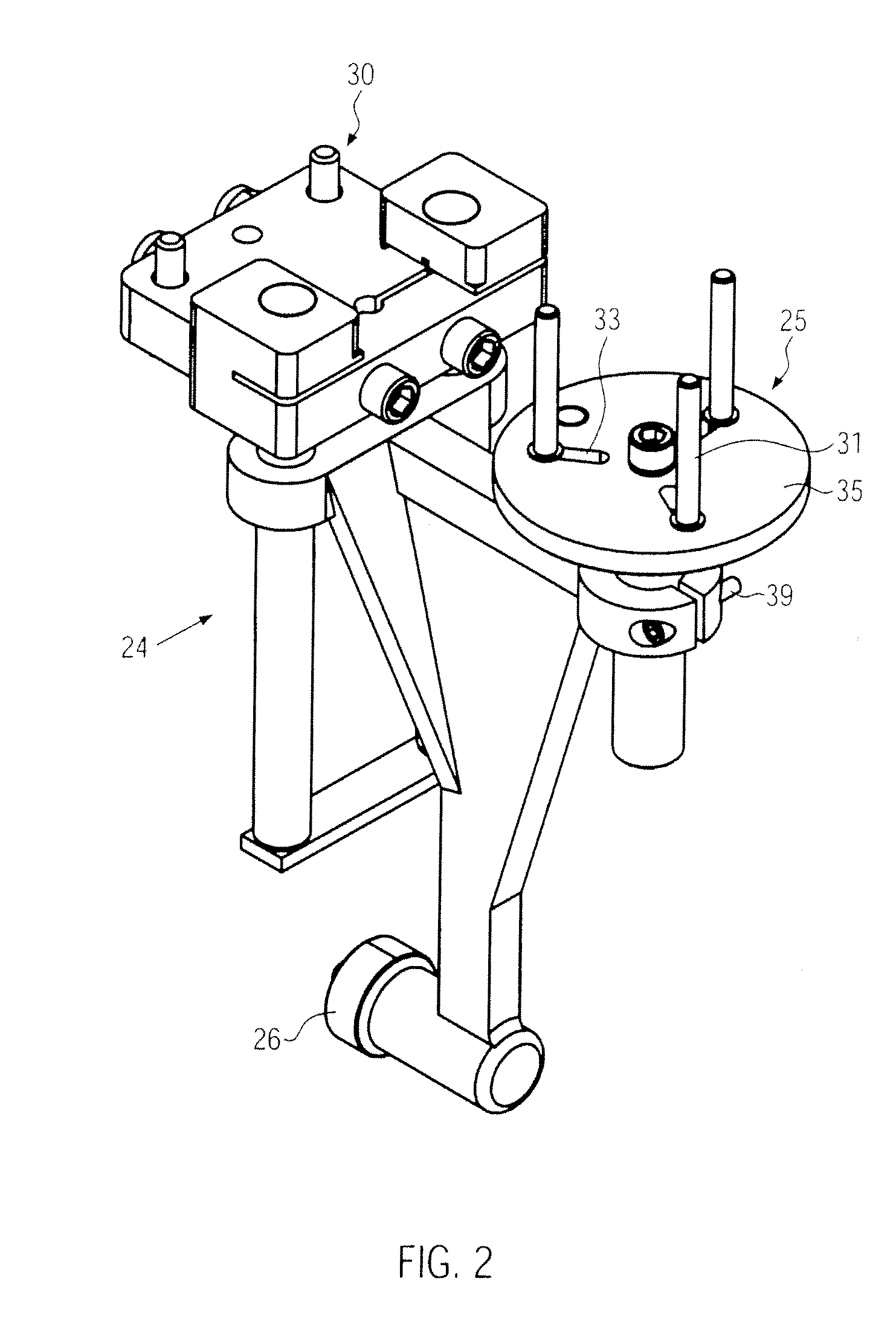

Quick change knife blade assembly for a tape roll dispensing cartridge assembly of a case sealing machine

ActiveUS8079395B2Efficient removalEffective forceLamination ancillary operationsLaminationCombined useEngineering

A quick change knife blade assembly, for use in conjunction with a tape roll dispensing cartridge assembly of a case sealing machine, comprises a knife blade mounted upon a knife blade mounting plate. A pin plate is fixedly connected to mounting pins passing through the knife blade, and springs are interposed between the pin plate and the mounting plate so as to normally bias the pin plate to a position at which the mounting pins prevent the removal of the knife blade from the mounting plate. When the pin plate is depressed against the biasing forces of the springs, the mounting pins are moved so as to permit the knife blade to be removed from the mounting plate.

Owner:SIGNODE IND GRP

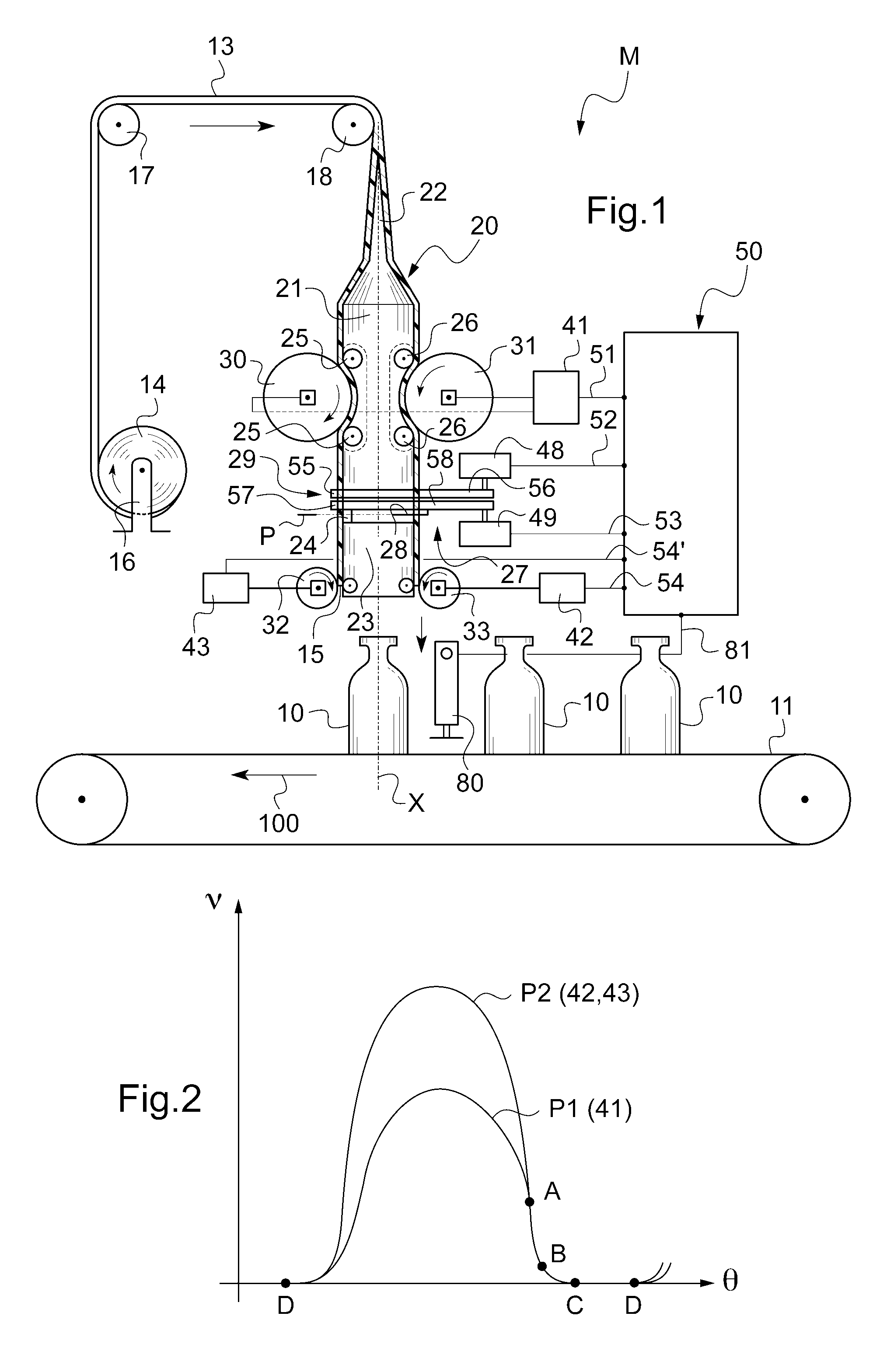

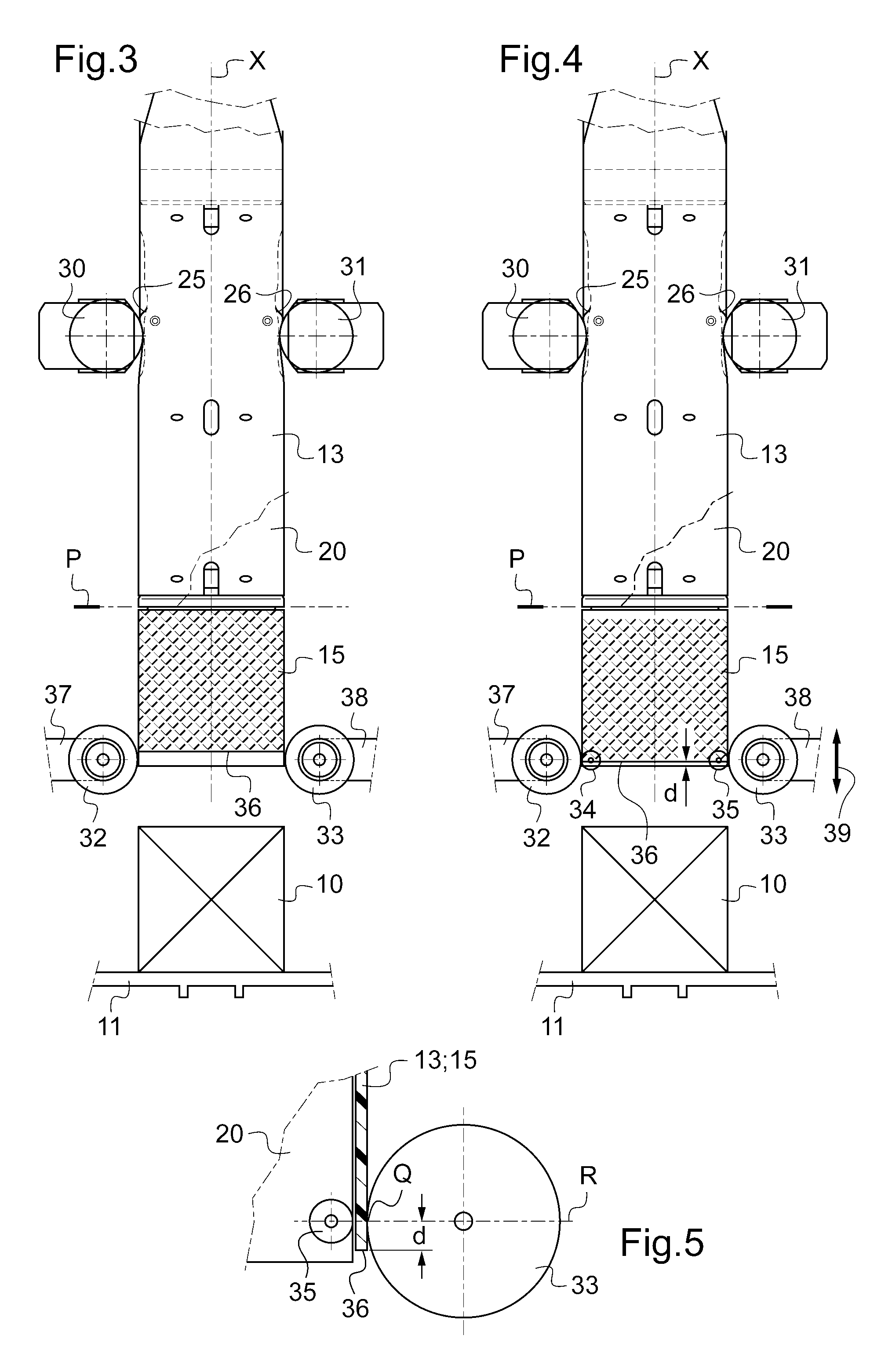

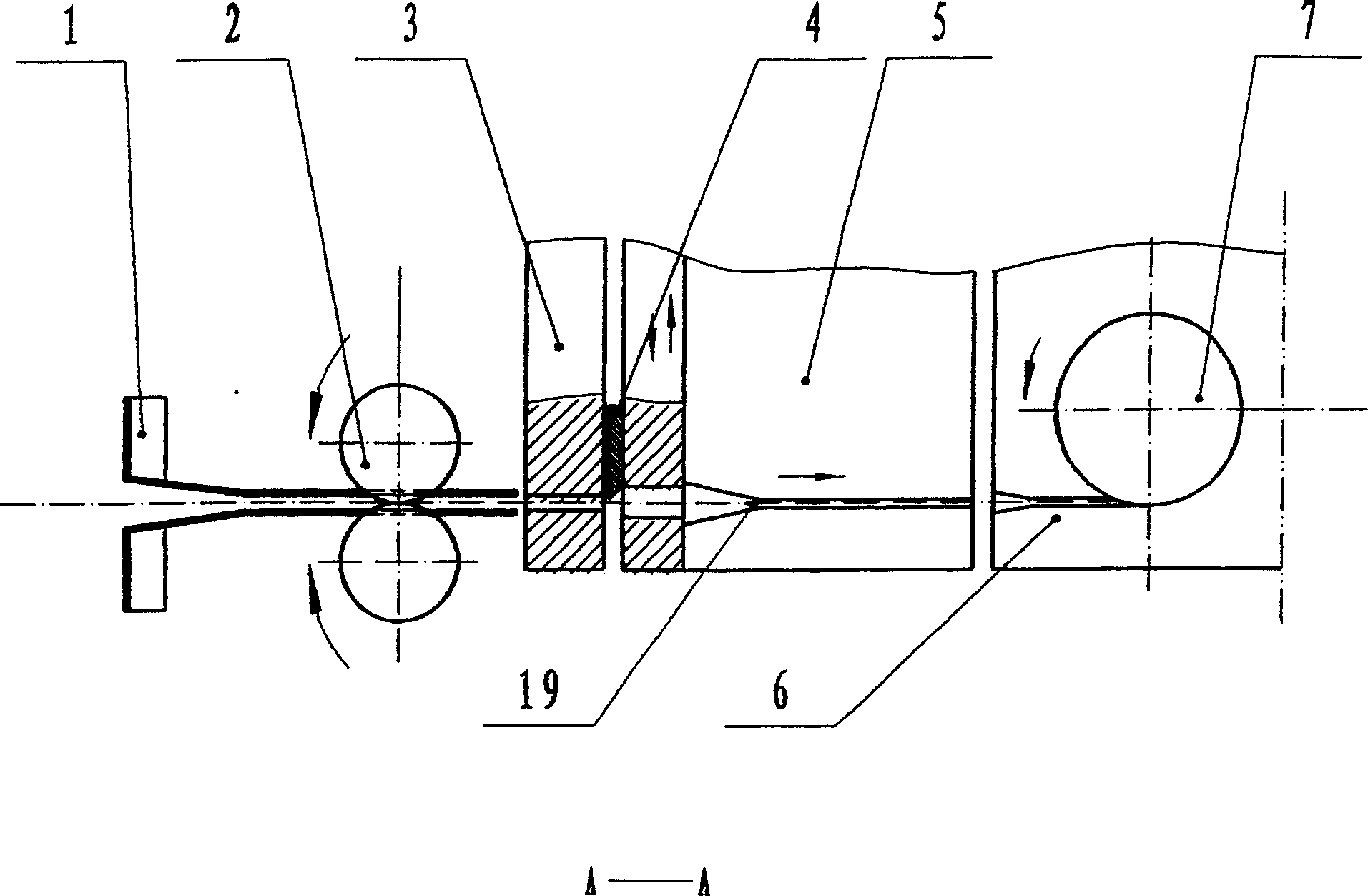

Device for placing sleeves on traveling articles

ActiveUS8146334B2Eliminate riskRegular cut edgeWrappers shrinkageWrapping material feeding apparatusTangential contactEngineering

The invention relates to a device for placing sleeves on traveling articles, said sleeves being cut from a continuous sheath passing over a sheath-opening shaper, first outer wheels serving to advance the sheath along the shaper, and second outer wheels being provided downstream from cutter means for the purpose of ejecting the cut-off sheath segment, said wheels being driven in rotation by associated electric motors controlled synchronously by a virtual-shaft common electronic programmer. In accordance with the invention, the programmer is arranged to determine a continuous profile of speed variation for the associated electric motors, said profiles being bell-shaped and having a common end segment in which the profiles coincide, this corresponding to the motors having identical speeds, the length of the common end segment being selected so that the sheath is advanced beyond the point of tangential contact with the second wheels so that said sheath is pinched by said second wheels prior to being held stationary for the cutting and ejection pass.

Owner:SLEEVER INT

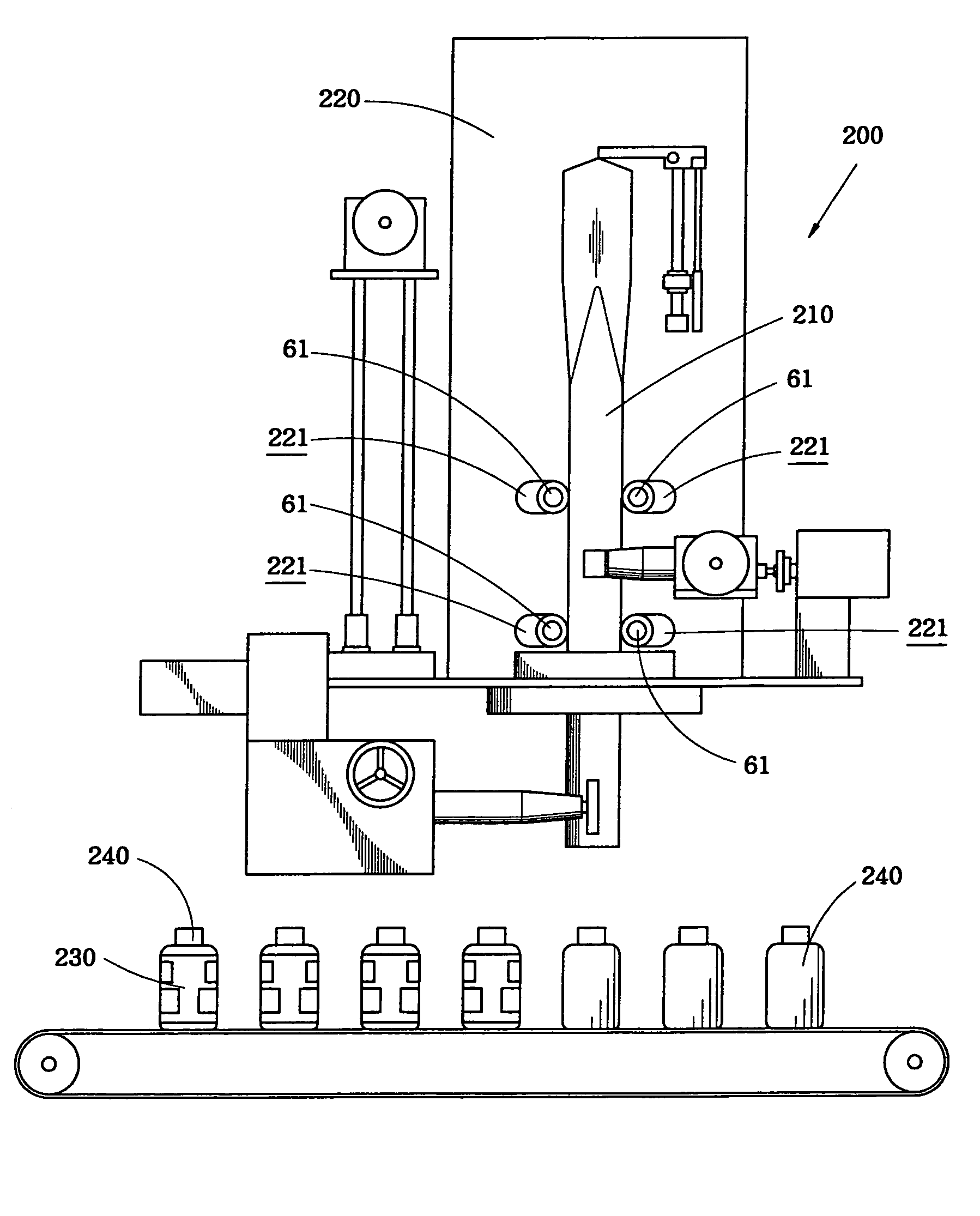

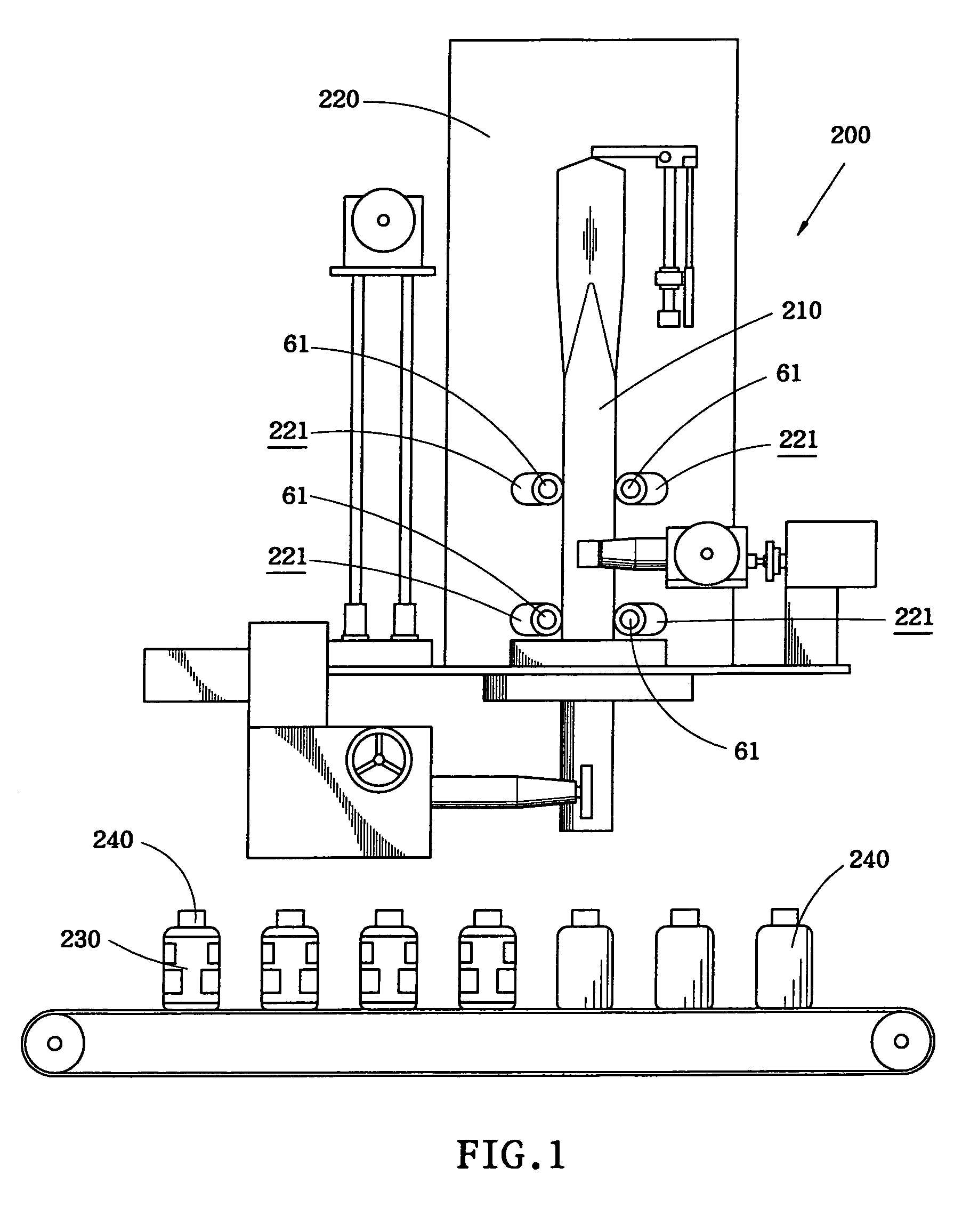

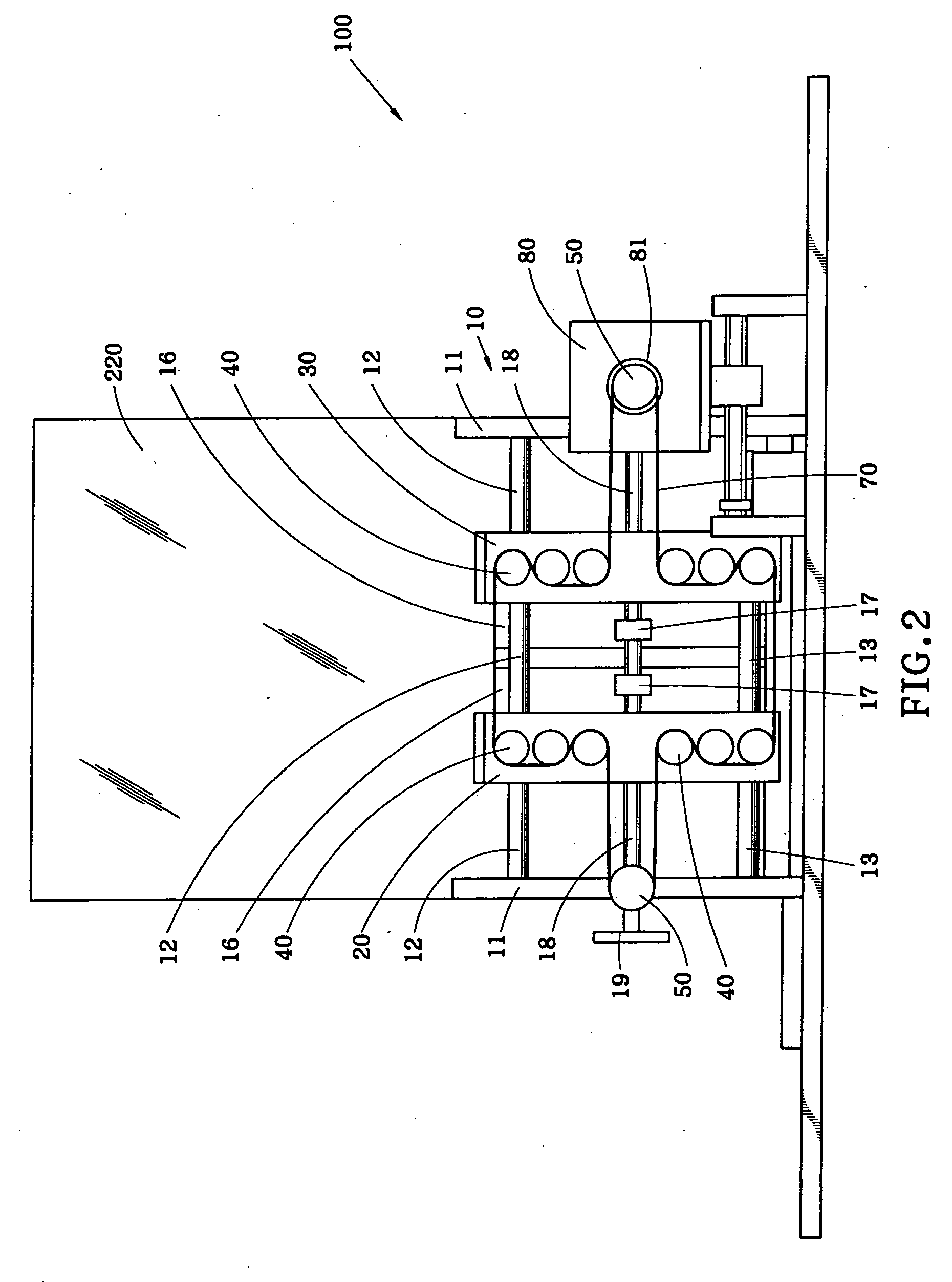

Adjusting device of film packaging machine

InactiveUS7231748B2Adjustable distanceSmooth movementEnvelopes/bags making machineryWrappers shrinkageElectric motorPackaging machine

Owner:BENISON

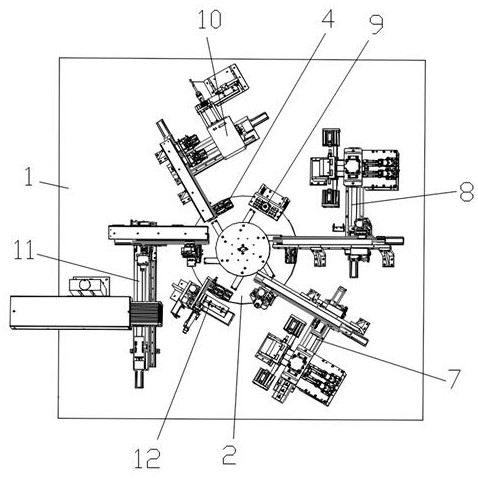

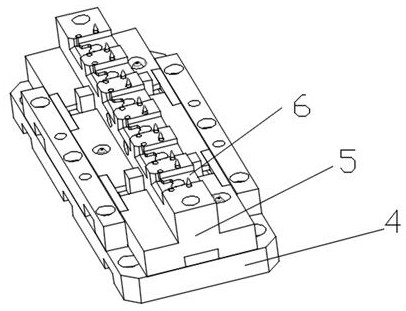

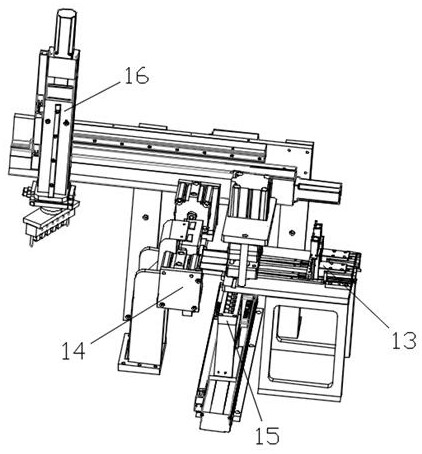

Mobile phone connector shell assembling equipment

ActiveCN112719926ASimple structureEasy to useOther manufacturing equipments/toolsLabellingEngineeringCam

The invention relates to the technical field of mobile phone connector production equipment, in particular to mobile phone connector shell assembling equipment. The equipment comprises a workbench, a rotary disc is arranged on the upper surface of the workbench, a cam divider is connected to the lower portion of the rotary disc, the cam divider drives the rotary disc to rotate, jig seats are arranged on the upper surface of the rotary disc in a concentric array manner, jig discs are detachably installed on the jig seats, and multiple workpiece grooves are horizontally formed in each jig disc side by side. A bottom shell feeding mechanism, a top shell feeding mechanism, a pressing mechanism, a welding mechanism, a marking mechanism and a discharging mechanism are fixedly arranged at the position, on the peripheral side of the rotary disc, on the workbench and matched with the jig seats. Compared with the prior art, the equipment has the beneficial effects that the above scheme is adopted, the equipment is simple in structure and convenient to use, automation is achieved, labor is saved, multiple workpieces can be machined at the same time, production efficiency is improved, and good market application value is achieved.

Owner:深圳市天歌信息技术有限公司

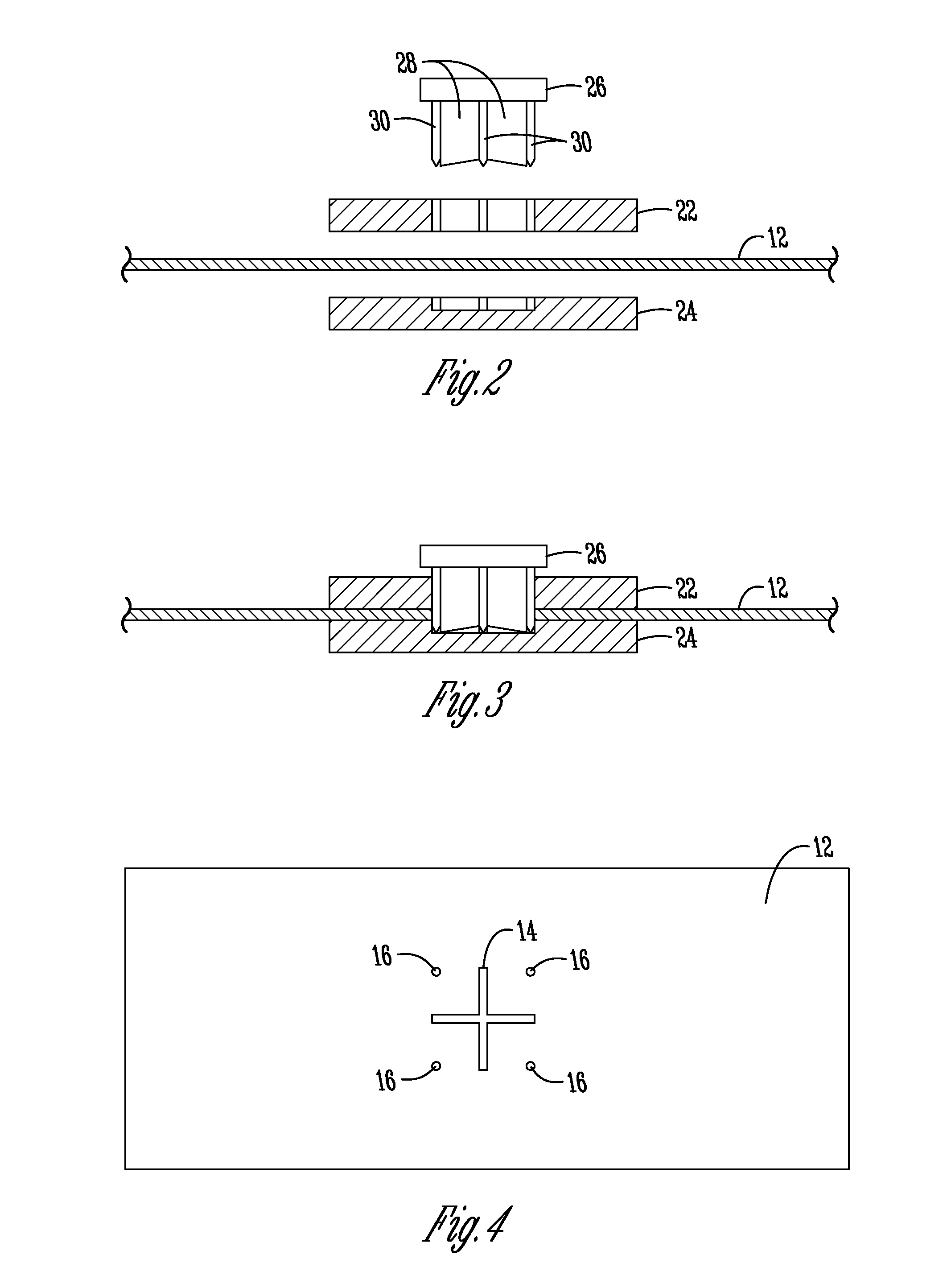

Method and apparatus for embedding ornamental objects into sheet material

Owner:LABOW EDWARD D

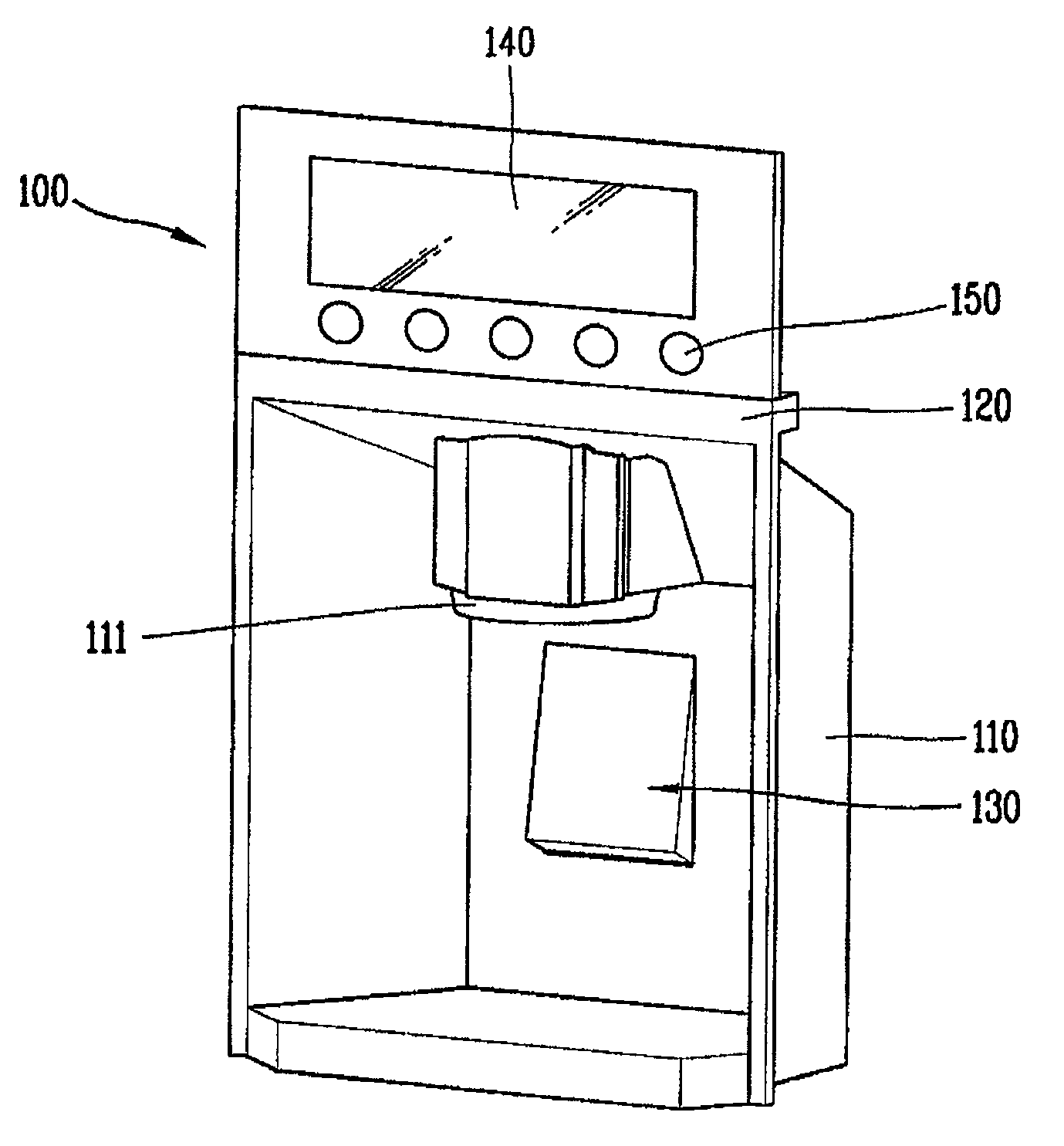

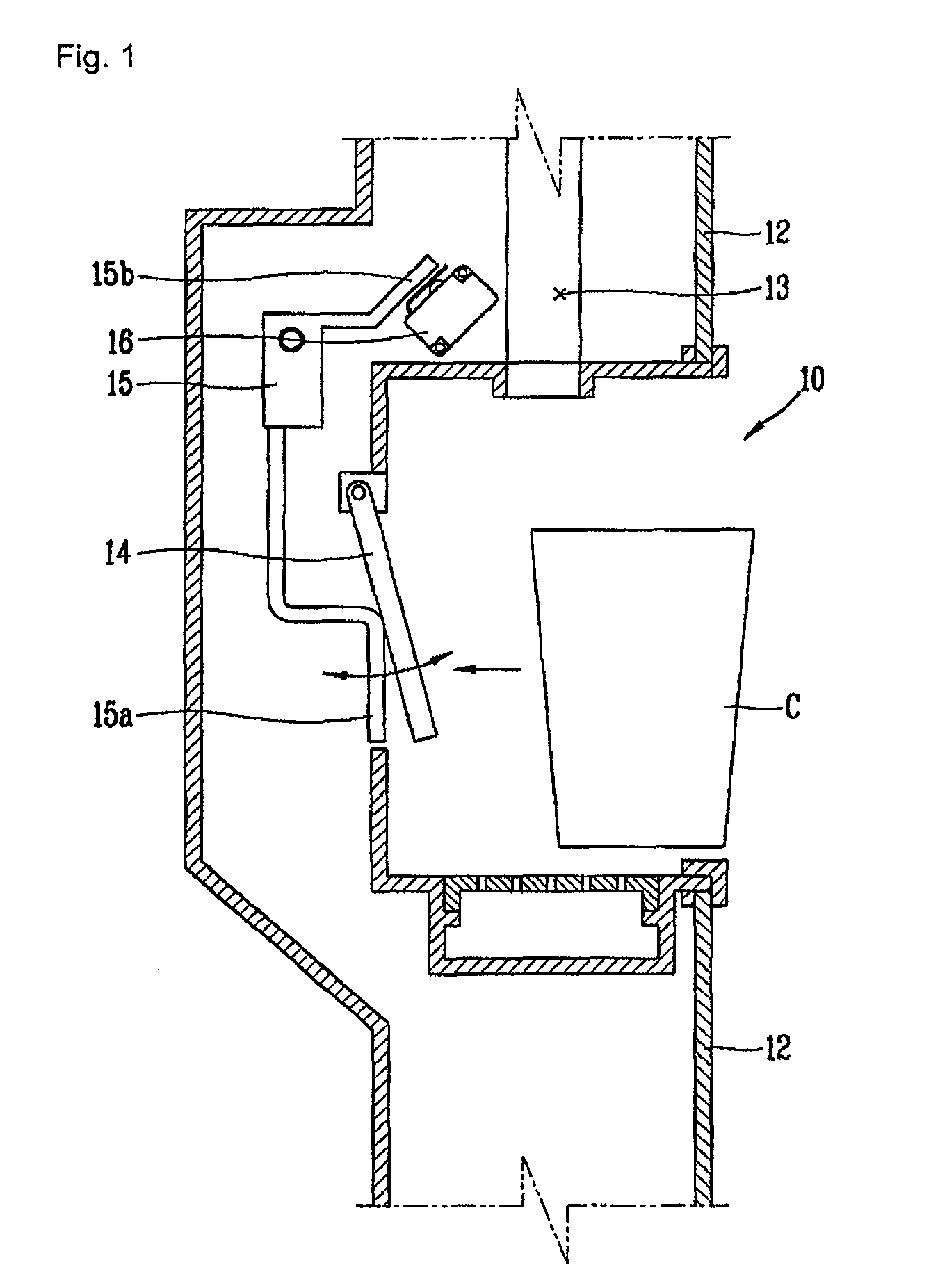

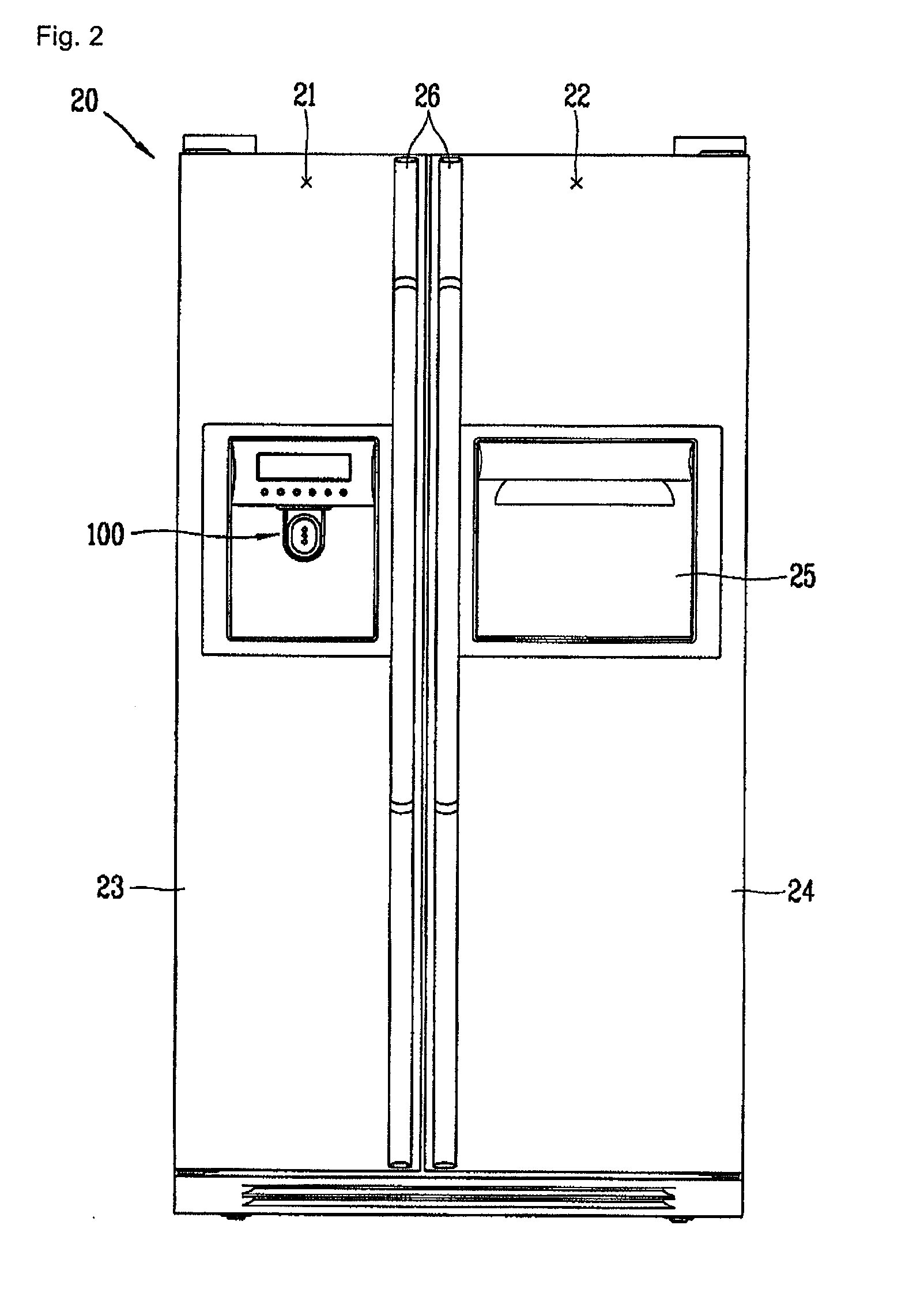

Dispenser for refrigerator

ActiveUS8348108B2Reduced space required for installationGuaranteed uptimeLighting and heating apparatusSolid materialEngineeringMechanical engineering

Owner:LG ELECTRONICS INC

Outdoor cooking station with griddle, system and method thereof

ActiveUS10327589B1Domestic stoves or rangesLighting and heating apparatusEngineeringMechanical engineering

Embodiments of a griddle of the type for an outdoor cooking station is provided herein. The griddle includes a flat cooking surface with a splash guard extending along a periphery of the flat cooking surface. The flat cooking surface defines a trough positioned adjacent a rear end of the cooking surface such that the trough includes a sloping surface extending downward toward a rear opening defined in the splash guard along and adjacent the rear end of the flat cooking surface. With this arrangement, as a user cooks food on the griddle, unwanted grease may be pushed to the rear of the griddle and into the trough so that the grease funnels down the sloped surface and through the rear opening and into a grease container centered below the rear opening.

Owner:NORTH ATLANTIC IMPORTS

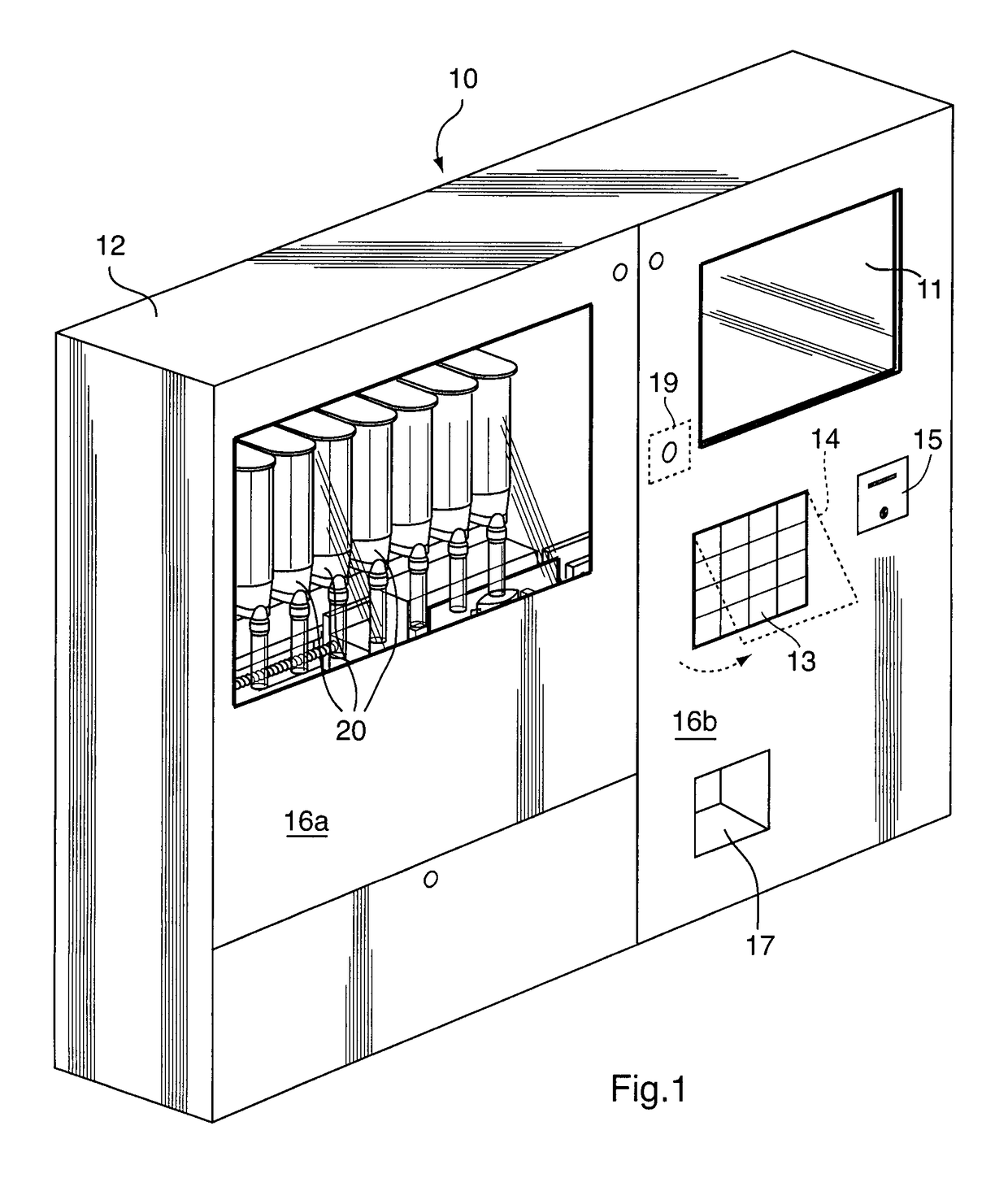

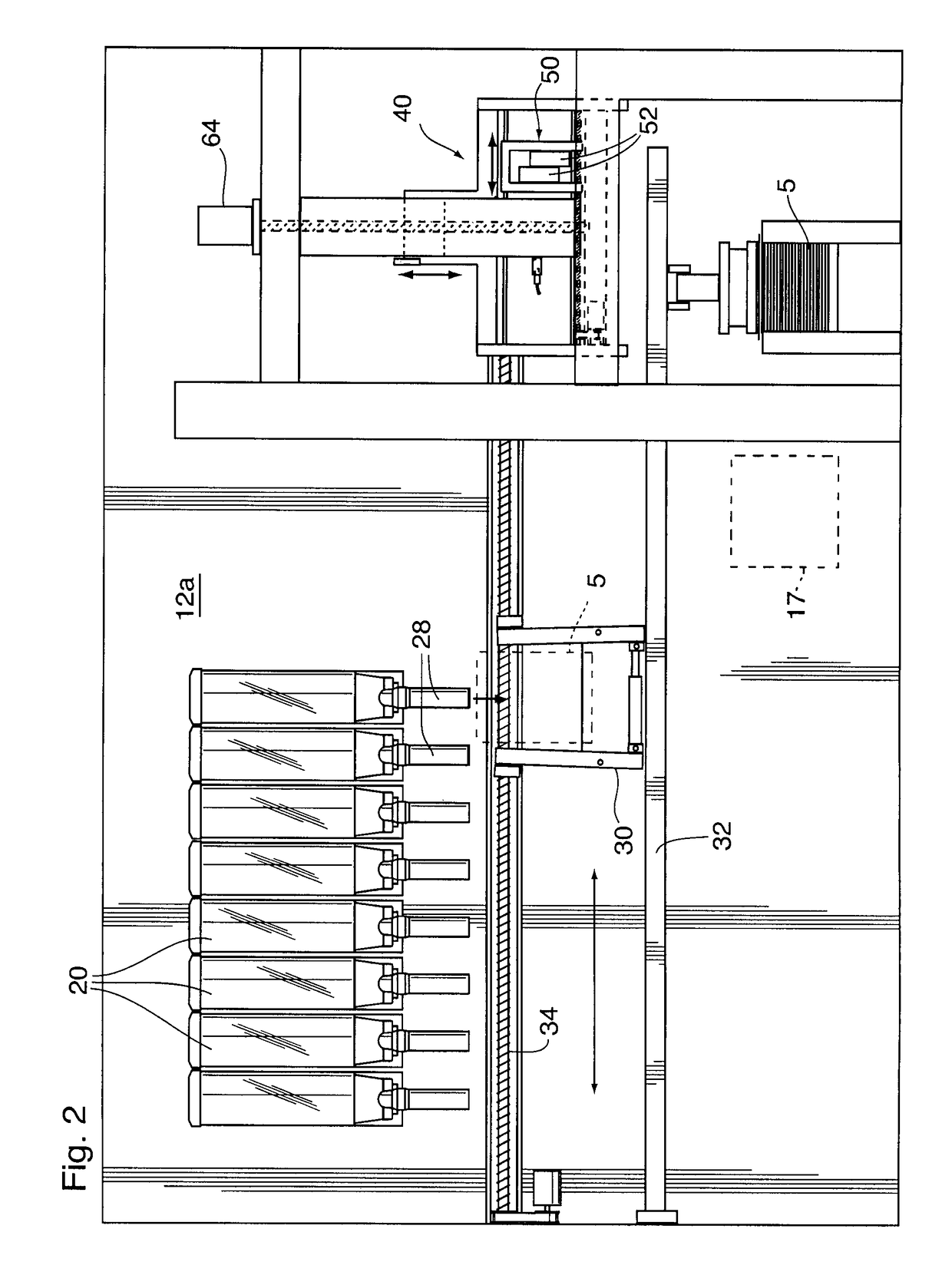

Printing system for a vending machine

ActiveUS10152841B2Special service provision for substationCoin-freed apparatus detailsEngineeringFinancial transaction

Owner:BEAVER MACHINE

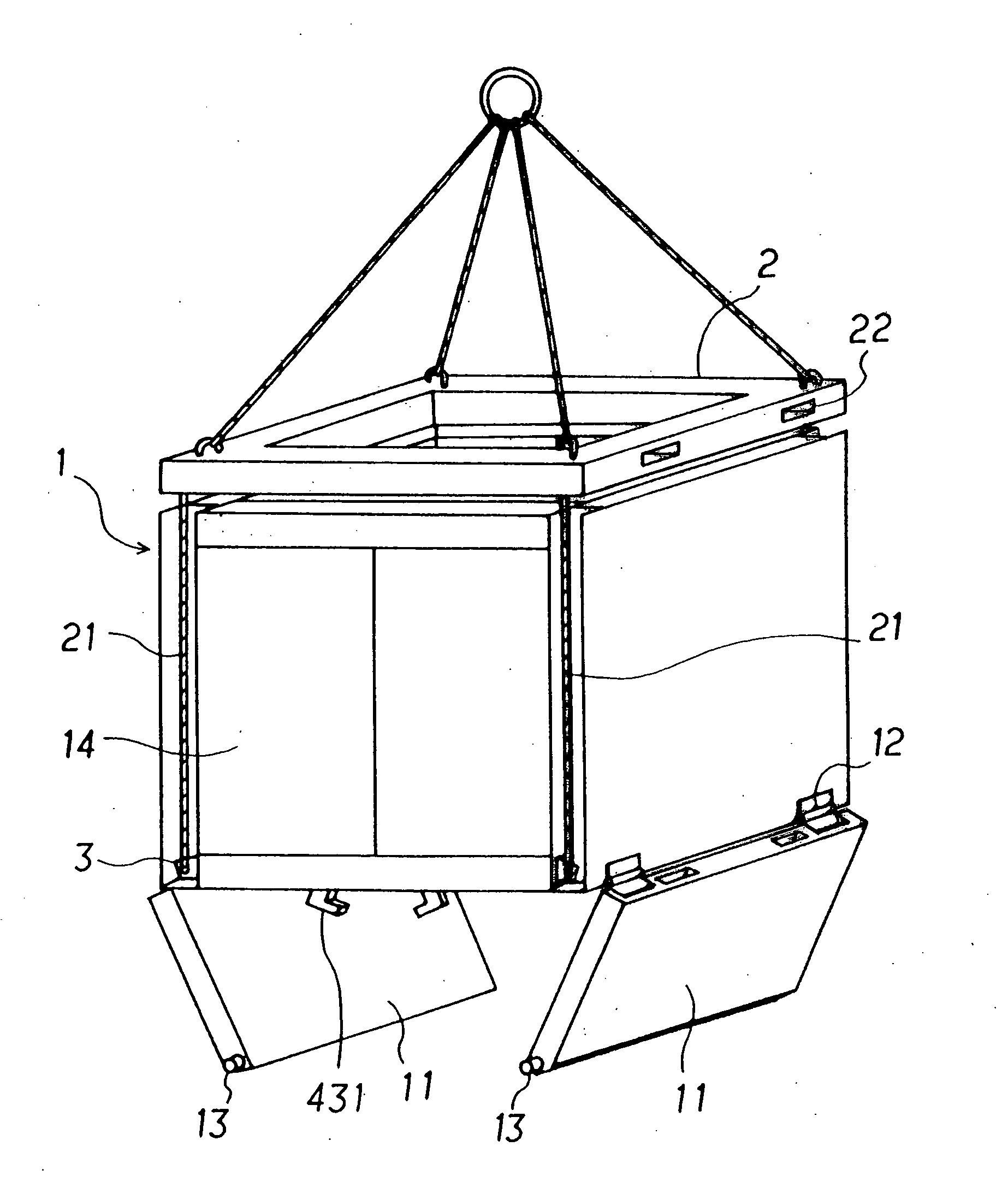

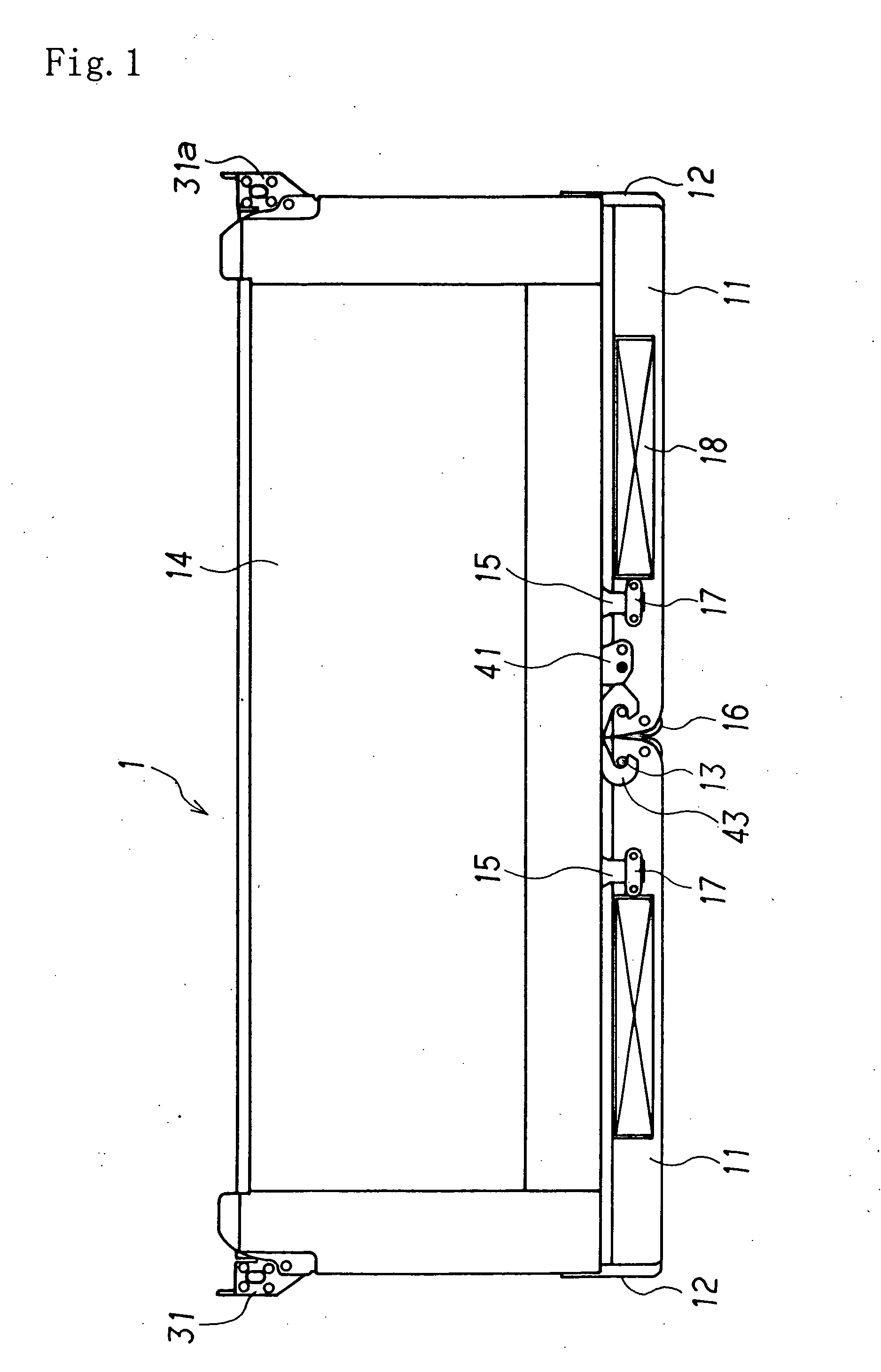

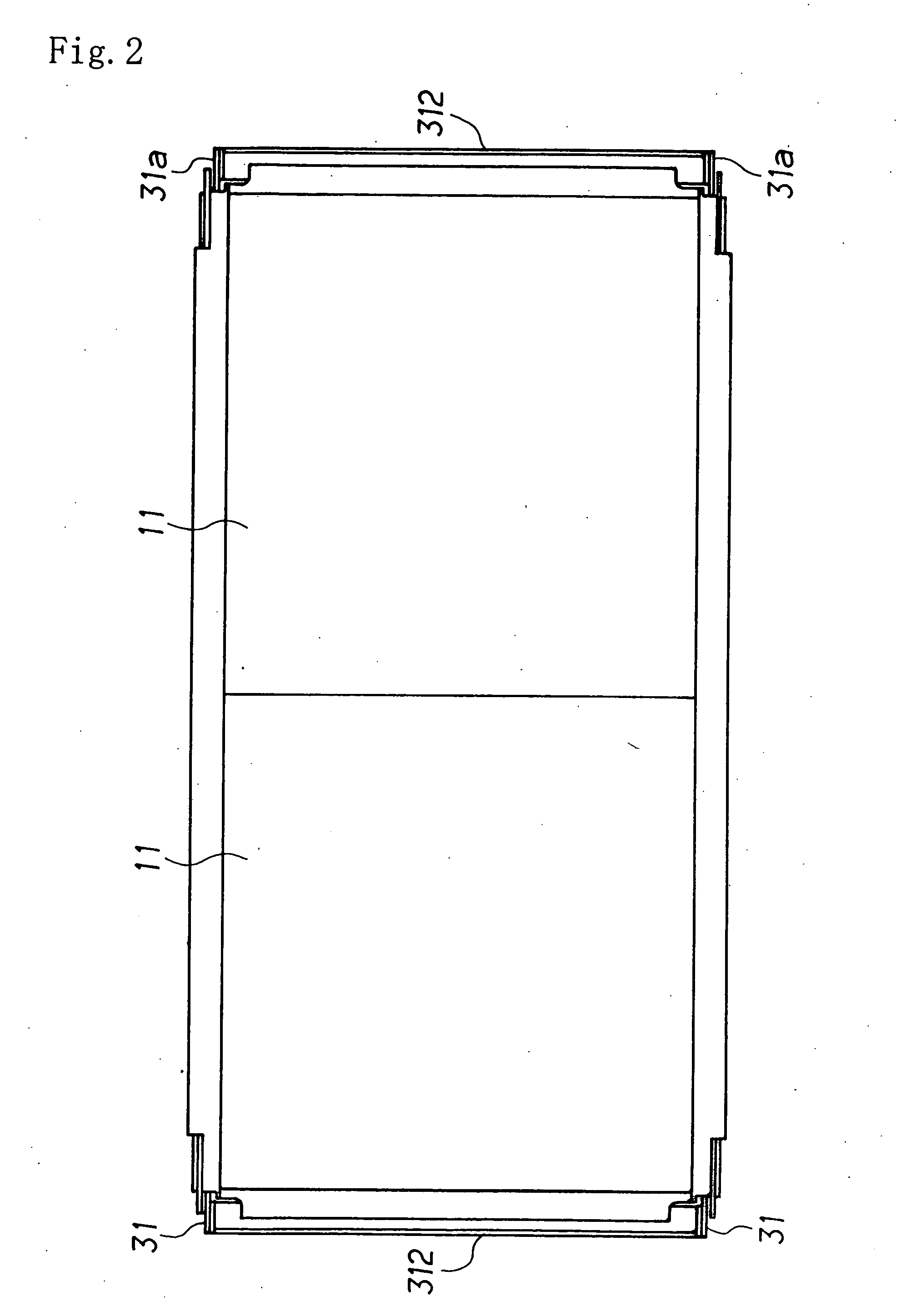

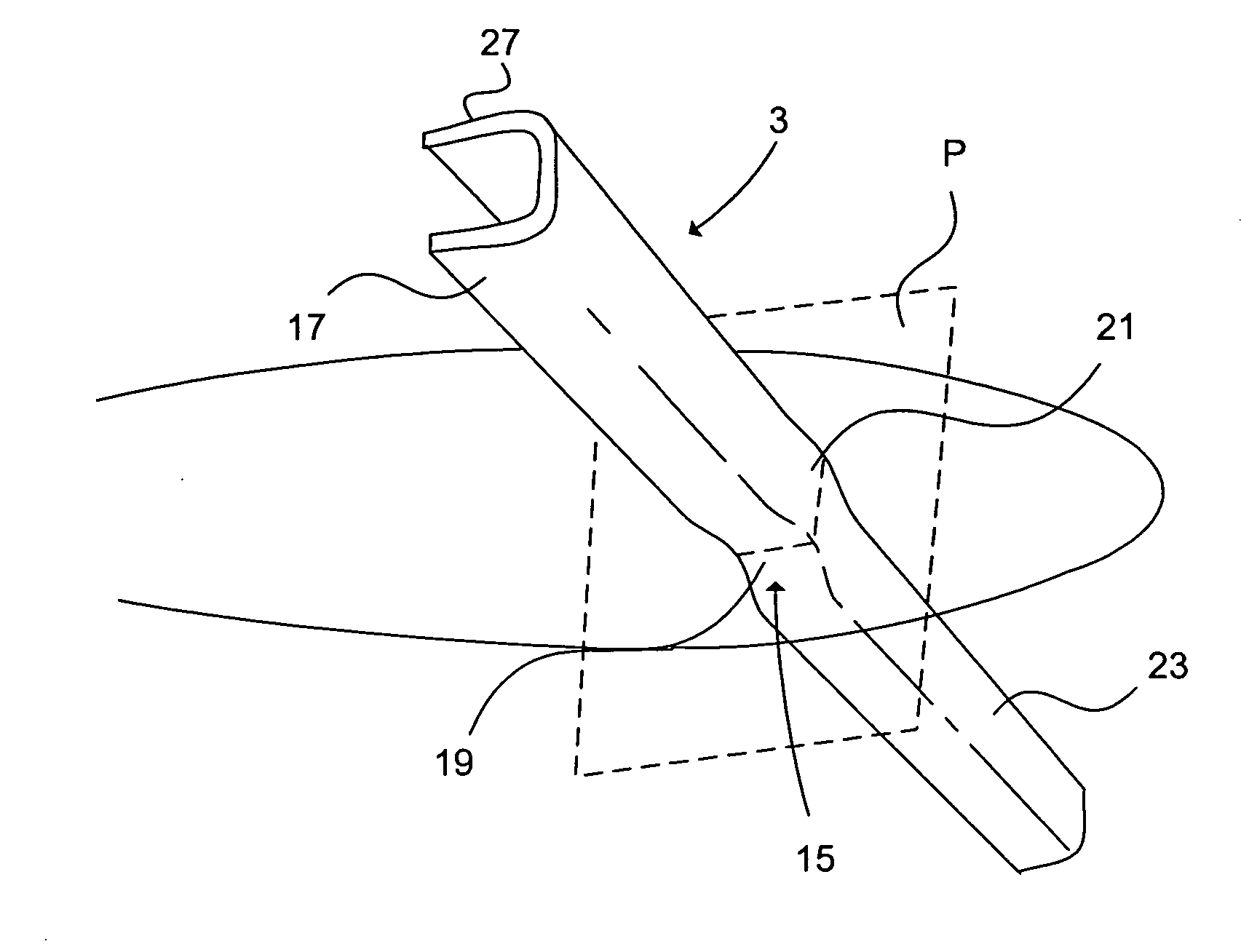

Bottom discharge container

InactiveUS20060071490A1ClosuresElectric locomotivesClosed stateElectrical and Electronics engineering

A bottom opening type container bottom plates of which can be opened only by a hoisting operation using a crane by performing a simple preparing operation can be realized. A vertical link 32, a lateral link 35, and a link 45 are arranged on a middle between a hoisting plate 31 and open / close arms 43, and an operation cam 41 is provided to the outside of the open / close arms 43. The operation cam 41 is turned to a rise posture or a down posture so that the open / close arms 43 can be switched freely between an opened state or a closed state by the hoisting force, and the state can be checked externally.

Owner:NAKAJIMA 1 3 RITSUO +2

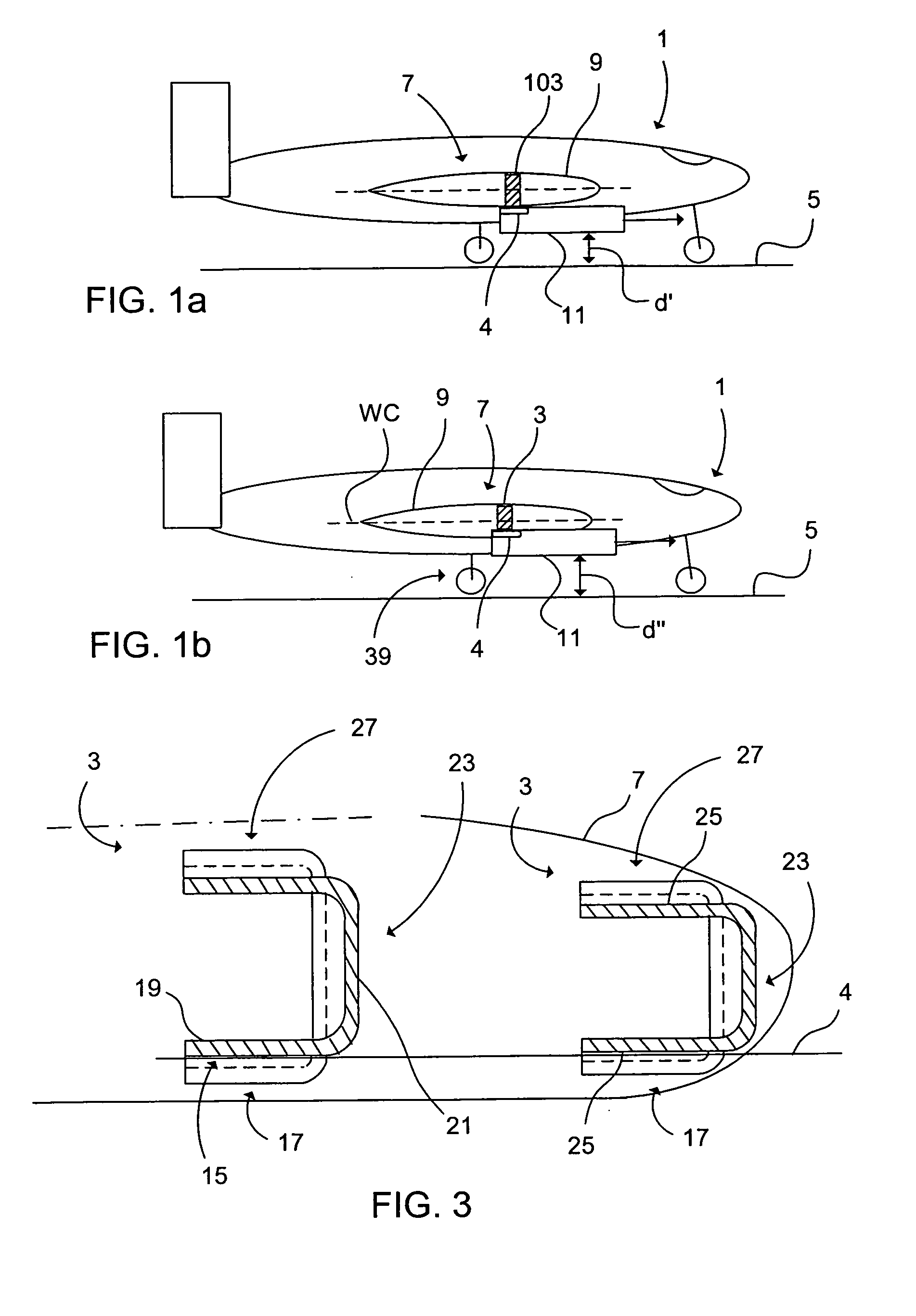

Method and apparatus for manufacturing of a wing spar profile element

InactiveUS20090025865A1Cost-effective manufacturingResistant to cureMechanical working/deformationLabellingEngineeringFlange

A method and an apparatus for manufacture of an elongated beam profile element including a recess configured to accommodate a support element. The method includes forming the blank into the web portion with at least one first protrusion formed to extend across the web portion and to protrude outward from the web portion's outer surface; and into the first flange portion with at least one second protrusion formed to extend across the first flange portion and to protrude inward from the first flange portion's inner surface, wherein this second protrusion merges into the first protrusion and constitutes the recess for accommodating the support element under a wing.

Owner:SAAB AB

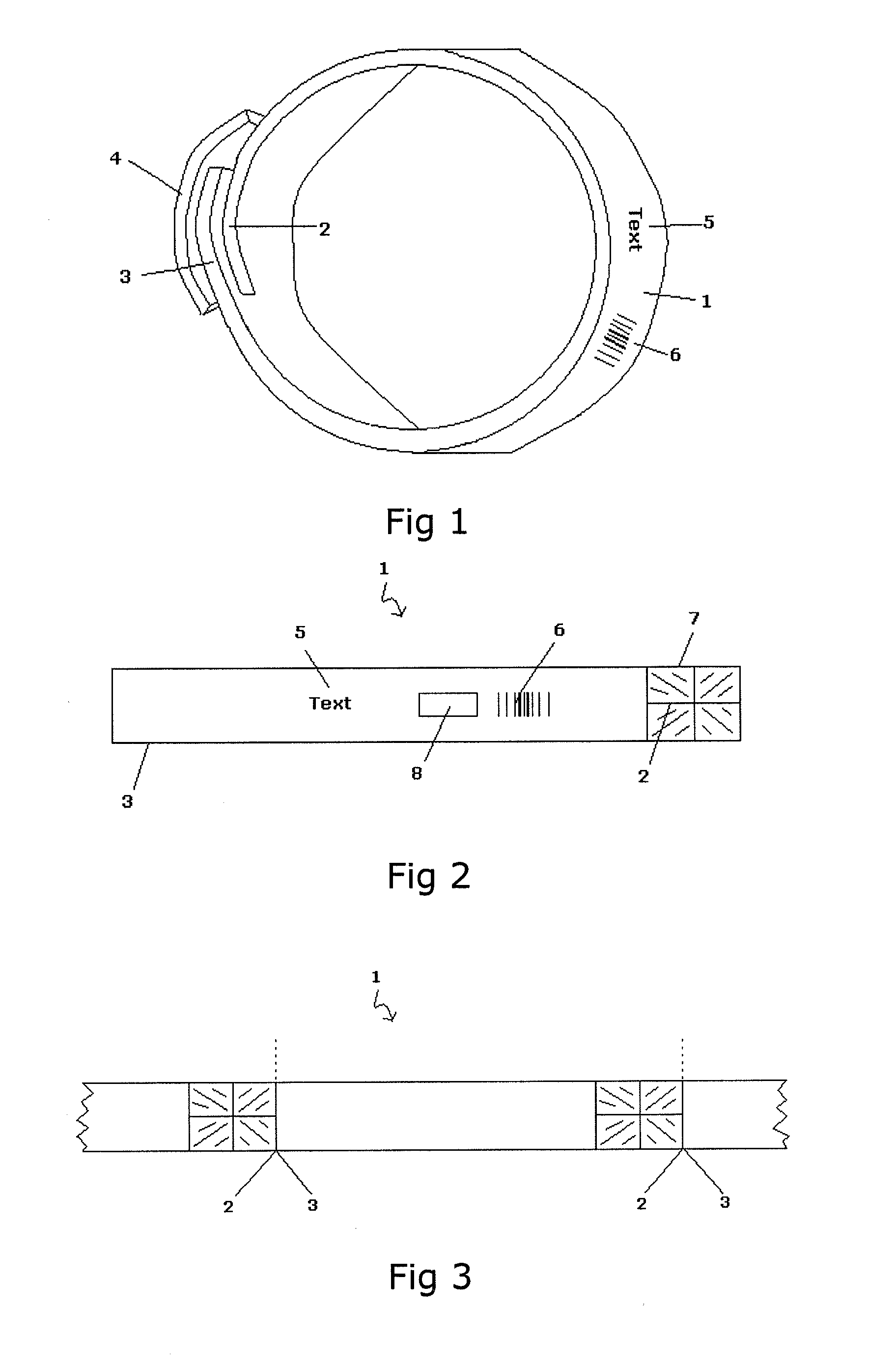

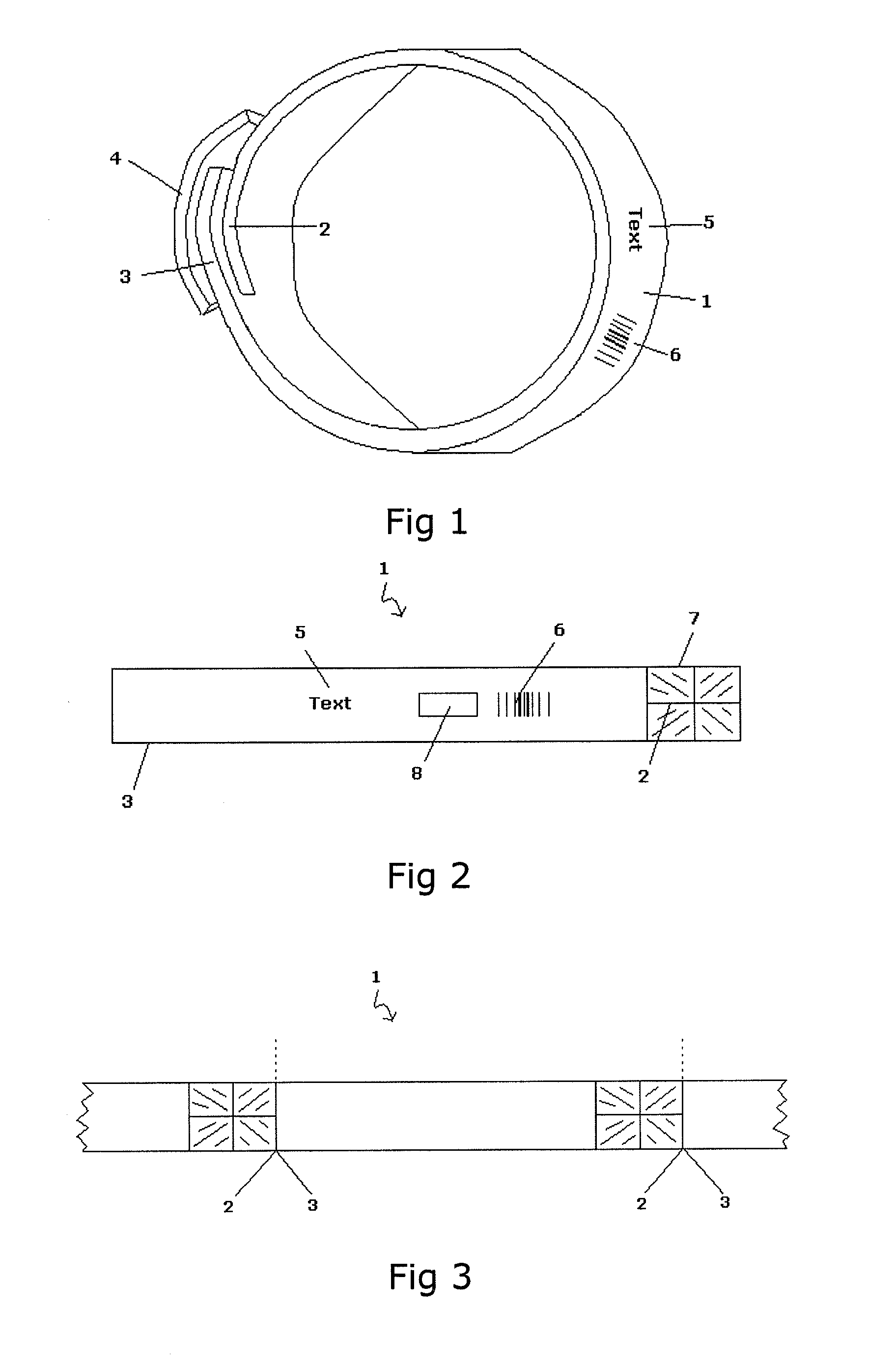

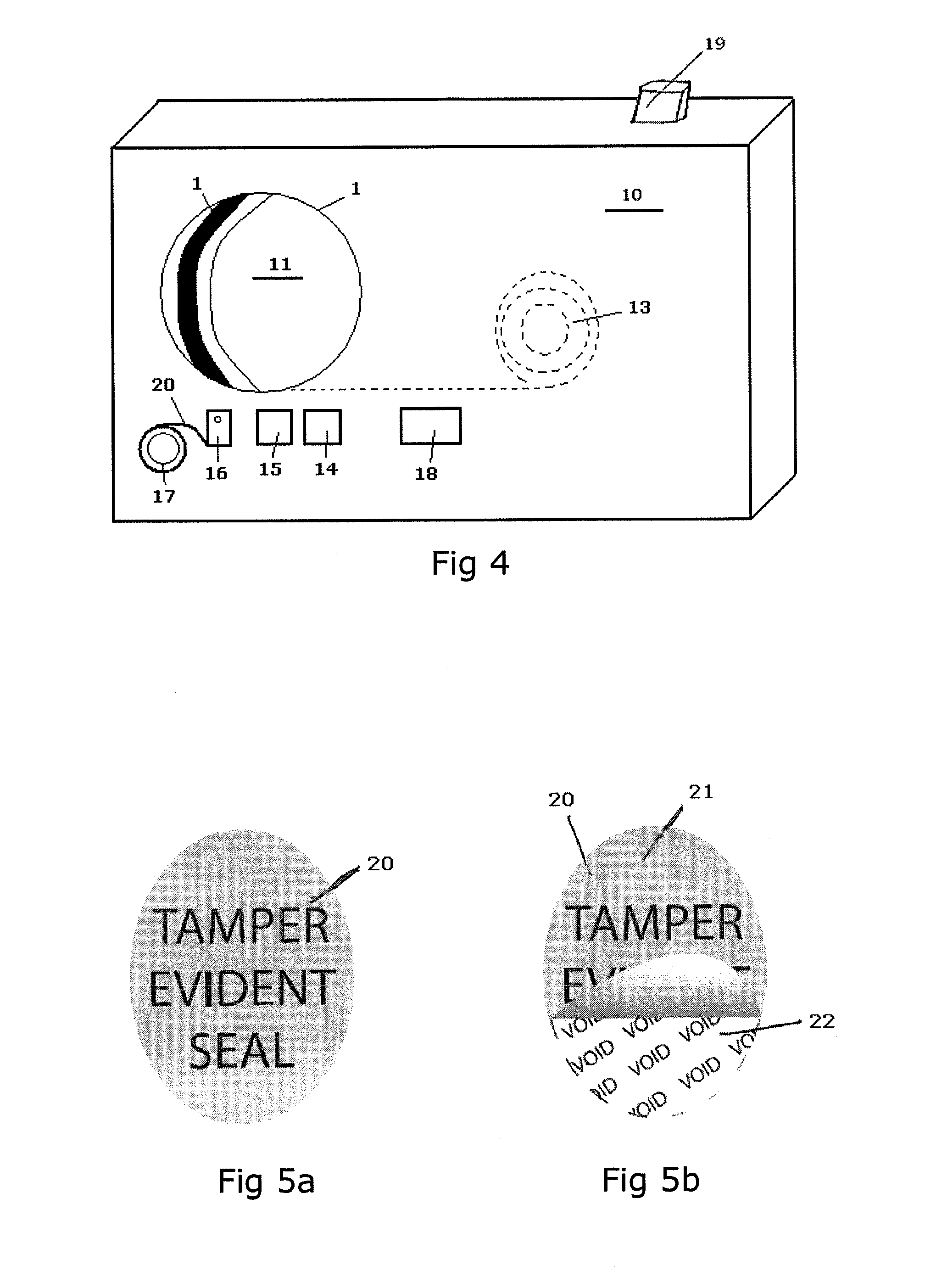

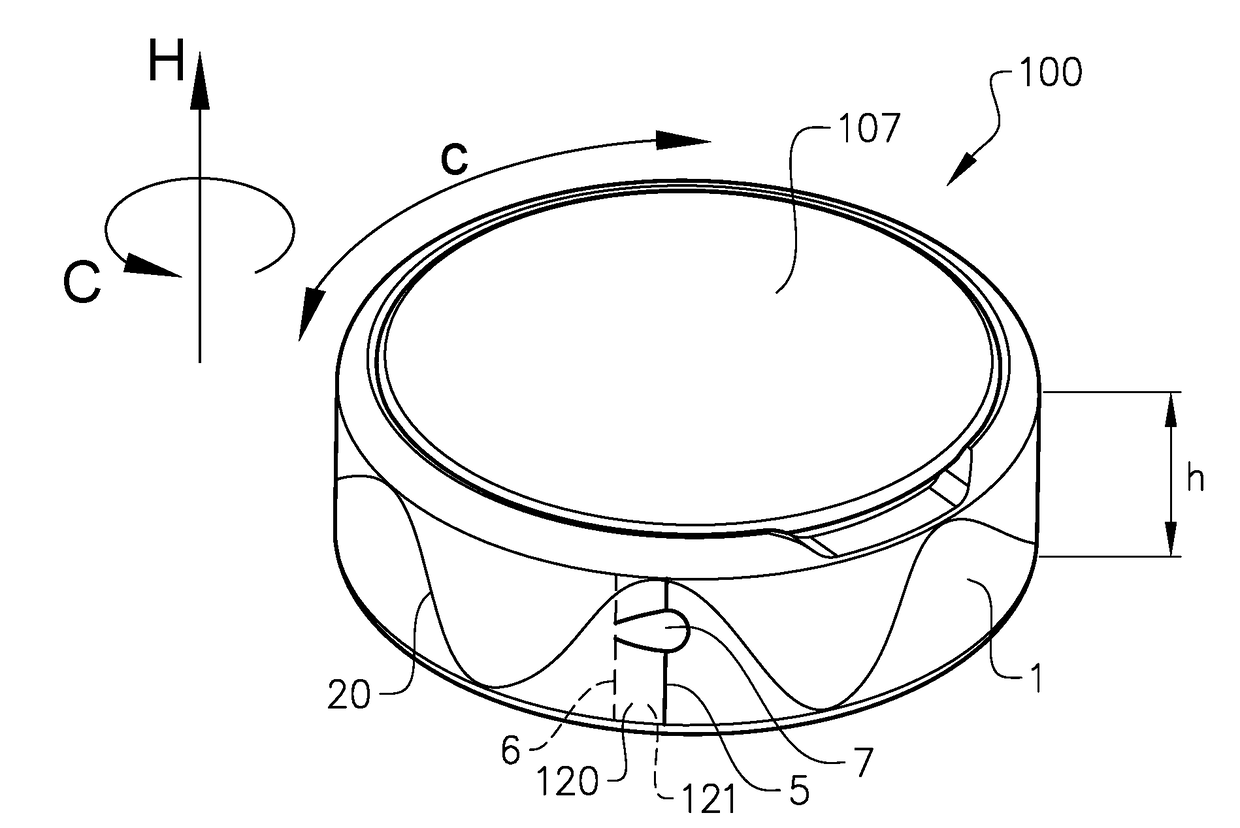

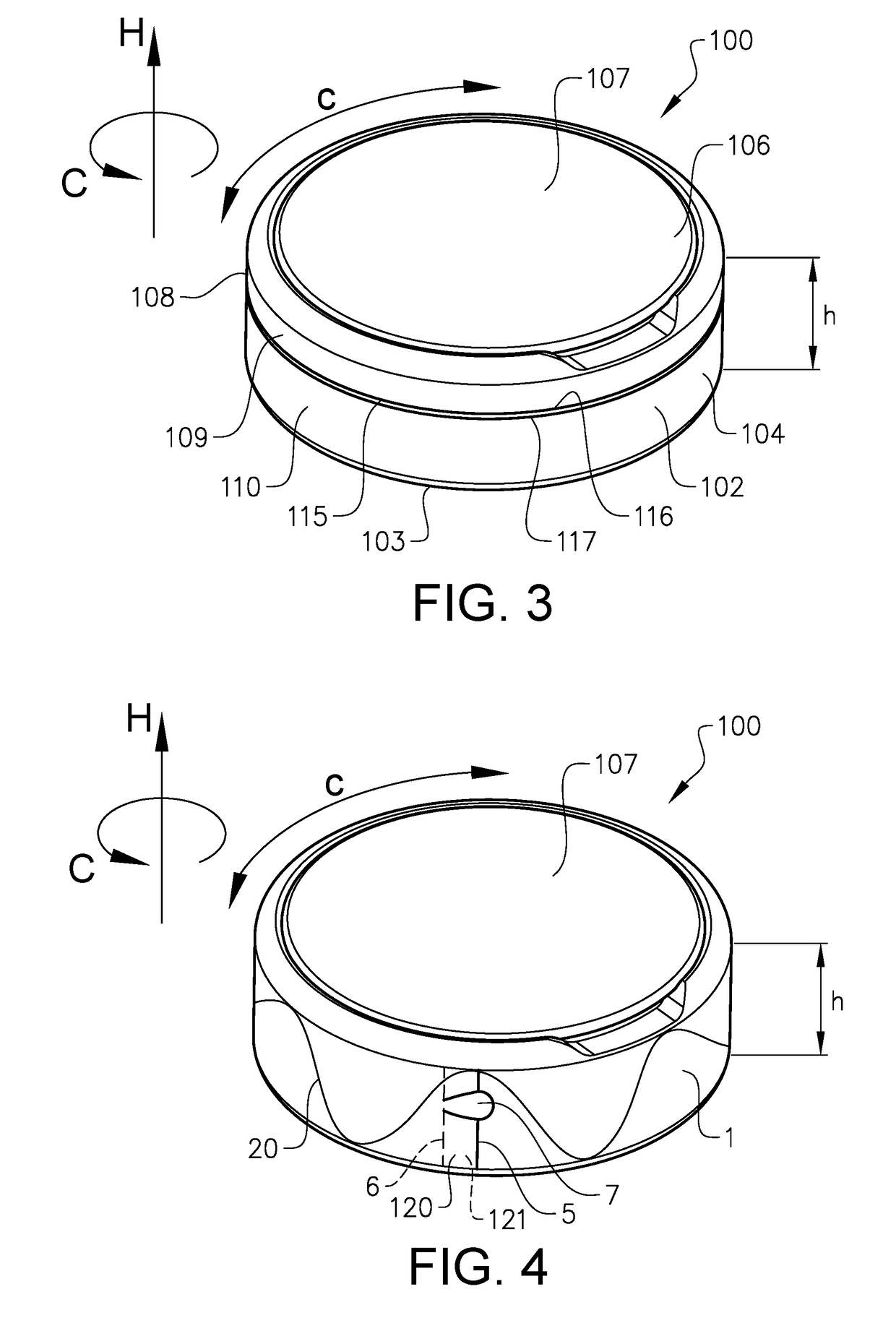

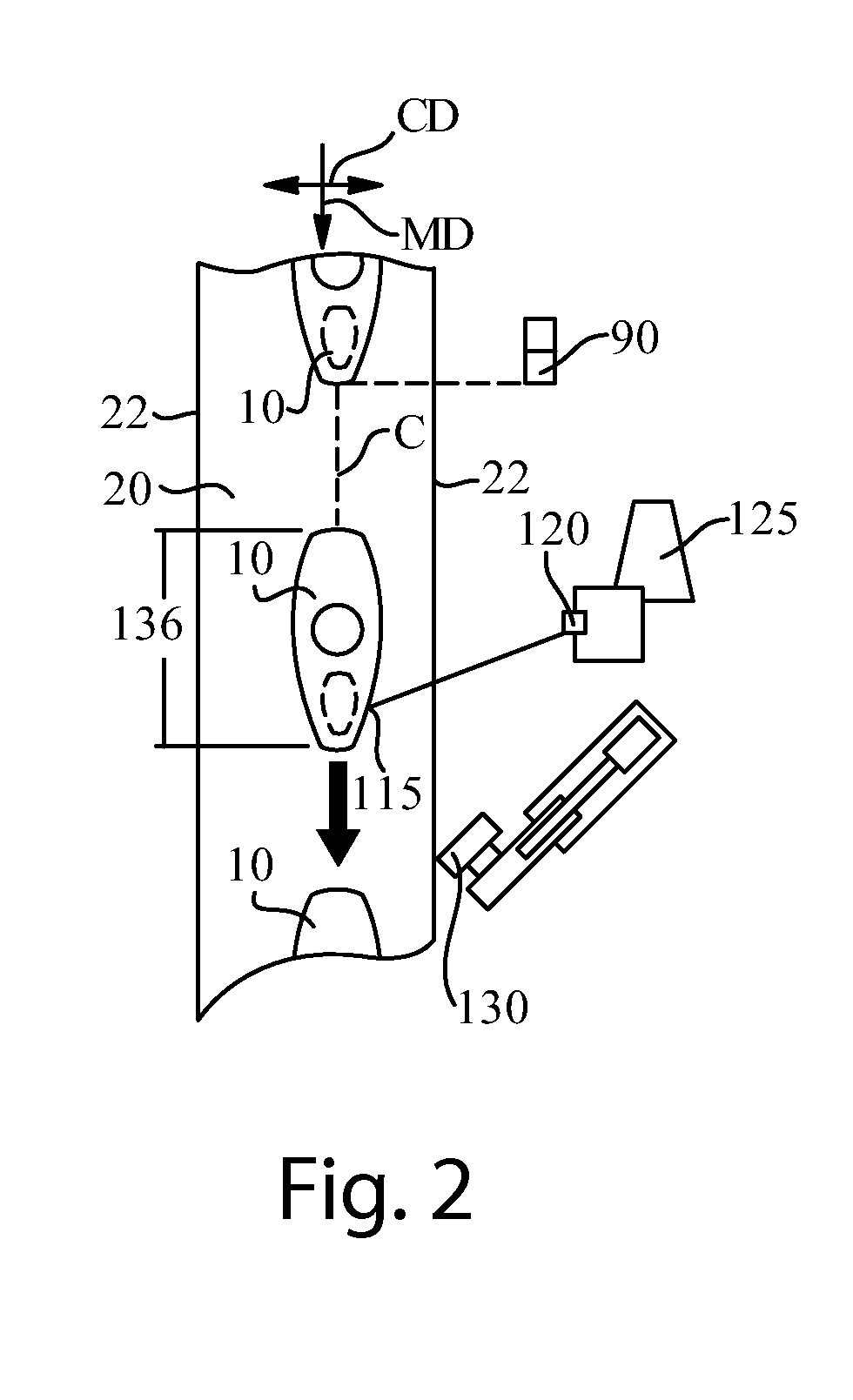

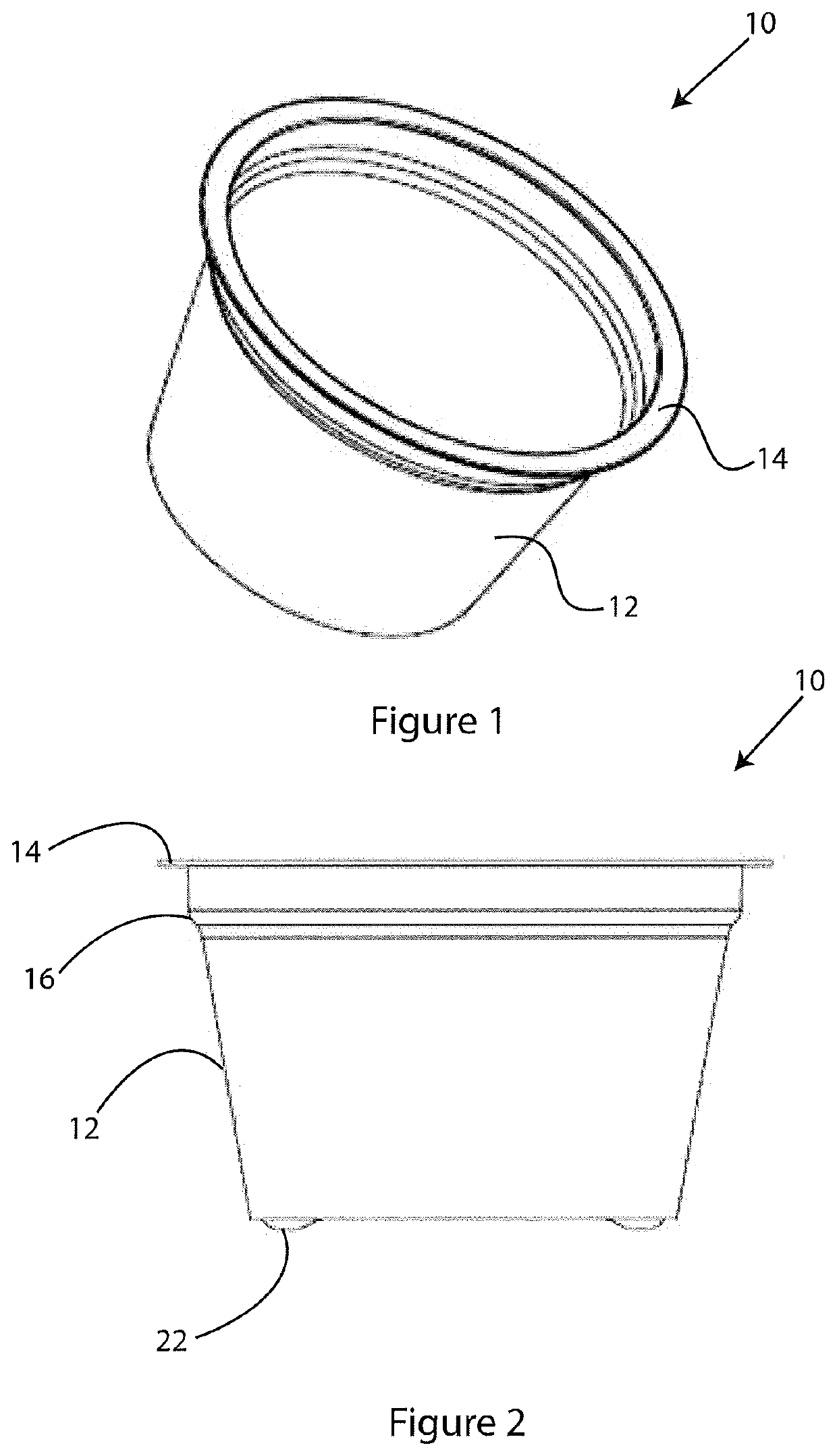

Sealing label and snuff container with a sealing label

ActiveUS20170369223A1Simplified and highly functional sealing labelImprove sealingStampsTobacco devicesEngineeringMechanical engineering

A sealing label for sealing a snuff container may include a structural layer and having first and second side edges extending in a length direction and first and second end edges extending in a width direction. The sealing label may be divided in the width direction into a container lid attachment area and a container base attachment area. A tear strip area may be arranged between the container lid attachment area and the container base attachment area and may be terminated by a pull tab arranged at the first end edge. The structural layer of the sealing label may be a single structural layer of the sealing label and may consist of a mono oriented polymer film having a direction of orientation coinciding with the length direction of the sealing label. A snuff container provided with the sealing label is also disclosed.

Owner:SWEDISH MATCH NORTH EURO

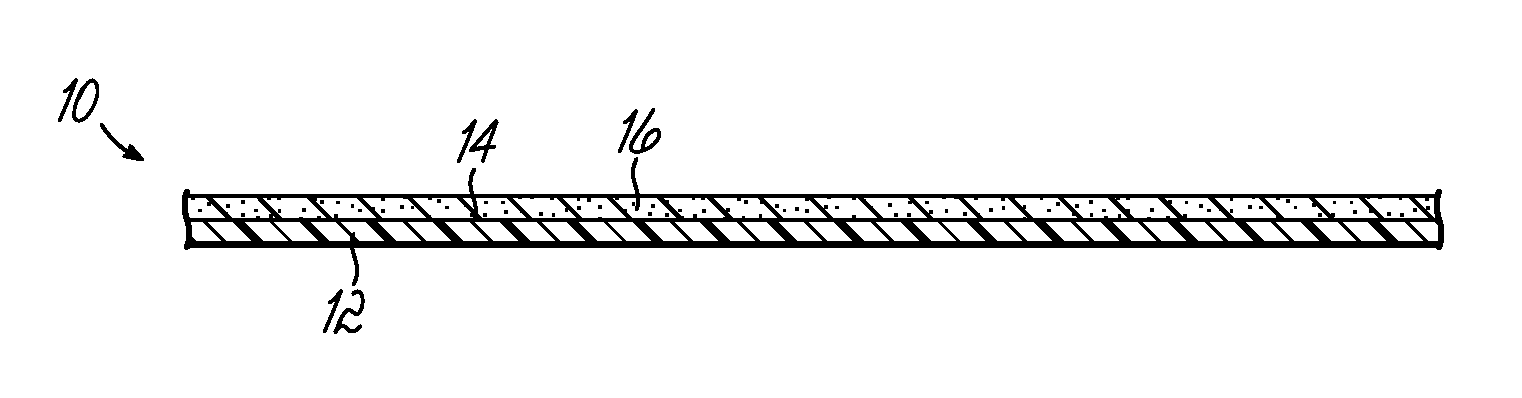

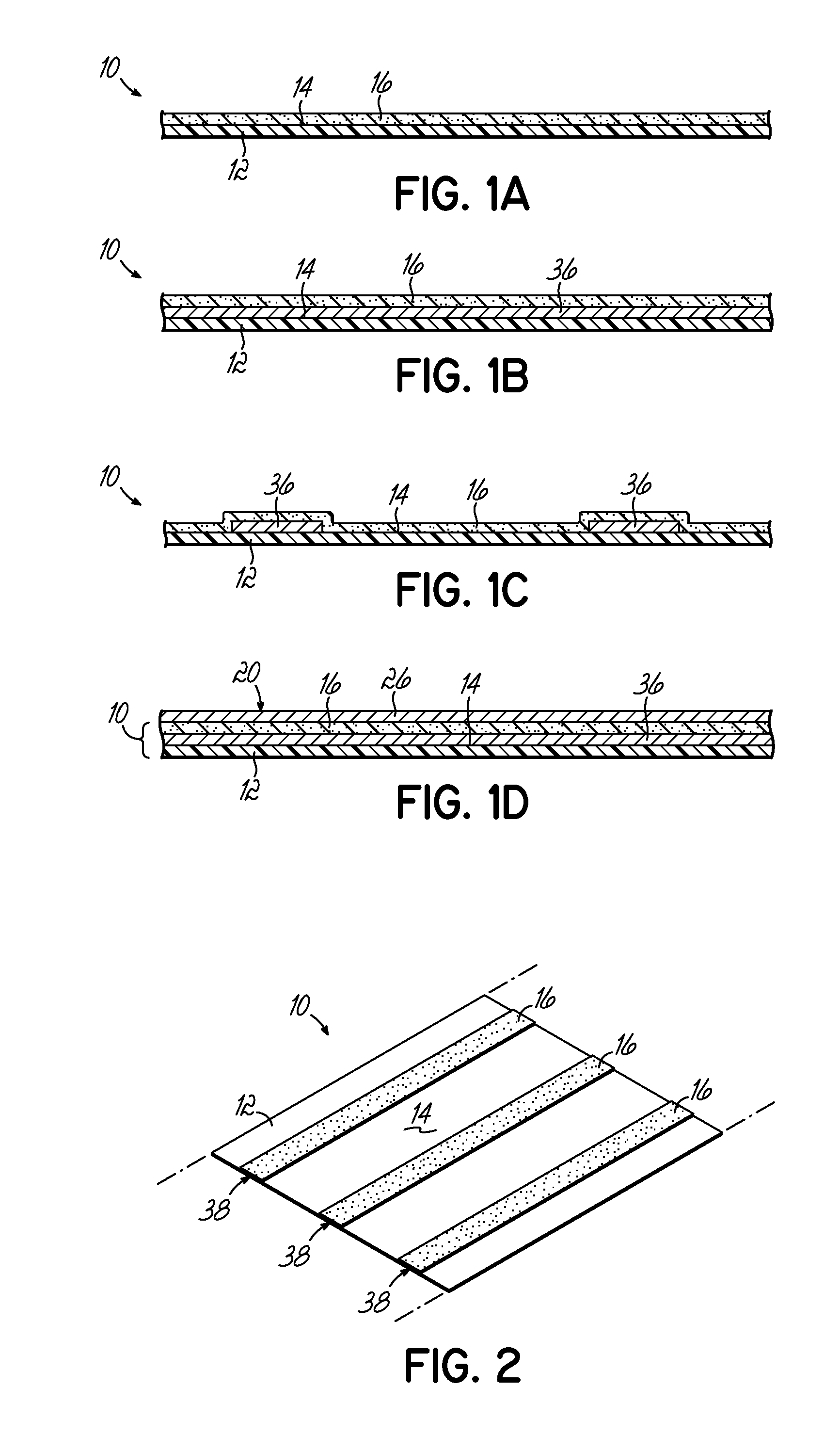

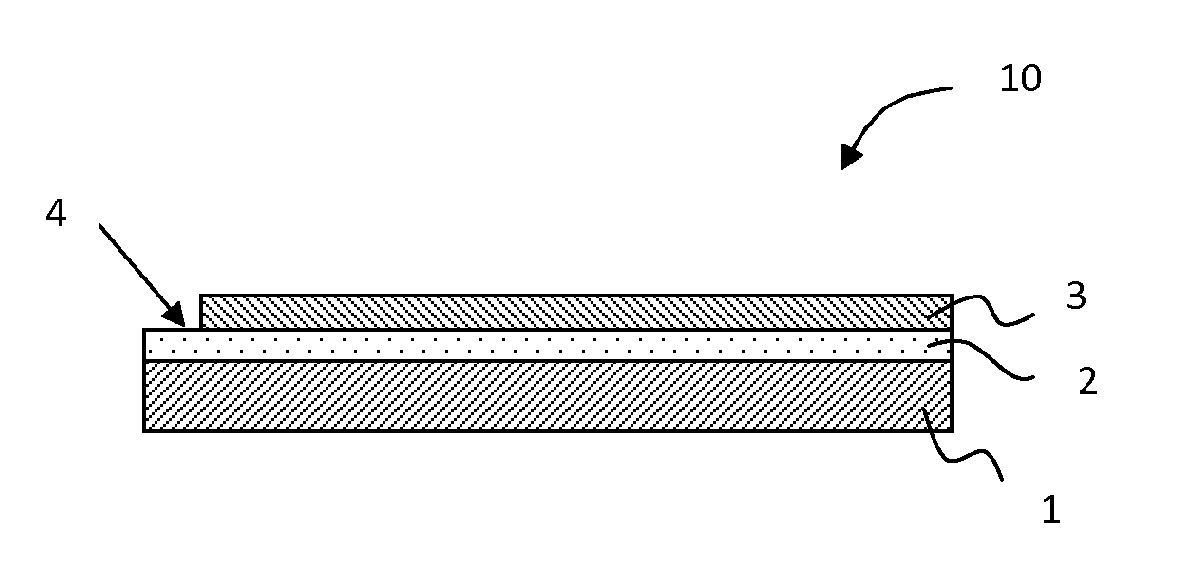

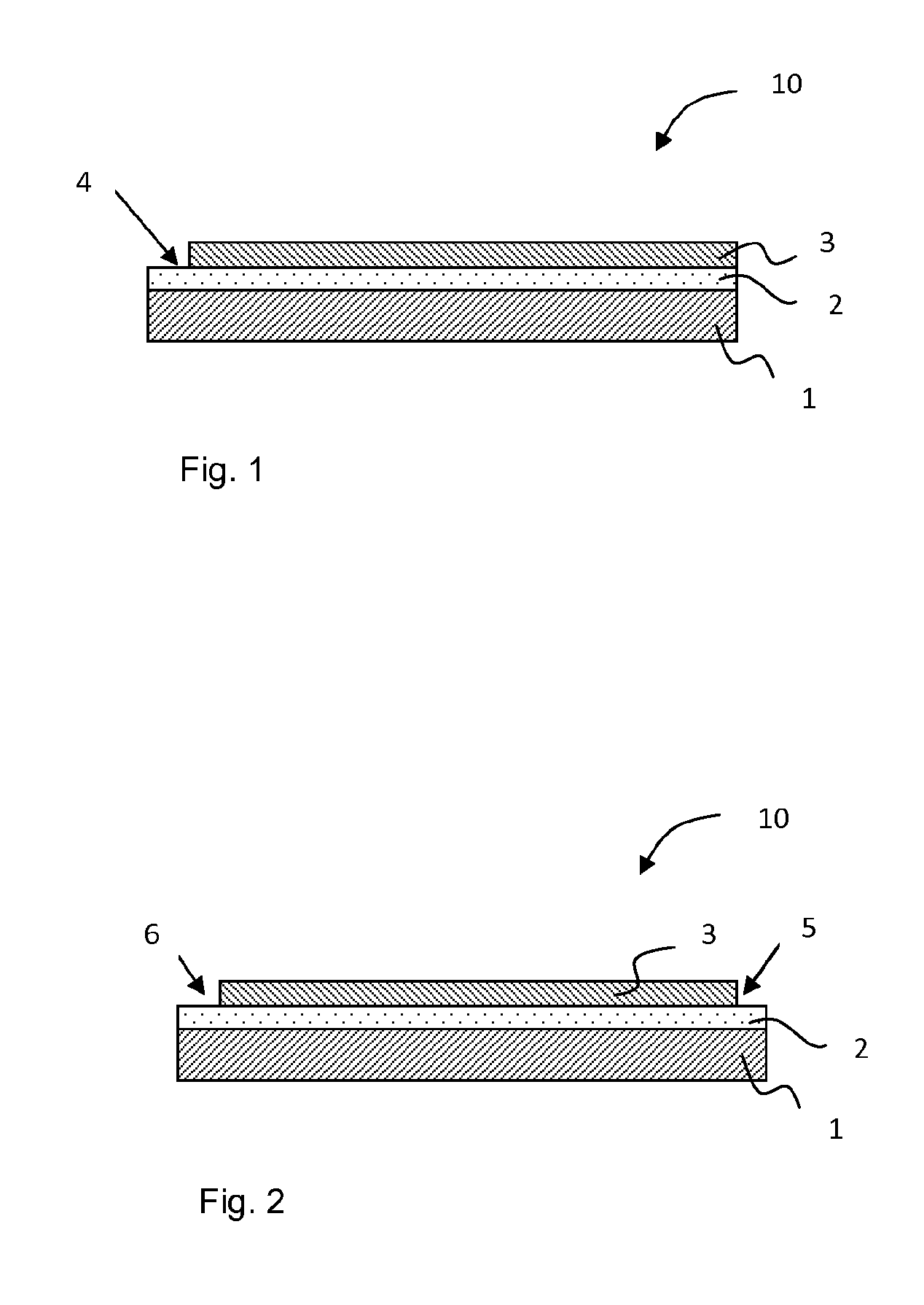

Shrink Film Labels Including Adhesive

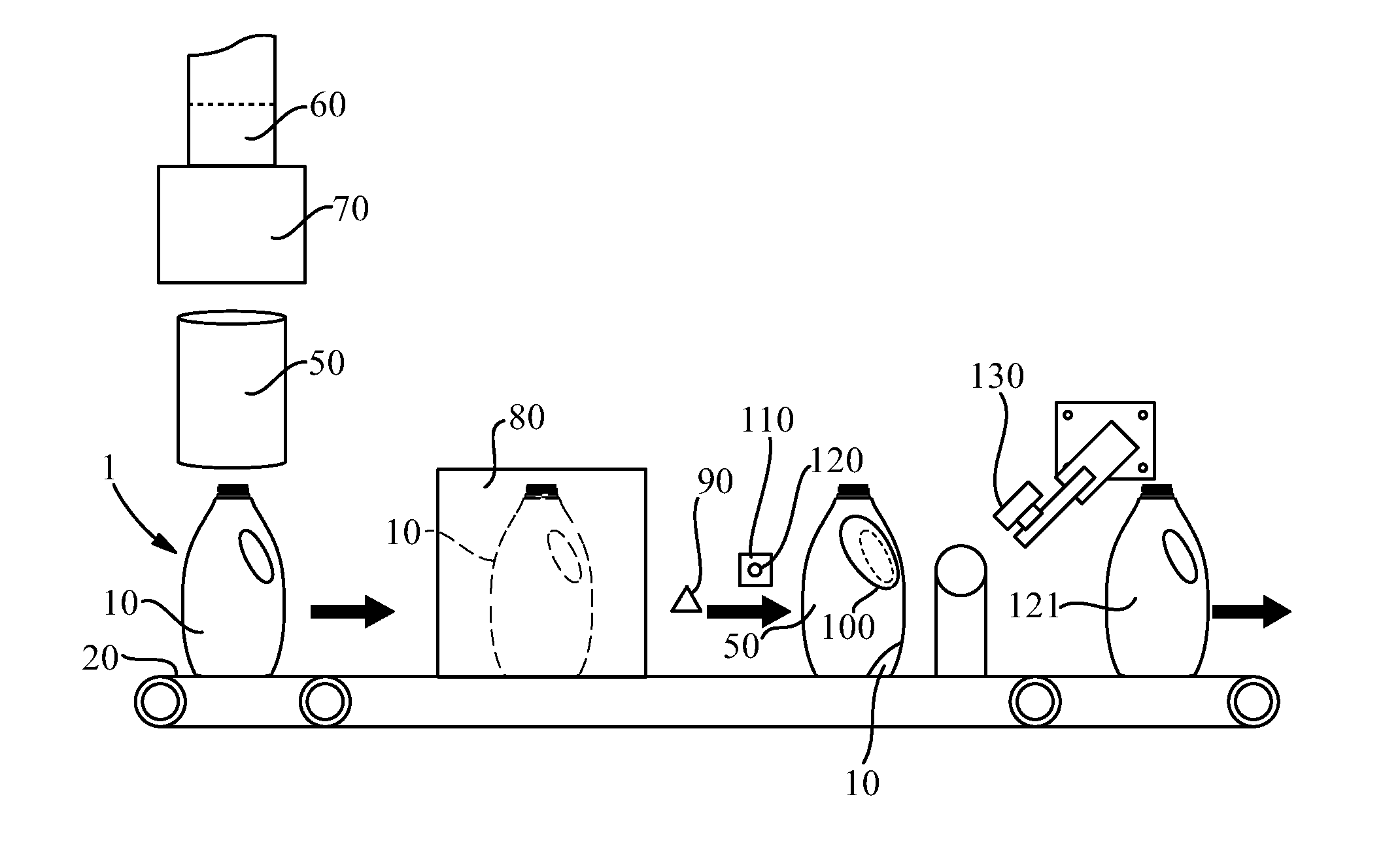

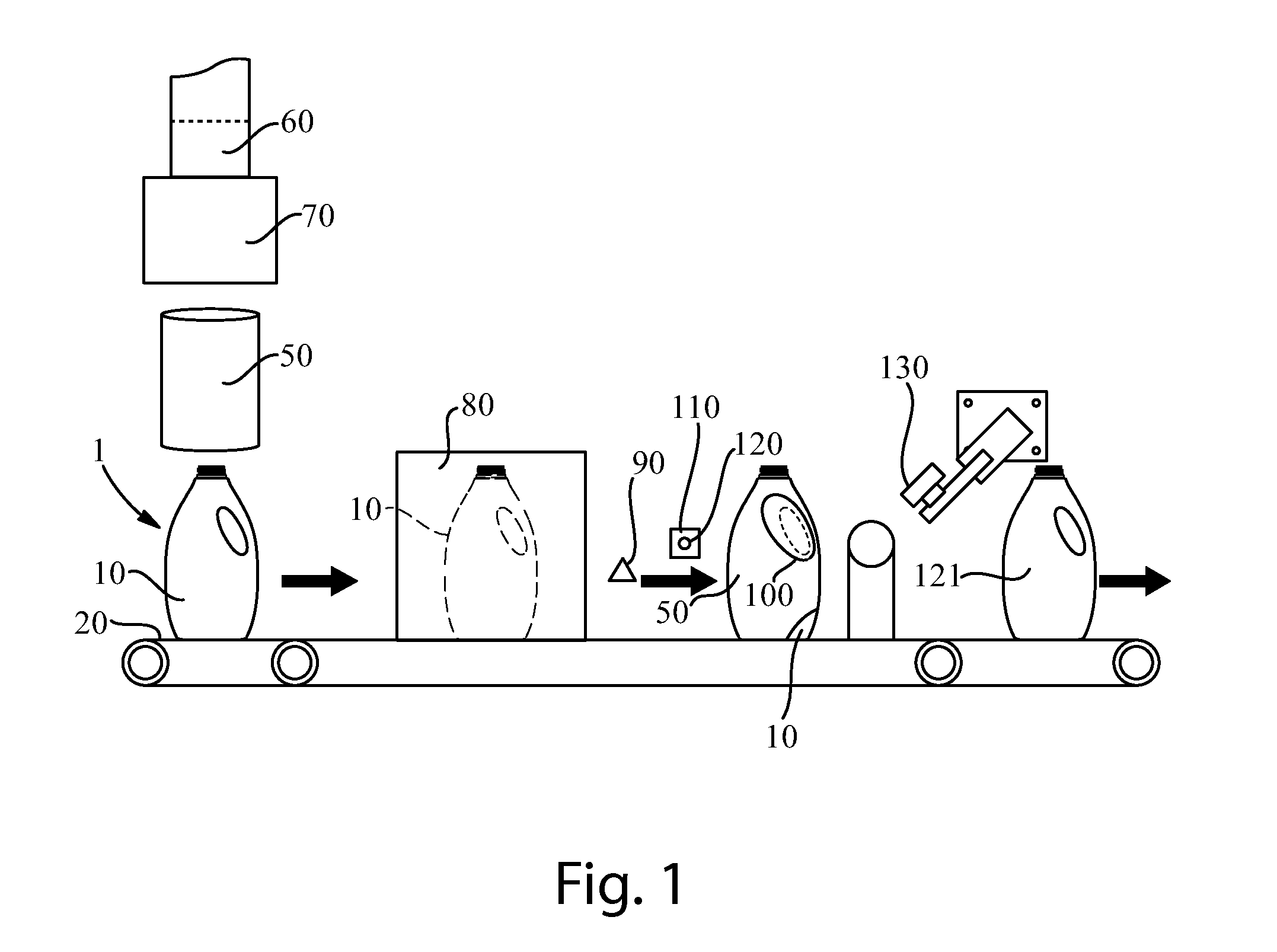

A label having an adhesive applied proximal to an inner surface of a shrink film (such as a shrink sleeve), which is not transferred to labeling apparatus during application of the shrink label to an article. Thus, the shrink sleeve does not result in a build-up of adhesive on label application apparatus, thereby preventing apparatus downtime; and cannot be removed from the article to which it is applied, (or cannot be removed without damage being done to the label), thereby preventing removal and re-use of the shrink sleeve on counterfeit goods.

Owner:MULTI COLOR CORP

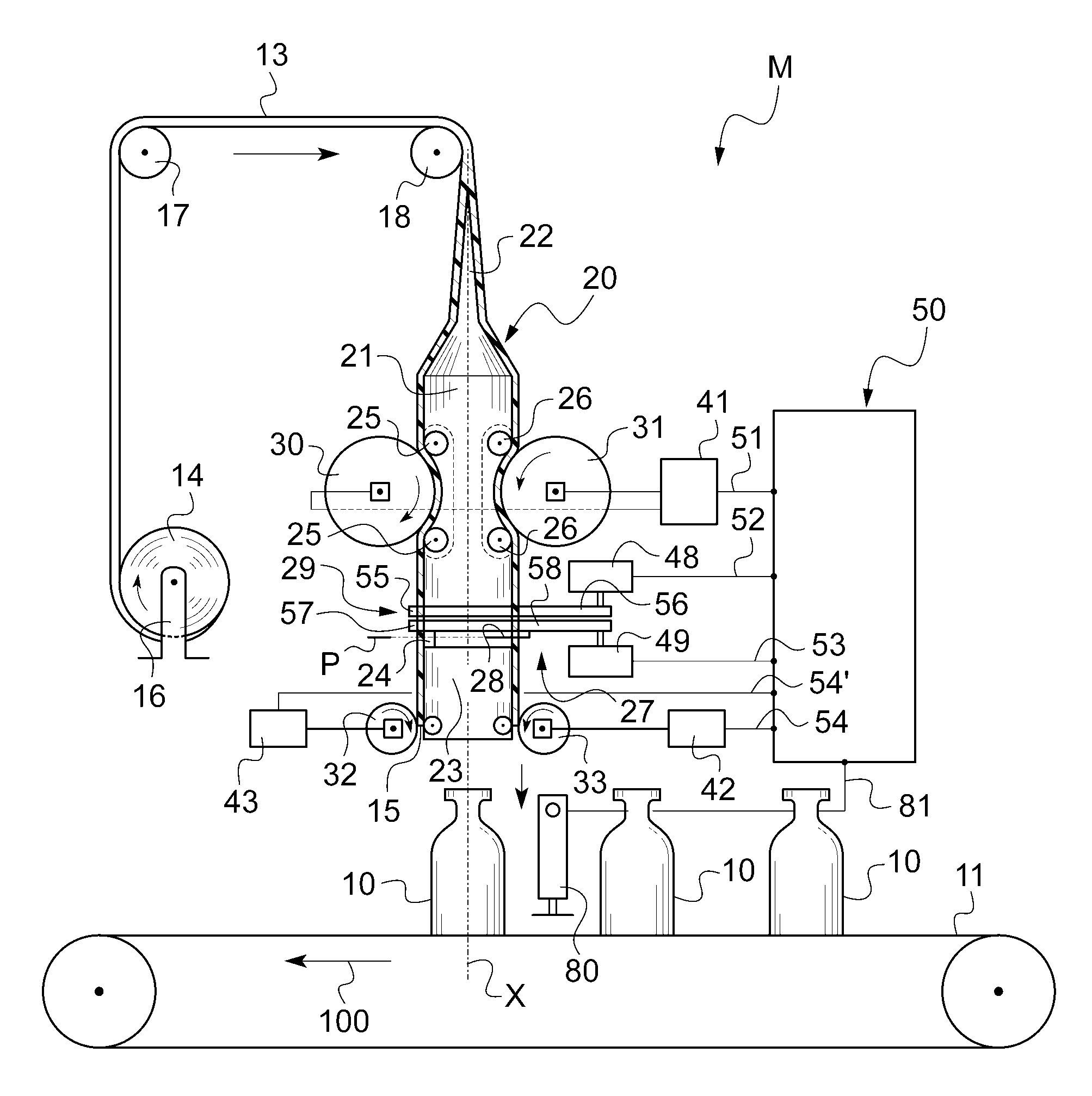

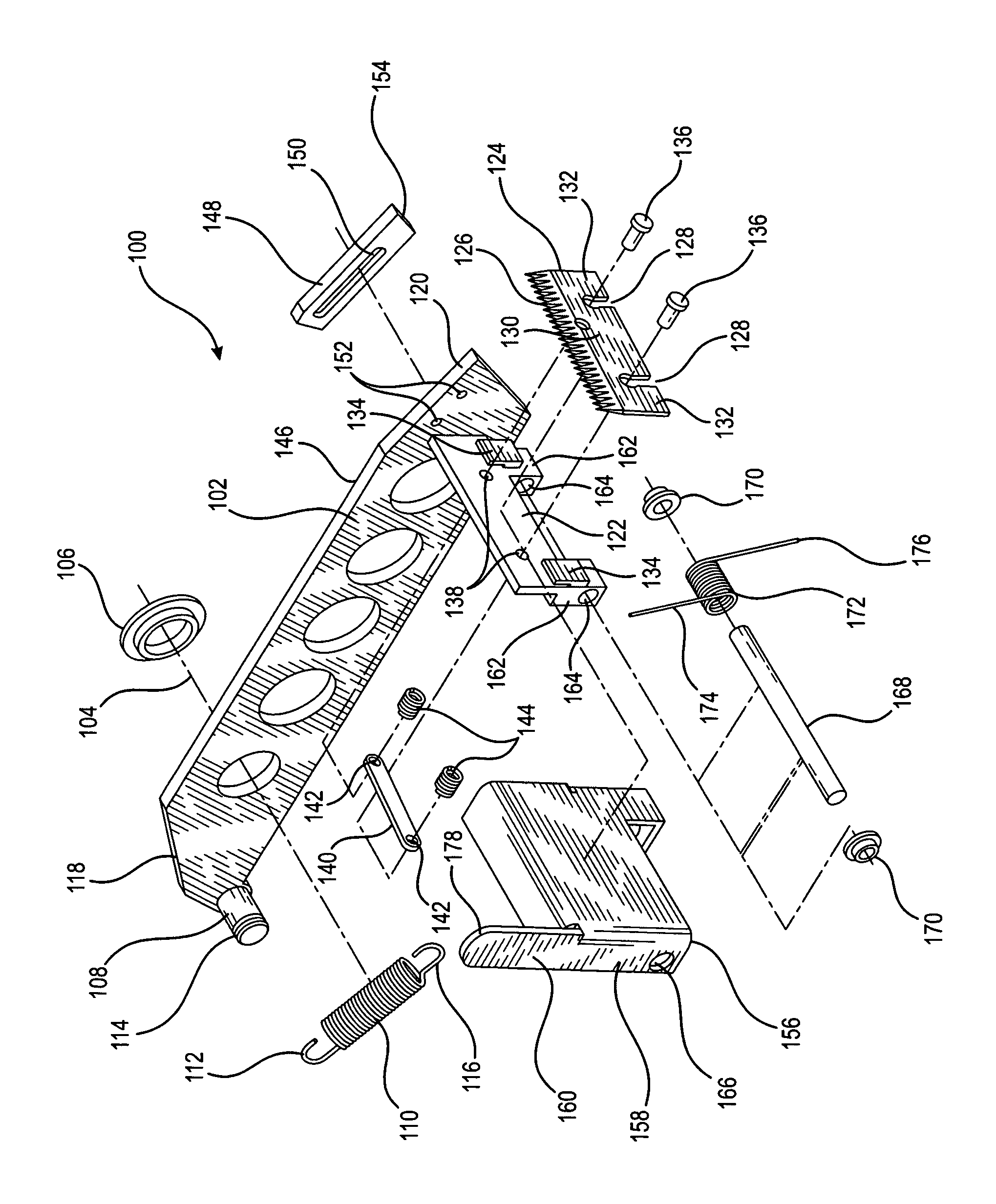

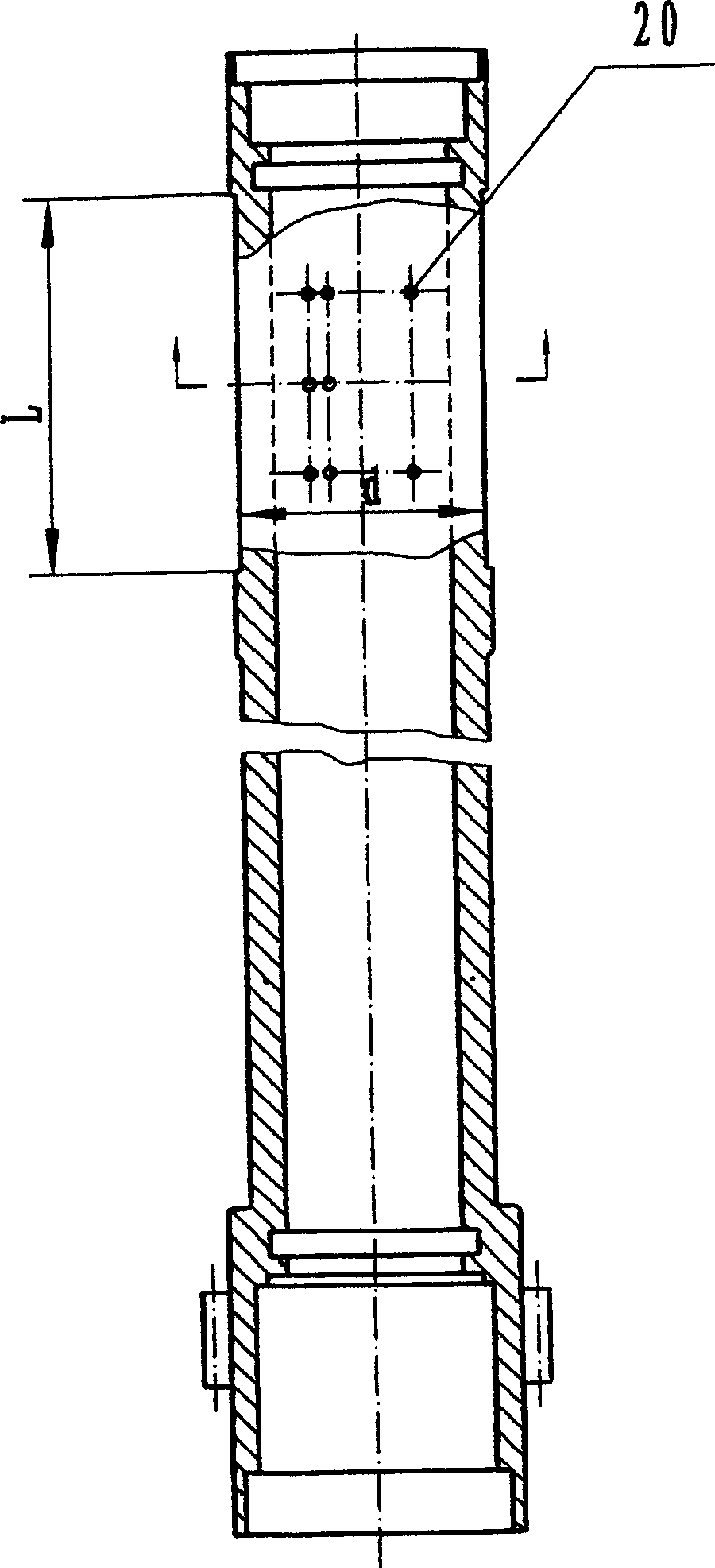

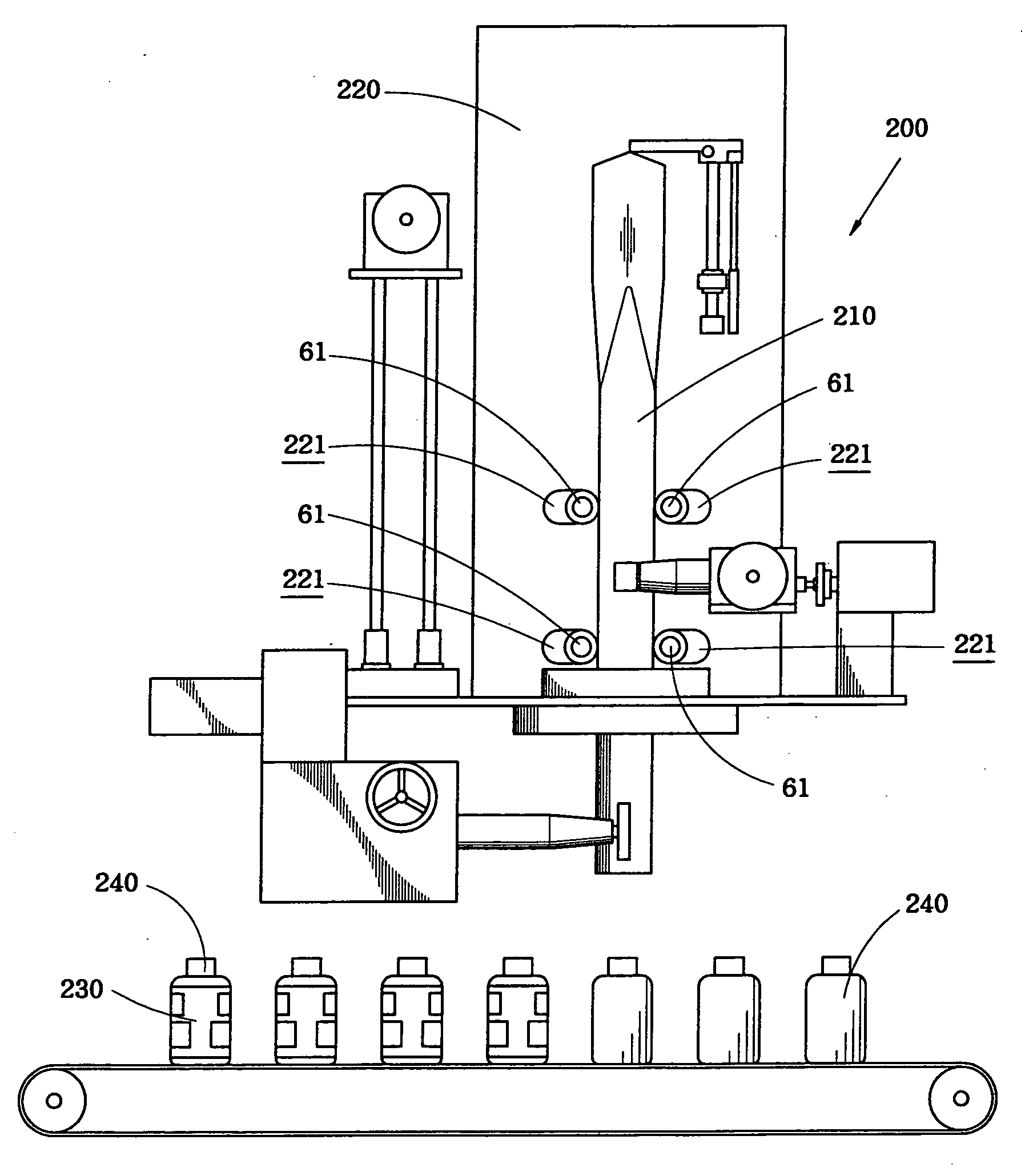

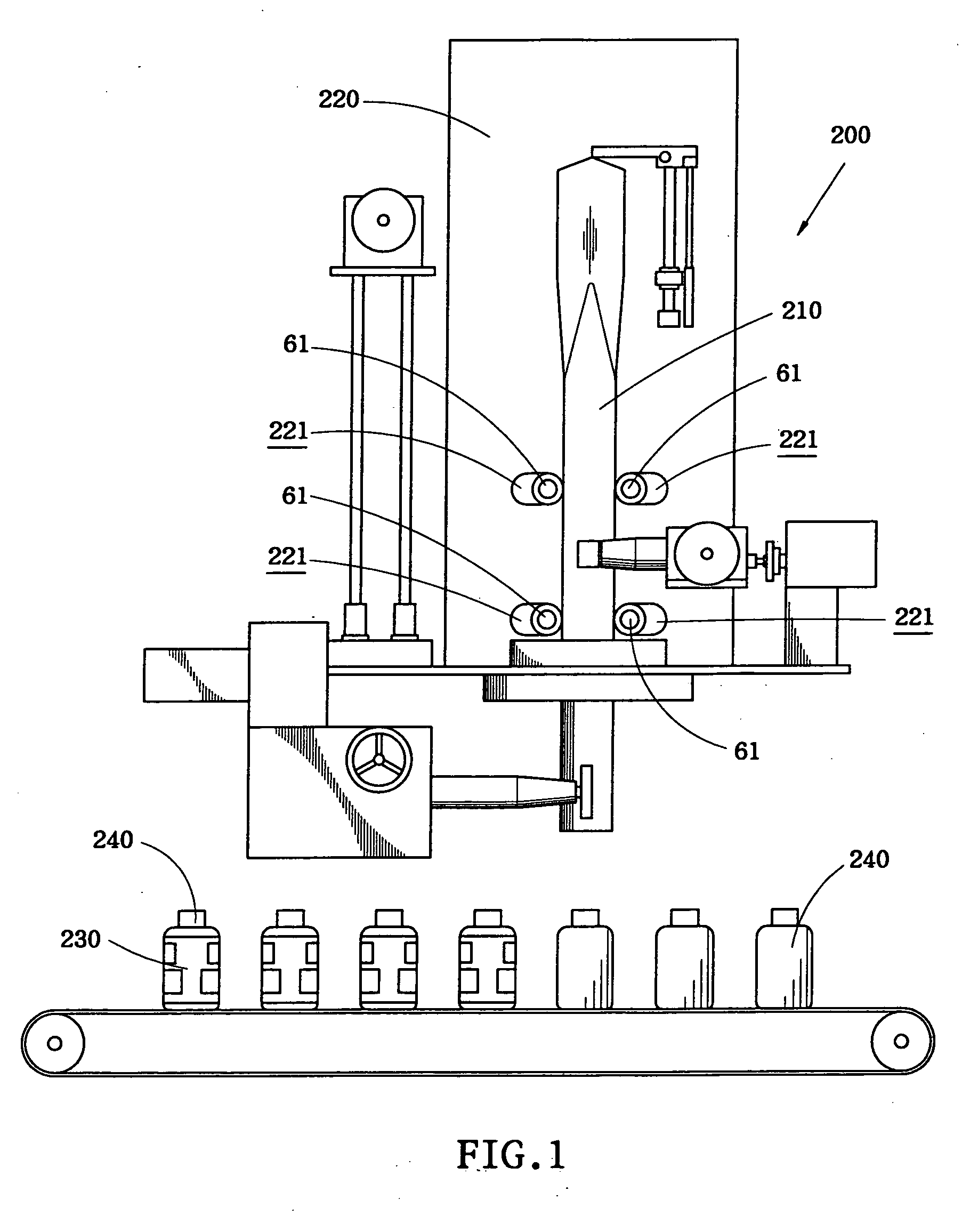

Method of producing shrink sleeve labels and device for their production

InactiveUS20150375450A1Effective tensionEasy to disassembleMechanical working/deformationLamination ancillary operationsEngineeringSolvent

A method of producing shrink sleeve labels comprises:unwinding a feed reel of heat-shrink film;separating at least one band of heat-shrink film from the feed reel;feeding the band of heat-shrink film to a formation spindle;winding the band of heat-shrink film around the formation spindle, there being provided an overlap region between a first longitudinal end of the band of heat-shrink film in contact with the formation spindle and the second longitudinal end of the band of heat-shrink film,transferring the sleeve label to a container to be labeled;interposing a layer of solvent, at the overlap region, between at least one portion of the first longitudinal end and at least one portion of the second longitudinal end, the layer of solvent having a thickness comprised between 0.002 mm and 0.09 mm.

Owner:SACMI VERONA SPA

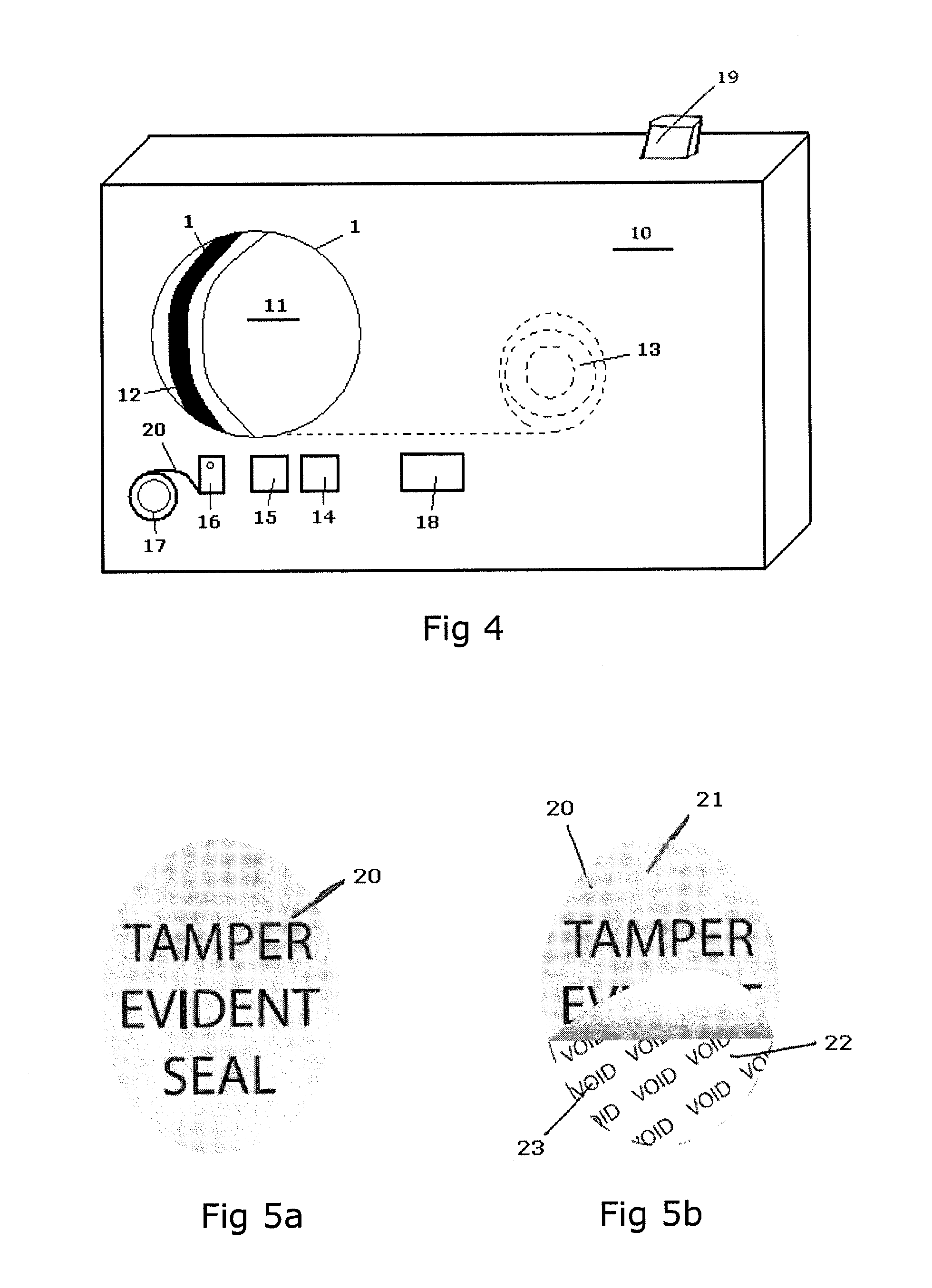

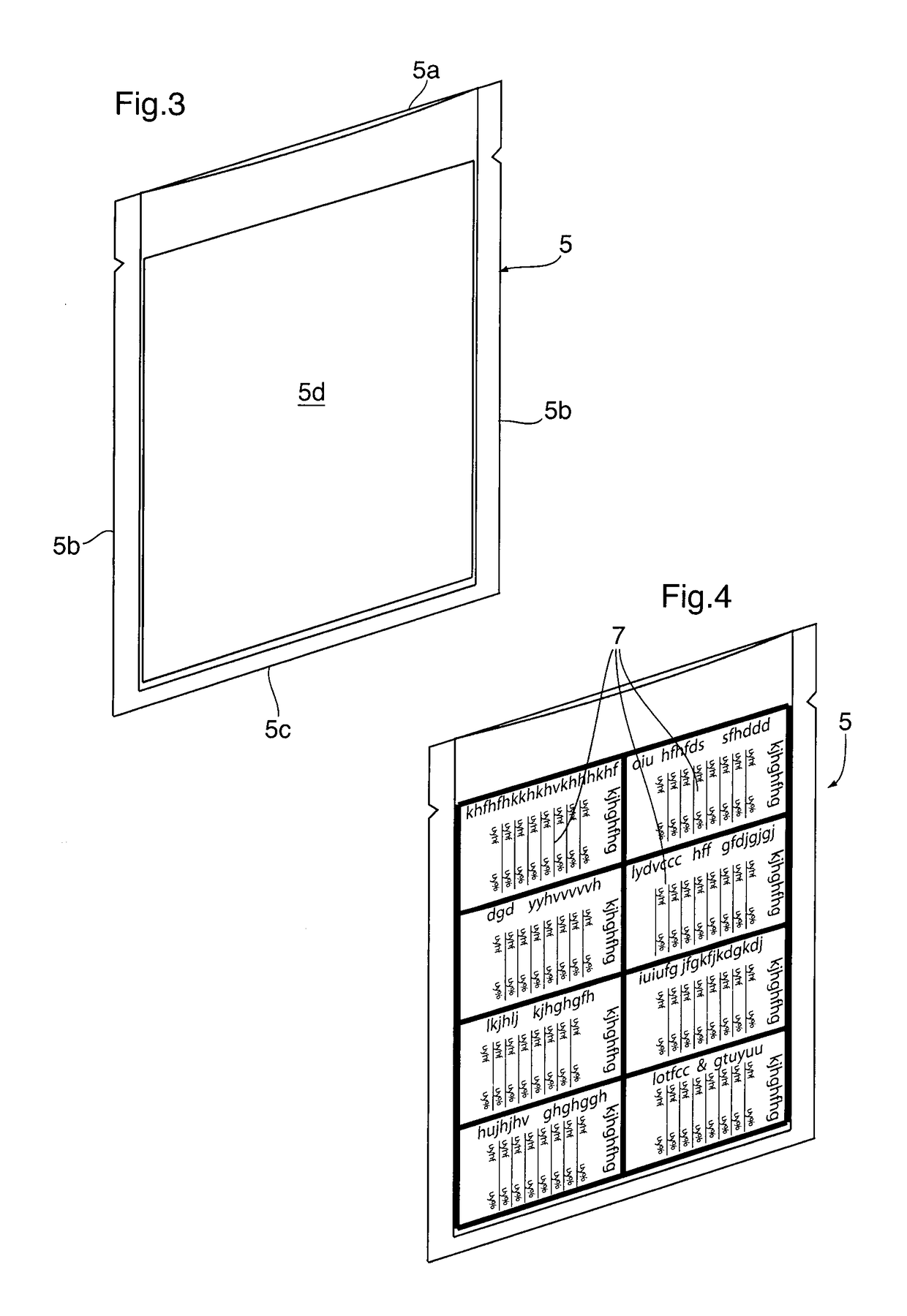

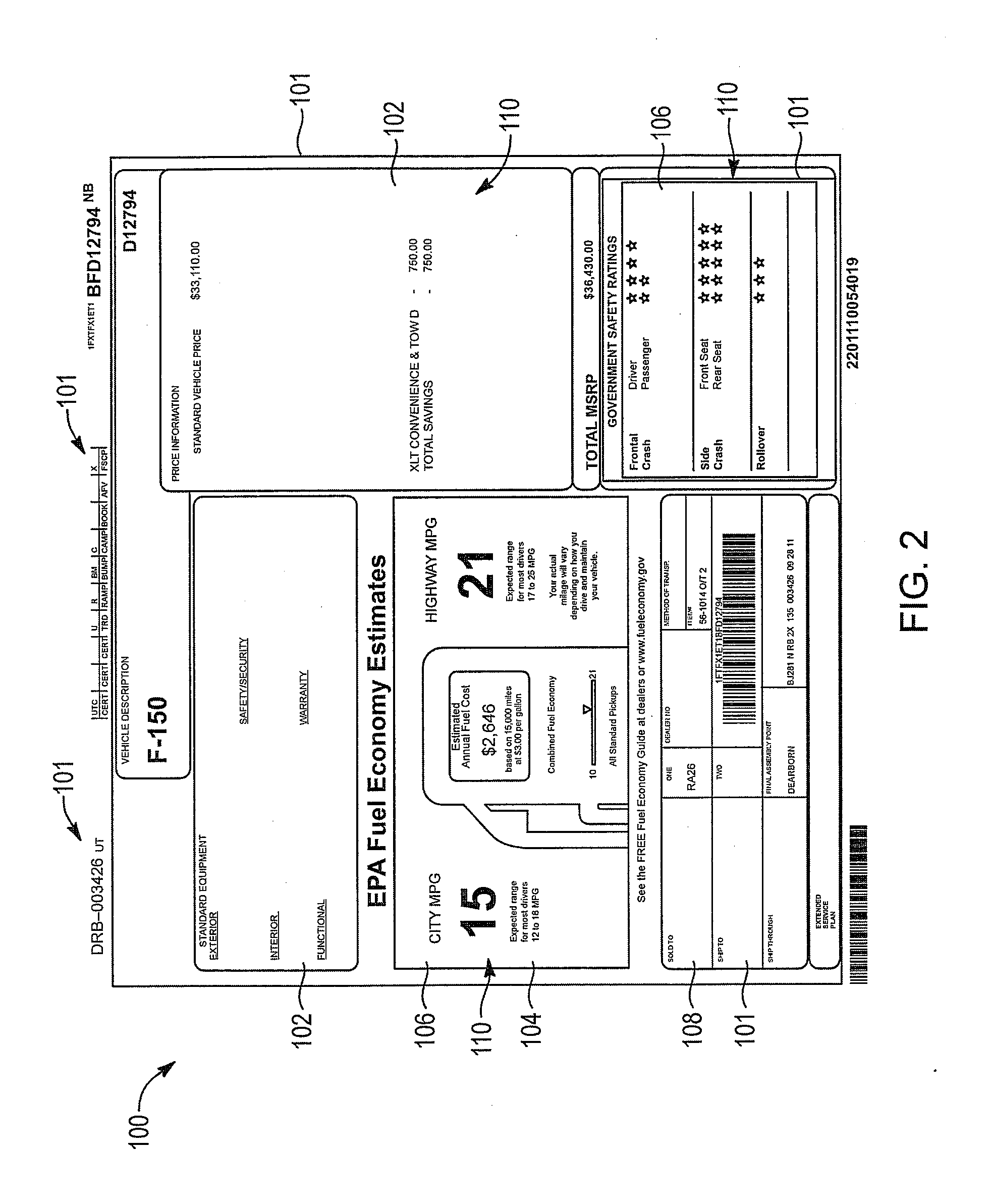

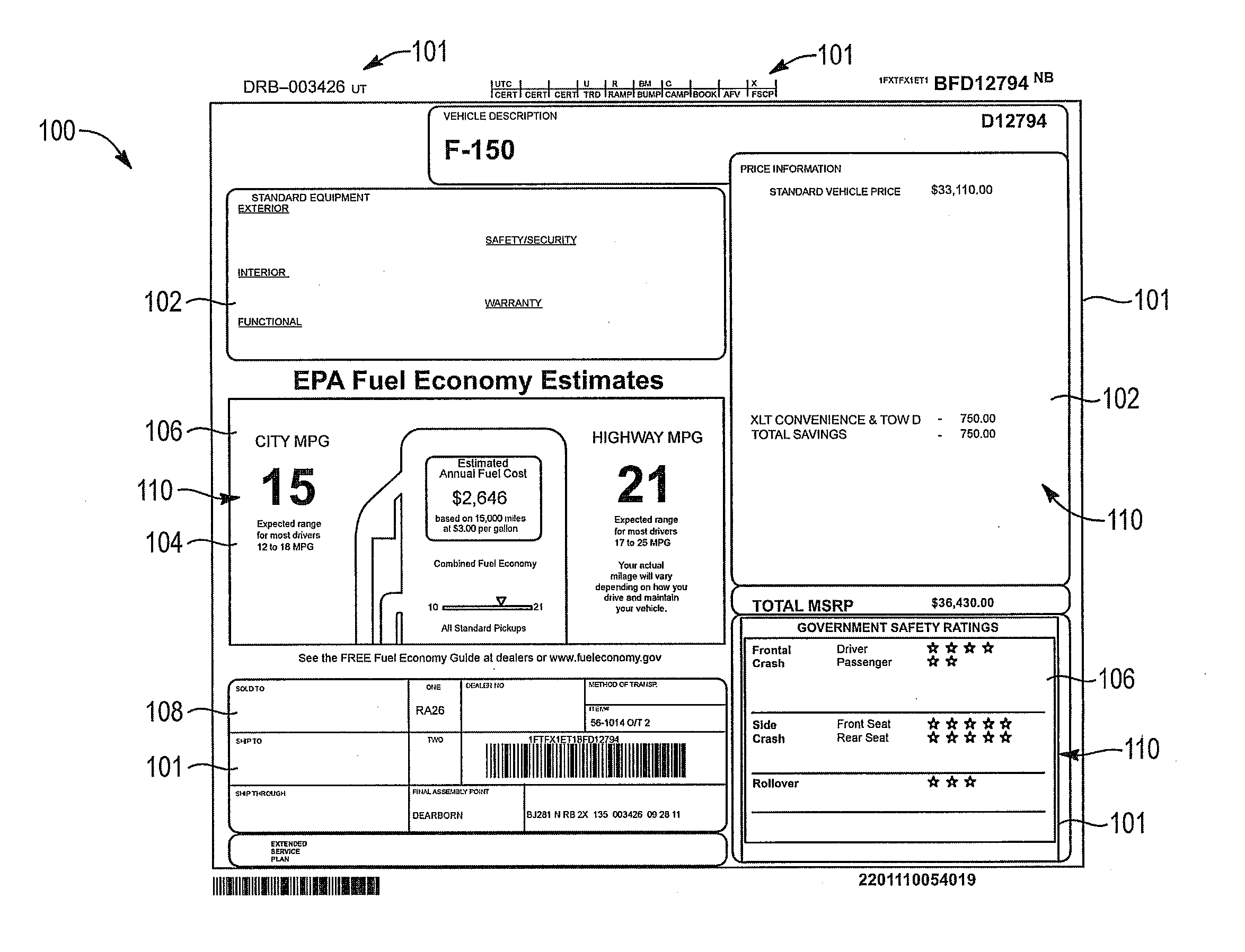

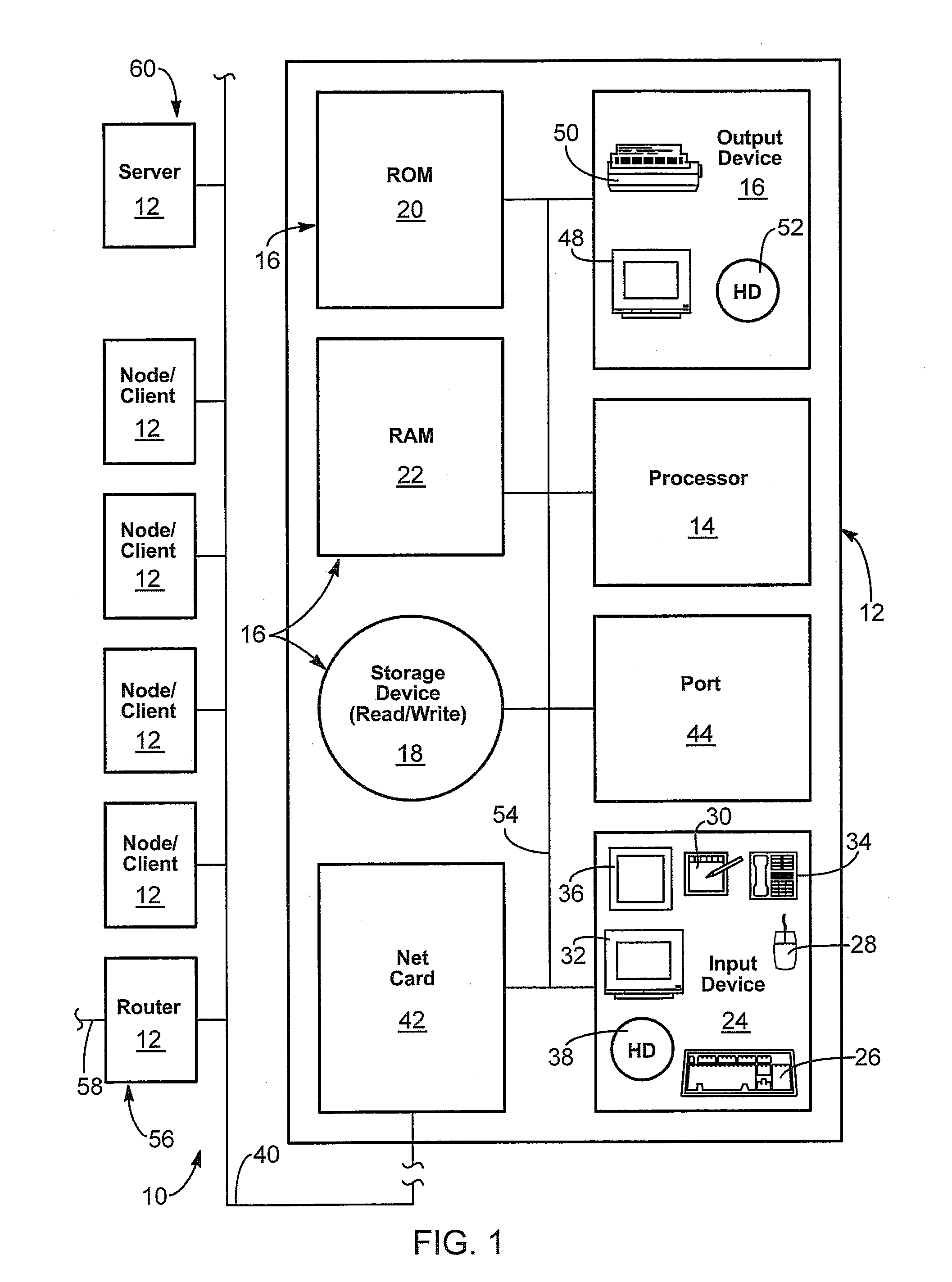

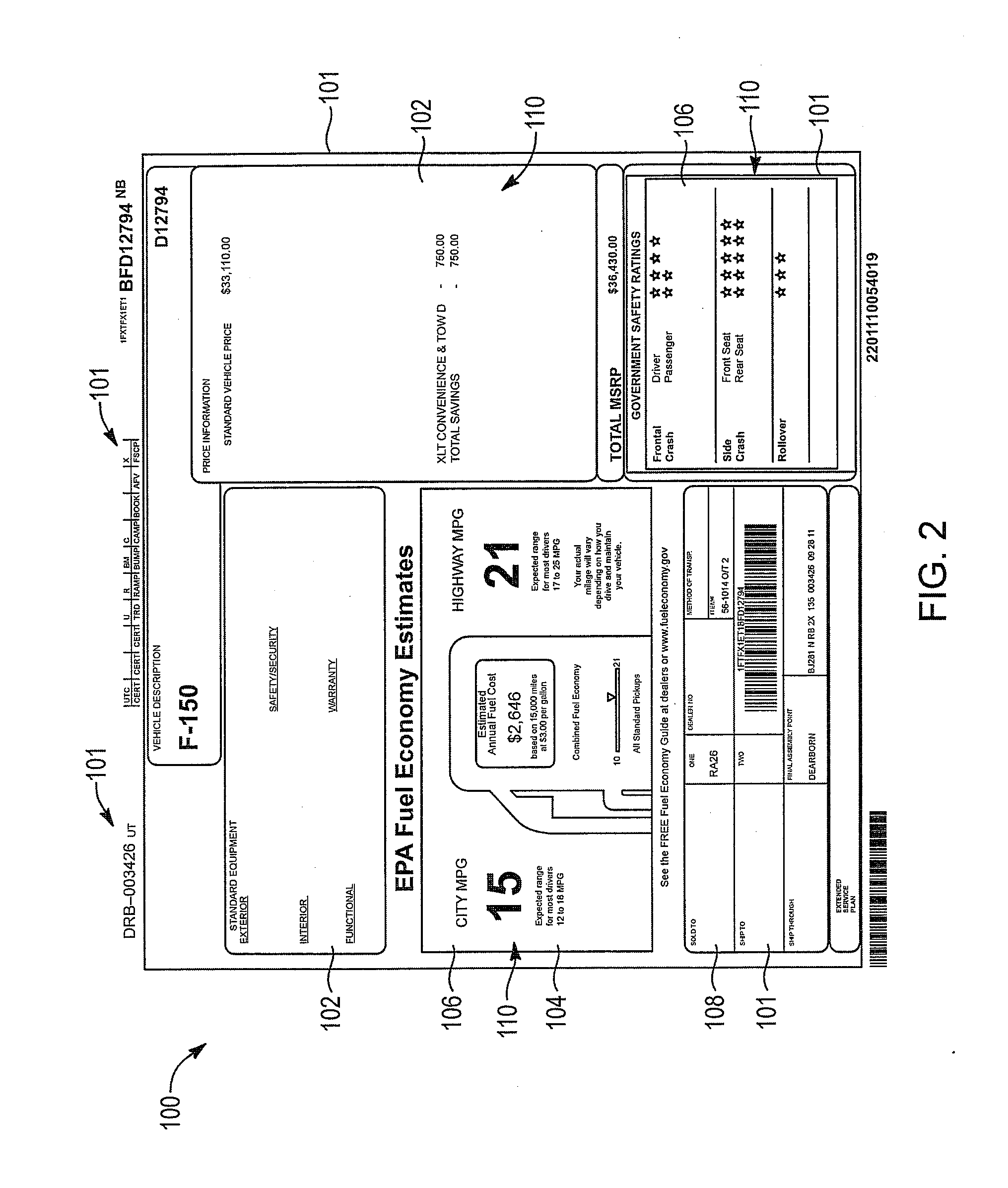

Regulatory label compliance apparatus and method

InactiveUS20130151427A1Effectively transparentEliminate detectionStampsLabellingDriver/operatorMonroney sticker

An apparatus and method for labeling products may be applied to vehicle labeling, where complying with legal requirements of one jurisdiction may otherwise violate legal requirements within a second jurisdiction. Label content, format, and placement on vehicles, as imposed by federal law, creates a visual obstruction in violation of state law when a prospective customer is driving the vehicle. A new product label configured as a panel, which may be the Monroney sticker for a vehicle, or which may contain the Monroney sticker information and extend beyond that label itself, acts as a one-way panel. The panel permits transmission of light inward toward the driver, thus appearing sufficiently transparent not to create a visual obstruction. The panel may be sized from the size of a conventional Monroney sticker, up to the size of the entire window, acting as a window shade and a window sticker.

Owner:WHELAN JENNY ANN +1

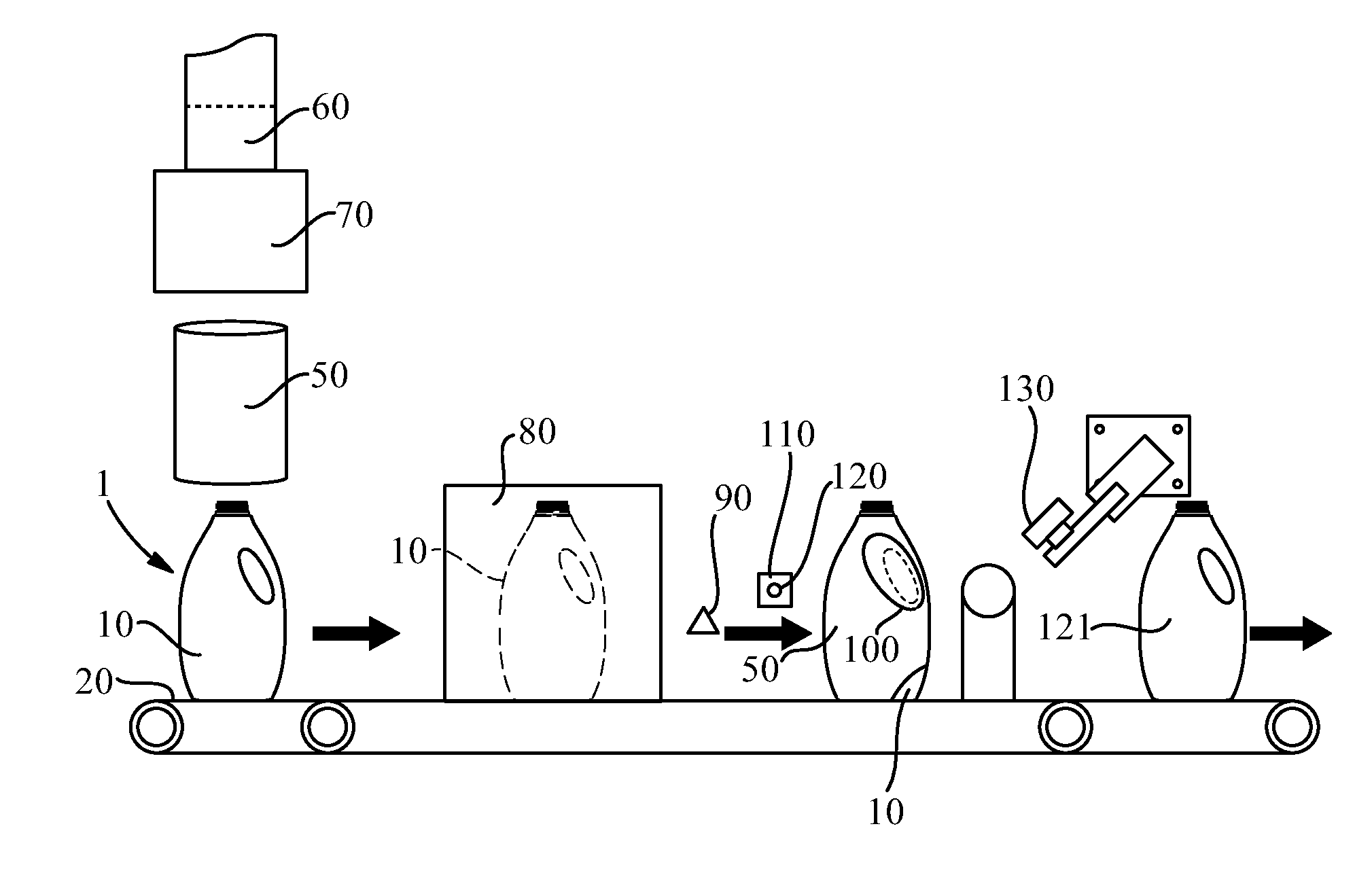

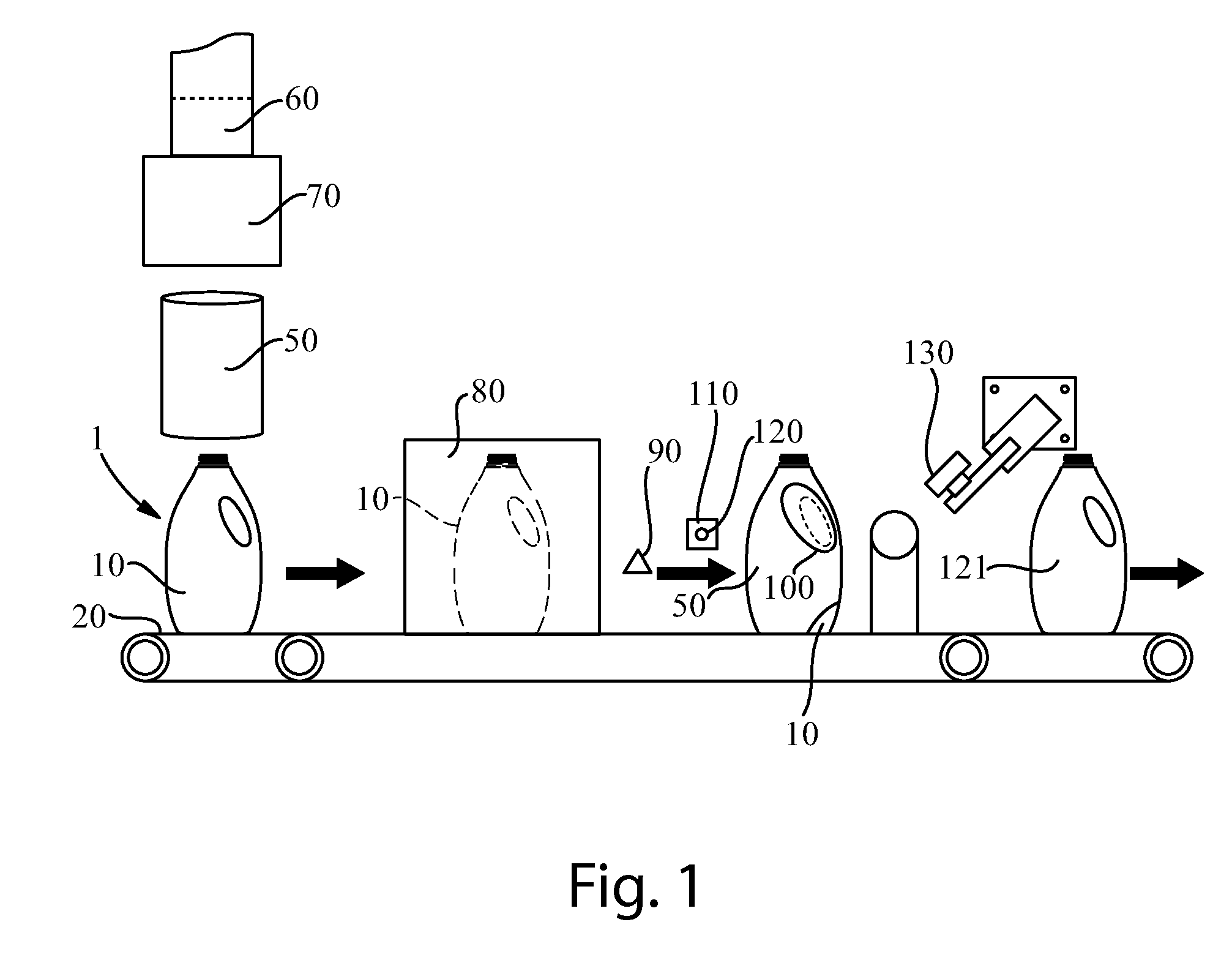

Process for forming a sleeve on a container

Owner:THE PROCTER & GAMBLE COMPANY

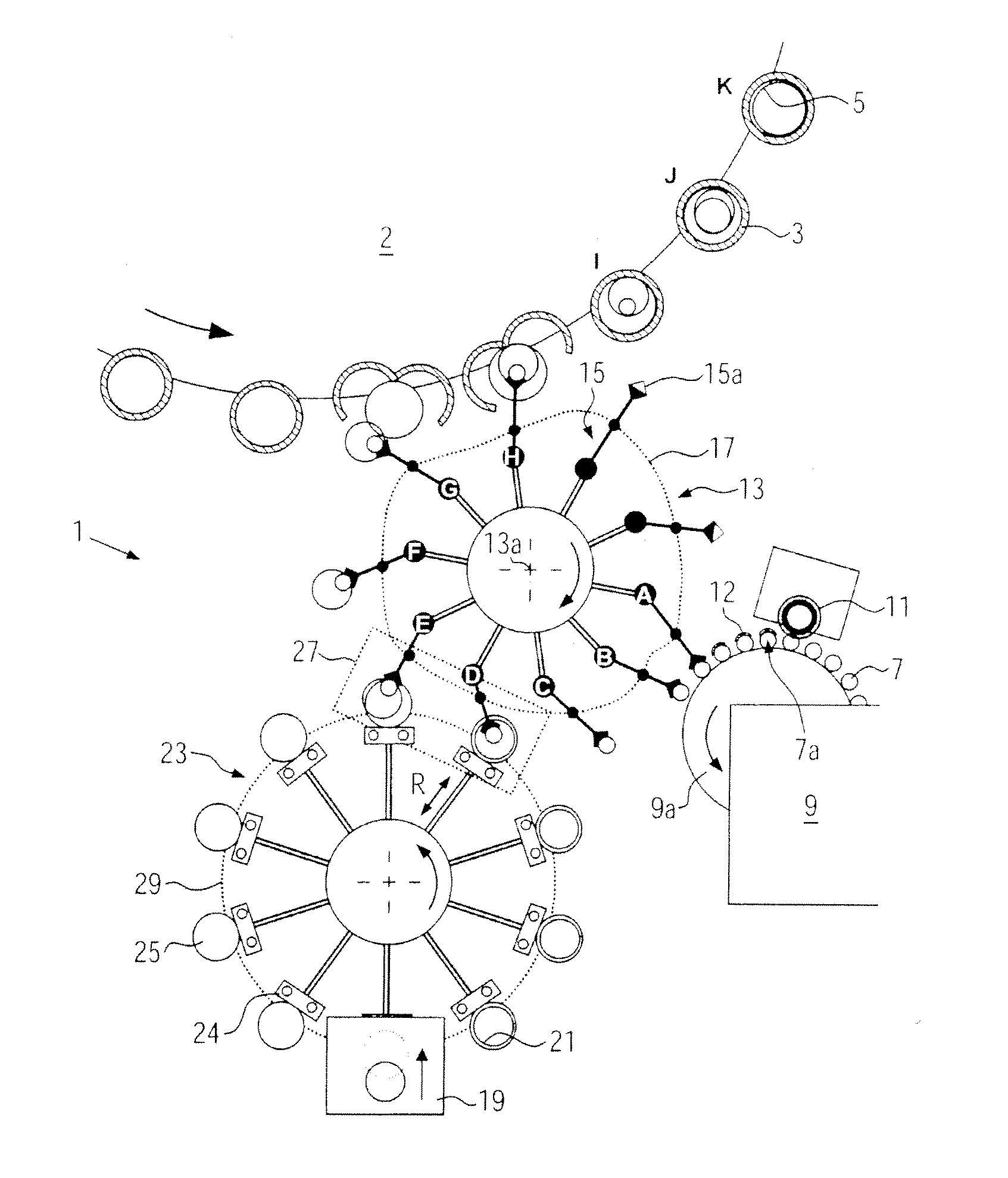

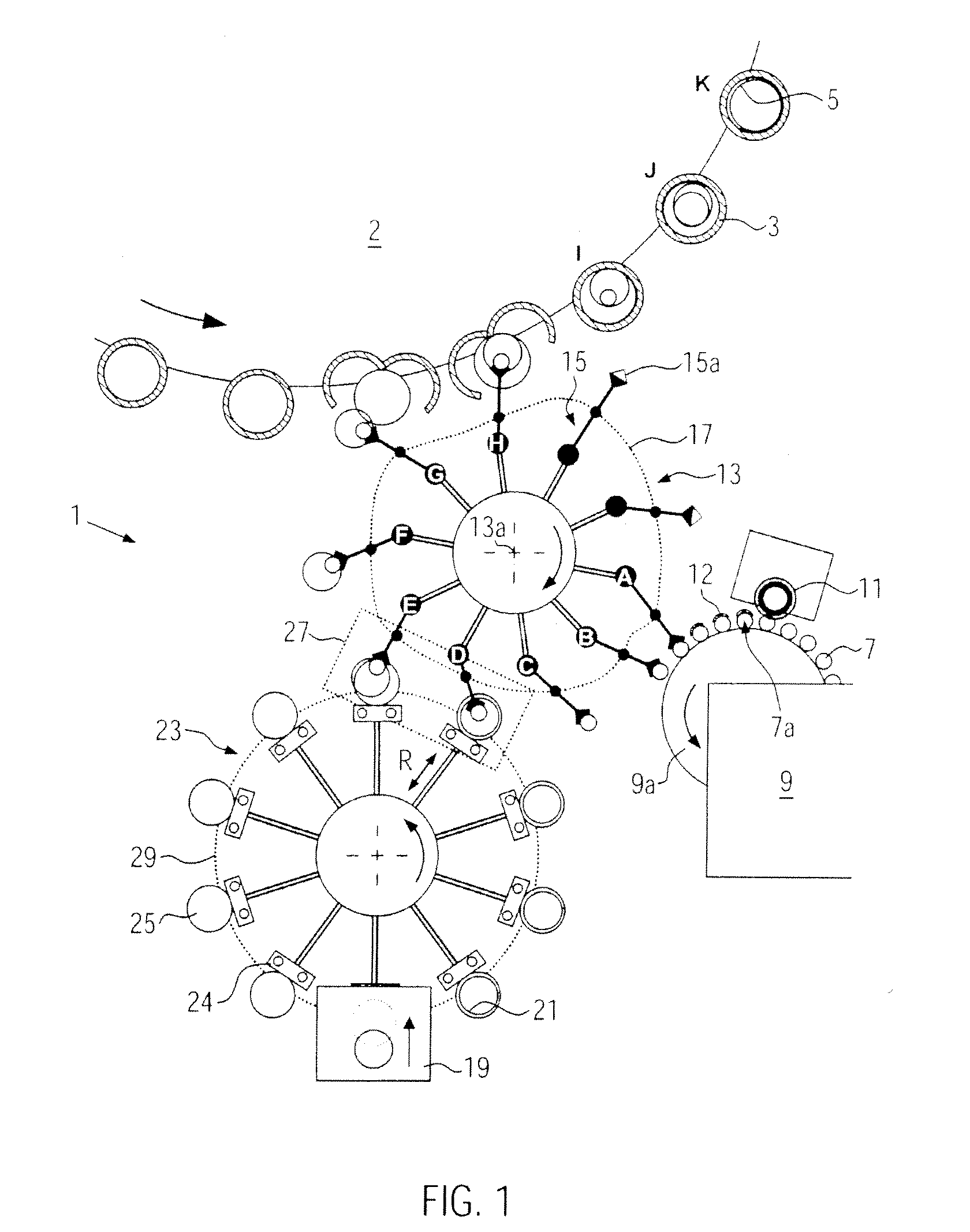

Labeler and a labeling method for labeling plastic bottles in a blow mold, in particular in a rotary blow molder

InactiveUS20110180974A1Increased process reliabilityImprove throughputCeramic shaping apparatusLabellingBlow moldingEngineering

A labeler for in-mold labeling of plastic bottles as well as to a labeling method for use of the labeler, including that a transfer star wheel and a transfer device of the labeler move the preforms and the labels in a transfer region towards one another in such a way that a respective label is only affixed to a circumferential subarea of a perform. In this manner, the label can be inserted in the blow mold in a particularly fast and reliable manner and excessive stretching of the label during blow molding can be avoided.

Owner:KRONES AG

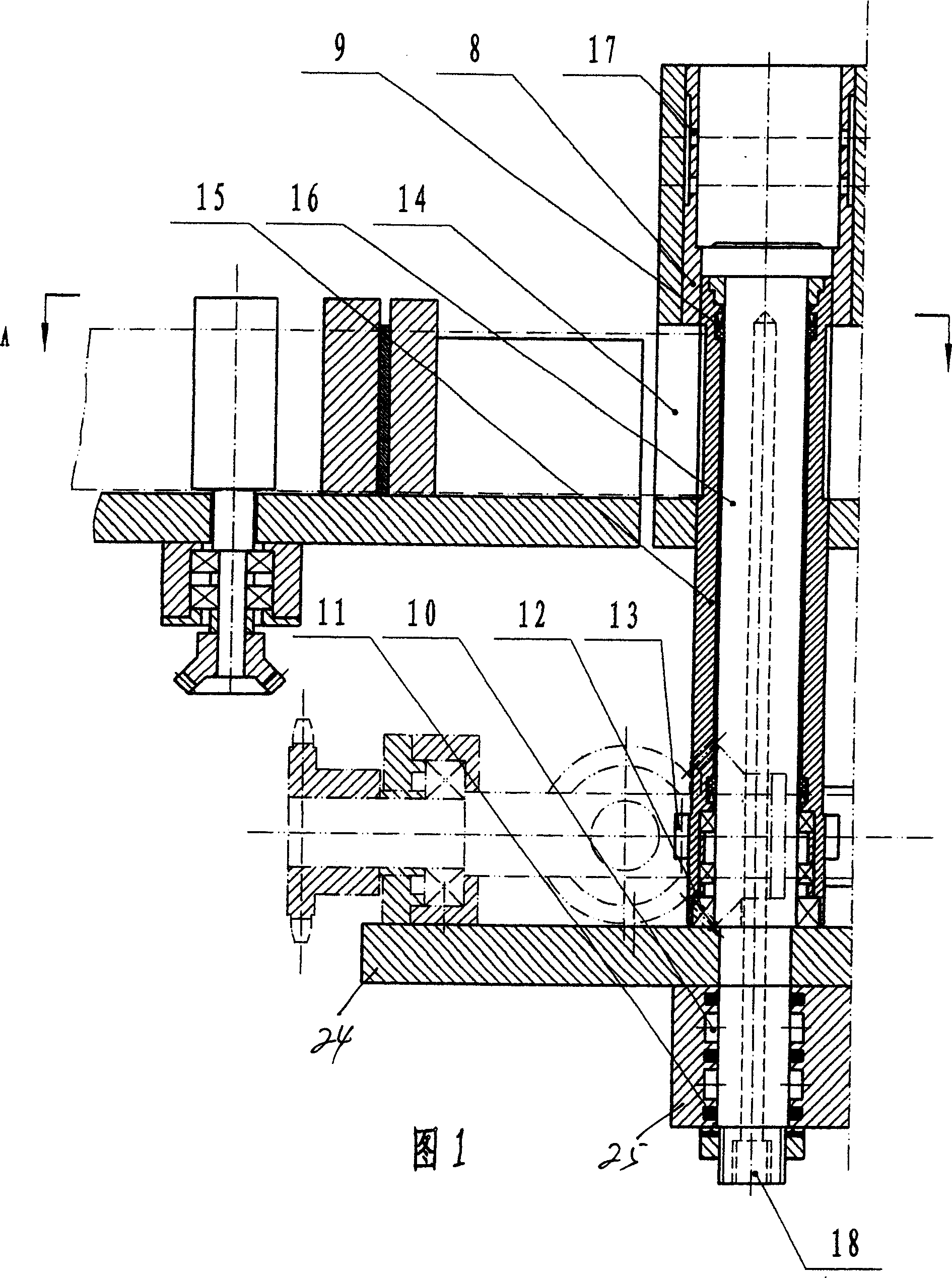

Label winding and sticking device

ActiveCN1751970AGuaranteed accuracyEnsure consistencyLabellingHot-melt adhesiveElectrical and Electronics engineering

A label rolling and sticking apparatus is composed of label sticking unit, transmission unit for driving said label sticking unit, label rolling unit under said label sticking unit, label conveying unit at the side of label rolling unit, label-sucking sleeve pipe in the label feeding die under said label sticking unit, label-sucking mandrel in said label-sucking sleeve pipe, and shaping die sleeve above label feed die and surrounding said sleeve pipe.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

Process for forming a sleeve on a container

Owner:THE PROCTER & GAMBLE COMPANY

Method of applying a label to a container and a container produced by said method

A method for applying a label to a container particularly suited for applying a polypropylene label to a polypropylene cup as it is moulded. The resultant container is made of a single type of plastic allowing it to be easily recycled. The mould used to produce the container has been designed to hold a label in place and stretch a portion of the label so it stays in place before injecting the plastic to form the container.

Owner:PAKPOT PTY LTD

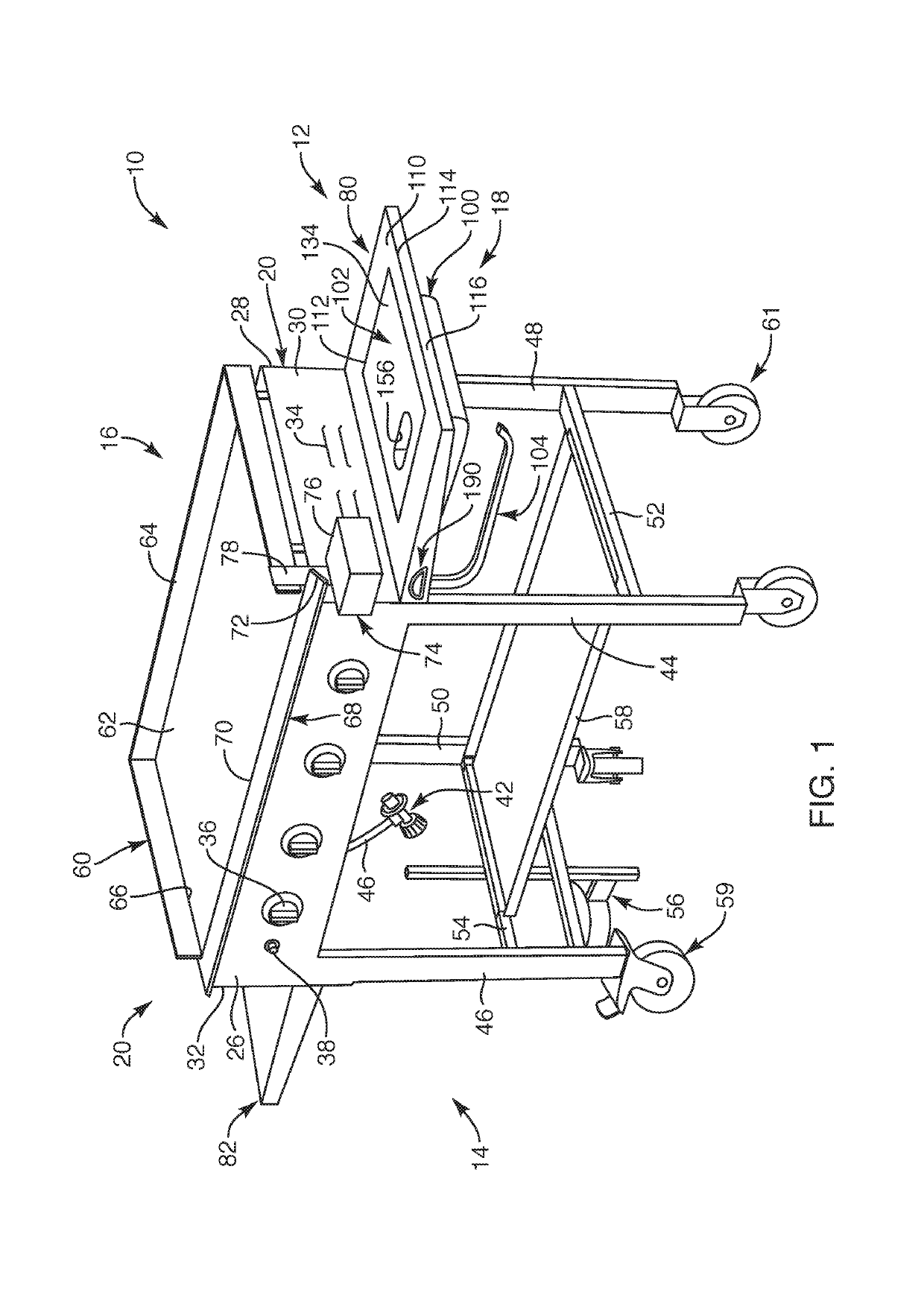

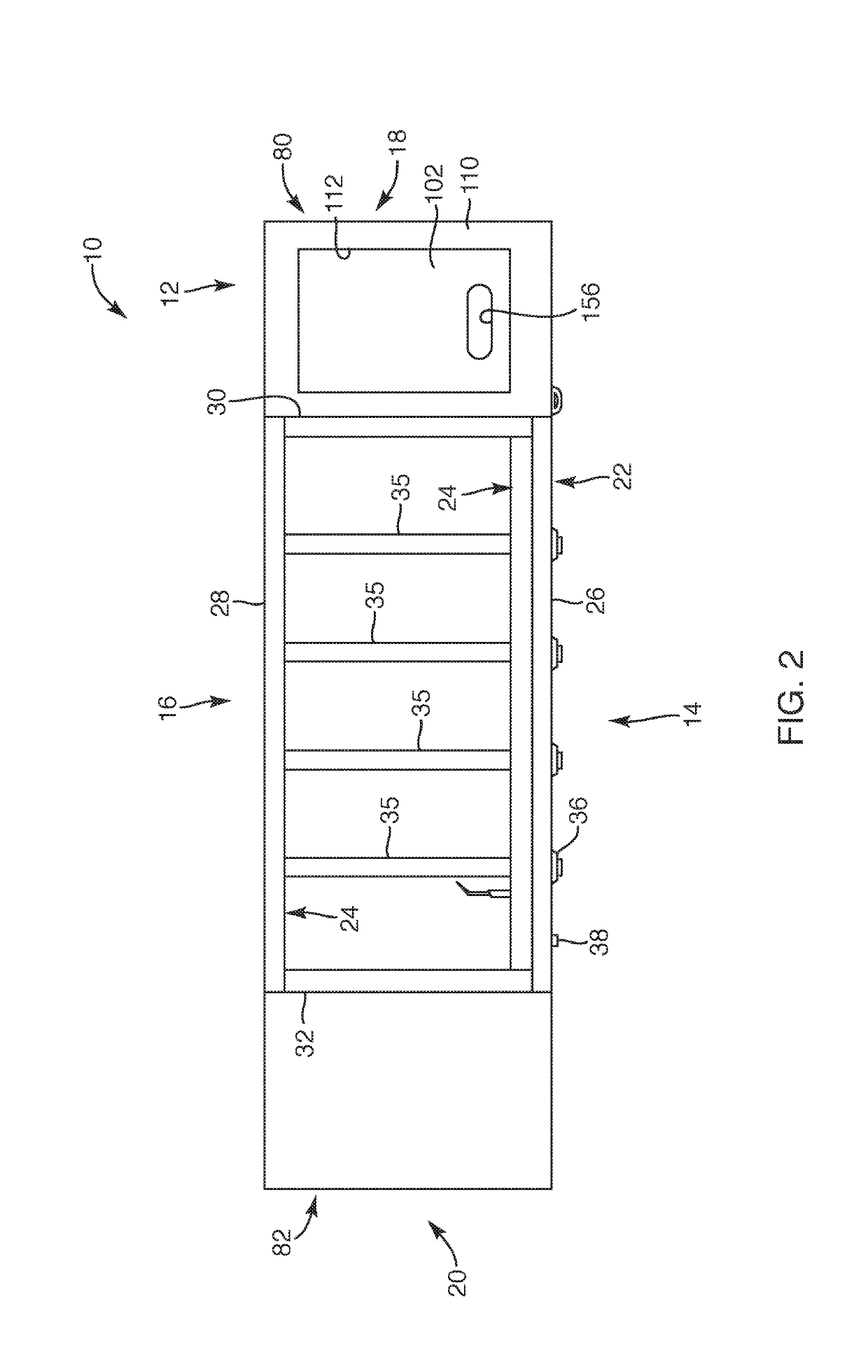

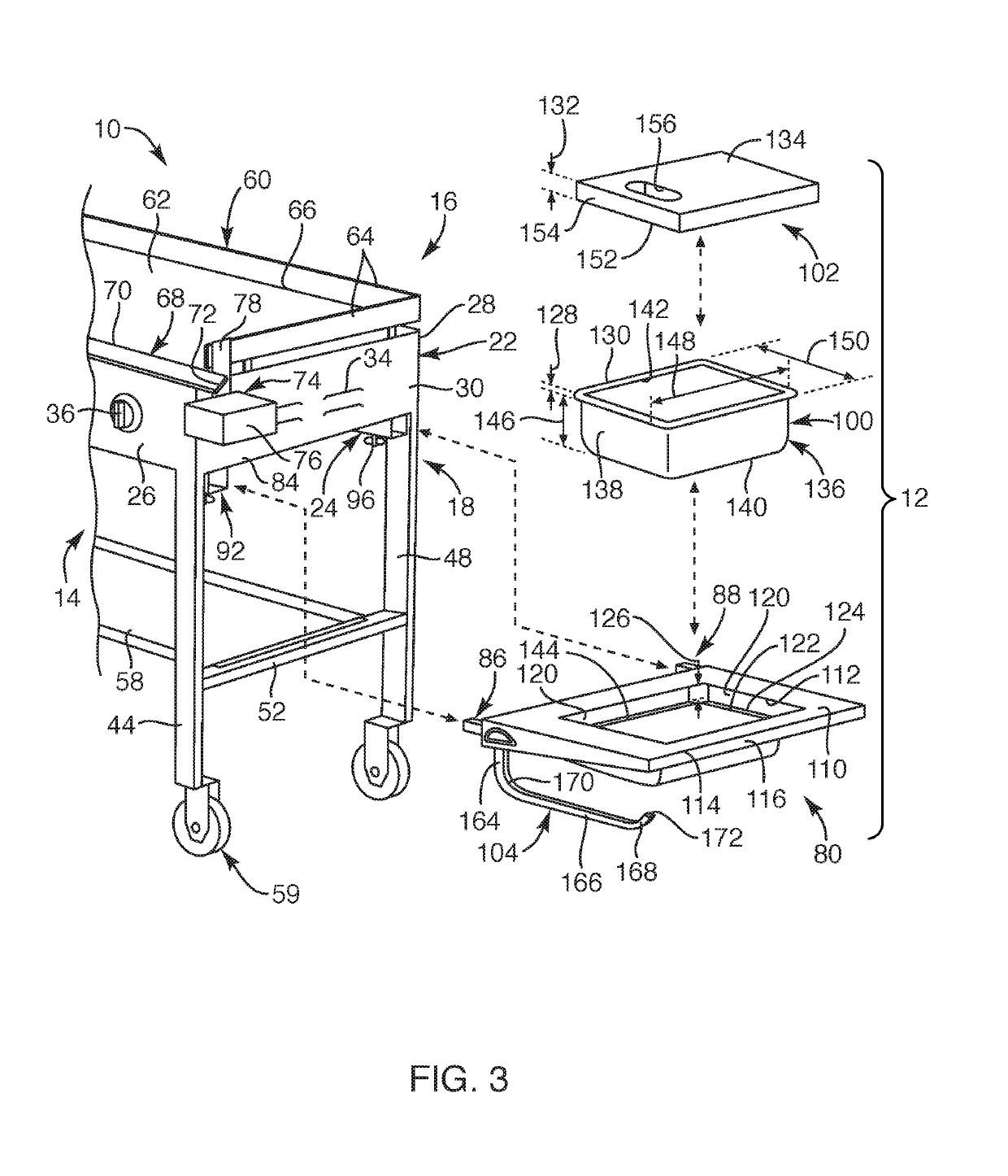

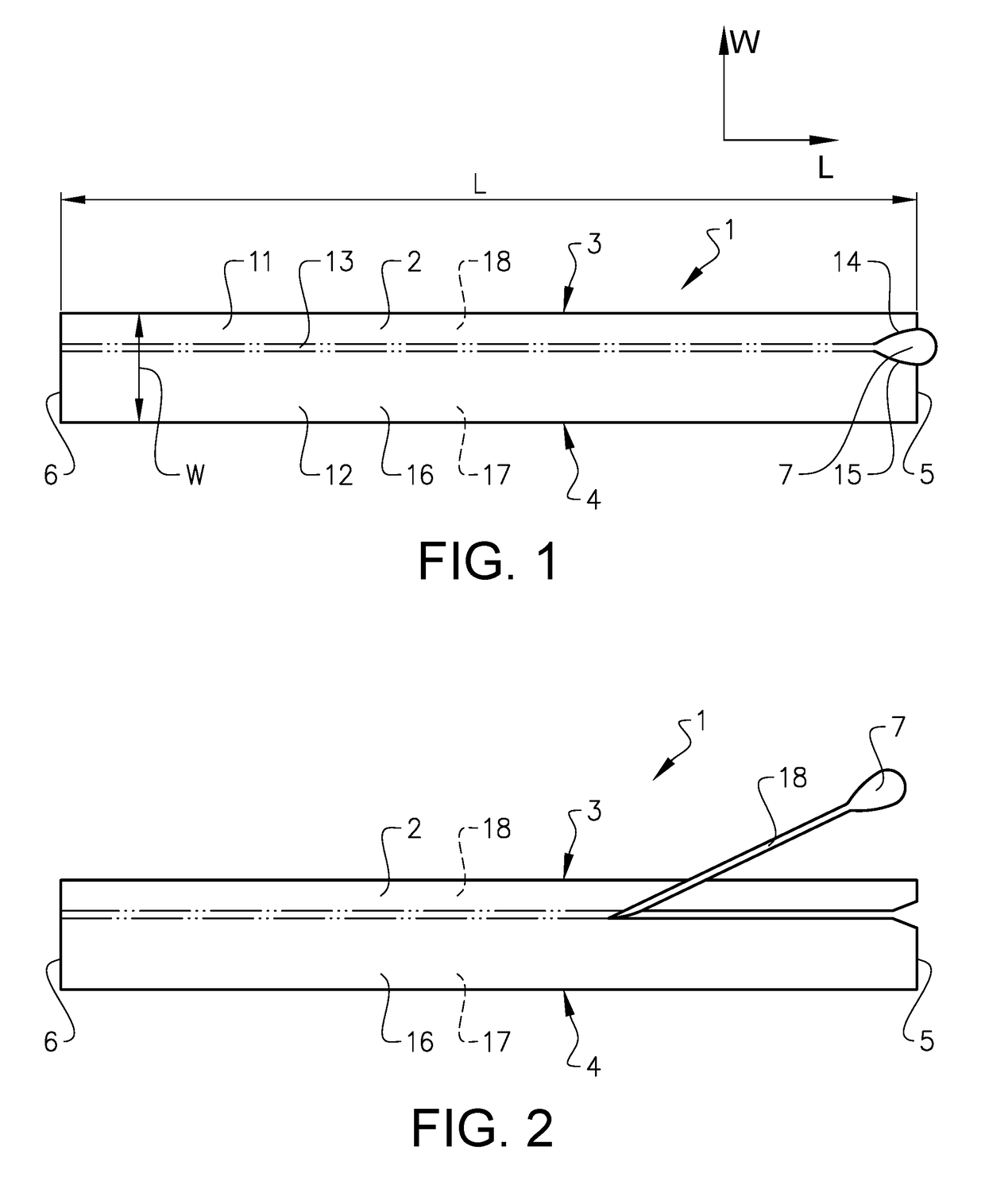

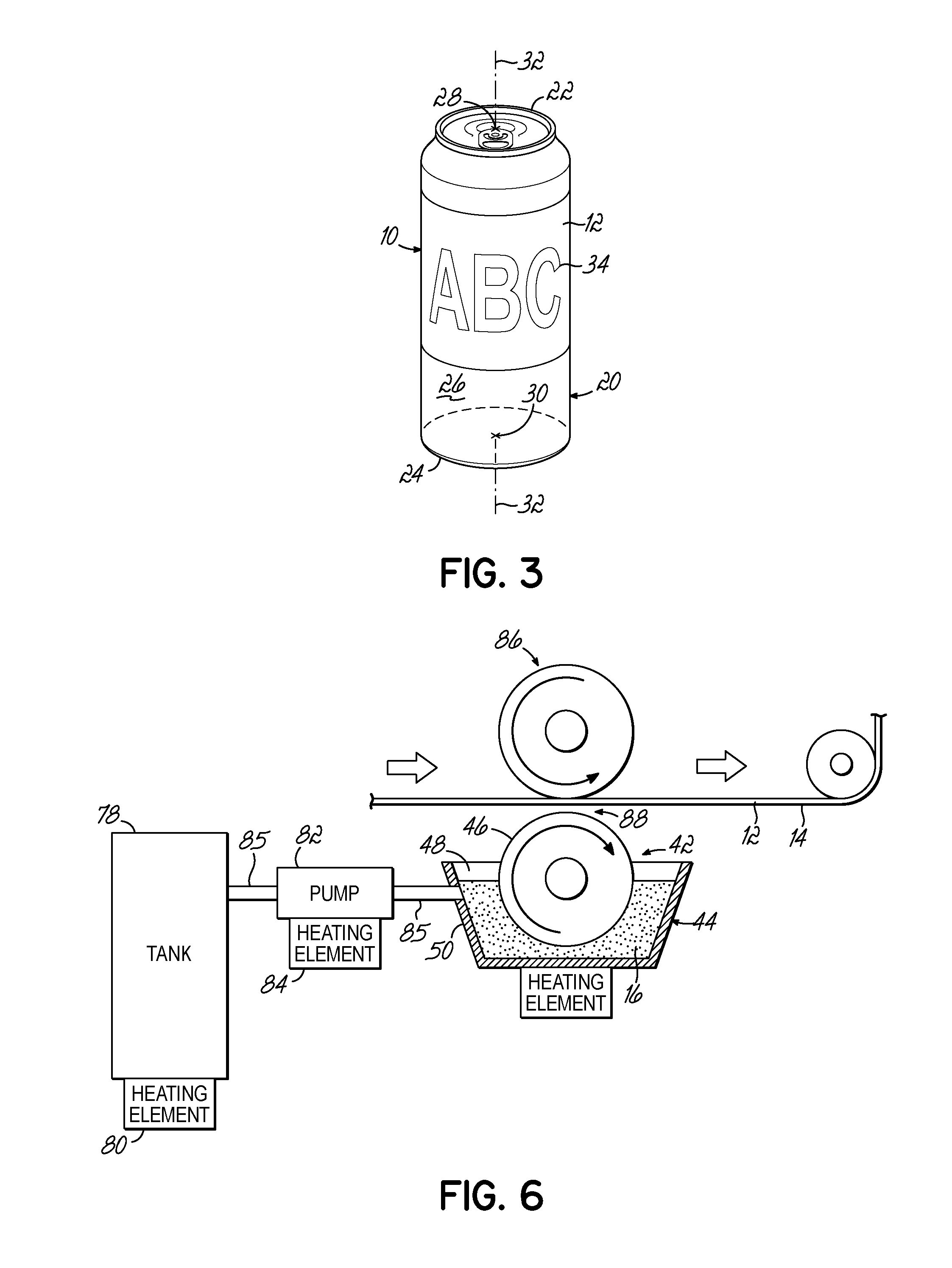

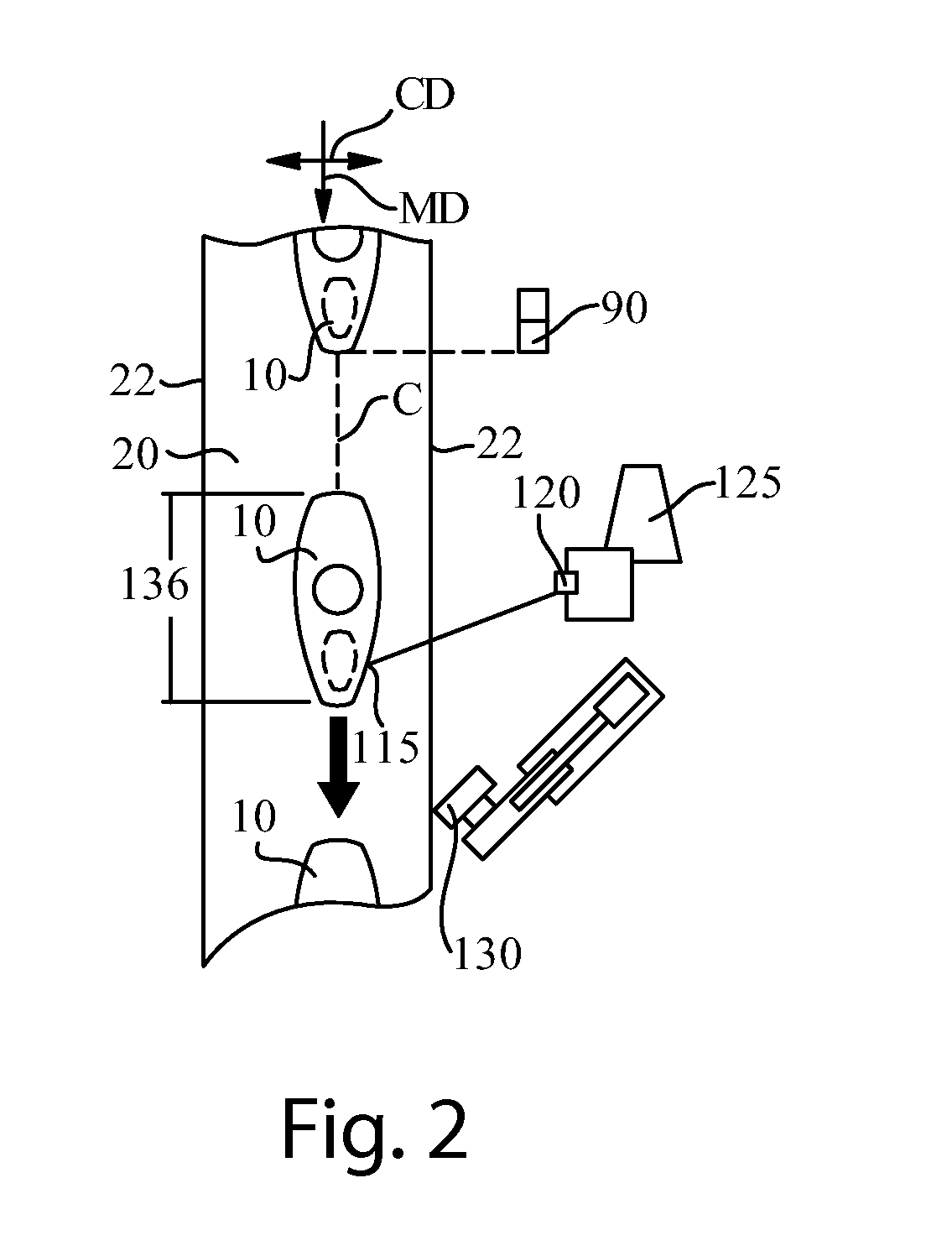

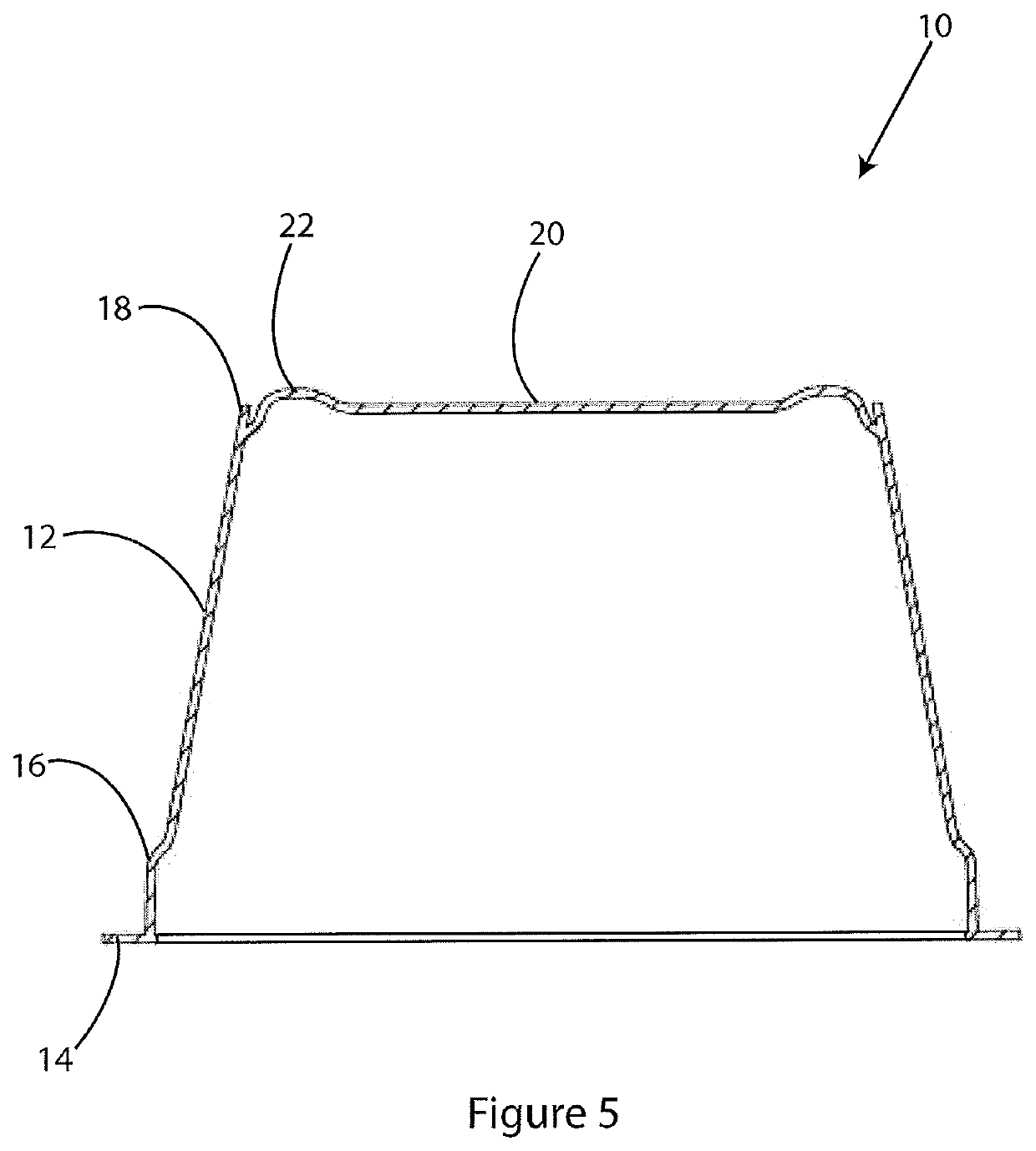

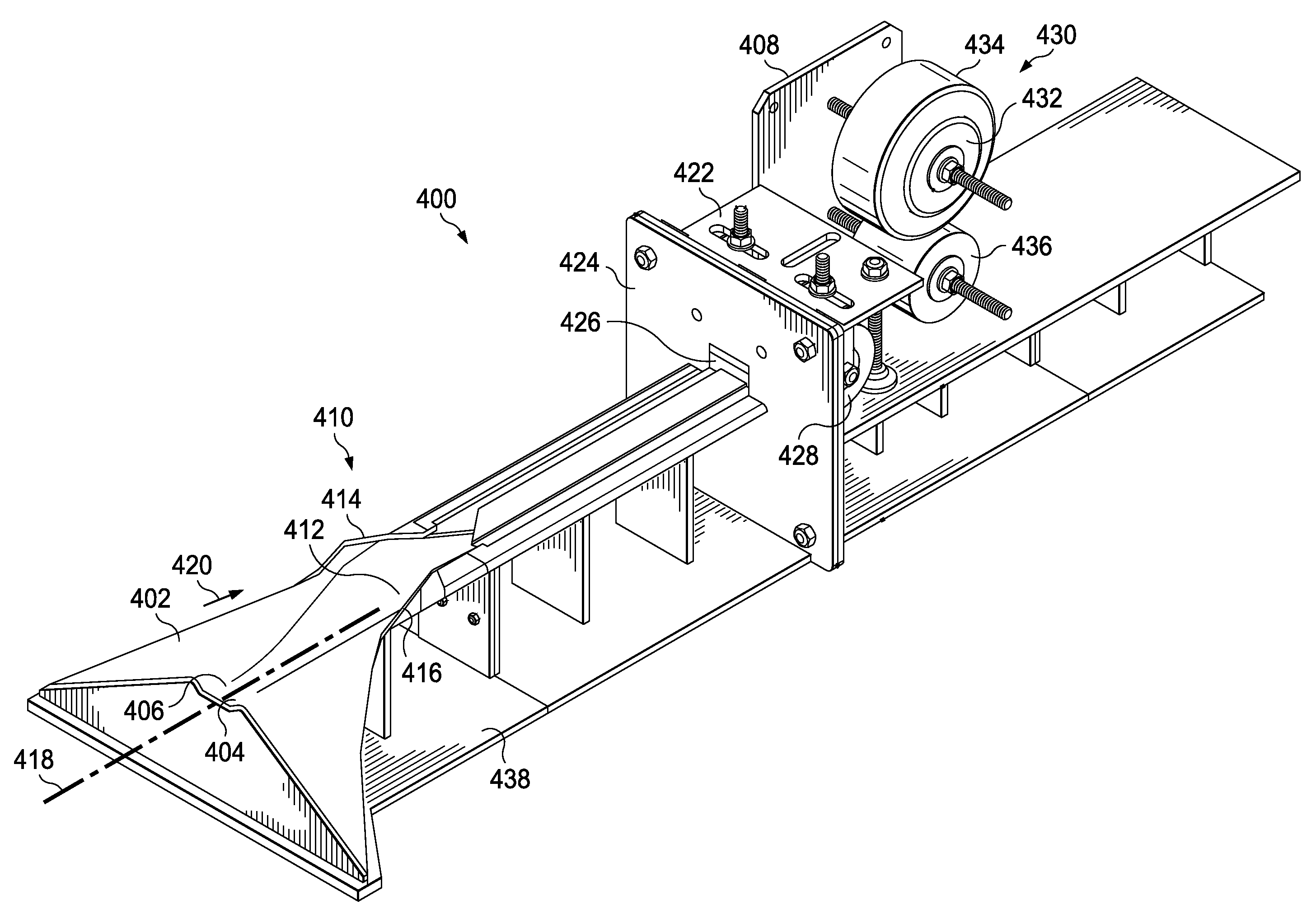

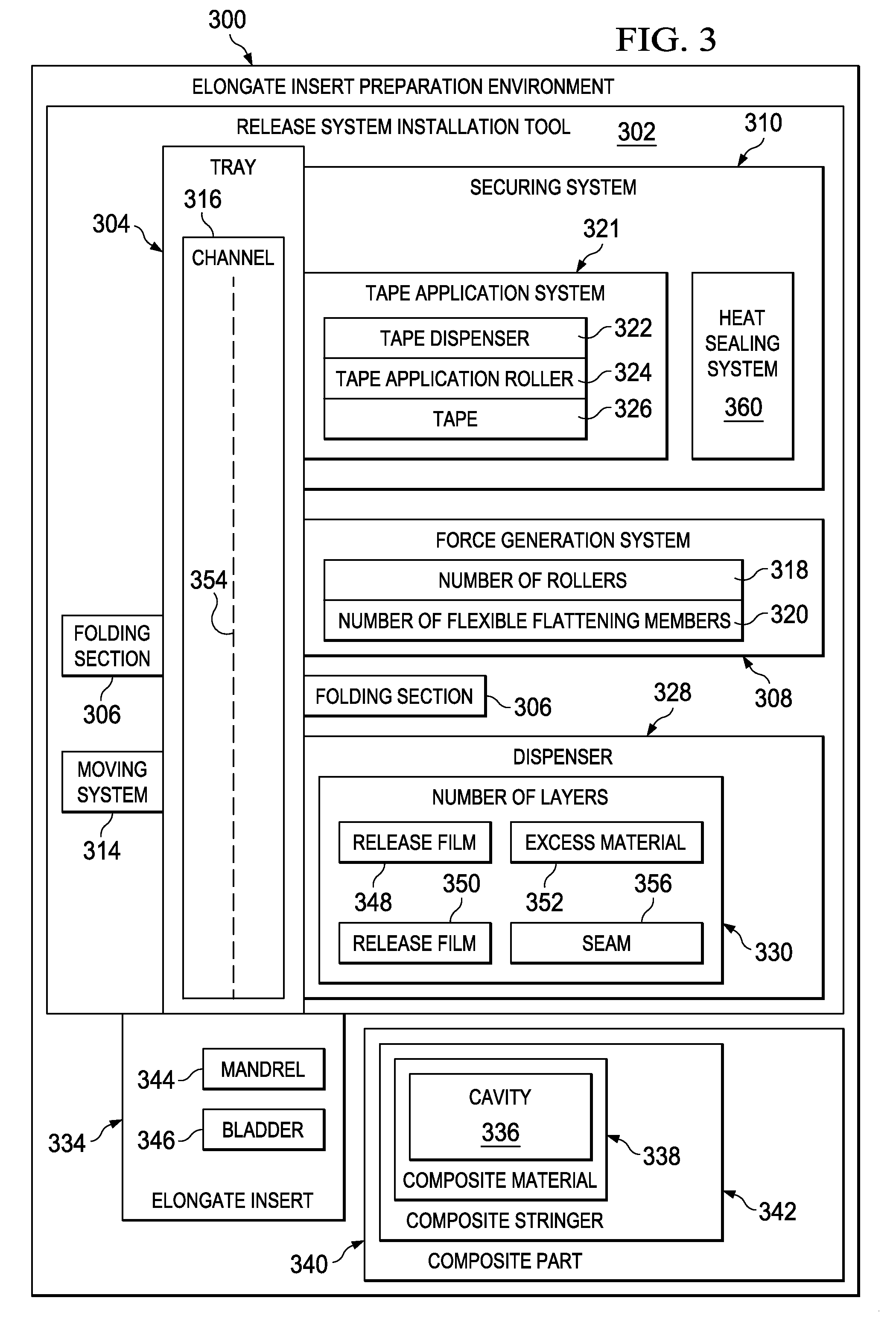

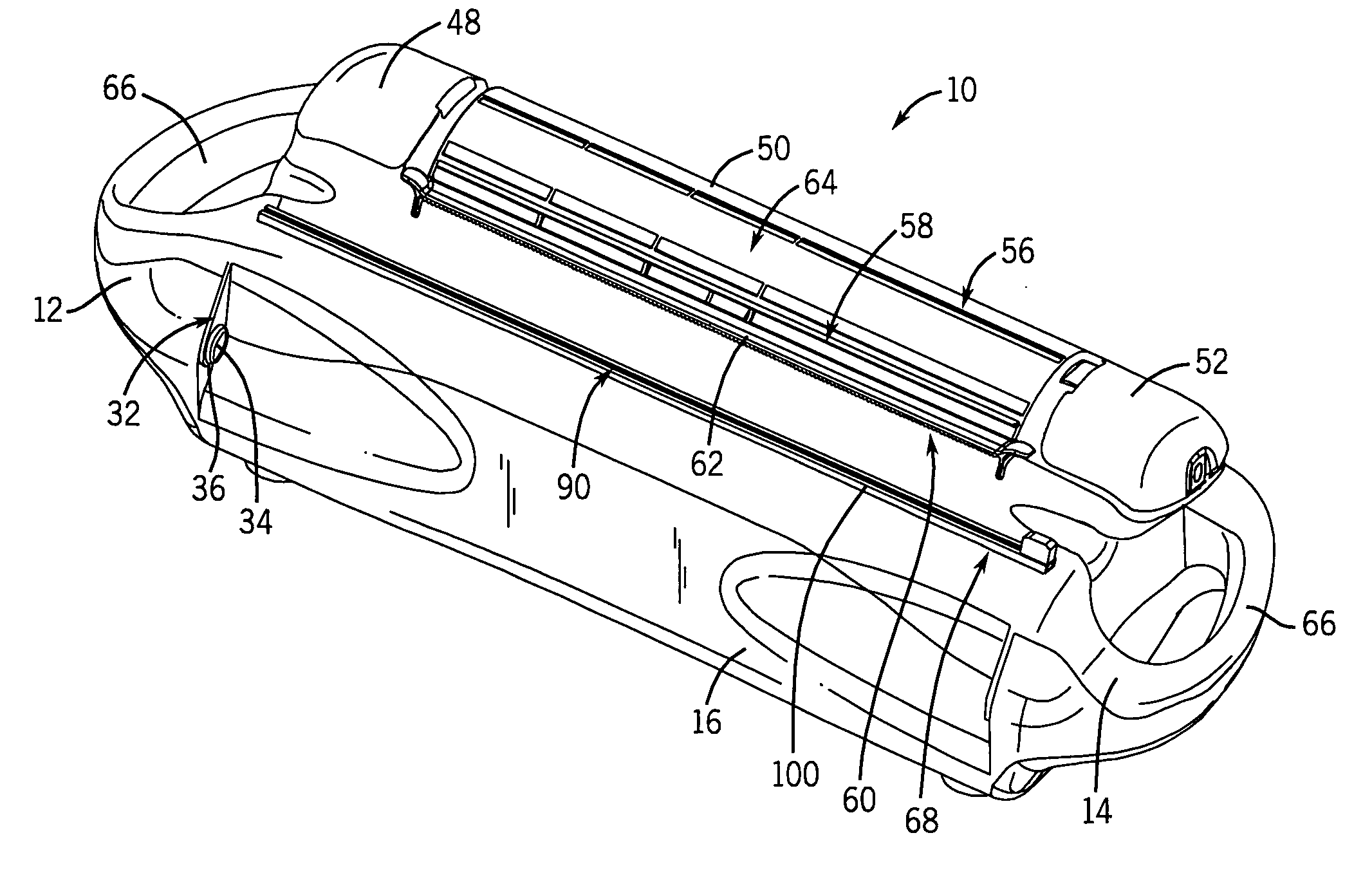

Automated elongate insert wrapping system

A method and apparatus for a tray, a folding section connected to the tray, and a tape application system. The tray has a channel for receiving an elongate insert for a composite material with a number of layers for a release system. The folding section is capable of folding a number of layers around the elongate insert to cover the elongate insert as the elongate insert is moved through the folding unit. The tape application system is capable of applying a tape to the number of layers for covering the elongate insert to form the release system.

Owner:THE BOEING CO

Regulatory label compliance apparatus and method

InactiveUS20130146204A1Effectively transparentEliminate detectionStampsLaminationDriver/operatorMonroney sticker

An apparatus and method for labeling products may be applied to vehicle labeling, where complying with legal requirements of one jurisdiction may otherwise violate legal requirements within a second jurisdiction. Label content, format, and placement on vehicles, as imposed by federal law, creates a visual obstruction in violation of state law when a prospective customer is driving the vehicle. A new product label configured as a panel, which may be the Monroney sticker for a vehicle, or which may contain the Monroney sticker information and extend beyond that label itself, acts as a one-way panel. The panel permits transmission of light inward toward the driver, thus appearing sufficiently transparent not to create a visual obstruction. The panel may be sized from the size of a conventional Monroney sticker, up to the size of the entire window, acting as a window shade and a window sticker.

Owner:WHELAN JENNY ANN +1

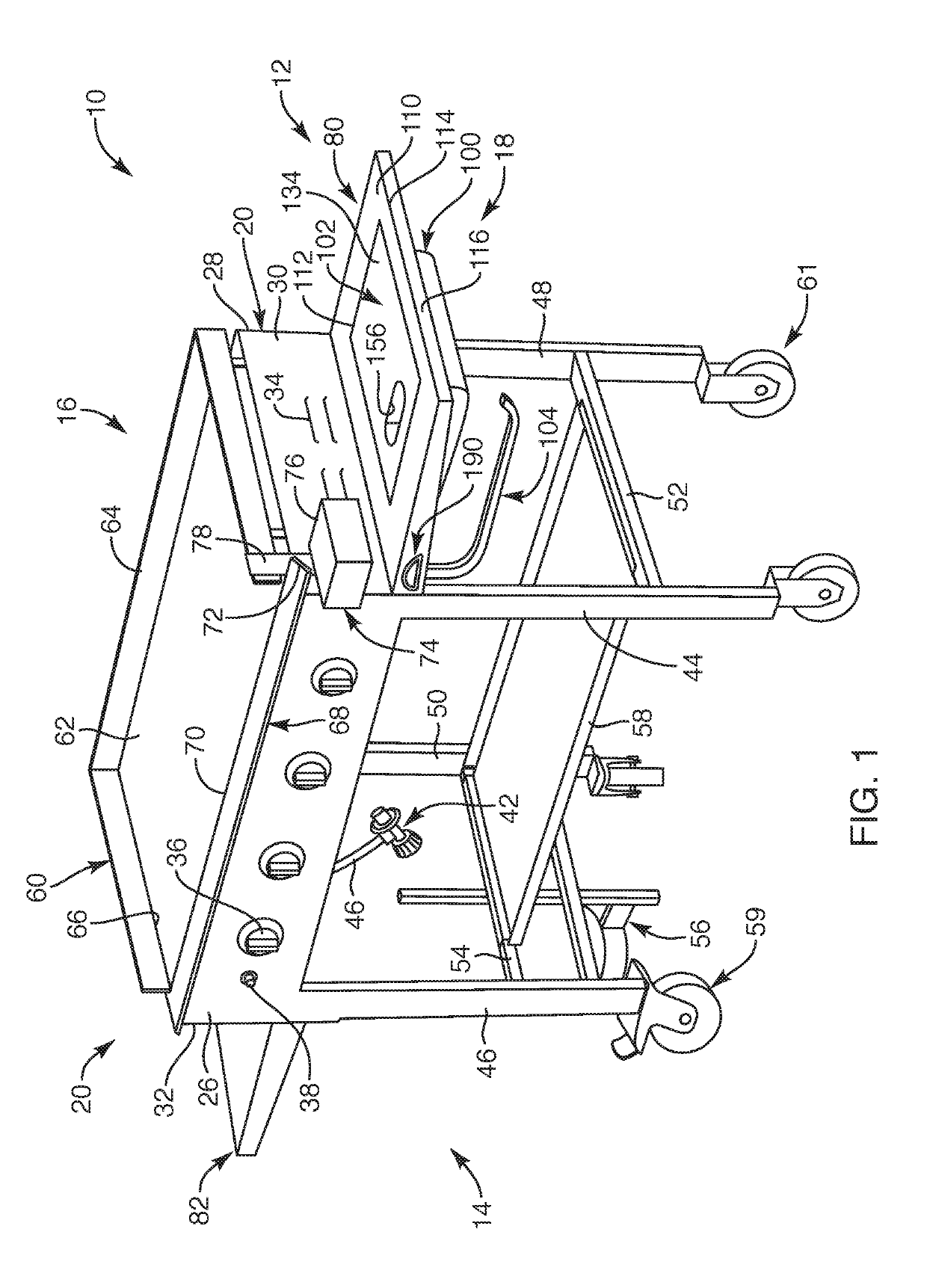

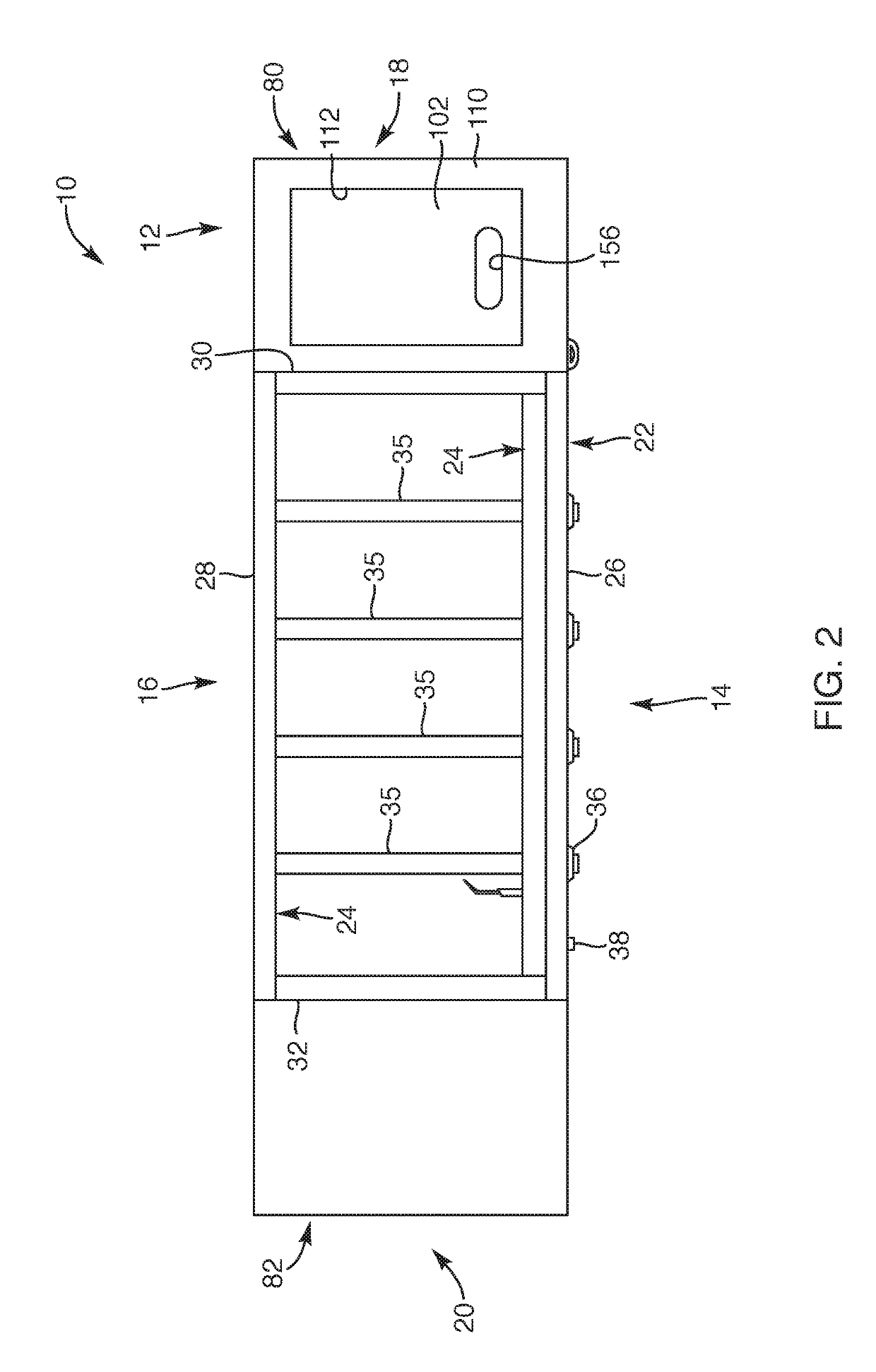

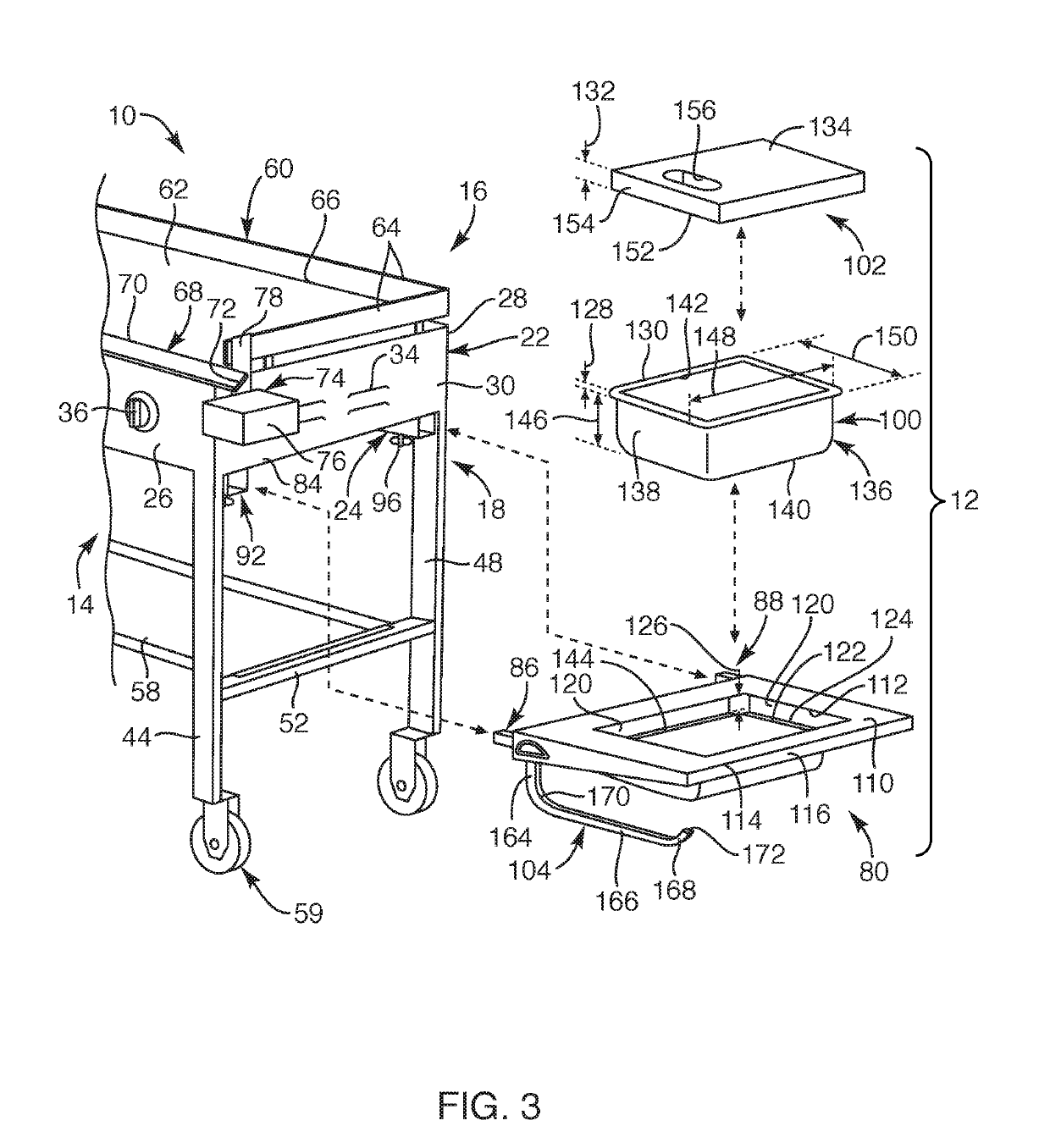

Wrap dispensing station and method

The present invention relates to a wrap dispensing station and a method for wrapping food products for storage. A selected size roll of material used to wrap food products is mounted in a housing. The leading edge of the roll of material is fed through a slot in the housing. At least one roll of labels is staged in a storage area in the housing. The leading edge of the labels is fed through a label feeding system. At least one writing implement is preferably staged in the storage area in the housing. The leading edge of the roll of material is pulled to a selected length to be used to wrap a food product. A cutting apparatus is used to cut the selected length of material. The food product is wrapped with the selected length of material. A label is removed from the roll of labels, marked with the staged writing implement and placed on the wrapped food product.

Owner:SAN JAMAR INC

Outdoor cooking station with griddle, system and method thereof

ActiveUS20190167039A1Domestic stoves or rangesLighting and heating apparatusEngineeringMechanical engineering

Embodiments of a griddle of the type for an outdoor cooking station is provided herein. The griddle includes a flat cooking surface with a splash guard extending along a periphery of the flat cooking surface. The flat cooking surface defines a trough positioned adjacent a rear end of the cooking surface such that the trough includes a sloping surface extending downward toward a rear opening defined in the splash guard along and adjacent the rear end of the flat cooking surface. With this arrangement, as a user cooks food on the griddle, unwanted grease may be pushed to the rear of the griddle and into the trough so that the grease funnels down the sloped surface and through the rear opening and into a grease container centered below the rear opening.

Owner:NORTH ATLANTIC IMPORTS

Adjusting device of film packaging machine

InactiveUS20060196149A1Smooth movementUniform applicationEnvelopes/bags making machineryWrappers shrinkageFilm (photographic)Packaging machine

An adjusting device that is mounted in a film packaging machine includes a moving mechanism that selectively moves two support blocks in opposite directions and toothed wheels mounted to the support blocks in a symmetric manner and driven by a timing belt that is mechanically coupled to a motor for rotating film drive rollers that are mounted to selected ones of the toothed wheels. Thus, the film drive rollers are movable in opposite directions with the support blocks for adjusting the distance between the rollers, which allows for accommodation of packaging films of different sizes between the rollers, while not interfering with the operation of the film drive roller for driving the packaging film therebetween. This arrangement allows for uniform application of driving force to the film by the film drive rollers and thus realizing smooth and stable movement of the film in packaging an article.

Owner:BENISON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com