Automatic fruit labeler

A labeling machine and fruit technology, applied in labeling machines, labels, packaging, etc., can solve the problems of uneven operation proficiency of each person, difficulty in meeting the unified requirements for labeling quality, and high labor intensity of operators. Achieve the effect of good labeling effect, high labeling efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

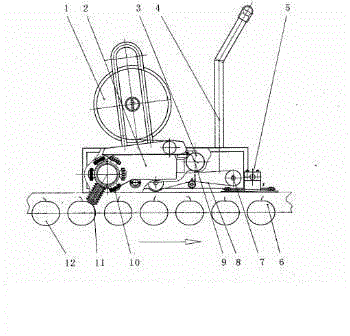

[0013] An automatic fruit labeling machine, characterized in that: the automatic fruit labeling machine mainly includes a labeling head assembly 1, a transmission box assembly 2, a label suction paper tube assembly 3, a labeling machine handle 4, a labeling machine Machine fixed hinge 5, frame 6, main motor 7, toothed transmission belt 8, label backing paper 9, rotary labeling head 10, stretched air bag 11 and fruit 12, etc.; wherein, the labeling head assembly 1 and The transmission box assembly 2 is connected; the label-absorbing paper tube assembly 3 is connected with the transmission box assembly 2; the labeling machine handle 4 is installed and fixed on the frame 6; the labeling machine fixes the hinge through the labeling machine 5 connections.

[0014] The main motor 7 drives the toothed transmission belt to rotate 8 .

[0015] Several retractable pneumatic air bags 11 are housed on the labeling head.

[0016] At the label taking position, there is negative pressure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com