Packing station and method for automated loading of piece goods on a load carrier including subsequent foil wrapping

a technology of automated loading and packing station, which is applied in the direction of wrapping/bundling articles, external supports, packaging, etc., can solve the problems of small deflection of the winding head, and achieve the effect of reducing the need for space of the winding device, reducing the deflection of the winding head, and sufficient space for loading the load carrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]During the subsequent description of the figures like elements will be designated with like reference numerals. Similar elements are provided with similar reference numerals. Modified features will be referred to explicitly.

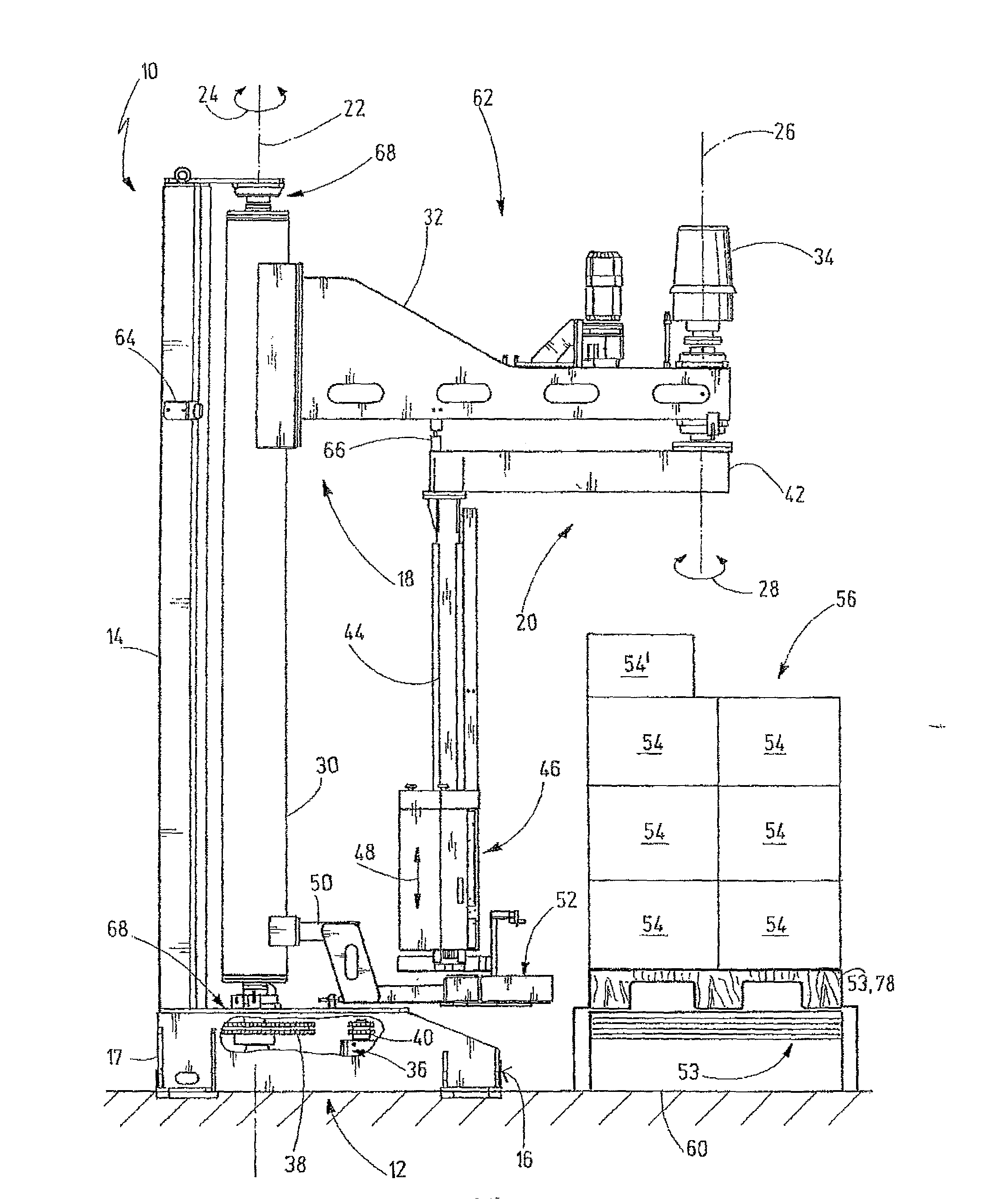

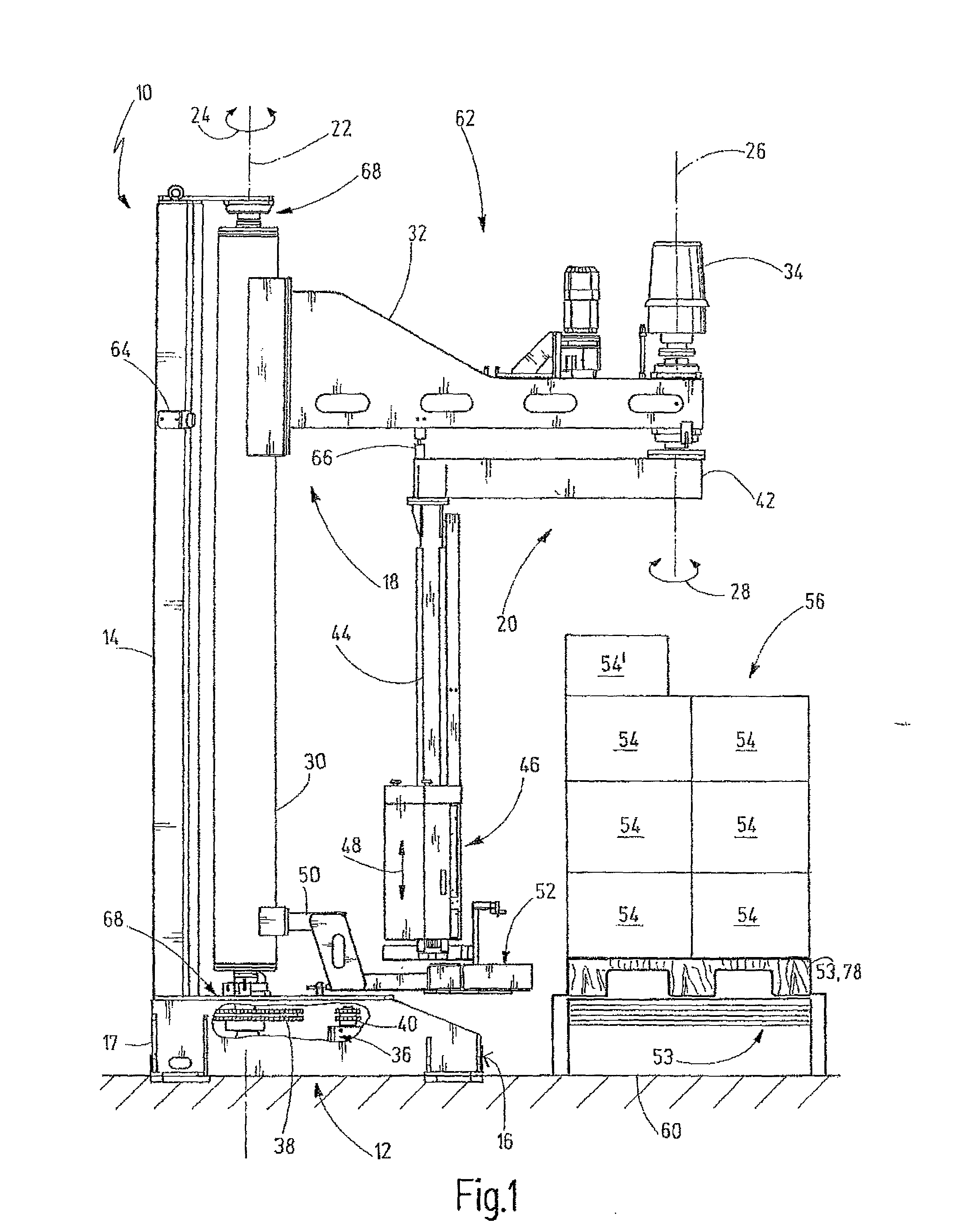

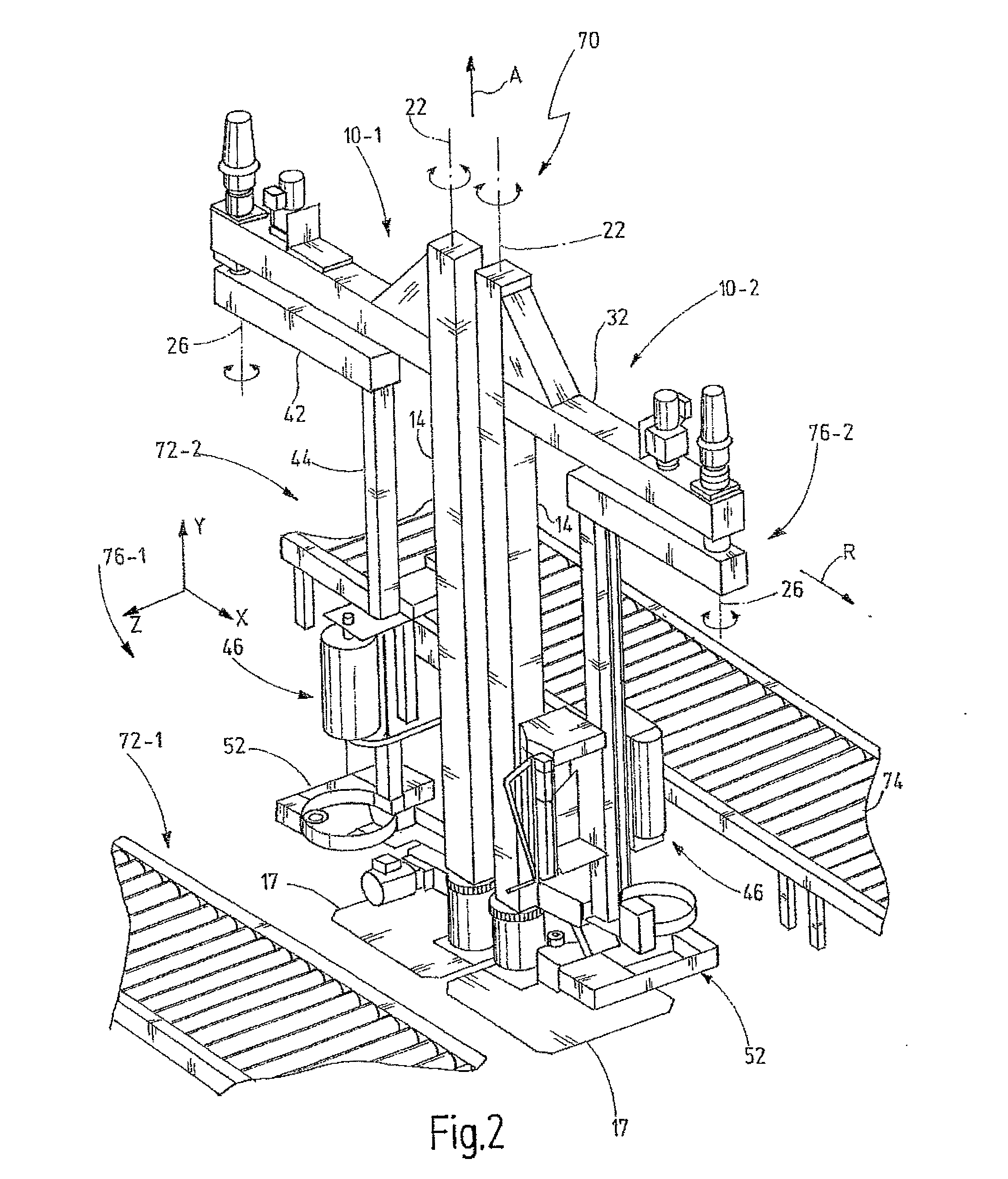

[0042]FIG. 1 shows a side view of a first embodiment of a rotational-arm winding device 10 (hereinafter also designated as winding device 10).

[0043]The winding device comprises a (machine) frame 12 having a main mast 14, preferably with one leg, and a foot element 16 forming a standing foot 17 of the frame 12. In the present example of FIG. 1 the foot element 16 is screwed fixedly, for example, to a floor of a hall and comprises a high weight for keeping the center of gravity of the winding device 10 as close as possible to the floor of the hall.

[0044]It is clear that the machine frame 12 can also be mounted to a wall, a ceiling or a working platform, dependent on a customer's desire.

[0045]The winding device 10 further comprises a rotatably-supported pivota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com