Plane glass sheet packing container for displays

A glass plate and display technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of increasing the number of workers, low operating efficiency, and injury to operating personnel, so as to reduce operating workers, improve operating efficiency, and save packaging costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

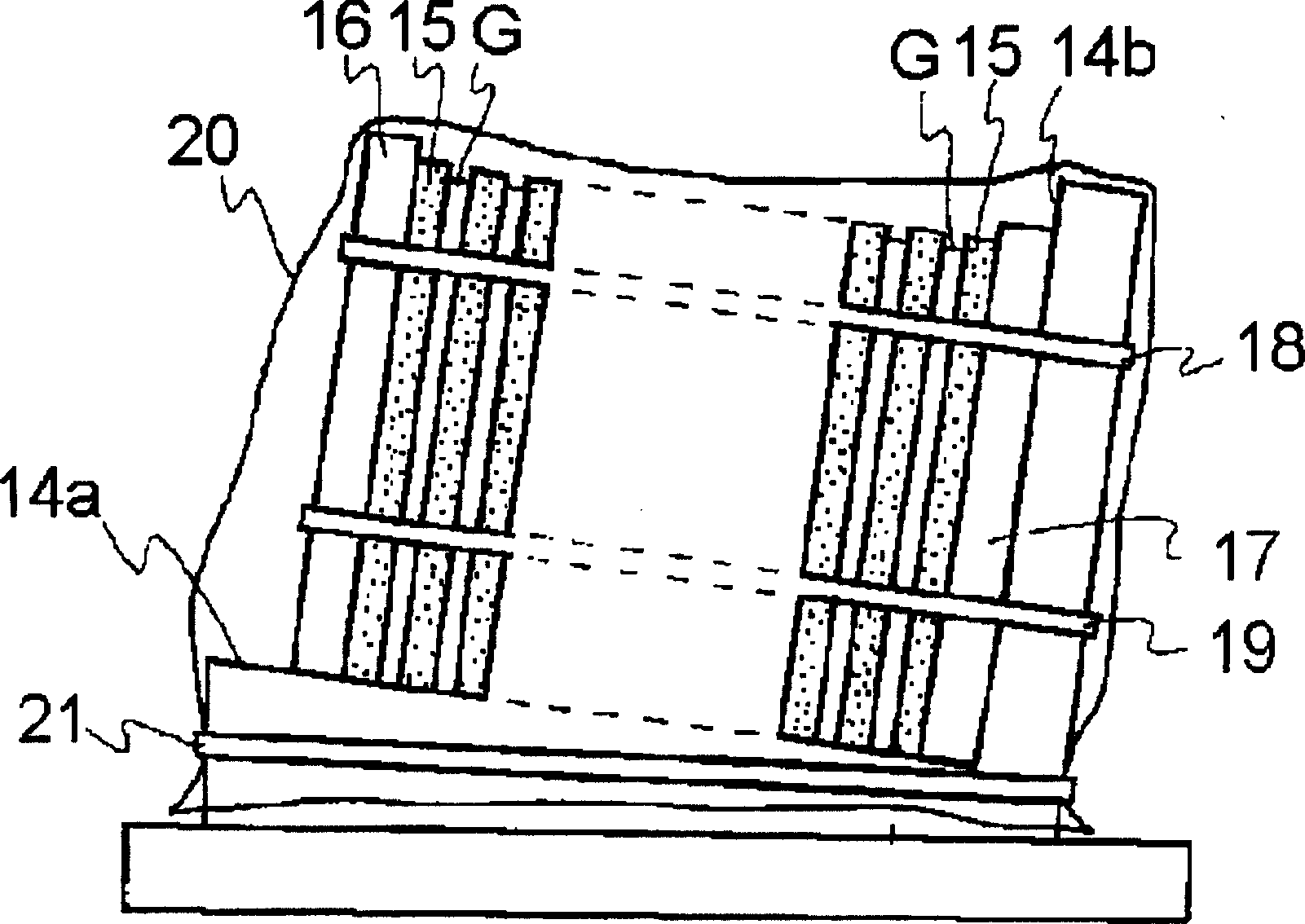

Image

Examples

Embodiment Construction

[0031] Hereinafter, how to implement the present invention will be described in detail based on the attached drawings.

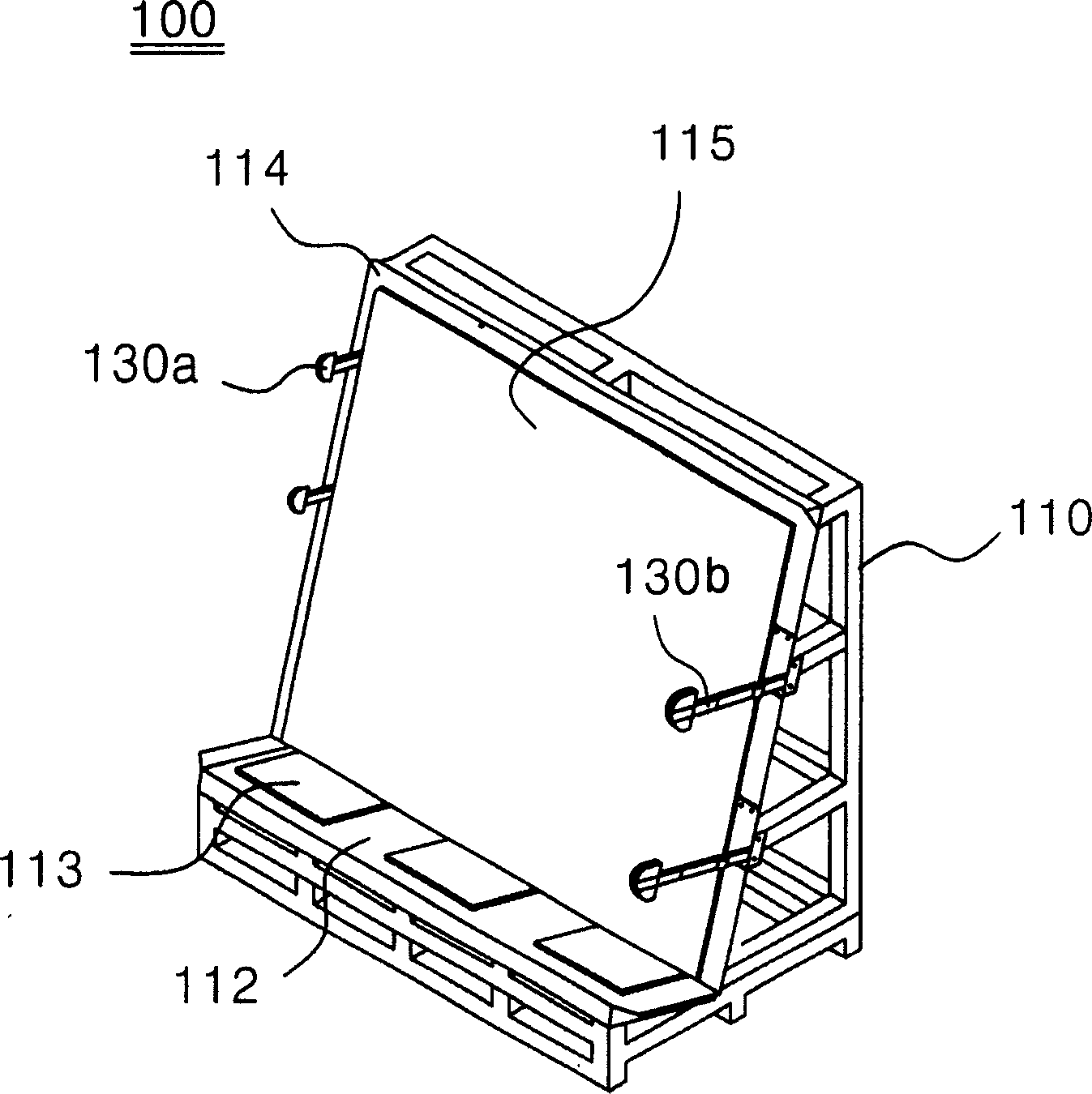

[0032] figure 2 Refers to the oblique view of the packaging box of the flat glass plate for display introduced by the present invention.

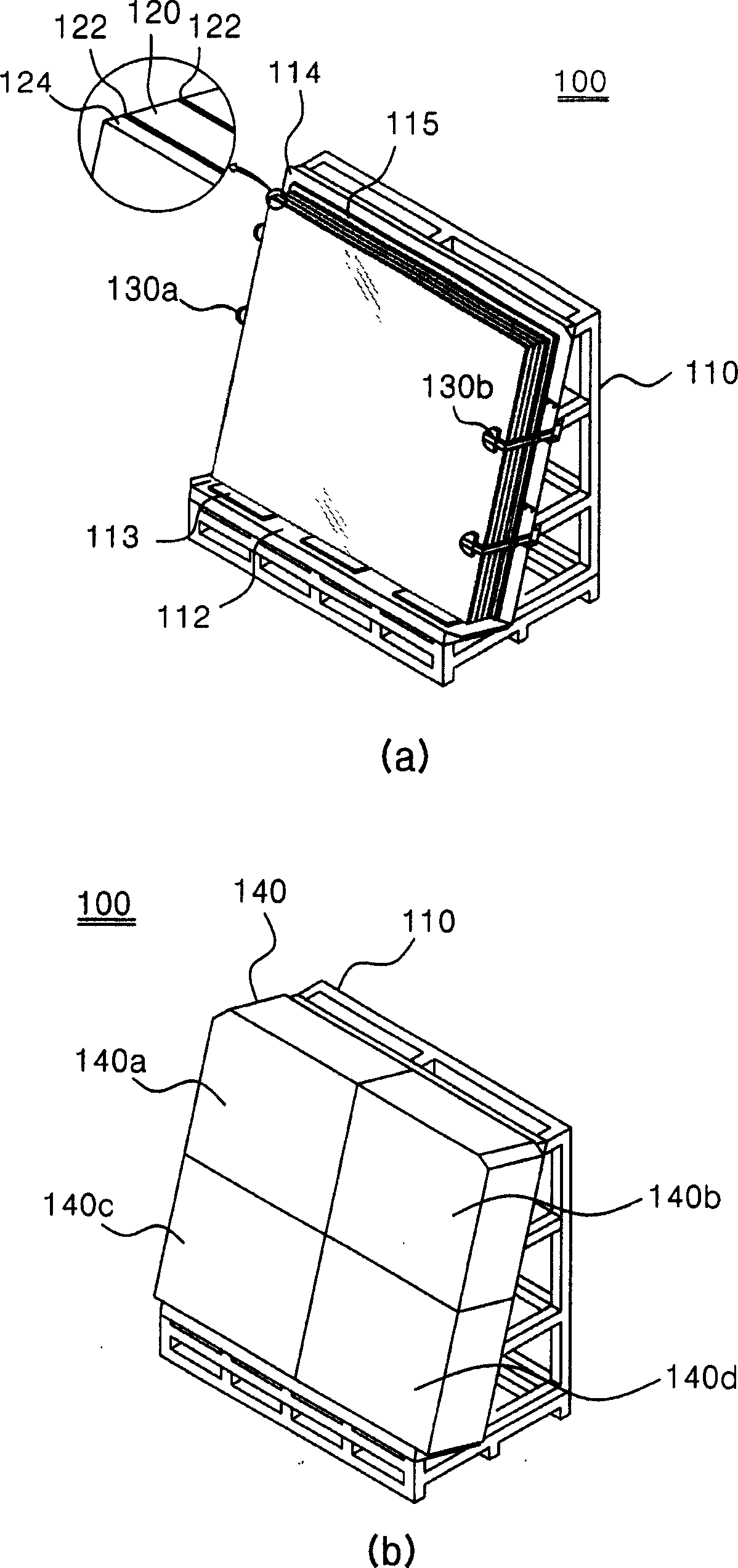

[0033] image 3 It is a diagram of the use state of the packing box of the display flat glass plate introduced by the present invention. (a) shows the state when the flat glass plate for display is placed in the packing box of the flat glass plate for display that the present invention introduces; The state diagram of the packing box after packing.

[0034] The following will refer to figure 2 and image 3 To illustrate the packing box of the flat glass plate for the display that the present invention introduces.

[0035] The packaging box 100 of the flat glass plate for the display that the present invention introduces is first to construct the packaging box to place the frame, and then to construct and place the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com