Rotary wrapping machine for packaging objects

A winding machine and film packaging technology, applied in the direction of packaging/bundling items, packaging, transportation packaging, etc., can solve the problems of packaging size restrictions, increased weight, complexity needs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

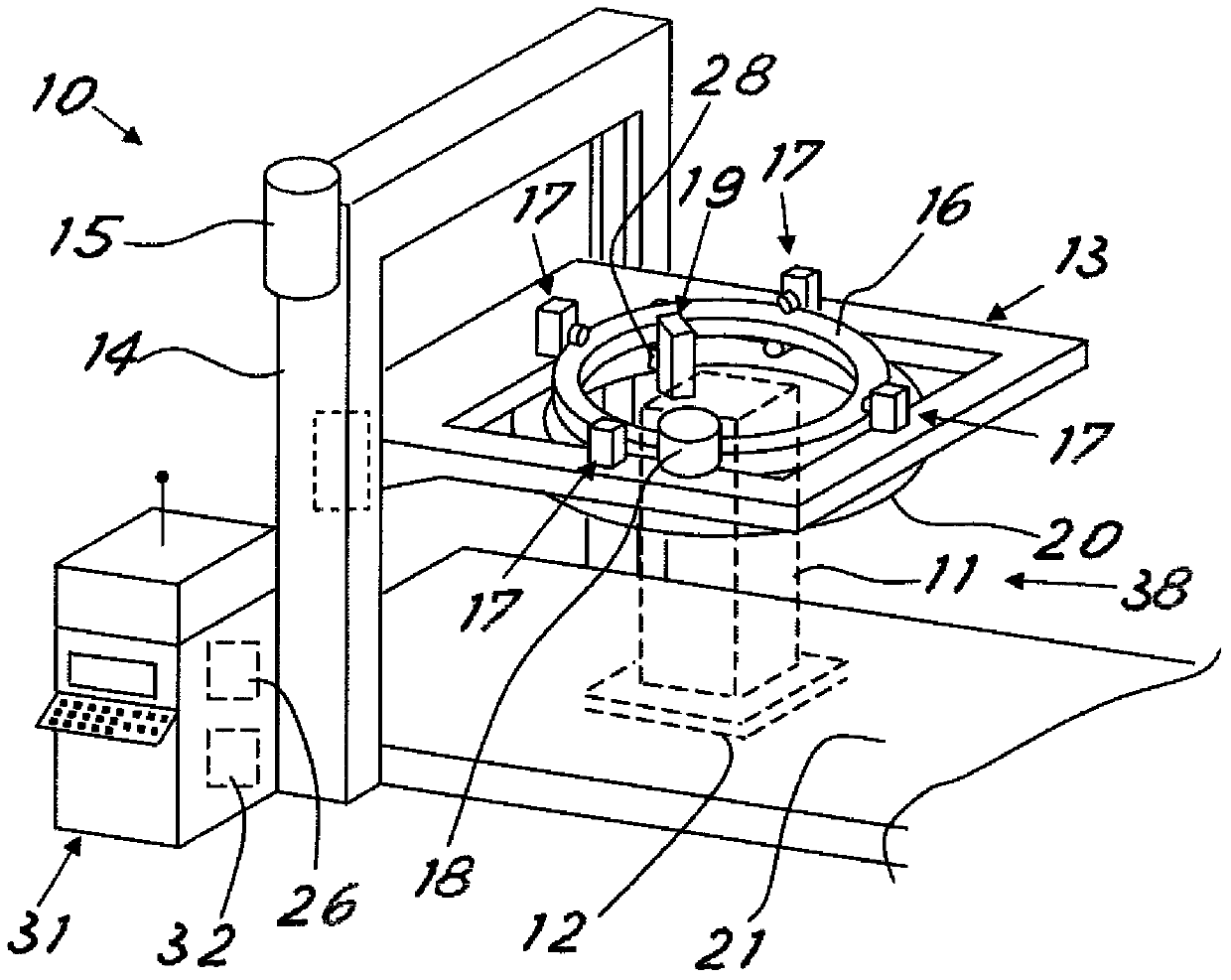

[0026] With reference to the accompanying drawings, figure 1 A winding device or winding machine according to the invention is shown, indicated generally at 10 .

[0027] As will be explained below, the device 10 is designed to wrap a strip of suitable plastic film around the articles 11 arranged in the packaging area 38 of the machine. The introduction of the articles into the packaging area 38 (and the optional removal of the articles) may be carried out, for example, by means of a conveyor line 21 , advantageously a belt conveyor or a roller table.

[0028] The winding station forms a station for packaging products, for example palletized, as can be easily imagined by a person skilled in the art. Typically, the article 11 may be formed by a group of products (eg boxes, bricks, etc.) Fastened in a single package.

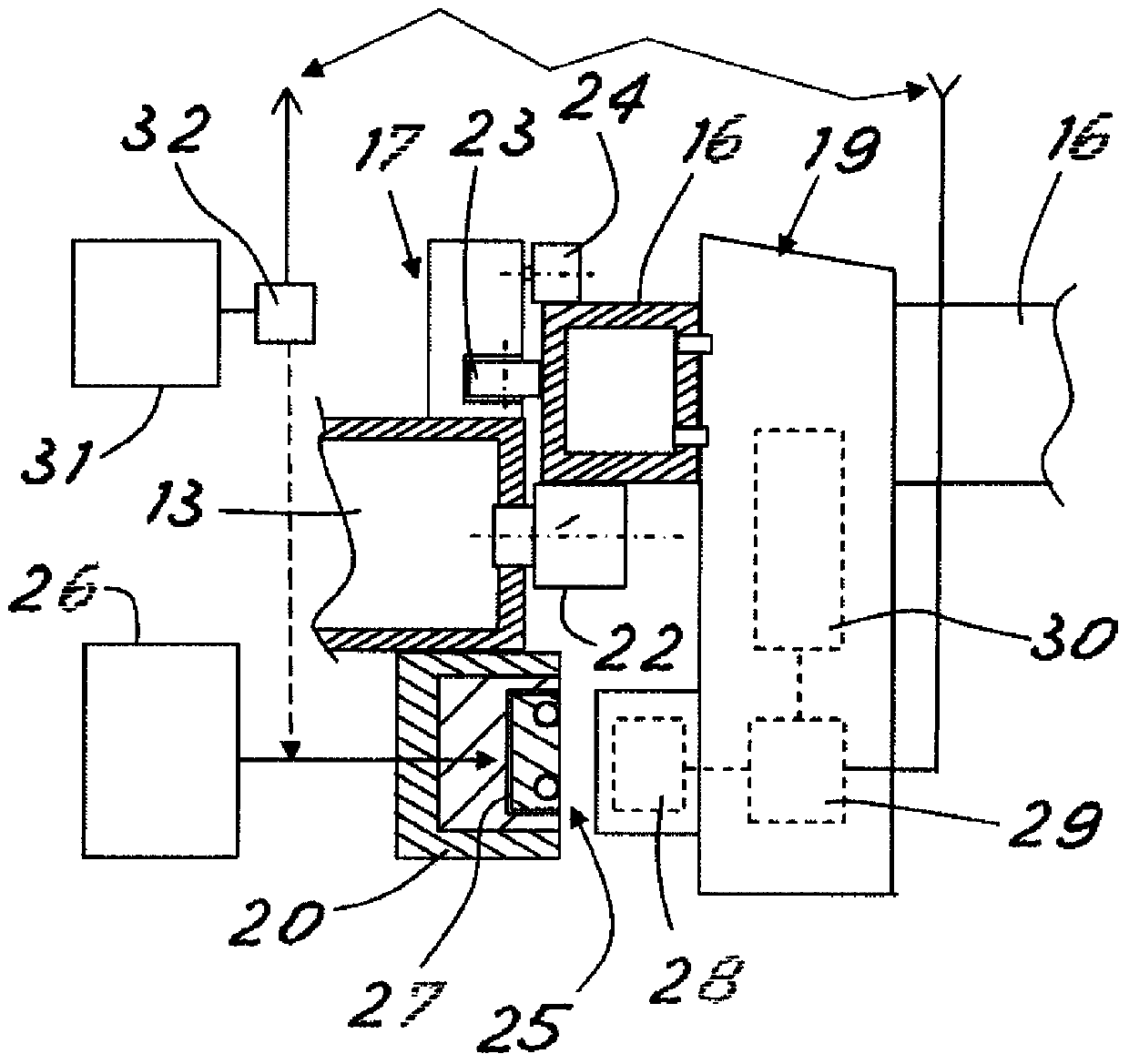

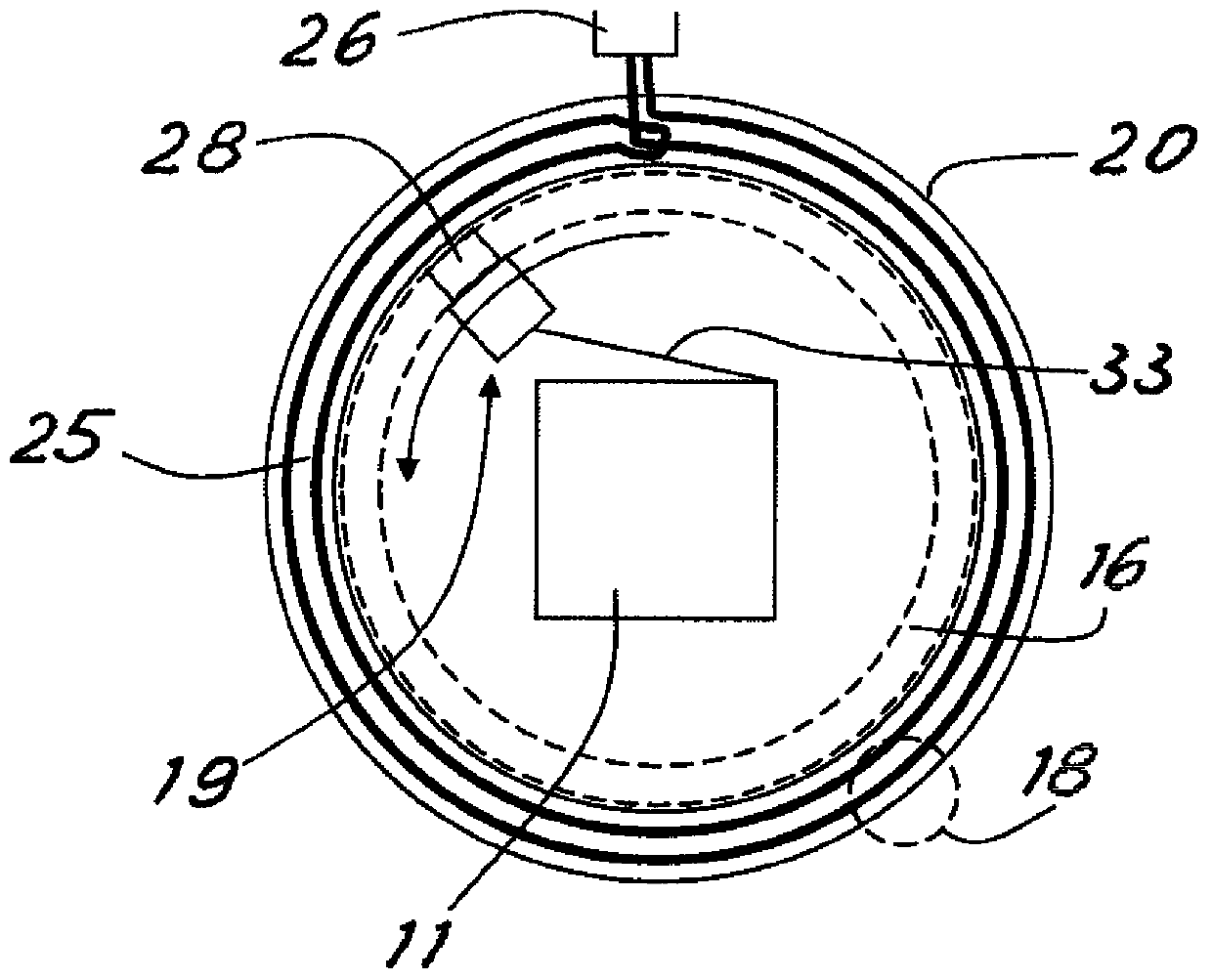

[0029] The winding machine 10 comprises a frame 13 carrying a dispensing unit 19 electrically controlled so as to dispense packaging film from the reels of fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com