Secondary bagging method and device

A bagging device and empty bag technology, which is applied in the direction of wrapping paper support device, packaging, transportation packaging, etc., can solve the problems of equipment shock and vibration, unsuitable bagging of objects into bags, etc., and achieve high production efficiency and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

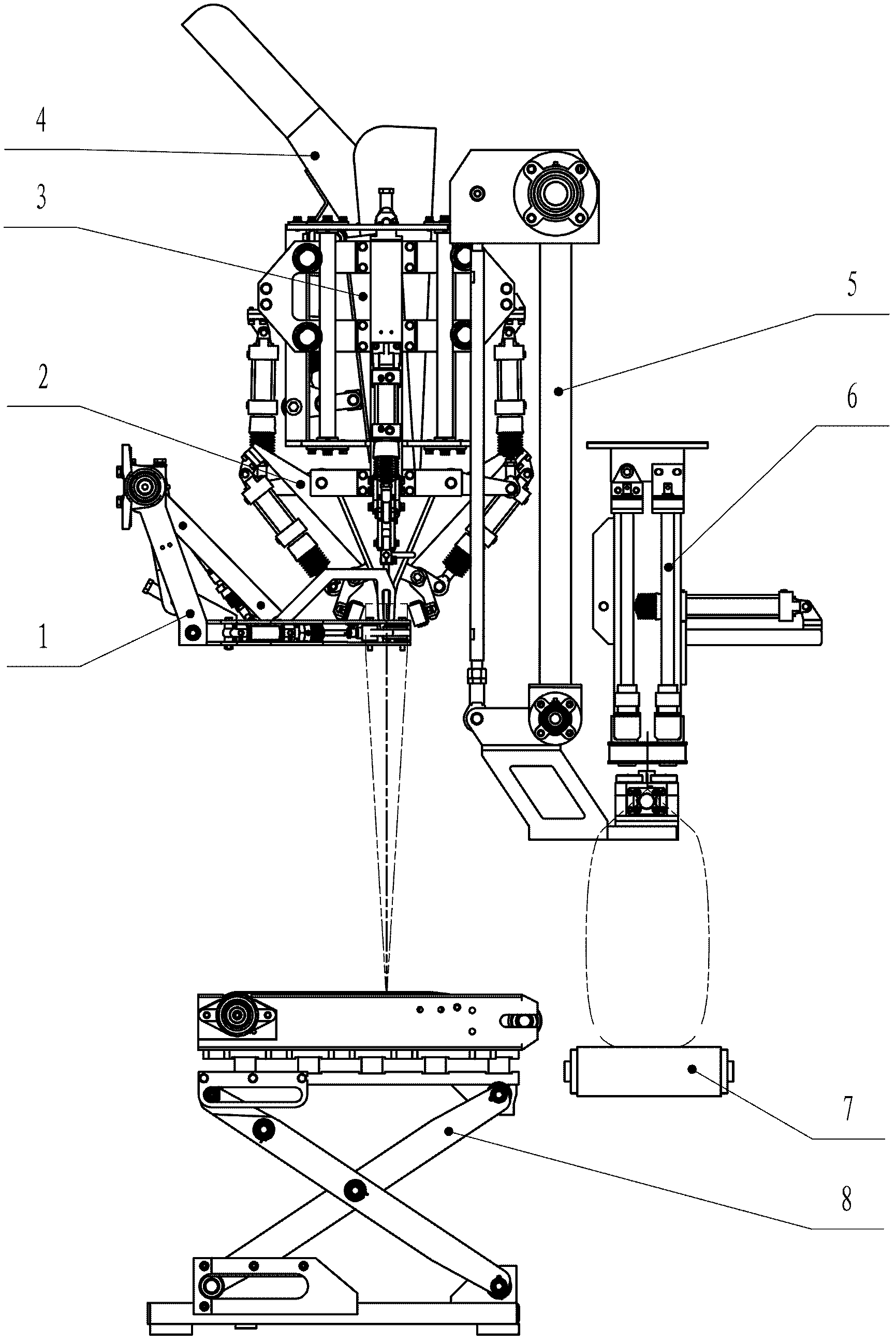

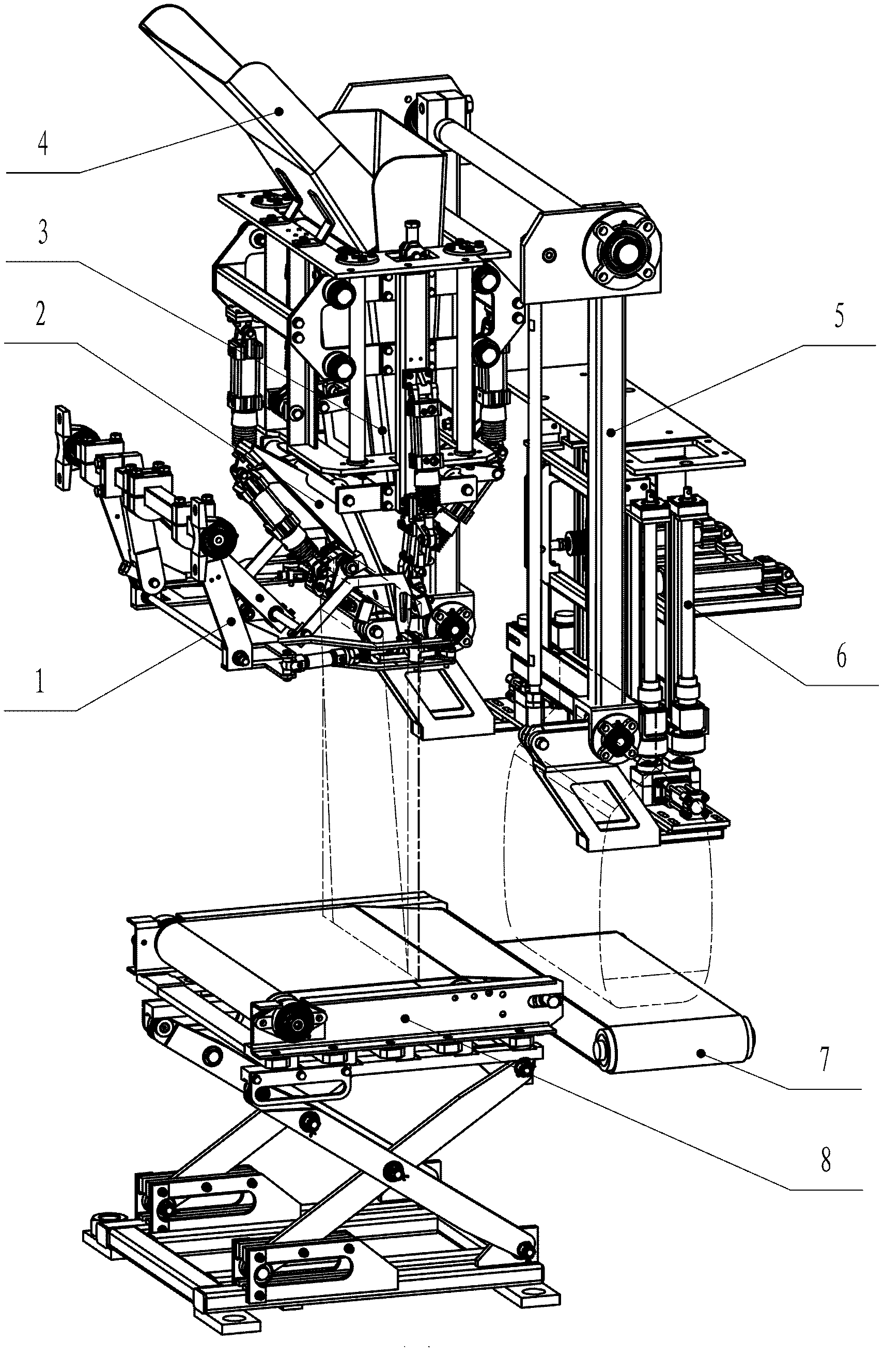

[0032] The specific embodiment of the present invention sees Figure 1 to Figure 11 , the secondary bagging method comprises the following process steps:

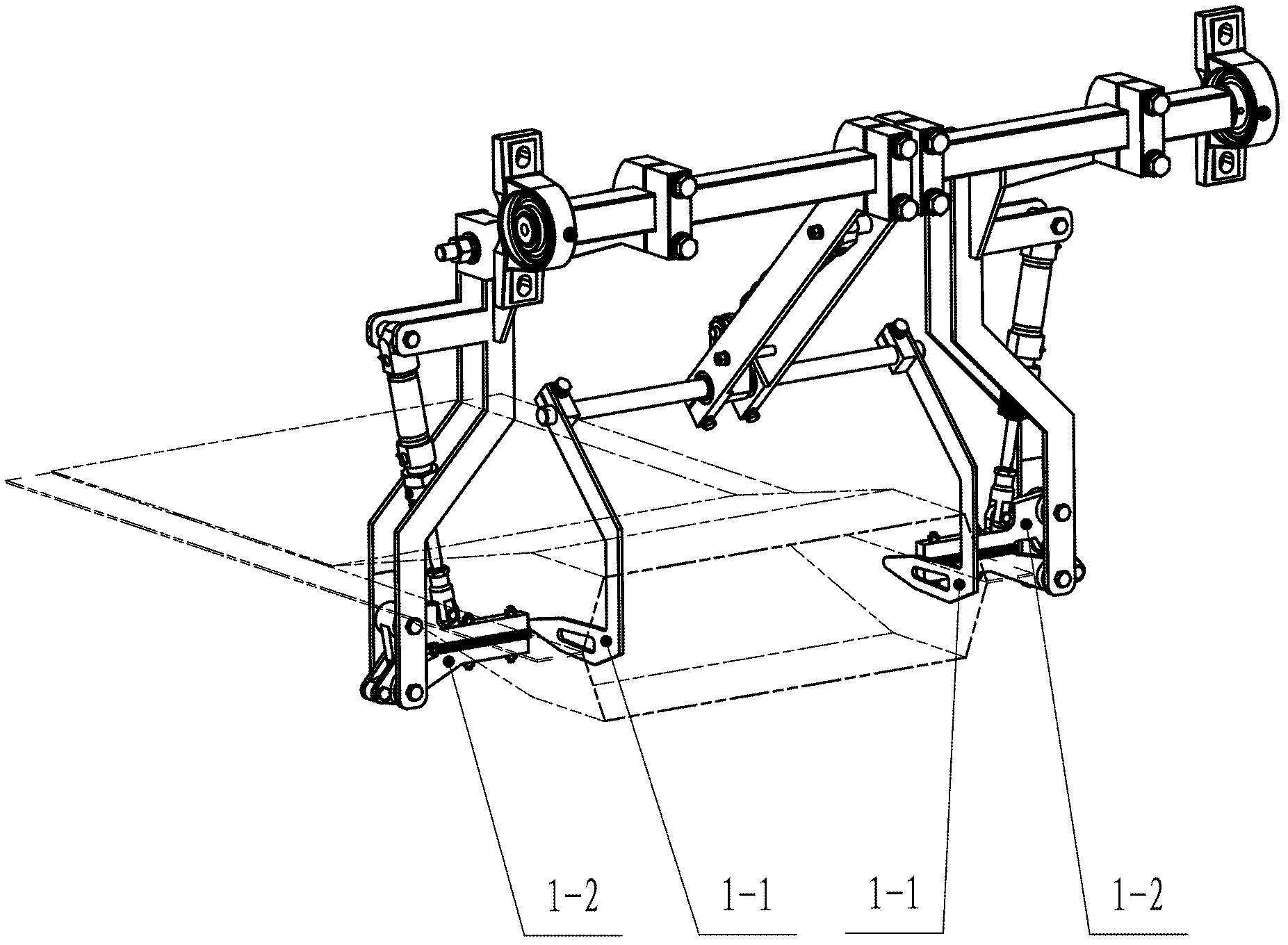

[0033] (1) Take out the empty bag: Insert the support plates (1-1) on the left and right sides into the opening of the opened empty bag (A), and the bagging handles (1-2) on the left and right sides are closed to clamp the empty bag (A) on the left and right sides;

[0034] (2) Empty bag: the support plate (1-1) and the bagging handle (1-2) swing up at an appropriate angle at the same time, so that the mouth of the empty bag (A) faces upward, and at the same time, the opened bag The muzzle is around the outer sides of the front and rear flaps (2-2) that are closed into a beak shape;

[0035] (3) Empty bag clamping: the front and rear two pressure plates (2-1) are closed, and the bag opening is pressed against the flap door (2-2), while the support plate (1-1) is lifted to separate from the empty bag (A ) pocket opening; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com