Layered structure and light-sensitive dry film used in same

A structure and photosensitivity technology, which is applied in the direction of photosensitive materials, optics, and optomechanical equipment used in optomechanical equipment, can solve the problem that it is difficult to ensure the initial adhesion of the laminate on the substrate when dealing with cracks, and achieve adhesion Improvement, high reliability, and the effect of no reduction in resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0182] The present invention will be specifically described below by giving Examples and Comparative Examples, but the present invention is not limited to the following Examples. Wherein, the following "parts" and "%" all refer to the mass basis unless otherwise specified.

Synthetic example 1

[0184] In an autoclave equipped with a thermometer, a nitrogen gas introduction device, an alkylene oxide introduction device, and a stirring device, 119.4 parts of novolak-type cresol resin (trade name "Shonol CRG951", manufactured by Showa Polymer Co., Ltd., OH equivalent: 119.4 ), 1.19 parts of potassium hydroxide and 119.4 parts of toluene, nitrogen replacement was carried out in the system while stirring, and the temperature was raised. Then, slowly add 63.8 parts of propylene oxide dropwise, at 125~132℃, at 0~4.8kg / cm 2 React for 16 hours. Then, it was cooled to room temperature, and 1.56 parts of 89% phosphoric acid was added and mixed in the reaction solution to neutralize potassium hydroxide to obtain a non-volatile component of 62.1%, a hydroxyl value of 182.2g / eq. Propane reaction solution. This is what added 1.08 mol of alkylene oxides on average with respect to 1 equivalent of phenolic hydroxyl groups.

[0185] 293.0 parts of the alkylene oxide reaction solutio...

Embodiment 1~12

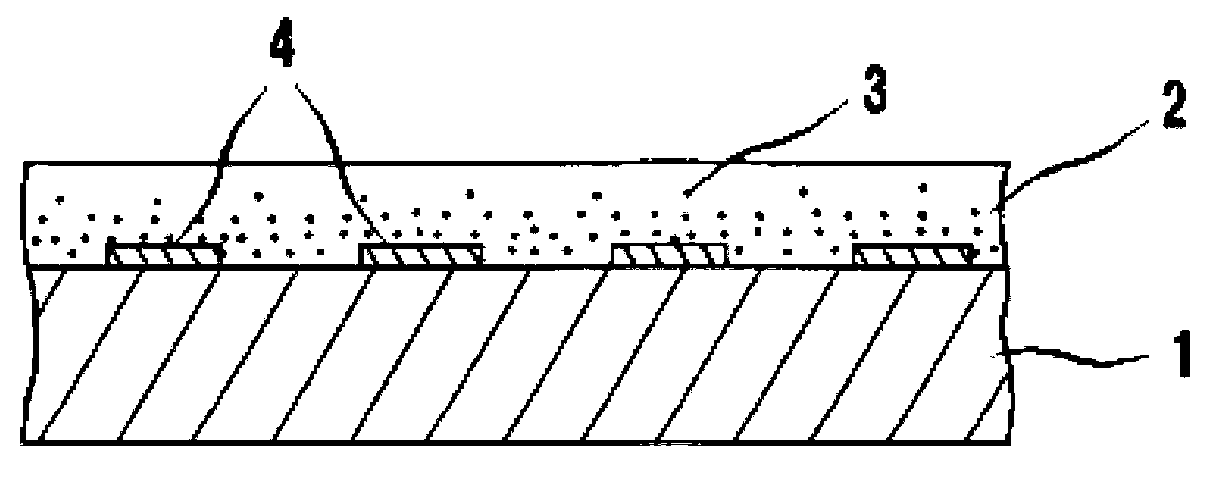

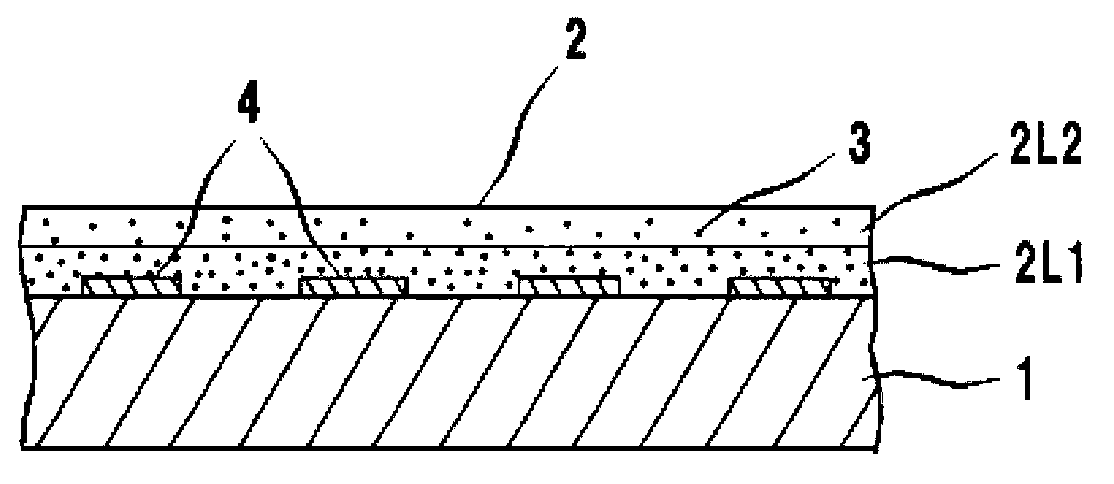

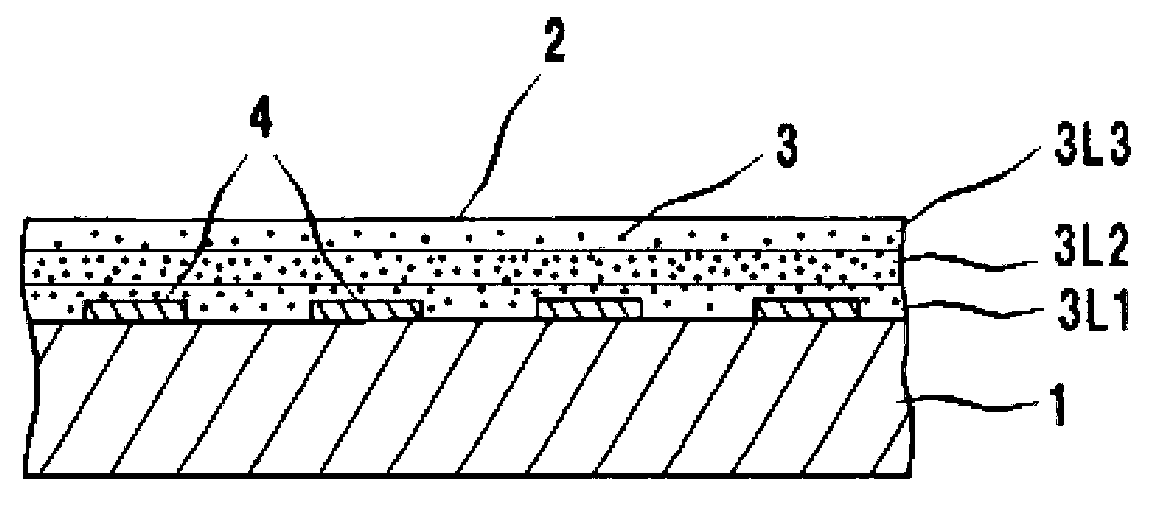

[0219] Using the above-mentioned photocurable thermosetting resin composition examples 1 to 12, according to the combinations shown in the following table 2, in examples 1 to 7, the first photosensitive resin layer in contact with the substrate was formed with a film thickness of 15 μm (2L1), form a second photosensitive resin layer (2L2) in contact with the first photosensitive resin layer (2L1) with a film thickness of 5 μm, and make a photosensitive resin layer with a two-layer structure capable of forming a pattern. dry film. In Examples 8 to 12, the first photosensitive resin layer (3L1) in contact with the substrate was formed with a film thickness of 5 μm, and the second photosensitive resin layer (3L1) in contact with the first photosensitive resin layer (3L1) was formed with a film thickness of 10 μm. Resin layer (3L2), on the second photosensitive resin layer (3L2), further form a third photosensitive resin layer (3L3) with a film thickness of 5 μm, and make a photos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com