Gripper for an automated manipulator and method for operation of the gripper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

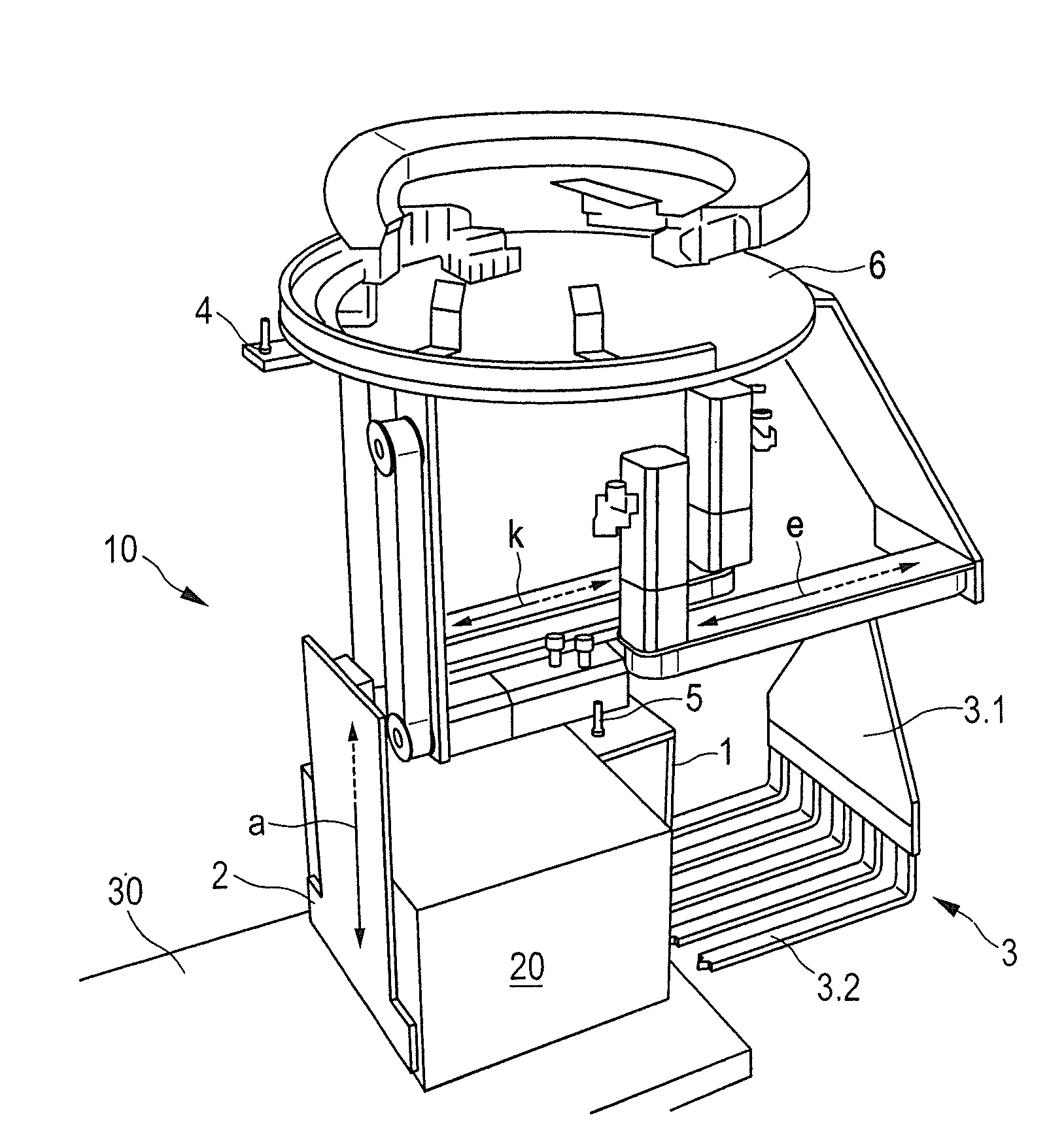

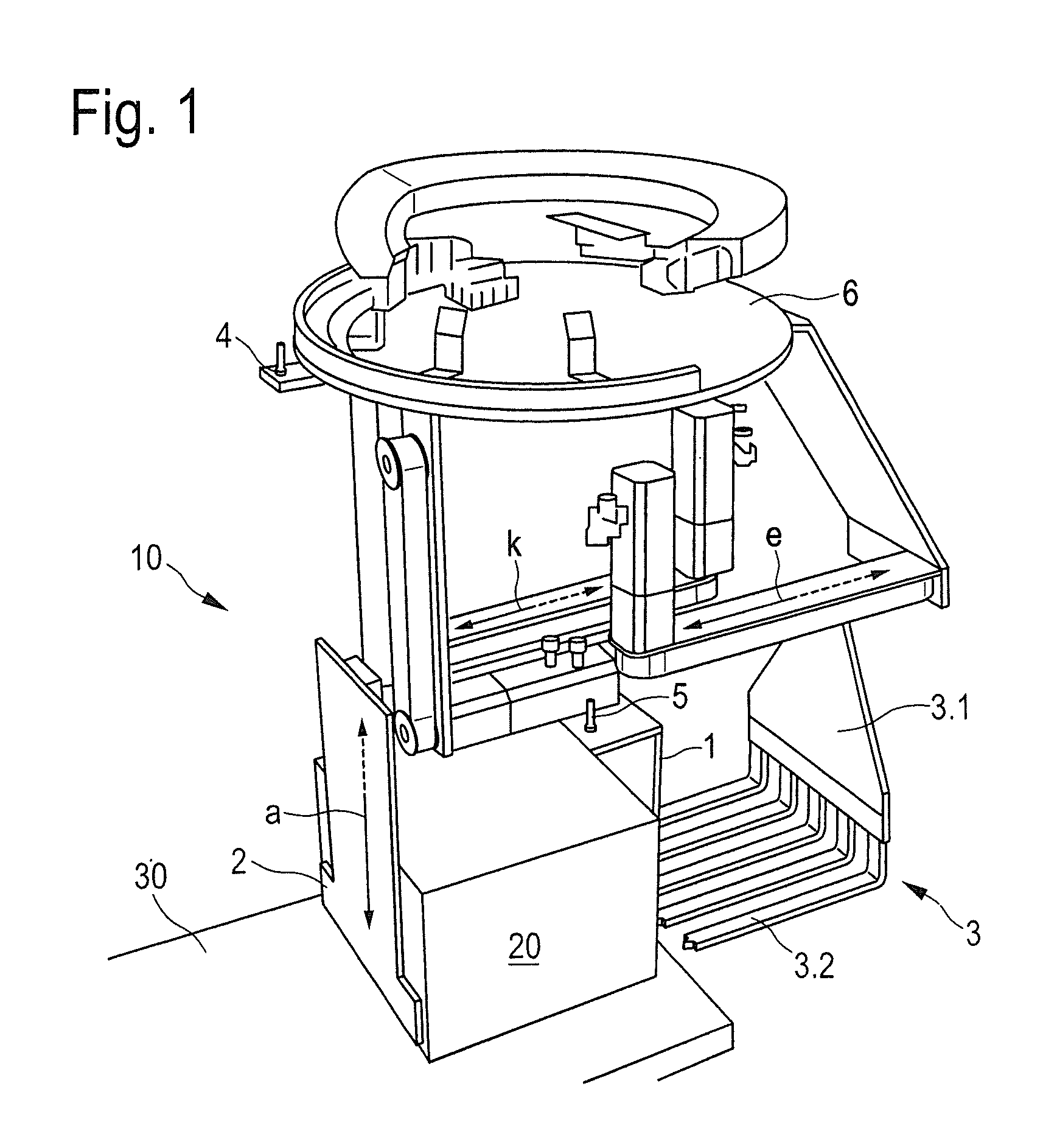

[0041]FIG. 1 shows a manipulator gripper 10 for palletizing and depalletizing bundles 20 by means of an articulated arm robot (not shown). It comprises a tool flange 6 for connection to the articulated arm robot. A trailing cable installation enables rotation movements by ±225°.

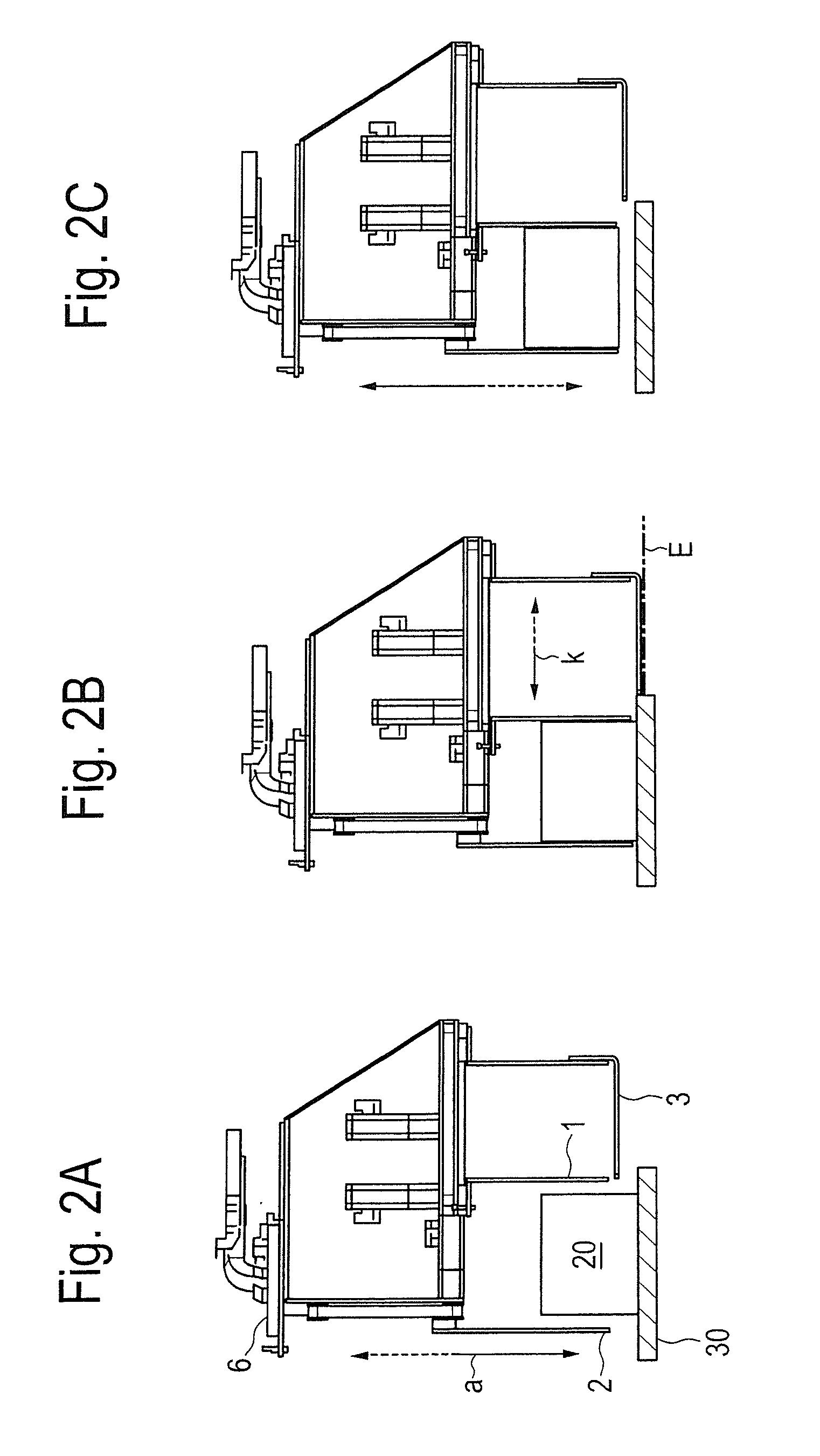

[0042]A bent support base 3 with its angle flange 3.1 is borne on the tool flange 6 such that said support base 3 can be shifted, and extends with a support plate 3.2 in an insertion plane E (see FIG. 2B) towards a counter-stop 2. This can be shifted on a lowering axis a towards the insertion plane E of the support base 3. A clamp stop 1 extends parallel to the counter-stop 2 along the lowering axis a and can be shifted relative to the tool flange 6 and the support base 3 along a clamp axis k towards the counter-stop 2. The support base 3 can be shifted, relative to the tool flange 6, towards the counter-stop 2 in the insertion plane E along an insertion axis essentially parallel to the clamp axis k.

[0043]Low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shape | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com