Patents

Literature

162results about "Wrapper supporting apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

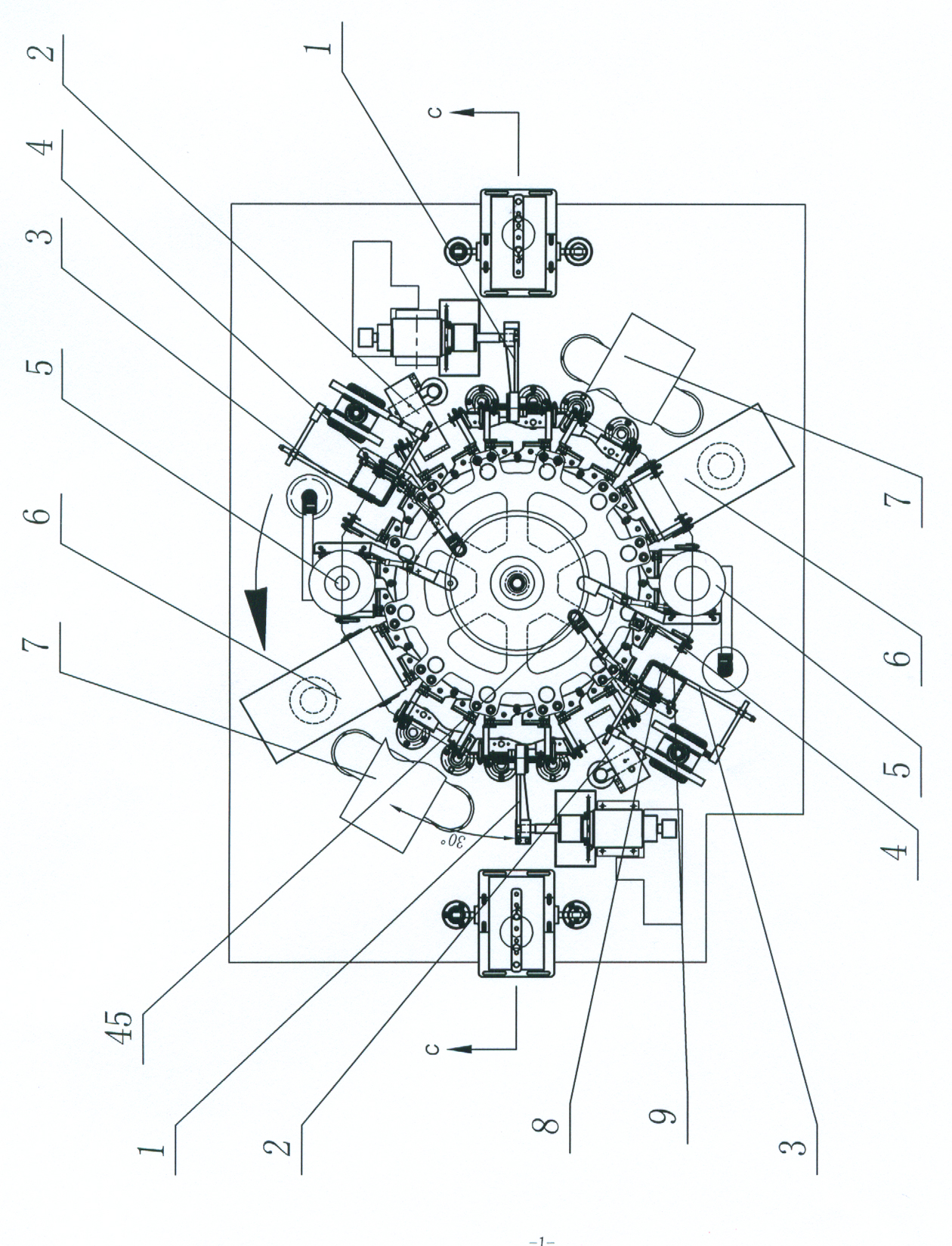

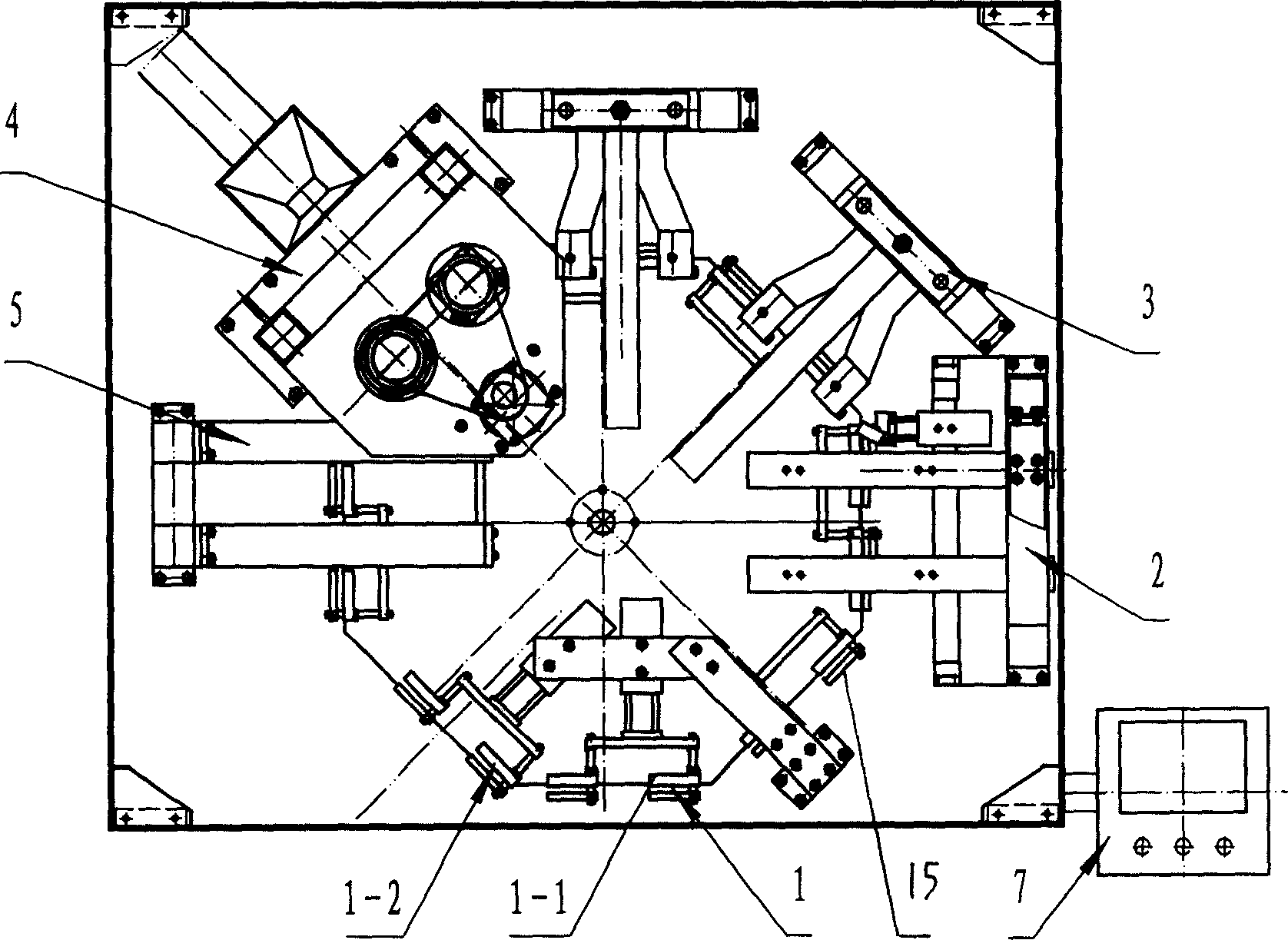

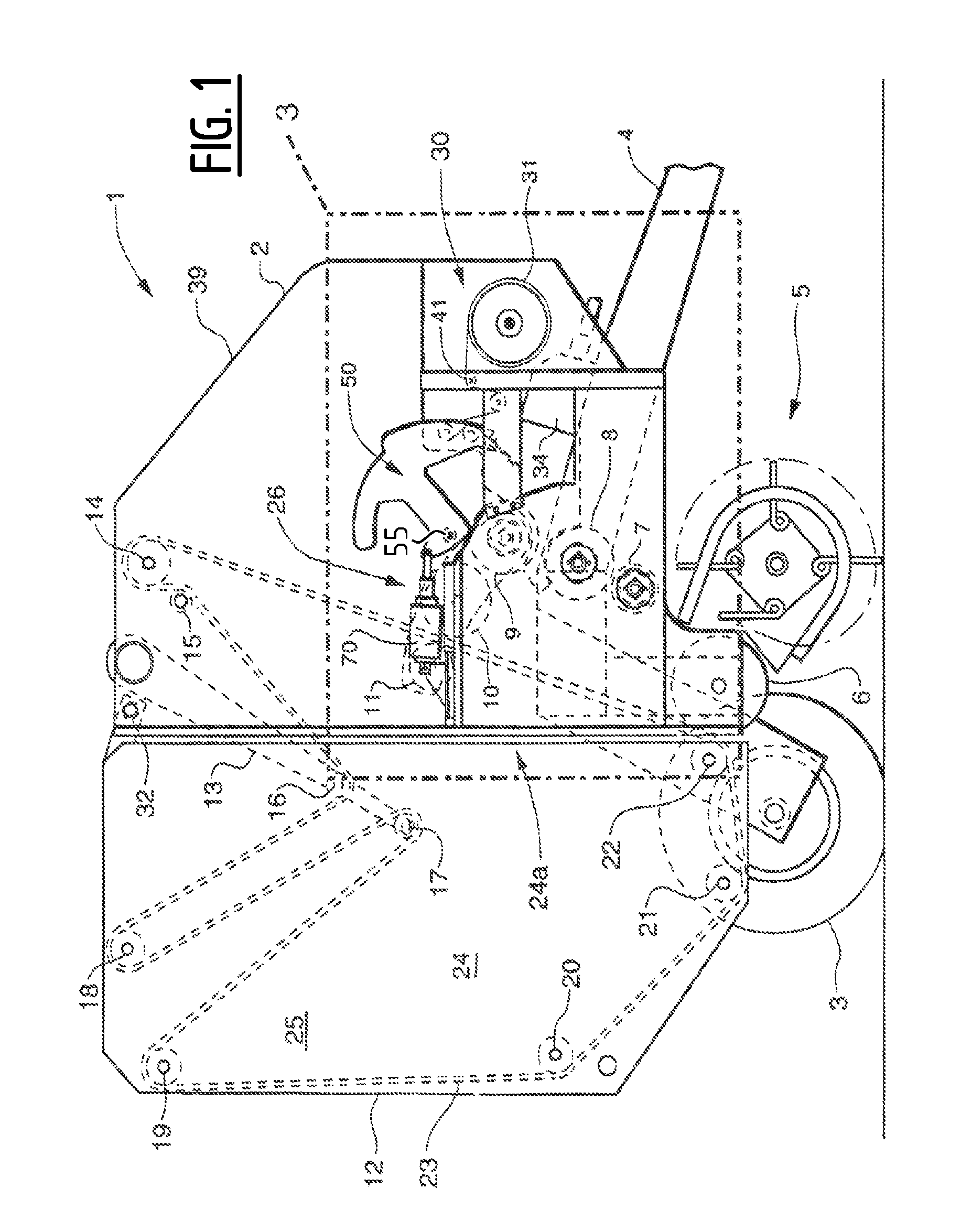

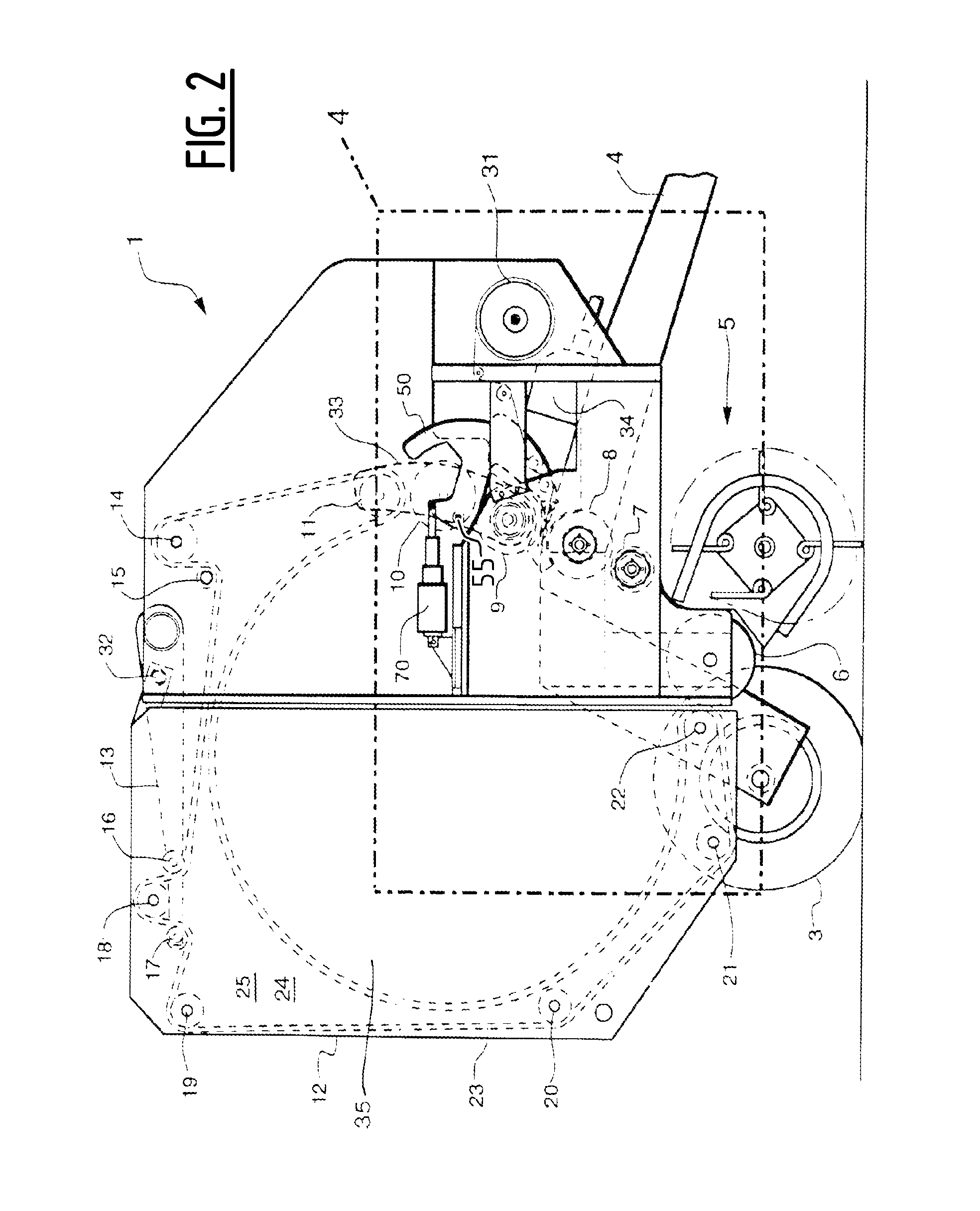

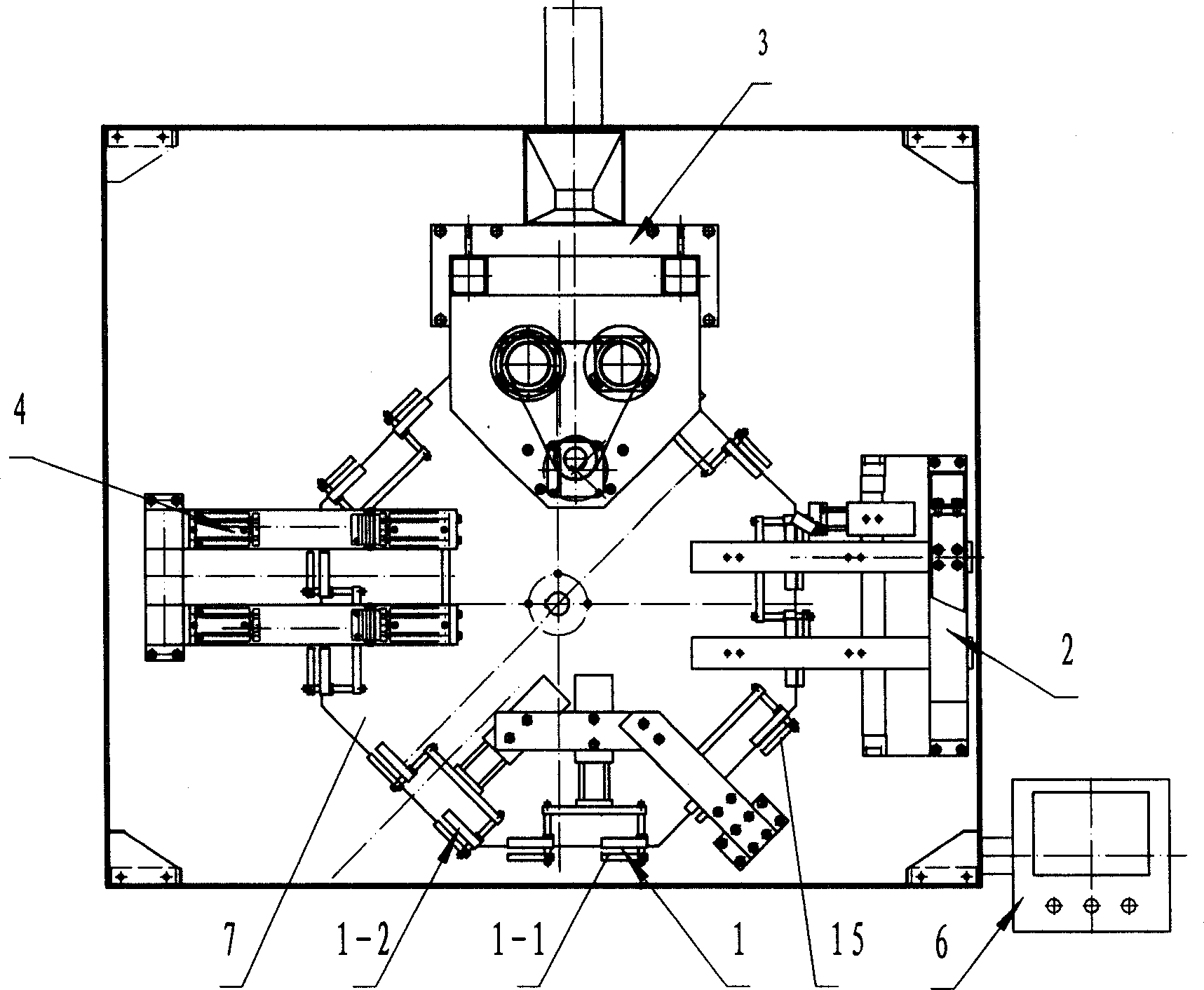

Full-automatic bag-feeding type packaging machine

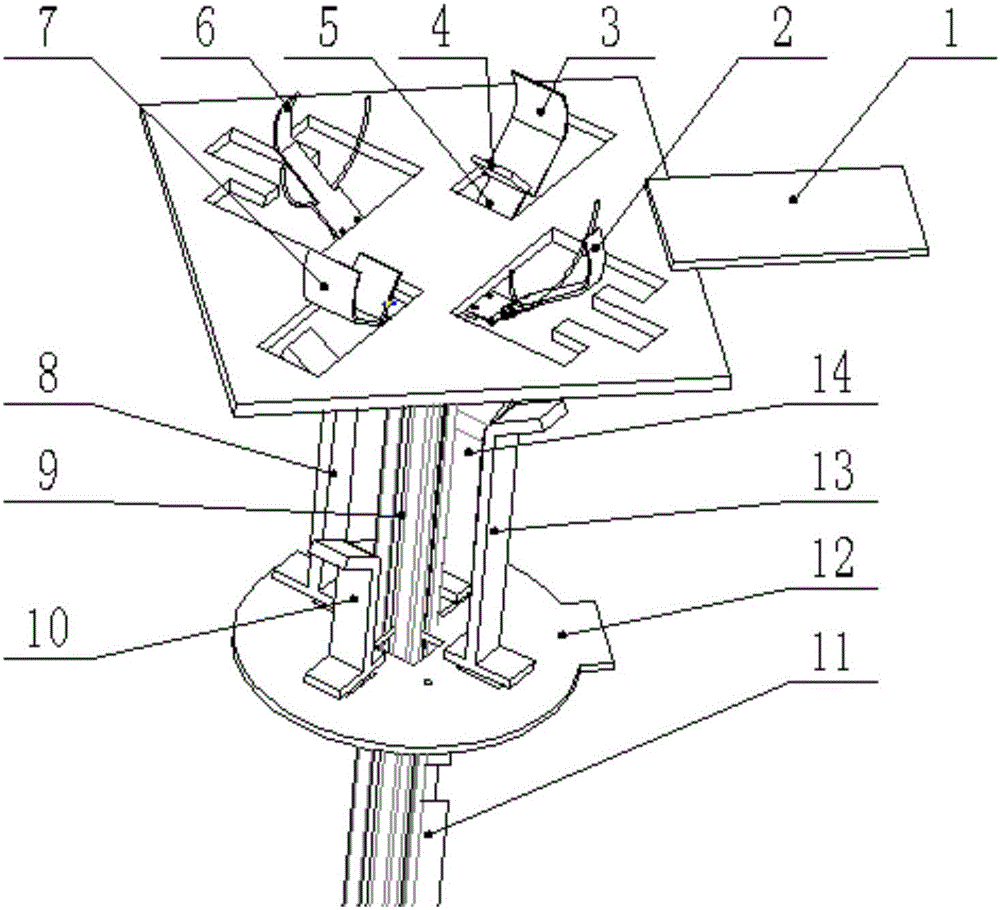

InactiveCN101837845AImprove packaging efficiencyAvoid the problem of not being able to hold the bagWrapper supporting apparatusWrapper twisting/gatheringRotating discPackaging machine

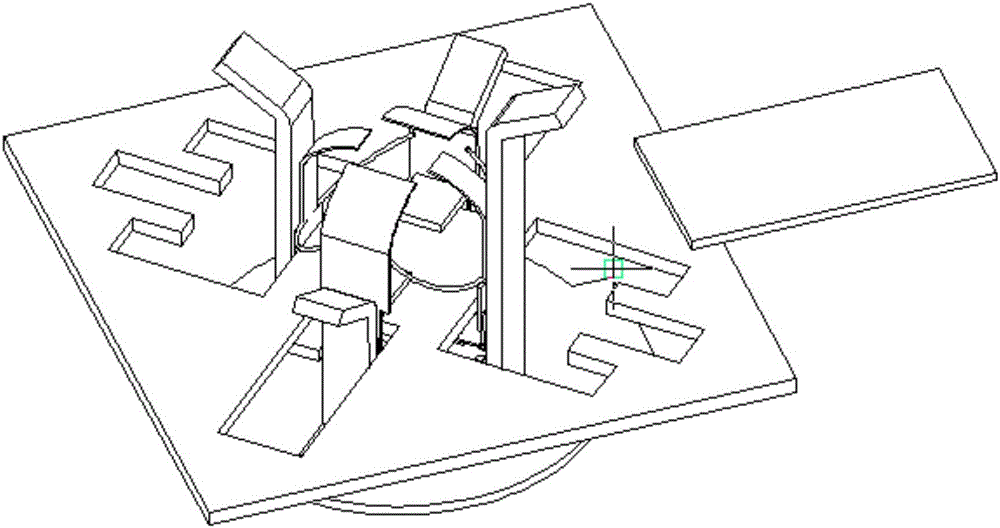

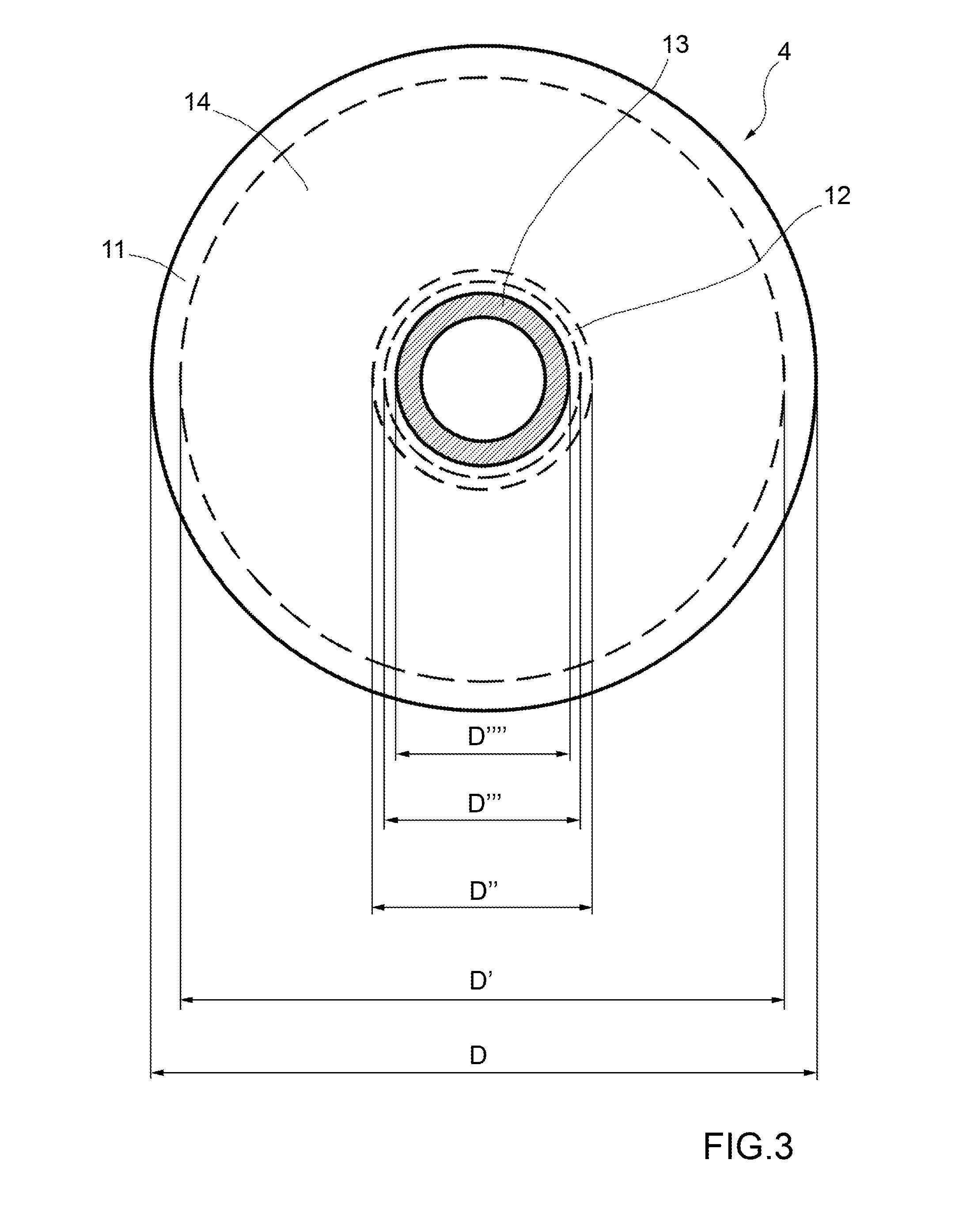

The invention discloses a full-automatic bag-feeding type packaging machine, comprising a rotating disc (13), a large cam (14), a bag feeding device (1), a marking device (2), a bag opening device (3), a material charging device (5), a heat-sealing device (6), a bag discharging device (7) and a bag bracing device (4). A bag clamping device (39) is arranged at the edges of the rotating disc (13); the bag feeding device (1), the marking device (2), the bag opening device (3), the material charging device (5), the heat-sealing device (6) and the bag discharging device (7) are all arranged outside the rotating disc (13); and the bag bracing device (5) is of a swing arm type and is movably mounted on the rotating disc (13). The packaging machine is characterized in that the bag feeding device (1), the bag opening device (3), the material charging device (5), the heat-sealing device (6) and the bag discharging device (7) are symmetrically arranged around the central point of the rotating disc (13); and the bag bracing device (4) is symmetrically arranged around the central point of the rotating disc (13). The full-automatic bag-feeding type packaging machine with the structure has the advantages of stable performance and high production efficiency.

Owner:WENZHOU READOR MACHINERY

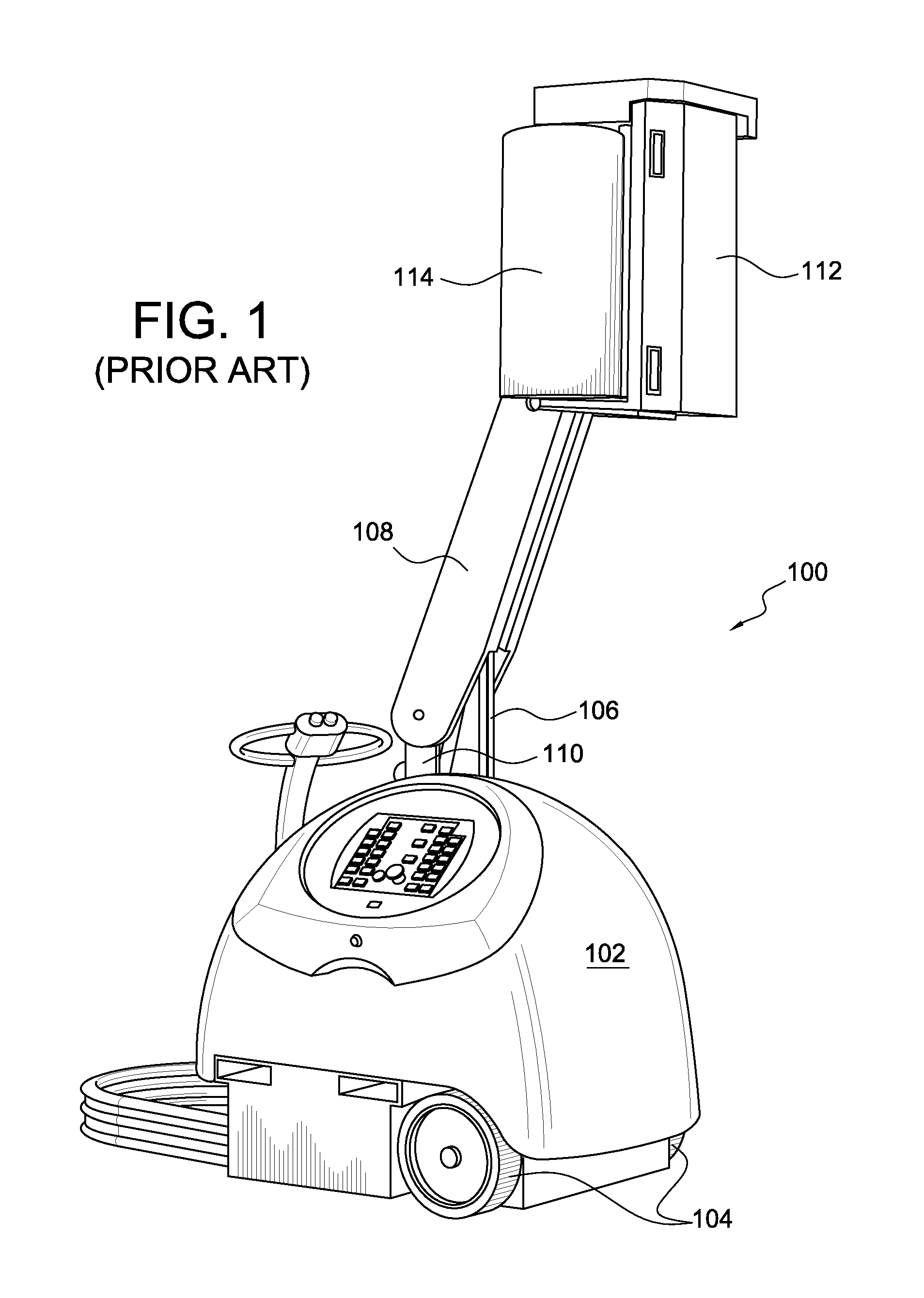

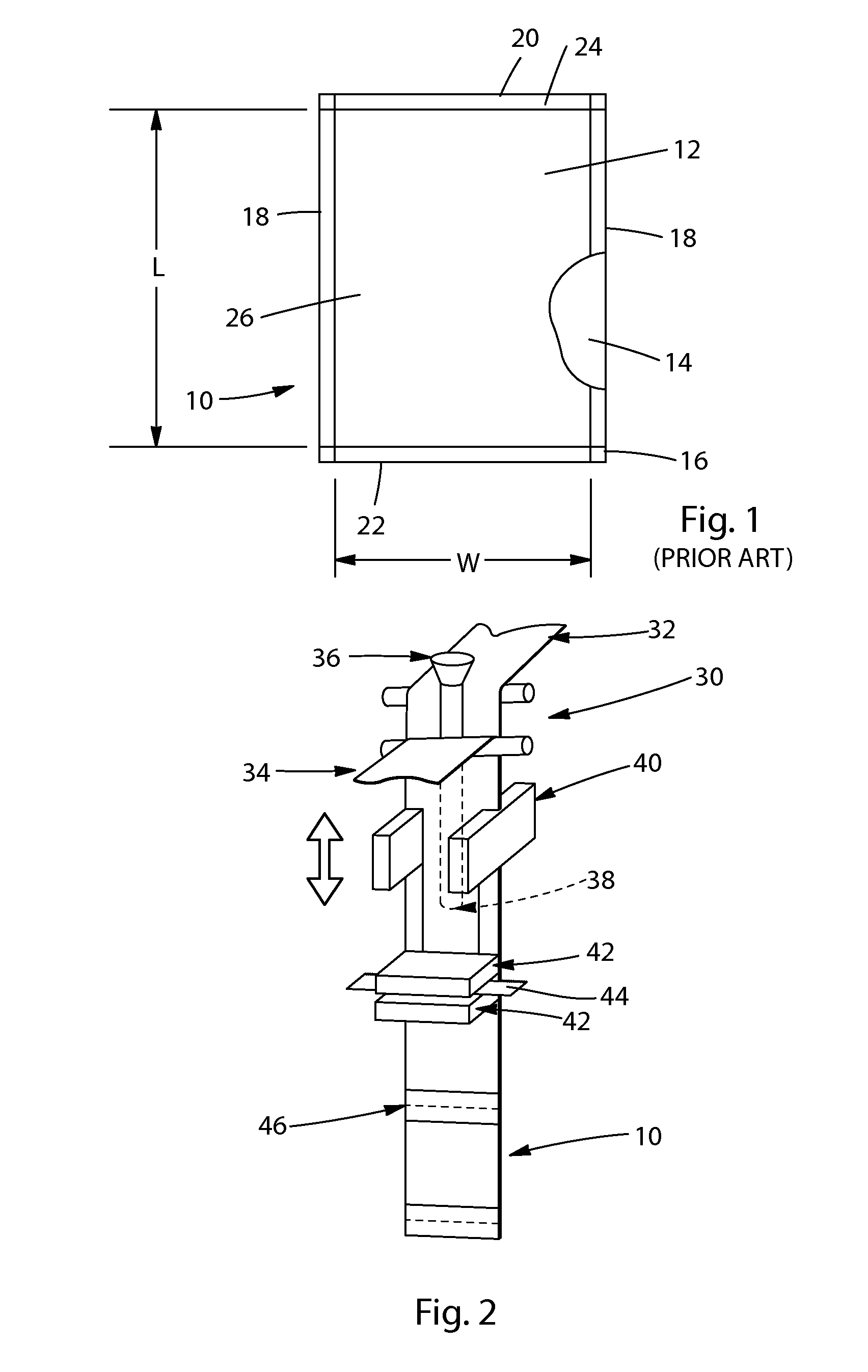

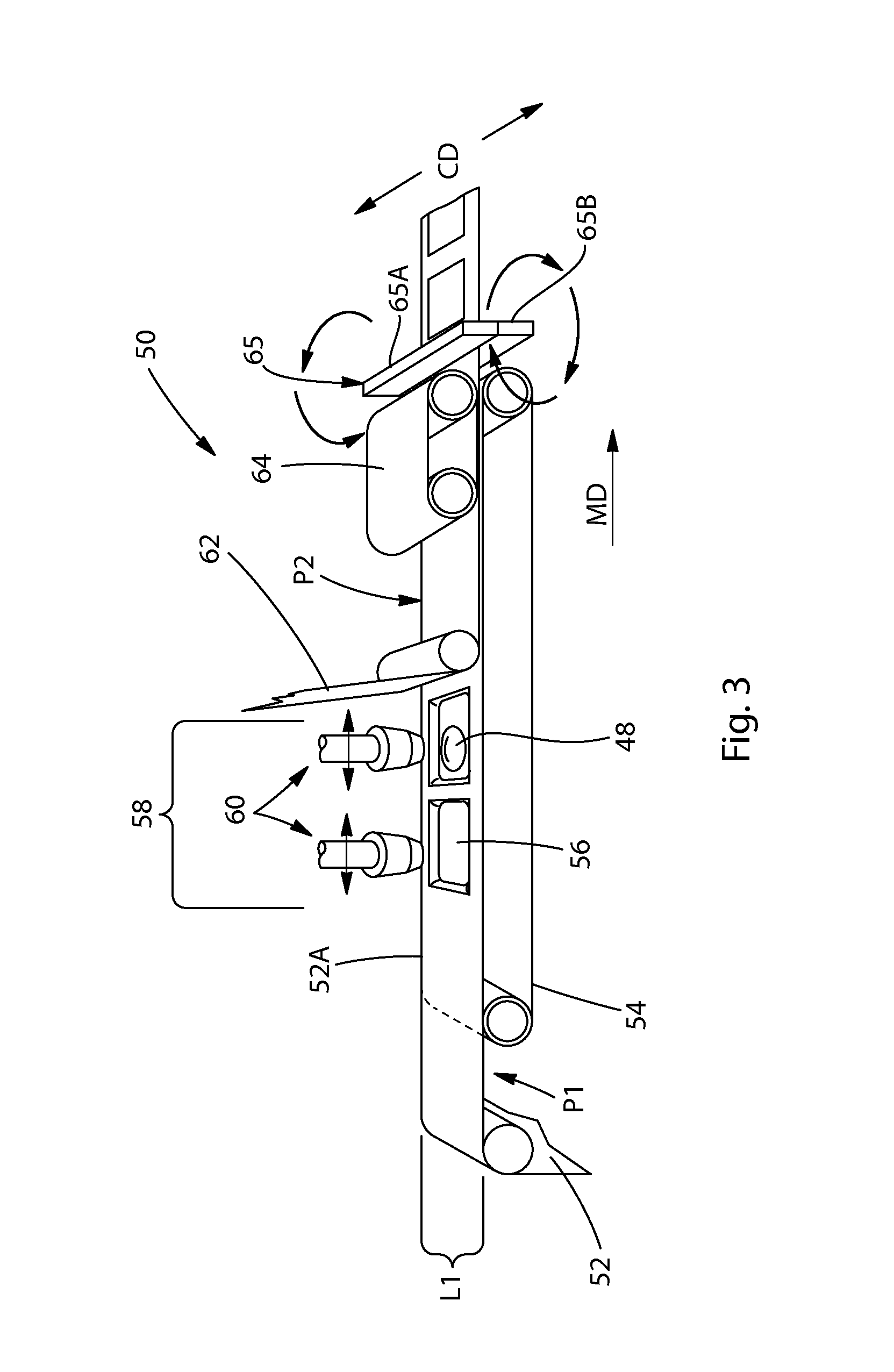

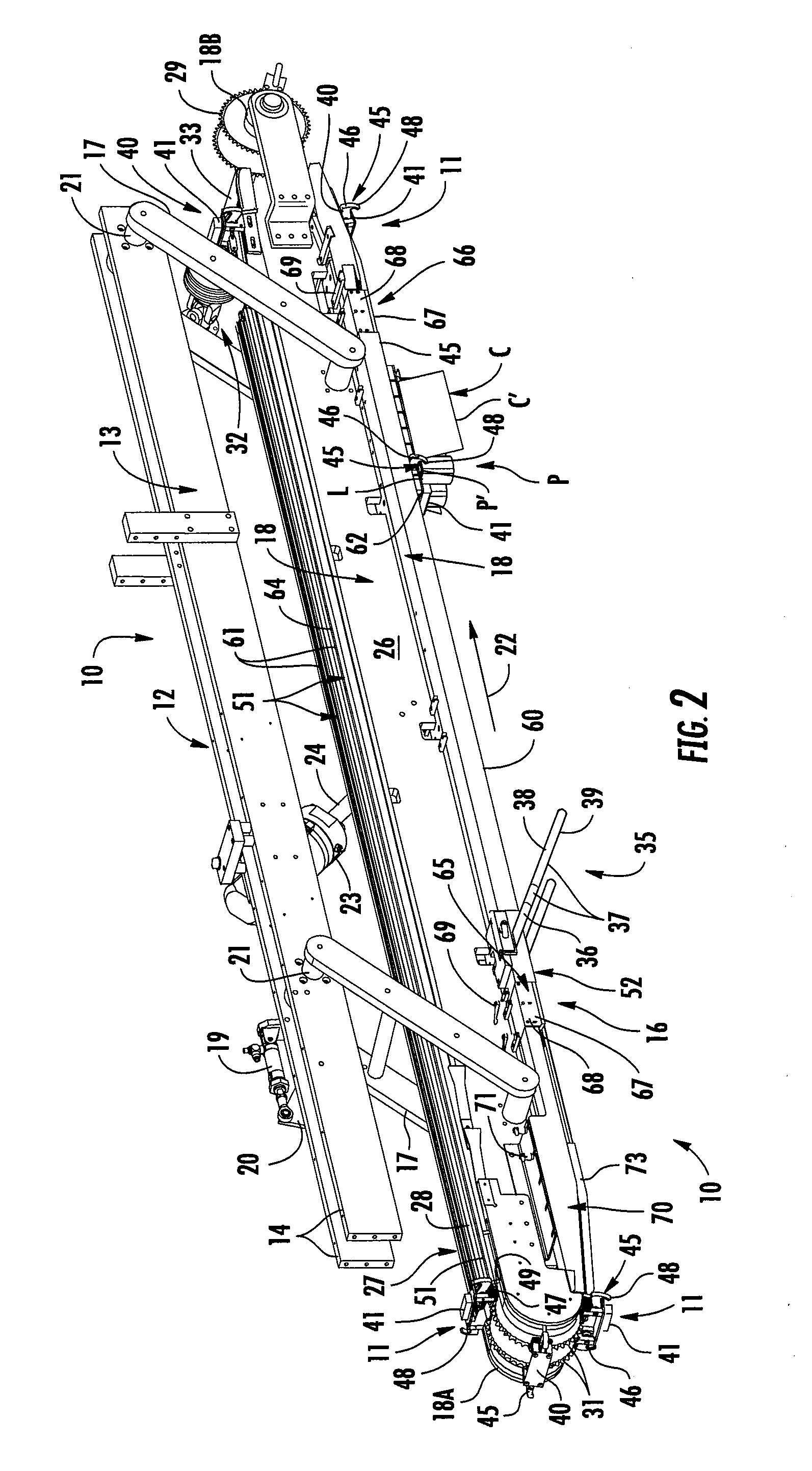

Package wrapping method and apparatus

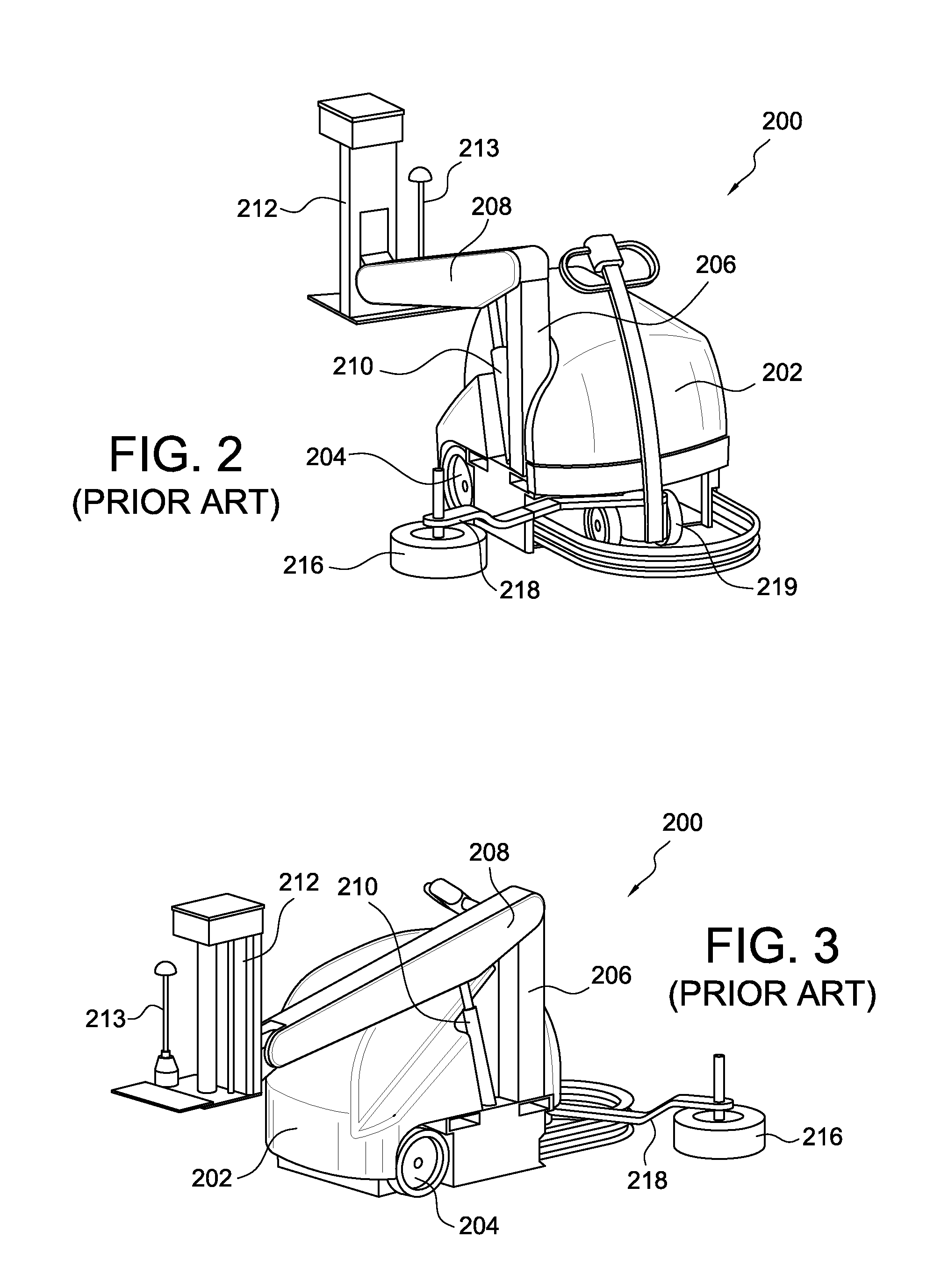

InactiveUS20070289253A1Improve matchWrapper folding/bending apparatusWrapper supporting apparatusSemi automaticTrailing edge

A semi-automatic gift or package wrapping method and apparatus is disclosed. The apparatus includes a machine frame that provides a work surface with measuring and wrapping sections. A sheet feed and cutting mechanism feeds paper from a role in two steps with a time pause in between for enabling a user or operator to partially wrap the package with part of the first section of dispensed paper web. Thereafter, the second section of paper web is dispensed and the web cut transversely at a trailing edge. Multiple selectable supply rolls are optionally provided, or a single roll machine can be used. Longitudinal cutters trim the sides of the paper to obtain a custom desired width for the full cut sheet. A user interface display controls machine functions such as start, continue and sheeter. In the sheeter mode, a selected number of sheets of a selected size can be dispensed and cut for use at another workstation to warp other boxes of known uniform size (i.e. shirt boxes at a department store).

Owner:MET TECH CORP A CORP ORGANIZED UNDER THELAWS OF THE STATE OF MISSISSIPPI

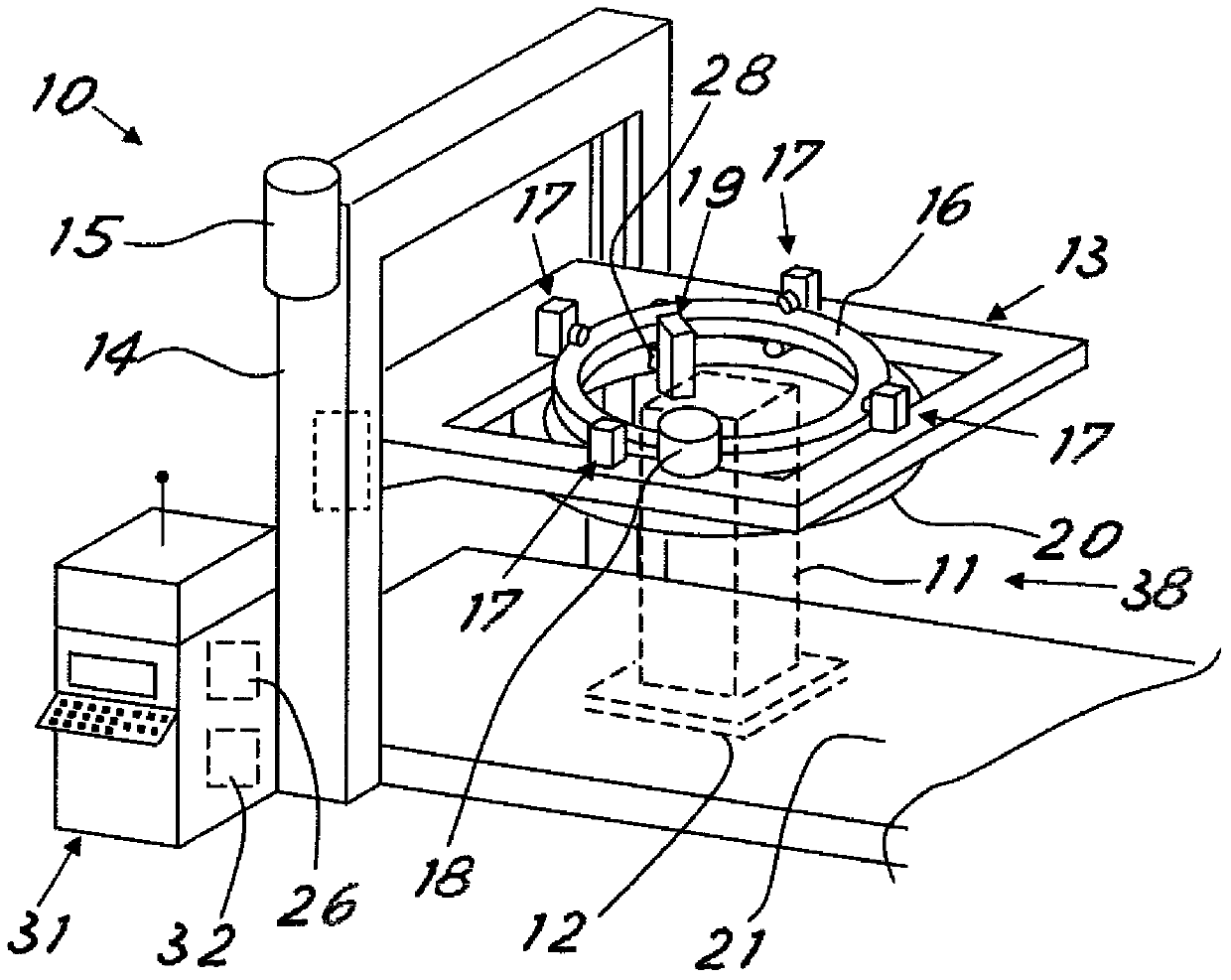

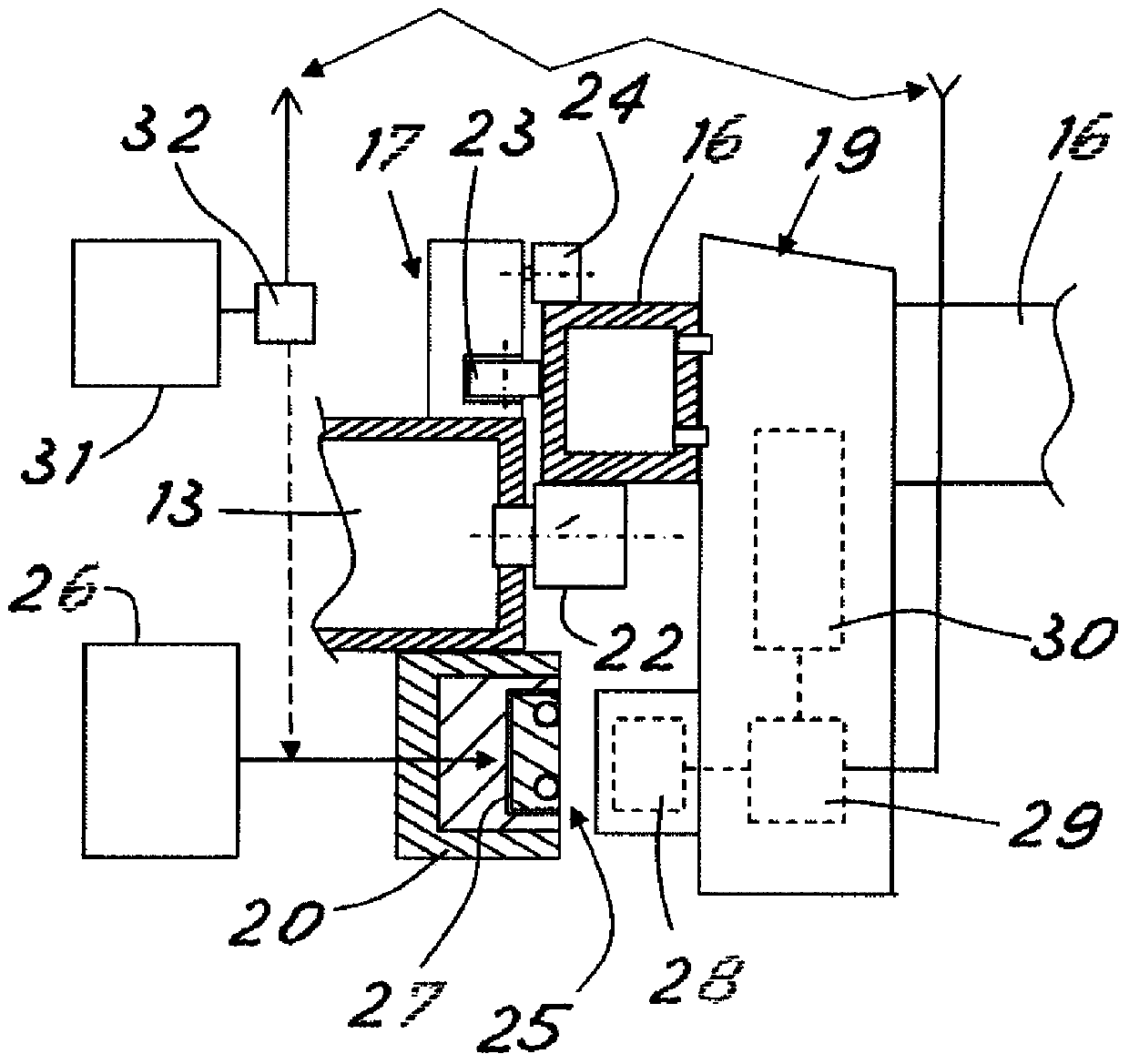

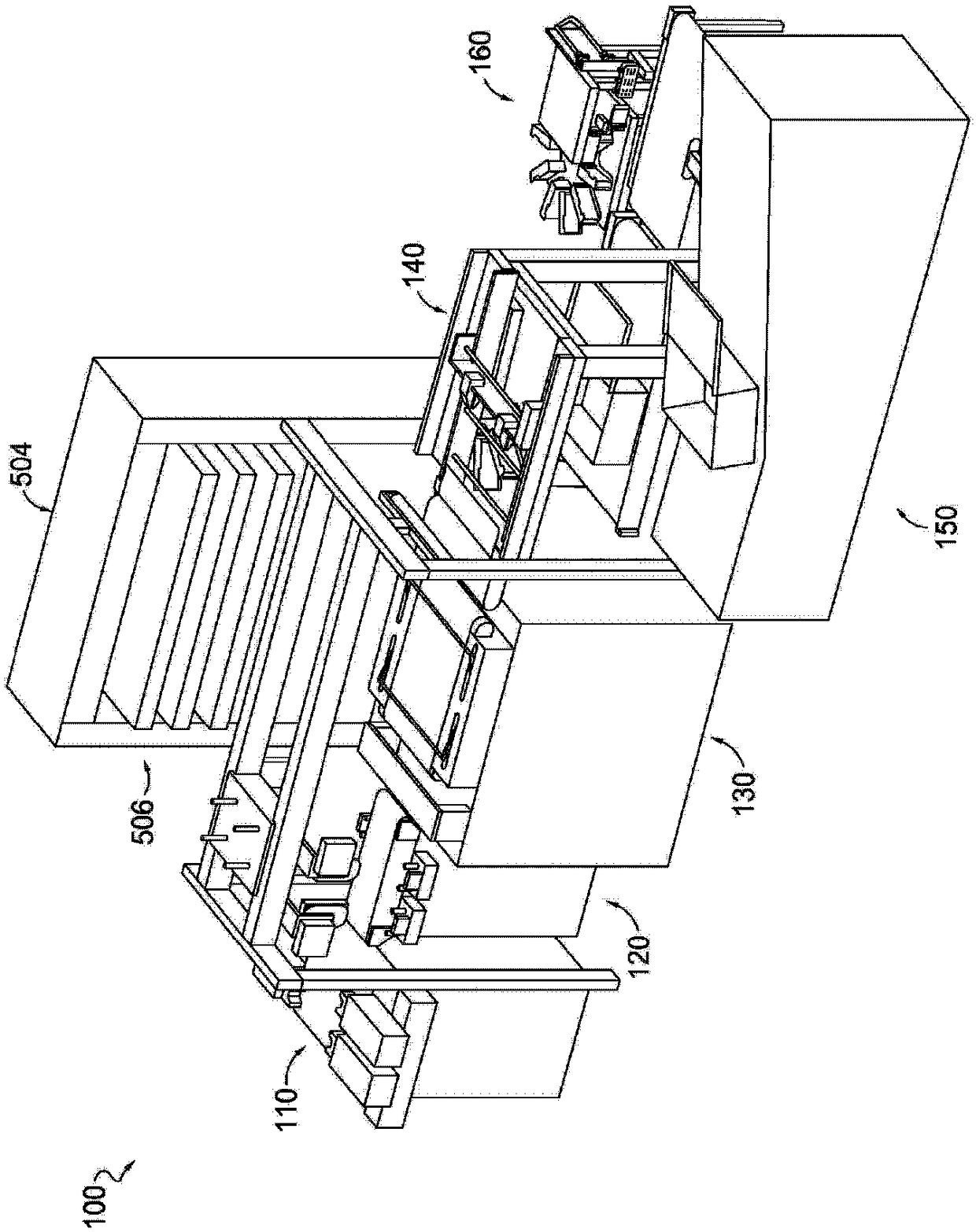

Multiple robot system

InactiveUS20130061558A1Web rotation wrappingWrapper folding/bending apparatusProgrammable logic controllerMultirobot systems

The present invention relates generally to film wrapping or packaging systems, and more particularly to a new and improved robotic film wrapping or packaging system which is not only substantially entirely automatic in its operation except for its initialization or START procedure, but in addition, a single programmable logic controller (PLC) can control the cyclic operations of one or more film wrapping or packaging robots.

Owner:SIGNODE IND GRP

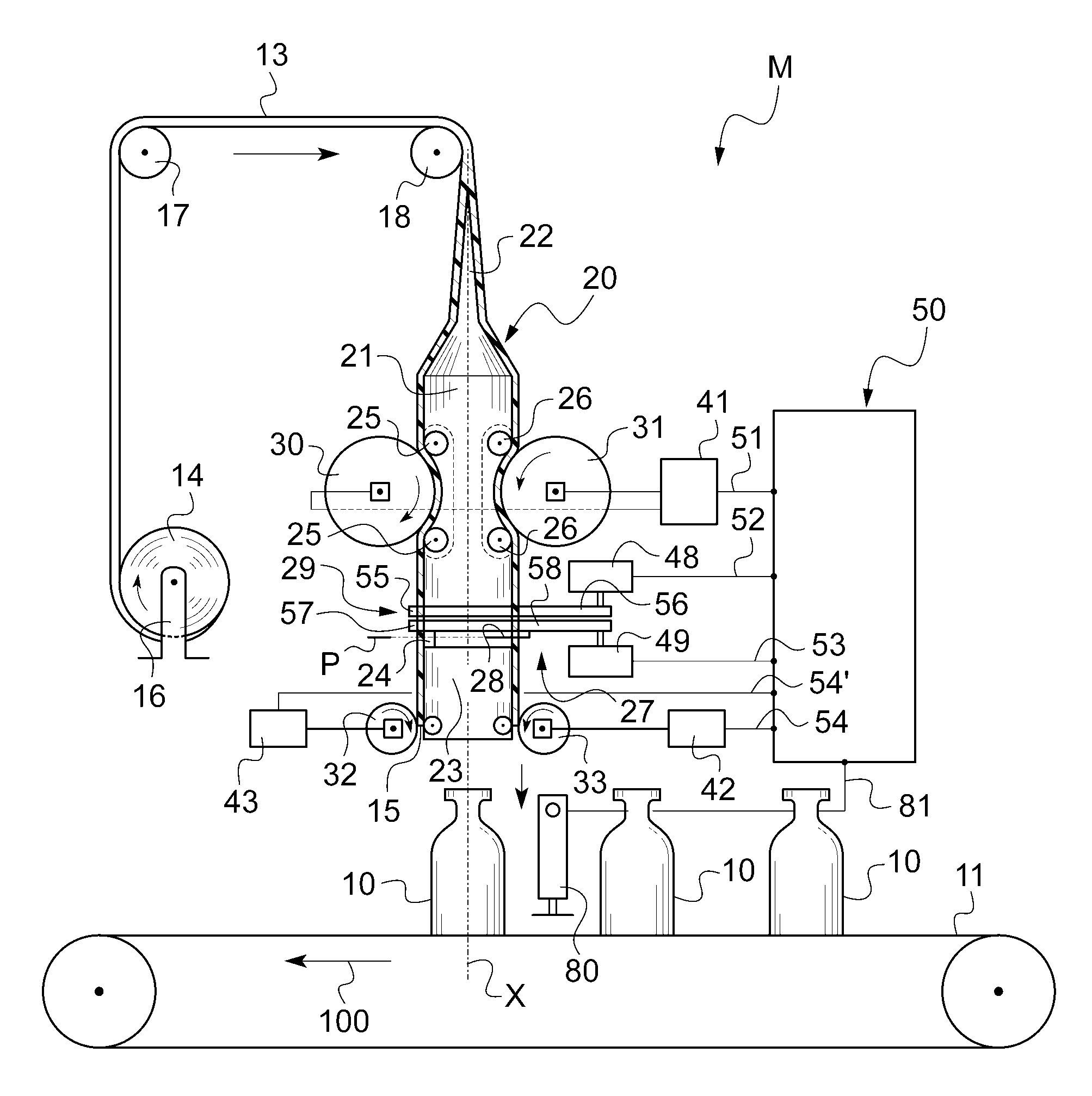

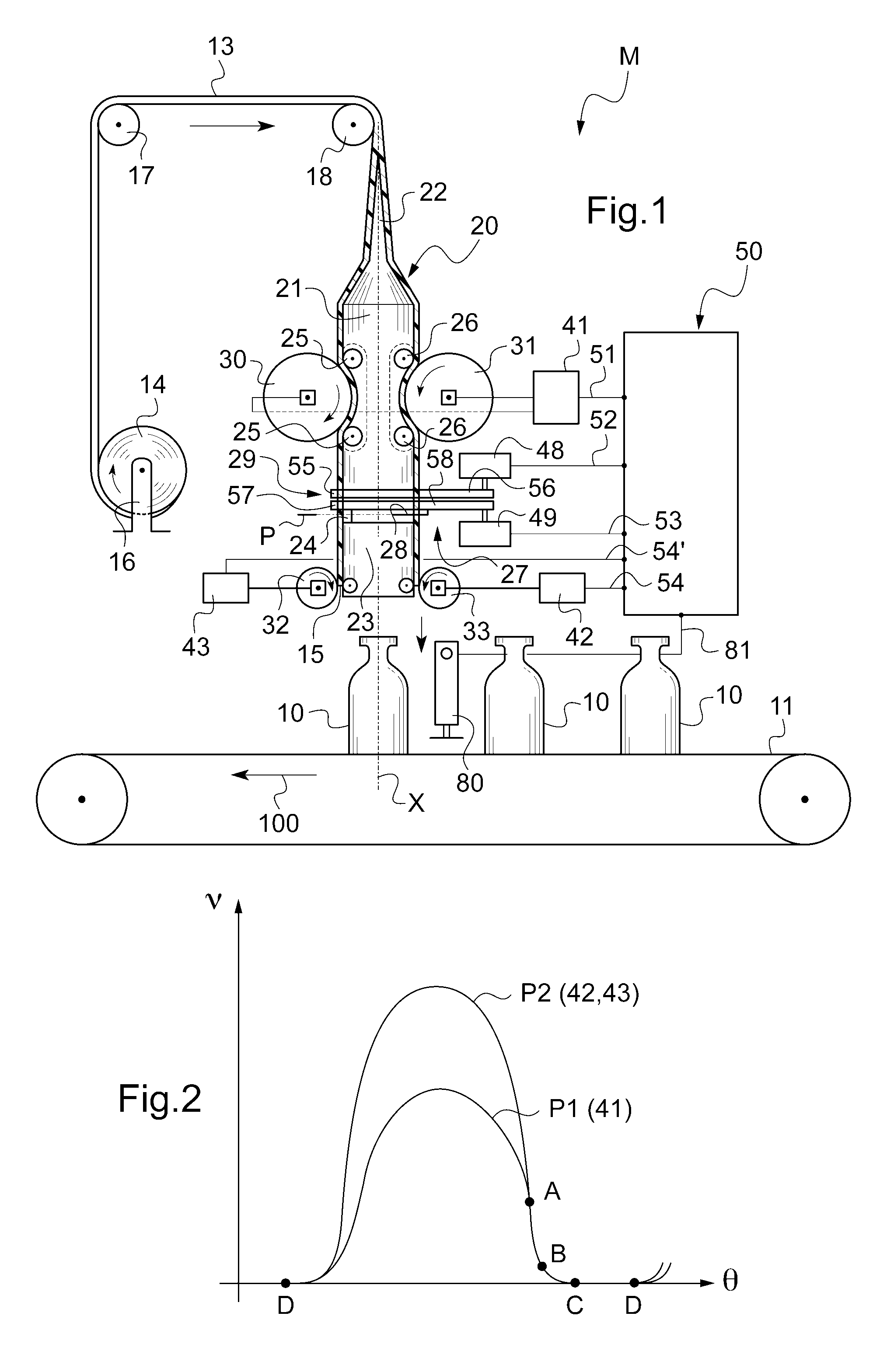

Device for placing sleeves on traveling articles

ActiveUS20100037556A1Eliminate riskRegular cut edgeWrappers shrinkageWrapping material feeding apparatusTangential contactEngineering

The invention relates to a device for placing sleeves on traveling articles, said sleeves being cut from a continuous sheath passing over a sheath-opening shaper, first outer wheels serving to advance the sheath along the shaper, and second outer wheels being provided downstream from cutter means for the purpose of ejecting the cut-off sheath segment, said wheels being driven in rotation by associated electric motors controlled synchronously by a virtual-shaft common electronic programmer. In accordance with the invention, the programmer is arranged to determine a continuous profile of speed variation for the associated electric motors, said profiles being bell-shaped and having a common end segment in which the profiles coincide, this corresponding to the motors having identical speeds, the length of the common end segment being selected so that the sheath is advanced beyond the point of tangential contact with the second wheels so that said sheath is pinched by said second wheels prior to being held stationary for the cutting and ejection pass.

Owner:SLEEVER INT

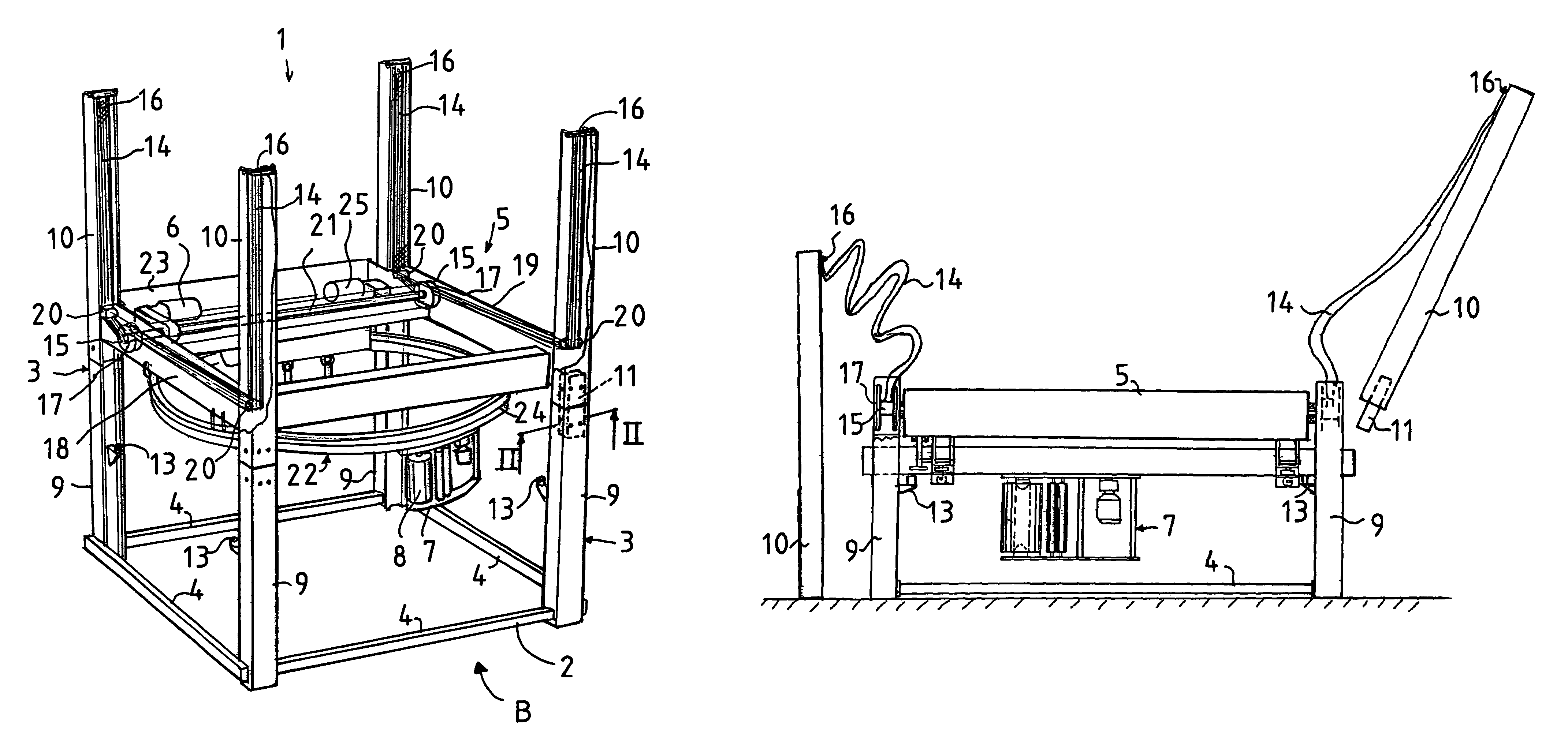

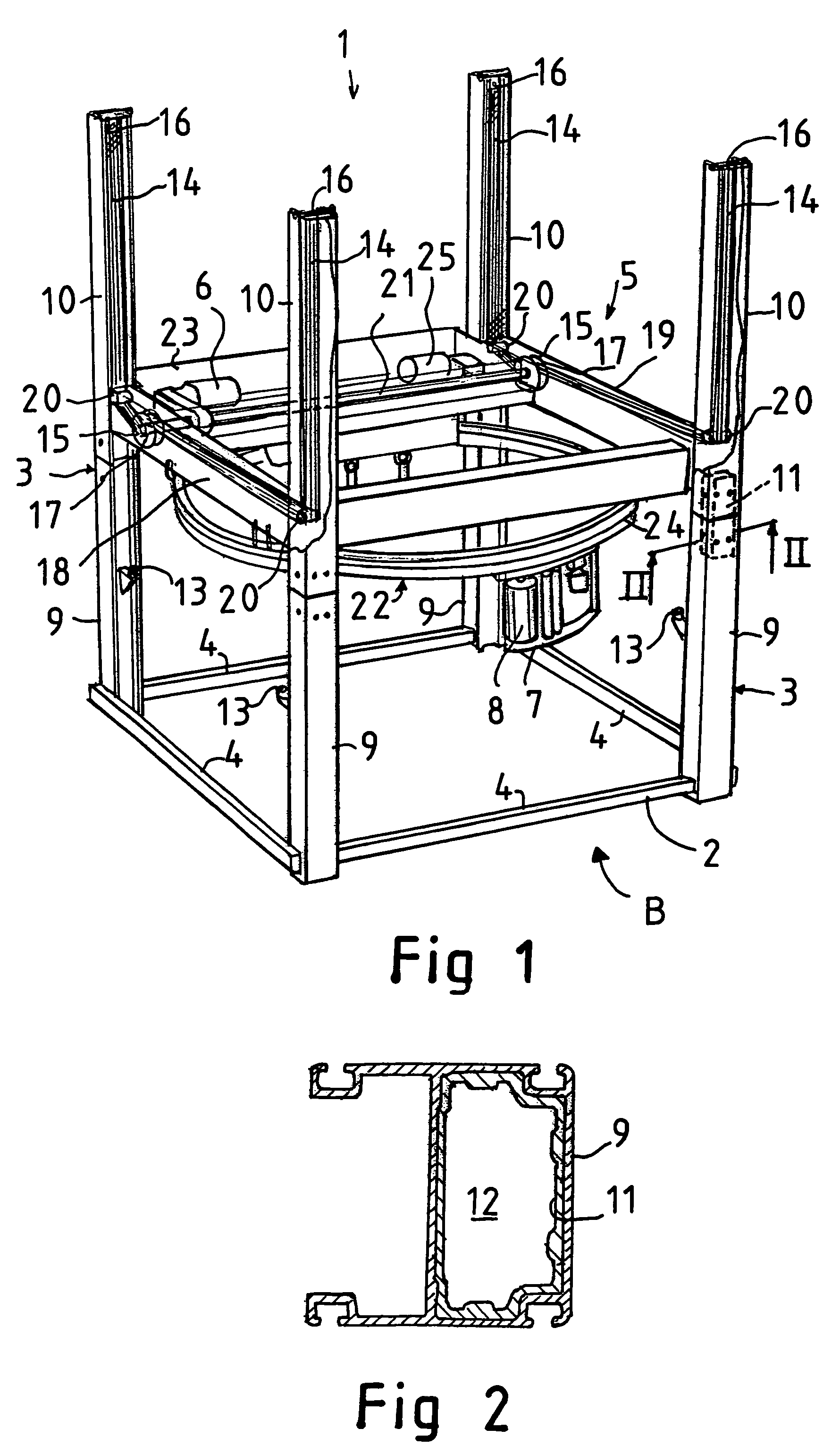

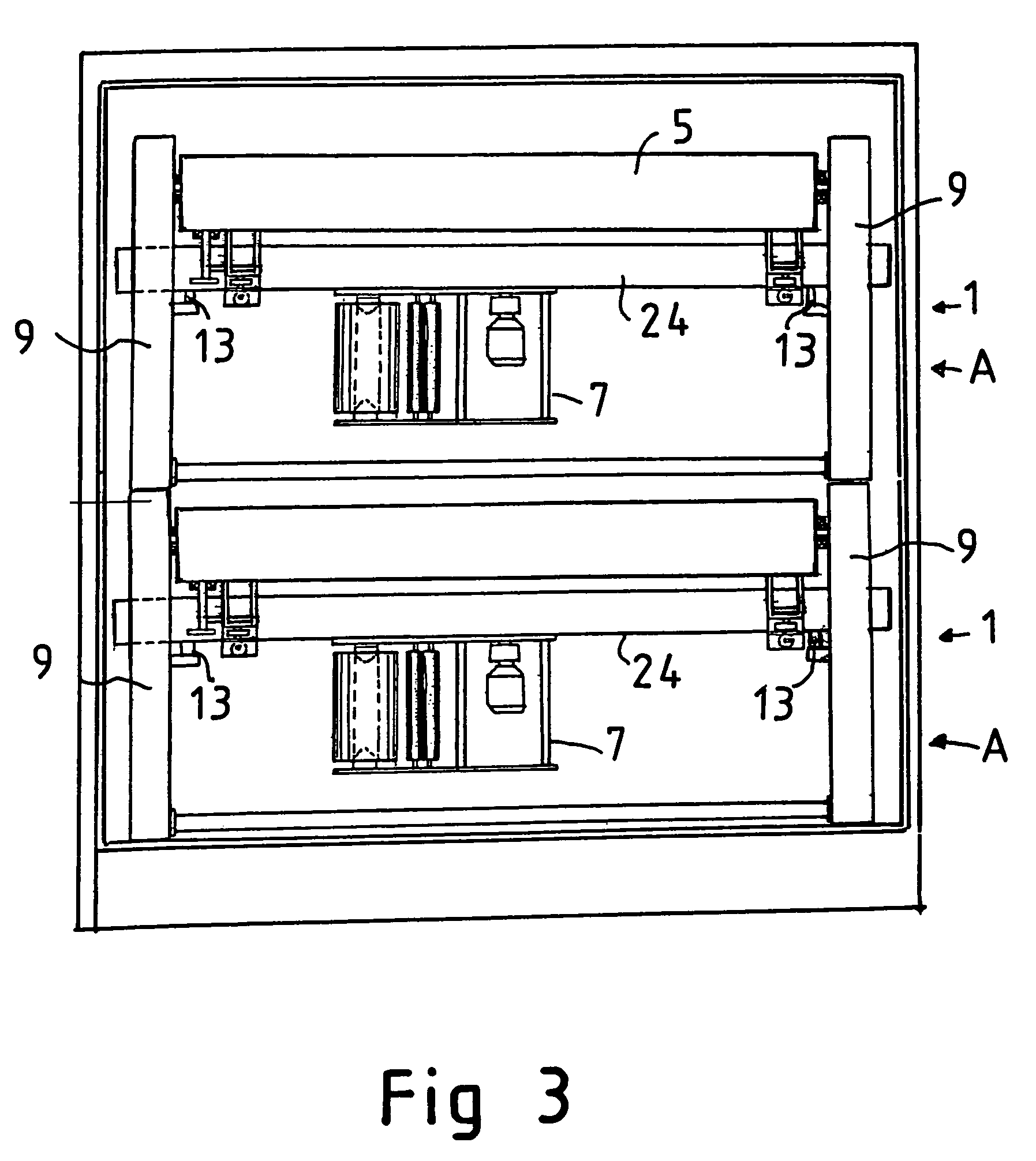

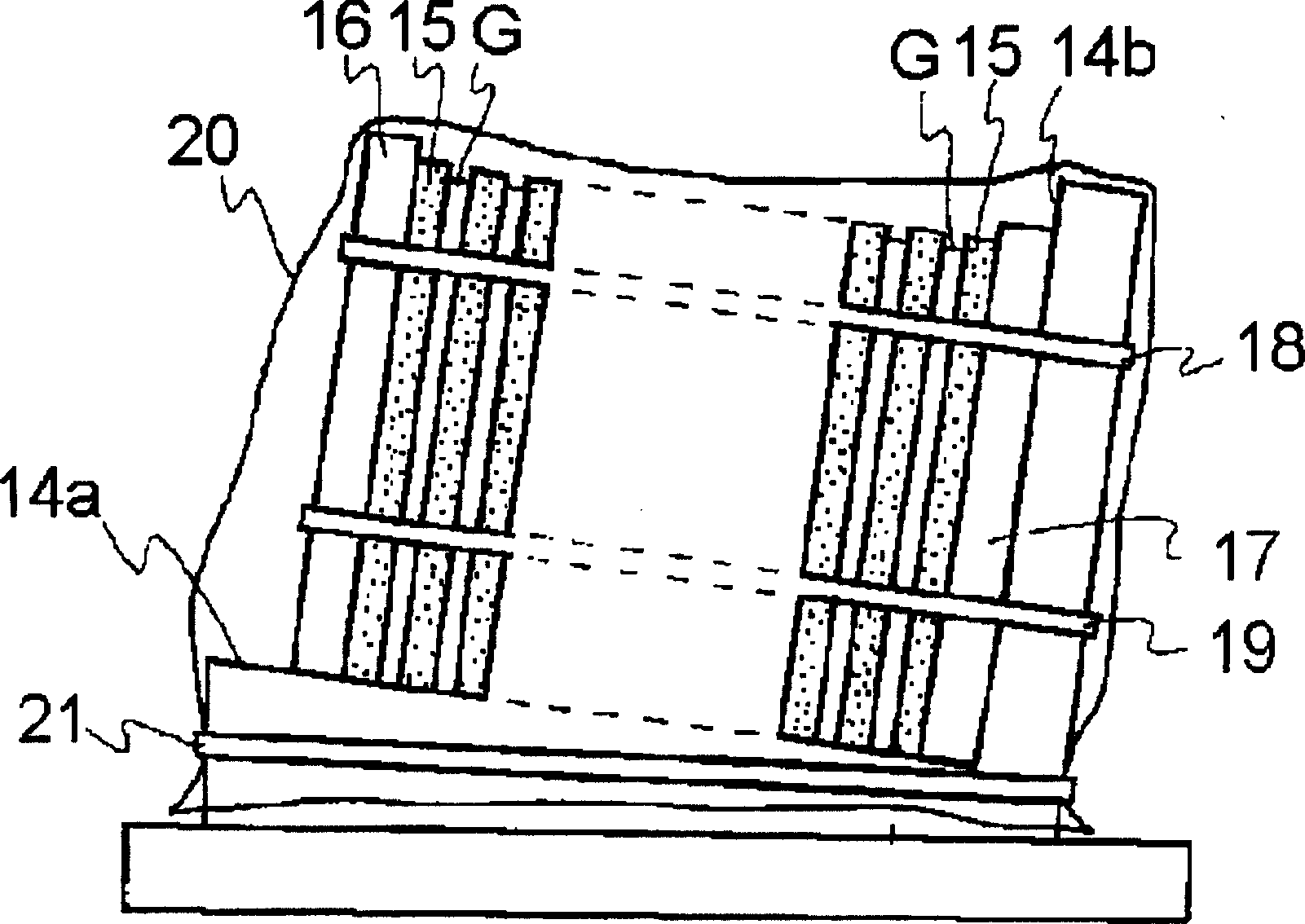

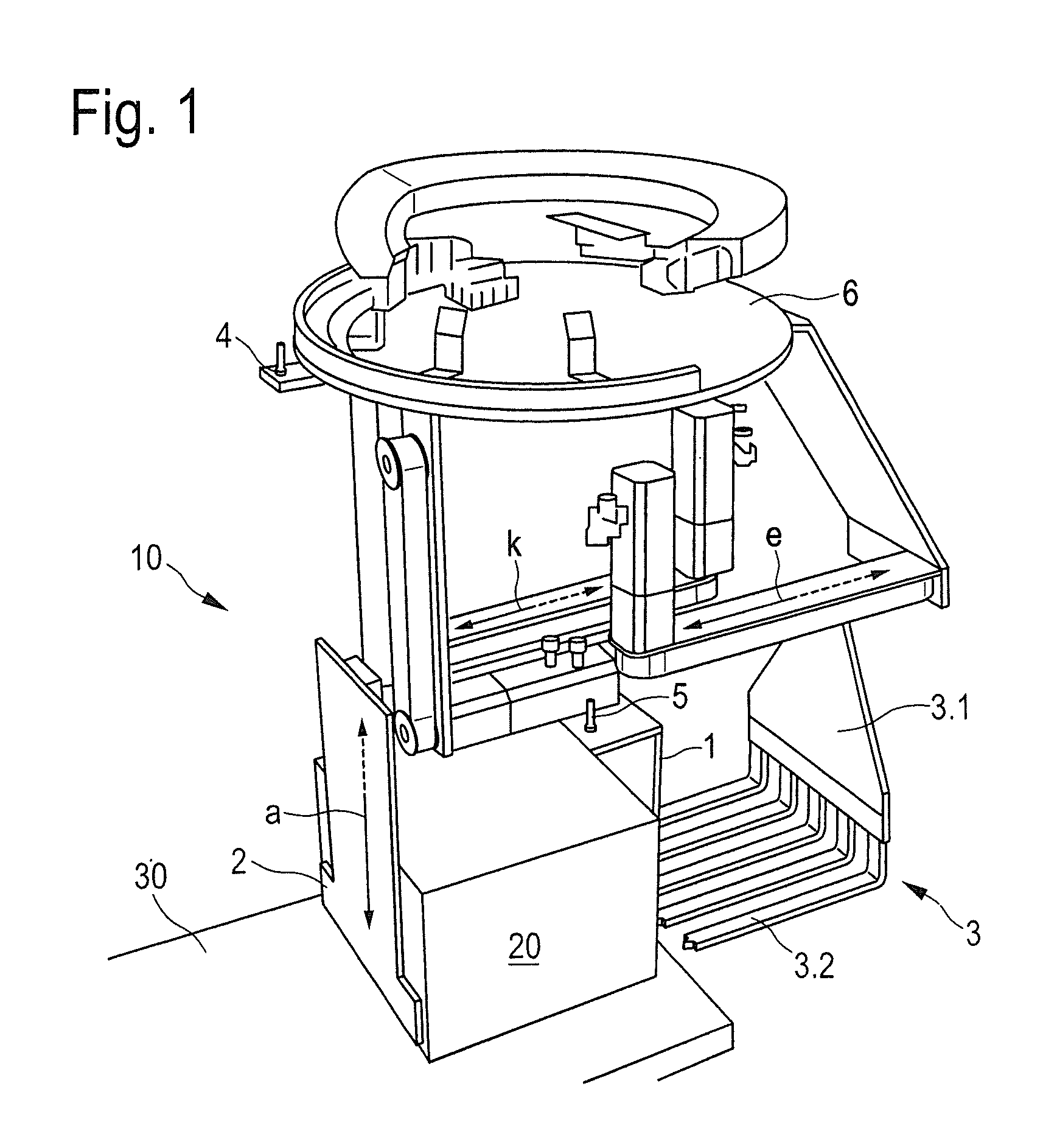

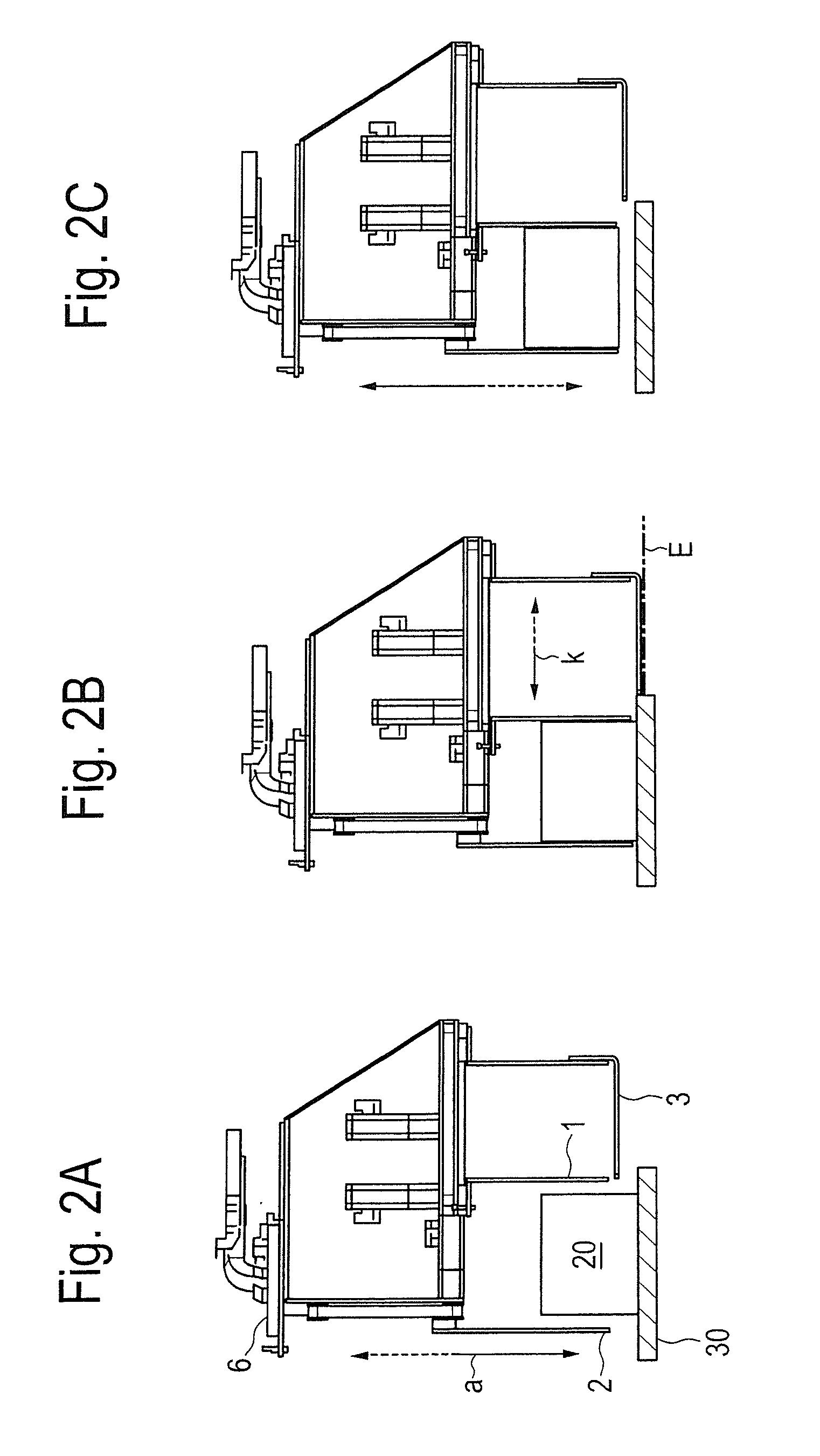

Wrapping machine and top foil wrapping machine

ActiveUS7036289B2Reduce Freight CostsEasily and quickly put into working orderWrappers shrinkageWeb rotation wrappingStructural engineeringEngineering

A wrapping machine and / or a top foil wrapping machine machine frame, which is supported on a fixed base and has upright vertical columns and horizontal cross members connecting the vertical columns to each other. Each vertical column has at least two column parts detachably joined together end on end, the column parts including a lower column part and an upper column part. Only the lower column parts of the vertical columns are connected to each other by the cross members while the upper column parts are not connected to each other. To store and / or transport the machine, the machine is reduced to a low size (A) for packaging, by detaching the upper column parts from the lower column parts of the vertical columns. The upper column parts may be reattached to the lower column parts to install the machine from the packaged size (A) to a full working size (B).

Owner:M HALOILA

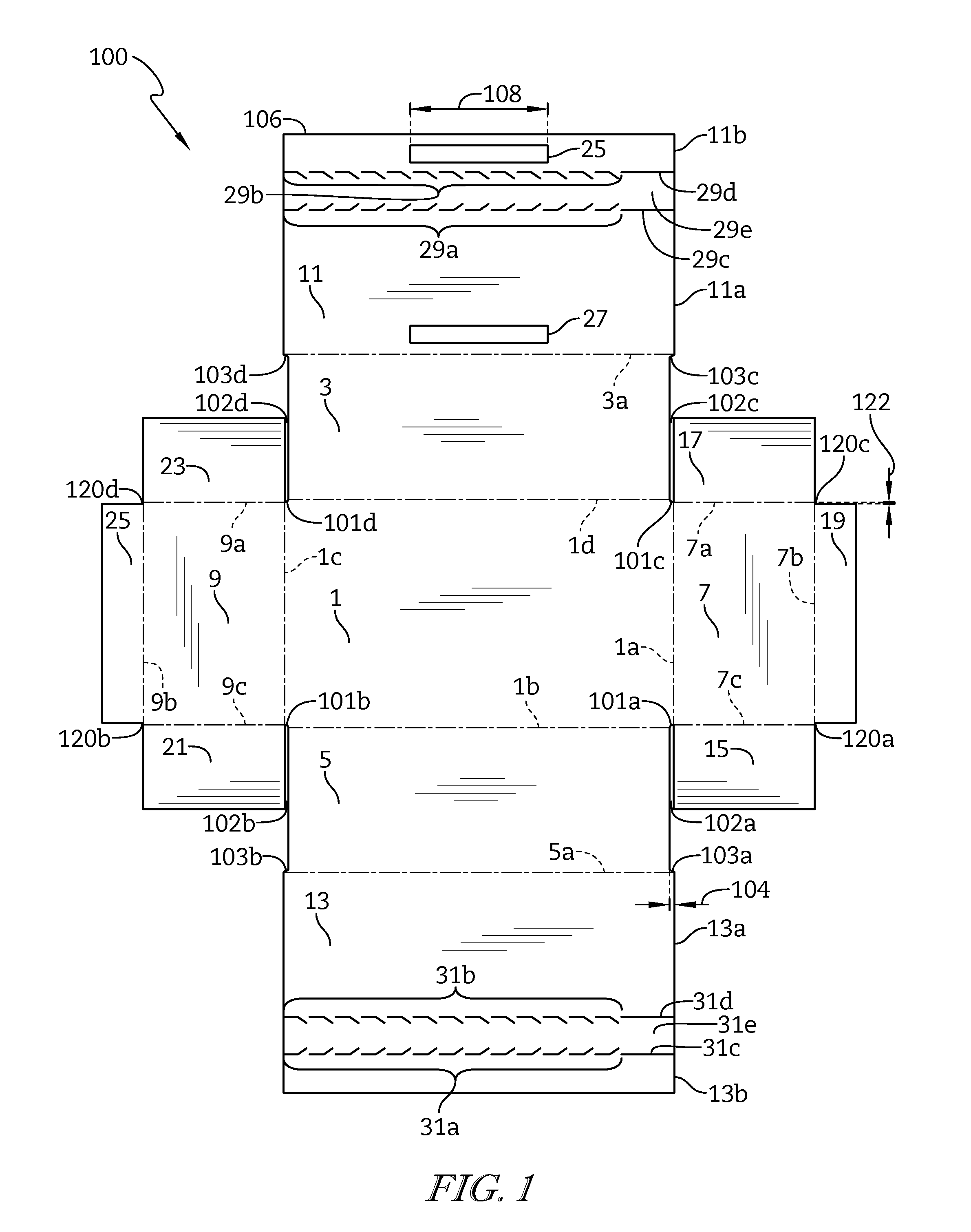

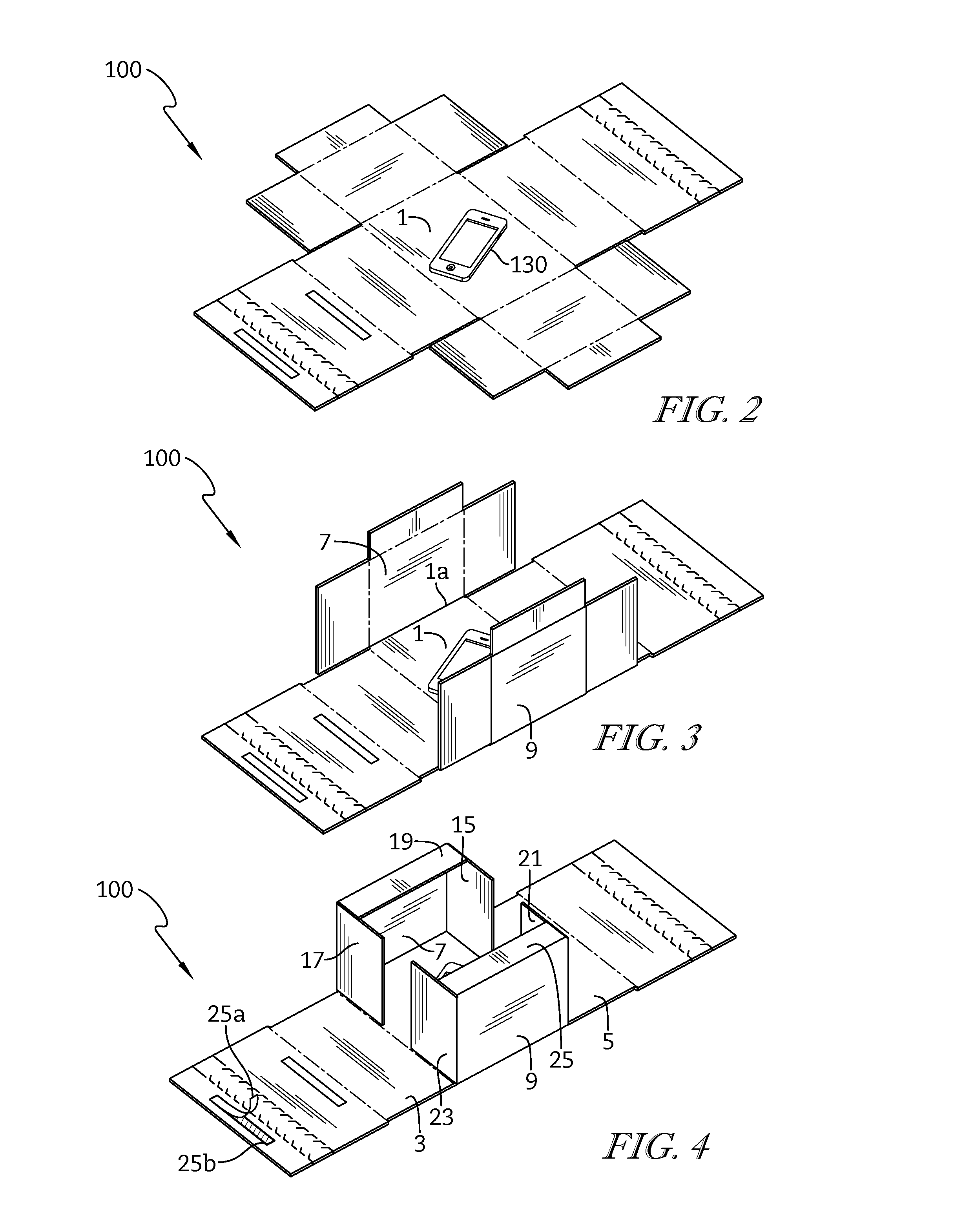

Reversible box with tear-away strips

ActiveUS20160122069A1Facilitate easyFacilitate efficient foldingWrapper folding/bending apparatusWrapper supporting apparatusPaperboardEngineering

A reversible paperboard container having a bottom panel, a front panel adjacent to and in foldable relationship with the bottom panel. A back panel is adjacent to and in foldable relationship with the bottom panel. A left side panel is adjacent to and in foldable relationship with the bottom panel, a right side panel is adjacent to and in foldable relationship with the bottom panel. A first top panel is adjacent to and in foldable relationship with the back panel, and a second top panel is adjacent to and in foldable relationship with the front panel. The first top panel includes a first adhesive strip to sealingly close the paperboard container into a closed configuration. A first tear-away strip is included on the first top panel to open the paperboard container from the closed configuration, and a second adhesive strip to sealingly close the paperboard container into a reversed, closed configuration. The second top panel includes a second tear-away strip to open the paperboard container from the reversed, closed configuration.

Owner:BIG BOY SCOTTY S

Rotary wrapping machine for packaging objects

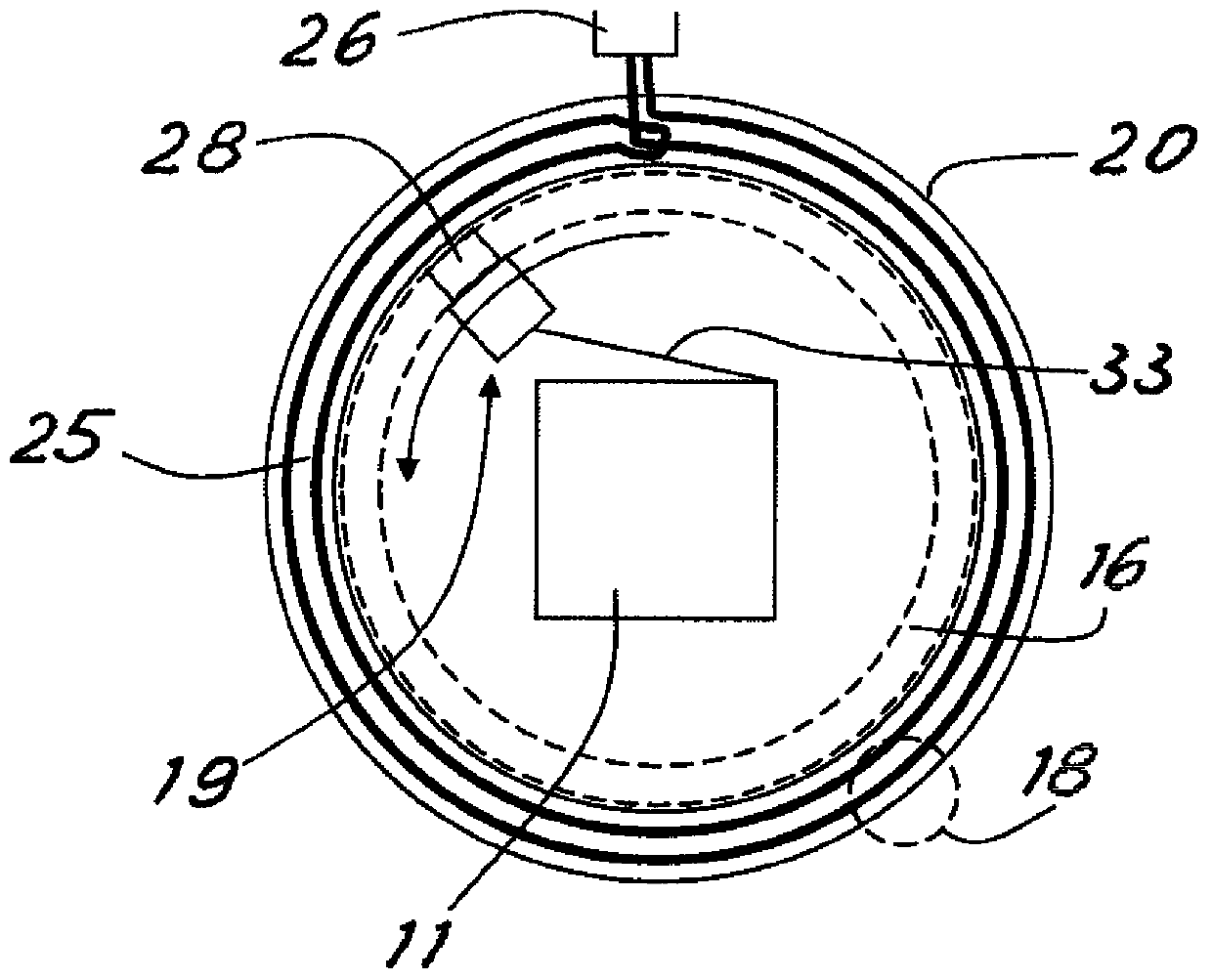

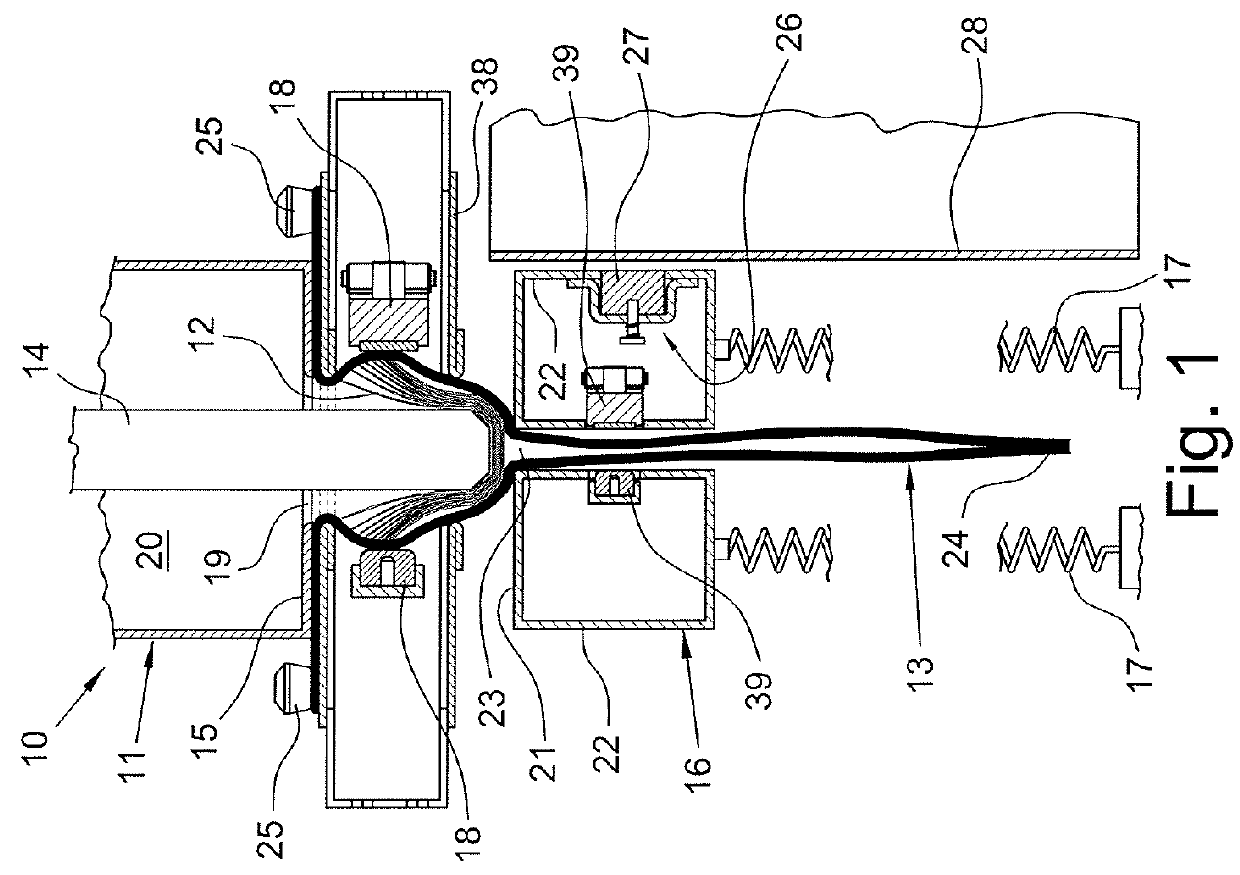

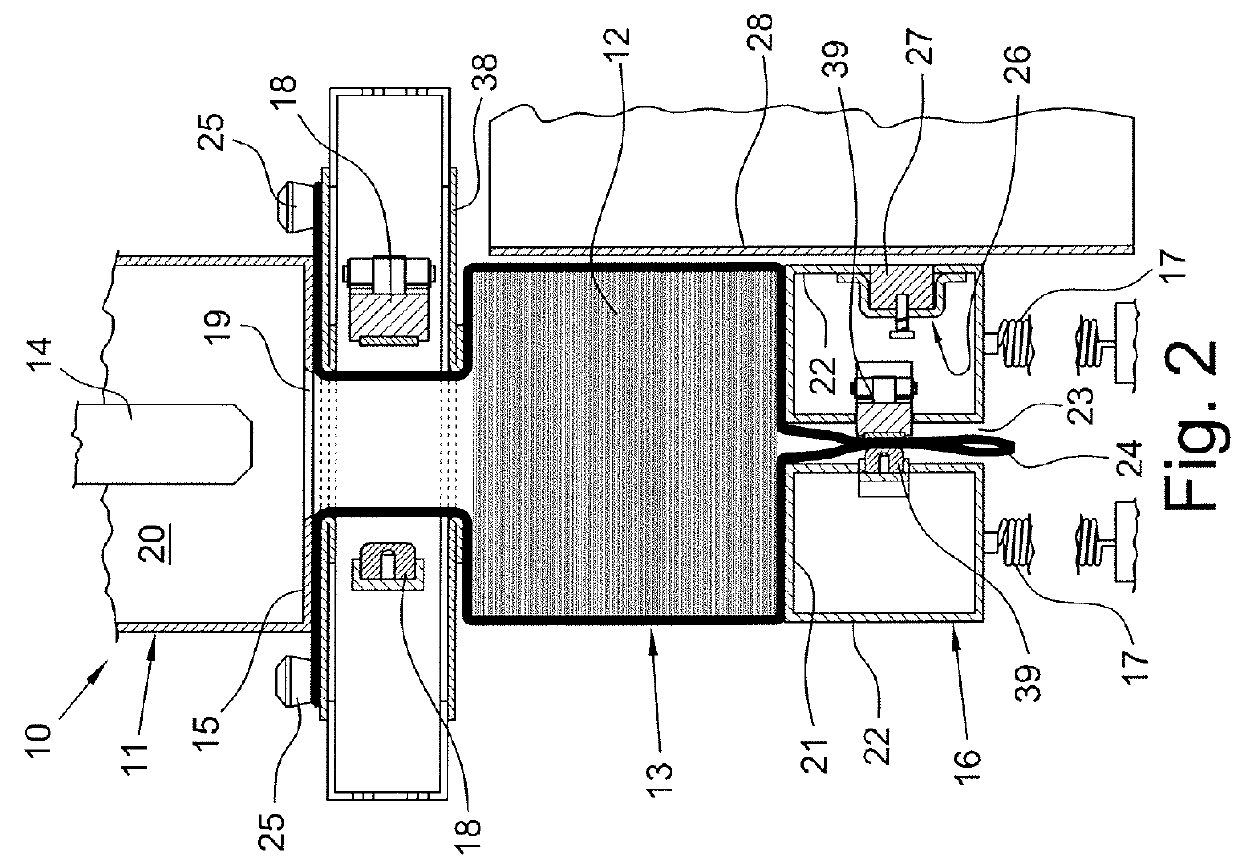

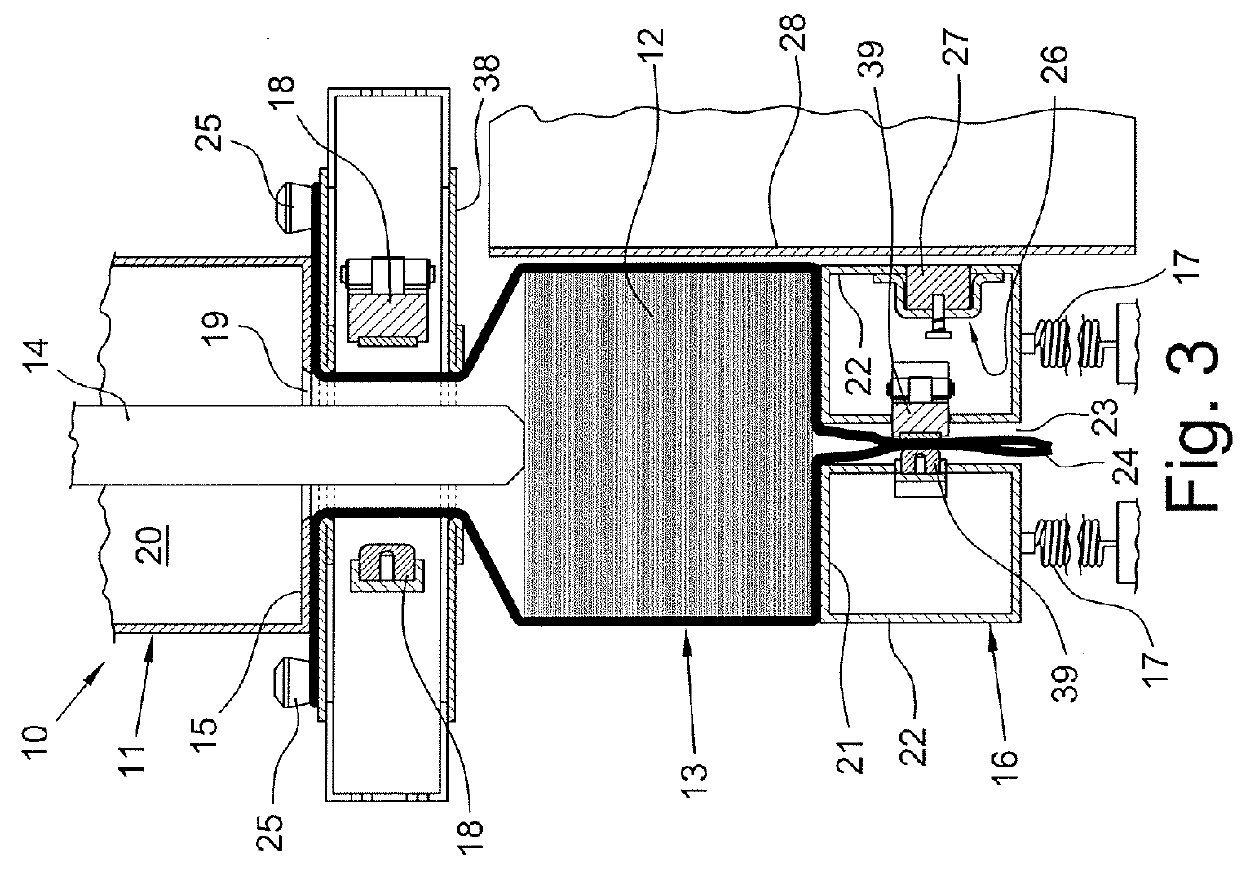

ActiveCN104203753AElectromagnetic wave systemWrapping material feeding apparatusElectricityElectric power transmission

A rotary wrapping machine (30, 110) for packaging products by means of a film unwound from a reel comprises a frame (13, 113) carrying a dispensing unit ( 19, 119) which is electrically controlled to dispense the packaging film from a reel of film present in the dispensing unit (19, 119). The dispensing unit is supported on the frame so as to be driven rotationally along a closed path around a packaging zone (38, 138) which contains a product to be wrapped with the film. Along the closed path there is a power supply antenna (25, 125) which is connected to an antenna power supply unit (26, 126) for transferring, by means of electrical induction, electric power to a corresponding receiver (28, 128) which is movable along the antenna together with the said dispensing unit and which supplies in turn electric power to the dispensing unit.

Owner:MESSERSI PACKAGING

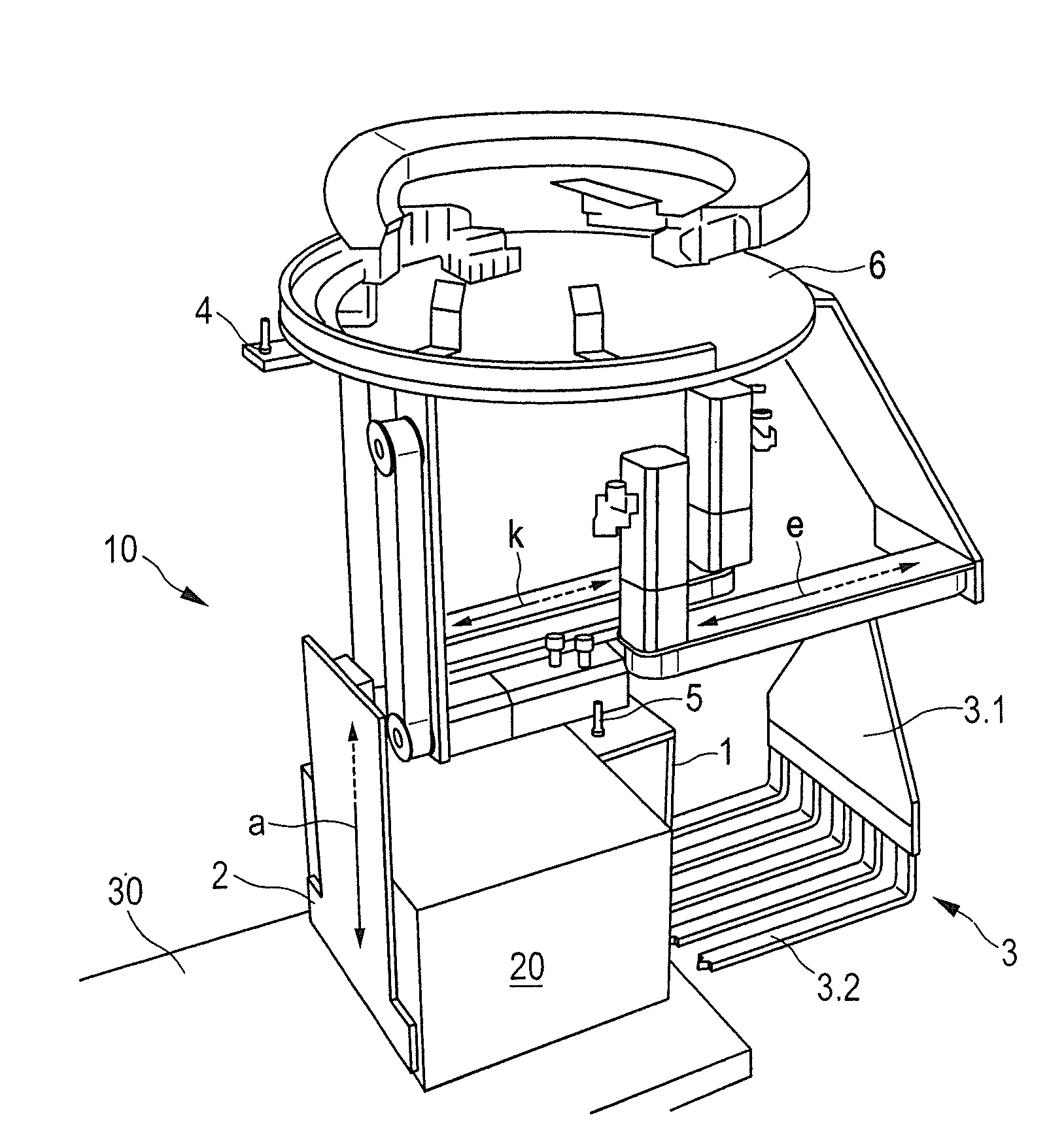

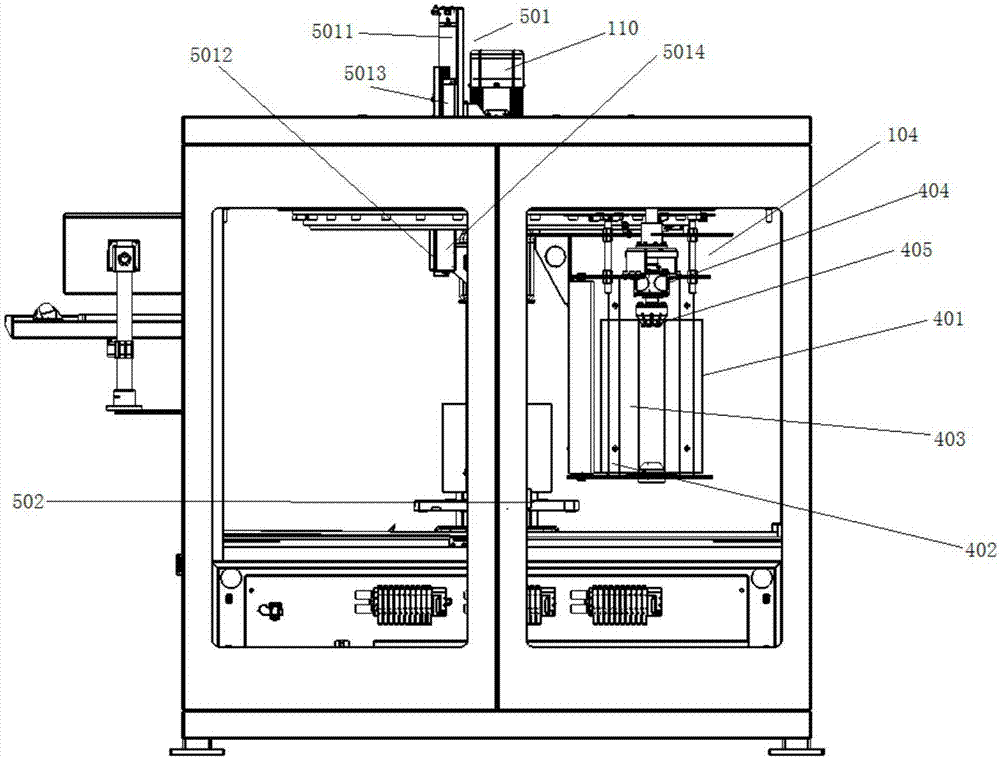

Device for filling and closing bags for containing paper documents, such as banknotes and the like

ActiveUS20160031574A1Simple and cost-effective and reliablePaper article packagingWrapper supporting apparatusThin membraneEngineering

A device for filling and closing disposable bags for containing banknotes comprises an upper container for temporarily housing banknotes, provided with a bottom with an opening for the exit of the banknotes from the container, a piston for pushing the banknotes towards the opening on the bottom of the container, a bag made of flexible plastic film, intended to be filled with the banknotes temporarily housed in the container, a support for the bag containing the banknotes, vertically movable through controlled lowering means and placed below the container, sealing bars arranged between the upper container and the movable support, and an electromagnetic stop element that can be controlled to lock the movable support with respect to the sealing bars, said electromagnetic stop element consisting of an electromagnet applied to the movable support and of a fixed element made of ferromagnetic material, adapted to face the electromagnet in operative condition.

Owner:CIMA SRL

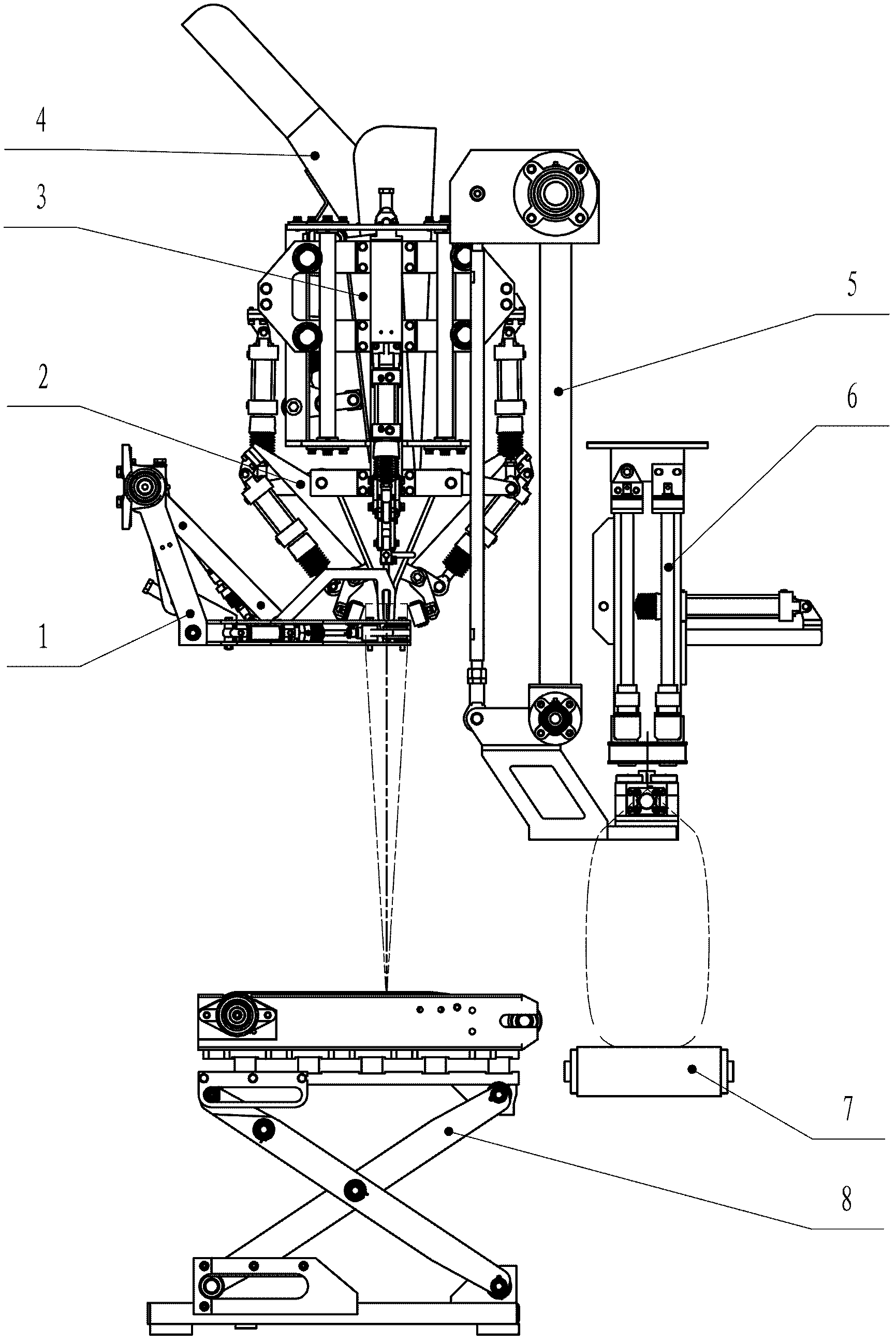

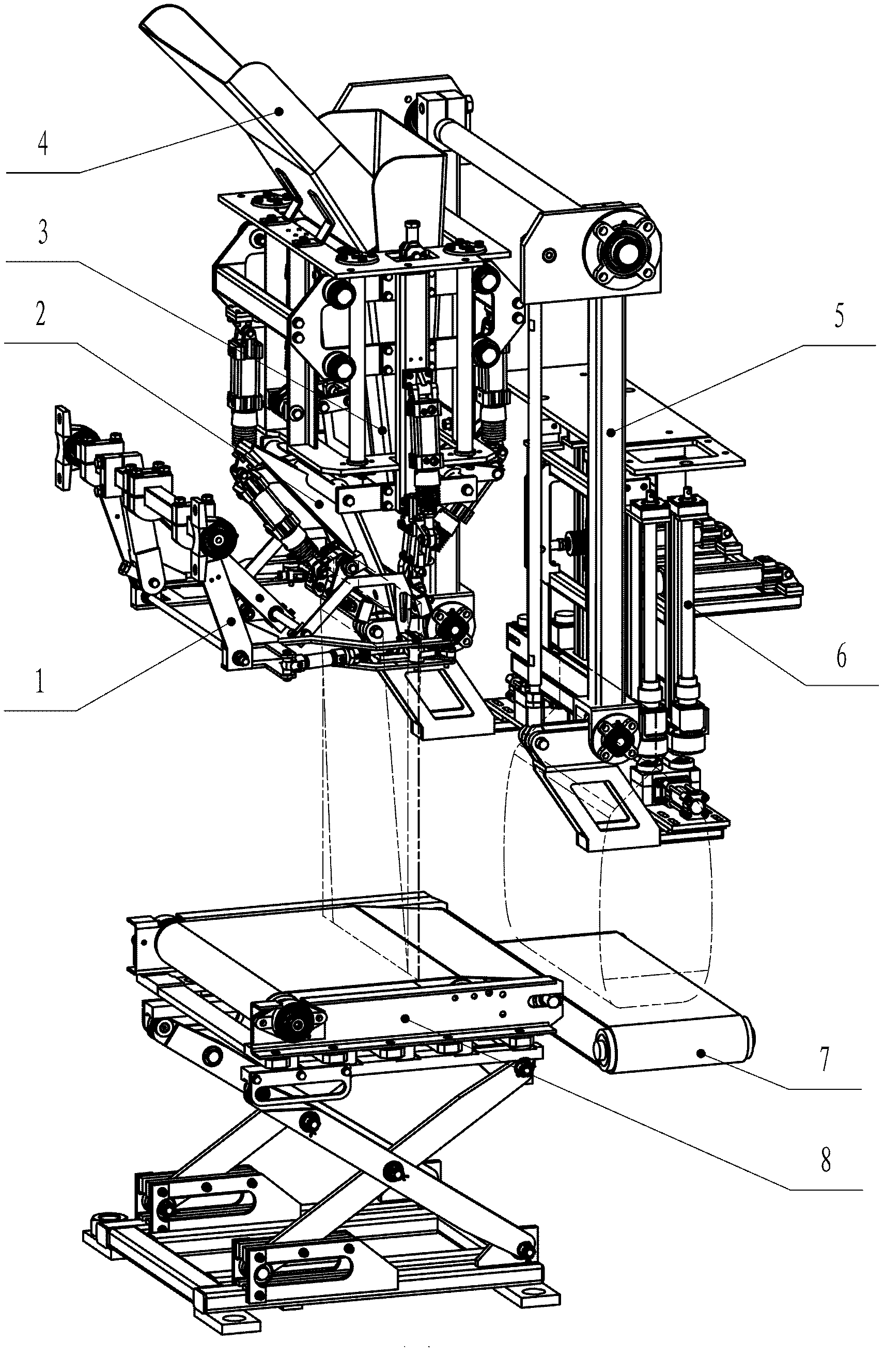

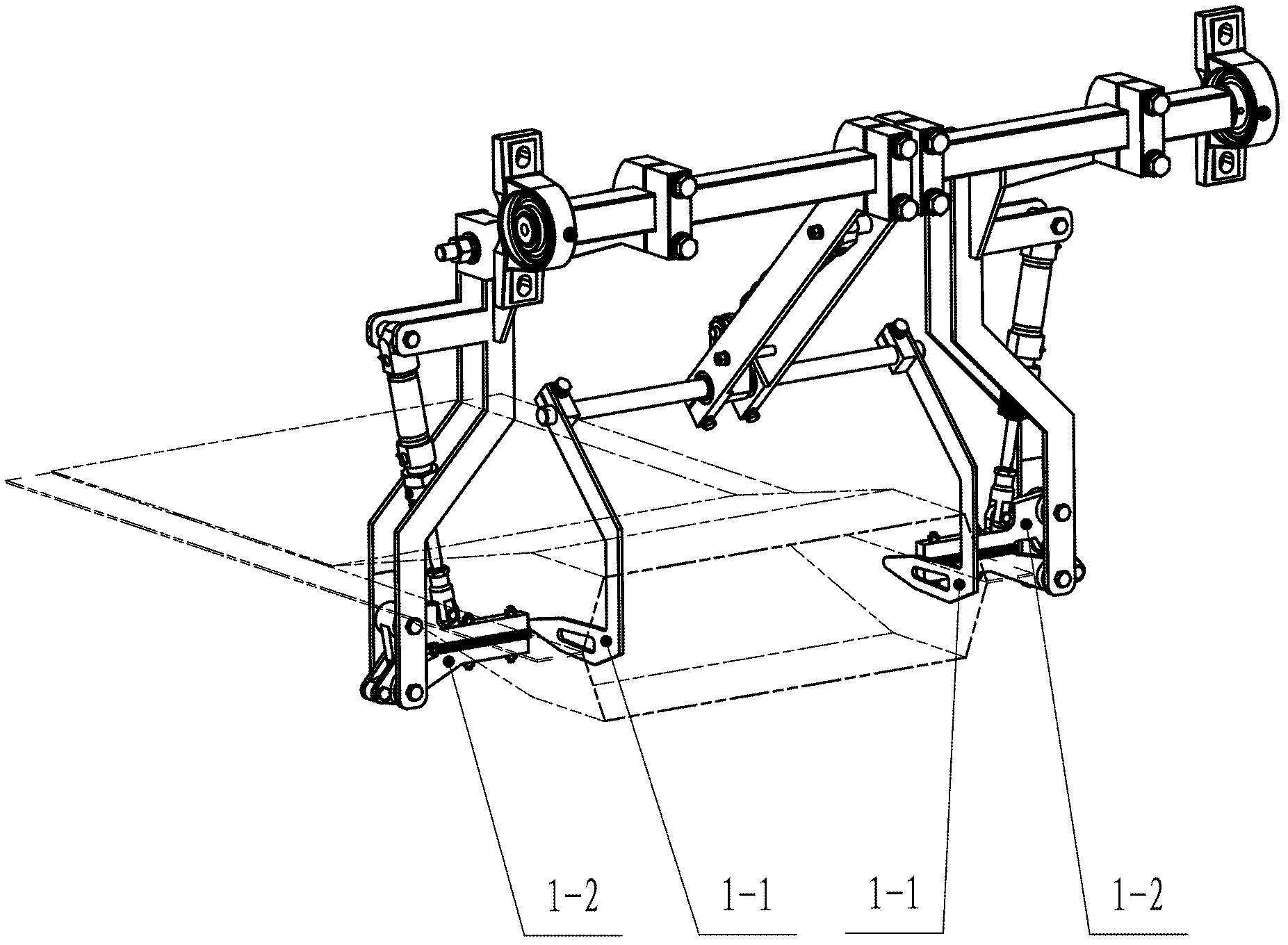

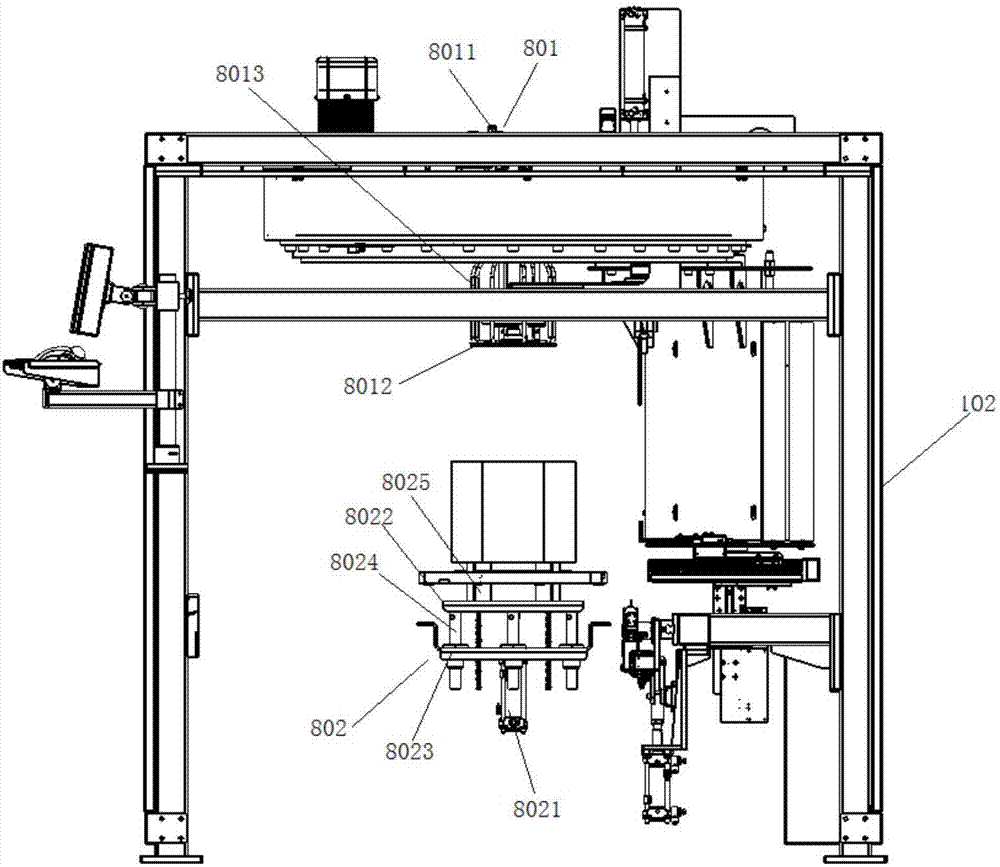

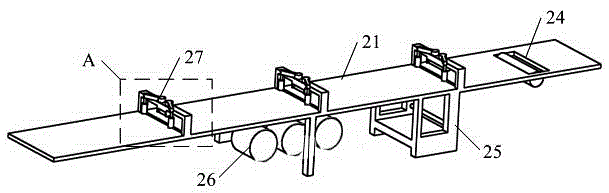

Secondary bagging method and device

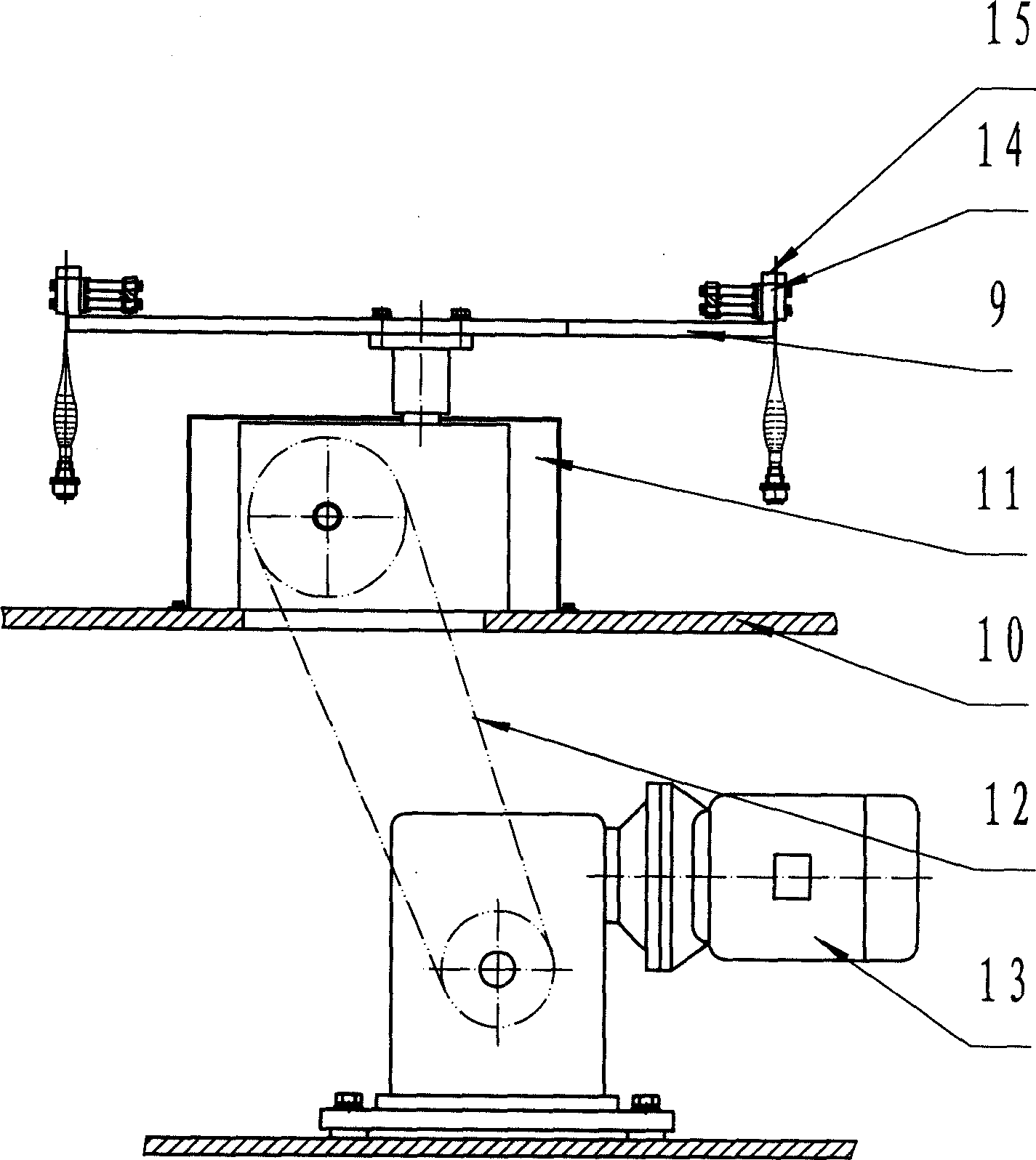

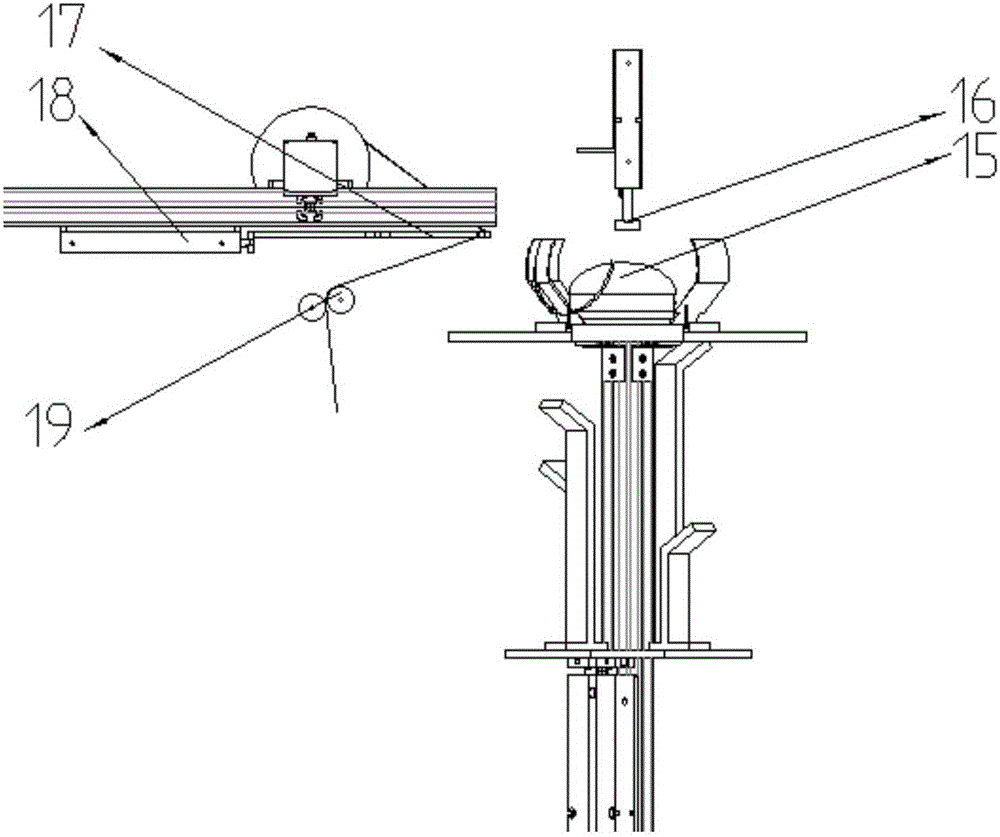

ActiveCN102633014ARealize the function of secondary baggingSimple structureWrapper supporting apparatusBelt conveyorEngineering

Discloses are a secondary bagging method and a device. The secondary bagging method includes steps: (1) taking an empty bag; (2) sleeving the empty bag; (3) clamping the empty bag; (4) opening a bag opening; (5) filling the bag; (6) dropping the bag; (7) shaping the bag opening; (8) grabbing the filled bag; (9) conveying the filled bag; (10) clamping the filled bag; and (11) outputting the filledbag. The device comprises a bag sleeving mechanism (1), a bag clamping mechanism (2), a buffering mechanism (3), an oblique chute (4), a bag shifting mechanism (5), an opening clamping mechanism (6),a belt conveyor (7) and a lifting conveyor (8). By the aid of the bagging method, bags of articles or rectangular blocky articles can be automatically filled in outer-layered packaging bags, and impact generated during bagging is reduced.

Owner:HARBIN BOSHI AUTOMATION

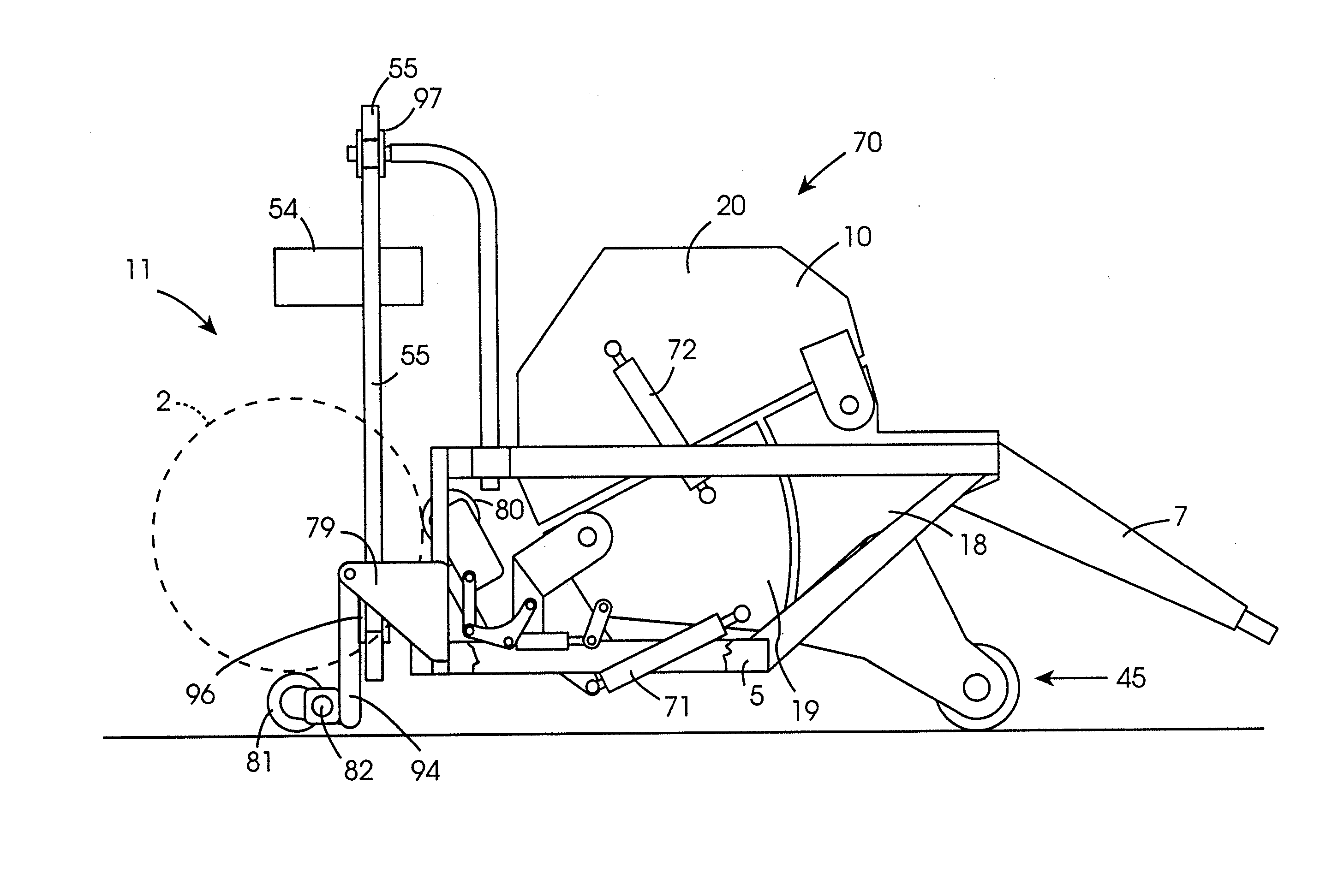

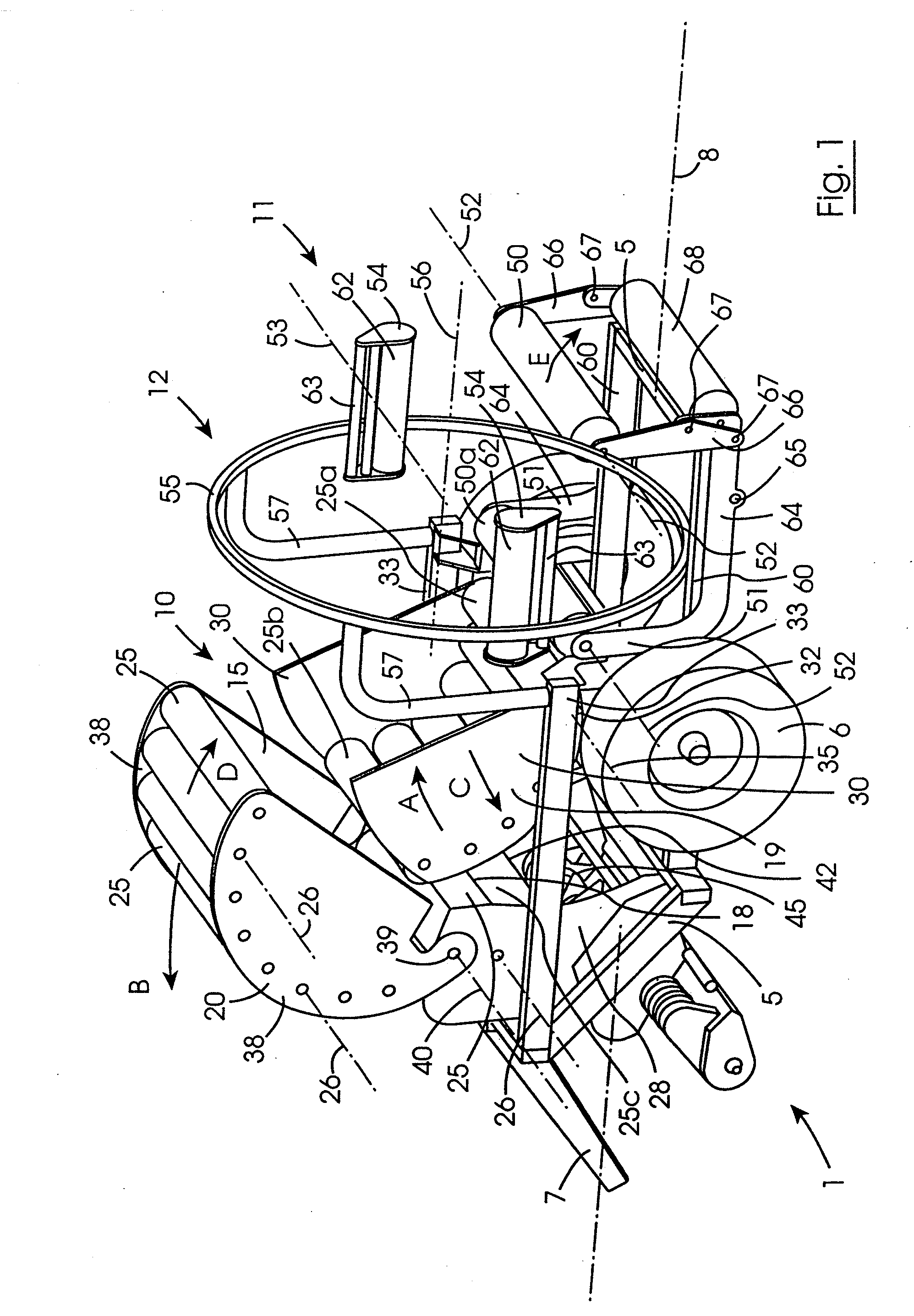

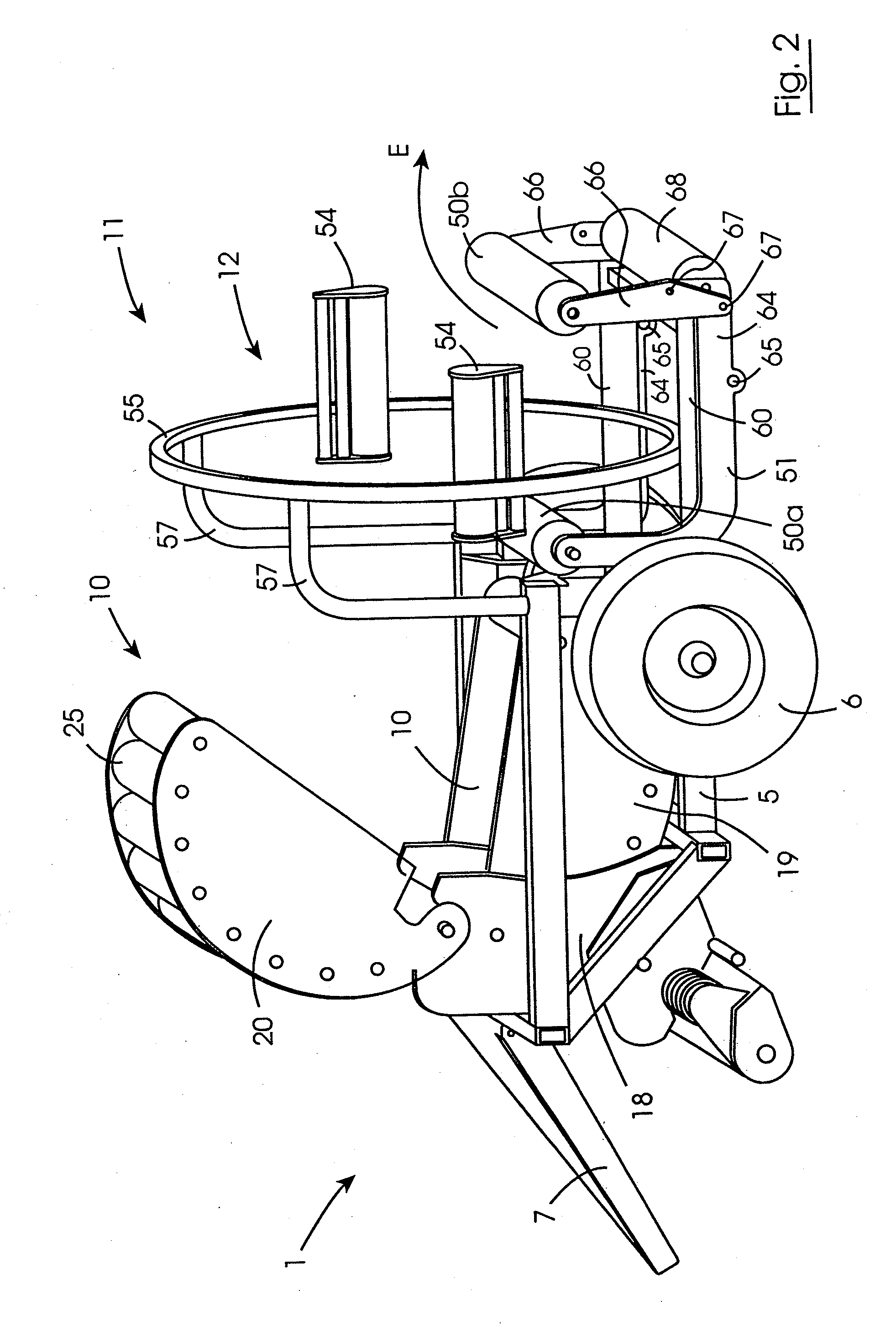

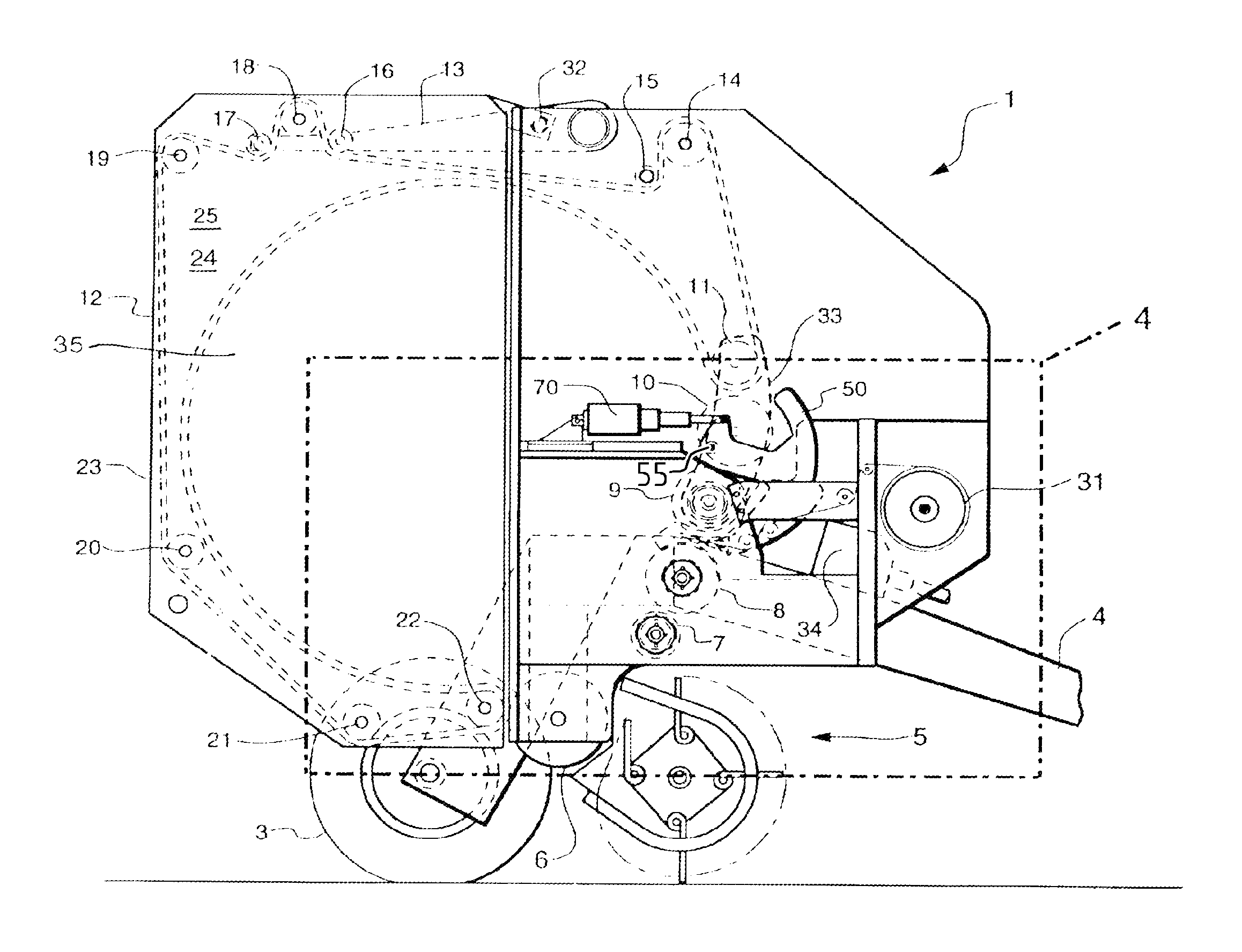

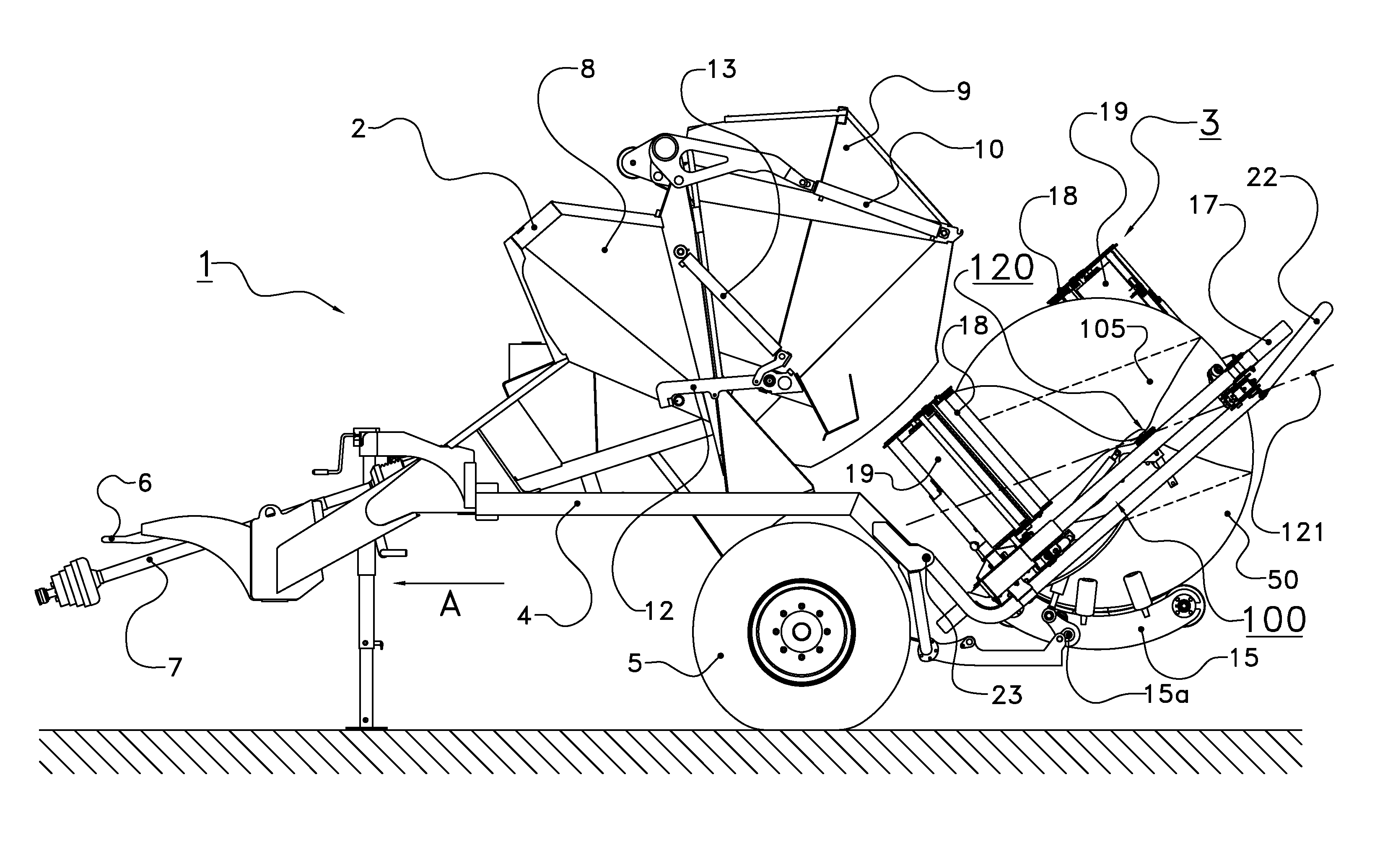

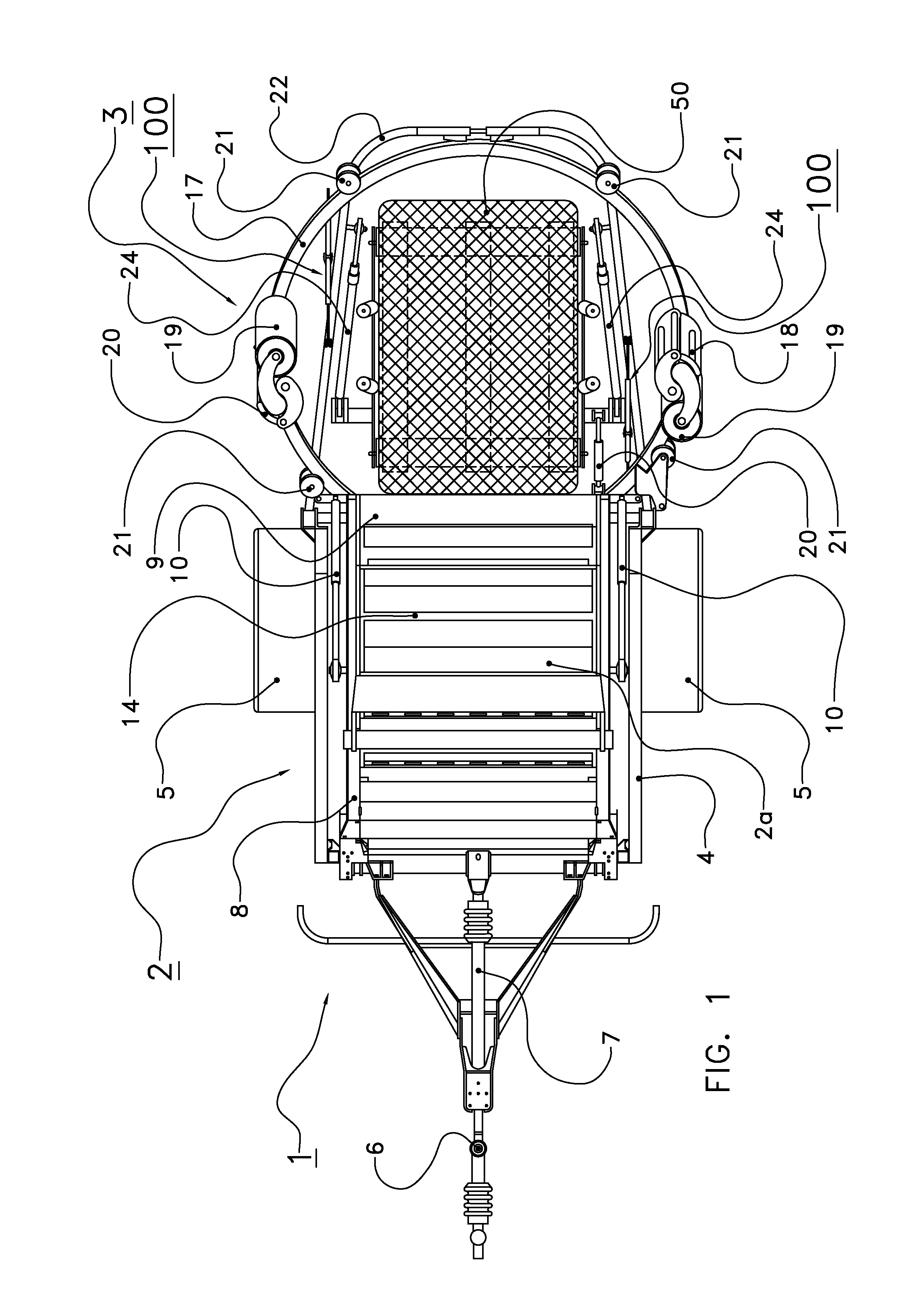

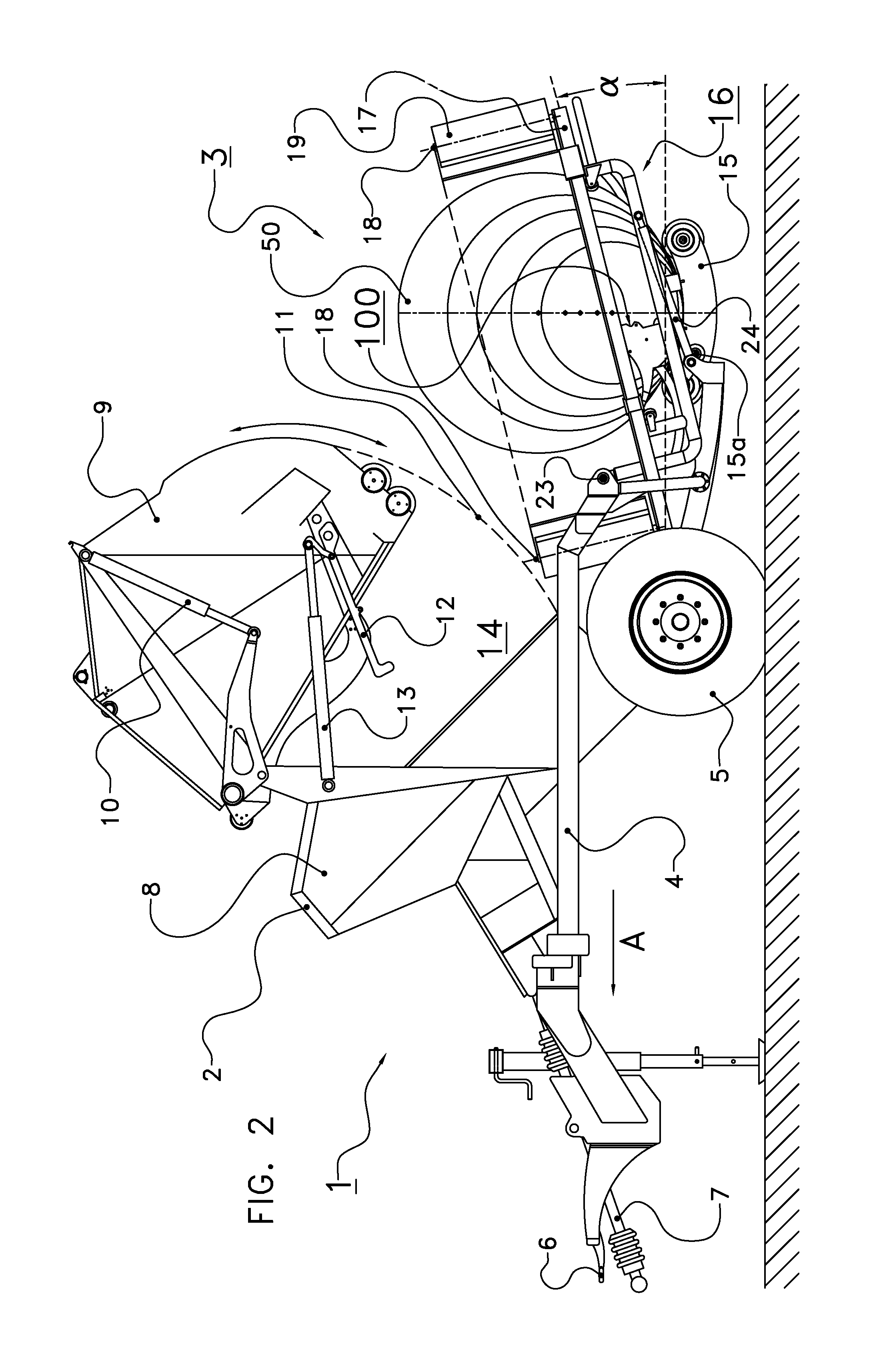

Combined baler/bale wrapper

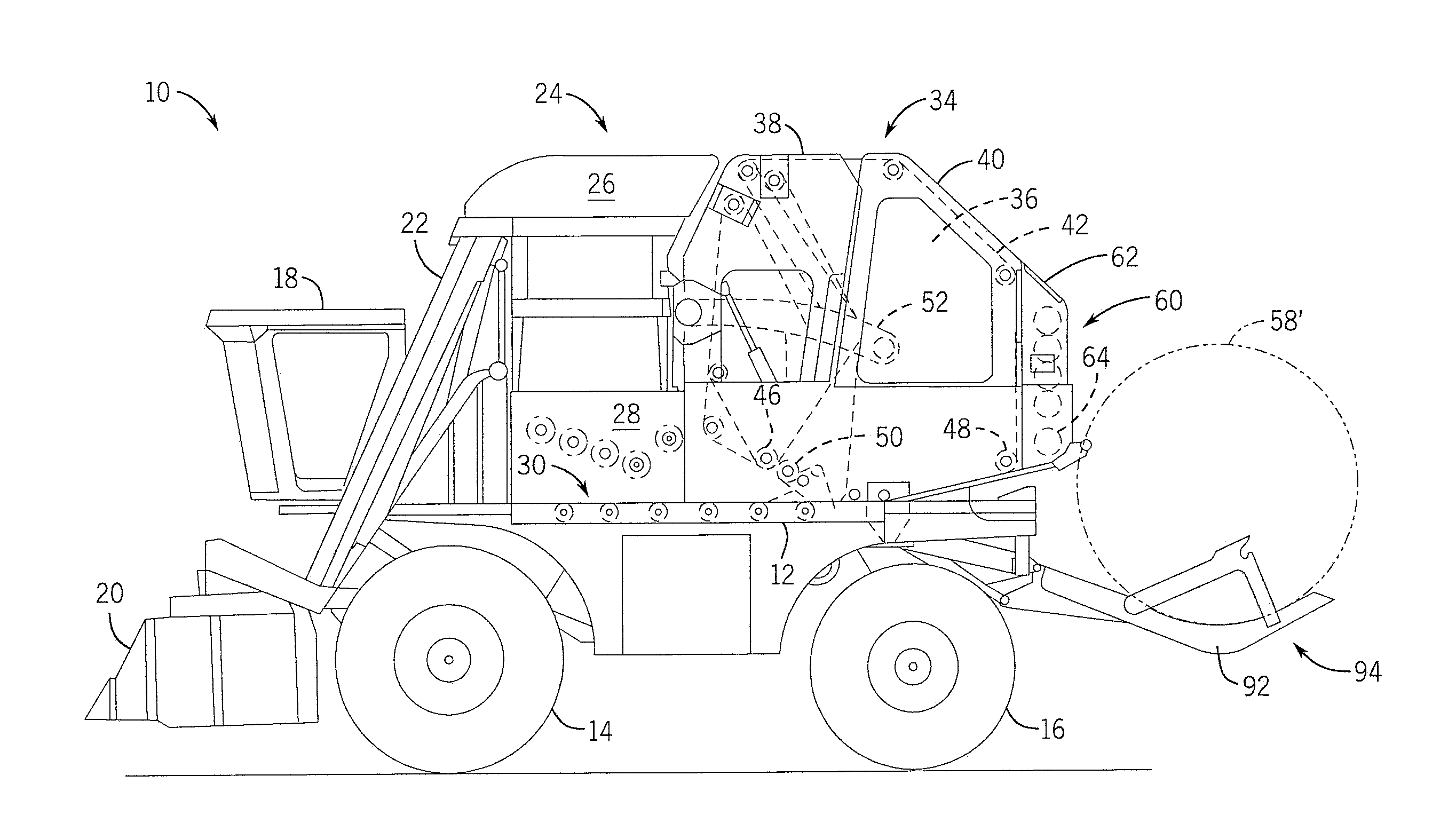

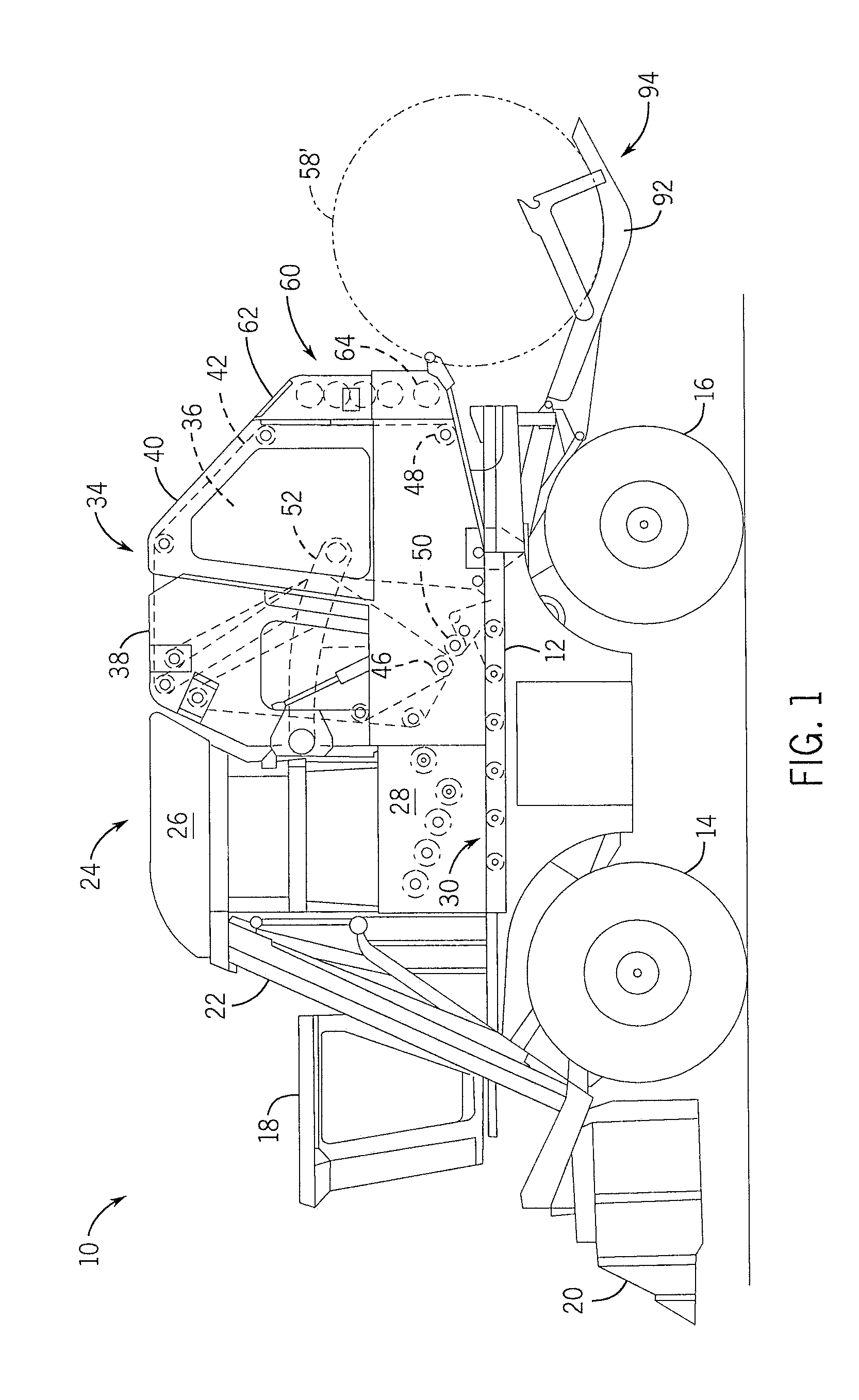

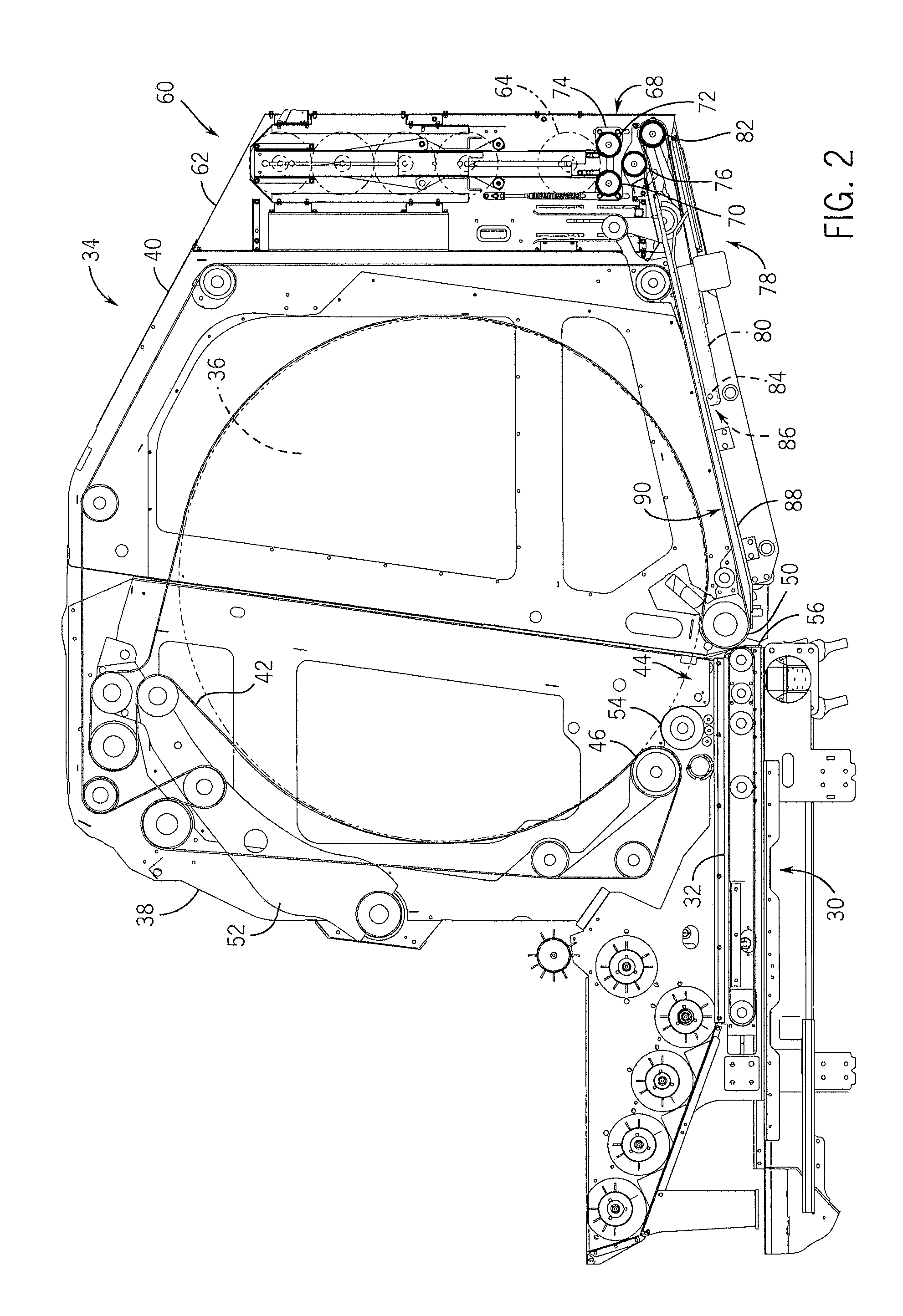

InactiveUS20120137630A1Efficient constructionSmooth transferWrapper supporting apparatusBalingEngineeringMechanical engineering

A combined baler / bale wrapper (1) comprises a chassis (5) on which a baler (10) and a bale wrapper (11) are mounted. The baler (10) comprises a stationary segment (18), a lower segment (19) and an upper segment (20) which together define a bale forming chamber (15) within which a round bale (2) is formed. The lower segment (19) and the upper segment (20) are pivotal from a bale forming position (FIG. 5) to a discharge position (FIG. 1) for transferring a bale of the bale forming chamber (15) onto bale supporting rollers (50) of the bale wrapper (11). The bale supporting rollers (50) rotate the bale (2) about a first wrapping axis (53) while a carrier ring (55) simultaneously revolves a pair of wrapping material dispensers (54) about a second wrapping axis (56) for dispensing wrapping material onto the bale (2).

Owner:WELMOUNT

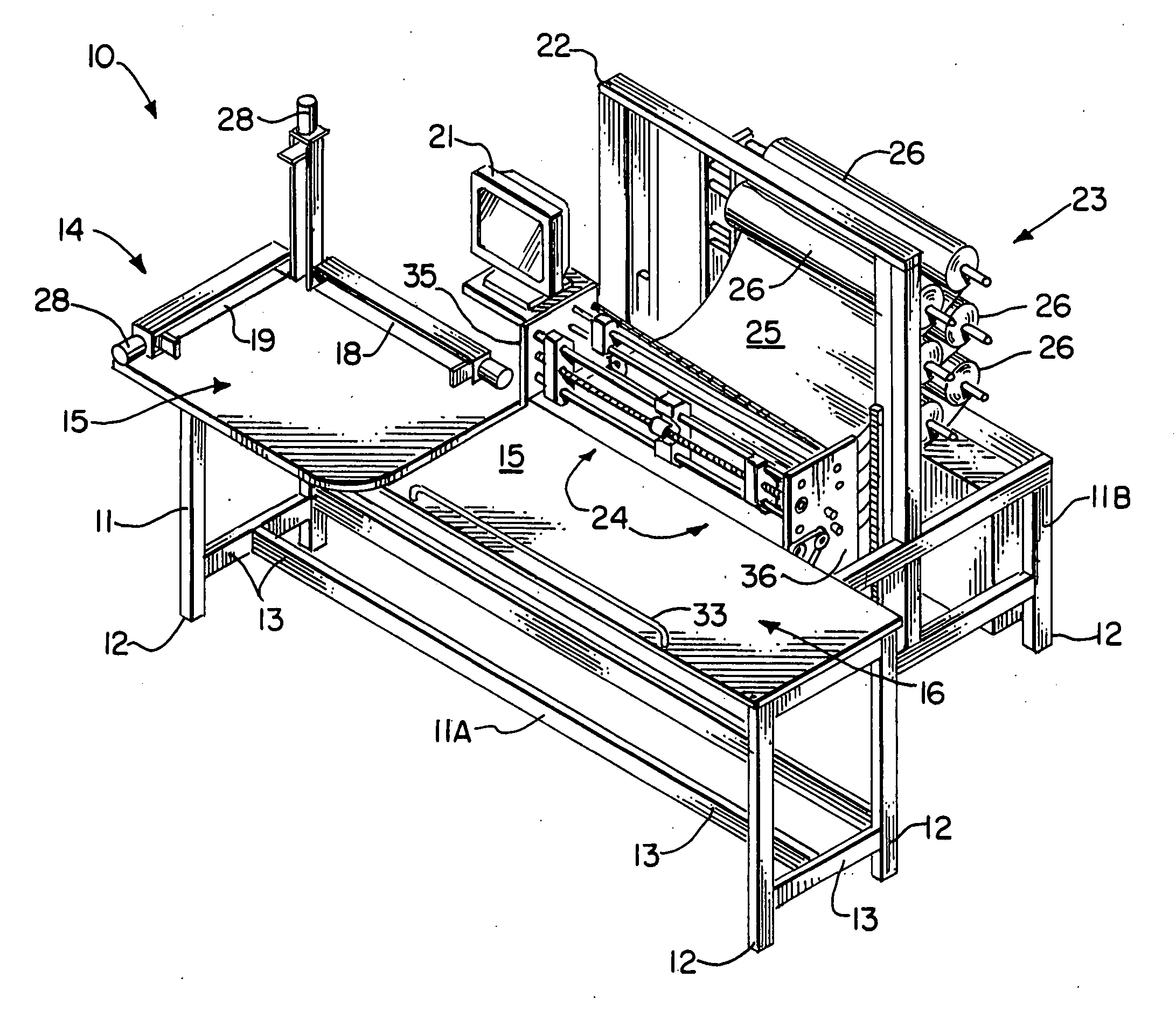

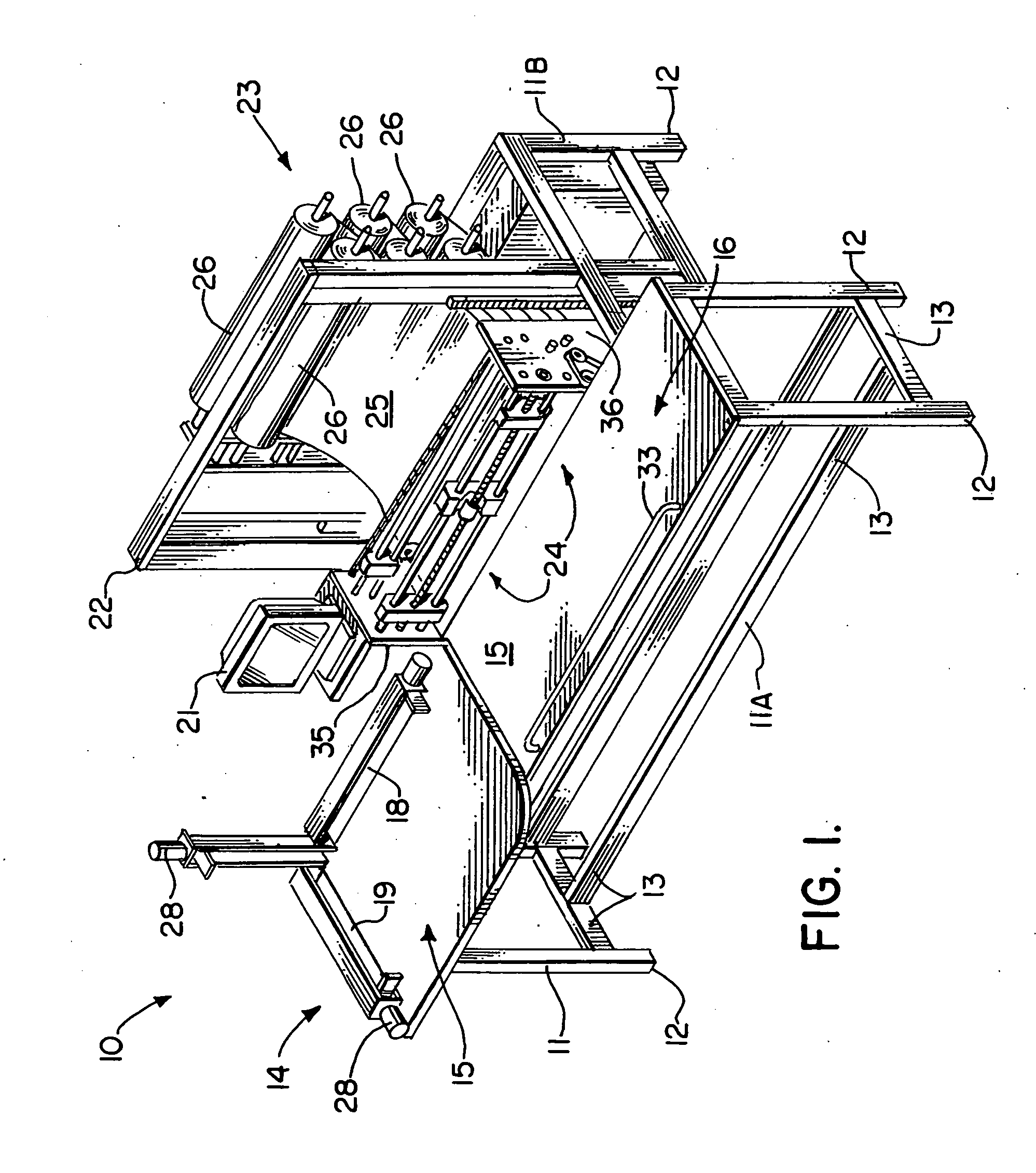

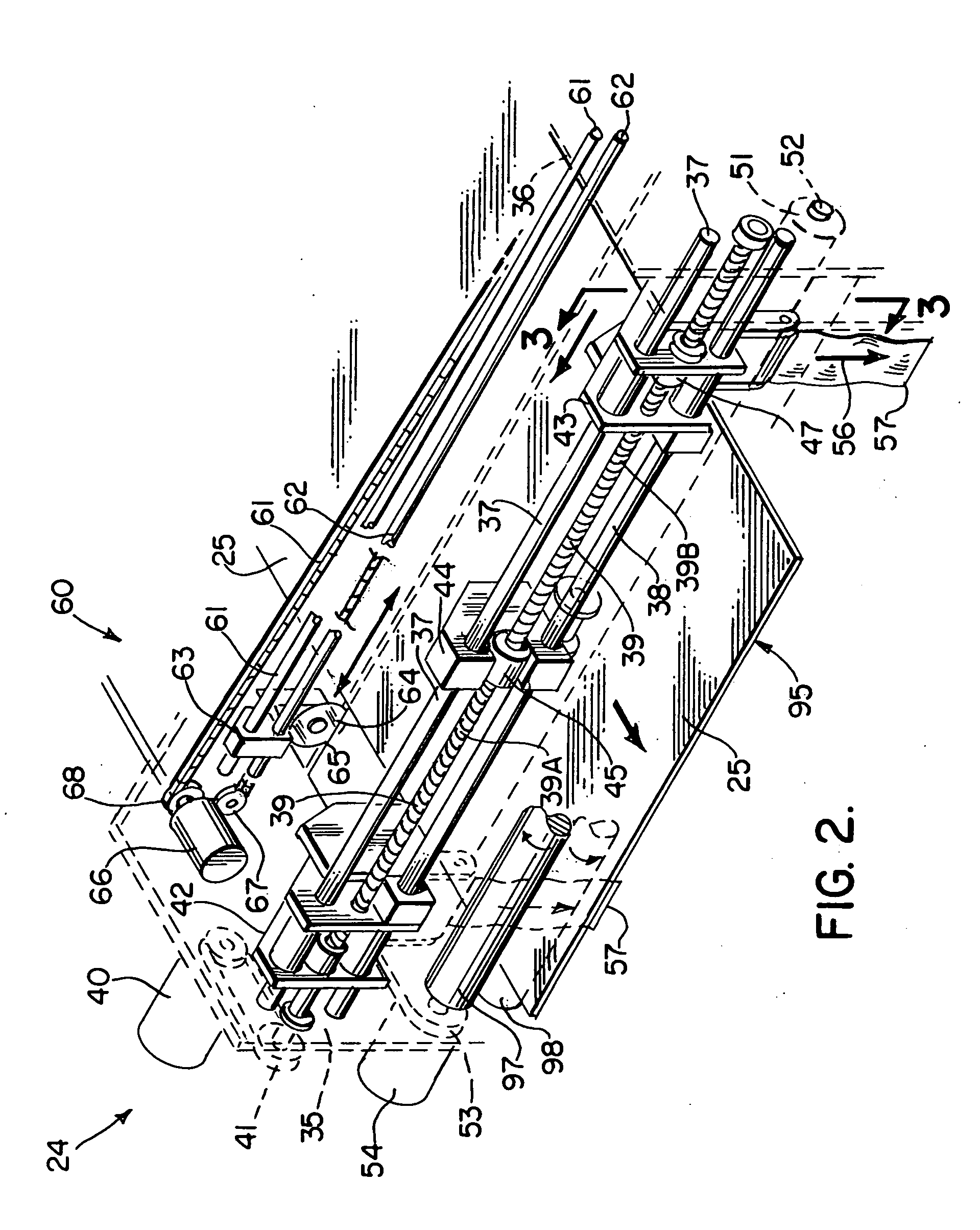

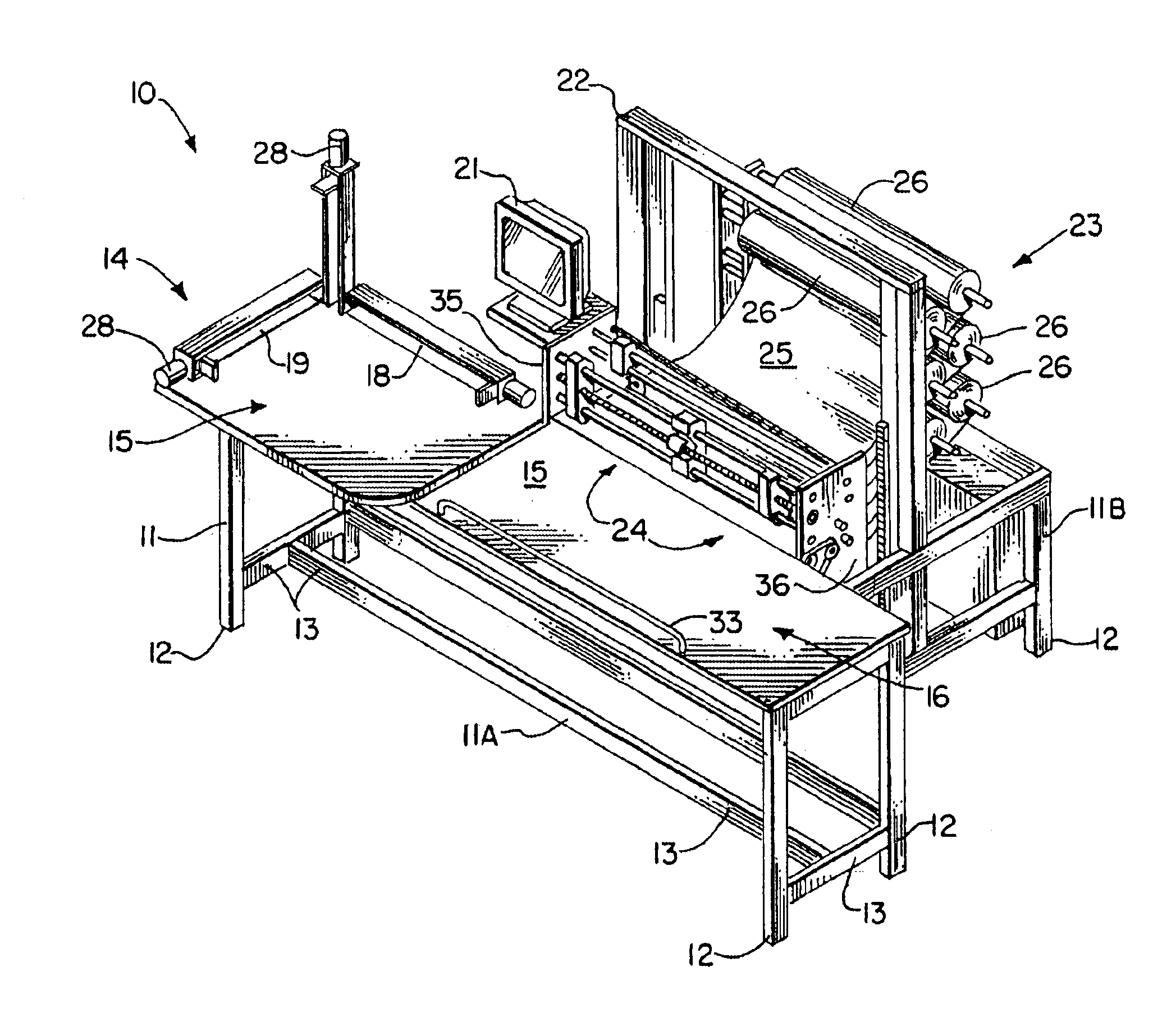

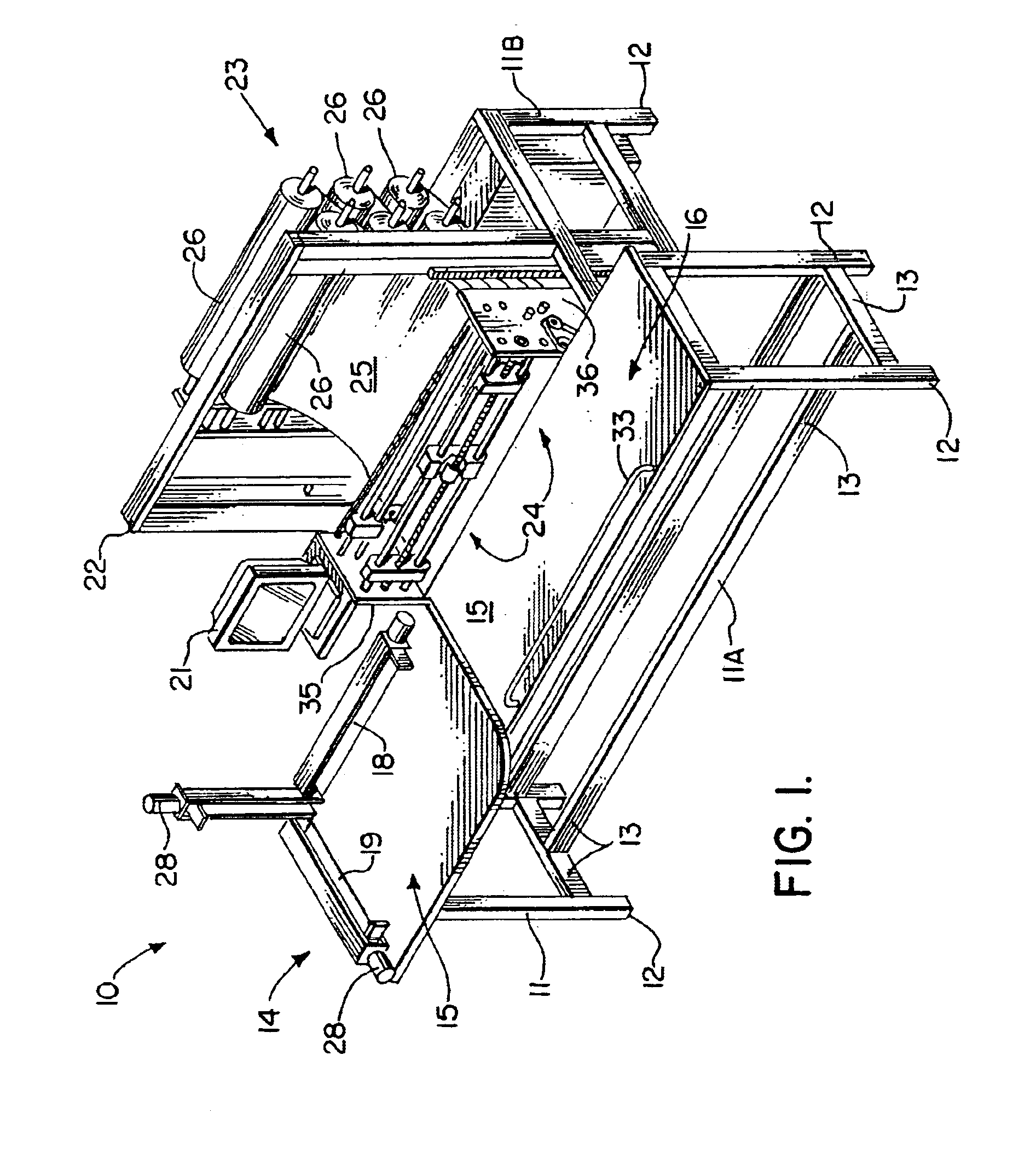

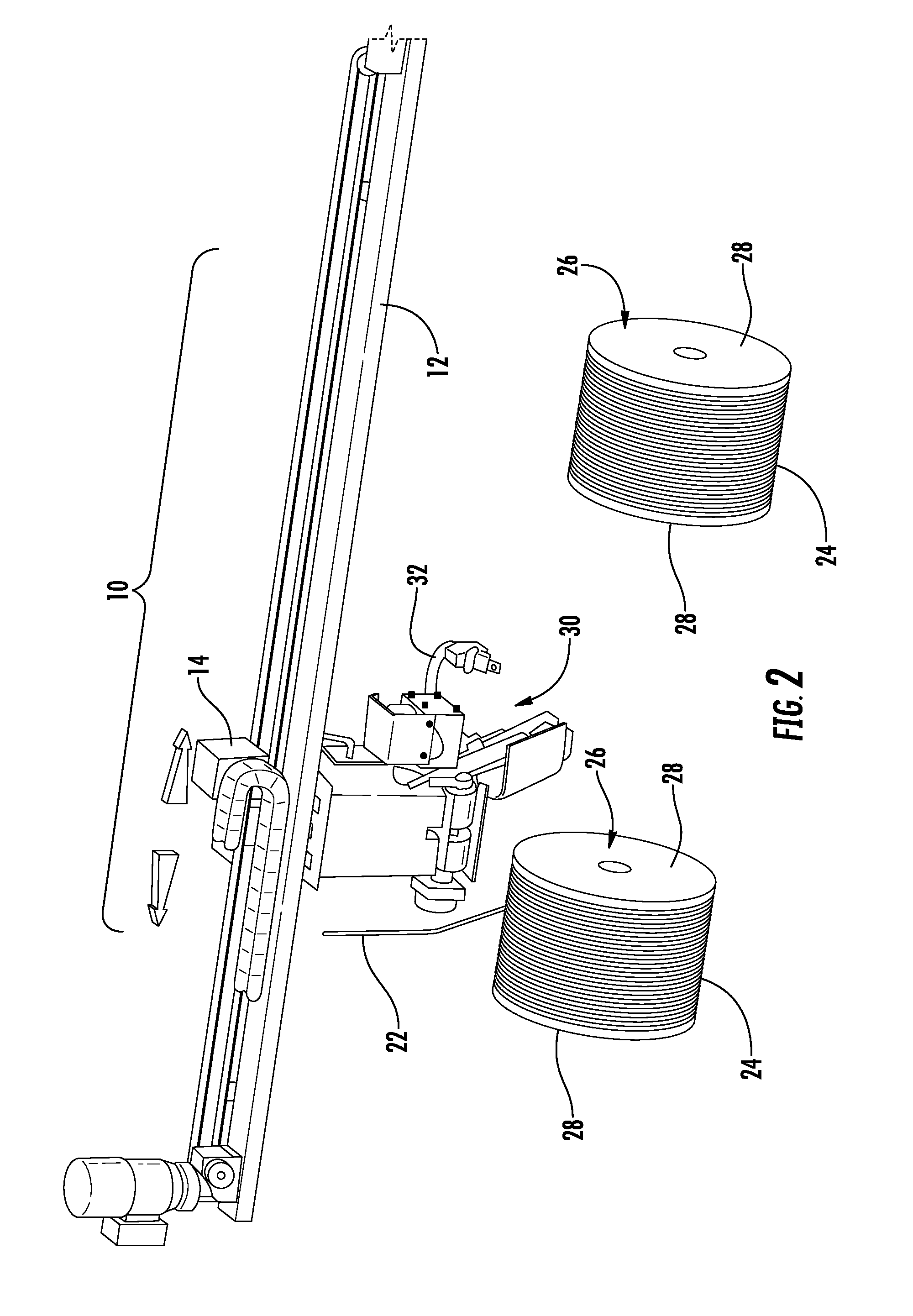

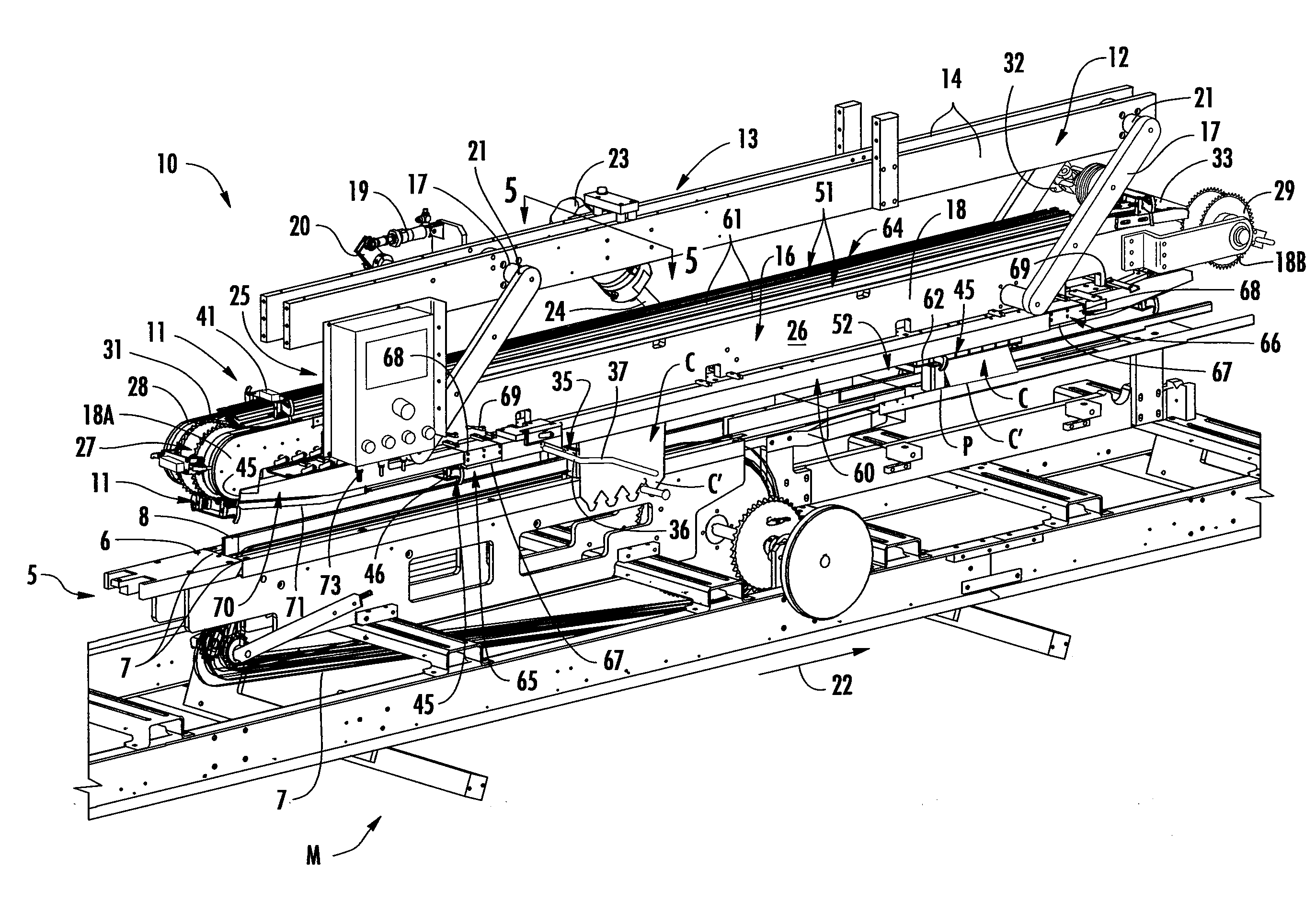

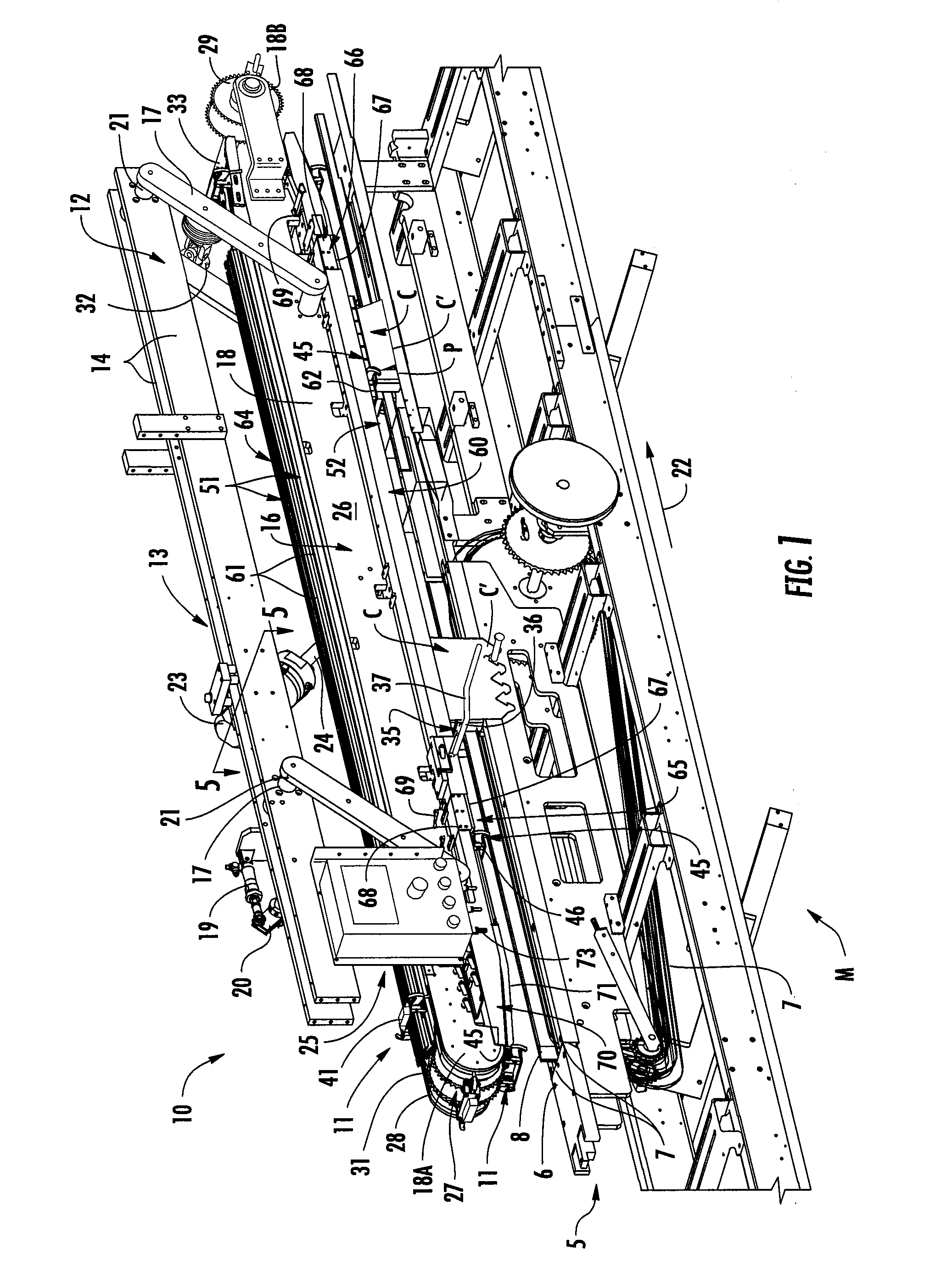

Package wrapping method and apparatus

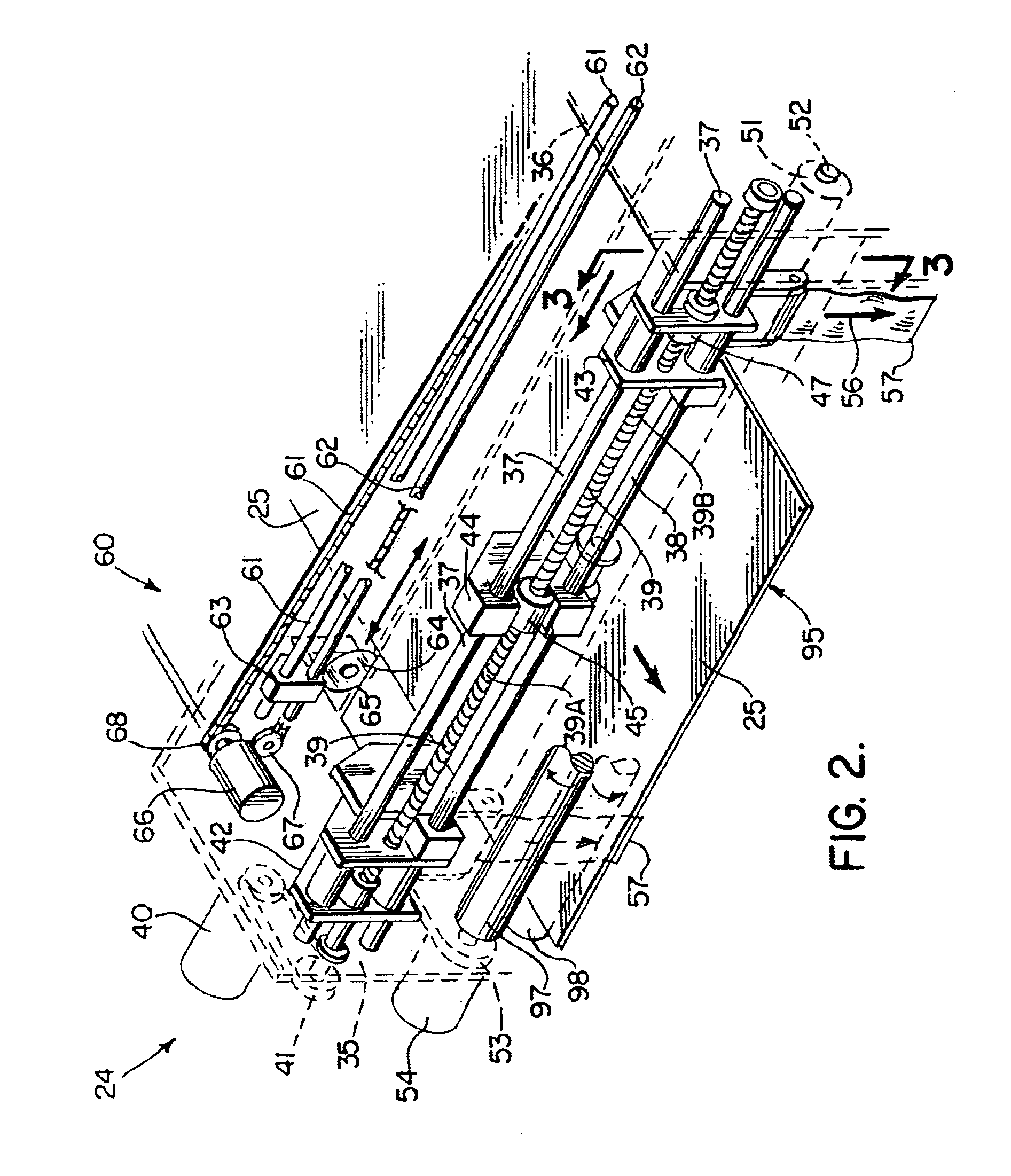

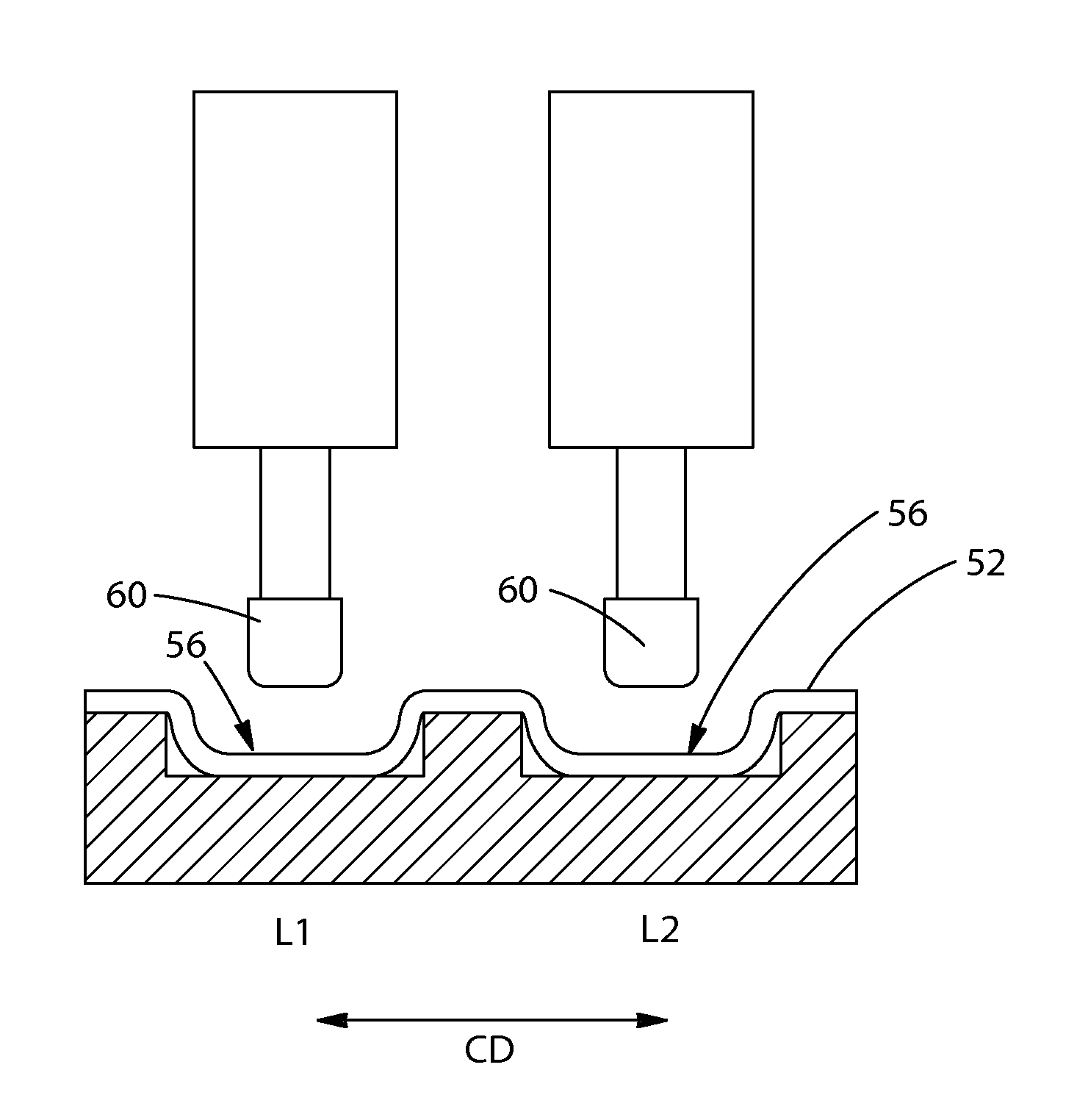

InactiveUS6938397B2Improve productivityQuality improvementWrapping material feeding apparatusWrapper folding/bending apparatusSemi automaticEngineering

A semi-automatic gift or package wrapping method and apparatus is disclosed. The apparatus includes a machine frame that provides a work surface with measuring and wrapping sections. A sheet feed and cutting mechanism feeds paper from a role in two steps with a time pause in between for enabling a user or operator to partially wrap the package with part of the first section of dispensed paper web. Thereafter, the second section of paper web is dispensed and the web cut transversely at a trailing edge. Multiple selectable supply rolls are optionally provided, or a single roll machine can be used. Longitudinal cutters trim the sides of the paper to obtain a custom desired width for the full cut sheet. A user interface display controls machine functions such as start, continue and sheeter. In the sheeter mode, a selected number of sheets of a selected size can be dispensed and cut for use at another workstation to warp other boxes of known uniform size (i.e. shirt boxes at a department store).

Owner:GWS OPERATIONS LLC

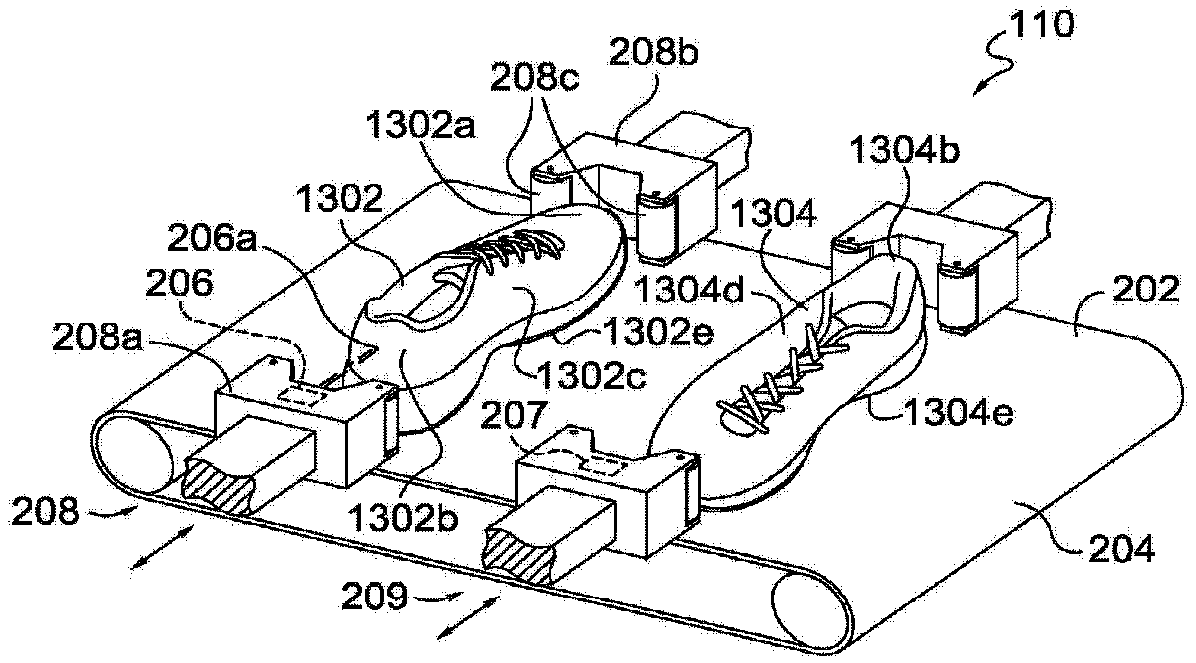

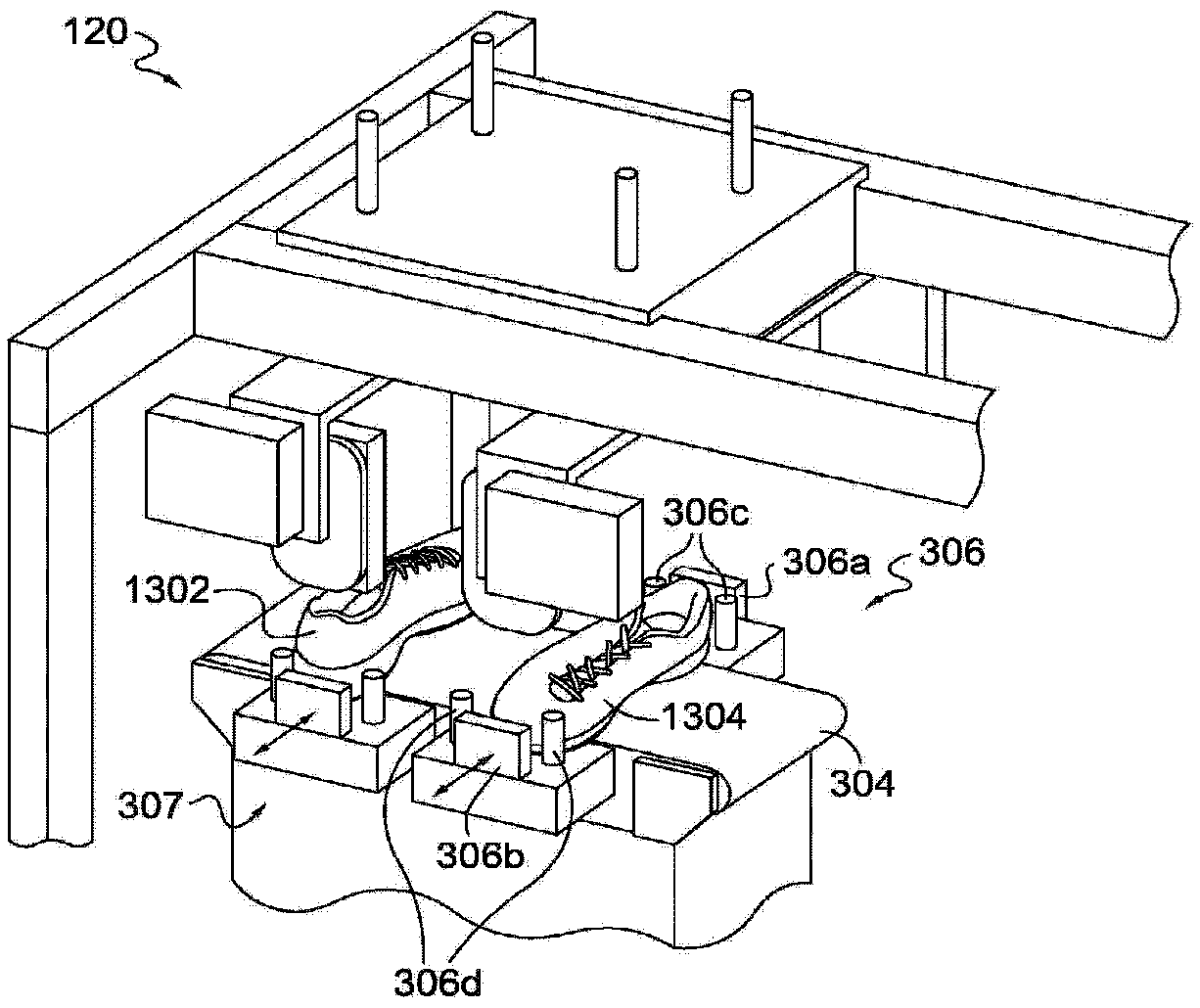

Method for Forming Packages

A method and apparatus for formation, filling, and sealing unit dose packages for consumer products are described herein. A filling system with a filling control system is also disclosed. Although the filling system is described in conjunction with a method for forming, filling, and sealing unit dose packages, the filling system and filling control system can be used in other dispensing processes.

Owner:THE PROCTER & GAMBLE COMPANY

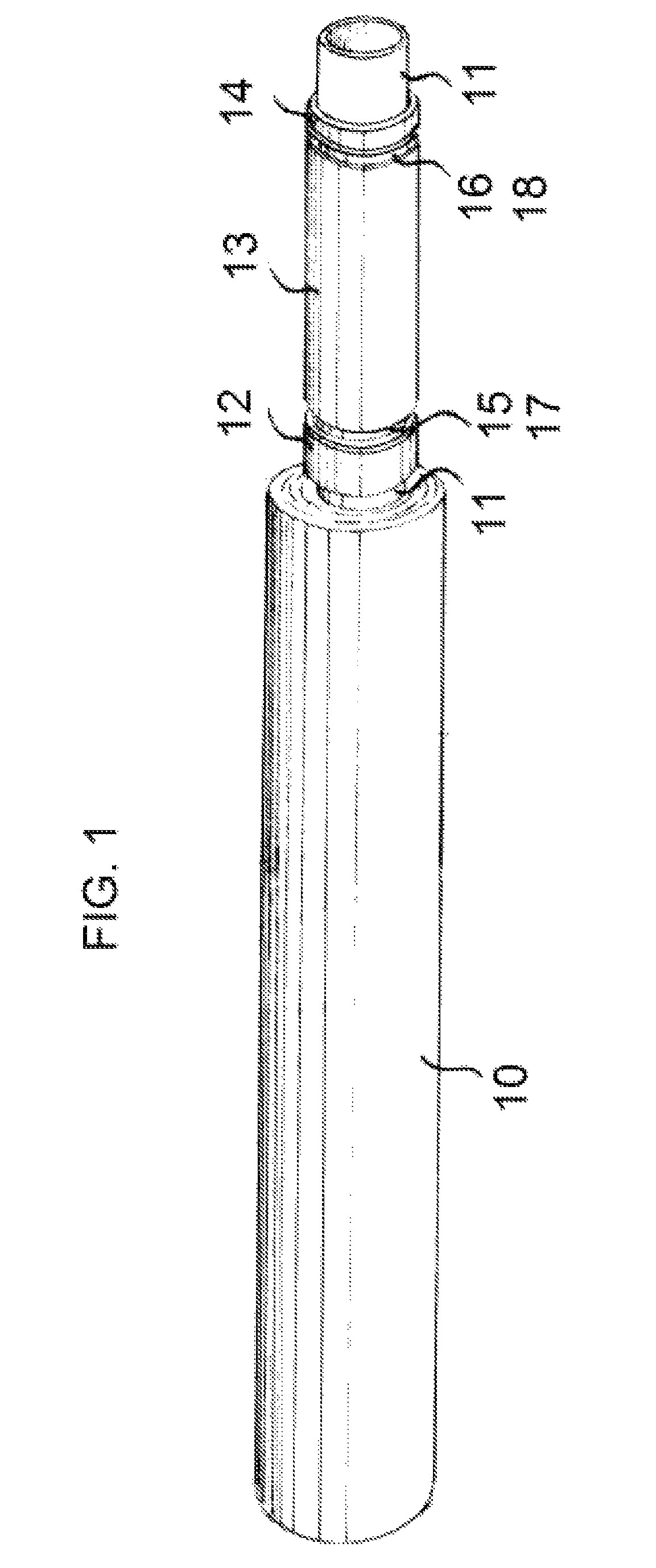

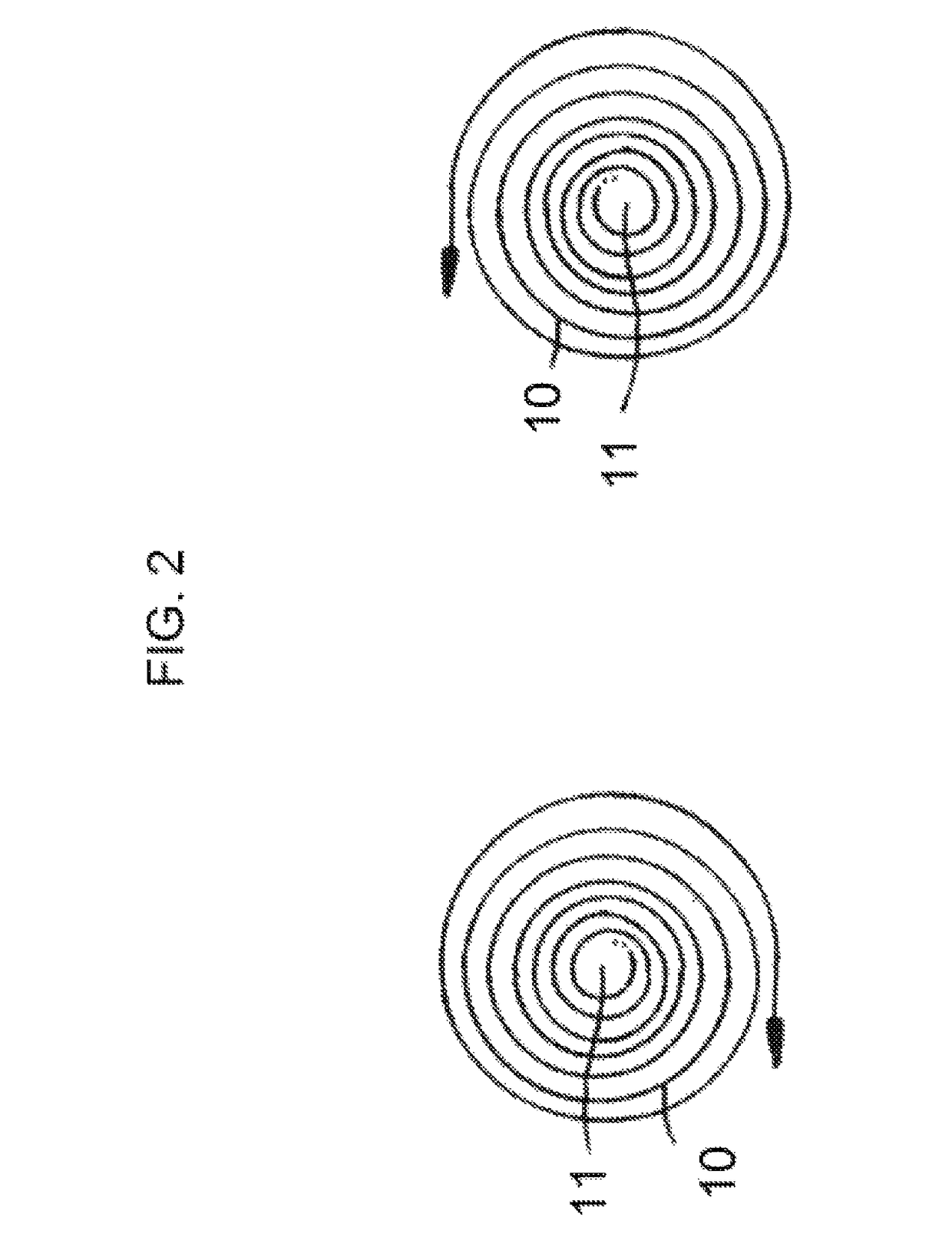

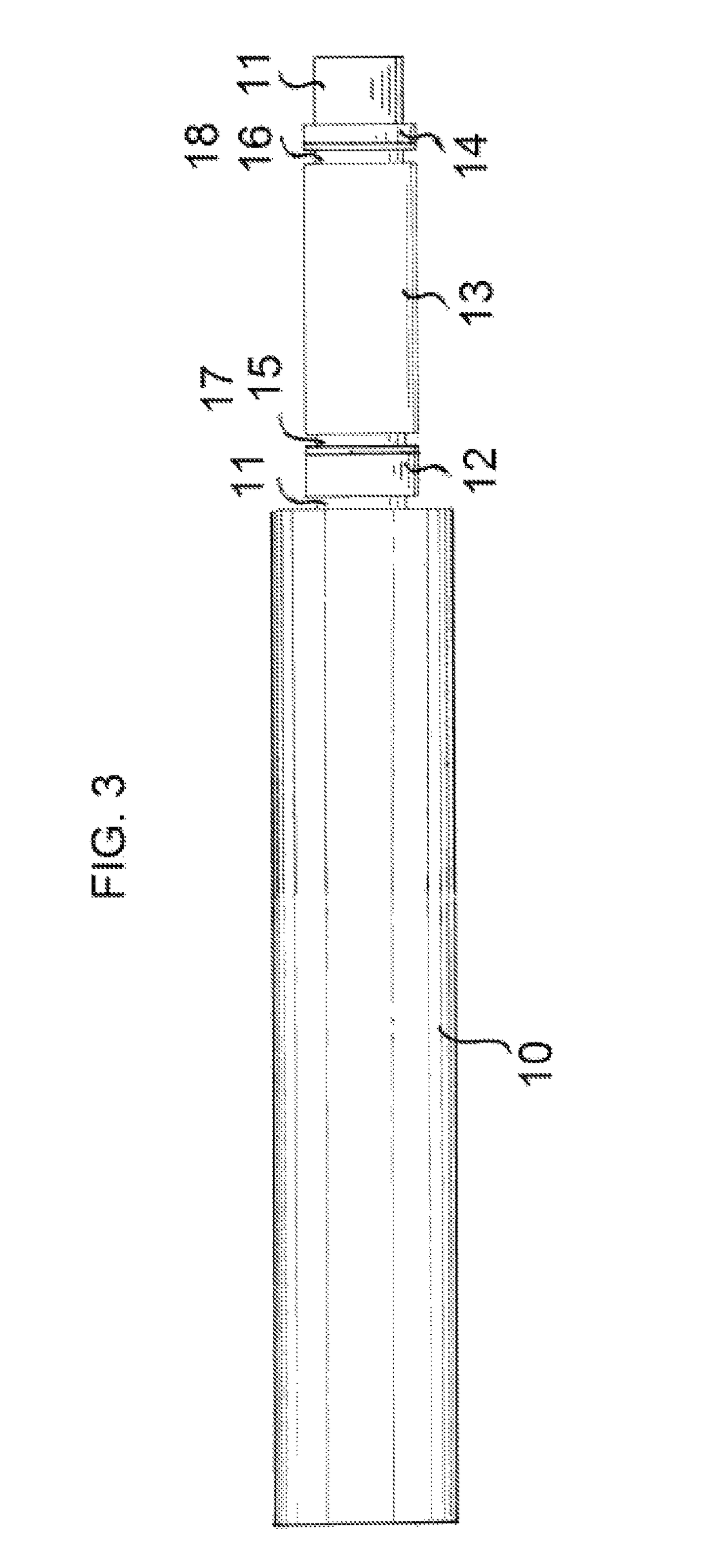

Single-hand self-contained cohesive stretch film baggage wrapping device

InactiveUS8468778B2Easy and safe and inexpensivePackaging cigaretteWrapper folding/bending apparatusFree rotationEngineering

The invention is a do-it-yourself baggage wrapping, protection, anti-tamper and anti-pilferage device. The all-in-one device consists of the stretch film, a dispenser able to draw, stretch and wrap film up to 12 inches in width, consisting of a stopper-ring secured at the very beginning of the extended core followed by a semi-compressible sleeve with embedded guide rings encircling core extension contoured guide-rings or an anti-clockwise coiled and freely rotating spiral-shape flexible sheet to let freely rotate same when film is being drawn off roll, thus followed by a second stopper-ring secured about one inch from the remote end of core extension. Both stopper-rings are dimensioned to prevent the sleeve from separating from the extension at any position or angle and total spacing between the two is greater than the total length of the sleeve to provide free rotation of latter.

Owner:WINDHEUSER FRIEDRICH

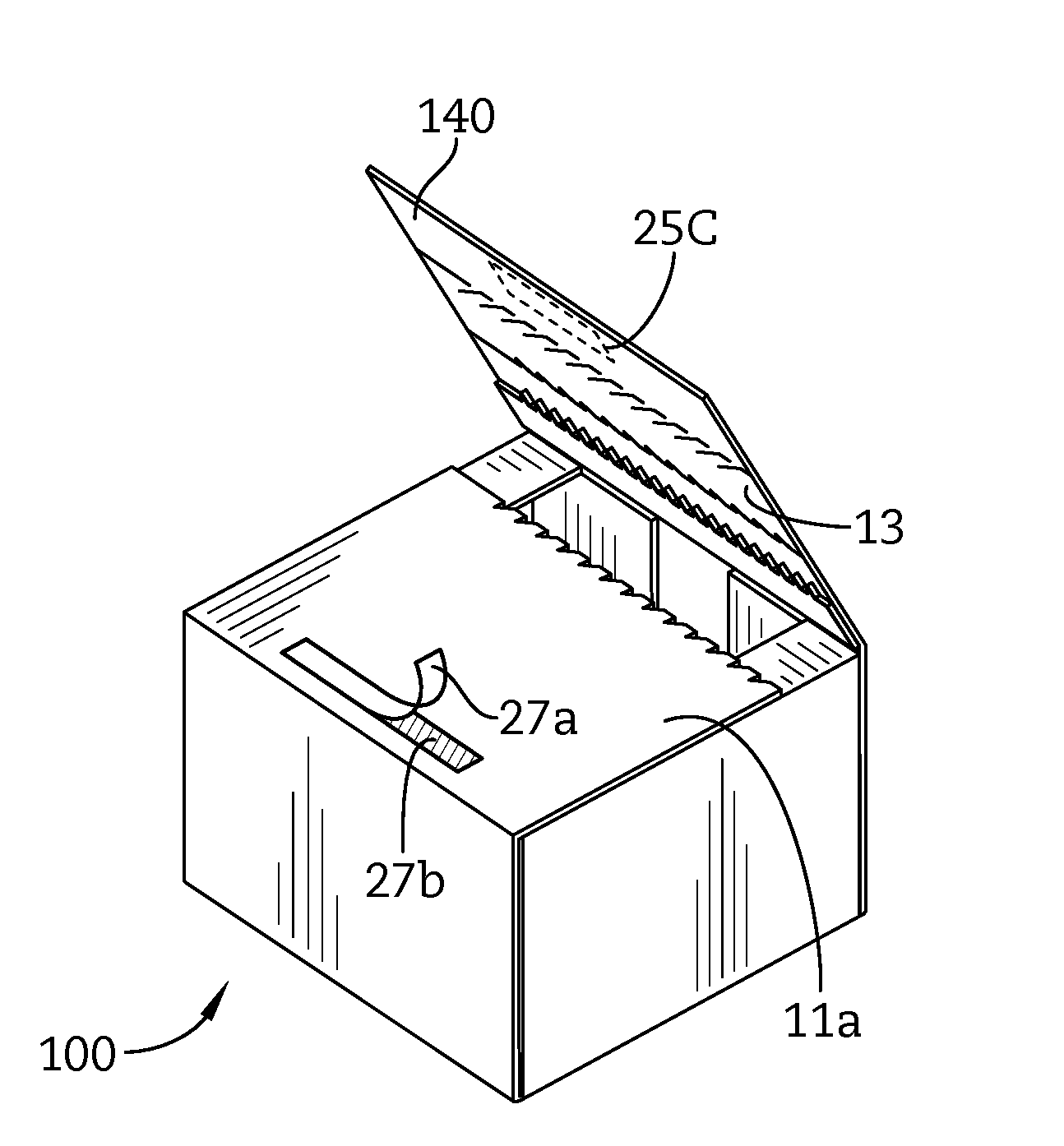

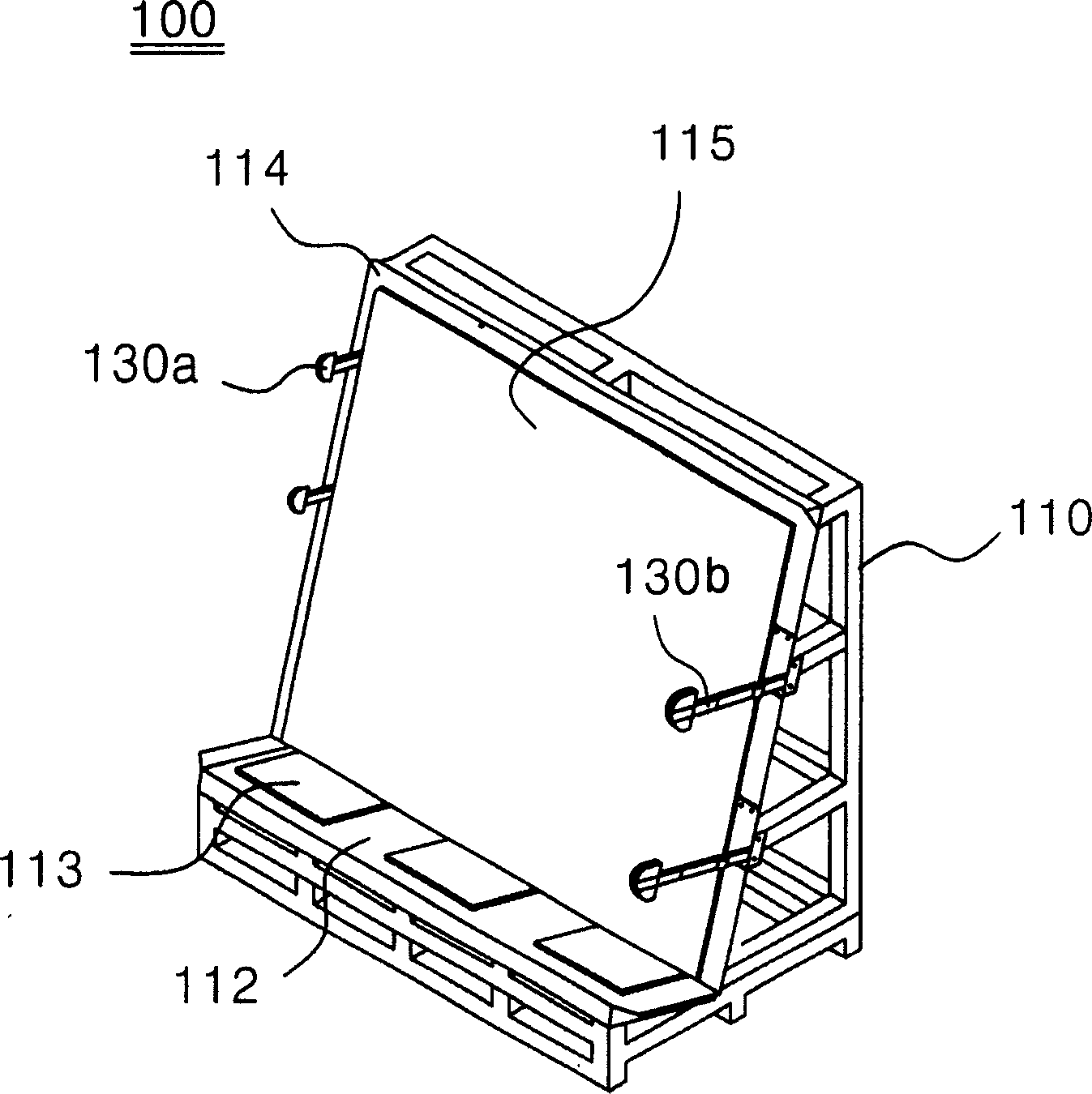

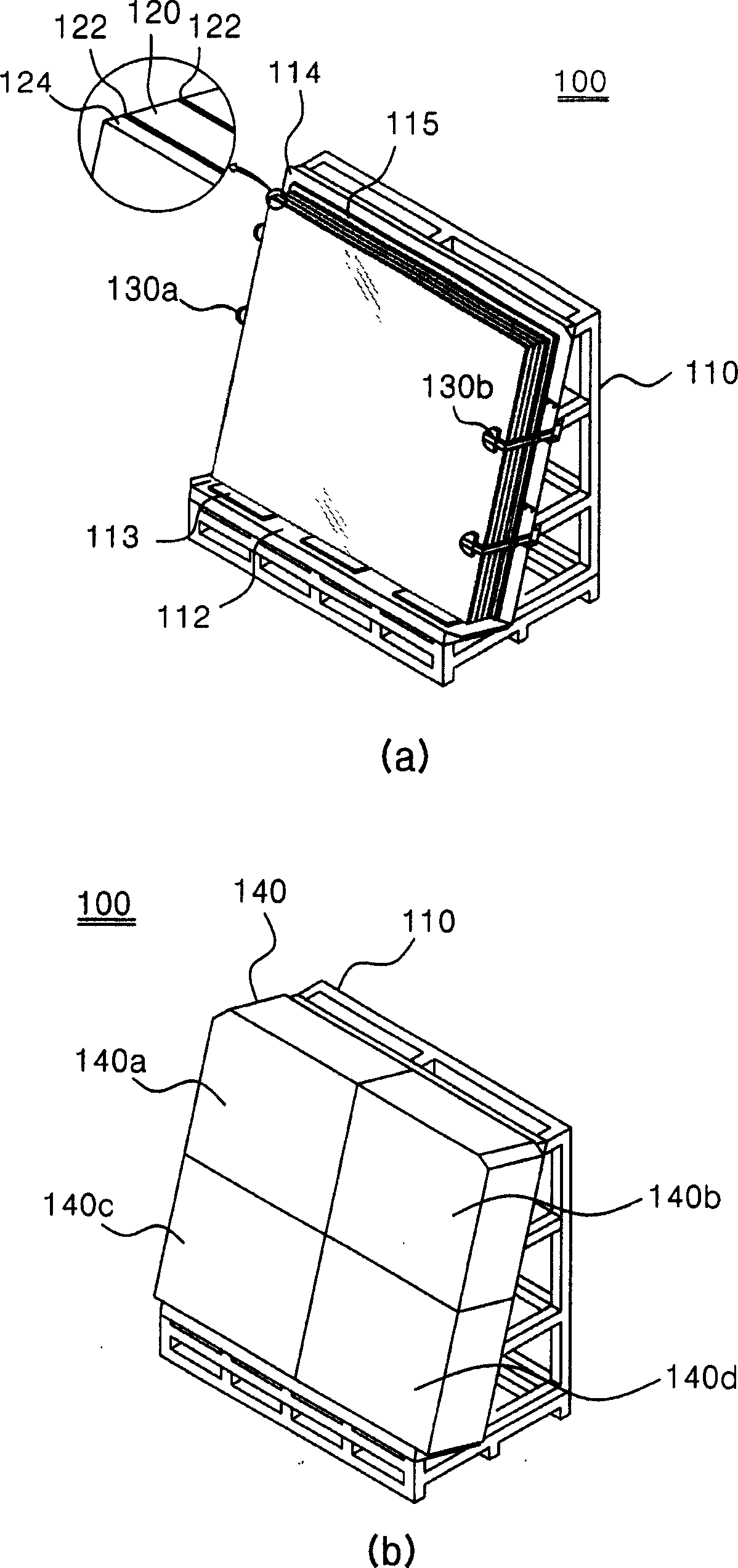

Plane glass sheet packing container for displays

ActiveCN1621322ASave on packaging costsImprove work efficiencyWrapper supporting apparatusDamagable goods packagingFlat glassDisplay device

PURPOSE: A packaging container for flat glass for display purpose is provided to safely and efficiently perform the packaging work of loaded flat glass for display purpose. CONSTITUTION: The packaging container(100) comprises: a loading frame(110) provided with a loading plane(112) and a backing plane(114); flat glass fixing devices(130a,130b) for fixing the loaded flat glass for display purpose; and a box-shaped case put on as being contacted to the front, side and top faces of the loaded flat glass for display purpose and blocking an open region of the loading frame(110) through which the loaded flat glass for display purpose is exposed.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

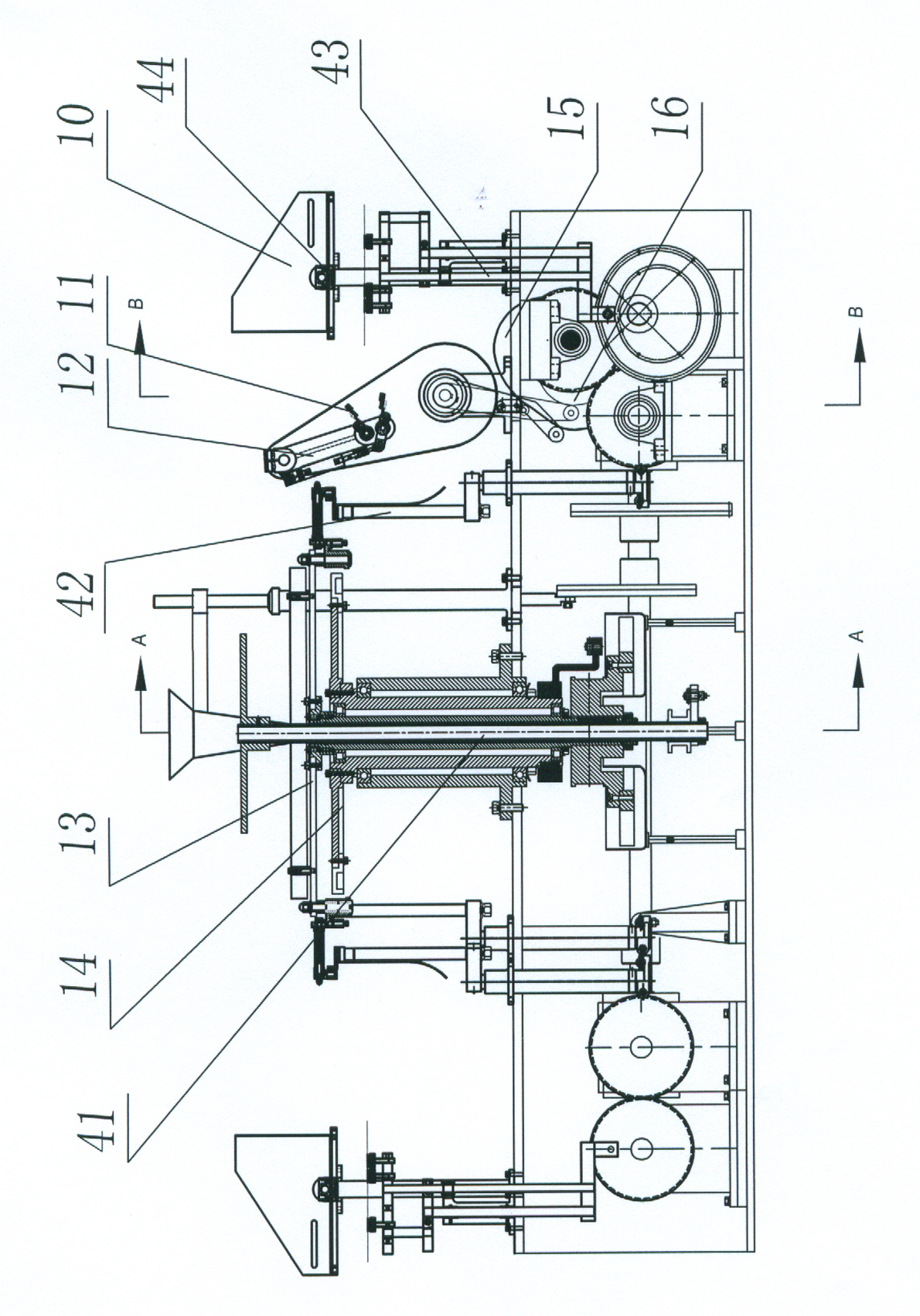

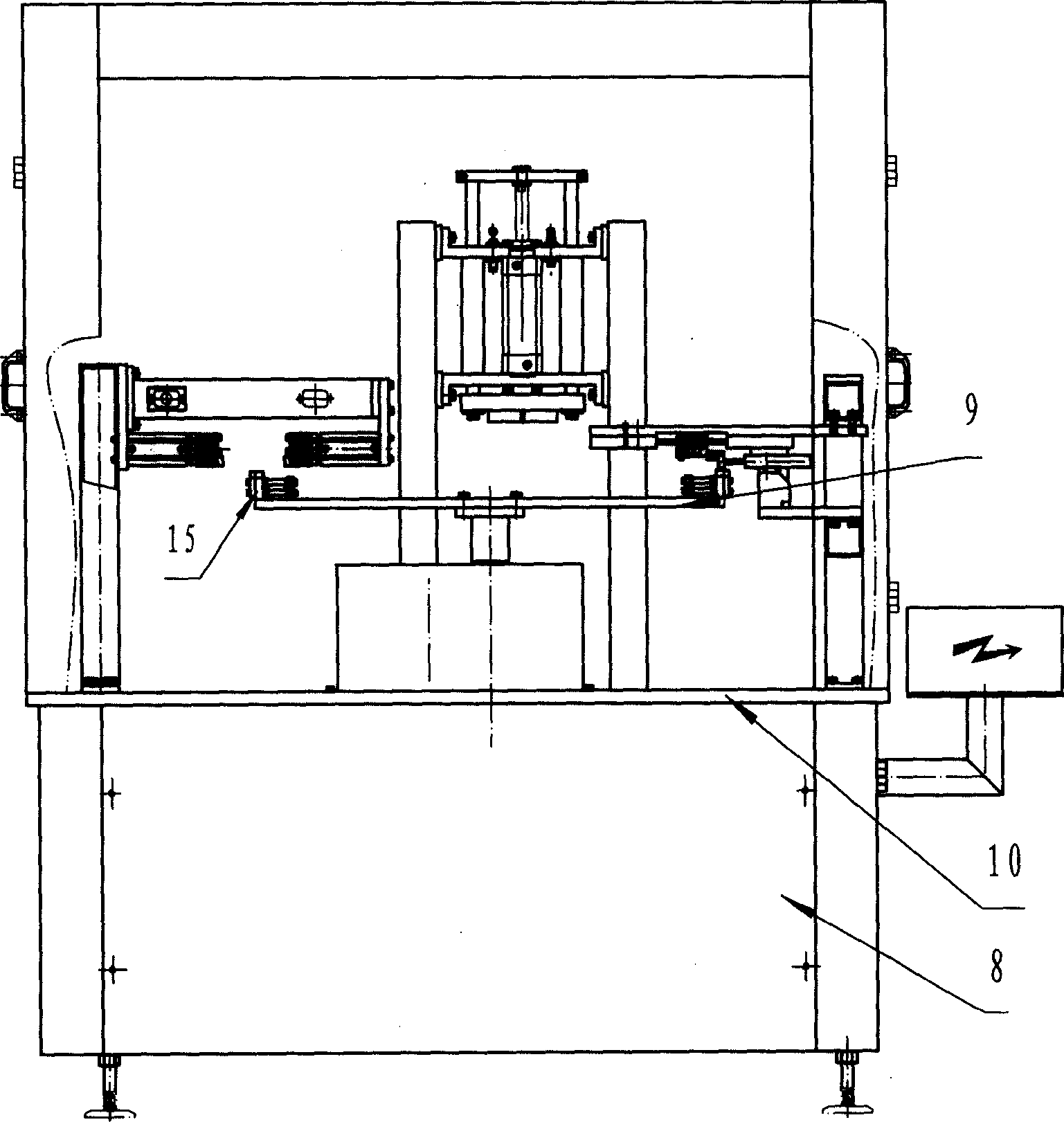

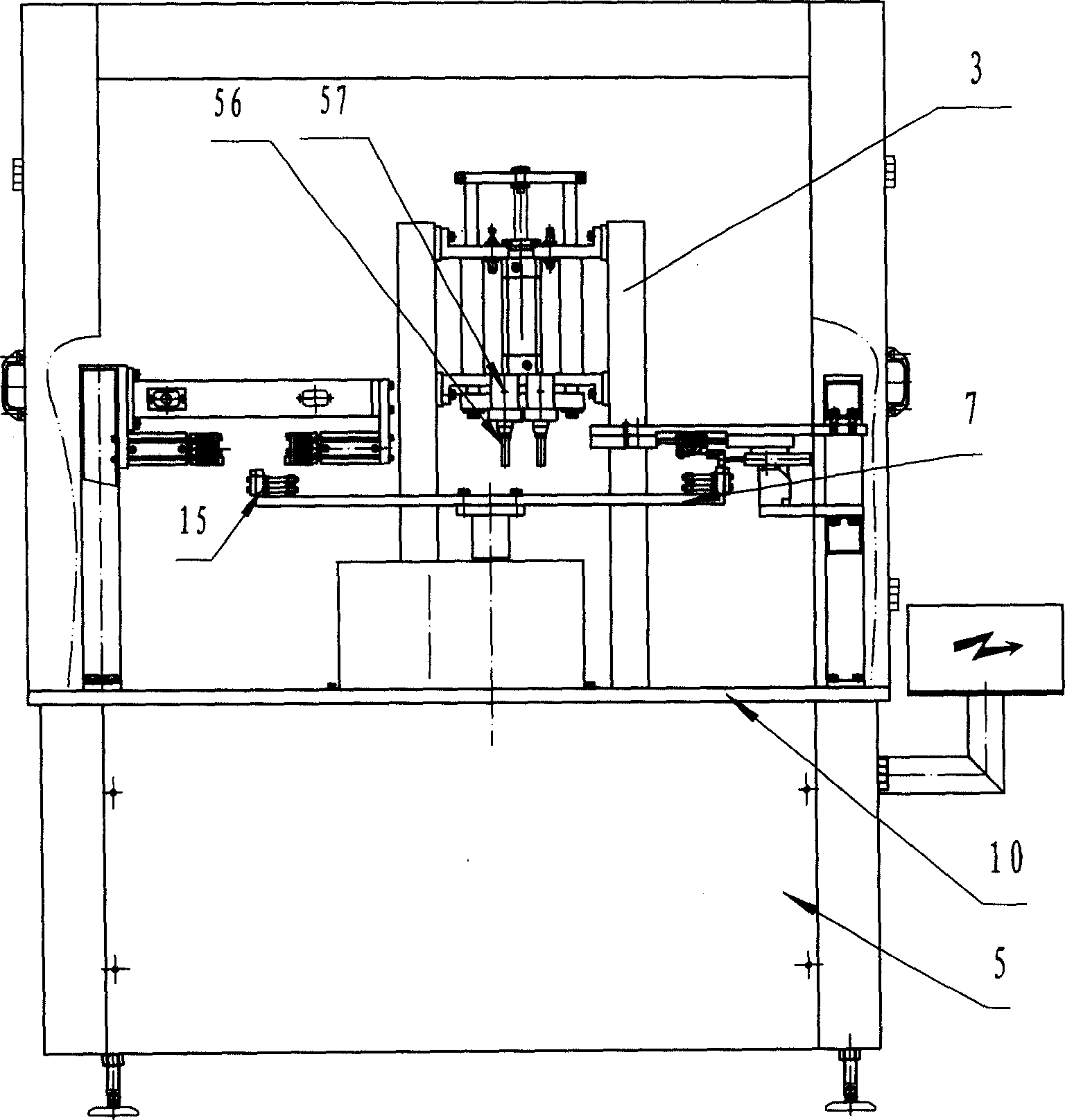

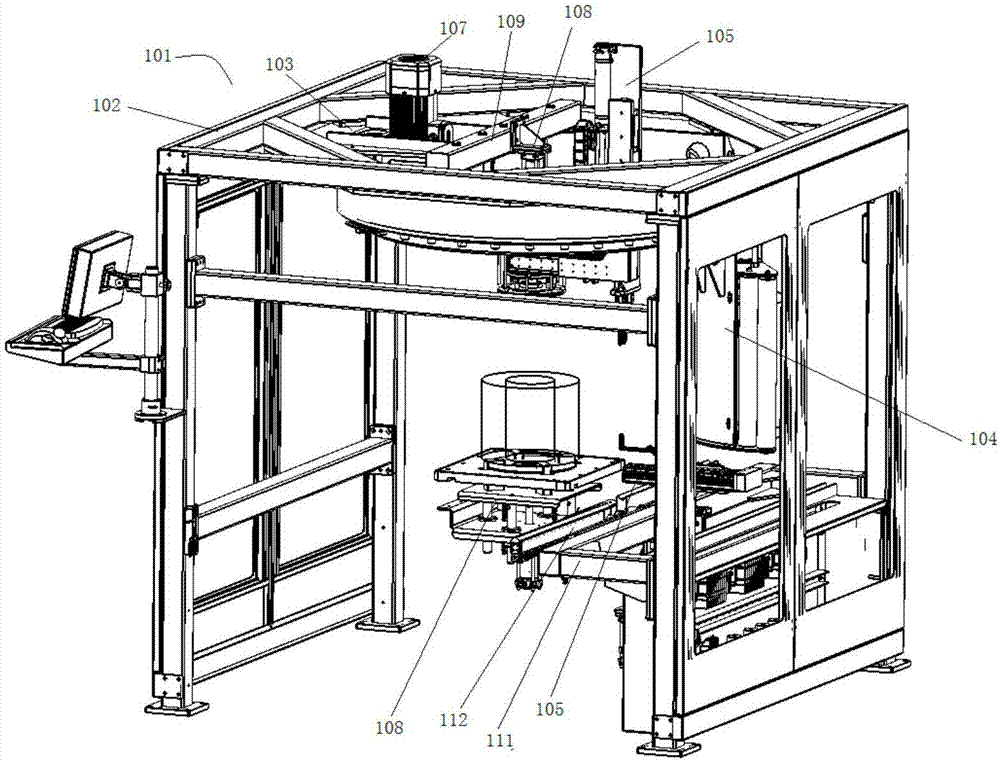

Intermittent rotary non-PVC large infusion soft-bag solid drug filling machine

ActiveCN1743232AChange the way the medicine is dispensedChange middle linkPharmaceutical product form changeWrapper supporting apparatusNitrogenEngineering

The solid medicine filling machine comprises power drive component, central dial, take-in and take-out component, bag-cutting part, part for filling clean air, part for filling nitrogen, thermal sealing part, rack and electric control cabinet. The parts above are set on the side of the center dial that connects with the power drive component and are supported by the rack to layout in turn. Around the central dial is fitted with a bag holder for hanging infusion bag.

Owner:HUNAN CHINASUN PHARMA MASCH CO LTD

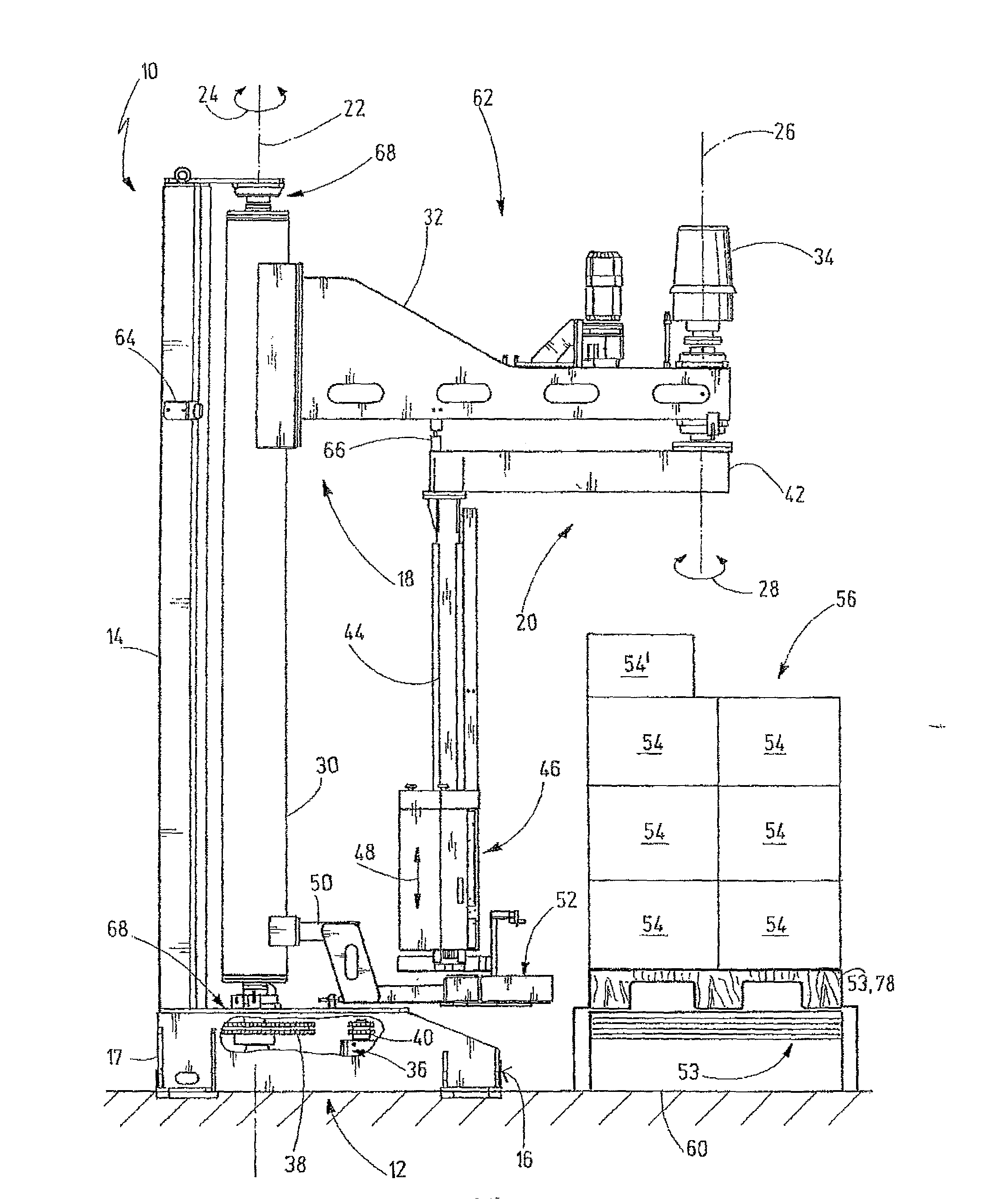

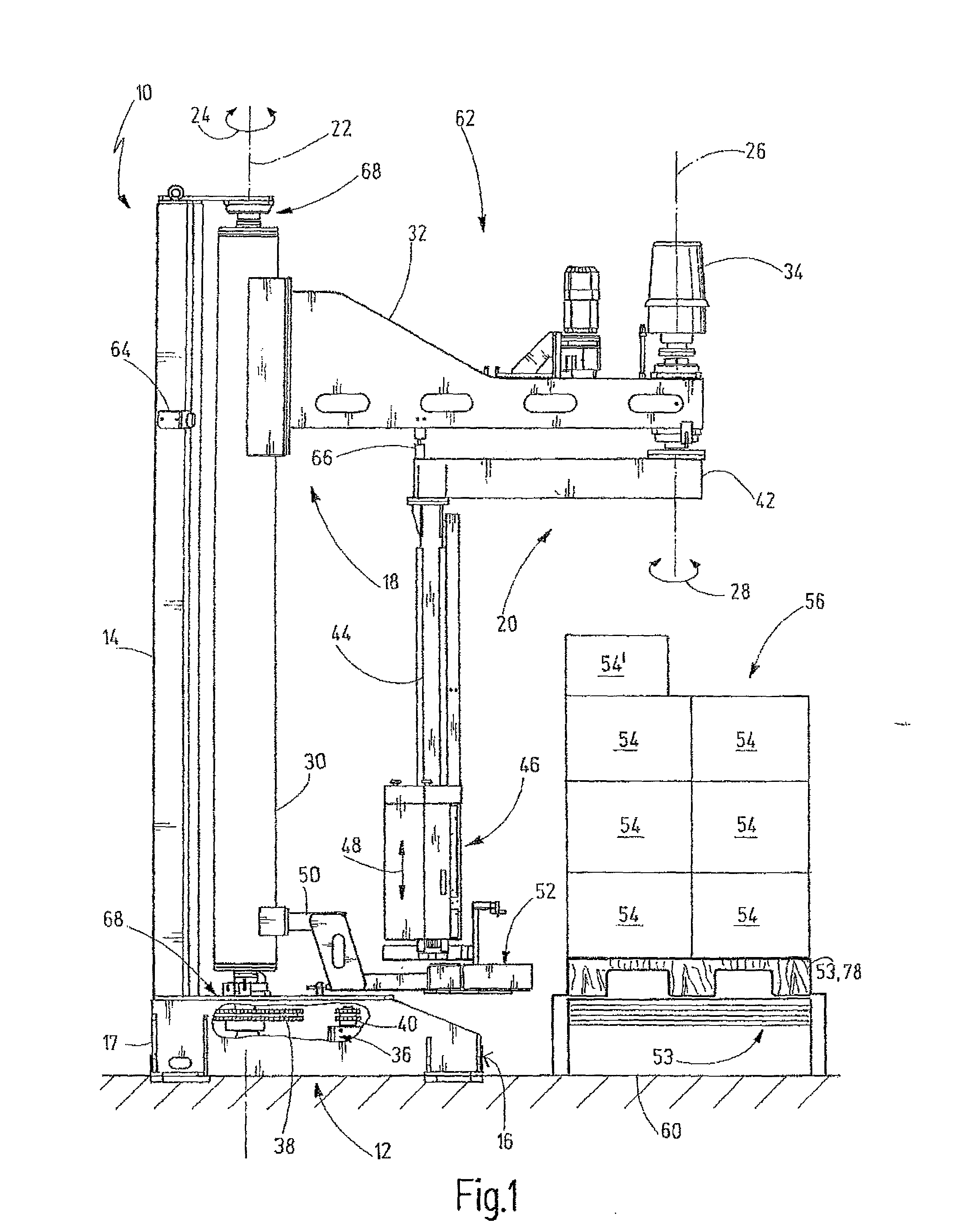

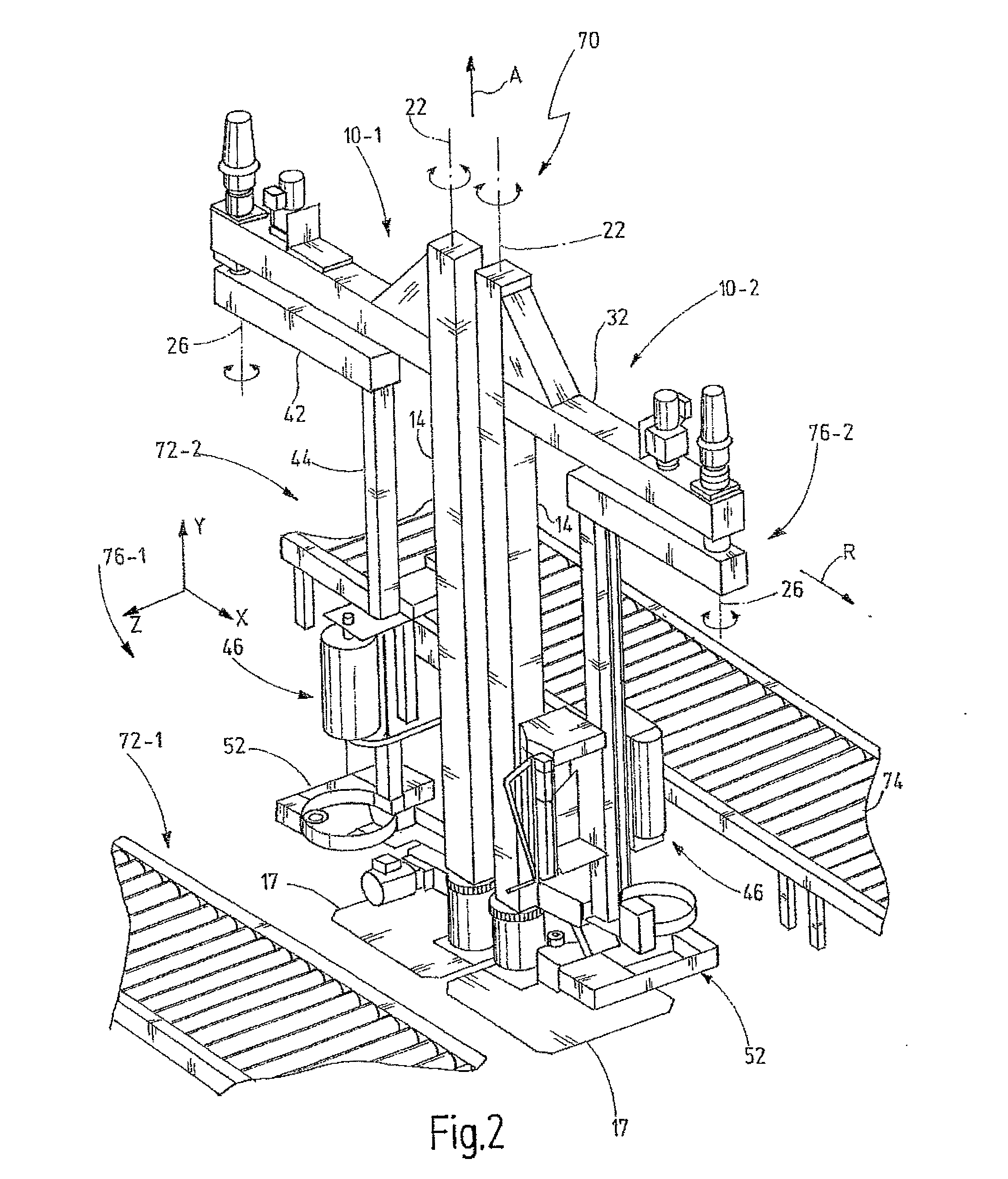

Packing station and method for automated loading of piece goods on a load carrier including subsequent foil wrapping

InactiveUS20130199133A1Prevent movementProvide spaceWrapping material feeding apparatusWeb rotation wrappingEngineeringMechanical engineering

An automated packing station for automated loading of load carriers with piece goods and for automated wrapping a stack with a foil, comprising: a fixedly arranged packing robot; and a rotational-arm winding device arranged adjacent to the packing robot and comprising a frame which is adapted to absorb forces which occur during the wrapping of the stack with the foil, and to forward the forces to an environment of the packing station.

Owner:SSI SCHFER NOELL GMBH LAGER UND SYSTTECHN

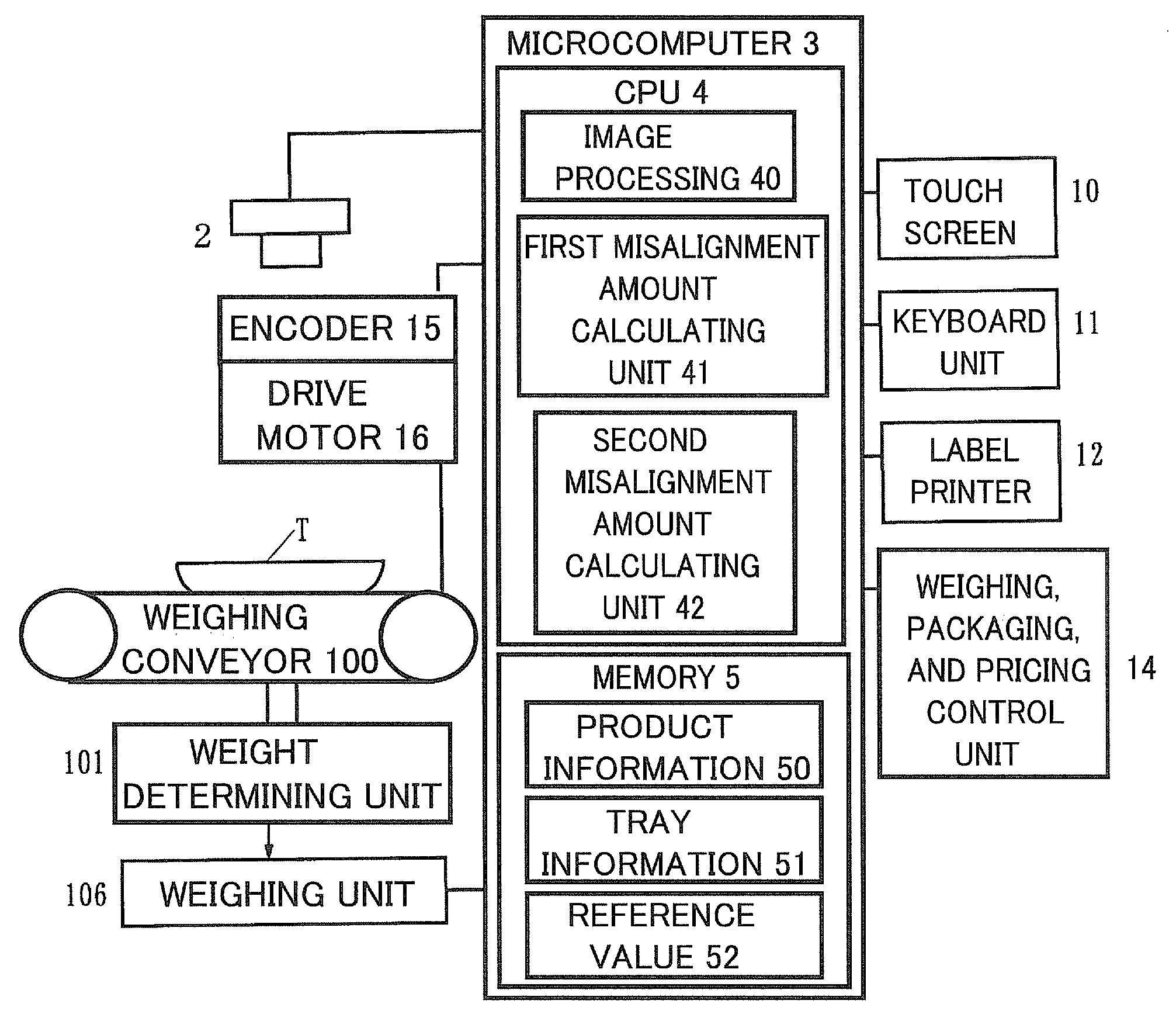

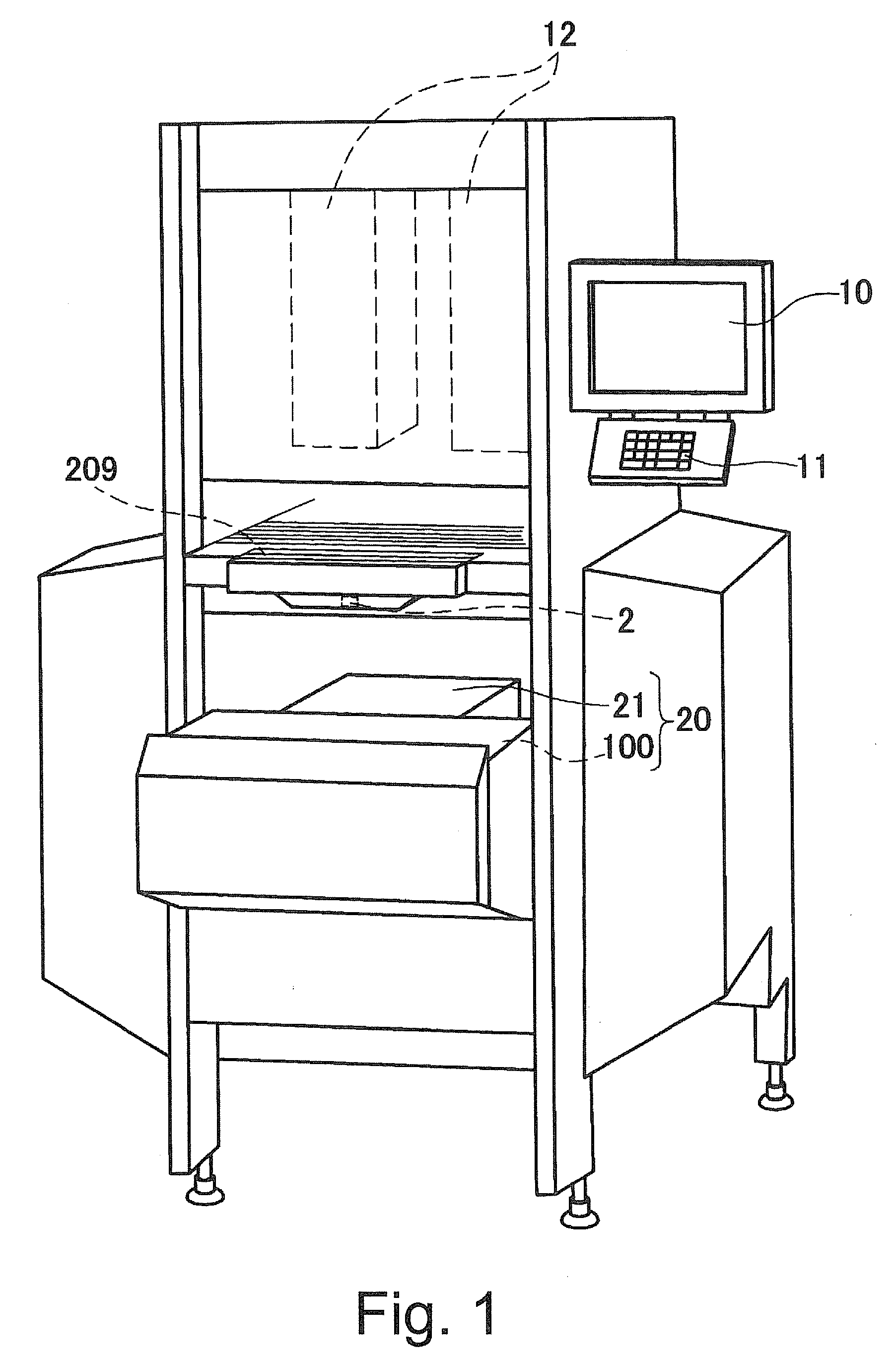

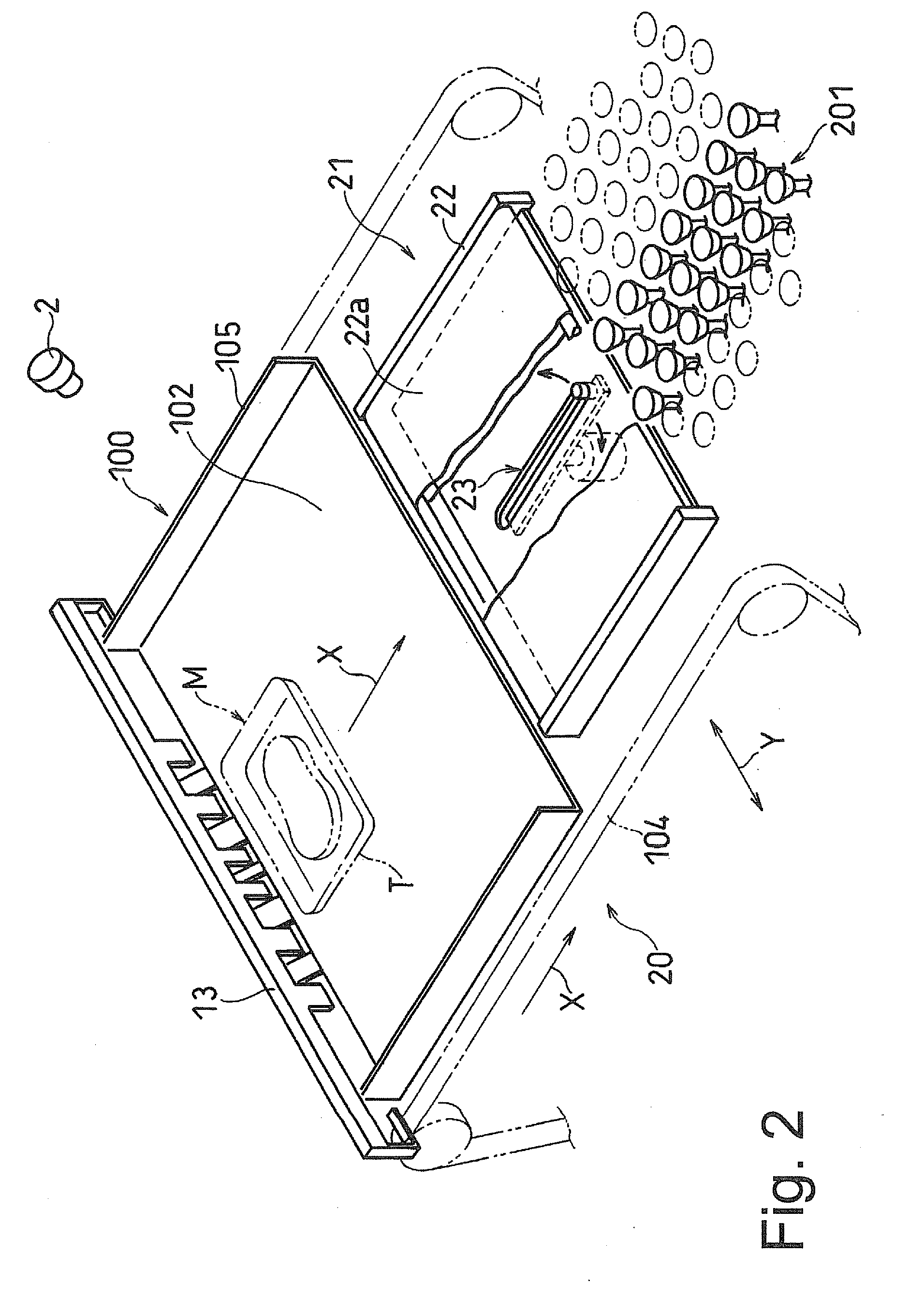

Packaging system

ActiveUS20060272283A1Excellent packaging finishCapsWrapping material feeding apparatusControl systemMechanical engineering

A packaging system is disclosed that packages a product by supplying the product onto a lifter by means of a supply device, pushing the product on the lifter up to a packaging station, and covering the top surface of the product with a film. The packaging system includes a conveying unit that contacts the rear end in the conveying direction of the product on the supply device and configured to convey the product onto the lifter, a detection unit configured to determine the amount of misalignment of the product in the conveying direction and / or the width direction that is orthogonal to the conveying direction, while the product is being conveyed by the conveying unit, and a control unit configured to control the devices in the system to perform in accordance with the amount of misalignment.

Owner:ISHIDA CO LTD

Bale Wrapping Mechanism

ActiveUS20160113204A1Not influence the tension on the wrapping materialEasy to controlWrapping material feeding apparatusMowersEngineeringMechanical engineering

A bale wrapping mechanism has a roll holding station and a duckbill provided for clamping one end of the roll of wrapping material, said duckbill being pivotally mounted, via at least a first hinge, to the baling chamber sidewalls, for delivering said wrapping material to said baling chamber by insertion of said duckbill between adjacent rolls of said baling chamber, wherein the wrapping mechanism further has at least a first guiding roll for guiding the wrapping material between said roll holding station and said duckbill, wherein said first guiding roll axis substantially coincides with the first hinge axis.

Owner:BLUE LEAF I P INC +1

Wrapping device

InactiveUS20120090273A1Simple designWrappers shrinkageWrapping material feeding apparatusEngineeringMechanical engineering

The invention relates to a wrapping device to wrap an object in foil material including a frame, a wrapping table mounted on the frame and configured to support the object during wrapping, one or more roll support devices to support one or more rolls of foil material to be rotated about the object during wrapping, a carrying structure mounted on the frame and configured to carry the one or more roll support devices, and a clamping and cutting device to clamp the foil material after wrapping of an object, and to cut the clamped foil material, wherein the clamping and cutting device is mounted on the carrying structure, and wherein the carrying structure is pivotable about a substantially horizontal pivot axis with respect to the frame.

Owner:LELY PATENT

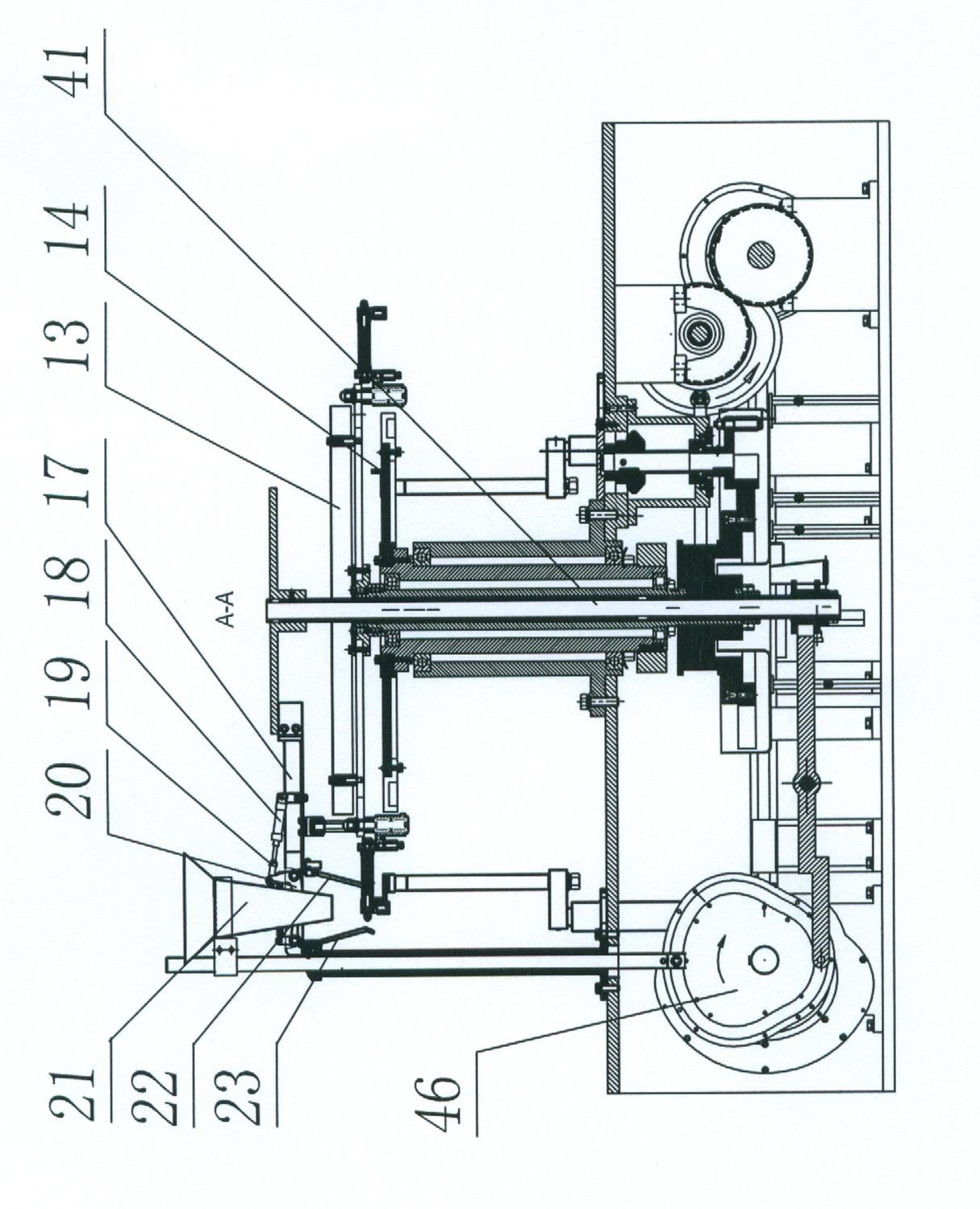

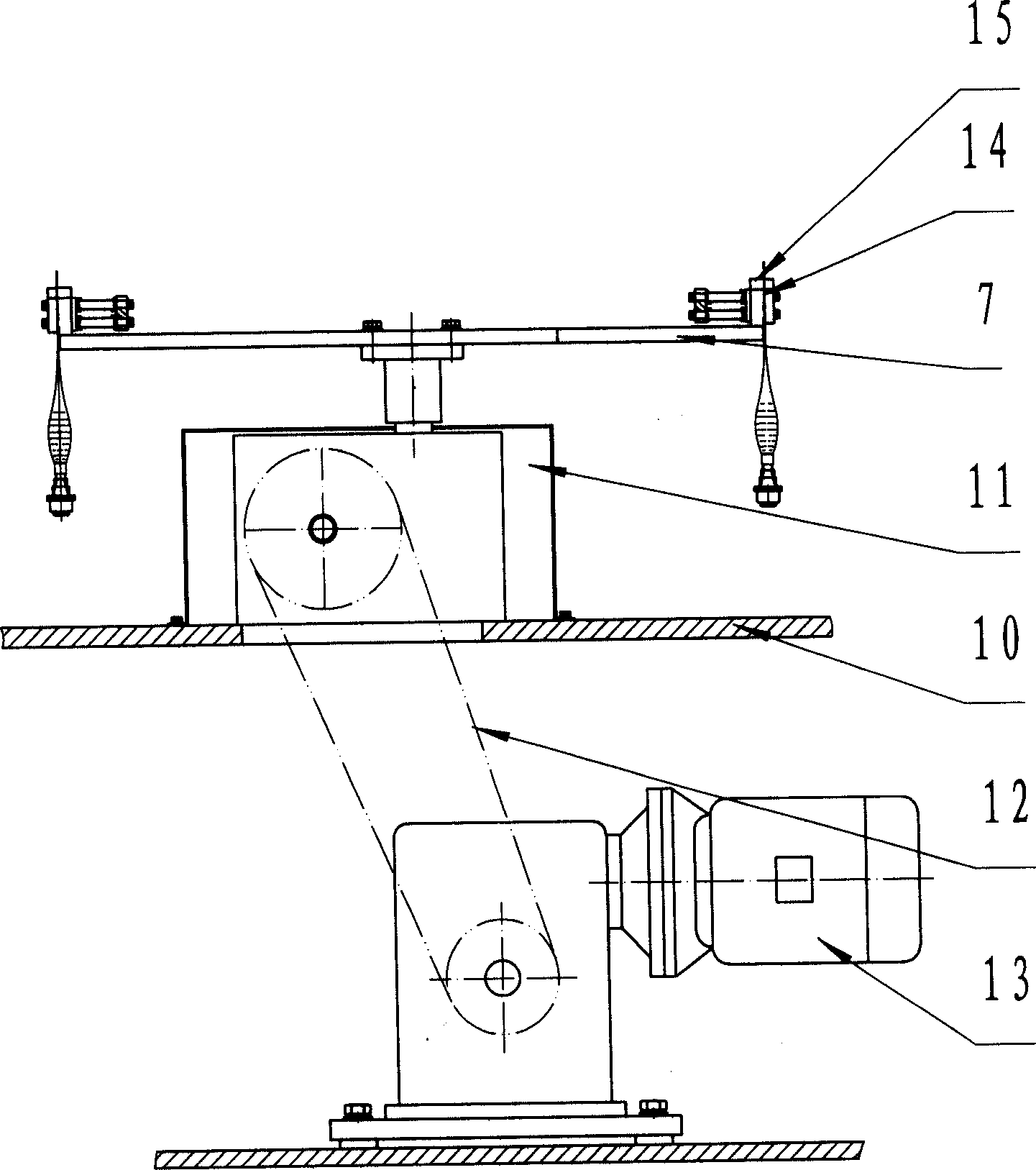

Intermittent rotary solid-drug-chargeable non-PVC infusion bag solid-drug filling machine

ActiveCN1743233AChange the way the medicine is dispensedChange middle linkPharmaceutical product form changeWrapper supporting apparatusEngineeringElectric control

The solid medicine-filling machine comprises power drive component, central dial, take-in and take-out component, bag-cutting part, thermal-sealing part, rack and electric control cabinet. The parts above are set on the side of the center dial that connects with the power drive component and are supported by the rack to layout in turn. Around the central dial is fitted with a bag holder for hanging infusion bag. On the filling part can be provided with a protective gas inlet.

Owner:HUNAN CHINASUN PHARMA MASCH CO LTD

Module wrap guide arrangement

ActiveUS20160353665A1Prevent and reduce occurrenceWrapping material feeding apparatusWrapper supporting apparatusMechanical engineeringEngineering

A wrap guide arrangement is provided for an agricultural harvesting machine having a module-forming chamber and wrapping system having a source of a wrapping material and a wrap conveyor arrangement for guiding the wrapping material from the source to the conveyor arrangement. The wrap guide arrangement has a wrap roll extending along an axis of rotation and having an outer circumference receiving the wrapping material. A guide plate has an axially extending body and at least one finger extending from the body toward the wrap roll. At least a part of the at least one finger extends proximate the outer circumference of the wrap roll between the wrap roll and the wrapping material.

Owner:DEERE & CO

Paper wrapping and pasting device of full-automatic hamburger packaging machine

ActiveCN105857702ARealize automatic paper wrappingThe process is complete and smoothWrapper folding/bending apparatusWrapper supporting apparatusMeat burgerPulp and paper industry

The invention discloses a paper wrapping and pasting device of a full-automatic hamburger packaging machine. The paper wrapping and pasting device comprises a rack, wherein a working platform is arranged on the rack; four mechanical claw arms are respectively arranged on the working platform; the four mechanical claw arms comprise two groups of front claw arms and rear claw arms arranged oppositely; sponge strips are arranged in the middle of the rear claw arms; the sponge strips face to a paper wrapping station; compression springs are arranged at the connecting parts of the four mechanical claw arms and the working platform; push rods are mounted on a push platform; the push platform is connected with a lifting driving component; through holes through which the mechanical claw arms are turned downwards and the push rods penetrate are formed in outer sides of the four mechanical claw arms on the working platform; a paper pressing cylinder and a pressing block are arranged above the paper wrapping station; a paper pasting mechanism is arranged on a side above the paper wrapping station; the moving end of the paper pressing cylinder is connected with a paper belt plate; an upper paper coiling wheel is mounted on the rack; a paper pasting piece is mounted on a roller of the upper paper coiling wheel in a sleeving manner; and the paper pasting piece penetrates through the end part of the paper belt plate and penetrates through a lower paper coiling wheel. The paper wrapping and pasting device is automatic in operation, saved in time and labor and relatively high in working efficiency, and automatic paper wrapping of hamburgers can be achieved.

Owner:ZHEJIANG UNIV OF TECH

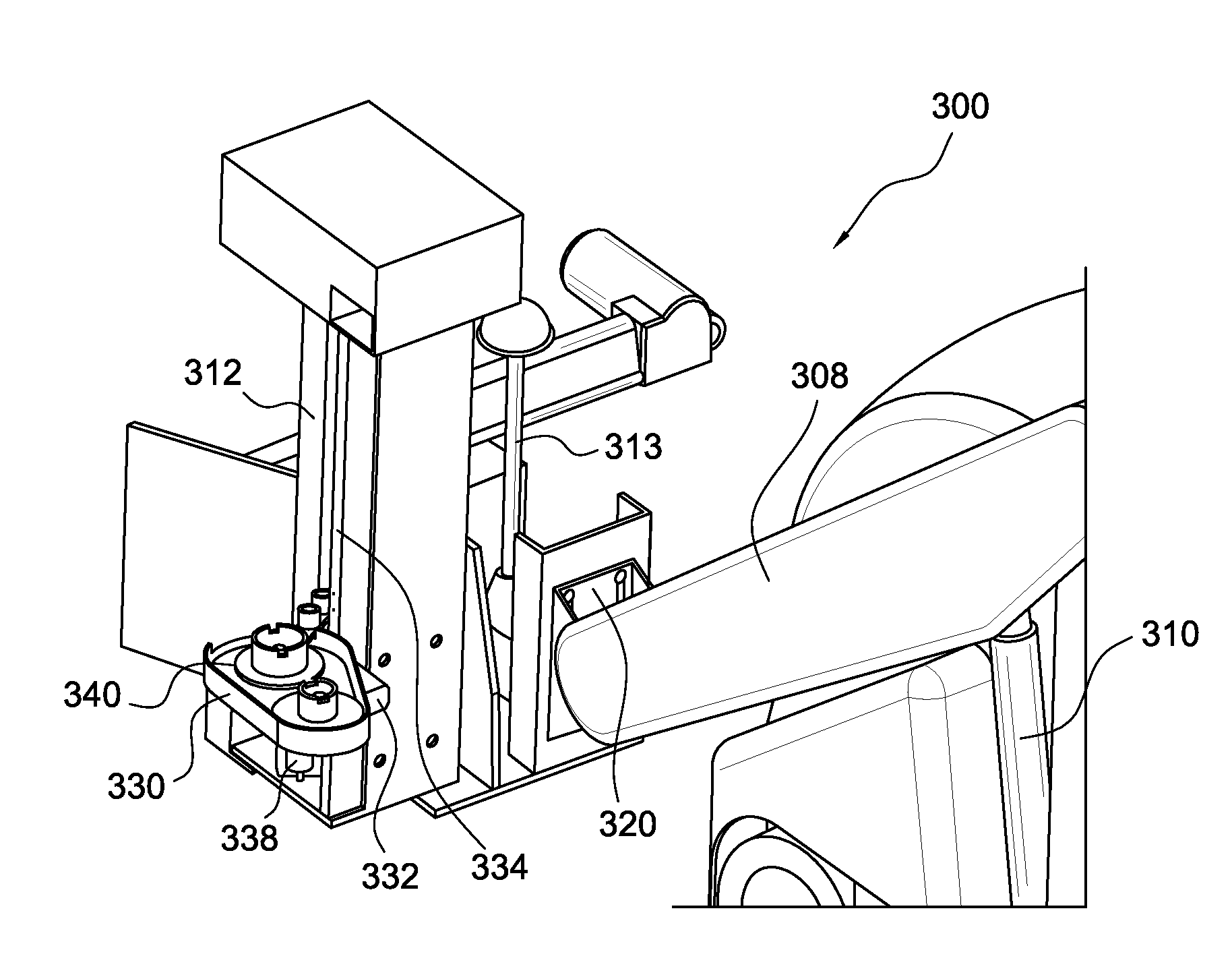

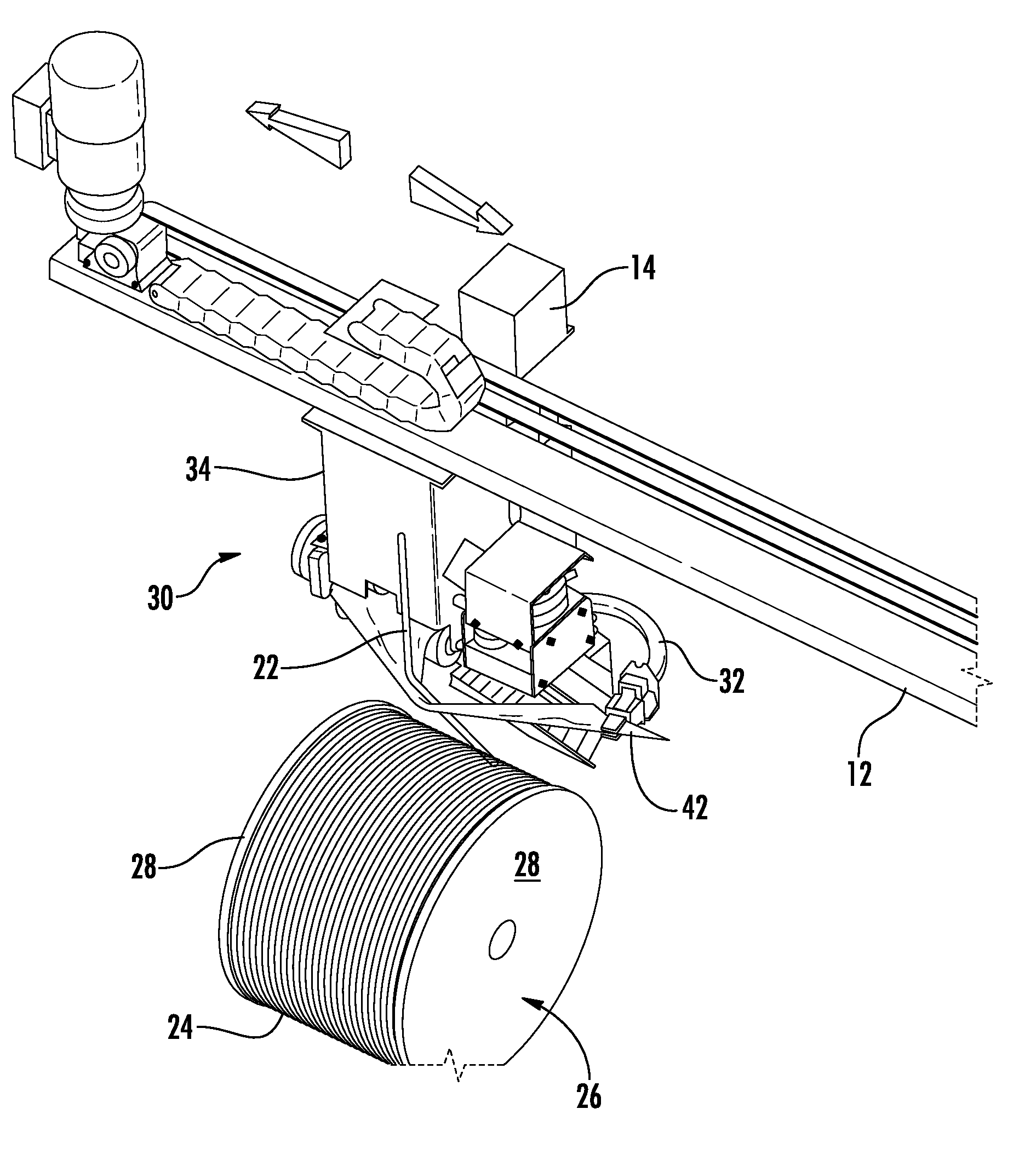

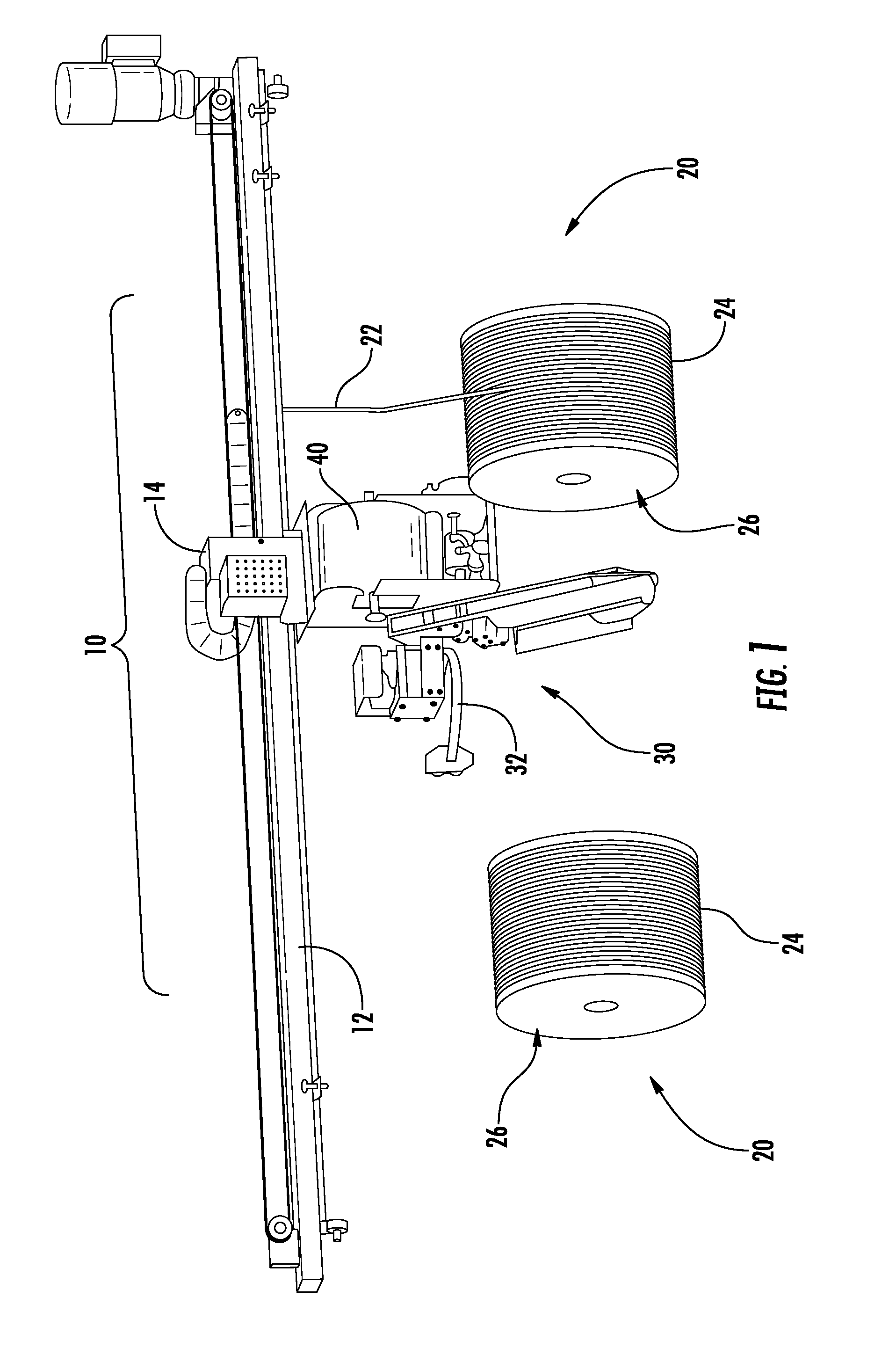

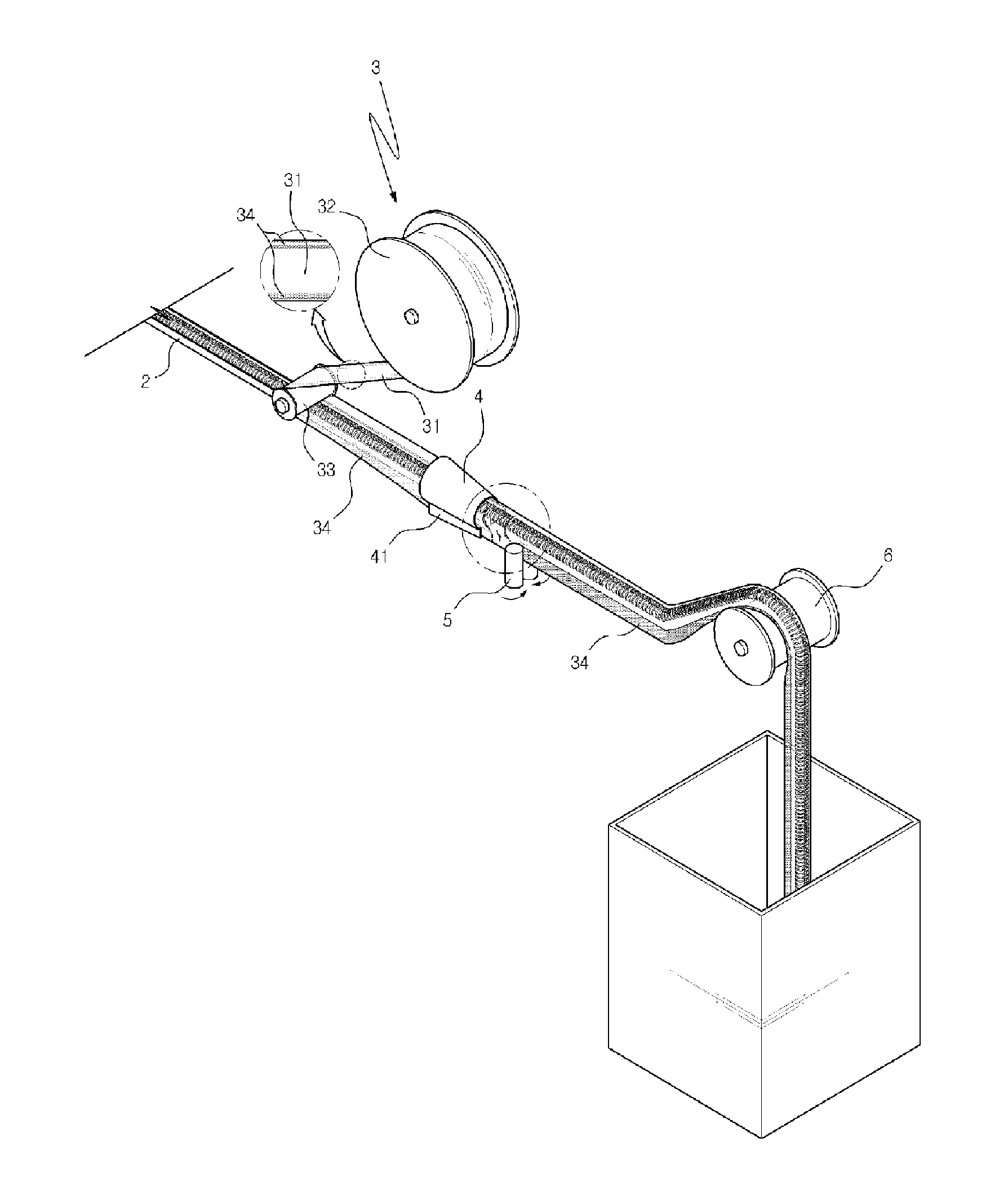

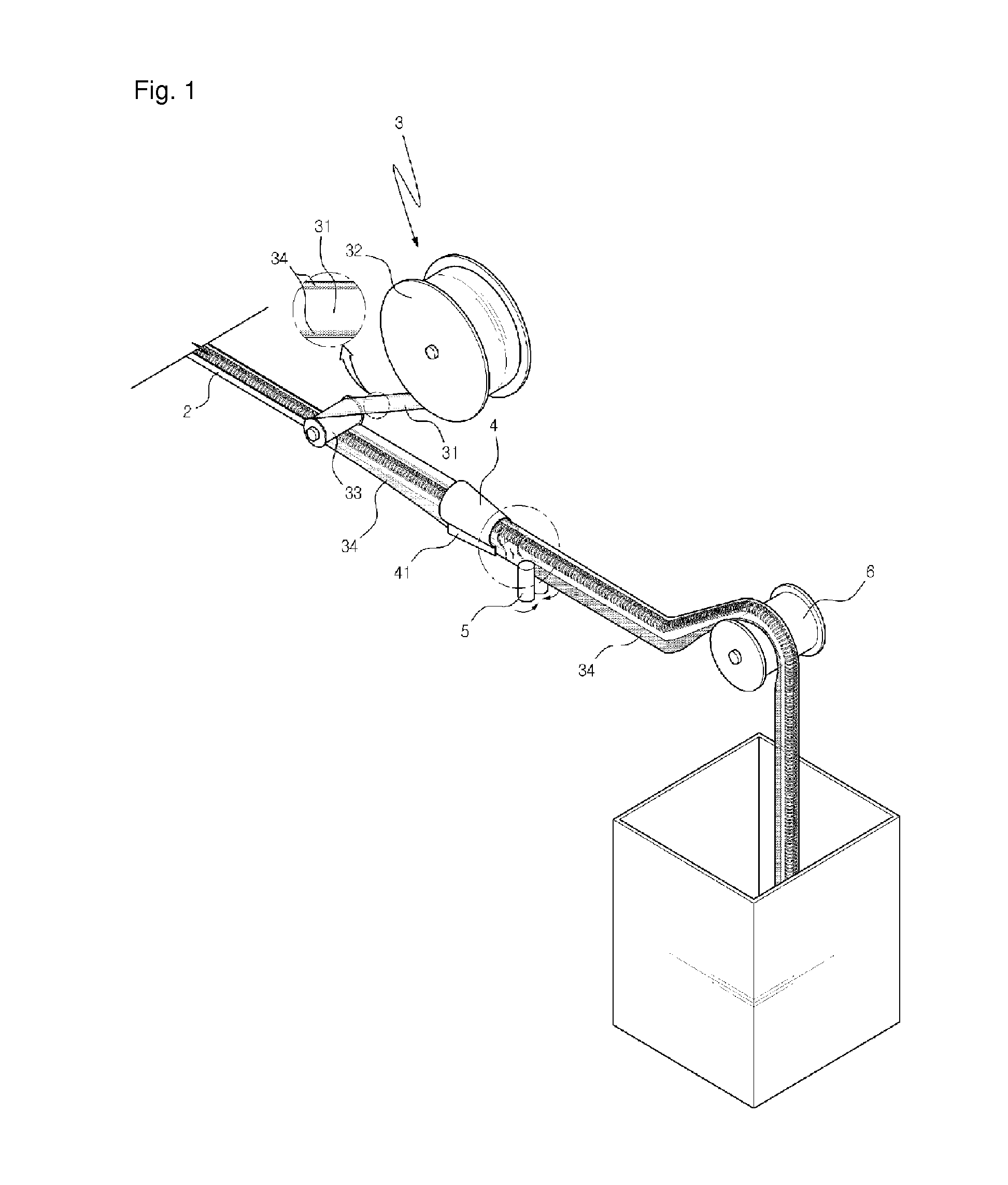

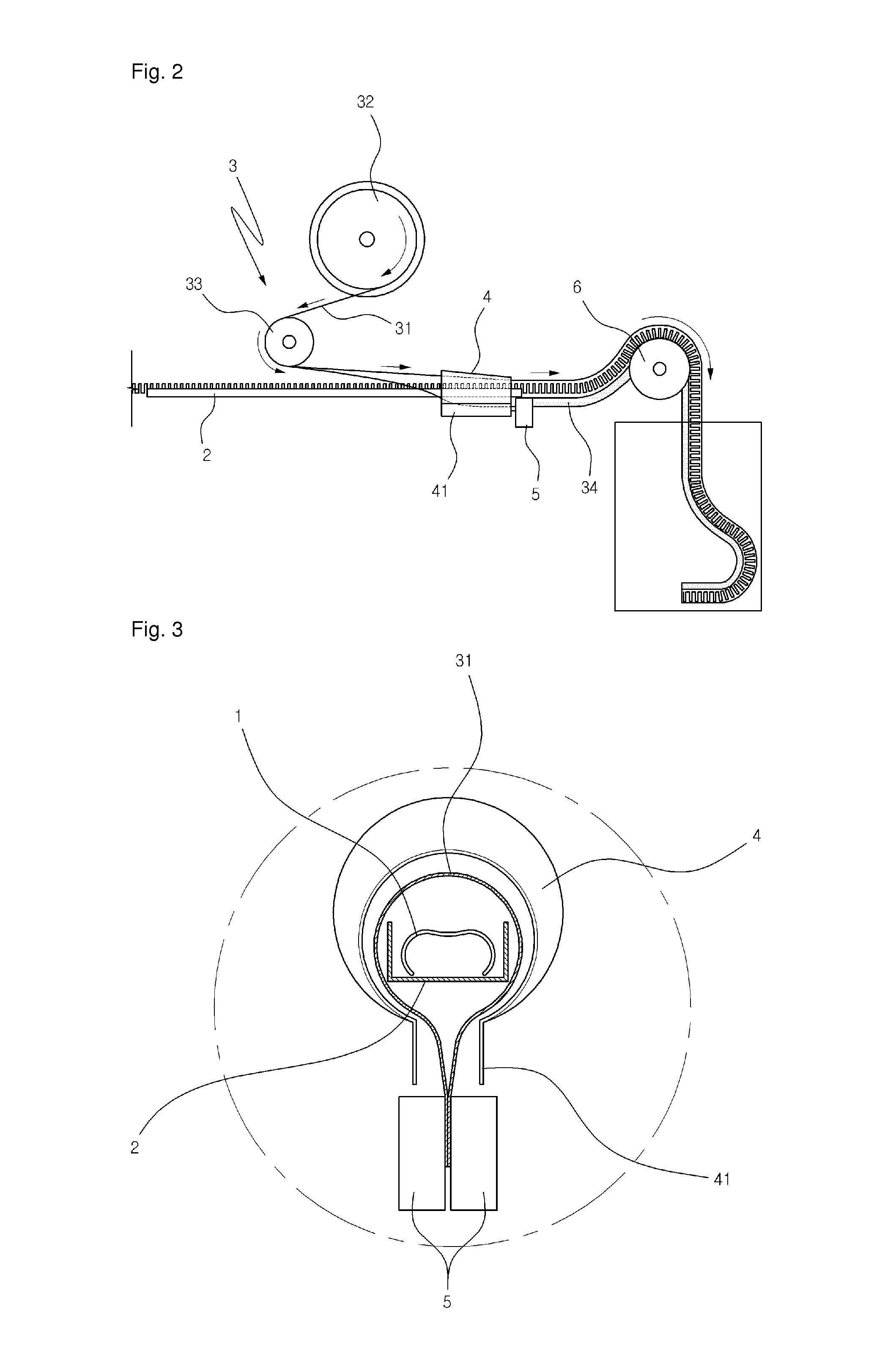

System and method for securing free end of wound cable

InactiveUS20150360800A1Wrappers shrinkageWrapping material feeding apparatusWinding machineStretch wrap

A system for securing a free end of a cable wound on a spool includes a spooling machine having at least one spooling head for winding a length of the cable onto the spool and a stretch wrap applicator for securing the free end of the cable on the spool with stretch wrap that is pinched between the free end of the cable and the outermost windings of the cable wound on the spool. A stretch wrap applicator for a spooling machine having at least one spooling head includes a housing, a roll of stretch wrap disposed within the housing and a pulling clamp for gripping and pulling a starting end of the stretch wrap so as to position the stretch wrap between a spool of wound cable having outermost windings and a free end of the cable wound on the spool. A method for securing the free end of a cable wound on a spool includes providing the spooling machine and the stretch wrap applicator, moving the pulling clamp from an initial position around a free end of the cable, gripping a starting end of the stretch wrap, moving the pulling clamp and the stretch wrap back to the initial position with the stretch wrap disposed between the free end and the outermost windings of the cable and moving the pulling clamp in a downward direction so as to pinch the stretch wrap within a nip defined between the outermost windings and the free end of the cable.

Owner:WINDAK

Systems and processes for packing articles of footwear

ActiveCN108974458AImprove efficiencyReduce mistakesWrapping material feeding apparatusWeb rotation wrappingSheet materialMechanical engineering

Systems and processes for packing complementary articles of footwear into a container are disclosed. The processes can include utilizing a reusable packing sheet positioned underneath complementary articles of footwear to transfer the complementary articles of footwear into a container. The processes can also include removing the reusable packing sheet from underneath the complementary articles offootwear while the complementary articles of footwear remain positioned in the container. Additional processes can include aligning and sizing complementary articles of footwear for packing in a container.

Owner:NIKE INNOVATE CV

Gripper for an automated manipulator and method for operation of the gripper

InactiveUS20100218464A1Compact designEasy to handleWrapper folding/bending apparatusWrapper supporting apparatusEngineeringManipulator

A manipulator gripper in particular for palletizing and / or depalletizing bundles by means of a robot, has a tool flange for connection to a manipulator; a clamp stop and a counter-stop. Both extend along a lowering axis. A support base extends toward the counter-stop in an insertion plane. The counter-stop and / or the clamp stop can be shifted toward the insertion plane of the support base along the lowering axis, relative to the tool flange.

Owner:KUKA ROBOTER

Overhead packaging machine with articulating lugs

ActiveUS20130111855A1Maintain alignmentWrapping material feeding apparatusWrapper folding/bending apparatusCartonProduct group

An overhead packaging machine with articulating lugs is mountable along a product packaging system for the application of cartons such as wrap-style cartons about sets or groups of products. The overhead packaging machine includes a lug conveyor having a series of articulating lug assemblies mounted thereto and which are moved along a path of travel for engaging the groups of products with their cartons applied thereto. Each of the articulating lug assemblies includes a pair of articulating lugs mounted to a carriage, which articulating lugs are moveable into engaging positions for engaging the cartons applied to the groups of products as the groups of products are moved along their path of travel for folding and locking of the cartons thereabout. After the cartons have been applied and secured about their product groups, the articulating lugs can be moved to non-engaging positions, out of engagement with the cartons and / or product groups as the packaged product groups are moved away from the overhead packaging machine, while the articulating lug assemblies can be moved along a return path of travel for engaging a next product group.

Owner:GRAPHIC PACKAGING INT

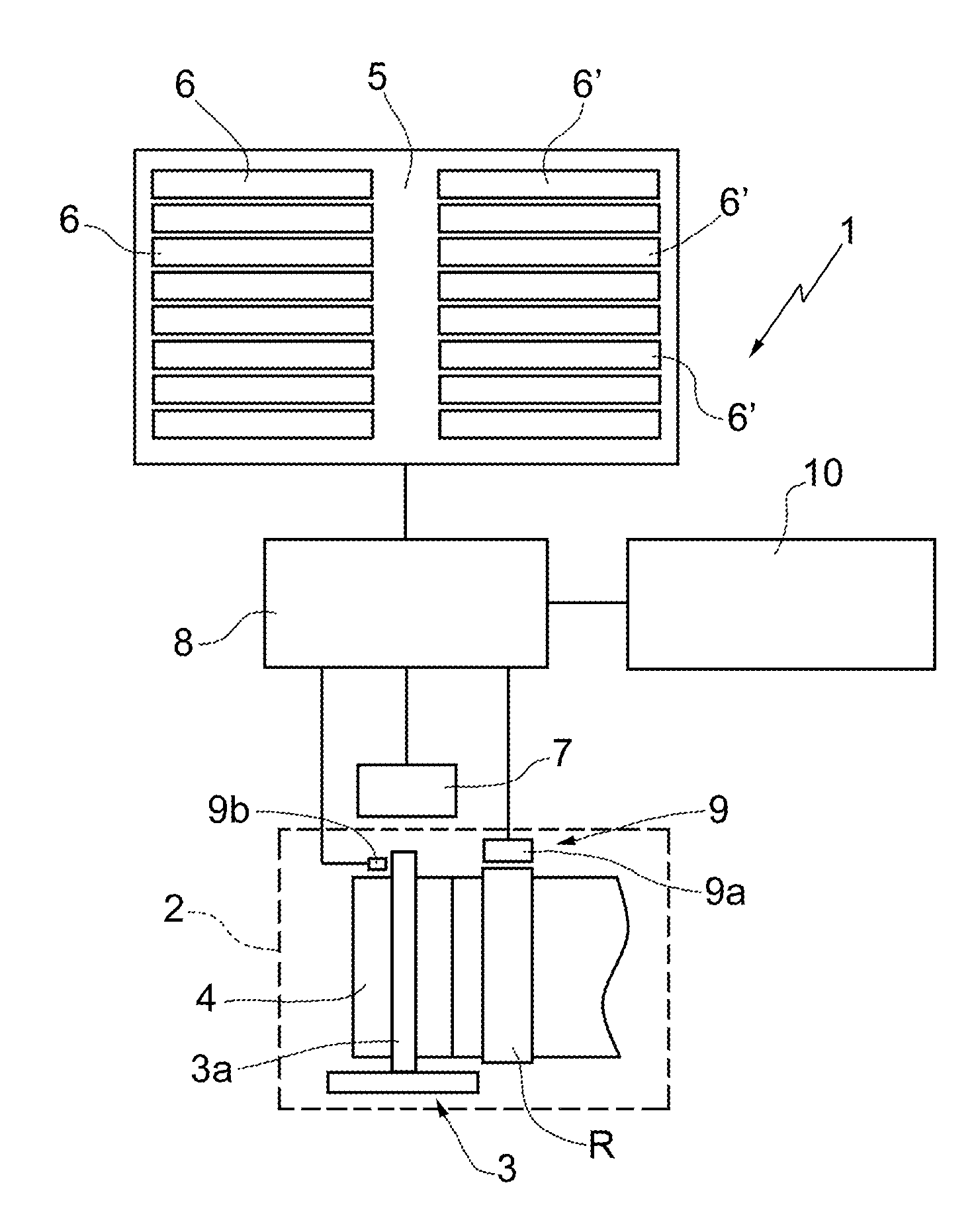

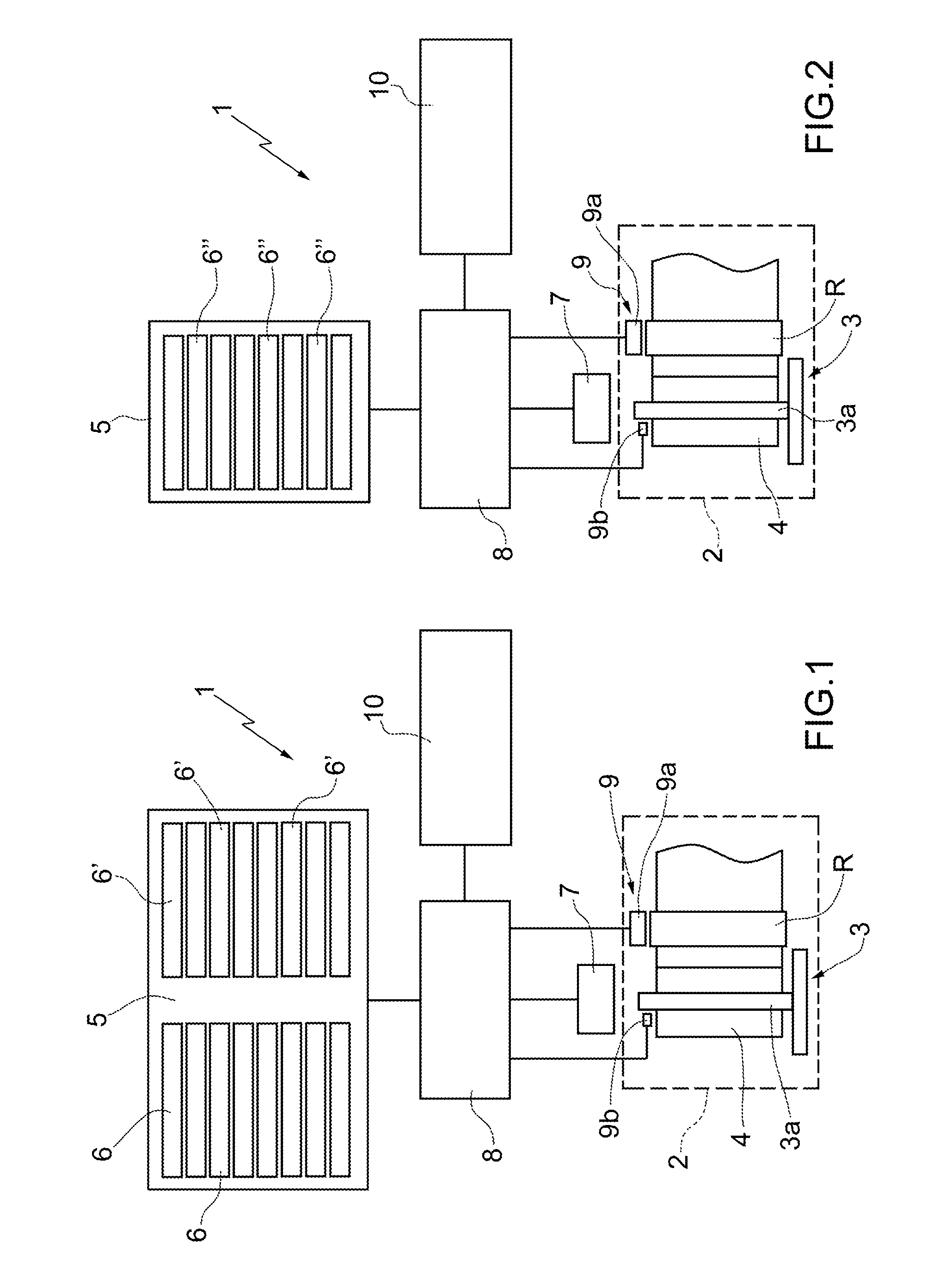

Device and method for checking the quality of extensible film for packaging

ActiveUS20160229573A1Increase heightGood conditionWrapping material feeding apparatusWrapper supporting apparatusEngineeringWrapping procedure

A device for checking the quality of extensible film for wrapping purposes available in reels, operatively associable to a wrapping machine including means for supporting at least one reel of extensible film, including at least one storage memory of a plurality of wrapping programs of a palletized load, each characterised by different operating parameters to carry out the wrapping operation, the means of detection of at least one parameter representative of the quality of the film on the reel, the means for measuring, instant by instant, the present diameter of the reel, an electronic processor, operatively associated with the storage memory, with said detection means and with said measuring means, suitable for selecting and / or changing a given wrapping program according to at least said parameter representative of the quality of the film on the reel. A method to inspect the quality of the packaging stretch film available in reels.

Owner:E80 GRP SPA

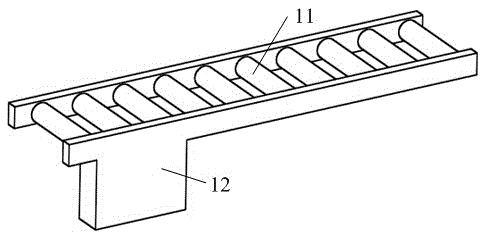

Packing instrument for a bookbinding spring

ActiveUS9139318B2Low costTime to workFilament handlingWrapper supporting apparatusEngineeringMechanical engineering

Owner:SPIRAL BINDING LLC

Film coating mechanism for yarn balls

ActiveCN107380507AAvoid the problem of not covering the surface of the yarn packageEnvelope realizationWrapping material feeding apparatusWeb rotation wrappingYarnElectric machine

The invention discloses a film coating mechanism for yarn balls. The film coating mechanism comprises a film coating support and a mounting plate arranged on the top of the film coating support, and further comprises a film feeding assembly and a film winding assembly. The film feeding assembly comprises an upper film clamping assembly arranged on the mounting plate and a lower film clamping assembly corresponding to the upper film clamping film assembly and arranged on the lower portion of the film coating support. A film coating gear ring is movably arranged in the middle of the mounting plate, a rotating motor is connected with one side of the film coating gear ring, the film winding assembly is arranged on one side of the film coating gear ring, and the film coating gear ring drives the film winding assembly to rotate. Coating films can be automatically conveyed to the side walls of the yarn balls through longitudinal moving and synchronous horizontal moving of the upper and lower film clamping assemblies, and film feeding is completed; right after each yarn ball is wrapped with one layer of coating film, the coating film is loosened, so that the problem that the coating films cannot cover the surfaces of the coating films is effectively avoided.

Owner:福德机器人(成都)有限责任公司

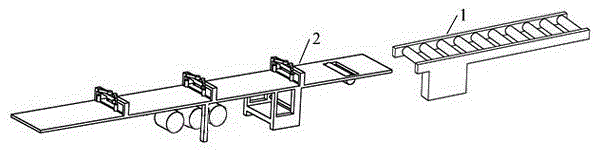

Full-automatic continuous feeding and discharging aluminum material packaging machine

ActiveCN105480470ASmooth fitImprove packaging efficiencyWrapper supporting apparatusEngineeringPaper sheet

The invention discloses a full-automatic continuous feeding and discharging aluminum material packaging machine. The full-automatic continuous feeding and discharging aluminum material packaging machine comprises a paper feeding device and a packaging device. The paper feeding device comprises a first conveying mechanism and a second conveying mechanism which are sequentially arranged; the packaging device comprises a rack and horizontal symmetric sliding seats arranged on the rack; the horizontal symmetric sliding seats can be close to or away from the material packaging machine, the conveying speed of the first conveying mechanism and the conveying speed of the second conveying mechanism are matched, so that before one set of an aluminum material to be packaged completely passes through a paper inlet, the aluminum material is in head-to-tail abut joint with the next set of aluminum material, a packaging pressing plate which abuts against one side and the upper surface of the aluminum material packages the aluminum material, constantly-continuous aluminum material packaging can be achieved, the packaging efficiency is improved, the packaging paper is attached to the aluminum material in a smooth manner, and the packaging quality is improved.

Owner:GUANGDONG JMA ALUMINUM PROFILE FACTORY GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com